Japanese Panko Bulk Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for japanese panko bulk

In an increasingly competitive global marketplace, sourcing high-quality Japanese panko in bulk poses a significant challenge for international B2B buyers. The unique texture and lightness of authentic panko make it an essential ingredient for a diverse range of culinary applications, from crispy coatings for fried dishes to delightful toppings for baked goods. However, navigating the complexities of supplier selection, pricing, and product authenticity can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, such as Vietnam and Nigeria.

This guide offers a comprehensive overview of the Japanese panko bulk market, empowering buyers with essential insights. We will explore various types of panko, including traditional and flavored options, and their applications in both commercial kitchens and food manufacturing. Additionally, we will provide actionable strategies for vetting suppliers to ensure product quality and authenticity, alongside considerations for cost management and logistics.

By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, helping businesses enhance their culinary offerings and maintain a competitive edge. Whether you are a restaurant owner, food distributor, or manufacturer, understanding the nuances of Japanese panko will enable you to meet customer demands while delivering exceptional quality.

Understanding japanese panko bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Authentic Japanese Panko | Made from crustless bread, larger and crispier | Restaurants, food manufacturers | Pros: Superior texture and taste; versatile for various dishes. Cons: Higher cost than standard breadcrumbs. |

| Seasoned Panko | Blended with spices and herbs for added flavor | Fast-casual dining, catering | Pros: Enhances flavor profiles; saves time on seasoning. Cons: May limit culinary versatility for some dishes. |

| Gluten-Free Panko | Made from gluten-free ingredients like rice flour | Health-focused restaurants, bakeries | Pros: Expands customer base; caters to dietary restrictions. Cons: May have a different texture than traditional panko. |

| Tempura Batter Mix | Designed for a light, crispy coating | Asian cuisine restaurants, food trucks | Pros: Easy to use; maintains crispiness longer. Cons: Requires additional liquid for preparation. |

| Custom Panko Blends | Tailored formulations to meet specific culinary needs | Large chains, industrial kitchens | Pros: Unique offerings; can enhance brand identity. Cons: Longer lead times for development. |

What Are the Characteristics of Authentic Japanese Panko?

Authentic Japanese Panko is crafted from specially baked, crustless bread, resulting in larger, airy crumbs that provide a unique crunch. This type is ideal for high-end restaurants and food manufacturers looking to elevate their menu offerings. When purchasing, consider the supplier’s authenticity and quality assurance processes, as the texture and taste significantly impact the final dish.

How Does Seasoned Panko Enhance Culinary Offerings?

Seasoned Panko features a blend of spices and herbs, making it a convenient option for fast-casual dining and catering services. This type allows chefs to save time on seasoning while adding flavor to dishes like fried chicken or vegetable fritters. Buyers should evaluate the flavor profiles and ingredient quality to ensure it aligns with their menu needs.

What Advantages Does Gluten-Free Panko Provide?

Gluten-Free Panko is made from alternative flours, such as rice, catering to health-conscious consumers and those with dietary restrictions. This variation is particularly relevant for bakeries and restaurants focusing on gluten-free options. Buyers should assess the texture and flavor differences compared to traditional panko to ensure customer satisfaction.

Why Choose Tempura Batter Mix for Your Menu?

Tempura Batter Mix is specifically designed to create a light, crispy coating for various foods. Its versatility makes it suitable for Asian cuisine restaurants and food trucks. When considering this product, buyers should look for options that maintain crispiness over time and are easy to prepare, as this can streamline kitchen operations.

How Can Custom Panko Blends Benefit Your Business?

Custom Panko Blends are tailored to meet specific culinary needs, making them an excellent choice for large chains and industrial kitchens. This option allows businesses to differentiate themselves in a competitive market. Buyers should be prepared for longer lead times and ensure that the supplier can deliver consistent quality in their custom formulations.

Key Industrial Applications of japanese panko bulk

| Industry/Sector | Specific Application of Japanese Panko Bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Manufacturing | Coating for Frozen Foods | Enhances texture and quality of frozen products | Consistency in size and quality; shelf life requirements |

| Restaurant & Catering | Menu Item Enhancement | Provides unique texture and flavor for various dishes | Customization options; bulk purchasing agreements |

| Snack Food Production | Ingredient for Snack Foods | Adds crispiness and visual appeal to snacks | Sourcing for specific granulation sizes; allergen control |

| Bakery Products | Topping for Baked Goods | Improves presentation and texture of baked items | Need for preservative-free options; storage conditions |

| Asian Cuisine Restaurants | Base for Tempura and Other Dishes | Authentic taste and texture for traditional dishes | Import regulations; ensuring authenticity and quality |

How is Japanese Panko Bulk Used in Food Manufacturing?

In food manufacturing, Japanese panko bulk serves as a premium coating for frozen foods such as chicken nuggets, fish sticks, and vegetable fritters. Its unique texture allows for a lighter, crispier finish compared to traditional bread crumbs, enhancing the overall quality of the product. For international buyers, particularly from regions like Africa and South America, sourcing panko that meets specific granulation and consistency standards is crucial. Additionally, manufacturers must consider shelf life and storage conditions to maintain product integrity.

What Role Does Japanese Panko Bulk Play in Restaurant and Catering Services?

For restaurants and catering services, Japanese panko bulk is a versatile ingredient that elevates menu offerings. It can be used to coat proteins or as a topping for casseroles, providing a satisfying crunch that enhances customer satisfaction. B2B buyers in this sector often seek customization options, allowing them to tailor the panko to their specific recipes. Establishing bulk purchasing agreements can also lead to cost savings and reliable supply chains, which are essential for maintaining consistent service quality.

Illustrative image related to japanese panko bulk

How is Japanese Panko Bulk Beneficial for Snack Food Production?

In the snack food production industry, Japanese panko bulk is used to create crispy coatings for various snack items, such as cheese balls and potato chips. The larger, airier texture of panko not only improves the mouthfeel but also adds visual appeal, making snacks more enticing to consumers. Buyers need to consider granulation sizes and allergen control measures when sourcing panko to ensure product safety and compliance with local regulations.

Why is Japanese Panko Bulk Important for Bakery Products?

Japanese panko bulk is increasingly being utilized in the bakery sector as a topping for items like bread, rolls, and pastries. It adds an appealing crunch and enhances the overall presentation of baked goods. For international buyers, the demand for preservative-free options is growing, making it essential to source high-quality panko that meets these dietary needs. Proper storage conditions must also be maintained to preserve the freshness and quality of the panko.

How Do Asian Cuisine Restaurants Use Japanese Panko Bulk?

Asian cuisine restaurants frequently incorporate Japanese panko bulk as a key ingredient in tempura and other fried dishes. Its ability to maintain a crispy texture even after frying makes it an ideal choice for chefs aiming to deliver authentic flavors. For B2B buyers, understanding import regulations and ensuring the authenticity of the panko is vital to meet customer expectations and maintain a competitive edge in the market.

3 Common User Pain Points for ‘japanese panko bulk’ & Their Solutions

Scenario 1: Inconsistent Quality of Panko Across Suppliers

The Problem: A restaurant chain sourcing Japanese panko in bulk often faces inconsistencies in quality from different suppliers. This variation can affect the texture and flavor of their dishes, leading to customer dissatisfaction. When a chef relies on panko to create signature dishes, any deviation from expected quality can result in failed recipes and wasted ingredients, ultimately impacting the restaurant’s reputation.

Illustrative image related to japanese panko bulk

The Solution: To ensure consistent quality, B2B buyers should establish long-term relationships with reputable suppliers who specialize in authentic Japanese panko. Conduct thorough research to identify suppliers with a proven track record and positive reviews from other businesses in the food service industry. Additionally, request samples before making bulk purchases to compare texture, flavor, and performance in cooking. Implementing a quality control process upon receipt of goods can also help ensure that the panko meets the required standards before it reaches the kitchen. This proactive approach not only safeguards against inconsistencies but also strengthens the partnership with suppliers, allowing for better communication regarding product specifications and expectations.

Scenario 2: Difficulties in Storage and Shelf Life Management

The Problem: Many businesses struggle with managing the storage and shelf life of bulk Japanese panko. Improper storage conditions can lead to moisture absorption, resulting in stale or clumpy breadcrumbs that lose their crispiness. This not only leads to food waste but can also impact the quality of dishes served, as stale panko fails to deliver the desired crunch and texture.

The Solution: To effectively manage storage and extend the shelf life of Japanese panko, buyers should invest in airtight containers to protect the product from moisture and air exposure. Ensure that the storage area is cool and dry, as high humidity can significantly reduce the quality of the panko. Additionally, consider implementing a first-in, first-out (FIFO) inventory system to utilize older stock first, minimizing the risk of spoilage. Educating kitchen staff about proper handling and storage practices is also crucial, as training them to close containers tightly after use can further protect the panko’s quality. For businesses that experience fluctuations in demand, freezing panko can be an excellent option, as it preserves texture and quality without affecting its culinary performance.

Scenario 3: Navigating Regulatory and Labeling Requirements

The Problem: International buyers of Japanese panko often encounter challenges related to regulatory compliance and labeling requirements in different regions. Misunderstandings about ingredient sourcing, allergen disclosures, and nutritional information can lead to costly delays, fines, or even product recalls, which can severely impact business operations.

The Solution: To navigate these complexities, B2B buyers should familiarize themselves with the food safety regulations and labeling requirements specific to their target markets. Consulting with legal experts or industry associations can provide valuable insights into compliance standards. When sourcing Japanese panko, request detailed ingredient lists and allergen information from suppliers to ensure transparency. Additionally, consider collaborating with suppliers who are experienced in exporting to your region, as they will be more knowledgeable about the necessary documentation and compliance processes. Keeping accurate records of all product specifications and certifications can further streamline the compliance process, reducing the risk of misunderstandings and ensuring that the product is market-ready upon arrival. By prioritizing compliance from the outset, buyers can mitigate risks and focus on delivering high-quality dishes to their customers.

Strategic Material Selection Guide for japanese panko bulk

What Are the Key Materials Used in Japanese Panko Bulk Production?

When considering the procurement of Japanese panko in bulk, it’s essential to understand the materials involved in its production. The primary components are wheat flour, yeast, cane sugar, and salt. Each of these materials has unique properties, advantages, and limitations that can significantly impact the final product’s quality and performance.

Wheat Flour: The Foundation of Panko

Wheat flour is the primary ingredient in Japanese panko. Its key properties include high gluten content, which contributes to the desired texture and crispiness of the breadcrumbs. The flour’s ability to absorb moisture also plays a crucial role in maintaining the panko’s light and airy structure during cooking.

Pros: Wheat flour is widely available and cost-effective, making it a staple in food production. Its versatility allows it to be used in various applications, from frying to baking.

Illustrative image related to japanese panko bulk

Cons: However, wheat flour is prone to spoilage if not stored correctly, which can lead to quality degradation. Additionally, it may not be suitable for gluten-free applications, limiting its market reach.

Impact on Application: The choice of wheat flour can influence the final product’s texture and flavor, making it critical for manufacturers to select high-quality flour that meets their specific needs.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the wheat flour complies with local food safety standards and regulations, including those set by the Codex Alimentarius.

Yeast: The Leavening Agent

Yeast is another vital ingredient in panko production, responsible for fermentation and contributing to the bread’s texture. The key property of yeast is its ability to produce carbon dioxide, which helps the bread rise during baking.

Pros: Yeast is relatively inexpensive and widely available, making it a practical choice for bulk production. It also enhances the flavor profile of the panko.

Cons: Yeast requires specific storage conditions to maintain its viability, and its activity can be affected by temperature and humidity. This can lead to inconsistencies in production if not monitored closely.

Impact on Application: The fermentation process can affect the panko’s crispiness and shelf life, making it essential for manufacturers to control the fermentation environment.

Considerations for International Buyers: Buyers should verify that the yeast used meets international standards, such as those established by the International Organization for Standardization (ISO), to ensure quality and safety.

Cane Sugar: Sweetness and Color

Cane sugar is used in panko primarily for flavor and browning during the cooking process. Its key property is its ability to caramelize, providing a golden color and enhancing the overall taste.

Pros: Cane sugar is a natural ingredient that appeals to consumers looking for clean-label products. It is also cost-effective and readily available.

Cons: Excessive sugar can lead to unwanted browning or burning, impacting the final product’s appearance. Additionally, sugar can attract moisture, potentially affecting the panko’s shelf life.

Impact on Application: The amount of cane sugar used can influence the flavor and color of the panko, making it crucial for manufacturers to balance sweetness with other ingredients.

Considerations for International Buyers: Buyers should ensure that the cane sugar complies with local regulations regarding food additives and labeling, particularly in regions with strict food safety laws.

Salt: Flavor Enhancer and Preservative

Salt is essential in panko production, serving as a flavor enhancer and preservative. Its key property is its ability to inhibit microbial growth, thus extending shelf life.

Illustrative image related to japanese panko bulk

Pros: Salt is inexpensive and enhances the overall flavor profile of the panko, making it more appealing to consumers.

Cons: Overuse of salt can lead to health concerns, particularly in markets where sodium intake is closely monitored. Additionally, high salt content can affect the panko’s texture.

Impact on Application: The right amount of salt is crucial for balancing flavor and preserving quality, making it a key consideration for manufacturers.

Considerations for International Buyers: Buyers should be aware of local regulations regarding sodium content in food products, especially in regions with high rates of hypertension.

Summary Table of Material Selection for Japanese Panko Bulk

| Material | Typical Use Case for Japanese Panko Bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wheat Flour | Base ingredient for panko production | Widely available and cost-effective | Prone to spoilage and gluten issues | Low |

| Yeast | Fermentation agent in bread production | Enhances flavor and texture | Requires specific storage conditions | Low |

| Cane Sugar | Flavoring and browning agent | Natural ingredient with clean label appeal | Can attract moisture and cause browning | Low |

| Salt | Flavor enhancer and preservative | Inexpensive and enhances flavor | Health concerns with high sodium content | Low |

This strategic material selection guide provides valuable insights for international B2B buyers looking to source Japanese panko in bulk. Understanding the properties, advantages, and limitations of each material will aid in making informed purchasing decisions that align with local regulations and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for japanese panko bulk

What are the Main Stages in the Manufacturing Process of Japanese Panko Bulk?

The manufacturing process of Japanese Panko is intricate and designed to maintain the quality and authenticity that make it a sought-after ingredient in culinary applications worldwide. The process typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary ingredient for Panko is high-quality wheat flour, which is selected for its gluten content and baking properties. Other ingredients may include cane sugar, yeast, and salt. Flour is first milled and then mixed with water to create a dough. The dough is allowed to rest and rise, promoting fermentation, which is crucial for developing flavor and texture.

-

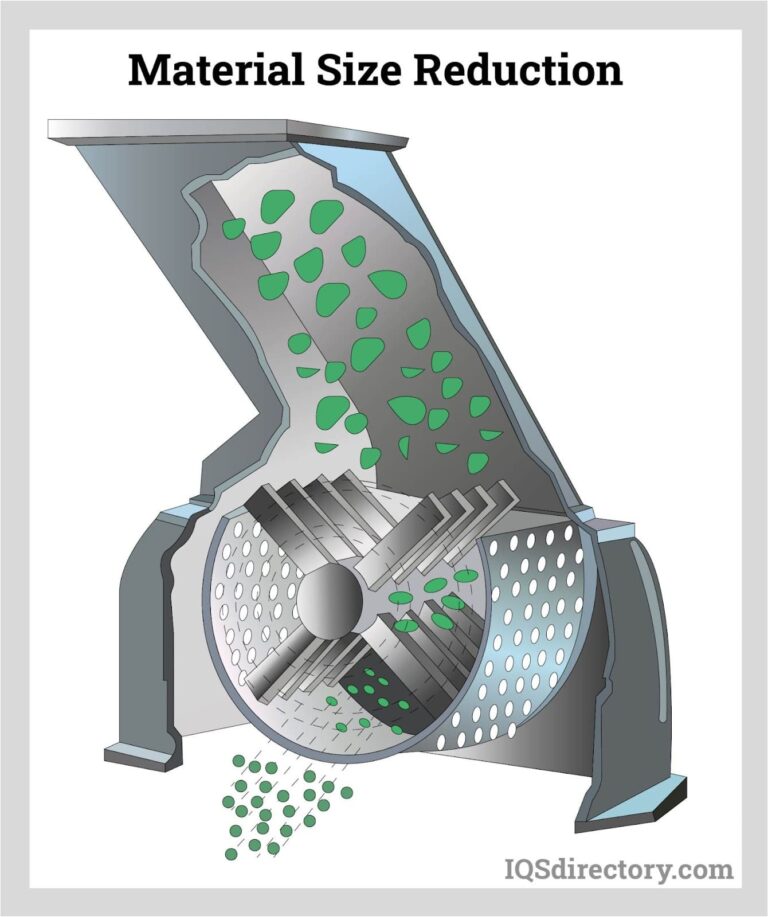

Forming: After the dough has risen, it is rolled out and cut into specific shapes. Traditional Japanese Panko is made from crustless bread, which results in larger, flakier crumbs compared to standard breadcrumbs. The dough is baked in specialized ovens that allow for even cooking and optimal moisture content. This step is essential, as it influences the final product’s lightness and crispiness.

-

Assembly: Once baked, the bread is cooled and then subjected to a grinding process. This process ensures uniformity in crumb size, which is vital for achieving the desired texture in various culinary applications. The grinding techniques used may vary, but they typically involve passing the bread through a series of screens to produce the characteristic flaky texture of Panko.

-

Finishing: The final stage involves packaging the Panko for distribution. Quality control measures are put in place to ensure that the product meets specific standards before packaging. This includes checking for moisture levels, texture consistency, and absence of contaminants.

What Quality Assurance Measures are in Place for Japanese Panko Production?

Quality assurance (QA) is a critical component of Panko production, ensuring that the product meets both international standards and customer expectations. Manufacturers often adhere to several established quality management systems.

-

International Standards: Many producers comply with ISO 9001, a standard that outlines criteria for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant for certain markets, ensuring compliance with safety and quality regulations.

-

Quality Control Checkpoints: The quality assurance process typically involves multiple checkpoints:

– Incoming Quality Control (IQC): Raw materials, such as flour and other ingredients, undergo rigorous testing upon arrival. This includes checking for moisture content, impurities, and conformity to specifications.

– In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor consistency in texture, size, and color. This step is essential for catching any deviations early in the process.

– Final Quality Control (FQC): Before packaging, the finished Panko is tested for moisture levels, texture, and flavor. This final inspection ensures that the product meets the established quality standards.

What Common Testing Methods are Used in Panko Quality Assurance?

Manufacturers utilize a variety of testing methods to ensure the quality of their Panko. Common methods include:

-

Moisture Analysis: This test measures the moisture content of the Panko, as excessive moisture can lead to spoilage and affect texture. Typical methods include the use of moisture analyzers or drying ovens.

-

Texture Analysis: Texture analyzers are used to assess the crunchiness and flakiness of the Panko. This is crucial for maintaining the desired eating experience in culinary applications.

-

Microbiological Testing: To ensure food safety, Panko is tested for microbial contamination. This may involve sampling and culturing to detect pathogens or spoilage organisms.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their Panko suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and verify the integrity of their operations.

-

Quality Reports: Requesting quality control reports from suppliers can help buyers understand the testing methods used and the results achieved. This transparency builds trust and helps buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These services can conduct random sampling and testing, providing an additional layer of assurance.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must be aware of specific nuances when it comes to quality control in the context of sourcing Japanese Panko.

-

Regulatory Compliance: Different regions have varying regulations regarding food safety and quality. Buyers from Africa, South America, the Middle East, and Europe should ensure that their suppliers comply with local regulations, including labeling requirements and safety standards.

-

Cultural Preferences: Taste and texture preferences can vary significantly across markets. Understanding these preferences can help buyers select the right type of Panko for their target audience, ensuring that the product meets local culinary standards.

-

Logistical Considerations: Importing Panko can involve challenges related to shipping and storage. Buyers should ensure that their suppliers have robust logistics in place to maintain product integrity during transport. This includes proper packaging to prevent moisture absorption and physical damage.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for Japanese Panko bulk can empower B2B buyers to make informed purchasing decisions. By focusing on supplier audits, quality reports, and international compliance, buyers can ensure they source high-quality Panko that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘japanese panko bulk’

In the competitive landscape of food service and manufacturing, sourcing high-quality Japanese panko in bulk is essential for enhancing menu offerings and maintaining product consistency. This guide serves as a comprehensive checklist for B2B buyers, ensuring that you make informed decisions when procuring Japanese panko.

Illustrative image related to japanese panko bulk

Step 1: Define Your Technical Specifications

Clearly outline the specific characteristics you need for your panko, such as size, texture, and flavor profile. Authentic Japanese panko is known for its light and crispy texture, which significantly impacts the quality of dishes. Specifying these details helps suppliers provide products that align with your culinary needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in Japanese panko. Utilize industry directories, trade shows, and online platforms to gather a list of potential vendors. Pay attention to their experience, range of products, and customer reviews to assess their reliability.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO, HACCP, and Kosher, which indicate adherence to quality and safety standards. These certifications not only ensure product quality but also demonstrate the supplier’s commitment to ethical sourcing and food safety practices.

Step 4: Request Samples for Quality Assessment

Before making bulk purchases, request samples to evaluate the quality of the panko. Assess factors such as texture, taste, and appearance to ensure it meets your culinary standards. This step is crucial as it allows you to compare different suppliers and make an informed choice based on firsthand experience.

Illustrative image related to japanese panko bulk

Step 5: Confirm Bulk Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms to ensure they align with your budget. Bulk orders often come with discounts, so inquire about tiered pricing based on order volume. Additionally, clarify payment methods and terms to avoid unexpected costs.

Step 6: Understand Logistics and Delivery Options

Discuss logistics with your chosen supplier, including shipping methods, lead times, and delivery costs. Understanding these factors is vital for planning your inventory and ensuring that you have a steady supply of panko to meet demand. Confirm that the supplier can handle international shipping if you’re sourcing from overseas.

Step 7: Establish a Communication Plan

Create a communication plan with your supplier to facilitate ongoing dialogue about your orders. Regular check-ins can help address any issues promptly and ensure that you receive consistent product quality. Establishing clear lines of communication fosters a strong supplier relationship, which is beneficial for future transactions.

By following this checklist, B2B buyers can streamline the sourcing process for Japanese panko, ensuring they select high-quality products that enhance their culinary offerings while meeting operational needs.

Comprehensive Cost and Pricing Analysis for japanese panko bulk Sourcing

What Are the Key Cost Components in Sourcing Japanese Panko in Bulk?

When considering the bulk sourcing of Japanese panko, understanding the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The core ingredient for panko is high-quality wheat flour. The cost of raw materials can fluctuate based on market demand and availability, especially in regions where wheat is a staple. Buyers should seek suppliers that can guarantee consistent quality and sourcing of raw materials.

-

Labor: Labor costs vary significantly depending on the country of production. Regions with lower labor costs may offer competitive pricing, but this can sometimes impact quality. It’s crucial to evaluate the labor practices of potential suppliers to ensure they adhere to ethical standards.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities, equipment maintenance, and general administrative expenses. Suppliers with streamlined operations may offer better pricing due to lower overhead costs.

-

Tooling: The initial investment in machinery and tools necessary for producing panko can influence pricing. Suppliers with advanced technology often achieve higher efficiency, which can translate into lower costs for buyers.

-

Quality Control (QC): Implementing stringent QC measures is vital for maintaining product integrity. While this may add to costs, it helps prevent issues that could arise from inferior products, ultimately safeguarding the buyer’s reputation.

-

Logistics: Shipping and handling costs are significant, particularly for international buyers. Factors such as distance, mode of transport, and packaging can all impact the total logistics costs. Buyers should consider suppliers that offer efficient and cost-effective shipping solutions.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the typical margin percentages in the industry can help buyers negotiate better deals.

How Do Pricing Influencers Affect Bulk Orders of Japanese Panko?

Several factors can influence the pricing of bulk orders, making it essential for buyers to assess these elements carefully.

-

Volume/MOQ: Suppliers often provide better pricing for larger volume orders or those that meet minimum order quantities (MOQs). Buyers should evaluate their needs and negotiate terms that allow for bulk purchasing to maximize cost savings.

-

Specifications/Customization: Customization requests can increase costs, as they may require additional materials or processes. Buyers should clearly outline their needs to avoid unexpected price hikes.

-

Materials and Quality Certifications: The quality of ingredients and certifications (e.g., Non-GMO, organic) will affect pricing. Higher quality often comes at a premium, but it can also lead to better end products that justify the investment.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The terms of delivery can significantly affect costs. Buyers should understand Incoterms (International Commercial Terms) to negotiate favorable shipping conditions that minimize risk and additional charges.

What Are Some Effective Buyer Tips for Cost-Efficient Bulk Sourcing of Japanese Panko?

B2B buyers can adopt several strategies to ensure cost-efficient sourcing of Japanese panko.

-

Negotiation: Always negotiate pricing and terms. Suppliers may have room for flexibility, especially for large orders or long-term contracts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost associated with sourcing, including shipping, storage, and potential quality issues. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Pricing Nuances for International Buyers: International buyers should be mindful of currency fluctuations, tariffs, and import duties that can impact overall costs. Engaging with local suppliers when possible can mitigate some of these costs.

-

Request Samples and Conduct Comparative Analysis: Before committing to a supplier, request samples to assess quality. Comparing different suppliers based on quality and price can uncover significant savings.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Loyalty can often result in discounts or priority service.

By understanding these cost components, pricing influencers, and strategic tips, international B2B buyers can make informed decisions when sourcing Japanese panko in bulk, ensuring they achieve quality products at competitive prices.

Alternatives Analysis: Comparing japanese panko bulk With Other Solutions

Understanding Alternatives to Japanese Panko Bulk

In the competitive landscape of food production and culinary innovation, businesses often seek alternatives to traditional ingredients to meet their specific needs. Japanese panko, known for its light, crispy texture and versatility, is a popular choice among chefs and food manufacturers. However, understanding other viable options can help B2B buyers make informed decisions that enhance their products and appeal to diverse markets.

Comparison Table

| Comparison Aspect | Japanese Panko Bulk | Traditional Breadcrumbs | Cornmeal Coatings |

|---|---|---|---|

| Performance | Superior crispiness and texture | Dense and can become soggy | Crunchy but grainy texture |

| Cost | Moderate to high depending on sourcing | Generally lower cost | Low cost, widely available |

| Ease of Implementation | Easy to incorporate in recipes | Simple, but may require additional seasoning | Simple, but may need flavor enhancement |

| Maintenance | Requires cool, dry storage | Similar storage requirements | Minimal storage concerns |

| Best Use Case | Ideal for frying and baking | Versatile, but less appealing for gourmet dishes | Excellent for rustic dishes and frying |

Detailed Breakdown of Alternatives

Traditional Breadcrumbs

Traditional breadcrumbs are made from dried and ground bread, offering a denser texture compared to panko. They are often more affordable and can be easily found in various markets. However, their tendency to absorb moisture can lead to sogginess, especially in fried applications. While they are versatile and can be used in a wide range of dishes, they may not provide the desired presentation or texture that many gourmet chefs seek.

Cornmeal Coatings

Cornmeal is another alternative that is often used for coating fried foods, providing a unique crunch and flavor profile. Its lower cost makes it an attractive option for high-volume operations. However, cornmeal can create a grainy texture that may not appeal to all consumers. Additionally, it may require additional seasoning to enhance its flavor, which could complicate the preparation process. Cornmeal is best suited for rustic dishes and Southern cuisine, but it may not perform as well in fine dining contexts.

Conclusion: How to Choose the Right Solution

When selecting an alternative to Japanese panko bulk, B2B buyers should consider their specific culinary goals, target audience, and budget constraints. Japanese panko excels in providing a light and crispy texture, making it ideal for upscale applications. Traditional breadcrumbs offer cost savings but may fall short in texture and presentation. Meanwhile, cornmeal coatings can be economical and flavorful but might not align with gourmet expectations. By evaluating these factors, businesses can choose the most suitable option that aligns with their operational needs and enhances their product offerings.

Essential Technical Properties and Trade Terminology for japanese panko bulk

What Are the Key Technical Properties of Japanese Panko Bulk?

Understanding the essential technical properties of Japanese Panko is crucial for B2B buyers looking to source high-quality ingredients. Here are some critical specifications to consider:

Illustrative image related to japanese panko bulk

1. Granulation Size

Granulation size refers to the particle size of the Panko crumbs. Japanese Panko is typically available in various granulation sizes, from fine to coarse. The choice of granulation affects the texture and crispiness of the final product. Coarser Panko provides a crunchier texture, ideal for fried foods, while finer Panko is better suited for baking applications. Buyers should consider the intended use when selecting the appropriate granulation size.

2. Moisture Content

Moisture content is a critical specification that influences the shelf life and quality of Panko. Ideally, Panko should have a moisture content of less than 10%. Excess moisture can lead to spoilage and affect the crispiness of the crumbs. For B2B buyers, ensuring low moisture levels is essential for maintaining product integrity during storage and transportation.

3. Ingredient Composition

Japanese Panko is primarily made from wheat flour, cane sugar, yeast, and salt, with no preservatives or artificial additives. Understanding the ingredient composition is vital for buyers concerned about dietary restrictions and allergens. Products labeled as Non-GMO or vegan can appeal to specific market segments, making ingredient transparency a valuable selling point.

Illustrative image related to japanese panko bulk

4. Shelf Life

The shelf life of Japanese Panko typically ranges from 12 months from the date of manufacture, assuming proper storage conditions. B2B buyers should prioritize suppliers that guarantee a minimum shelf life upon delivery to ensure product viability for their operations. Proper storage in a cool, dry place is also critical to extending shelf life.

5. Packaging Standards

Bulk Panko is usually packaged in bags or boxes that adhere to specific packaging standards to ensure freshness and prevent contamination. Packaging specifications may include weight, material type, and seal integrity. Buyers should verify that the packaging aligns with their distribution and retail requirements.

6. Nutritional Information

Nutritional content, including calorie count, fat content, and protein levels, is an important specification for buyers targeting health-conscious consumers. Providing accurate nutritional information can enhance the product’s marketability and meet regulatory requirements in various regions.

What Are Common Trade Terms Related to Japanese Panko Bulk?

Familiarity with industry jargon can streamline communication and negotiations in the B2B landscape. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. In the context of Panko, an OEM might produce bulk Panko for food manufacturers who package it under their brand names. Understanding OEM relationships can help buyers identify potential suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Japanese Panko, MOQs can vary based on the supplier and the packaging format. B2B buyers should inquire about MOQs to ensure that their purchasing needs align with supplier capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing Japanese Panko, B2B buyers should prepare an RFQ that clearly outlines their needs, including granulation size, packaging, and delivery requirements.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risk responsibilities, and delivery terms when importing Japanese Panko.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order after it is placed. For bulk Panko orders, lead time can vary based on production schedules and shipping logistics. Buyers should factor in lead times when planning inventory levels.

6. BRC (British Retail Consortium) Certification

BRC certification is a global standard for food safety and quality. Suppliers with BRC certification demonstrate compliance with high food safety standards, which can be a crucial factor for B2B buyers concerned about product quality and safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Japanese Panko in bulk, ensuring they select high-quality products that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the japanese panko bulk Sector

What Are the Current Market Dynamics and Key Trends Affecting Japanese Panko Bulk Sourcing?

The global demand for Japanese panko bulk has been significantly influenced by the rising trend towards healthier eating and gourmet cooking. As consumers worldwide seek lighter, crispier alternatives to traditional bread crumbs, panko has gained popularity for its unique texture and versatility. This surge is notably evident in regions like Africa, South America, the Middle East, and Europe, where culinary diversity is expanding. B2B buyers in these markets are increasingly looking for authentic, high-quality products that enhance their menus, making sourcing from reputable suppliers essential.

Emerging technologies are also reshaping the sourcing landscape. The integration of e-commerce platforms allows international buyers to access suppliers directly, facilitating comparisons and ensuring better pricing. Additionally, advancements in logistics and supply chain management are improving the efficiency of bulk orders, reducing lead times, and enhancing product traceability. This is particularly beneficial for regions with limited access to traditional distribution channels, such as certain areas in Africa and South America.

Sustainability is becoming a vital consideration for B2B buyers. Many companies are now prioritizing suppliers who adhere to ethical sourcing practices, which can influence purchasing decisions. As the market evolves, the focus on health, quality, and sustainability is expected to drive innovation in product offerings, including gluten-free and organic panko options.

Illustrative image related to japanese panko bulk

How Is Sustainability and Ethical Sourcing Impacting the Japanese Panko Bulk Market?

Sustainability and ethical sourcing are crucial factors for B2B buyers in the Japanese panko bulk sector. The environmental impact of food production is under increasing scrutiny, and suppliers are responding by adopting practices that minimize their carbon footprint. This includes utilizing renewable energy sources in production facilities and implementing waste reduction strategies.

Buyers are increasingly looking for suppliers who can demonstrate a commitment to ethical sourcing. This not only ensures compliance with international regulations but also enhances brand reputation. Certifications such as Non-GMO, organic, and fair trade are becoming essential for suppliers aiming to attract discerning buyers. Moreover, the use of environmentally friendly packaging materials is gaining traction, aligning with the broader consumer shift towards sustainability.

Incorporating sustainable practices not only appeals to eco-conscious consumers but can also lead to operational efficiencies and cost savings. For B2B buyers, aligning with suppliers who prioritize sustainability can create a competitive advantage in the market, fostering loyalty among customers who value ethical consumption.

What Is the Brief Evolution and History of Japanese Panko?

The origins of panko can be traced back to Japan, where it was developed in the late 19th century. Initially, panko was created as a way to enhance the texture of fried foods, providing a light and crispy coating that differs from traditional breadcrumbs. The unique production process, which involves using crustless bread baked in a specific manner, gives panko its characteristic flaky texture.

Over the decades, panko has transcended its Japanese roots and gained international popularity, becoming a staple in various cuisines. As chefs and food manufacturers recognize its versatility, panko is now used in everything from gourmet dishes to everyday meals. The evolution of panko has been marked by a growing appreciation for quality and authenticity, prompting international buyers to seek out genuine Japanese panko for their culinary applications. This historical context underscores the importance of sourcing authentic products to maintain the integrity and flavor profiles of diverse dishes.

Frequently Asked Questions (FAQs) for B2B Buyers of japanese panko bulk

-

How do I ensure the quality of Japanese panko before purchasing in bulk?

To ensure the quality of Japanese panko, request samples from potential suppliers to evaluate texture and flavor. Check for certifications such as Non-GMO, Kosher, or organic labels, which indicate adherence to specific quality standards. Additionally, inquire about the manufacturing process, including ingredient sourcing and preservation methods. Conducting a factory visit or third-party inspection can also provide insight into their quality assurance practices. This due diligence helps mitigate risks associated with bulk purchases. -

What are the key factors to consider when selecting a supplier for bulk Japanese panko?

When selecting a supplier, consider their reputation, experience in the industry, and production capabilities. Look for suppliers with positive customer reviews and verified references. Assess their ability to meet your specific needs, such as customization options and minimum order quantities (MOQs). Additionally, evaluate their logistical capabilities, including shipping methods, lead times, and compliance with international trade regulations. A supplier with robust communication and customer service can further ensure a smooth procurement process. -

What is the typical shelf life of Japanese panko, and how should it be stored?

Japanese panko typically has a shelf life of 12 months from the date of manufacture when stored properly. To maintain its quality, keep panko in a cool, dry place, away from moisture and direct sunlight. Once opened, transfer the panko to an airtight container to prevent exposure to air and humidity. For extended shelf life, consider freezing the product, as this will not affect its quality. Always check the packaging for specific storage instructions provided by the manufacturer. -

What are the minimum order quantities (MOQs) for bulk Japanese panko purchases?

MOQs for bulk Japanese panko can vary significantly by supplier and region. Generally, suppliers may set MOQs ranging from 100 kg to several tons, depending on their production capacity and your specific needs. Discuss your requirements directly with potential suppliers to negotiate an appropriate MOQ that aligns with your purchasing strategy. Smaller businesses may also inquire about group purchasing options or shared containers to meet MOQ requirements more easily. -

Can I customize the flavor or texture of the panko I order?

Yes, many suppliers offer customization options for panko, including variations in flavor, granulation size, and seasoning. If your business requires specific attributes—such as gluten-free or seasoned panko—discuss these needs with your supplier. Some suppliers may also provide custom blends or formulations tailored to your product specifications. Ensure you clarify these options during the negotiation process to align the product with your culinary requirements. -

What payment terms should I expect when sourcing Japanese panko in bulk?

Payment terms for bulk purchases of Japanese panko typically range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your creditworthiness. Some suppliers may offer discounts for early payments or larger orders. It’s essential to discuss payment options upfront and agree on terms that suit both parties. Be mindful of any additional costs such as shipping, customs duties, and taxes that may affect the overall pricing. -

How can I ensure compliance with international trade regulations when importing Japanese panko?

To ensure compliance with international trade regulations, familiarize yourself with import regulations specific to your country regarding food products. Verify that the supplier provides necessary documentation, such as certificates of origin, health certificates, and compliance with food safety standards. Engaging a customs broker can help navigate the complexities of import laws and facilitate smoother transactions. Regularly consult with legal experts to stay updated on changing regulations in your target market. -

What logistics considerations should I keep in mind when sourcing Japanese panko from abroad?

When sourcing Japanese panko internationally, consider shipping methods (air vs. sea), transit times, and costs associated with each option. Ensure your supplier has reliable logistics partners to handle transportation and customs clearance. Plan for potential delays by factoring in additional time for shipping and customs processing. Lastly, assess the packaging used to protect the panko during transit, as proper packaging can prevent damage and maintain product quality upon arrival.

Top 3 Japanese Panko Bulk Manufacturers & Suppliers List

1. Kikkoman – Panko Bread Crumbs 25 lbs

Domain: costcobusinessdelivery.com

Registered: 1998 (27 years)

Introduction: Kikkoman Panko Japanese Style Bread Crumbs, 25 lbs

2. Kikkoman – Japanese Style Panko Bread Crumbs

Domain: marinamarket.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Kikkoman Japanese Style Panko Bread Crumbs”, “size”: “8 oz”, “brand”: “Kikkoman”, “description”: “Kikkoman® Panko Bread Crumbs are made fresh from specially baked, crustless bread. With an oblong shape, Panko crumbs are larger, crispier and lighter, so they coat without ‘packing’ like regular bread crumbs, allowing foods to stay crispier longer. Their delicate, crisp texture make…

3. Upper Crust Enterprises – Panko Extra Large Grind Breadcrumbs

Domain: warehouse115.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Panko Extra Large Grind Authentic Japanese Breadcrumbs”, “size”: “24oz”, “pack_count”: “6”, “price_per_unit”: “$5.46”, “total_price”: “$32.76”, “brand”: “Upper Crust Enterprises”, “description”: “Elongated white bread crumb manufactured using original Asian methods. Delivers a premium coating that maintains its crunchy texture under heat lamps. Can be breaded 8 hours in advance f…

Strategic Sourcing Conclusion and Outlook for japanese panko bulk

In conclusion, the strategic sourcing of Japanese panko in bulk presents a significant opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the unique qualities of authentic Japanese panko—its light, crispy texture and versatility—can enhance product offerings and cater to diverse culinary needs. Buyers should prioritize sourcing from reputable suppliers who guarantee high-quality, preservative-free products, ensuring both taste and consistency in their applications.

As the demand for innovative food solutions continues to rise, leveraging Japanese panko can help businesses differentiate themselves in competitive markets. Whether for food service, manufacturing, or retail, the ability to provide superior quality panko will not only enhance customer satisfaction but also foster brand loyalty.

Illustrative image related to japanese panko bulk

Looking ahead, it is essential for B2B buyers to explore partnerships with trusted suppliers and consider bulk purchasing strategies that optimize both cost and quality. By investing in authentic Japanese panko, businesses can elevate their culinary offerings and capture emerging market trends. Engage with suppliers today to experience the benefits of premium panko and position your brand for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.