K20A Engine For Sale: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for k20a engine for sale

In the competitive landscape of automotive parts, sourcing a reliable K20A engine for sale presents unique challenges for international B2B buyers. With varying regulations, quality standards, and market dynamics across regions such as Africa, South America, the Middle East, and Europe—including countries like Germany and Saudi Arabia—making informed purchasing decisions is crucial. This guide aims to demystify the complexities of the K20A engine market, providing actionable insights that will empower you to navigate the intricacies of sourcing this high-performance engine.

We delve into various facets of the K20A engine market, including types of engines available, their applications across different vehicle models, and essential factors to consider when vetting suppliers. Additionally, we offer a comprehensive overview of pricing structures and the potential for cost savings when sourcing engines globally. By equipping you with the knowledge to assess engine specifications, compatibility, and supplier reliability, this guide ensures that your purchasing decisions are well-informed and strategically sound.

Whether you’re looking to enhance your automotive offerings or fulfill specific project requirements, understanding the global market for K20A engines will place you at a significant advantage. We invite you to explore the insights within this guide and take the first step toward optimizing your procurement strategy in the K20A engine sector.

Understanding k20a engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| K20A Type R Engine | High-performance variant, VTEC technology, 2.0L | Performance tuning, motorsports, high-end builds | Pros: Superior power and reliability; Cons: Higher cost and limited availability. |

| K20A Base Model Engine | Standard VTEC engine, lower horsepower than Type R | General replacements, economy builds | Pros: Cost-effective; Cons: Less performance-oriented. |

| K20-KT1200 Race Engine | Turbocharged, designed for high horsepower (1200hp) | Racing, competitive motorsports | Pros: Exceptional power output; Cons: High maintenance and initial investment. |

| K20A Hybrid Engine | Combines K20A with hybrid technology | Eco-friendly vehicles, hybrid conversions | Pros: Fuel efficiency; Cons: Complex integration and potential for higher repair costs. |

| K20A Remanufactured Engine | Factory-rebuilt with new components | Fleet maintenance, cost-sensitive applications | Pros: Warranty coverage; Cons: Performance may not match original specs. |

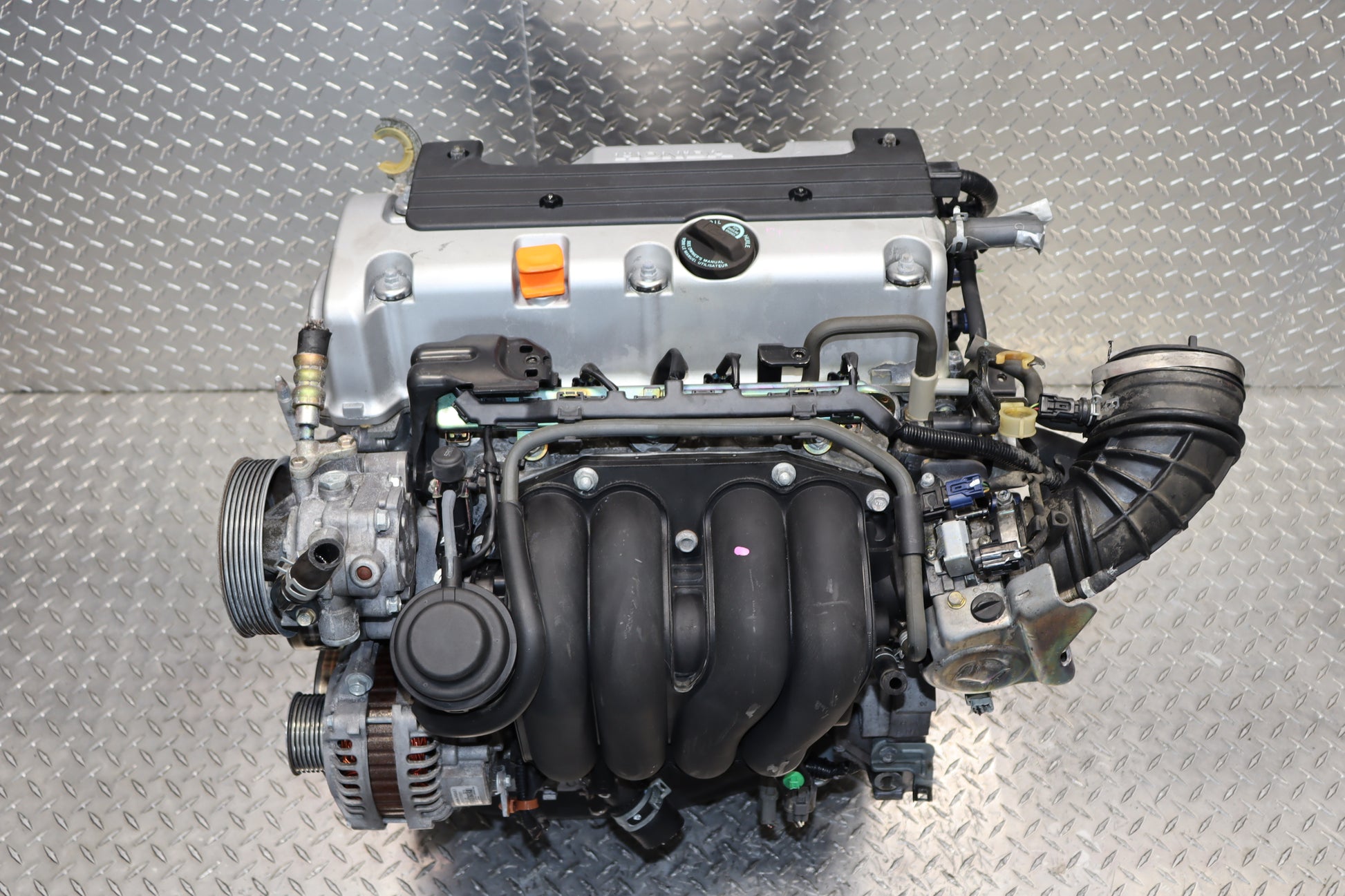

What are the Key Characteristics of the K20A Type R Engine?

The K20A Type R engine is renowned for its high-performance capabilities, featuring advanced VTEC technology and a displacement of 2.0 liters. This engine variant is primarily used in performance tuning, motorsports, and high-end builds, making it a favorite among enthusiasts. B2B buyers should consider its superior power and reliability, although it comes at a higher price point and can be harder to source.

How Does the K20A Base Model Engine Compare?

The K20A base model engine serves as a more economical choice, offering standard VTEC technology with lower horsepower than the Type R variant. It is ideal for general replacements and economy builds, making it accessible for businesses focused on cost-effective solutions. While it presents a more affordable option, buyers should be aware that it lacks the performance edge of the Type R.

What Makes the K20-KT1200 Race Engine Unique?

Designed specifically for high-performance applications, the K20-KT1200 is a turbocharged engine capable of exceeding 1200 horsepower. It is tailored for racing and competitive motorsports, providing exceptional power output for those looking to dominate the track. However, potential buyers must consider the high maintenance requirements and significant initial investment involved.

Illustrative image related to k20a engine for sale

Why Consider the K20A Hybrid Engine?

The K20A hybrid engine combines traditional K20A features with hybrid technology, making it suitable for eco-friendly vehicles and hybrid conversions. This engine variant appeals to businesses looking to invest in greener technologies. While it offers excellent fuel efficiency, the complexity of integration and potential repair costs may be drawbacks for some buyers.

What are the Benefits of Purchasing a K20A Remanufactured Engine?

K20A remanufactured engines are factory rebuilt with new components, making them a solid choice for fleet maintenance and cost-sensitive applications. They often come with warranty coverage, providing buyers with peace of mind. However, performance may not match that of original specifications, so it’s crucial for buyers to assess their specific needs before purchasing.

Key Industrial Applications of k20a engine for sale

| Industry/Sector | Specific Application of k20a engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement engines for performance vehicles like Honda Civic Type R | Enhances customer satisfaction through reliable performance | Ensure compatibility with various models and mileage limits |

| Motorsports | High-performance engines for racing applications | Increases competitive edge with superior power output | Look for engines with proven track records in racing |

| Automotive Parts Retailers | Reselling refurbished k20a engines | Expands product offerings and attracts performance enthusiasts | Verify quality certifications and warranty provisions |

| Fleet Management | Upgrading older fleet vehicles with k20a engines | Improves fuel efficiency and reduces maintenance costs | Assess engine durability and after-sales support |

| Export/Import Dealers | Sourcing k20a engines for international markets | Taps into growing demand for performance engines abroad | Ensure compliance with local regulations and shipping logistics |

How is the K20A Engine Used in Automotive Repair Shops?

Automotive repair shops often utilize the K20A engine as a direct replacement for aging or damaged engines in popular models like the Honda Civic Type R. This engine’s reliability and performance capabilities make it an attractive option for shops aiming to provide high-quality repairs. Buyers in this sector need to consider the compatibility of the engine with various models and the mileage limits, typically between 35K to 65K miles, to ensure customer satisfaction and optimal performance.

What Role Does the K20A Engine Play in Motorsports?

In the motorsports industry, the K20A engine is favored for its high-performance capabilities, often used in racing applications where power and speed are critical. Racing teams seek out these engines to gain a competitive edge, as they can be modified to deliver impressive horsepower. Buyers must look for engines with a proven history in racing environments and consider factors such as engine build quality and tuning options to maximize performance on the track.

Illustrative image related to k20a engine for sale

How Can Automotive Parts Retailers Benefit from Selling K20A Engines?

Automotive parts retailers can expand their inventory by offering refurbished K20A engines, catering to a niche market of performance vehicle enthusiasts. By providing these engines, retailers can attract customers looking for reliable performance upgrades. It’s essential for these businesses to verify quality certifications and warranty provisions to build trust with their clientele and ensure they are selling a product that meets high standards.

Why is the K20A Engine Ideal for Fleet Management?

Fleet management companies may find the K20A engine beneficial for upgrading older vehicles to improve fuel efficiency and reduce overall maintenance costs. By integrating this engine into their fleet, businesses can enhance vehicle reliability and performance, resulting in lower operational costs. Buyers in this sector should assess the engine’s durability and the availability of after-sales support to ensure that they can maintain a reliable fleet over time.

How Do Export/Import Dealers Leverage the K20A Engine?

Export and import dealers can capitalize on the growing demand for performance engines in international markets by sourcing K20A engines. This engine is particularly popular in regions where performance upgrades are sought after, such as in Africa and South America. Dealers need to ensure compliance with local regulations and manage shipping logistics effectively to meet the demands of international buyers while maintaining cost efficiency.

3 Common User Pain Points for ‘k20a engine for sale’ & Their Solutions

Scenario 1: Difficulty in Verifying Engine Authenticity

The Problem:

B2B buyers often face the challenge of ensuring the authenticity of the K20A engines they are considering for purchase. With the prevalence of counterfeit parts and engines in the market, the risk of acquiring a subpar or fake engine is a significant concern. This can lead to costly repairs, compatibility issues, and ultimately, a loss of trust in suppliers. Buyers from regions like Africa and South America, where aftermarket parts can be abundant and unregulated, may find it particularly difficult to navigate these risks.

The Solution:

To mitigate the risk of purchasing a counterfeit K20A engine, buyers should prioritize sourcing from reputable vendors with a proven track record in the industry. Look for suppliers that provide comprehensive documentation, including original manufacturer certifications, warranty information, and detailed specifications of the engine. Additionally, consider requesting engine history reports that detail previous usage and maintenance records. Engaging in direct communication with suppliers can also help clarify any doubts regarding authenticity. Establishing long-term relationships with trusted suppliers can facilitate better insights into engine provenance and reliability.

Illustrative image related to k20a engine for sale

Scenario 2: Navigating Compatibility Issues with Vehicle Models

The Problem:

Another common pain point for B2B buyers is the compatibility of K20A engines with various vehicle models. Given the diverse range of Honda and Acura vehicles that utilize the K20A engine, buyers may struggle to determine which specific models the engine is suitable for. This uncertainty can result in incorrect purchases, leading to wasted time and resources in sourcing additional components or modifying existing systems to fit the engine.

The Solution:

Buyers should conduct thorough research on the specific vehicle models they intend to equip with the K20A engine. This includes consulting technical manuals, compatibility charts, and manufacturer guidelines that outline the engine specifications and fitment requirements. It’s also beneficial to leverage online forums and communities where automotive professionals discuss engine swaps and compatibility issues. By gathering insights from experienced users, buyers can make more informed decisions. Additionally, working with a supplier that offers customization options or support for vehicle integration can alleviate compatibility concerns, ensuring a smoother installation process.

Scenario 3: Concerns Over Engine Performance and Longevity

The Problem:

Performance and longevity are critical factors for B2B buyers when investing in K20A engines. Buyers often worry about the engine’s ability to withstand rigorous usage, especially in high-performance applications. Concerns regarding the quality of parts, potential for premature failure, and the engine’s overall performance can deter buyers from making a purchase. This is particularly relevant for buyers in competitive markets where engine performance directly impacts business success.

The Solution:

To address performance and longevity concerns, buyers should seek engines that have undergone rigorous testing and come with performance guarantees. Requesting detailed specifications about the engine’s components, such as the quality of materials used, and the manufacturing processes can provide reassurance about durability. Additionally, consider investing in engines that come with performance tuning options or enhancements that can optimize engine output. Engaging with suppliers that offer post-purchase support, including performance tuning and maintenance services, can also help maximize the engine’s lifespan and efficiency. Regular maintenance checks and adhering to manufacturer-recommended service intervals will further ensure the engine remains in optimal condition throughout its service life.

By understanding and addressing these pain points, B2B buyers can make more informed decisions when sourcing K20A engines, ultimately leading to greater satisfaction and success in their automotive endeavors.

Illustrative image related to k20a engine for sale

Strategic Material Selection Guide for k20a engine for sale

What Are the Key Materials Used in K20A Engine Manufacturing?

When considering the K20A engine for sale, understanding the materials used in its construction is crucial for B2B buyers. The choice of materials impacts performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in the K20A engine, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Aluminum Alloys: The Lightweight Champion

Aluminum alloys are widely used in the K20A engine, particularly for the engine block and cylinder head. These alloys offer excellent thermal conductivity and are relatively lightweight, which enhances the engine’s performance by reducing overall weight.

Key Properties: Aluminum alloys typically have a high strength-to-weight ratio and good corrosion resistance. They can withstand temperatures up to 200°C (392°F) and pressures of around 300 psi.

Illustrative image related to k20a engine for sale

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, which contributes to better fuel efficiency and performance. However, they can be more expensive than cast iron and may require specialized machining, increasing manufacturing complexity.

Impact on Application: Aluminum’s compatibility with various media, including oil and coolant, makes it an ideal choice for engine components. However, it is essential to ensure that the alloy used meets specific standards (e.g., ASTM or JIS) for durability.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should verify compliance with local regulations regarding aluminum alloys. In Germany, for instance, adherence to DIN standards is crucial for quality assurance.

Illustrative image related to k20a engine for sale

Cast Iron: The Traditional Workhorse

Cast iron is often used for engine blocks due to its durability and excellent wear resistance. This material has been a staple in engine manufacturing for decades.

Key Properties: Cast iron can withstand high temperatures (up to 400°C or 752°F) and has a pressure rating of around 500 psi. It also offers good vibration damping characteristics.

Pros & Cons: The main advantage of cast iron is its robustness and longevity, making it suitable for high-stress applications. However, it is heavier than aluminum, which can negatively impact fuel efficiency. Additionally, cast iron can be more challenging to machine, increasing production costs.

Impact on Application: Cast iron’s compatibility with various engine oils and coolants ensures its effectiveness in engine applications. However, it is essential to consider the environmental impact, as cast iron can be less eco-friendly than alternatives.

Considerations for International Buyers: Buyers in South America and Africa should be aware of the varying standards for cast iron quality. Ensuring compliance with local regulations can prevent issues related to engine performance and reliability.

Illustrative image related to k20a engine for sale

Steel Alloys: Strength and Durability

Steel alloys are commonly utilized in components such as crankshafts and connecting rods within the K20A engine. Their strength and durability make them ideal for high-performance applications.

Key Properties: Steel alloys can withstand high temperatures (up to 600°C or 1112°F) and pressures exceeding 700 psi, making them suitable for demanding environments.

Pros & Cons: The primary advantage of steel alloys is their exceptional strength and fatigue resistance. However, they are heavier than aluminum and can be more expensive, impacting overall engine weight and cost.

Impact on Application: Steel’s compatibility with engine lubricants ensures reliable performance. However, the weight factor should be considered, especially in performance-oriented applications.

Illustrative image related to k20a engine for sale

Considerations for International Buyers: Buyers from the Middle East and Europe should ensure that the steel alloys used meet international standards, such as ASTM or DIN, to guarantee quality and performance.

Composite Materials: The Future of Engine Design

Composite materials are increasingly being considered for certain engine components due to their lightweight and high-strength properties. While not yet mainstream in K20A engines, their use is growing.

Key Properties: Composites can withstand temperatures up to 300°C (572°F) and offer excellent corrosion resistance.

Pros & Cons: The main advantage is their lightweight nature, which can significantly improve engine efficiency. However, they can be costly and may require specialized manufacturing techniques.

Illustrative image related to k20a engine for sale

Impact on Application: Composites are compatible with various fluids but may not be suitable for high-stress applications without adequate testing.

Considerations for International Buyers: Buyers should be aware of the evolving standards for composite materials and ensure that any products sourced comply with local regulations.

Summary Table of Material Selection for K20A Engine

| Material | Typical Use Case for k20a engine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Engine block, cylinder head | Lightweight, excellent thermal conductivity | Higher cost, complex machining | High |

| Cast Iron | Engine block | Robustness and longevity | Heavier, challenging to machine | Medium |

| Steel Alloys | Crankshafts, connecting rods | Exceptional strength and durability | Heavier, more expensive | Medium |

| Composite Materials | Advanced engine components | Lightweight, high strength | Costly, may require specialized manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, aiding them in making informed decisions when sourcing K20A engines.

In-depth Look: Manufacturing Processes and Quality Assurance for k20a engine for sale

In the competitive landscape of automotive engine manufacturing, particularly for the sought-after K20A engine, understanding the manufacturing processes and quality assurance measures is crucial for international B2B buyers. This section delves into the intricate stages of production and the robust quality control standards that ensure the reliability and performance of the K20A engine.

What Are the Key Stages in the Manufacturing Process of the K20A Engine?

The manufacturing of the K20A engine involves several critical stages, each designed to ensure precision and quality.

Material Preparation: What Materials Are Used in K20A Engine Manufacturing?

The first step in the manufacturing process is the careful selection and preparation of materials. High-grade aluminum alloys are typically used for the engine block and cylinder head due to their lightweight and durability. Steel is often used for critical components such as crankshafts and camshafts. Material preparation includes:

- Sourcing: Ensuring materials meet industry standards and specifications.

- Inspection: Conducting initial quality checks on incoming materials to eliminate defects before production begins.

How Are the Engine Components Formed?

Once materials are prepared, the forming stage involves several techniques to shape the engine components. Common techniques include:

- Casting: Engine blocks and cylinder heads are typically produced through sand casting or die casting, ensuring precise dimensions and surface finishes.

- Machining: Components are machined to exact specifications using CNC (Computer Numerical Control) machines, which provide high precision and repeatability.

- Forging: Components like crankshafts and connecting rods are often forged for enhanced strength and fatigue resistance.

What Does the Assembly Process Involve?

The assembly stage is where the individual components come together to create the complete engine. Key aspects of this stage include:

- Subassembly: Critical subcomponents, such as the valvetrain and oil pump, are assembled separately before being integrated into the engine block.

- Precision Assembly: Skilled technicians use torque specifications and assembly guides to ensure components are assembled correctly. This may involve the use of specialized tools for critical components to ensure they meet the required tolerances.

How Is the Engine Finished to Ensure Quality?

The finishing stage focuses on the final touches that prepare the engine for sale. This includes:

- Surface Treatment: Components may undergo surface treatments such as anodizing or coating to enhance durability and corrosion resistance.

- Final Inspection: Each engine is subjected to a thorough inspection to ensure it meets the required specifications before leaving the factory.

What Quality Assurance Measures Are Essential for K20A Engine Production?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that every engine meets rigorous standards of performance and reliability.

Which International Standards Are Relevant for K20A Engine Manufacturing?

B2B buyers should be aware of several international standards that govern quality assurance in engine manufacturing:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is applicable to any organization. Manufacturers of K20A engines must adhere to these standards to ensure consistent quality.

- ISO/TS 16949: This specific standard for the automotive industry focuses on defect prevention and the reduction of variation and waste in the supply chain.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are established throughout the manufacturing process to catch any defects early. These include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Inspections during the manufacturing process help identify issues in real-time, reducing the risk of defective products.

- Final Quality Control (FQC): Before an engine is shipped, a final inspection checks for performance and compliance with specifications.

How Are Common Testing Methods Utilized in Quality Assurance?

Manufacturers employ various testing methods to ensure the K20A engine meets performance and safety standards:

- Dyno Testing: Engines are tested on dynamometers to evaluate performance under load conditions.

- Leak Testing: Checking for oil and coolant leaks is crucial to ensure reliability.

- Vibration Analysis: This testing helps identify potential issues in engine balance and component integrity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality assurance practices of suppliers is essential. Consider the following methods:

Illustrative image related to k20a engine for sale

What Steps Can Buyers Take to Conduct Supplier Audits?

- Supplier Audits: Requesting audits of the manufacturing facilities can help buyers assess the quality control measures in place. This includes reviewing quality management systems and production processes.

- Documentation Review: Buyers should ask for documentation related to quality control, including inspection reports and certifications.

Are Third-Party Inspections Useful for Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process. These services can:

- Conduct Random Inspections: They can perform checks at various stages of production to ensure compliance with quality standards.

- Provide Detailed Reports: Third-party inspections often come with comprehensive reports that outline findings and compliance levels.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider specific nuances in quality control:

- Regulatory Compliance: Different regions may have specific regulations regarding engine emissions and safety. Understanding these requirements is crucial for compliance.

- Cultural Considerations: Buyers should be aware of cultural differences in business practices, which may affect communication and expectations regarding quality.

In summary, understanding the manufacturing processes and quality assurance measures for the K20A engine is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can ensure they are sourcing engines that meet their standards for performance and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘k20a engine for sale’

When sourcing a K20A engine for sale, it is essential to approach the process methodically to ensure you secure a reliable product that meets your operational needs. This guide outlines a step-by-step checklist to facilitate your procurement process, helping you make informed decisions and establish successful partnerships.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clarify the specific technical requirements for the K20A engine. Consider factors such as horsepower, compatibility with vehicle models, and any modifications needed for your applications. Having a clear understanding of your needs will help you communicate effectively with suppliers and ensure you receive engines that meet your performance standards.

Step 2: Research Potential Suppliers

Take the time to identify and research suppliers who specialize in K20A engines. Look for companies with a solid reputation in the industry, focusing on those that provide detailed information about their products. Reliable suppliers often have certifications, warranties, and a history of positive customer feedback, which can provide peace of mind in your purchasing decision.

Step 3: Evaluate Supplier Certifications and Compliance

Verifying supplier certifications is crucial to ensure that the engines meet international quality and safety standards. Check for ISO certifications or other relevant industry standards that indicate a commitment to quality assurance. This step is vital in avoiding issues with engine performance and compliance, especially when dealing with international shipments.

Step 4: Request Detailed Product Information

Once you have identified potential suppliers, request comprehensive product specifications and documentation for the K20A engines. This should include mileage, condition, and warranty information. Reviewing this documentation allows you to assess the engines’ reliability and ensures that they align with your operational requirements.

Step 5: Assess Pricing and Payment Terms

Compare pricing across different suppliers while considering the total cost of ownership, including shipping and any additional fees. Negotiate payment terms that are favorable to your business, such as payment upon delivery or installment options. This step is crucial for managing your budget and ensuring that you are getting a competitive price for the engines.

Illustrative image related to k20a engine for sale

Step 6: Conduct a Supplier Visit or Virtual Inspection

If possible, arrange a visit to the supplier’s facility or request a virtual inspection. This firsthand experience allows you to evaluate the supplier’s operations, quality control processes, and overall professionalism. Building a relationship with your supplier can also facilitate smoother transactions and ongoing support.

Step 7: Finalize Contracts and Delivery Arrangements

Once you have selected a supplier, ensure that all terms are clearly outlined in a contract. This should include delivery timelines, warranty details, and any return policies. Clear agreements help protect your interests and ensure that you receive the engines in the agreed-upon condition and timeframe.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing K20A engines, ensuring that they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for k20a engine for sale Sourcing

What Are the Key Cost Components for K20A Engine Sourcing?

When sourcing K20A engines for sale, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to k20a engine for sale

-

Materials: The engine’s components, such as the cylinder head, pistons, and crankshaft, are made from high-quality materials that ensure performance and durability. Sourcing these materials at competitive rates can significantly affect the overall cost.

-

Labor: Skilled labor is necessary for assembly and quality assurance. The complexity of K20A engines means that labor costs can be higher than simpler engine types.

-

Manufacturing Overhead: This includes the costs of running the manufacturing facility, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Specialized tooling is often required for precision assembly. Investing in high-quality tools can enhance production efficiency and product quality, impacting the final price.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that each engine meets performance standards. The costs associated with testing and certification contribute to the overall pricing.

-

Logistics: Shipping and handling costs can vary significantly, especially for international buyers. Understanding the logistics involved, including customs fees and shipping times, is crucial for accurate cost estimation.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand and supplier competition.

How Do Price Influencers Affect K20A Engine Costs?

Several factors can influence the pricing of K20A engines:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounted pricing. Negotiating favorable terms for larger orders can yield significant savings.

-

Specifications and Customization: Customizing engines for specific applications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Engines made from premium materials or those that carry quality certifications (like ISO) typically command higher prices. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind regarding performance.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can help buyers anticipate additional costs related to shipping and insurance, which can significantly impact the total cost.

What Negotiation Strategies Can Help Buyers Achieve Cost-Efficiency?

Effective negotiation strategies are essential for maximizing value in B2B transactions:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, warranty, and potential resale value. A higher upfront cost may lead to lower long-term expenses.

-

Leverage Multiple Quotes: Obtain quotes from multiple suppliers to compare pricing and negotiate better terms. This competitive approach can help secure more favorable deals.

-

Build Relationships with Suppliers: Establishing a strong relationship can lead to better pricing, priority service, and flexibility in future orders.

-

Be Aware of Pricing Nuances for International Buyers: When sourcing from different regions, consider currency fluctuations, tariffs, and local market conditions. This knowledge can help in negotiating effectively and understanding true costs.

What Should International Buyers Consider When Sourcing K20A Engines?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should consider:

-

Local Market Conditions: Understanding regional demand and pricing dynamics can provide leverage in negotiations.

-

Customs Regulations: Familiarize yourself with import duties and regulations in your country to avoid unexpected costs and delays.

-

Shipping Options and Lead Times: Evaluate shipping methods and times to ensure timely delivery. Express shipping may incur higher costs but could be necessary for urgent needs.

-

Warranty and Support Services: Confirm the warranty terms and availability of support services in your region. This can significantly impact the overall value of your purchase.

Disclaimer on Indicative Prices

Please note that prices for K20A engines can vary significantly based on supplier, specifications, and market conditions. The figures mentioned in this analysis are indicative and should be verified with suppliers for the most accurate quotes.

Alternatives Analysis: Comparing k20a engine for sale With Other Solutions

Introduction to Alternatives in the Automotive Engine Market

When considering the purchase of a K20A engine, international B2B buyers must evaluate various alternatives that may meet their specific requirements. The K20A engine, known for its performance and reliability, is popular in various applications, particularly in motorsports and performance vehicles. However, there are alternative engine solutions that may offer different benefits in terms of performance, cost, and suitability for specific projects. This analysis compares the K20A engine against other viable options, including the K24A engine and high-performance crate engines, to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | K20A Engine For Sale | K24A Engine | High-Performance Crate Engine |

|---|---|---|---|

| Performance | 2.0L, VTEC, up to 220hp | 2.4L, VTEC, up to 200hp | Up to 1200hp (e.g., K20-KT1200) |

| Cost | $5,999 – $6,499 | $1,000 – $1,500 | $13,445 |

| Ease of Implementation | Moderate | Easy (direct swap for many models) | Complex (requires setup) |

| Maintenance | Standard Honda parts | Standard Honda parts | Specialized, requires expertise |

| Best Use Case | Performance street cars | Daily drivers, mild performance | Racing applications |

Detailed Breakdown of Alternatives

K24A Engine: A Practical Alternative

The K24A engine is a 2.4L variant that offers slightly less horsepower compared to the K20A but provides a broader torque band, making it an excellent choice for daily drivers and moderate performance applications. Its cost-effectiveness and ease of installation as a direct swap for many Honda models make it an attractive alternative for businesses looking to upgrade engines without extensive modifications. However, it may not satisfy those seeking high-performance capabilities.

High-Performance Crate Engine: Power and Precision

For buyers focused on maximum performance, high-performance crate engines like the K20-KT1200 represent a top-tier option. Designed for extreme applications, these engines can produce upwards of 1200hp, making them ideal for serious racing teams. However, the significant cost and the requirement for specialized installation and maintenance can be drawbacks for businesses with budget constraints or limited technical resources. This option is best suited for competitive racing environments where performance is paramount.

Conclusion: How to Choose the Right Engine Solution

When selecting an engine for B2B applications, it is crucial to assess the specific needs and goals of your project. The K20A engine is an excellent choice for those prioritizing performance in a compact package, while the K24A offers a more budget-friendly alternative for everyday use. On the other hand, high-performance crate engines cater to those demanding the utmost power for competitive settings. By carefully evaluating performance, cost, ease of implementation, and maintenance considerations, buyers can determine the most suitable engine solution that aligns with their operational requirements and budgetary constraints.

Illustrative image related to k20a engine for sale

Essential Technical Properties and Trade Terminology for k20a engine for sale

What are the Key Technical Properties of the K20A Engine for Sale?

When considering the purchase of a K20A engine, understanding its technical specifications is crucial for making an informed decision. Here are some essential properties to consider:

-

Displacement

The K20A engine features a 2.0-liter (1998cc) displacement. This specification is vital as it directly affects the engine’s power output and efficiency. In the context of performance, a larger displacement often translates to higher horsepower and torque, making it a preferred choice for racing and performance vehicles. -

Compression Ratio

The K20A typically has a compression ratio of around 11.0:1. This ratio indicates the engine’s efficiency and performance potential; a higher compression ratio usually results in better fuel efficiency and power output. Understanding this metric helps B2B buyers assess the engine’s suitability for specific applications, whether for daily driving or competitive racing. -

Power Output

The K20A engine can produce approximately 200 horsepower at 7,400 RPM. This specification is critical for buyers looking for performance engines, as it determines the engine’s capability in various automotive applications, from street use to motorsports. -

VTEC Technology

VTEC (Variable Valve Timing and Lift Electronic Control) is a hallmark feature of the K20A engine. This technology allows for variable timing of the intake and exhaust valves, optimizing performance across different RPM ranges. For B2B buyers, understanding VTEC’s benefits can help in marketing the engine’s capabilities to end-users seeking performance and efficiency. -

Material Composition

The K20A engine is typically constructed with high-strength aluminum alloy for the engine block and cylinder head. This material choice ensures a balance between weight savings and durability. For buyers, knowing the material properties can influence their assessment of the engine’s longevity and suitability for heavy-duty applications. -

Fuel System

The K20A engine uses a multi-point fuel injection system, which provides precise fuel delivery and improved combustion efficiency. This specification is essential for buyers as it can affect the engine’s performance characteristics, fuel economy, and emissions standards compliance.

What are Common Trade Terms Related to K20A Engine Sales?

Understanding industry jargon is equally important for navigating the B2B landscape effectively. Here are several terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the original manufacturer of the vehicle. In the context of the K20A engine, OEM parts ensure compatibility and reliability. B2B buyers often prefer OEM components to maintain quality standards in their vehicle offerings. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. For buyers, understanding MOQ is crucial for budgeting and inventory management, especially when purchasing engines in bulk. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers. It is a common practice in B2B transactions, allowing buyers to compare pricing and terms from different vendors for the K20A engine. -

Incoterms (International Commercial Terms)

These are international standards for shipping and freight logistics, defining the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B buyers involved in international transactions, as they specify who bears the risk and cost of transportation. -

Aftermarket

This term refers to parts and accessories that are not sourced from the OEM but are instead produced by third parties. Buyers should be aware of aftermarket options for the K20A engine, as they can provide cost-effective alternatives for performance enhancements and replacements. -

Core Charge

A core charge is an additional fee applied to the sale of remanufactured engines, which is refunded when the old engine is returned. Understanding this term helps buyers manage costs effectively during the purchasing process.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when considering the K20A engine for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the k20a engine for sale Sector

What Are the Key Trends Driving the K20A Engine Market for International Buyers?

The global market for the K20A engine is influenced by various dynamic factors that international B2B buyers need to consider. One of the primary drivers is the increasing demand for high-performance engines among automotive enthusiasts and racing communities. This trend is particularly pronounced in regions like Europe and the Middle East, where motorsports are popular, and vehicle customization is a cultural norm. Additionally, the rise of e-commerce platforms has made it easier for buyers in Africa and South America to access quality engines from reputable suppliers across the globe.

Emerging technologies, such as advanced engine diagnostics and 3D printing, are also reshaping the sourcing landscape. These technologies enable manufacturers to produce more efficient engines and spare parts, thereby enhancing performance and longevity. Furthermore, the shift towards digital marketplaces allows buyers to compare prices and specifications easily, facilitating informed purchasing decisions.

Another trend is the growing focus on remanufactured and refurbished engines, which offers a cost-effective alternative to new purchases. International buyers are increasingly seeking suppliers that provide detailed histories of engine mileage and condition, thereby ensuring they are making sound investments. Additionally, the integration of artificial intelligence in supply chain management is improving inventory accuracy and reducing lead times, which is crucial for buyers who require timely delivery.

How Is Sustainability Shaping Sourcing Decisions for K20A Engines?

Sustainability has become a cornerstone of modern B2B sourcing strategies, and the K20A engine market is no exception. As environmental regulations tighten globally, international buyers are increasingly concerned about the ecological impact of their purchases. This has led to a heightened demand for engines that meet stringent emissions standards and utilize eco-friendly materials.

Illustrative image related to k20a engine for sale

Ethical sourcing practices are also gaining traction. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable manufacturing processes, such as using recycled materials or ensuring fair labor practices. Certifications related to environmental management systems, such as ISO 14001, can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the trend towards remanufactured engines not only offers cost savings but also contributes to waste reduction. By opting for refurbished K20A engines, buyers can significantly decrease their carbon footprint while still achieving high performance. As the industry evolves, those who prioritize sustainability and ethical sourcing will likely gain a competitive edge in attracting environmentally conscious consumers.

What Is the Historical Context of the K20A Engine Market?

The K20A engine has a rich history that dates back to its introduction in the early 2000s. Originally developed by Honda, this engine was designed to deliver both performance and reliability, quickly becoming a favorite among automotive enthusiasts. Its application in popular models such as the Honda Civic Type R and Acura RSX solidified its reputation for high performance.

Over the years, the K20A engine has undergone various enhancements, including improvements in fuel efficiency and emissions control technologies. As automotive technology advanced, the K20A became a versatile engine choice for both street and race applications. This evolution reflects broader trends in the automotive industry, where performance is increasingly being balanced with environmental responsibility.

As the market continues to evolve, understanding the historical context of the K20A engine can provide valuable insights for international B2B buyers looking to navigate current market dynamics effectively.

Illustrative image related to k20a engine for sale

Frequently Asked Questions (FAQs) for B2B Buyers of k20a engine for sale

-

How can I ensure the quality of a K20A engine before purchasing?

To guarantee the quality of a K20A engine, it is essential to conduct thorough research on potential suppliers. Request detailed specifications, performance data, and quality assurance certifications. Furthermore, consider asking for references or customer testimonials. If possible, arrange for a pre-shipment inspection or third-party verification to ensure the engine meets your requirements and industry standards. Establishing clear quality control processes with the supplier can also mitigate risks associated with engine performance and longevity. -

What are the most important specifications to consider when buying a K20A engine?

When purchasing a K20A engine, focus on specifications such as engine type, displacement, horsepower, torque, and compatibility with your vehicle model. Additionally, inquire about mileage, service history, and any modifications made to the engine. Understanding the engine’s intended use—whether for daily driving or racing—will help you assess its suitability for your needs. Finally, confirm that the engine includes necessary components, such as wiring harnesses and ECUs, to facilitate installation. -

What are the common payment terms for purchasing K20A engines internationally?

Payment terms can vary widely depending on the supplier and the buyer’s negotiation. Common practices include upfront payments, deposits followed by balance payments upon shipment, or letters of credit for larger transactions. Ensure to clarify the payment method, currency, and any associated fees, such as bank transfer costs. Additionally, consider using escrow services for added security, particularly in international transactions, to safeguard your investment until the engine is received and verified. -

What is the minimum order quantity (MOQ) for K20A engines?

The minimum order quantity for K20A engines typically depends on the supplier and their production capabilities. Some suppliers may offer individual engines, while others might set a MOQ of 5-10 units to accommodate bulk buyers. It is advisable to communicate your purchasing needs upfront, as many suppliers are willing to negotiate terms based on your business requirements. Establishing a solid relationship with the supplier may also lead to more favorable terms and conditions in the future. -

How can I vet suppliers for K20A engines effectively?

Vetting suppliers involves a multi-step process. Start by researching their business background, checking online reviews, and exploring their industry reputation. Request their business licenses, certifications, and warranty policies. Additionally, reach out to previous clients to gather insights on their experiences. If possible, conduct a site visit or virtual tour of their facilities to assess their operational standards. Transparency in communication and willingness to provide documentation are key indicators of a reliable supplier. -

What logistics considerations should I be aware of when importing K20A engines?

Logistics play a critical role in the importation of K20A engines. Consider shipping methods, costs, and timeframes, as well as customs regulations and duties applicable in your country. Collaborate with a freight forwarder experienced in handling automotive parts to streamline the process. Additionally, ensure proper packaging to prevent damage during transit. It’s wise to factor in insurance for your shipment to protect against potential loss or damage during transportation. -

Can I customize the K20A engine for specific applications?

Many suppliers offer customization options for K20A engines to meet specific performance needs. This may include tuning for horsepower, adjusting compression ratios, or modifying components like the intake and exhaust systems. Discuss your requirements with the supplier, and inquire about available packages or additional features. Customization may affect lead times and costs, so ensure to clarify these aspects before finalizing your order. -

What warranty options are available for K20A engines?

Warranty options for K20A engines vary by supplier and can significantly impact your purchasing decision. Many reputable suppliers offer warranties that cover defects in materials and workmanship for a specified period or mileage. Be sure to read the warranty terms carefully, including what is covered and any conditions that may void it. Understanding the warranty policy can provide peace of mind and protect your investment in the event of unforeseen issues post-purchase.

Top 10 K20A Engine For Sale Manufacturers & Suppliers List

1. Honda – K20 Engine Listings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: K20 Engine listings on eBay include various models such as JDM 02-06 Honda Civic, Acura RSX i-VTEC K20A DOHC 2.0L Engine, K20A HONDA ACCORD JDM EURO R CL7 2.0L i-VTEC ENGINE, 2002-2006 JDM HONDA ACURA RSX DC5 TYPE R K20A ENGINE with 6 SPEED LSD TRANSMISSION, and 2019 Honda Civic Type R Engine K20C1 Motor 2.0L Turbo OEM Assembly. Prices range from $20.00 for parts to $6,930.00 for complete engines,…

2. JDM Engine Depot – Honda K-Series Engines

Domain: jdmenginedepotinc.com

Registered: 2017 (8 years)

Introduction: Honda K-Series Engines for Sale with mileage between 45-65K miles. Available products include: 1. 2003-2006 Honda Element 2.4L DOHC 4CYL IVTEC Engine JDM K24A – Price: $999.00, Rating: 4.86/5 2. 2007-2011 Honda Element Engine 2.4L DOHC 4CYL IVTEC JDM K24A – Price: $999.00, Rating: 5.00/5 3. 2003-2007 Honda Accord 2.4L DOHC 4CYL IVTEC Engine JDM K24A – Price: $999.00 4. 2002-2005 Honda Civic Type R…

3. 4 Piston Racing – K20-KT1200 2.1L Complete Engine

Domain: 4pistonracing.com

Registered: 2015 (10 years)

Introduction: {“name”: “K20-KT1200 2.1L Complete Engine – SFWD Turbo Race Engine”, “price”: “$13,445.00”, “description”: “The 4 Piston Racing K20-KT1200 Crate Engine is specifically designed for SFWD and Outlaw Class turbocharged race cars looking to exceed 1200hp. This engine is meticulously assembled with the best components to ensure that you can go round after round pushing 60+psi boost. It features a purpo…

4. HMotorsOnline – JDM 2008 K24A Engine

Domain: hmotorsonline.com

Registered: 2002 (23 years)

Introduction: [{‘name’: ‘JDM 2008 Year Model K24A Engine with RBB-4 Cylinder Head (3-Lobe) i-VTEC’, ‘price’: ‘$1,395.00’}, {‘name’: ‘Brand New OEM Honda K20A 5.062 Final Drive Set’, ‘price’: ‘$499.00’, ‘original_price’: ‘$549.00’}, {‘name’: ‘JDM 02-06 K20A RSX Base Model Long Block’, ‘price’: ‘$899.00’}, {‘name’: ’04-05 Year JDM K24A (Japan Replacement TSX) Long Block’, ‘price_range’: ‘$1,099.00 – $1,124.00’}, …

5. JDM Racing Motors – K24A and K20A Engines for Sale

Domain: jdmracingmotors.com

Registered: 2005 (20 years)

Introduction: K24A Motors and K20A Acura RSX Type R DC5 for Sale. Various models available including K24A 2.4L JDM RBB-3 High Compression, JDM DOHC High Compression 2.4L Honda Accord/Acura, JDM 2.4L Automatic Honda Accord, and JDM K20A 2002-2006 Honda Civic/RSX I-VTEC. Prices range from $695 to $5,495 USD. All items are in stock with some offering free shipping.

6. JDM Orlando – K20A Engine

Domain: jdmorlandoinc.com

Registered: 2013 (12 years)

Introduction: K20A Engine for Sale – Part of Honda’s K-series engines, found in 04-08 Honda Accord, 02-06 Acura Integra, and 02-05 Honda Civic Si. Four-cylinder, four-stroke engine introduced in 2001. Features roller rockers to reduce friction, DOHC valvetrains, and a distributorless ignition system. Two variants with different deck heights; K20A has a 212mm deck height. DOHC i-VTEC engine producing either 155 …

7. Honda – K20 Engine Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking to buy a new K20 engine. Possible options include K20A2, K20Z1, K20Z3, or K24A2. Prices for a clean low mileage K20 engine are comparable to a K24A2 swap, including engine management. A reputable source for Honda engines mentioned is Hmotors online, with prices for a K20A from Japan starting at around $6k.

8. Honda – Civic TYPE R K20A Engine with Transmission

Domain: nearautosparts.com

Registered: 2022 (3 years)

Introduction: {“Product Name”:”Honda Civic TYPE R K20A K20 2.0L Engine with Transmission”,”Price”:”$4,200.00″,”Availability”:”In Stock”,”Engine Code”:”K20A K20″,”Transmission”:”6-Speed LSD”,”Cylinder Arrangement”:”Inline 4″,”Displacement”:”2.0L”,”Fuel Type”:”Gasoline/Petrol”,”Cooling System”:”Liquid Cooled”,”Warranty”:”90-day warranty”,”Condition”:”Used”,”Mileage”:”37,000″,”Max Power”:”200hp”,”Torque”:”202Nm”,”…

9. JDM – Acura RSX K20A Engine

Domain: jdmcalifornia.com

Registered: 2014 (11 years)

Introduction: {“name”:”JDM Acura Rsx 2002-2006 K20a Engine | Honda Civic Si 2002-2005 | K20A 2.0L 4 Cylinder Engine”,”price”:”$750.00″,”engine_type”:”JDM Honda K20A 2.0L DOHC i-VTEC Engine”,”compatible_models”:[“2002-2006 RSX Base model”,”2002-2005 Civic Si”],”parts_included”:[“COMPLETE ENGINE HEAD AND BLOCK”,”INTAKE AND EXHAUST MANIFOLD”,”COILS”,”ALTERNATOR”,”POWER STEERING PUMP”],”mileage”:”approximately 70,0…

10. Honda – Civic FD Parts & Accessories

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: {“product_name”:”Honda Civic FD PH Parts and Accessories”,”engine”:”K20″,”price”:”45k”,”negotiable”:”Yes”,”location”:”Qc”}

Strategic Sourcing Conclusion and Outlook for k20a engine for sale

In conclusion, the strategic sourcing of K20A engines presents a significant opportunity for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By understanding the compatibility and performance characteristics of the K20A, buyers can make informed decisions that enhance their automotive offerings. The K20A engine, with its robust specifications and reliable performance, is ideal for a range of vehicles, making it a versatile choice for businesses aiming to cater to diverse consumer needs.

The value of strategic sourcing cannot be overstated. By partnering with reputable suppliers, buyers can ensure access to high-quality engines that meet stringent performance standards while also benefiting from competitive pricing and efficient logistics. This approach not only reduces operational risks but also enhances supply chain resilience.

Looking ahead, the demand for high-performance engines like the K20A is poised to grow as automotive markets evolve. We encourage businesses to explore sourcing options proactively, leveraging the insights provided in this guide to secure the best products for their needs. Engaging with trusted suppliers will pave the way for success in a competitive landscape, ensuring that your offerings remain ahead of the curve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to k20a engine for sale

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.