Kiss Cut: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for kiss cut

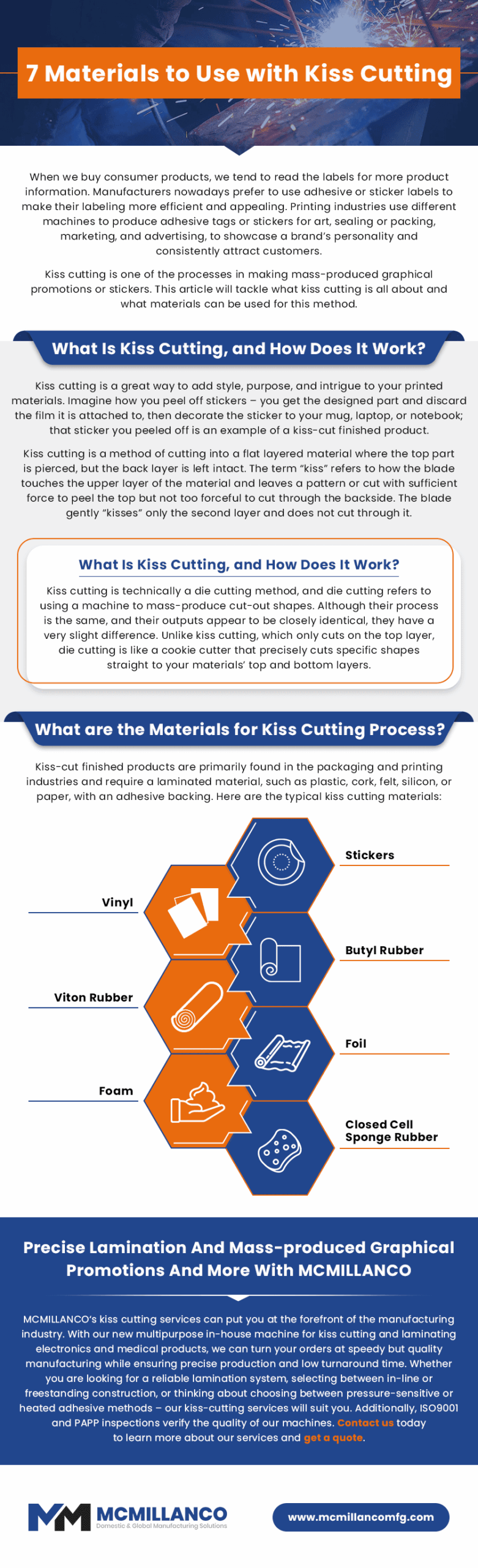

In an increasingly competitive landscape, sourcing kiss cut stickers presents a unique challenge for international B2B buyers. These versatile marketing tools, designed with an intricate cutting technique that allows for easy peeling and application, are essential for branding and labeling across diverse industries. However, navigating the global market involves understanding various types of kiss cut stickers, their applications, and how to effectively vet suppliers to ensure quality and reliability.

This comprehensive guide aims to empower B2B buyers—particularly those in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil—by providing in-depth insights into the kiss cut sticker market. We will explore the differences between kiss cut and die cut stickers, highlight their practical uses in branding and packaging, and discuss factors influencing pricing and production timelines. Additionally, we will outline best practices for supplier selection, ensuring that buyers can confidently choose partners who meet their quality and service expectations.

By equipping businesses with the knowledge needed to make informed purchasing decisions, this guide not only demystifies the kiss cut sticker market but also enhances your ability to leverage these products effectively in your marketing strategies. Whether you are looking to enhance brand visibility or streamline production processes, understanding the nuances of kiss cut stickers will position your business for success in a global marketplace.

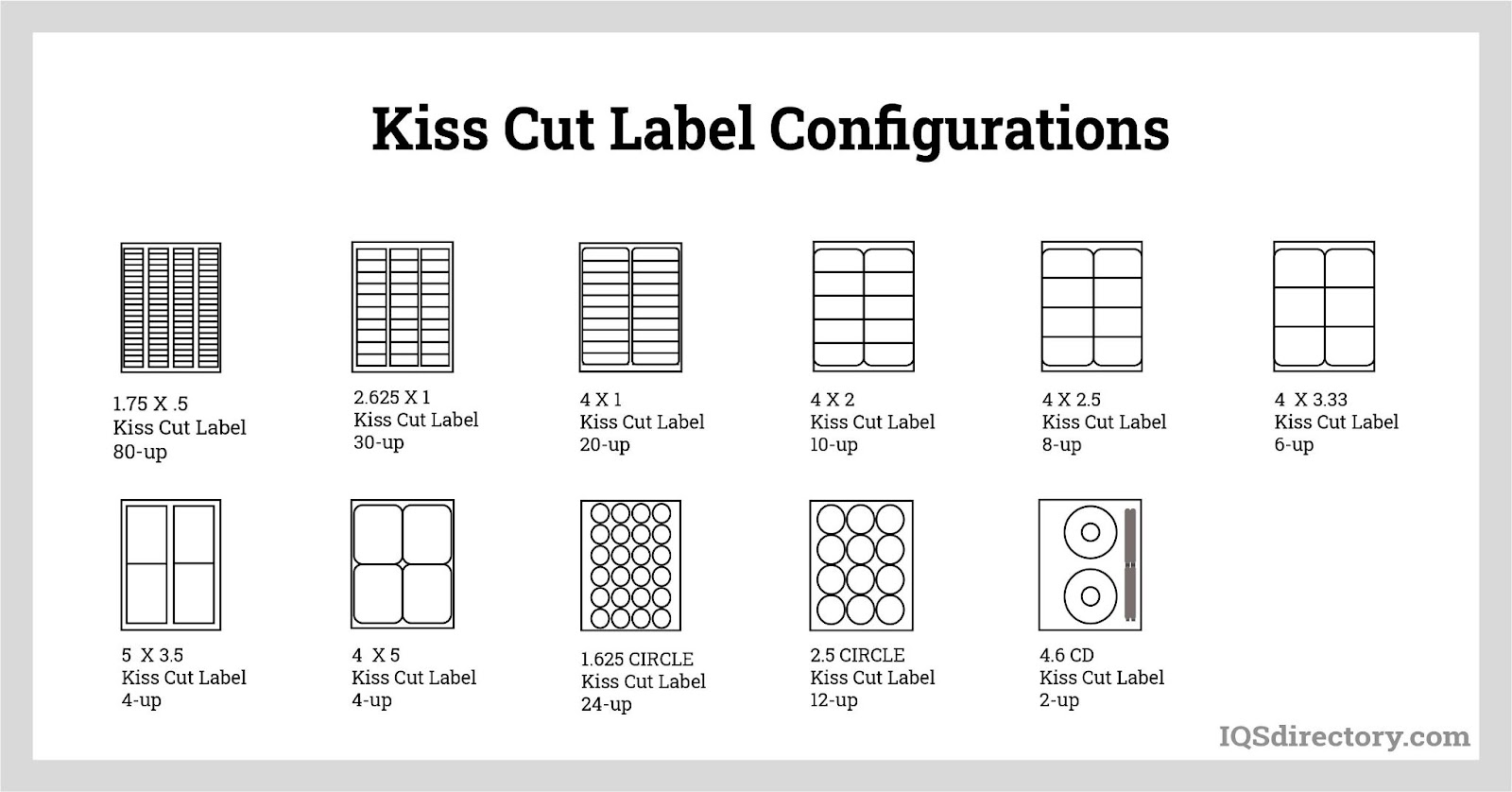

Understanding kiss cut Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Kiss Cut | Cut through vinyl only, leaving the backing intact; square or rectangular shape around the design. | Branding, packaging, and promotional materials. | Pros: Easy to peel, ideal for intricate designs. Cons: Less visually striking than die cut. |

| Custom Kiss Cut | Personalized shapes and sizes, with the option for unique cutlines. | Custom branding, event giveaways, and product labels. | Pros: Tailored to specific needs, enhances brand visibility. Cons: Can be more expensive due to customization. |

| Back-Printed Kiss Cut | Additional printed information on the backing paper surrounding the sticker. | Informational labels, event promotions, and business cards. | Pros: Offers extra branding space; functional. Cons: May require more design effort. |

| Multi-Layer Kiss Cut | Multiple layers of stickers with varying designs stacked on the backing. | Creative marketing materials and product demonstrations. | Pros: Eye-catching, allows for complex branding. Cons: More challenging to produce; higher costs. |

| Eco-Friendly Kiss Cut | Made from sustainable materials with recyclable backing. | Green branding initiatives and eco-conscious businesses. | Pros: Aligns with sustainability goals; attracts eco-aware clients. Cons: Limited material options may affect design choices. |

What Are the Key Characteristics of Standard Kiss Cut Stickers?

Standard kiss cut stickers are characterized by their unique cutting method that only slices through the vinyl layer, preserving the backing material. This makes them easier to peel and apply, making them ideal for branding and promotional materials. Businesses often use these stickers for giveaways or to label products, ensuring they can be easily handled without damaging the design. When purchasing, consider the ease of application and the potential for intricate designs, as these stickers are well-suited for detailed artwork.

How Do Custom Kiss Cut Stickers Enhance Branding?

Custom kiss cut stickers allow businesses to create stickers in personalized shapes and sizes, offering flexibility in design. This type is particularly beneficial for branding, as it can feature logos or unique designs that stand out. B2B buyers should consider their target audience when ordering, as tailored designs can significantly improve brand recognition. While the customization may come at a higher cost, the return on investment can be substantial through enhanced visibility and engagement.

What Are the Benefits of Back-Printed Kiss Cut Stickers?

Back-printed kiss cut stickers feature additional printed information on the backing paper, which can be utilized for branding or informational purposes. This type is particularly useful for event promotions, where crucial details like dates and contact information can be included. Buyers should evaluate the design complexity since this option requires careful planning to ensure that the additional content is both informative and visually appealing. The added functionality can justify the extra design effort.

How Do Multi-Layer Kiss Cut Stickers Stand Out?

Multi-layer kiss cut stickers consist of several layers of stickers stacked on the backing, allowing for a dynamic presentation. This type is particularly effective for creative marketing campaigns or product demonstrations, as it can showcase various designs or messages in a single sticker. B2B buyers should consider production challenges and costs, as these stickers can be more complex to manufacture. However, their eye-catching appeal can significantly enhance promotional efforts.

Illustrative image related to kiss cut

Why Choose Eco-Friendly Kiss Cut Stickers?

Eco-friendly kiss cut stickers are produced using sustainable materials and recyclable backing, appealing to businesses that prioritize sustainability. This type is perfect for companies aiming to align their branding with eco-conscious values. When purchasing, B2B buyers should assess the material options available, as they may influence design capabilities. Despite the potential limitations, the alignment with sustainability goals can attract a growing demographic of environmentally aware clients, making this option increasingly popular.

Key Industrial Applications of kiss cut

| Industry/Sector | Specific Application of kiss cut | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Custom labels for product packaging | Enhances brand visibility and provides essential product information | Material quality, printing options, and durability for various environments |

| Retail | Promotional stickers for product displays | Attracts customer attention and increases sales through visual appeal | Customization options, ease of application, and cost-effectiveness |

| Logistics | Shipping labels and barcodes | Streamlines inventory management and ensures accurate tracking | Adhesive strength, weather resistance, and compatibility with shipping materials |

| Events and Marketing | Event branding and giveaway stickers | Builds brand recognition and engages customers at events | Design flexibility, production speed, and bulk order discounts |

| Art and Crafts | Custom stickers for artists and crafters | Allows for intricate designs and personal branding for creators | Material variety, ease of application, and unique design options |

How is Kiss Cut Used in Packaging and What Problems Does It Solve?

In the packaging industry, kiss cut stickers are extensively used for custom labels that convey vital product information, including ingredients, usage instructions, and branding. This method allows businesses to create intricate designs that stand out on shelves, enhancing brand visibility. For international buyers, especially in regions like Africa and South America, sourcing high-quality materials that withstand various environmental conditions is crucial. Additionally, ensuring that the adhesive is durable yet removable can help maintain the integrity of the packaging.

What Role Do Kiss Cut Stickers Play in Retail Promotions?

Retailers leverage kiss cut stickers as promotional tools to enhance product displays and attract customer attention. These stickers can feature discounts, product details, or eye-catching designs that encourage purchases. The ease of application is particularly beneficial for businesses looking to implement quick marketing strategies. Buyers from Europe, such as Germany, should consider the customization options available, ensuring that stickers align with their brand identity while being cost-effective for large-scale use.

How Do Kiss Cut Stickers Improve Logistics Operations?

In logistics, kiss cut stickers are vital for creating shipping labels and barcodes that facilitate efficient inventory management. By using kiss cut technology, companies can produce labels that are easy to peel and apply, ensuring accuracy in tracking shipments. International buyers must focus on adhesive strength and weather resistance, particularly in regions with varying climates, to prevent label degradation during transit. Compatibility with different shipping materials is another key consideration to ensure seamless operations.

How Are Kiss Cut Stickers Utilized in Events and Marketing?

Kiss cut stickers serve as powerful branding tools at events and trade shows. They can be used as giveaways that not only promote a brand but also engage customers, creating a lasting impression. The ability to print additional information around the sticker enhances its utility, making it a versatile marketing asset. Buyers should prioritize design flexibility and production speed to ensure timely delivery, especially for large events in the Middle East and Africa where logistics may pose challenges.

Why Are Kiss Cut Stickers Popular Among Artists and Crafters?

For artists and crafters, kiss cut stickers offer a unique way to showcase intricate designs while allowing for personal branding. These stickers can be applied to various surfaces, making them ideal for merchandise like notebooks, laptops, or water bottles. The diverse material options available cater to different artistic needs, and ease of application is a significant advantage for creators. Buyers should explore unique design options and the ability to customize sizes, ensuring that their products resonate with target audiences across different markets.

3 Common User Pain Points for ‘kiss cut’ & Their Solutions

Scenario 1: Difficulty with Sticker Removal and Application

The Problem: B2B buyers often encounter issues with the ease of peeling and applying kiss cut stickers. For instance, companies that produce promotional materials or labels may find that their employees struggle to quickly and efficiently remove stickers from the backing, leading to delays in production and dissatisfaction among end-users. This is particularly problematic when large quantities of stickers need to be applied in a short timeframe, as inefficiencies can lead to increased labor costs and time wasted.

Illustrative image related to kiss cut

The Solution: To mitigate this issue, it is crucial to select high-quality kiss cut stickers that are specifically designed for easy peeling. Look for manufacturers that utilize precision cutting technology, ensuring that the kiss cut is done accurately without compromising the integrity of the adhesive backing. Additionally, consider ordering stickers with a thicker backing material, which can enhance the peeling process. Providing staff with training on proper peeling techniques can also improve efficiency. For large-scale applications, investing in tools that assist in the quick application of stickers can further streamline the process, reducing labor time and increasing productivity.

Scenario 2: Managing Intricate Designs and Branding Elements

The Problem: Many B2B buyers want to leverage kiss cut stickers for intricate designs that include logos, contact information, or promotional messages. However, the challenge lies in ensuring that these complex designs are accurately produced and remain visually appealing without compromising the functionality of the sticker. If the cut lines are not precise, the stickers may appear unprofessional, diminishing the brand image and effectiveness of the promotional materials.

The Solution: To address this concern, it is essential to collaborate closely with a reputable printing partner who specializes in kiss cut stickers. When placing an order, provide clear artwork files with distinct cut lines and consider requesting a proof before full production. This allows for adjustments to be made if necessary, ensuring the final product aligns with your vision. Additionally, consider utilizing back paper print options to include branding elements or additional information around the sticker, enhancing its utility without cluttering the design. By prioritizing quality control and effective communication with your printing partner, you can achieve striking stickers that represent your brand effectively.

Scenario 3: Cost Concerns with Ordering Kiss Cut Stickers

The Problem: B2B buyers often face budget constraints when ordering kiss cut stickers, especially when purchasing in bulk. They may worry about the cost-effectiveness of producing large quantities while still meeting quality standards. This is particularly relevant for startups and small businesses that rely on stickers for marketing but may not have the financial flexibility to experiment with different materials or designs.

The Solution: To make the most of your budget, consider optimizing your order by evaluating the necessity of various design elements. For example, if the primary goal is brand recognition, focus on simple designs that utilize fewer colors or materials. Additionally, investigate suppliers that offer tiered pricing models, where larger orders yield significant discounts. By comparing quotes from multiple vendors and exploring options for custom materials, you can find a balance between quality and cost. Engage in negotiations to see if bulk order discounts or promotional deals are available, allowing you to maximize your investment while still receiving high-quality kiss cut stickers that serve your business needs effectively.

Strategic Material Selection Guide for kiss cut

What Are the Common Materials Used for Kiss Cut Stickers?

When selecting materials for kiss cut stickers, it is essential to consider various factors, including durability, cost, and application compatibility. Here, we analyze four common materials used in kiss cut sticker production, providing insights relevant to international B2B buyers.

What Are the Key Properties of Vinyl for Kiss Cut Stickers?

Vinyl is one of the most popular materials for kiss cut stickers due to its versatility and durability. It typically has a temperature rating of -40°F to 150°F (-40°C to 65°C) and is resistant to moisture and UV light, making it suitable for both indoor and outdoor applications.

Illustrative image related to kiss cut

Pros: Vinyl is highly durable, weather-resistant, and can be printed in vibrant colors, making it ideal for branding and promotional materials. It also offers ease of application due to its flexibility.

Cons: While vinyl is relatively affordable, the production process can be complex, especially for intricate designs. Additionally, it may not be biodegradable, raising environmental concerns.

Impact on Application: Vinyl’s compatibility with various printing techniques allows for detailed designs, making it a favorite among businesses looking to create eye-catching stickers.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations regarding vinyl use, particularly in Europe, where stricter standards may apply.

Illustrative image related to kiss cut

How Does Polypropylene Compare as a Material for Kiss Cut Stickers?

Polypropylene (PP) is another widely used material for kiss cut stickers. It offers excellent chemical resistance and a temperature range of -20°F to 176°F (-29°C to 80°C).

Pros: PP is lightweight, durable, and resistant to moisture, making it suitable for various applications, including food packaging and labeling. It is also recyclable, which appeals to environmentally conscious businesses.

Cons: Polypropylene can be more expensive than vinyl and may not offer the same color vibrancy. Additionally, its printing surface can be less forgiving, requiring careful handling during production.

Illustrative image related to kiss cut

Impact on Application: The chemical resistance of PP makes it ideal for applications in industries like food and beverage, where exposure to liquids is common.

Considerations for International Buyers: Buyers should check for compliance with food safety standards in their respective regions, especially in South America and Europe, where regulations can vary significantly.

What Are the Advantages of Using Paper for Kiss Cut Stickers?

Paper is often used for kiss cut stickers, especially for promotional materials and temporary applications. It generally has a temperature rating of -10°F to 120°F (-23°C to 49°C) and is less resistant to moisture compared to vinyl and polypropylene.

Pros: Paper is cost-effective and easily customizable, allowing for a wide range of designs. It is also biodegradable, making it an environmentally friendly choice.

Cons: The primary limitation of paper is its durability; it is more susceptible to tearing and water damage. This makes it less suitable for outdoor applications.

Illustrative image related to kiss cut

Impact on Application: Paper stickers are ideal for short-term promotions, events, or giveaways, where cost is a significant factor.

Considerations for International Buyers: Buyers should be aware of the varying standards for paper quality and sustainability certifications in different regions, particularly in Europe, where eco-labels can influence purchasing decisions.

How Does Polyester Fit into the Kiss Cut Sticker Material Landscape?

Polyester is a robust material often chosen for kiss cut stickers intended for long-term use. It offers a temperature range of -40°F to 180°F (-40°C to 82°C) and is resistant to UV light and moisture.

Pros: Polyester is highly durable, scratch-resistant, and can withstand harsh environmental conditions, making it suitable for outdoor applications. It also provides excellent print quality.

Illustrative image related to kiss cut

Cons: The cost of polyester can be higher than other materials, and the manufacturing process may be more complex, which could lead to longer lead times.

Impact on Application: Polyester’s durability makes it ideal for industrial applications, labeling, and outdoor branding.

Considerations for International Buyers: Buyers should ensure that the polyester used complies with international standards for durability and safety, particularly in the Middle East and Africa, where product longevity is often critical.

Summary Table of Material Selection for Kiss Cut Stickers

| Material | Typical Use Case for Kiss Cut | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Branding, promotional stickers | Highly durable and vibrant colors | Environmental concerns | Medium |

| Polypropylene | Food packaging, labeling | Chemical resistance and recyclability | Higher cost, less vibrant printing | High |

| Paper | Short-term promotions | Cost-effective and biodegradable | Less durable, moisture-sensitive | Low |

| Polyester | Industrial applications | Scratch-resistant and long-lasting | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions when sourcing kiss cut stickers across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for kiss cut

What Are the Key Stages in the Kiss Cut Sticker Manufacturing Process?

The manufacturing process for kiss cut stickers involves several critical stages, each designed to ensure high-quality output.

Material Preparation: Choosing the Right Materials

The first step in the manufacturing process is the selection of materials. Kiss cut stickers typically utilize vinyl, which is favored for its durability and versatility. Depending on the intended application, manufacturers may also choose different finishes, such as glossy or matte, to enhance aesthetic appeal. The selected materials must be prepped appropriately, which includes cutting them into manageable sheets that fit the machinery used in the next stages.

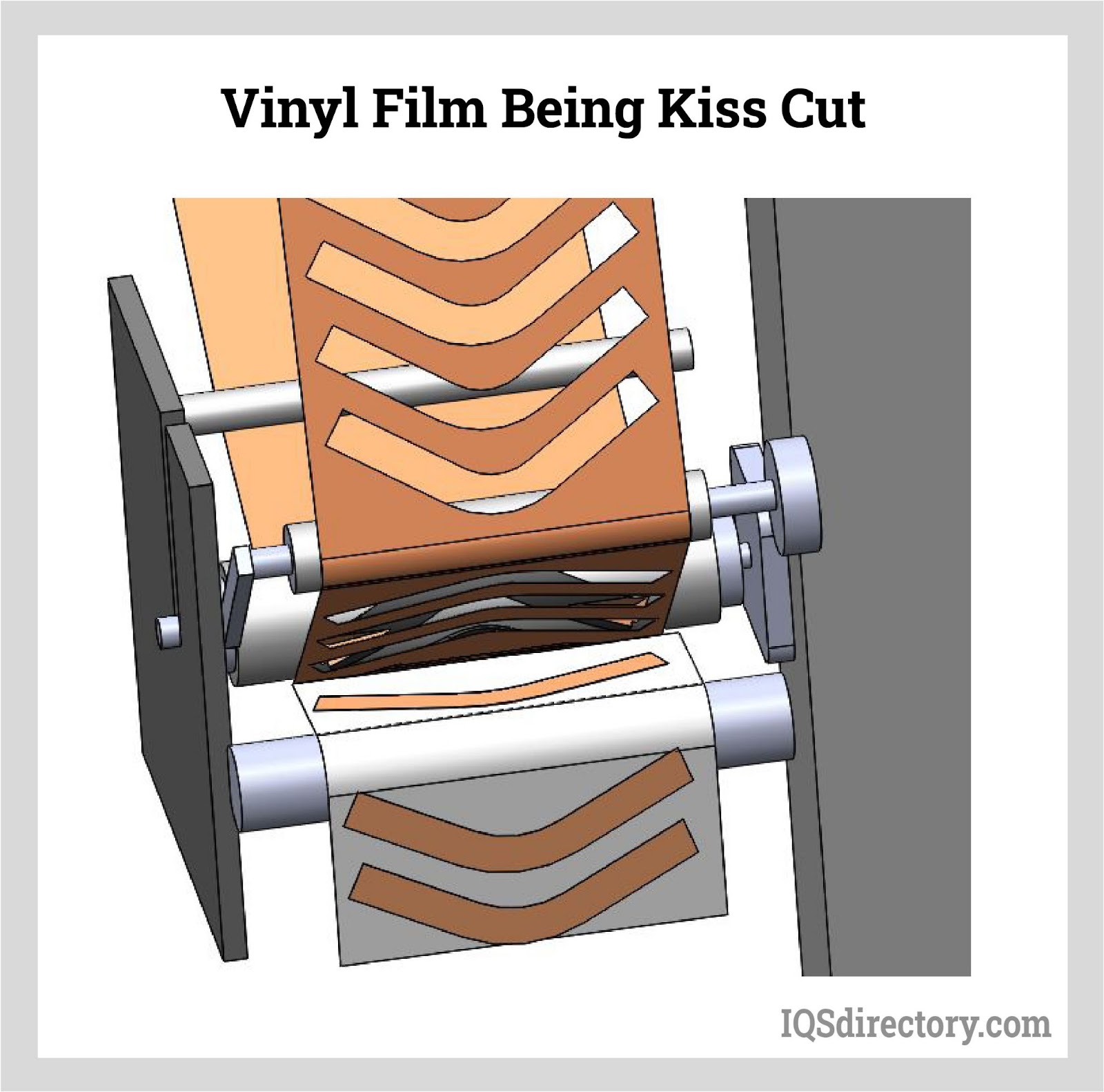

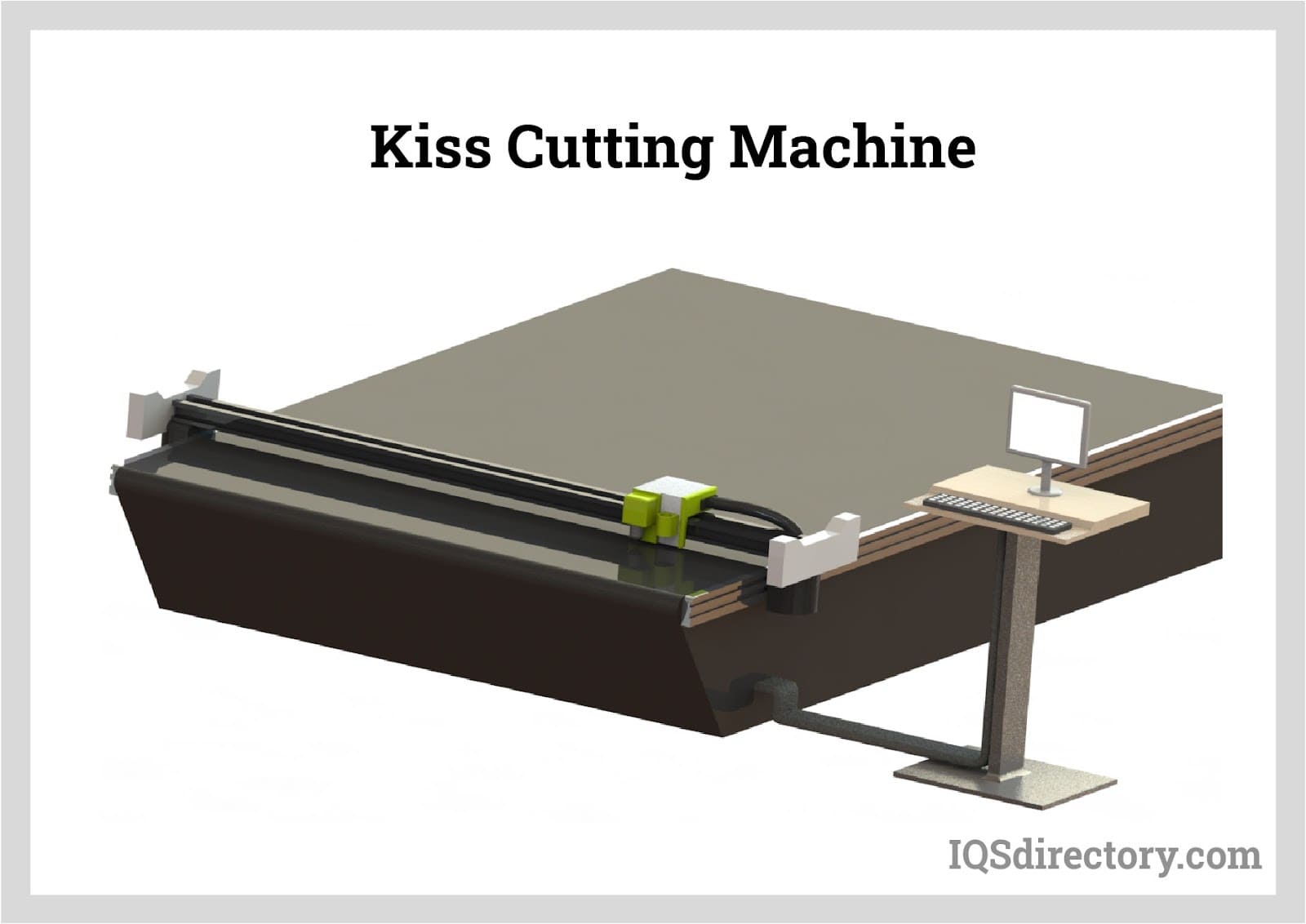

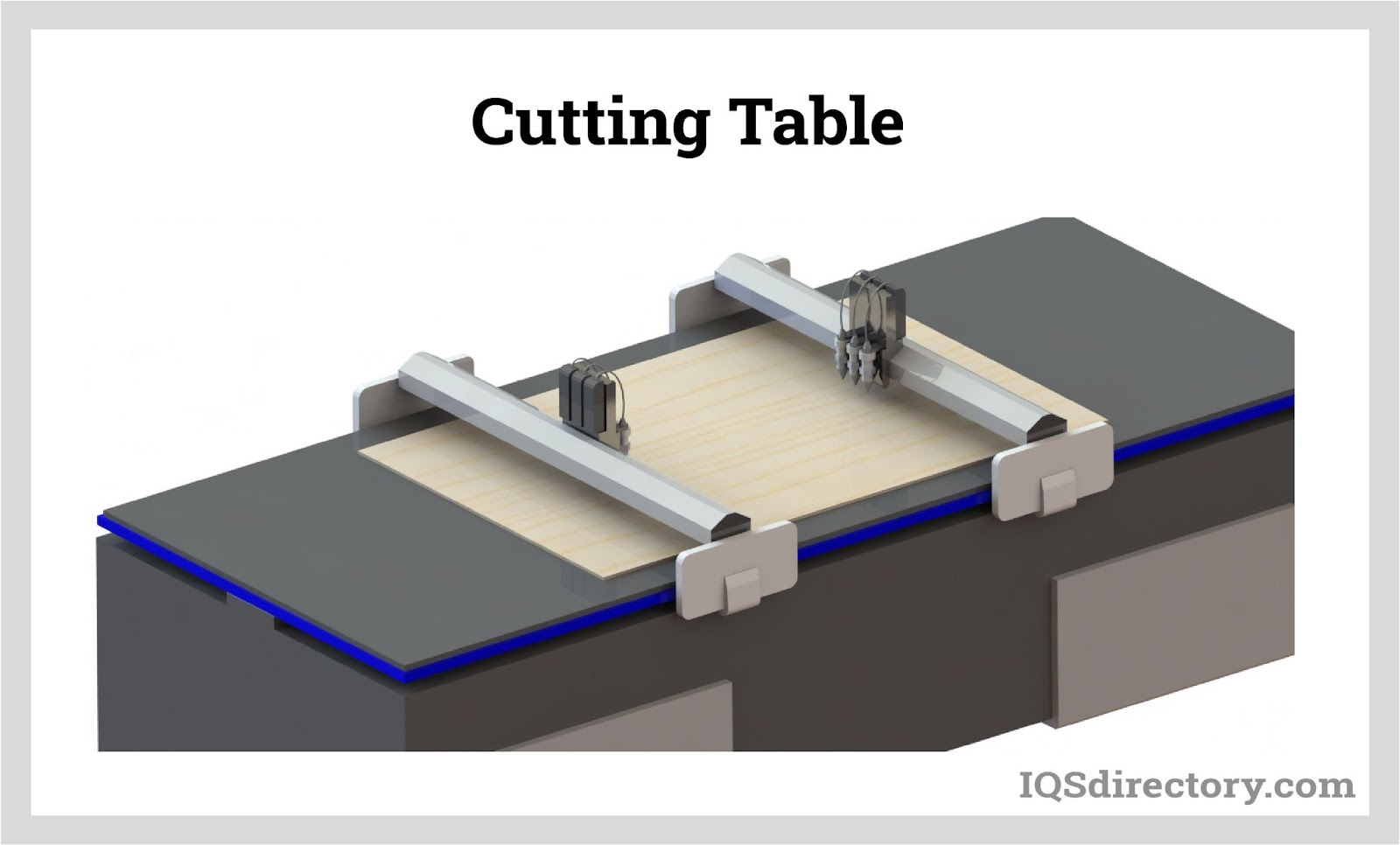

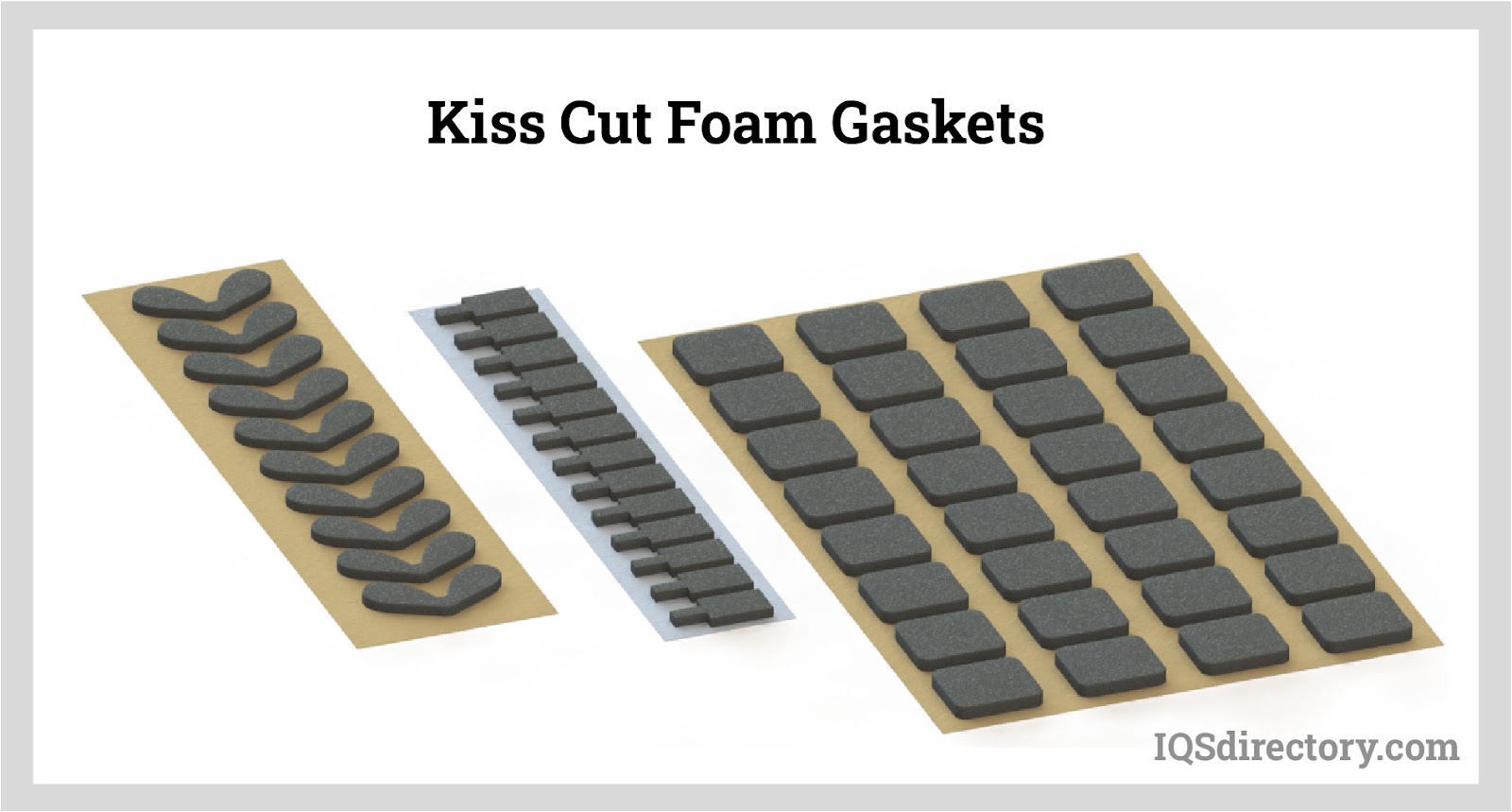

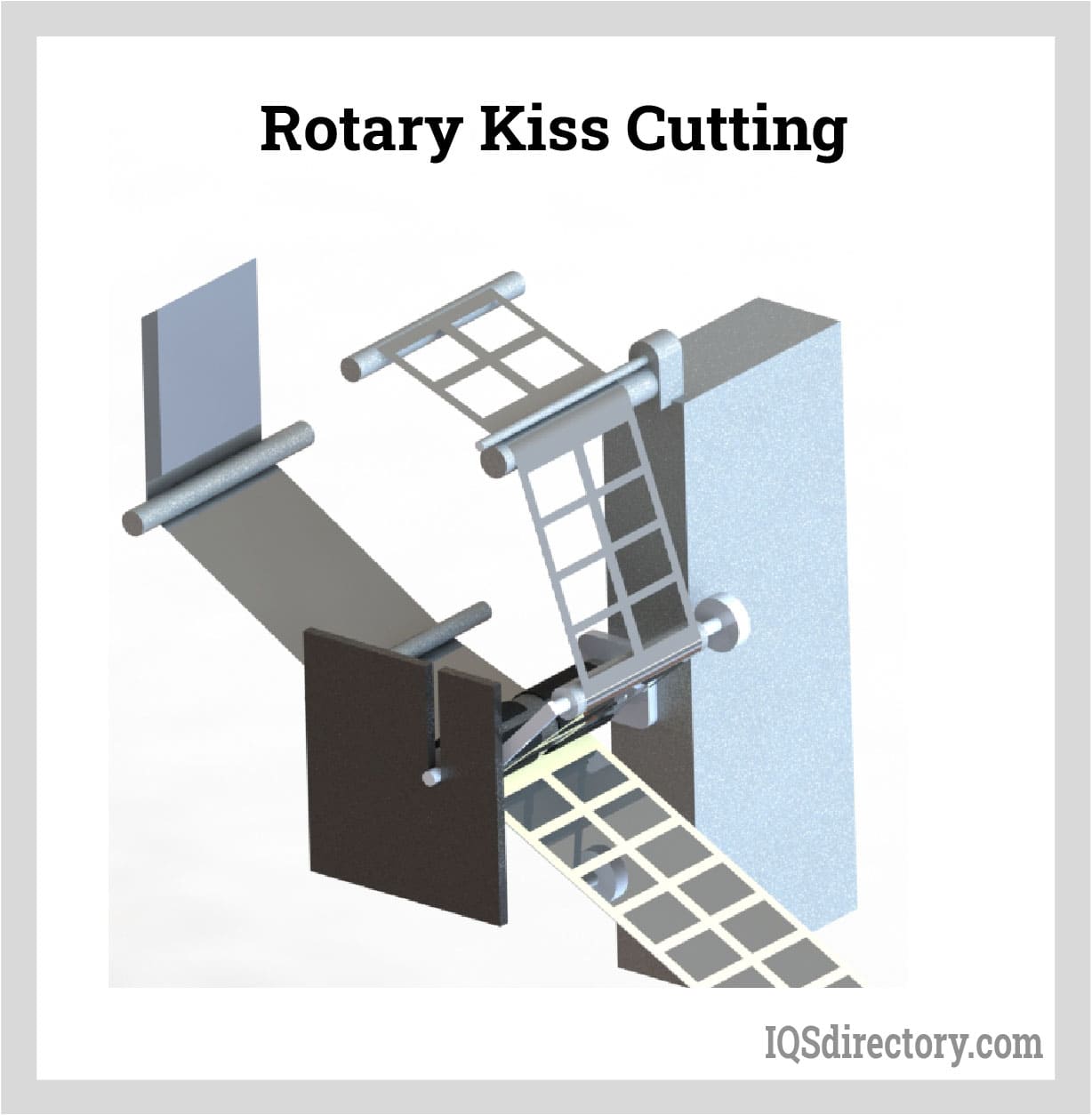

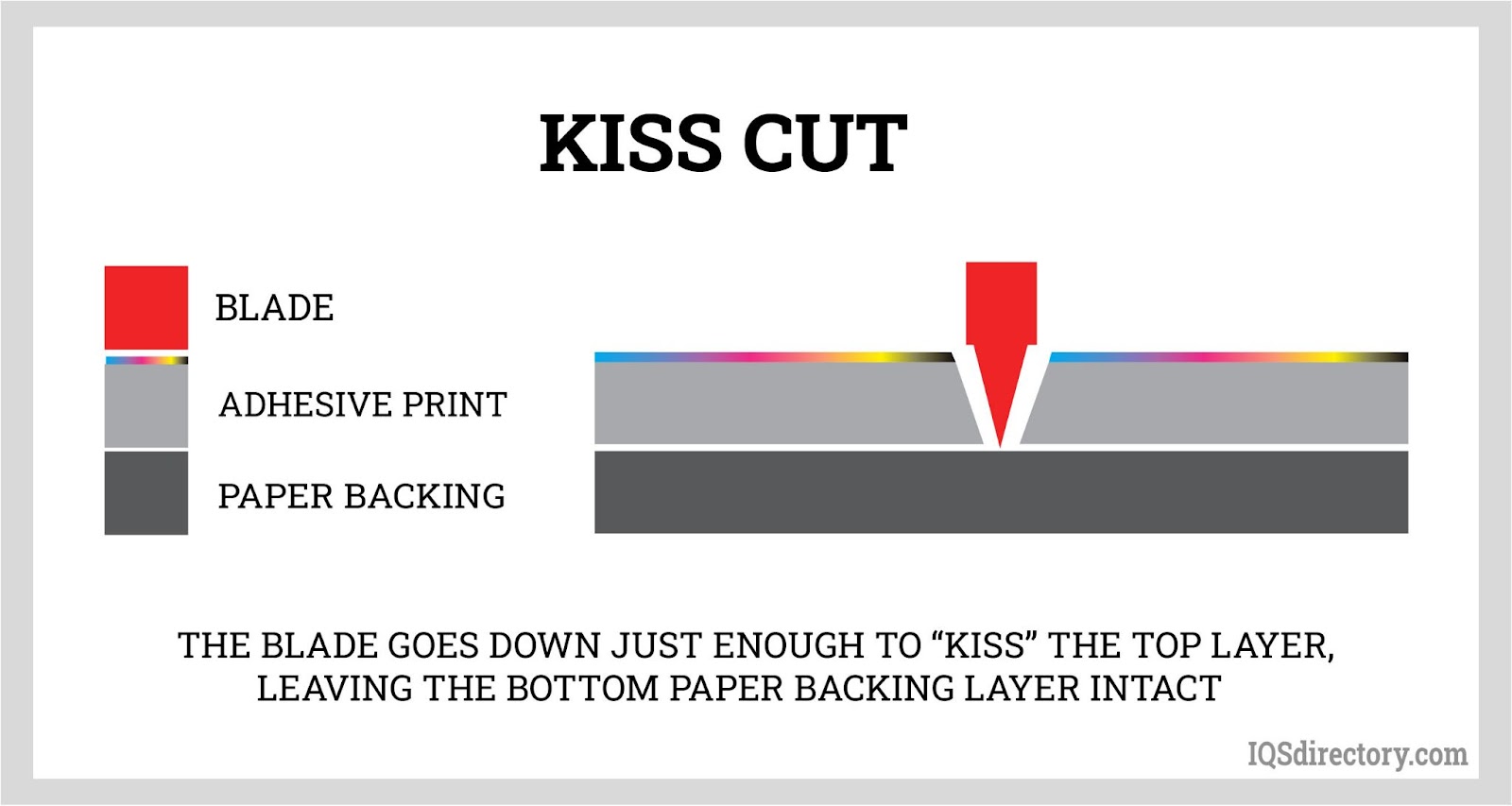

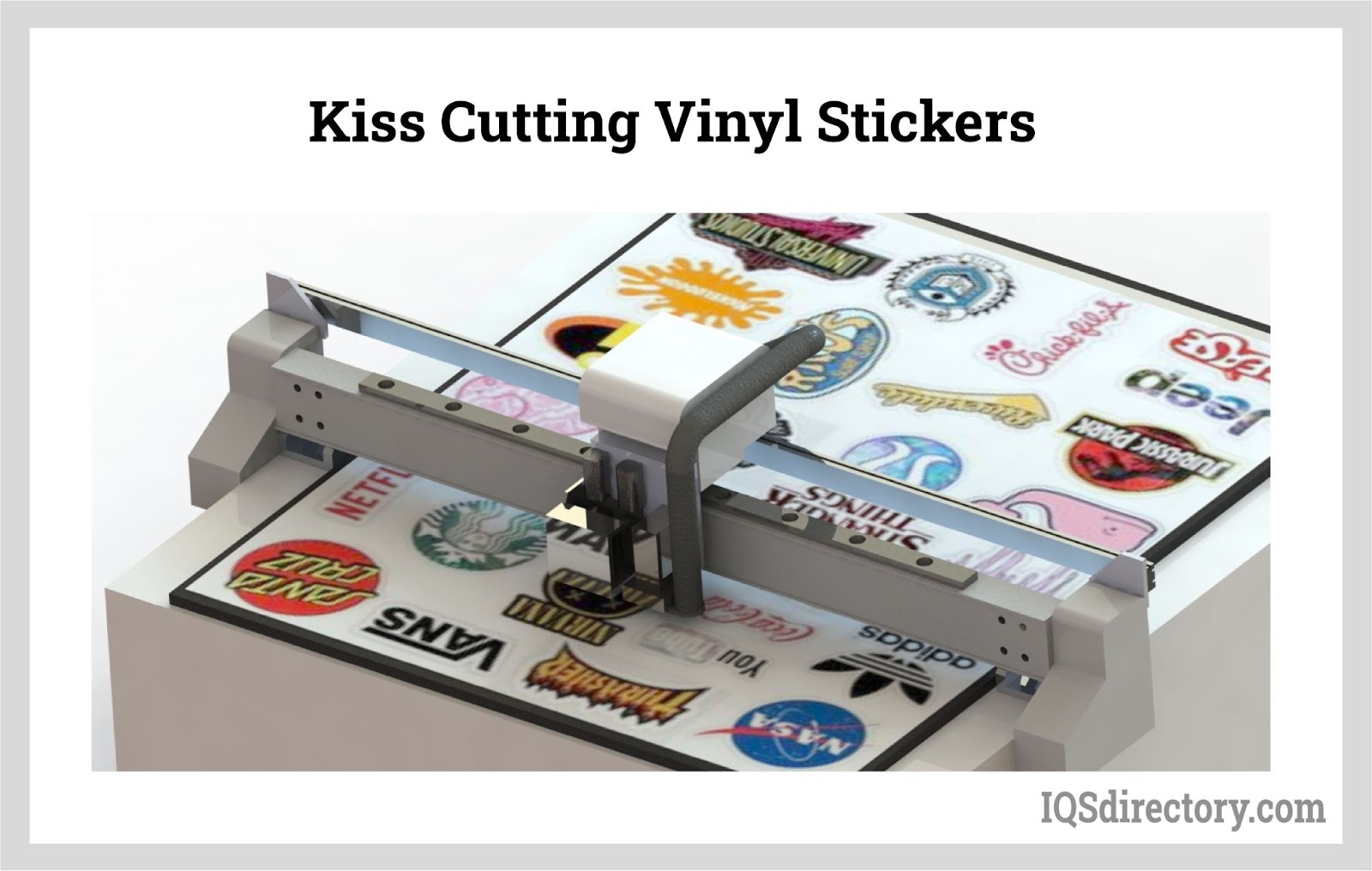

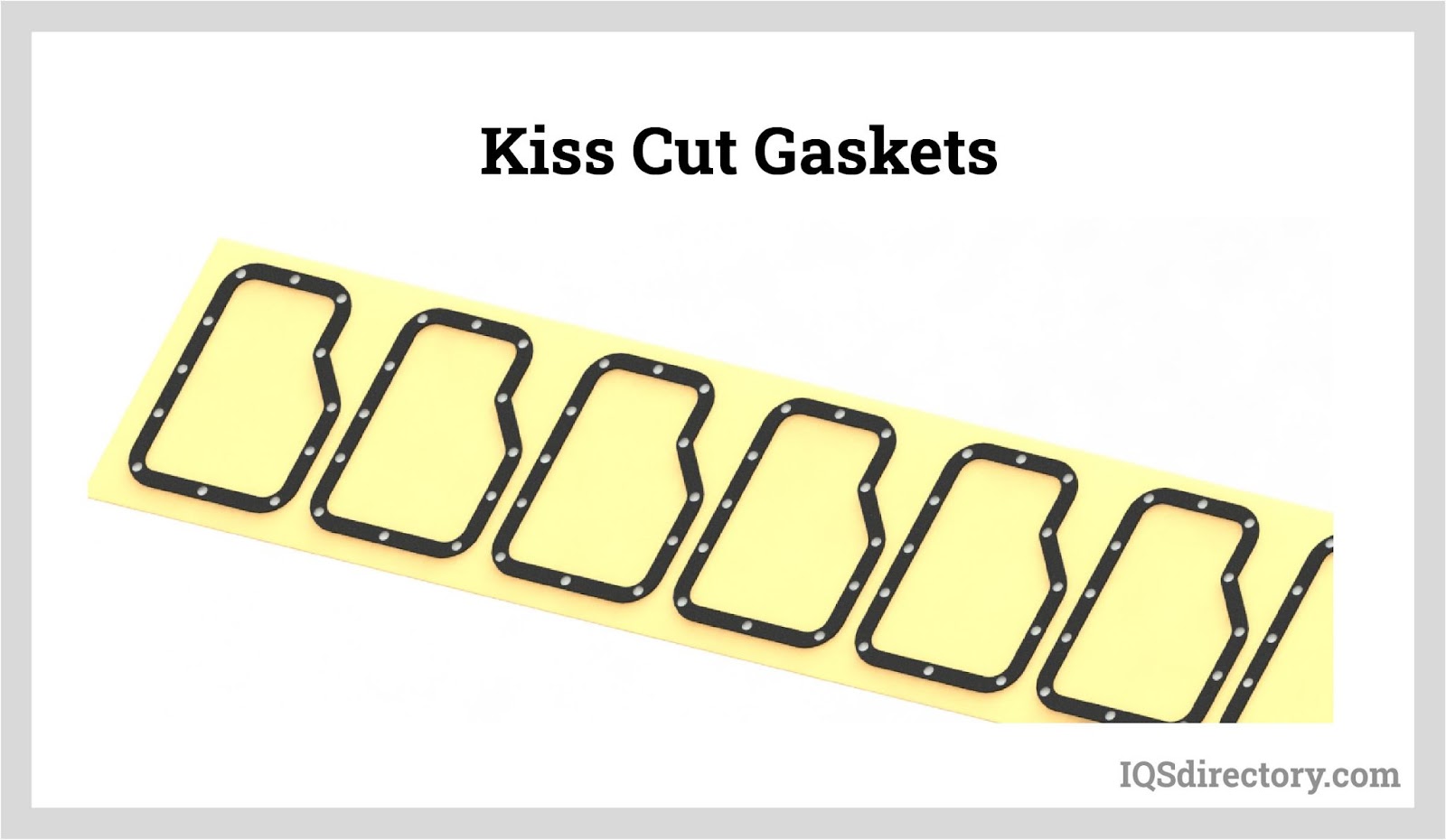

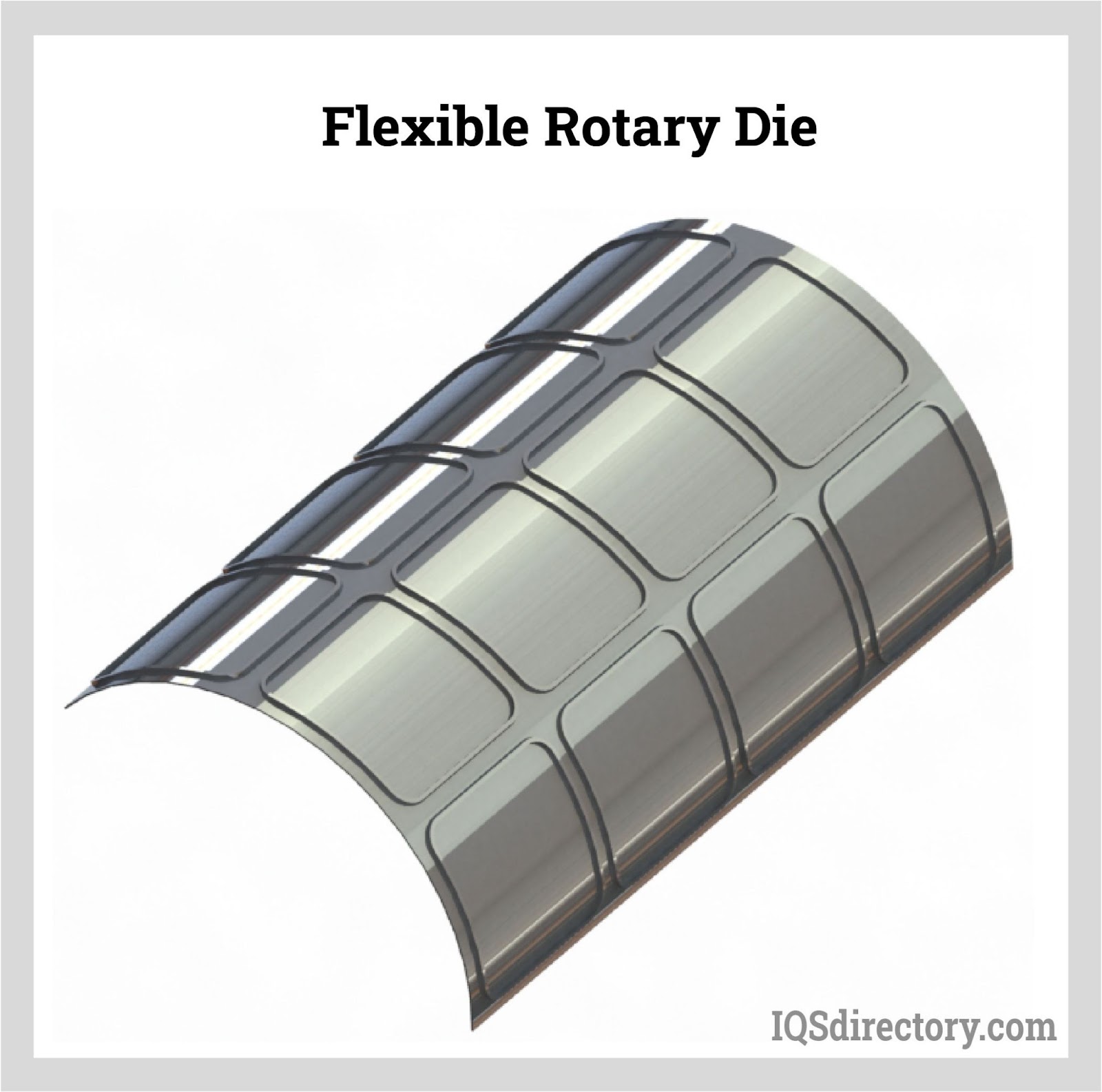

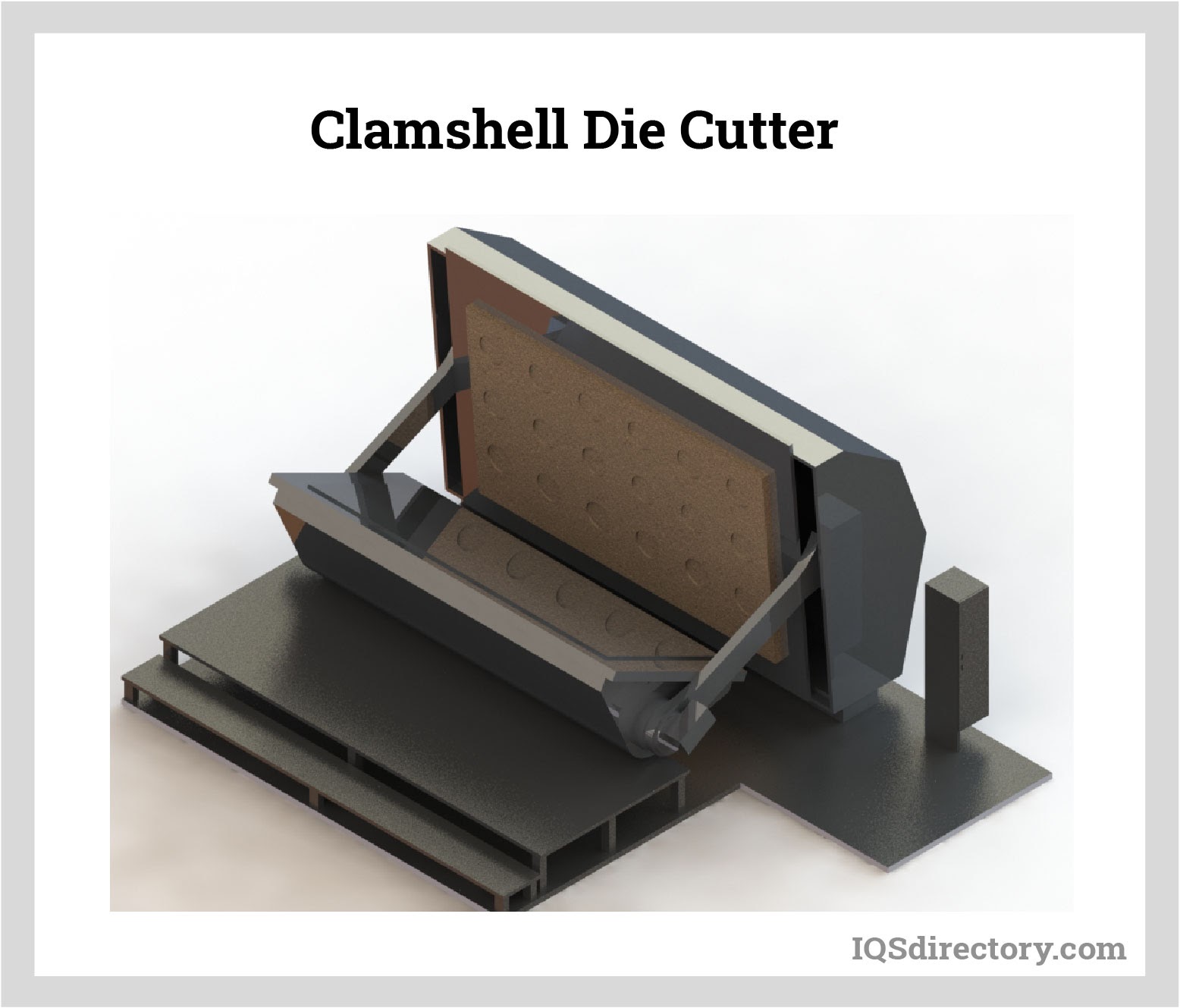

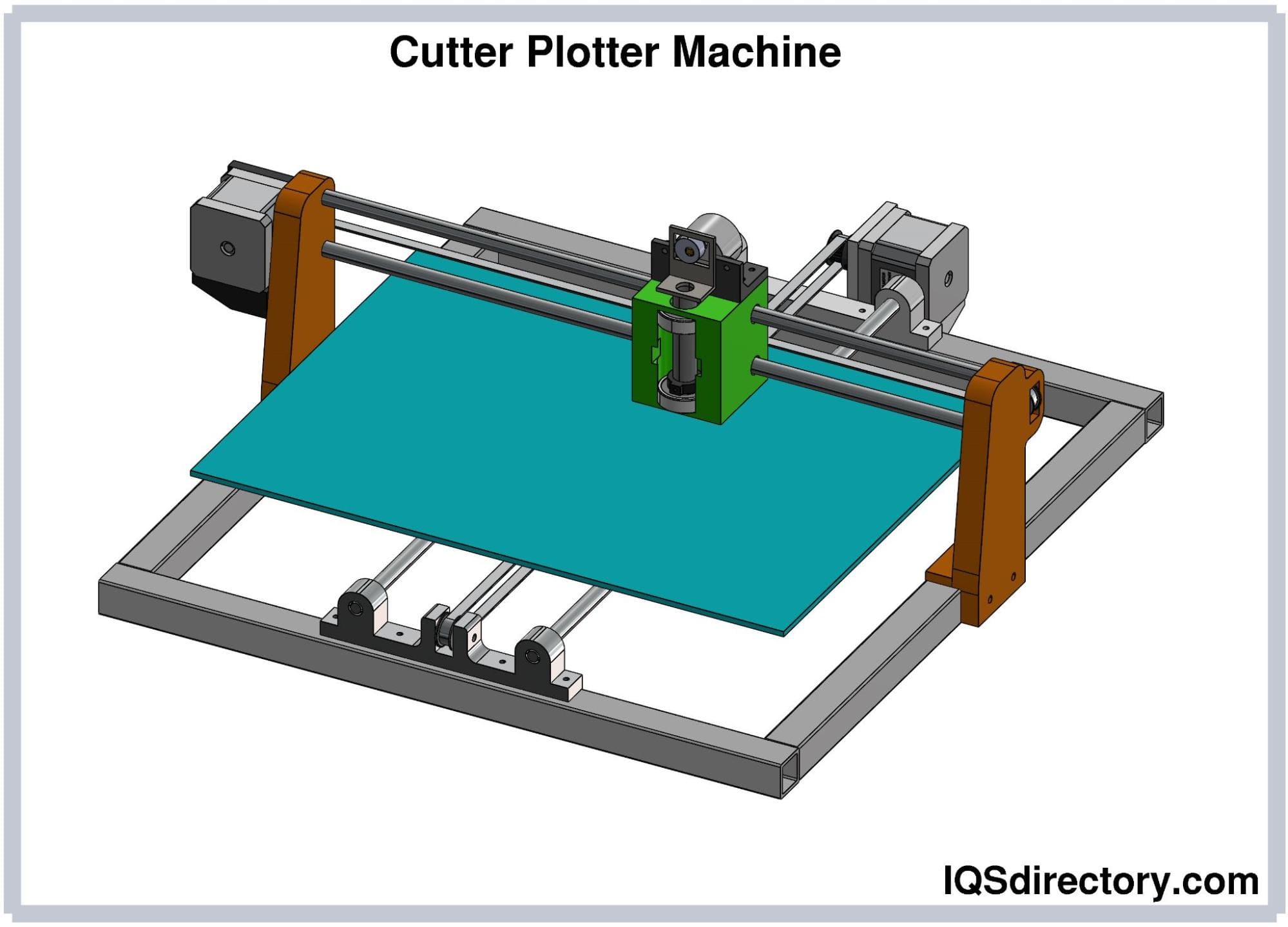

Forming: The Kiss Cutting Process

The forming stage is where the unique kiss cutting occurs. This process involves using a specialized die or laser cutter that precisely cuts through the vinyl layer while leaving the backing intact. This technique ensures that the stickers are easy to peel and apply, making them particularly suitable for intricate designs. The kiss cutting equipment must be calibrated correctly to ensure that the cuts are consistent and meet specified tolerances, which is crucial for maintaining quality across large production runs.

Assembly: Quality Control During Sticker Production

While kiss cut stickers typically do not require extensive assembly, quality checks are integrated into the production line. After the kiss cutting is completed, the stickers are often inspected for defects such as misalignment or incomplete cuts. This step is essential to ensure that each sticker meets the quality standards expected by B2B buyers.

Finishing: Adding Value to the Final Product

The finishing stage can include additional processes such as laminating, printing on the backing, or applying special coatings. For instance, adding a gloss finish can enhance the visual appeal of the stickers and increase their durability against wear and tear. Custom printing on the backing paper allows businesses to include branding information, which can be a valuable marketing tool.

How Is Quality Assurance Ensured in Kiss Cut Sticker Production?

Quality assurance (QA) is a vital component of the kiss cut sticker manufacturing process. To uphold international standards, manufacturers often adhere to recognized quality management systems such as ISO 9001. This certification ensures that the manufacturing processes are consistently monitored and improved.

Illustrative image related to kiss cut

What International Standards Apply to Kiss Cut Sticker Manufacturing?

International standards like ISO 9001 set the groundwork for quality management systems across various industries, including sticker manufacturing. Compliance with these standards assures B2B buyers that the products meet specific quality criteria. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe may also be relevant, depending on the end use of the stickers.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated at various stages of the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting the raw materials upon arrival. Suppliers must provide documentation that verifies the quality of the materials used.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators perform regular inspections to catch any defects early on. This includes monitoring the kiss cutting process to ensure accuracy.

-

Final Quality Control (FQC): Once production is complete, the final inspection involves checking the finished stickers for consistency, peeling ease, and overall quality. Any stickers that do not meet the standards are discarded or reworked.

What Testing Methods Are Commonly Used in Kiss Cut Sticker Quality Control?

Manufacturers employ various testing methods to ensure that kiss cut stickers meet quality standards. These may include:

-

Adhesion Testing: This checks how well the sticker adheres to surfaces, ensuring that it will perform as expected once applied.

-

Durability Testing: Stickers are subjected to conditions that mimic real-world usage, including exposure to moisture, UV light, and abrasion, to assess their longevity.

-

Visual Inspection: Trained quality control personnel conduct visual inspections to identify any cosmetic defects, ensuring that the final product meets aesthetic standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take several steps to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can provide valuable insights into the supplier’s operational capabilities.

-

Requesting Quality Reports: Suppliers should be able to provide documentation regarding their quality control processes, including inspection reports and certifications. Reviewing these documents can help buyers gauge the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an objective assessment of the supplier’s quality control practices. This is particularly useful for international buyers who may not be able to visit the manufacturing facility themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Cultural Differences: Understanding the cultural context of suppliers can help buyers navigate quality expectations and communication styles more effectively.

-

Regulatory Compliance: Different regions may have varying regulatory requirements for product safety and labeling. Buyers should ensure that their suppliers are compliant with these regulations to avoid any legal issues.

-

Logistical Considerations: Quality control doesn’t end at manufacturing. Buyers must consider how stickers will be stored and shipped, as these factors can also affect product quality.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for kiss cut stickers is essential for B2B buyers looking to source these products internationally. By focusing on material selection, the kiss cutting process, and robust quality control measures, buyers can ensure that they are partnering with reliable suppliers who deliver high-quality products that meet their specific needs.

Illustrative image related to kiss cut

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kiss cut’

Introduction

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for procuring kiss cut stickers. Kiss cut stickers offer versatility and ease of use, making them a popular choice for branding and promotional materials. By following this step-by-step guide, you can ensure a successful procurement process that meets your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for kiss cut stickers. This includes dimensions, material type, adhesive quality, and desired finish (e.g., glossy or matte).

– Why it matters: Specific requirements help suppliers understand your needs, reducing the chances of errors and ensuring that the final product aligns with your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in producing kiss cut stickers. Look for companies that specialize in custom sticker production and have positive reviews from other B2B clients.

– What to look for: Supplier experience, production capacity, and geographic location can impact lead times and shipping costs.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers comply with relevant industry standards and certifications. Look for suppliers who adhere to environmental regulations and quality control processes.

– Why this is essential: Certifications can indicate a supplier’s commitment to quality and sustainability, which can enhance your brand’s image and help you avoid potential legal issues.

Illustrative image related to kiss cut

Step 4: Request Samples

Before finalizing a supplier, request samples of their kiss cut stickers. This allows you to evaluate the quality of materials, print accuracy, and overall finish.

– Considerations: Assess the ease of peeling, durability, and how well the stickers adhere to various surfaces. Ensure the sample meets your expectations in terms of design and functionality.

Step 5: Discuss Customization Options

Engage in discussions about customization possibilities, including size variations, additional print on the backing paper, and unique shapes.

– Why customization matters: Custom options can enhance branding efforts by incorporating logos or contact information directly onto the sticker’s backing, providing added value to your marketing materials.

Step 6: Compare Pricing and Minimum Order Quantities

Review the pricing structures and minimum order quantities (MOQs) from different suppliers. Ensure you understand the cost implications of various sizes and quantities.

– What to consider: Look for bulk order discounts and explore if suppliers offer flexible MOQs that can accommodate your business needs without overcommitting financially.

Illustrative image related to kiss cut

Step 7: Confirm Production and Shipping Timelines

Finally, confirm the production lead times and shipping options with your chosen supplier. Make sure to discuss any potential delays and how they can be mitigated.

– Why this is crucial: Timely delivery is essential for aligning with marketing campaigns or product launches. Understanding the supplier’s capabilities can help you plan effectively.

By following these steps, B2B buyers can streamline their sourcing process for kiss cut stickers, ensuring a successful partnership with suppliers that meets both quality and logistical requirements.

Comprehensive Cost and Pricing Analysis for kiss cut Sourcing

What Are the Key Cost Components in Kiss Cut Sticker Sourcing?

Understanding the cost structure of kiss cut stickers is essential for B2B buyers to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of vinyl and adhesive used for kiss cut stickers significantly influences costs. High-quality materials enhance durability and aesthetics but come at a premium. Options range from polypropylene to PVC-free materials, each impacting the overall price.

-

Labor: Labor costs encompass the workforce needed for design, production, and finishing processes. Skilled labor may be required for intricate designs, leading to higher costs. Automation can reduce labor costs but may require initial investment in machinery.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Overhead costs vary by region and facility efficiency. In countries with lower operational costs, such as some South American and African nations, manufacturers might offer more competitive pricing.

-

Tooling: Kiss cut stickers require specific cutting tools and dies, which can be costly. The initial investment is often spread across production runs, making it essential to consider minimum order quantities (MOQs) to amortize these costs effectively.

-

Quality Control (QC): Ensuring the quality of stickers through inspections and testing adds to the cost. Buyers should prioritize suppliers who emphasize QC to avoid defects that could lead to additional expenses down the line.

-

Logistics: Shipping costs can vary significantly based on distance, volume, and chosen Incoterms. Buyers should factor in customs duties and local taxes when importing stickers, especially from suppliers in different continents.

-

Margin: Supplier margins vary based on their operational costs and market positioning. Understanding the margin can help buyers assess whether they are receiving a fair price.

How Do Volume and Customization Affect Kiss Cut Sticker Prices?

Volume plays a crucial role in pricing; larger orders often lead to significant discounts. Suppliers typically have tiered pricing structures, where the cost per unit decreases as the order quantity increases. For instance, ordering 500 kiss cut stickers can yield a price reduction of up to 65% compared to smaller orders.

Customization also influences pricing. Complex designs or unique shapes may require additional setup time and tooling, raising costs. Buyers should communicate their specifications clearly to avoid unexpected charges.

What Are the Key Pricing Influencers for International B2B Buyers?

When sourcing kiss cut stickers, several pricing influencers come into play:

-

Specifications and Quality: Stickers with special finishes (e.g., glossy or matte) or certifications (e.g., eco-friendly materials) often come at a higher price. Buyers should weigh the importance of these features against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their experience and quality assurance practices, while newer companies might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms affect shipping costs and responsibilities. For instance, using DDP (Delivered Duty Paid) can simplify logistics but may also increase upfront costs.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

To optimize costs, buyers should consider the following negotiation strategies:

-

Leverage Volume Discounts: Consolidating orders or collaborating with other businesses can increase order size and secure better pricing.

-

Explore Alternative Materials: Discussing material options with suppliers can reveal cost-saving alternatives without compromising quality.

-

Assess Total Cost of Ownership (TCO): Look beyond the sticker price. Consider factors like durability and potential reorders, which can affect long-term costs.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local market conditions that can influence pricing.

Final Thoughts on Kiss Cut Sticker Pricing

While the prices for kiss cut stickers can vary widely based on numerous factors, buyers are encouraged to conduct thorough market research and supplier evaluations. As an indicative guideline, small orders might start around $27 for 19 pieces, while larger orders can yield substantial discounts, making it essential to balance budget constraints with quality requirements. Understanding these dynamics can empower international B2B buyers to make strategic sourcing decisions tailored to their unique needs.

Alternatives Analysis: Comparing kiss cut With Other Solutions

Exploring Alternatives to Kiss Cut Stickers

When evaluating sticker production methods, understanding the alternatives to kiss cut stickers can help businesses make informed decisions. Each option comes with its unique advantages and challenges that cater to different branding and marketing needs. This analysis compares kiss cut stickers against die cut stickers and label printing, two viable alternatives in the sticker production landscape.

| Comparison Aspect | Kiss Cut | Die Cut | Label Printing |

|---|---|---|---|

| Performance | High, easy to peel | High, precise cut | Moderate, depends on material quality |

| Cost | Moderate, cost-effective for bulk | Higher due to custom dies | Generally low, varies with materials |

| Ease of Implementation | User-friendly design process | Requires specialized setup | Simple, often template-driven |

| Maintenance | Low, durable materials | Low, but custom dies may wear | Moderate, can require replacement |

| Best Use Case | Branding, intricate designs | Unique shapes, logos | General labeling, product information |

What are the Pros and Cons of Die Cut Stickers?

Die cut stickers are cut through both the vinyl and backing, allowing for intricate designs that match the exact shape of the artwork. Pros include their eye-catching appearance and the ability to create unique shapes that stand out. However, they typically come at a higher cost due to the need for custom die creation and can be more challenging to produce in bulk. Businesses looking for highly customized designs that need to grab attention might find die cut stickers beneficial despite the higher price point.

Illustrative image related to kiss cut

How Does Label Printing Compare to Kiss Cut Stickers?

Label printing provides a more straightforward approach, ideal for businesses needing simple product identification or branding. Pros of label printing include lower costs and ease of implementation, as many businesses can use standard printers and templates. However, the quality and durability of labels can vary significantly depending on the materials used, which may not be as resilient as kiss cut stickers. Companies focused on functional labeling rather than artistic designs may prefer this method for its efficiency and cost-effectiveness.

Conclusion: How Should B2B Buyers Choose the Right Sticker Solution?

When selecting the right sticker solution, B2B buyers should consider their specific needs, including the desired visual impact, budget constraints, and the intended use of the stickers. Kiss cut stickers excel in branding and detailed designs, making them ideal for businesses focused on marketing and customer engagement. Die cut stickers offer unique aesthetic advantages but come at a higher cost, suitable for companies looking to make a bold statement. Label printing serves as an economical option for straightforward applications but may lack the artistic flair of the other two methods. By carefully assessing these factors, businesses can choose the most appropriate sticker solution to enhance their branding efforts and meet their operational requirements.

Essential Technical Properties and Trade Terminology for kiss cut

What Are the Key Technical Properties of Kiss Cut Stickers?

Understanding the technical specifications of kiss cut stickers is essential for B2B buyers looking to make informed purchasing decisions. Here are the critical properties to consider:

1. Material Grade

Kiss cut stickers can be produced from various materials, including vinyl, polypropylene, and specialty papers. The choice of material affects durability, flexibility, and application suitability. For instance, vinyl offers superior weather resistance, making it ideal for outdoor use. Buyers should select materials that align with their intended application—whether for branding, packaging, or promotional purposes.

2. Adhesive Type

The adhesive used in kiss cut stickers can be classified as permanent or removable. Permanent adhesives provide strong bonding, suitable for long-term applications, whereas removable adhesives allow for easy repositioning without leaving residue. This distinction is crucial for businesses that may need to adjust branding elements or promotions frequently.

Illustrative image related to kiss cut

3. Finish Options

Kiss cut stickers are available in various finishes, including glossy, matte, and textured. Glossy finishes enhance color vibrancy and are often used for eye-catching designs, while matte finishes offer a more subdued look that can be preferable for sophisticated branding. The finish can significantly impact the visual appeal of the sticker, so it’s important for buyers to consider how the finish aligns with their brand identity.

4. Cut Tolerance

Cut tolerance refers to the precision with which the sticker is cut. A tighter tolerance ensures that the kiss cut lines are consistent, which is especially important for intricate designs. Higher precision reduces waste and enhances the quality of the final product, making it a vital specification for businesses looking to maintain high standards in their branding materials.

5. Size and Shape Customization

Kiss cut stickers can be customized in various sizes and shapes, allowing businesses to create unique branding elements tailored to their needs. This flexibility is beneficial for companies wanting to stand out in a competitive market. It’s important for buyers to specify their desired dimensions and shapes to ensure that the final product meets their expectations.

Illustrative image related to kiss cut

What Are Common Trade Terminologies Related to Kiss Cut Stickers?

Navigating the B2B landscape requires familiarity with industry jargon. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

In the sticker industry, OEM refers to companies that produce stickers for other brands to sell under their name. Understanding OEM relationships can help businesses identify potential suppliers that can produce high-quality kiss cut stickers without the need for extensive in-house production.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For kiss cut stickers, MOQs can vary significantly between manufacturers. Knowing the MOQ is essential for businesses to manage inventory costs and ensure they are ordering enough product to justify production runs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information based on specific requirements. When considering kiss cut stickers, companies should prepare an RFQ detailing their needs, including material, size, and quantity, to receive accurate quotes from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms can help businesses navigate shipping logistics more effectively, particularly when sourcing kiss cut stickers from international suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order to delivery. Understanding lead times for kiss cut stickers is crucial for businesses with tight deadlines, ensuring that promotional materials are available when needed. Buyers should always inquire about expected lead times when placing orders.

By grasping these essential properties and terminologies, B2B buyers can make informed decisions when purchasing kiss cut stickers, ensuring they meet their branding and marketing needs effectively.

Navigating Market Dynamics and Sourcing Trends in the kiss cut Sector

What Are the Current Market Dynamics and Key Trends in the Kiss Cut Sector?

The kiss cut sticker market is experiencing significant growth, driven by the increasing demand for custom branding and labeling solutions across various industries. As businesses aim to enhance their visibility, kiss cut stickers have emerged as an effective tool for marketing, allowing companies to display intricate designs, logos, and essential information on their products. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where local businesses are leveraging cost-effective sticker solutions to reach broader audiences.

Emerging technologies in the printing and cutting processes are also reshaping the kiss cut sector. Innovations such as digital printing and automated cutting machines are streamlining production, reducing lead times, and allowing for greater customization. This is crucial for international B2B buyers who prioritize efficiency and responsiveness in their supply chains. Additionally, the rise of e-commerce has propelled the demand for high-quality, easily shippable products, making kiss cut stickers an attractive option for businesses operating in competitive markets.

Illustrative image related to kiss cut

Furthermore, as the global market becomes increasingly interconnected, buyers are encouraged to evaluate suppliers not only on price but also on their technological capabilities and flexibility in meeting custom orders. This shift emphasizes the importance of strategic partnerships and reliable sourcing strategies to navigate the complexities of international trade.

How Important Is Sustainability and Ethical Sourcing in the Kiss Cut Industry?

As environmental concerns gain traction worldwide, sustainability and ethical sourcing have become critical considerations for B2B buyers in the kiss cut sector. The production of stickers often involves materials such as vinyl and adhesives, which can have negative environmental impacts if not sourced responsibly. Buyers are increasingly seeking suppliers who utilize eco-friendly materials, such as biodegradable or recyclable options, to minimize their carbon footprint.

The importance of ethical supply chains cannot be overstated. Companies that prioritize sustainability are not only responding to consumer demands but also enhancing their brand reputation. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 can serve as indicators of a supplier’s commitment to sustainable practices. These certifications assure buyers that the materials used in kiss cut stickers are sourced responsibly, reducing environmental harm.

Moreover, sustainable practices can lead to cost savings in the long run. By implementing waste reduction measures and energy-efficient processes, suppliers can offer competitive pricing while maintaining quality. This shift toward sustainability not only benefits the environment but also aligns with the growing preference for brands that demonstrate corporate social responsibility.

Illustrative image related to kiss cut

How Has the Kiss Cut Sticker Market Evolved Over Time?

The kiss cut sticker market has evolved significantly since its inception, transitioning from simple decorative elements to vital marketing tools for businesses. Initially popular among artists and hobbyists, kiss cut stickers gained traction in the 1980s as a cost-effective way for brands to promote their products. The advent of digital printing technology in the late 1990s further revolutionized the industry, allowing for high-quality, customized designs at scale.

Today, kiss cut stickers are widely used across various sectors, including retail, food and beverage, and technology, to enhance branding and customer engagement. As businesses continue to recognize the versatility and effectiveness of kiss cut stickers, the market is poised for further growth, driven by innovation and a heightened focus on sustainability. International buyers are encouraged to stay informed about these trends to make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of kiss cut

-

How do I ensure high-quality kiss cut stickers for my business?

To ensure the quality of kiss cut stickers, start by selecting a reputable supplier with experience in custom printing. Request samples to assess the material, adhesive strength, and finish. It’s also beneficial to communicate your design specifications clearly, including cut lines and dimensions. Consider suppliers that offer quality assurance processes, such as pre-production proofs, to verify the design and material before the full run. -

What are the benefits of using kiss cut stickers for branding?

Kiss cut stickers are ideal for branding because they provide a clean and professional look while being easy to peel and apply. The extra backing allows for additional printed information, such as contact details or promotional messages, enhancing your brand visibility. They are versatile for various applications, including product labeling, giveaways, and packaging, making them a valuable asset for marketing strategies. -

What should I consider when choosing a kiss cut sticker supplier?

When selecting a supplier for kiss cut stickers, consider their production capabilities, minimum order quantities (MOQs), and lead times. Review customer testimonials and portfolio samples to gauge their quality and service. Ensure they have the necessary certifications, especially if you are exporting products internationally, and inquire about their customization options to meet your specific branding needs. -

What is the typical minimum order quantity (MOQ) for kiss cut stickers?

MOQs for kiss cut stickers can vary significantly among suppliers, ranging from as low as 10 to 1000 or more. It’s crucial to discuss your needs with potential suppliers, as some may offer flexible options for smaller businesses or startups. Keep in mind that larger orders often benefit from cost savings per unit, so consider your budget and projected usage when ordering. -

How can I customize my kiss cut stickers for international markets?

Customizing kiss cut stickers for international markets involves understanding local preferences and regulations. Collaborate with your supplier to incorporate specific designs, colors, or languages that resonate with your target audience. Additionally, ensure that the materials used comply with local safety and environmental standards, as these can vary by region. Offering multi-language options can also enhance market acceptance. -

What payment terms should I negotiate with my kiss cut sticker supplier?

Payment terms can vary widely, so it’s essential to negotiate terms that suit both parties. Common arrangements include upfront deposits (usually 30-50%) with the balance due upon delivery. For larger orders or long-term partnerships, consider negotiating more favorable terms, such as extended payment periods or discounts for early payments. Always clarify the acceptable payment methods, especially for international transactions. -

What are the shipping options for kiss cut stickers when sourcing internationally?

Shipping options for kiss cut stickers typically include air freight, sea freight, and courier services. The choice depends on your urgency and budget. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but slower. Ensure your supplier provides reliable logistics support, including tracking and customs documentation, to facilitate smooth international shipping. -

How do I address potential quality assurance issues with kiss cut stickers?

To mitigate quality assurance issues, establish clear quality expectations and specifications with your supplier before production begins. Request regular updates and samples during the production process to ensure alignment with your requirements. Additionally, consider implementing a final inspection process upon receipt of your stickers to identify any discrepancies. If issues arise, maintain open communication with your supplier to resolve them promptly.

Top 4 Kiss Cut Manufacturers & Suppliers List

1. RONT – Vinyl Sticker Paper

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Glossy vinyl sticker paper, HTV RONT paper, Cricut machine settings for kiss cut stickers, suggested settings include washi or sticky note settings, importance of custom cut settings based on material and machine type.

2. FourthWall – Kiss Cut Stickers

Domain: fourthwall.com

Registered: 1998 (27 years)

Introduction: Kiss Cut Stickers, sizes available: 3″ x 3″, 4″ x 4″, 5.5″ x 5.5″, 15″ x 3.75″, starting from $2.29. Customizable shapes with a wide border for easy peeling. Made of durable vinyl, suitable for indoor use, with high opacity film. Thickness: 95µ. Fast, bubble-free application. Manufactured by Printful. No minimum orders. Ships from US, EU, CA, UK, JP, and AU.

3. UPrinting – Custom Kiss Cut Stickers

Domain: uprinting.com

Registered: 2004 (21 years)

Introduction: Kiss Cut Stickers – Custom Kiss Cut Sticker Printing | High Quality | On Time Delivery | Everyday Fair Prices. Features: Easily peels away from backing, custom shapes & sizes, available in paper & waterproof BOPP material. Available sizes: 2″ x 2″, 3″ x 4″, 3″ x 3″, 4″ x 4″, 5″ x 5″ and custom widths/heights up to 11″. Materials: Matte White Paper, Gloss White Paper, 100% Recycled Kraft Paper, Wat…

4. VistaPrint – Custom Kiss-Cut Stickers

Domain: vistaprint.com

Registered: 1999 (26 years)

Introduction: Custom Kiss-Cut Stickers Printing from VistaPrint. Available in various shapes including circle, oval, rectangle, and square. Options for die-cut sticker sheets and individual kiss-cut stickers. No minimum order quantity. Express shipping available. Ideal for personal or business use.

Strategic Sourcing Conclusion and Outlook for kiss cut

Kiss cut stickers present a unique opportunity for businesses looking to enhance their branding and marketing strategies. Their versatility allows for intricate designs while maintaining easy peel-off functionality, making them ideal for promotional materials, product packaging, and event giveaways. As international B2B buyers from diverse markets, including Africa, South America, the Middle East, and Europe, consider integrating kiss cut stickers into your product offerings, it’s essential to evaluate suppliers based on quality, pricing, and customization capabilities.

Strategic sourcing in this area can lead to improved cost efficiency and enhanced product presentation, ultimately driving customer engagement. Understanding the nuances between kiss cut and die cut stickers will empower your organization to make informed decisions that align with your branding objectives.

Looking ahead, the demand for customizable and visually appealing branding solutions is expected to rise. By leveraging kiss cut stickers, you can not only stand out in competitive markets but also build lasting connections with your audience. Engage with reliable suppliers today to explore how kiss cut stickers can elevate your brand presence and meet your specific business needs.

Illustrative image related to kiss cut

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.