Key Maker Machine: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for key maker machine

In today’s fast-paced global economy, sourcing key maker machines can present significant challenges for B2B buyers. With a diverse range of options available, from manual key duplicators to advanced automated systems, understanding which machine best fits your business needs is crucial. This guide offers a comprehensive overview of key maker machines, covering various types, applications, and essential factors to consider when making a purchasing decision. Whether you are operating in the bustling markets of Nigeria, the oil-rich economies of Saudi Arabia, or the diverse landscapes of South America and Europe, knowing how to navigate this market can empower you to make informed choices.

Throughout this guide, we will delve into the intricacies of key maker machines, including performance metrics, supplier vetting processes, and cost analysis. By providing actionable insights and expert recommendations, we aim to equip international B2B buyers with the knowledge necessary to identify reliable suppliers and secure high-quality machines that meet their operational demands. Understanding these factors not only enhances your purchasing power but also positions your business for sustained growth in an increasingly competitive landscape. As we explore the global market for key maker machines, you will gain clarity on how to optimize your investments and elevate your service offerings.

Understanding key maker machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Key Duplicators | Operated by hand; requires skill; cost-effective. | Small locksmith shops, mobile services. | Pros: Low initial cost, simplicity. Cons: Labor-intensive, slower output. |

| Semi-Automatic Key Machines | Combines manual and automated features; user-friendly. | Small to medium locksmith businesses. | Pros: Faster than manual, less skill required. Cons: Higher cost than manual. |

| Automatic Key Cutting Machines | Fully automated; high precision; quick key duplication. | Large locksmith operations, retail kiosks. | Pros: High efficiency, consistent quality. Cons: Higher upfront investment, maintenance costs. |

| Code Cutting Machines | Reads key codes for precise cutting; versatile. | Automotive locksmiths, security firms. | Pros: Ideal for complex keys, reduces human error. Cons: Requires training, more expensive. |

| Portable Key Cutting Machines | Battery-operated; lightweight and easy to transport. | On-site services, emergency locksmiths. | Pros: Convenient for mobile services, versatile. Cons: Limited cutting capabilities, battery dependency. |

What Are the Characteristics of Manual Key Duplicators?

Manual key duplicators are the most basic form of key-making machines, requiring the operator to manually align and cut the key. They are often used in small locksmith shops and by mobile service providers due to their low initial cost and simplicity. However, the process is labor-intensive and can be time-consuming, which may not suit businesses needing high-volume production.

How Do Semi-Automatic Key Machines Enhance Efficiency?

Semi-automatic key machines offer a blend of manual and automated functions, making them user-friendly while still allowing for significant output. These machines are well-suited for small to medium-sized locksmith businesses, enhancing productivity while requiring less skill than fully manual machines. They come at a higher cost than manual options but provide faster duplication, making them a worthwhile investment for growing operations.

Why Choose Automatic Key Cutting Machines for High Volume Needs?

Automatic key cutting machines are designed for high efficiency and precision, capable of producing multiple keys quickly and consistently. They are ideal for large locksmith operations and retail kiosks where speed and accuracy are crucial. While they come with a higher upfront investment and ongoing maintenance costs, their ability to streamline operations and reduce labor can significantly enhance profitability.

What Makes Code Cutting Machines Essential for Automotive Locksmiths?

Code cutting machines are specialized tools that read the specific codes of keys, allowing for precise duplication of complex key types, particularly in the automotive sector. These machines are invaluable for locksmiths dealing with high-security keys and are typically more expensive. However, their accuracy significantly reduces human error, making them an essential investment for businesses focused on automotive services.

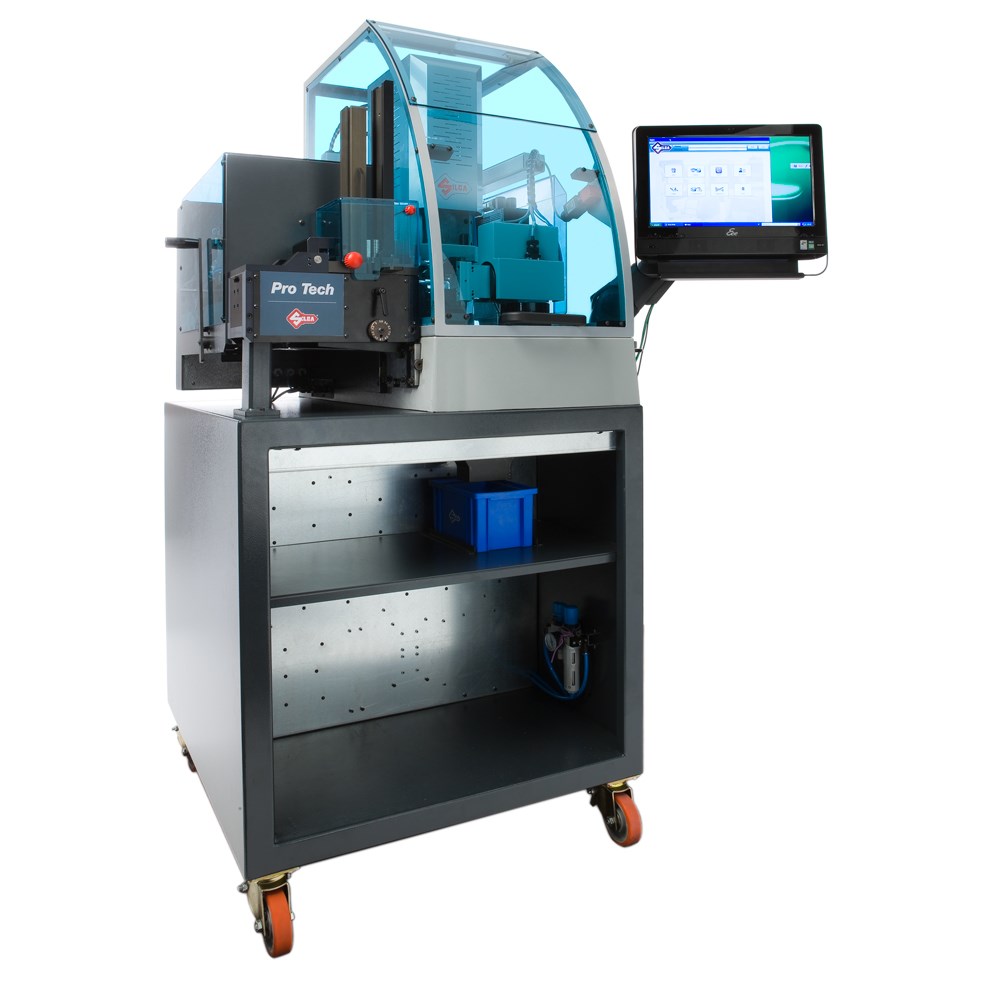

Illustrative image related to key maker machine

How Do Portable Key Cutting Machines Benefit On-Site Services?

Portable key cutting machines are lightweight and battery-operated, making them ideal for on-site services and emergency locksmith operations. These machines offer versatility and convenience, allowing locksmiths to provide immediate service without needing to return to a shop. However, they may have limited cutting capabilities compared to larger machines and rely on battery power, which can be a drawback in high-demand situations.

Key Industrial Applications of key maker machine

| Industry/Sector | Specific Application of key maker machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Key duplication for vehicles | Increased customer satisfaction and service speed | Compatibility with various car key types and security features |

| Hospitality | Master key systems for hotels | Enhanced security and ease of access | Durability and ability to handle high usage |

| Real Estate | Key cutting for rental properties | Efficient management of multiple properties | Portability and range of key types supported |

| Manufacturing | Access control keys for industrial equipment | Streamlined operations and security | Ability to handle specialized keys and rapid production |

| Retail | Self-service key duplication kiosks | Attracting customers and generating additional revenue | User-friendly design and reliable technology |

How is Key Maker Machine Used in the Automotive Industry?

In the automotive sector, key maker machines are essential for duplicating keys for various vehicles, including traditional keys and modern smart keys. This application addresses the problem of lost or damaged keys, providing a quick solution for both consumers and automotive businesses. B2B buyers in this sector should consider machines that accommodate a wide range of key types, including transponder and laser-cut keys, ensuring compatibility with various vehicle models.

What Role Does Key Maker Machine Play in the Hospitality Sector?

In hospitality, key maker machines are utilized to create master key systems that simplify access for staff while enhancing security. Hotels and resorts often require a reliable method to duplicate keys for guest rooms and service areas, minimizing the risk of unauthorized access. For international buyers, sourcing machines that offer high durability and can handle extensive usage is crucial, as these establishments often operate 24/7 and require efficient key management solutions.

How Do Key Maker Machines Benefit Real Estate Management?

Real estate agencies leverage key maker machines to manage key cutting for multiple rental properties efficiently. This application allows agents to quickly provide tenants with keys while maintaining a secure and organized system for property access. Buyers from regions like Africa and South America should focus on portable key maker machines that can handle various key types, as this flexibility is vital for managing diverse property portfolios.

Illustrative image related to key maker machine

What is the Importance of Key Maker Machines in Manufacturing?

In the manufacturing industry, key maker machines are vital for producing access control keys for machinery and equipment. This application ensures that only authorized personnel can access sensitive areas, thereby enhancing operational security. B2B buyers should seek machines capable of producing specialized keys tailored to specific industrial applications, as well as those that can deliver rapid production to keep up with operational demands.

How Do Retailers Utilize Key Maker Machines for Customer Engagement?

Retailers increasingly use self-service key duplication kiosks to enhance customer experience and generate additional revenue streams. These kiosks allow customers to duplicate keys on-site, providing convenience and immediate service. For B2B buyers in retail, sourcing user-friendly and reliable key maker machines is essential, as these kiosks must operate efficiently to attract and retain customers while minimizing maintenance issues.

3 Common User Pain Points for ‘key maker machine’ & Their Solutions

Scenario 1: Struggling with Machine Reliability and Maintenance Costs

The Problem: Many B2B buyers face the challenge of maintaining key maker machines that are prone to frequent breakdowns. This is particularly common in regions where the availability of skilled technicians is limited, leading to extended downtime. For businesses in Africa or South America, where access to replacement parts can be a logistical nightmare, the cost of repairs and maintenance can quickly escalate. This not only affects productivity but also leads to lost revenue opportunities as customers seek services elsewhere.

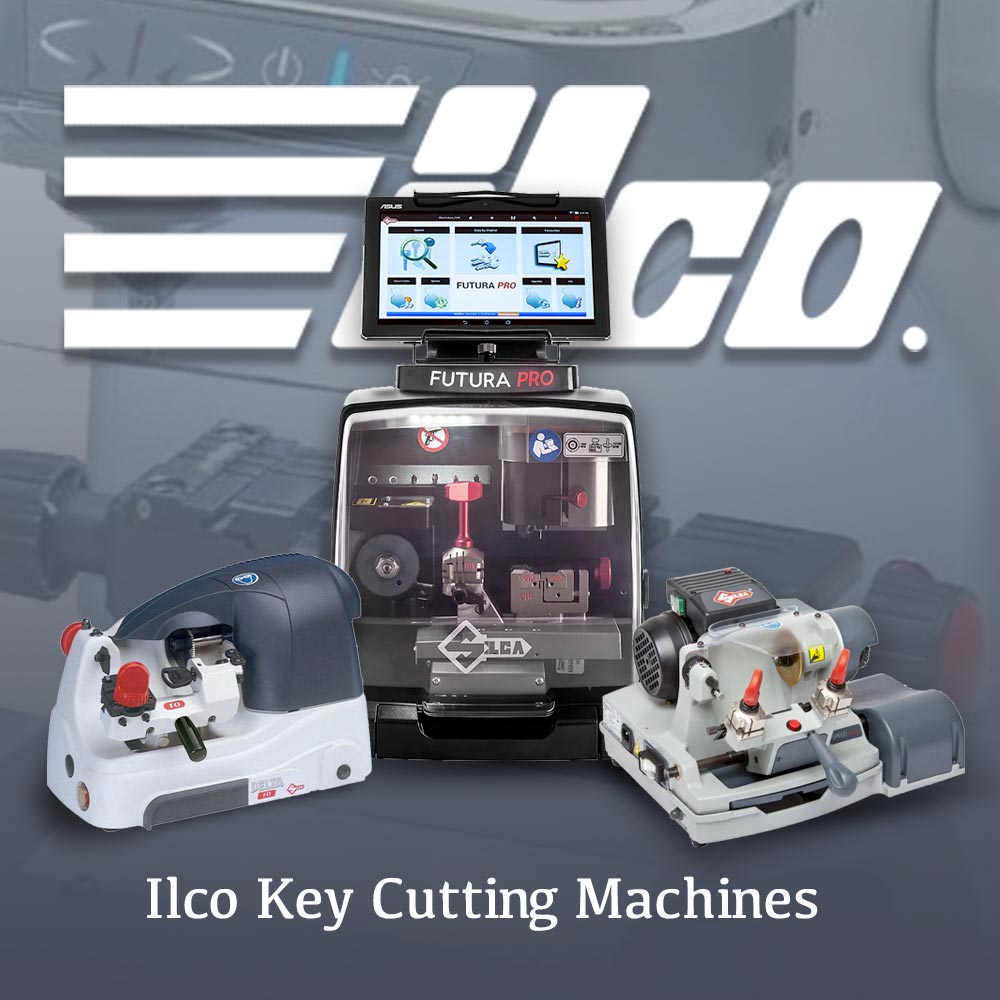

The Solution: To mitigate reliability issues, buyers should consider investing in high-quality machines known for their durability and low maintenance needs. Brands like ILCO and Silca offer robust key cutting machines that are designed for heavy use. When sourcing these machines, inquire about warranty options and after-sales support, ensuring that the manufacturer or supplier provides comprehensive technical assistance. Additionally, establishing a relationship with local technicians who can perform routine maintenance can significantly reduce long-term costs. Regularly scheduled maintenance checks can help catch potential issues before they escalate into major repairs, thereby ensuring continuous operation.

Scenario 2: Navigating the Complexity of Key Types and Cutting Techniques

The Problem: As the locksmith industry evolves, the variety of key types—from traditional to high-security and electronic fobs—can overwhelm buyers. Businesses often struggle to keep up with the technology and the specific cutting techniques required for each key type. This complexity can lead to mistakes during the cutting process, resulting in wasted materials and dissatisfied customers, particularly in competitive markets in the Middle East and Europe.

Illustrative image related to key maker machine

The Solution: To address this challenge, B2B buyers should prioritize machines that offer versatility in key cutting. Look for models that support multiple key types and come equipped with various cutting adapters. Training is also crucial; investing in staff training programs on the latest cutting techniques can enhance their skill set and confidence. Many manufacturers provide training resources or workshops that can be invaluable. Furthermore, maintaining a catalog of key specifications and cutting guidelines can serve as a quick reference for operators, minimizing errors and improving service quality.

Scenario 3: Managing Inventory and Supply Chain Issues

The Problem: For businesses relying on key maker machines, managing inventory can become a significant pain point, especially when dealing with international suppliers. Delays in receiving parts, whether due to shipping issues or customs regulations, can hinder service delivery. This is particularly problematic for businesses in regions like Nigeria or Saudi Arabia, where supply chain disruptions can be frequent. A lack of readily available inventory can lead to lost sales and customer dissatisfaction.

The Solution: To effectively manage inventory challenges, businesses should consider diversifying their suppliers. Establish relationships with multiple vendors to reduce reliance on a single source, and explore local suppliers for critical parts. Implementing an inventory management system that tracks stock levels and predicts reorder points can also be beneficial. This proactive approach ensures that essential components are always on hand, thus reducing the risk of service interruptions. Additionally, consider investing in a just-in-time inventory model, which can minimize storage costs while ensuring that parts are available when needed. This strategy not only improves efficiency but also enhances customer satisfaction by ensuring timely service delivery.

Strategic Material Selection Guide for key maker machine

What Are the Key Materials Used in Key Maker Machines?

When selecting materials for key maker machines, it is essential to consider properties that directly impact performance, durability, and manufacturing processes. The following analysis focuses on four common materials: steel, aluminum, plastic, and composite materials. Each material has unique characteristics that can influence the machine’s effectiveness and longevity.

Illustrative image related to key maker machine

How Does Steel Perform in Key Maker Machines?

Steel is one of the most widely used materials in key maker machines due to its exceptional strength and durability. It typically has a high-temperature rating and excellent corrosion resistance when treated or alloyed appropriately.

Pros: Steel’s primary advantages include its high tensile strength, which allows for precise cutting and durability under heavy use. It is also relatively cost-effective, making it a popular choice for manufacturers.

Cons: However, steel can be heavy, which may impact the portability of smaller machines. Additionally, if not properly treated, it can be susceptible to rust, especially in humid environments.

Illustrative image related to key maker machine

Impact on Application: Steel is compatible with various media types, including brass and aluminum keys, making it versatile for different key-making tasks.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that steel components comply with local standards, such as ASTM or DIN, to avoid issues related to quality and performance.

Why Choose Aluminum for Key Maker Machines?

Aluminum is another popular material, particularly for components that require lightweight properties without sacrificing strength.

Pros: The key advantages of aluminum include its low weight and excellent corrosion resistance, which makes it suitable for portable machines. It is also easier to machine than steel, allowing for more intricate designs.

Cons: On the downside, aluminum is generally less durable than steel and may not withstand the same level of wear and tear. Its cost can also be higher than that of basic steel options.

Illustrative image related to key maker machine

Impact on Application: Aluminum is suitable for applications requiring lightweight components, such as portable key cutting machines that need to be easily transported.

Considerations for International Buyers: Buyers in South America and Europe should consider the availability of aluminum and its compliance with local manufacturing standards to ensure quality.

What Role Does Plastic Play in Key Maker Machines?

Plastic is often used in non-critical components of key maker machines, such as housings and covers.

Pros: The main advantages of plastic include its lightweight nature and resistance to corrosion. It can be molded into complex shapes, allowing for innovative designs.

Cons: However, plastic is less durable than metal and may not withstand high temperatures or heavy use, which can limit its application in high-performance machines.

Illustrative image related to key maker machine

Impact on Application: Plastic components are ideal for applications where weight is a concern, but they may not be suitable for heavy-duty tasks.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant safety and quality standards, particularly in regions with stringent regulations.

How Are Composite Materials Used in Key Maker Machines?

Composite materials, which combine various substances to enhance performance, are becoming increasingly popular in key maker machines.

Pros: Composites offer the advantage of high strength-to-weight ratios and can be engineered for specific applications, providing excellent durability and resistance to environmental factors.

Cons: The primary drawback is the higher manufacturing complexity and cost associated with composites, which can deter some manufacturers.

Impact on Application: Composites can be tailored for specific media compatibility, making them suitable for specialized key-making tasks.

Considerations for International Buyers: Buyers should assess the availability and compliance of composite materials with local standards, especially in emerging markets in Africa and South America.

Summary Table of Material Selection for Key Maker Machines

| Material | Typical Use Case for key maker machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Cutting and durable machine parts | High strength and durability | Heavy and susceptible to rust | Medium |

| Aluminum | Portable key cutting machines | Lightweight and corrosion-resistant | Less durable than steel | High |

| Plastic | Non-critical components | Lightweight and moldable | Less durable and temperature-sensitive | Low |

| Composite | Specialized applications | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of the materials commonly used in key maker machines, offering B2B buyers critical insights for informed decision-making.

In-depth Look: Manufacturing Processes and Quality Assurance for key maker machine

What Are the Key Stages in the Manufacturing Process of Key Maker Machines?

The manufacturing process of key maker machines involves several critical stages, each designed to ensure the final product meets industry standards for functionality and reliability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically metals like aluminum, steel, and plastic components. These materials are sourced from certified suppliers to guarantee durability and performance. Before use, the materials undergo inspection for quality, which is essential for minimizing defects in the final product.

-

Forming: Once the materials are prepared, they are subjected to various forming techniques. Common methods include CNC machining, stamping, and laser cutting, which allow for precise shaping of the machine parts. CNC (Computer Numerical Control) technology is particularly favored for its accuracy, enabling manufacturers to produce intricate designs that meet specific customer needs.

-

Assembly: Following the forming stage, the individual components are assembled. This stage often involves both manual and automated processes. Skilled technicians ensure that each part is correctly fitted, which is crucial for the machine’s overall functionality. Assembly lines may include stations for installing motors, cutting blades, and electronic components.

-

Finishing: The final stage of manufacturing involves finishing processes such as coating, painting, and polishing. These processes not only enhance the aesthetic appeal of the machines but also protect against corrosion and wear. Quality control checks are performed at this stage to ensure that the machines are ready for shipping and meet all design specifications.

How Is Quality Assurance Implemented in Key Maker Machine Manufacturing?

Quality assurance is a vital aspect of the manufacturing process, ensuring that key maker machines are reliable and perform as expected. Various international and industry-specific standards govern quality assurance practices.

-

Relevant International Standards: Compliance with ISO 9001 is a foundational requirement for manufacturers aiming to demonstrate a commitment to quality management systems. This standard emphasizes a process-oriented approach, encouraging continuous improvement and customer satisfaction. Additionally, CE marking is essential for products sold within the European Economic Area, signifying compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Quality checks during the manufacturing stages help identify and rectify issues early, reducing waste and rework.

– Final Quality Control (FQC): Comprehensive testing of the assembled machine is conducted before shipping, ensuring that all functions operate correctly. -

Common Testing Methods: Manufacturers employ various testing methods to validate the performance of key maker machines. These include functional testing, where machines are operated to assess performance, and durability testing, which simulates long-term use. Additionally, safety tests are conducted to ensure compliance with relevant safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to mitigate risks associated with product defects.

-

Audits and Reports: Regular audits of manufacturing facilities can provide insights into a supplier’s adherence to quality standards. Buyers should request access to audit reports, which detail the findings of internal or third-party assessments. This transparency can foster trust and facilitate better decision-making.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process. These inspectors assess compliance with international standards and can provide certifications that bolster the credibility of the supplier.

-

Quality Certifications: Buyers should look for suppliers with relevant quality certifications, such as ISO 9001 and CE marking. These certifications indicate that the supplier has implemented robust quality management systems and adheres to industry standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements and quality control nuances when sourcing key maker machines. Understanding these factors can help mitigate risks and ensure compliance with local regulations.

-

Regional Standards: Different regions may have specific standards that must be met. For example, in the European market, CE marking is mandatory, while in other regions, different certifications may apply. Buyers should familiarize themselves with the relevant standards for their target markets.

-

Customs and Import Regulations: When importing key maker machines, it is essential to comply with local customs regulations. This may include providing proof of quality certifications, which can help expedite the import process and avoid potential fines or delays.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality control practices. Engaging in collaborative discussions about quality expectations and standards can lead to improved products and services.

In conclusion, understanding the manufacturing processes and quality assurance practices of key maker machines is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘key maker machine’

Introduction

Navigating the procurement of key maker machines can be complex, especially for international B2B buyers. This guide provides a structured checklist to help you make informed decisions, ensuring you select the right equipment to meet your business needs. By following these steps, you will enhance your sourcing process, reduce risks, and ultimately achieve greater satisfaction with your purchase.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to outline your specific requirements for a key maker machine. Consider factors such as the types of keys you need to duplicate (e.g., standard, automotive, high-security) and the expected volume of production. A clear understanding of your technical specifications will help you filter potential machines that best fit your operational needs.

Step 2: Research Available Models and Features

Conduct thorough research on various key maker machines available in the market. Look for features that enhance efficiency, such as automatic versus manual operation, precision cutting capabilities, and compatibility with different key types. Understanding the technological advancements and functionalities will guide you toward selecting a machine that not only meets current demands but also accommodates future growth.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request comprehensive company profiles, including their manufacturing history, customer testimonials, and case studies from similar industries. Ensure that the suppliers are reputable by checking their certifications and affiliations with recognized industry organizations. This step is crucial in building trust and ensuring that you are investing in quality machinery.

Step 4: Request Quotes and Compare Pricing

After identifying suitable machines and suppliers, request detailed quotes. Ensure that each quote includes a breakdown of costs, including shipping, installation, and any potential maintenance fees. Comparing pricing not only helps you stay within budget but also gives insight into the value offered by different suppliers. Don’t hesitate to negotiate terms, as many suppliers are open to discussion, especially for larger orders.

Step 5: Verify Warranty and Support Services

It’s vital to understand the warranty terms associated with the key maker machine you are considering. Check the duration and coverage of the warranty, as well as the availability of technical support services. Reliable after-sales support can save your business time and money in the long run, ensuring that you can quickly address any operational issues that may arise.

Step 6: Assess Shipping and Delivery Options

When purchasing internationally, shipping logistics can significantly impact your procurement timeline. Confirm the shipping methods available and the estimated delivery times. Consider the supplier’s experience with international shipping, including customs clearance and handling procedures. This step is essential to ensure that you receive your machine promptly and without unexpected delays.

Step 7: Finalize Your Purchase and Prepare for Installation

Once you have selected a supplier and finalized your order, prepare for the installation of your key maker machine. Ensure that your facility is equipped with the necessary space and utilities for operation. Additionally, coordinate with the supplier regarding any installation support they offer to facilitate a smooth setup process. This preparation is key to minimizing downtime and maximizing productivity from the outset.

By following this checklist, B2B buyers can streamline the sourcing process for key maker machines, ensuring a successful investment that meets their operational needs.

Comprehensive Cost and Pricing Analysis for key maker machine Sourcing

What Are the Key Cost Components for Key Maker Machines?

When sourcing key maker machines, understanding the cost structure is crucial for informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used significantly influence the machine’s price. High-grade metals and durable plastics are common in high-quality machines, which increases upfront costs but can enhance longevity.

-

Labor: Labor costs vary by region and can impact the final price. Skilled labor is essential for assembling complex machinery, and labor costs in countries with higher wages will be reflected in the machine’s price.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administration. Efficient manufacturing processes can reduce overhead, making machines more competitively priced.

-

Tooling: Custom tooling for specific machine designs can be a substantial cost. Buyers should consider whether the machine design requires unique tools that could increase costs, especially for specialized machines.

-

Quality Control (QC): Rigorous QC processes ensure that machines function correctly and meet safety standards. Enhanced QC measures can raise production costs, which may be passed on to the buyer.

-

Logistics: Shipping costs depend on the machine’s size, weight, and the distance from the supplier to the buyer. International shipping can incur additional fees, particularly for bulky or heavy equipment.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the typical margins within the industry can help buyers gauge whether pricing is fair.

How Do Price Influencers Impact Key Maker Machine Sourcing?

Several factors can influence the pricing of key maker machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses planning to scale.

-

Specifications and Customization: Custom features or specifications can significantly impact pricing. Buyers should evaluate whether the additional costs for customization align with their operational needs.

-

Materials and Quality Certifications: Machines that meet specific quality certifications (such as ISO standards) may come at a premium. Certifications ensure reliability and performance, which can justify higher initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a strong track record may charge more for their products due to perceived quality and service.

-

Incoterms: Understanding shipping terms and responsibilities is essential. Different Incoterms can shift costs and responsibilities between buyers and sellers, affecting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Key Maker Machine Procurement?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, can maximize cost-efficiency through strategic approaches:

-

Negotiation: Engaging in negotiations can yield better pricing, especially when purchasing in bulk. Establishing a strong relationship with suppliers can also facilitate better terms over time.

-

Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. Investing in higher-quality machines might reduce TCO in the long run.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, customs duties and taxes can vary widely by country, influencing the overall cost.

-

Supplier Research: Conduct thorough research on potential suppliers, including reviews and case studies from other businesses. This can provide insights into the reliability and performance of their machines.

Conclusion

Understanding the comprehensive cost and pricing structure of key maker machines is essential for B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic sourcing tips, businesses can make informed decisions that align with their operational needs and budget constraints. While indicative prices for machines vary widely, careful consideration of these factors will lead to more effective procurement strategies.

Alternatives Analysis: Comparing key maker machine With Other Solutions

Exploring Alternative Solutions to Key Maker Machines

In the realm of key duplication and cutting, businesses often seek efficient and cost-effective solutions. While key maker machines are a popular choice, there are several alternatives that can meet similar needs. This analysis will compare key maker machines to self-service key kiosks and manual key duplication services, providing insights into their respective advantages and disadvantages.

Comparison Table

| Comparison Aspect | Key Maker Machine | Self-Service Key Kiosk | Manual Key Duplication Service |

|---|---|---|---|

| Performance | High accuracy and speed | Moderate accuracy; quick | High accuracy; variable speed |

| Cost | High initial investment | Low initial cost, pay-per-use | Moderate costs per duplication |

| Ease of Implementation | Requires technical setup | Simple installation; user-friendly | Requires skilled labor |

| Maintenance | Regular maintenance needed | Minimal maintenance | Low maintenance; skill training required |

| Best Use Case | High volume commercial use | Residential or small business use | Custom or specialized key needs |

In-Depth Analysis of Alternatives

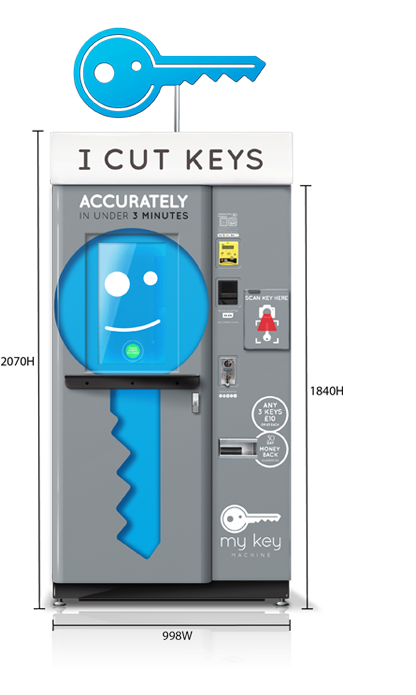

Self-Service Key Kiosks

Self-service key kiosks, like those offered by Minute Key, allow users to duplicate keys on-the-spot without needing a technician. These kiosks are particularly effective in high-traffic areas such as retail stores. The primary advantage is their accessibility and low cost per use, making them ideal for residential customers or small businesses that require occasional key duplication. However, the trade-off includes moderate accuracy compared to professional key maker machines and a limited range of key types that can be duplicated.

Manual Key Duplication Services

Manual key duplication services involve trained technicians who cut keys using handheld tools. This method excels in terms of precision and can handle specialized keys that automated machines may struggle with. Manual services are particularly advantageous for businesses that require custom keys or have unique locking systems. While the upfront costs are generally lower than purchasing a key maker machine, the cost per duplication can add up over time. Additionally, the efficiency of this method can vary significantly based on the technician’s skill level.

Conclusion: Choosing the Right Key Duplication Solution

When evaluating key duplication solutions, B2B buyers must consider their specific operational needs and budget constraints. Key maker machines are well-suited for high-volume environments where speed and accuracy are paramount. Conversely, self-service kiosks offer a cost-effective solution for lower demand, while manual duplication services cater to specialized requirements. By understanding the strengths and weaknesses of each option, businesses can make informed decisions that align with their key duplication needs and operational strategies.

Essential Technical Properties and Trade Terminology for key maker machine

What are the Key Technical Properties of a Key Maker Machine?

When considering the procurement of a key maker machine, understanding its technical properties is essential for making an informed purchase. Below are critical specifications that every B2B buyer should evaluate:

Illustrative image related to key maker machine

-

Material Grade: The construction material of key maker machines typically includes high-grade steel or aluminum. High-grade materials ensure durability and resistance to wear, which is crucial for machines that experience frequent use. Investing in machines made from superior materials can significantly reduce maintenance costs and extend the equipment’s lifespan.

-

Cutting Tolerance: This specification refers to the precision with which keys are cut. A typical cutting tolerance may range from ±0.1mm to ±0.5mm. Machines with tighter tolerances produce more accurate duplicates, which is vital for high-security applications. For B2B buyers, selecting a machine with appropriate tolerance levels can enhance customer satisfaction and reduce rework.

-

Power Source: Key maker machines can be manual, semi-automatic, or fully automatic, powered by electricity or batteries. Automatic machines often offer higher efficiency and ease of use, making them suitable for high-demand environments. Understanding the power source is crucial for operational compatibility and can influence long-term operational costs.

-

Cutting Speed: Measured in keys per hour, cutting speed indicates how quickly a machine can produce duplicates. Machines that cut faster can increase throughput, making them ideal for businesses with high volume requirements. A higher cutting speed can lead to better service levels and increased revenue potential.

-

Versatility: This refers to a machine’s ability to cut different types of keys, including standard, dimple, and automotive keys. A versatile machine can cater to a broader market, allowing businesses to serve various customer needs without additional equipment investments.

-

User Interface: An intuitive user interface can significantly reduce training time and operational errors. Machines with digital displays and straightforward controls enhance usability, making it easier for staff to operate the equipment effectively.

What are Common Trade Terms in the Key Maker Machine Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms relevant to the key maker machine sector:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are sold under another company’s brand. In the context of key maker machines, OEMs are crucial for sourcing high-quality parts and ensuring compatibility.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory and budget constraints while negotiating with suppliers.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. In the key maker machine industry, RFQs facilitate competitive bidding, allowing buyers to secure the best possible deals.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and responsibilities.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is critical for inventory planning and ensuring that businesses can meet customer demands without delays.

-

Calibration: Calibration involves adjusting and fine-tuning a machine to ensure it operates within specified tolerances. Regular calibration is essential for maintaining the accuracy and efficiency of key maker machines, impacting overall service quality.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the key maker machine Sector

What Are the Key Trends Driving the Key Maker Machine Market?

The global key maker machine market is experiencing significant transformations, driven by advancements in technology, changing consumer preferences, and evolving market dynamics. A primary driver of growth is the increasing demand for key duplication services, particularly in emerging economies in Africa, South America, and the Middle East. These regions are witnessing rapid urbanization and a growing middle class, leading to a surge in residential and commercial developments that require efficient key-making solutions.

Technological innovations are also shaping the market landscape. Automated and semi-automated key cutting machines are gaining traction, offering enhanced precision, efficiency, and ease of use. The integration of digital solutions, such as cloud-based inventory management systems and mobile applications for service bookings, is becoming increasingly popular among B2B buyers seeking to streamline operations and improve customer experience.

Furthermore, the rise of self-service key copy kiosks is a noteworthy trend. These kiosks provide a convenient, on-demand solution for key duplication, catering to busy consumers and businesses alike. As international buyers from regions such as Nigeria and Saudi Arabia explore these opportunities, it’s essential to consider the local market’s unique demands and preferences, ensuring that products and services align with regional expectations.

How Important Is Sustainability and Ethical Sourcing in the Key Maker Machine Sector?

In today’s business landscape, sustainability and ethical sourcing are paramount considerations for B2B buyers in the key maker machine sector. The environmental impact of manufacturing processes, including the carbon footprint associated with production and transportation, is increasingly scrutinized. Buyers are increasingly favoring suppliers who demonstrate commitment to sustainable practices, such as using eco-friendly materials and minimizing waste.

Ethical supply chains are also becoming a focal point, as companies strive to ensure fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as valuable indicators for buyers looking to partner with manufacturers committed to sustainable and ethical practices. By prioritizing suppliers with these credentials, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Moreover, the shift towards ‘green’ materials, such as recycled metals and biodegradable components, is gaining momentum. International buyers should assess the sustainability practices of their suppliers, as these factors can significantly influence purchasing decisions and long-term partnerships.

What is the Evolution of Key Maker Machines and Its Relevance Today?

The evolution of key maker machines has been marked by significant technological advancements, transitioning from manual duplication methods to sophisticated automated systems. Early key cutting was a labor-intensive process requiring skilled artisans to create duplicates using hand tools. However, the introduction of electric key cutting machines in the mid-20th century revolutionized the industry, dramatically increasing efficiency and precision.

Illustrative image related to key maker machine

In recent years, the advent of digital technology has further transformed the landscape. Modern key maker machines are equipped with advanced features such as programmable cutting paths and laser technology, enabling the production of complex key designs and high-security options. This evolution is particularly relevant for B2B buyers who require reliable and versatile solutions to meet the demands of an increasingly sophisticated market.

Today, the integration of software that allows for code cutting and compatibility with various key types illustrates the ongoing innovation in the sector. As businesses continue to seek advanced solutions that enhance productivity and customer satisfaction, understanding the historical context of key maker machines can provide valuable insights into selecting the right equipment and suppliers for their needs.

Frequently Asked Questions (FAQs) for B2B Buyers of key maker machine

-

1. How do I choose the right key maker machine for my business needs?

Selecting the right key maker machine involves assessing your specific requirements, such as the types of keys you will be duplicating (e.g., residential, automotive, or high-security keys). Consider the machine’s cutting capabilities, speed, and ease of use. Additionally, evaluate the manufacturer’s reputation, warranty options, and the availability of spare parts or technical support. Conducting a cost-benefit analysis can also help you determine the best fit for your budget and operational goals. -

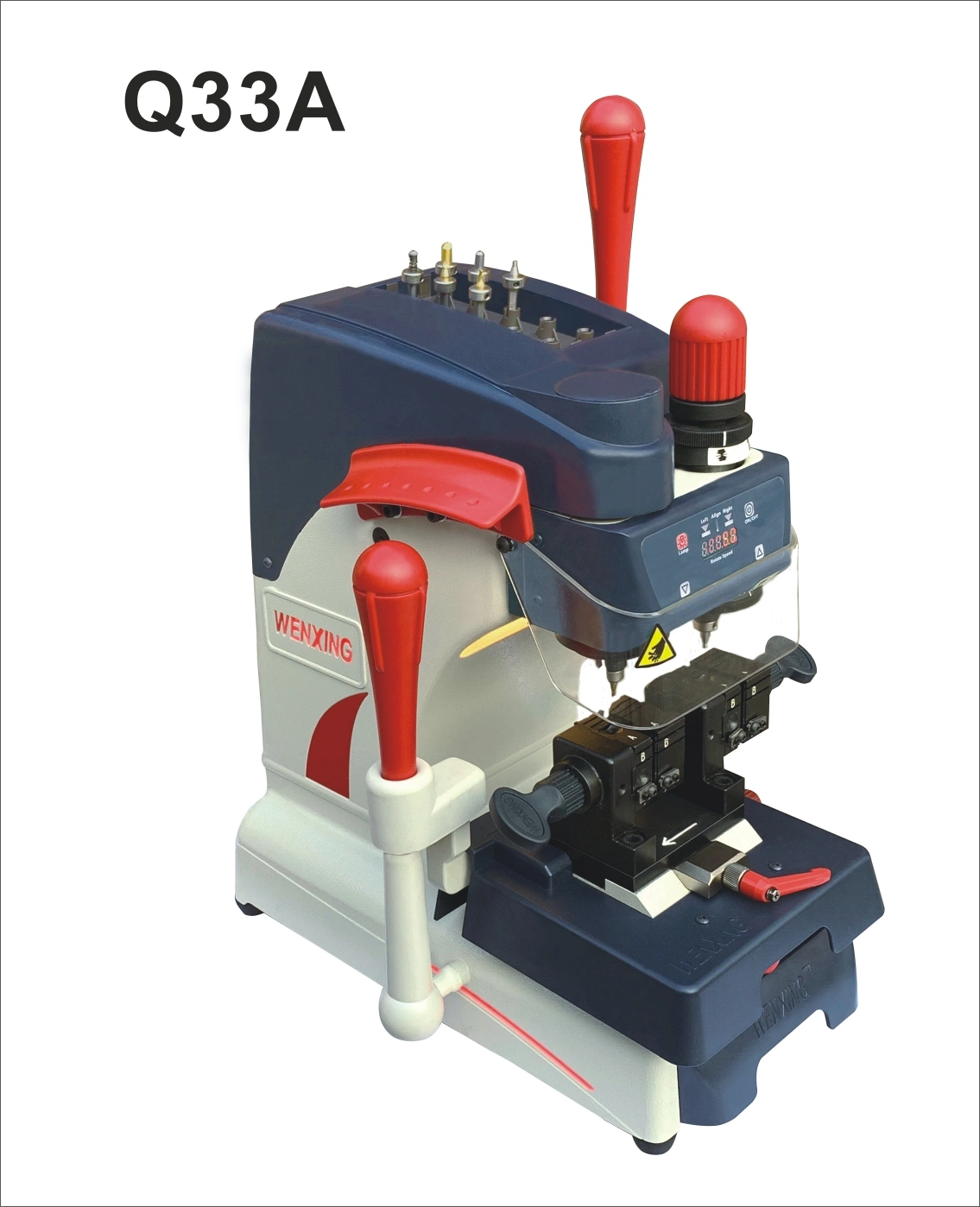

2. What is the best key maker machine for small to medium locksmith businesses?

For small to medium locksmith businesses, machines like the ILCO Speed 040 and the Wenxing W288E are excellent choices. They offer a balance of affordability, reliability, and versatility, allowing for both automatic and manual key cutting. Look for machines that have a good track record in your region, and ensure they can handle a variety of key types, including dimple and laser-cut keys, to meet diverse customer demands. -

3. What are the typical minimum order quantities (MOQs) for key maker machines?

Minimum order quantities (MOQs) for key maker machines can vary significantly depending on the supplier and the type of machine. Generally, MOQs can range from one unit for smaller suppliers to several units for larger manufacturers. It’s advisable to communicate your specific needs with the supplier to negotiate favorable terms, especially if you are looking to establish a long-term relationship or plan to purchase additional machines in the future. -

4. How can I vet suppliers of key maker machines effectively?

To effectively vet suppliers, start by checking their credentials, industry reputation, and customer reviews. Look for certifications or memberships in recognized industry associations. Request references from previous clients and verify their experience with the specific machines you are interested in. Additionally, consider visiting the supplier’s facility, if possible, to assess their production capabilities and quality control measures. -

5. What payment terms should I expect when purchasing key maker machines internationally?

Payment terms for international purchases can vary widely. Common options include upfront payments, partial payments, or letter of credit arrangements. Many suppliers may require a deposit (often 30-50%) before production begins, with the balance due upon shipment or delivery. It’s crucial to clarify these terms in advance to ensure both parties are aligned and to mitigate risks associated with international transactions. -

6. How do I ensure quality assurance when sourcing key maker machines?

To ensure quality assurance, request detailed product specifications and certifications from the manufacturer. Inquire about their quality control processes and whether they conduct third-party inspections. It may also be beneficial to ask for a sample unit before placing a large order. Additionally, consider establishing a quality assurance protocol that includes testing the machines upon receipt to confirm they meet your operational standards. -

7. What logistics considerations should I keep in mind when importing key maker machines?

When importing key maker machines, consider shipping methods, customs clearance, and delivery timelines. Engage a freight forwarder experienced in handling machinery to navigate these complexities. Be aware of any import duties or taxes that may apply in your region. Ensure that the machines are properly packaged to avoid damage during transit, and confirm that the supplier provides all necessary documentation for customs. -

8. Can key maker machines be customized for specific key types or branding?

Yes, many manufacturers offer customization options for key maker machines. This can include modifications for specific key types, such as dimple or laser-cut keys, as well as branding opportunities like adding your company logo. Discuss your customization needs with potential suppliers early in the negotiation process to ensure they can accommodate your requests and provide a solution that aligns with your business identity.

Top 6 Key Maker Machine Manufacturers & Suppliers List

1. Minute Key – Key Copy Kiosks

Domain: minutekey.com

Registered: 2007 (18 years)

Introduction: Key Copy Kiosks allow users to duplicate keys for home, office, or padlocks quickly and easily. The kiosks are self-service and can copy keys within minutes. Additional services include key fobs and car keys. Locations can be found by entering a ZIP code, city, or state.

2. KeyMe – 24/7 Locksmith Services

Domain: key.me

Registered: 2008 (17 years)

Introduction: KeyMe offers 24/7 locksmith services, including key copying for home, office, vehicle, and specialty keys at kiosks located in various retailers such as Walmart, Kroger, and 7-Eleven. The service includes a 100% money-back guarantee and is available across the majority of the USA. Vehicle keys can be made for many top models at up to 70% less than dealer prices, and RFID keys can be copied to key …

3. ILCO – Key-Cutting Machines & Accessories

Domain: locksmithkeyless.com

Registered: 2015 (10 years)

Introduction: ILCO Key-Cutting Machines & Accessories, high-quality locksmith equipment, precision and accuracy in key cutting, suitable for businesses and professionals.

4. WENXING – Key Cutting Machines

Domain: lockpicks.com

Registered: 1997 (28 years)

Introduction: Key Cutting Machines available for purchase include:

1. WENXING Automatic Key Machine (w/Manual Override & 4-Way Jaws!) – $899.00

2. WENXING W288E Automatic Key Machine – $799.00

3. JMA NOMAD Key Duplicating Machine – $520.00

4. PRO-LOK “BluePunch” Machine for “SCHLAGE” – BP201SC – $1,179.85

5. SILCA Speed 040 Automatic / Manual Key Machine – $2,713.71

6. HPC Mini Speedex Key Cutting Machine – $49…

5. HPC – Mini Speedex Manual Key Machine

Domain: clksupplies.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘HPC Mini Speedex Manual Key Machine’, ‘original_price’: ‘$495.04’, ‘current_price’: ‘$495.04’, ‘description’: ‘Lightweight, industrial-grade duplicator, one of the most accurate.’}, {‘name’: ‘Ilco Flash 008 Key Machine 120V’, ‘original_price’: ‘$1,122.05’, ‘current_price’: ‘$1,122.05’, ‘description’: ‘Easily duplicates most edge cut cylinder, cruciform, large bow and long blade keys.’},…

6. Key Cutting Machines – JMA Nomad & X-Horse Condor Dolphin XP007

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Key cutting machines mentioned: JMA Nomad, X-Horse Condor Dolphin XP007. Price range: $800 or less. Primary concern: cutting duplicates of Best brand keys and company vehicle keys.

Strategic Sourcing Conclusion and Outlook for key maker machine

In the competitive landscape of key-making machinery, strategic sourcing emerges as an essential tool for international buyers aiming to optimize their operations. By carefully evaluating suppliers from diverse regions—including Africa, South America, the Middle East, and Europe—businesses can access a wide array of innovative products, from automatic key duplicators to high-precision manual machines. This diversity not only fosters competitive pricing but also enhances the quality and efficiency of key duplication services.

Illustrative image related to key maker machine

Investing in high-quality key-making machines, such as those from reputable manufacturers like ILCO and Wenxing, ensures that businesses can meet the increasing demand for fast and reliable key duplication. Additionally, leveraging local partnerships can streamline the supply chain, reduce lead times, and improve service delivery.

Looking ahead, the key-making industry is poised for growth as technological advancements and consumer expectations evolve. International B2B buyers are encouraged to stay informed about emerging trends and innovations in key-making technologies. By embracing strategic sourcing and fostering strong supplier relationships, businesses can position themselves for success in this dynamic market. Engage with trusted suppliers today to explore how you can enhance your key-making capabilities and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.