Japanese Claw Machine Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for japanese claw machine

Navigating the intricate landscape of sourcing Japanese claw machines presents a unique challenge for international B2B buyers. As demand grows across diverse markets in Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—understanding the nuances of this specialized product category becomes essential. This guide will explore the multifaceted world of Japanese claw machines, offering insights into various types, their applications in entertainment venues, and the vibrant prize offerings that attract customers.

In addition to examining the different styles and functionalities of claw machines, this guide will provide actionable strategies for vetting suppliers effectively, ensuring quality and reliability in your procurement process. Cost considerations will also be a focal point, helping you to navigate pricing models and negotiate favorable terms that align with your business objectives. By leveraging the comprehensive insights presented here, B2B buyers can make informed purchasing decisions that enhance their offerings and cater to the evolving preferences of their clientele.

Ultimately, this guide serves as a valuable resource, empowering you to confidently enter the global market for Japanese claw machines. Whether you are looking to expand your entertainment portfolio or enhance customer engagement through innovative gaming experiences, understanding these key aspects will position you for success in a competitive landscape.

Understanding japanese claw machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Claw Machines | Traditional design, single claw, manual operation | Arcades, entertainment centers | Pros: Familiarity, low maintenance. Cons: Limited prize selection. |

| Online Claw Machines | Digital interface, remote play, real-time interaction | E-commerce, online gaming platforms | Pros: Global reach, diverse inventory. Cons: Dependence on technology. |

| Prize Grab Machines | Variable prize mechanics, free-play options | Promotions, events, customer engagement | Pros: Increased engagement, flexible pricing. Cons: Potentially lower profit margins. |

| Mini Claw Machines | Compact size, lower cost, ideal for small spaces | Retail stores, small entertainment venues | Pros: Space-efficient, affordable. Cons: Limited prize visibility. |

| Themed Claw Machines | Custom designs based on popular franchises or themes | Themed events, promotional campaigns | Pros: Attracts niche audiences, enhances brand visibility. Cons: Higher initial investment. |

What Are the Characteristics of Standard Claw Machines?

Standard claw machines are the traditional arcade staple, featuring a single claw that players maneuver to grab prizes. These machines are typically easy to operate, making them suitable for a wide range of venues, from arcades to family entertainment centers. B2B buyers should consider their familiarity and low maintenance requirements, as these machines often have a proven track record. However, the limited prize selection and potential for lower engagement can be drawbacks, especially in competitive environments.

Illustrative image related to japanese claw machine

How Do Online Claw Machines Operate?

Online claw machines leverage digital technology to allow players to engage remotely, often through a web interface. They provide real-time interaction where players can control the claw from their devices to win physical prizes that are shipped to their homes. This model suits e-commerce businesses and online gaming platforms aiming to reach a global audience. While they offer diverse inventory and increased player engagement, their dependence on technology and potential logistical challenges can pose risks for B2B buyers.

What Are the Unique Features of Prize Grab Machines?

Prize grab machines introduce variable prize mechanics, often featuring free-play options that encourage user engagement. These machines are ideal for promotions and events where businesses aim to attract customers and boost brand interaction. The flexibility in pricing and game mechanics can enhance customer retention. However, businesses must be cautious of potentially lower profit margins, as the focus on engagement might lead to increased operational costs.

Why Choose Mini Claw Machines for Small Spaces?

Mini claw machines are compact versions designed for smaller venues, making them perfect for retail stores or small entertainment venues. Their lower cost and space-efficient design appeal to businesses with limited floor space. While they are affordable and easy to manage, B2B buyers should be aware that these machines may offer limited prize visibility and engagement, which could affect overall profitability.

What Benefits Do Themed Claw Machines Provide?

Themed claw machines are customized to align with popular franchises or specific events, enhancing their appeal to niche audiences. These machines can significantly boost brand visibility during promotional campaigns or themed events. Although they may require a higher initial investment, the potential for increased foot traffic and customer engagement can justify the cost for businesses looking to capitalize on trends. However, B2B buyers should evaluate the longevity of the theme to ensure sustained interest.

Key Industrial Applications of japanese claw machine

| Industry/Sector | Specific Application of Japanese Claw Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Amusement and Entertainment | Arcade centers using claw machines for prize redemption | Attracts customers, increases dwell time, and boosts revenue | Quality of machine, prize variety, maintenance support |

| Retail and E-commerce | Retail stores incorporating claw machines for promotional events | Engages customers, drives foot traffic, and enhances brand loyalty | Customization options, product safety, and compliance |

| Online Gaming | Virtual claw machines in online gaming platforms | Expands market reach, offers unique user experiences, and generates revenue | Technology integration, user experience design, and security |

| Event Management | Claw machines at trade shows and corporate events | Creates interactive experiences, enhances brand visibility, and engages attendees | Logistics, machine portability, and prize selection |

| Education and Training | Claw machines used in educational settings for skill development | Teaches hand-eye coordination and problem-solving skills | Durability, educational content, and ease of use |

How Are Japanese Claw Machines Used in Amusement and Entertainment Venues?

In amusement parks and arcade centers, Japanese claw machines serve as a primary attraction, enticing visitors with the chance to win plush toys and collectibles. Their engaging nature encourages longer playtime, which directly correlates with increased revenue. For businesses in regions like Africa and South America, selecting machines with robust construction and appealing prize options is crucial to withstand high traffic and diverse customer preferences.

Illustrative image related to japanese claw machine

What Role Do Claw Machines Play in Retail and E-commerce?

Retailers are increasingly adopting claw machines as a marketing tool to enhance customer engagement. By offering unique prizes and promotional events, businesses can drive foot traffic and foster brand loyalty. B2B buyers from the Middle East and Europe should consider customization options that align with local cultural preferences, as well as compliance with safety standards to ensure a positive customer experience.

How Can Online Gaming Benefit from Virtual Claw Machines?

Virtual claw machines are revolutionizing the online gaming landscape by providing players with interactive experiences that mimic physical arcade games. This innovation allows gaming platforms to reach a global audience while diversifying revenue streams. International buyers should focus on sourcing technology that ensures seamless integration with existing platforms, prioritizing user experience and security to maintain player trust.

How Do Claw Machines Enhance Experiences at Events?

Event organizers are leveraging claw machines to create engaging and memorable experiences at trade shows and corporate events. These machines not only entertain but also serve as a marketing tool to enhance brand visibility. Buyers should consider logistics and portability when sourcing machines, ensuring they can be easily transported and set up at various venues, along with a diverse selection of prizes that resonate with event attendees.

Why Are Claw Machines Valuable in Educational Settings?

In educational environments, claw machines can be utilized as engaging tools for teaching hand-eye coordination and problem-solving skills. They provide a fun and interactive way for students to learn while promoting teamwork and strategic thinking. When sourcing machines for educational purposes, durability and ease of use are key considerations to ensure they can withstand frequent handling by students.

3 Common User Pain Points for ‘japanese claw machine’ & Their Solutions

Scenario 1: Difficulty in Sourcing Authentic Japanese Claw Machines

The Problem: For B2B buyers, particularly those in regions like Africa and South America, sourcing authentic Japanese claw machines can be a significant challenge. Many suppliers offer replicas or lower-quality versions that do not deliver the same gaming experience, leading to customer dissatisfaction. Moreover, language barriers and unfamiliarity with the Japanese market may complicate the procurement process, causing delays and potential losses.

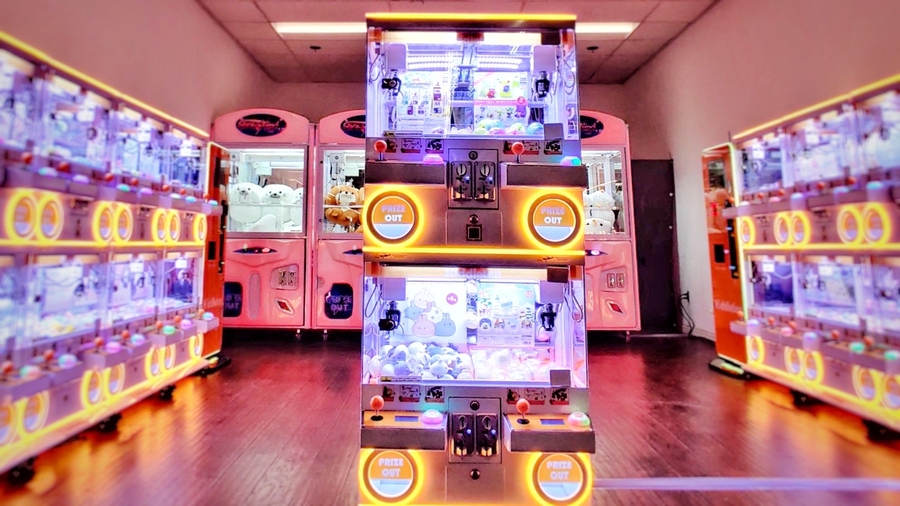

Illustrative image related to japanese claw machine

The Solution: To effectively source genuine Japanese claw machines, buyers should establish relationships with reputable manufacturers or distributors based in Japan. Utilizing platforms like Alibaba or direct manufacturer websites can help identify verified suppliers. It is advisable to request product samples or detailed specifications before placing bulk orders. Furthermore, engaging with trade shows or industry expos in Japan can provide firsthand experience with products and facilitate direct negotiations. Establishing a clear communication channel and using professional translation services can help mitigate language barriers and ensure that all specifications and quality standards are met.

Scenario 2: Challenges with Maintenance and Parts Availability

The Problem: After purchasing Japanese claw machines, buyers often encounter issues related to maintenance and the availability of spare parts. Machines may require regular servicing or replacement of components to ensure optimal performance. In regions with limited access to authentic parts, businesses may face prolonged downtimes, negatively impacting customer satisfaction and revenue.

The Solution: B2B buyers should proactively establish a maintenance plan with the supplier that includes regular check-ups and a reliable supply of spare parts. This plan should detail the expected lifespan of various components and the recommended intervals for replacements. Additionally, buyers can consider partnering with local technicians who have experience with claw machines to provide on-the-ground support. To facilitate parts availability, negotiating contracts with suppliers for bulk spare parts purchases or setting up a local inventory can prevent delays and reduce overall maintenance costs. Ensuring that the machines are designed for easy repairs can also streamline maintenance processes.

Scenario 3: Adapting to Local Market Preferences

The Problem: Japanese claw machines often feature prizes that may not resonate with local customers in markets across Africa, South America, or the Middle East. If the prizes do not appeal to the local demographic, it could lead to decreased player engagement and ultimately lower revenue for businesses. Understanding local preferences and cultural differences is crucial for success.

The Solution: B2B buyers should conduct thorough market research to identify popular trends and products within their target demographic. This research can involve surveys, focus groups, or analyzing social media trends to understand what types of prizes are most appealing. Once local preferences are identified, businesses can work with suppliers to customize their claw machines with appropriate prizes, such as local toys, collectibles, or branded merchandise. Additionally, developing promotional strategies that incorporate local festivities or cultural events can enhance engagement. Collaborating with local influencers or brands can also help in curating attractive prize offerings that resonate with the audience, driving up participation and profitability.

Strategic Material Selection Guide for japanese claw machine

What Materials Are Commonly Used in Japanese Claw Machines?

Japanese claw machines are renowned for their engaging design and functionality, which rely heavily on the materials used in their construction. Understanding the properties, advantages, and limitations of these materials can help international B2B buyers make informed decisions.

How Does ABS Plastic Benefit Japanese Claw Machines?

Acrylonitrile Butadiene Styrene (ABS) plastic is a popular choice for the outer casing and internal components of claw machines. ABS is known for its high impact resistance and durability, making it suitable for environments where machines may experience rough handling. It also has a good temperature resistance, typically rated up to 80°C (176°F), which is essential for machines that may operate in varying climates.

Pros: ABS is lightweight and cost-effective, which contributes to lower shipping costs. Its ease of manufacturing allows for intricate designs, appealing to the aesthetic preferences of players.

Cons: While ABS is durable, it can be susceptible to chemical corrosion if exposed to certain solvents. Additionally, it may not perform well in extreme temperatures, which could limit its application in hotter regions.

Illustrative image related to japanese claw machine

International Considerations: Buyers from regions like Africa and South America should ensure that ABS components comply with local safety standards, such as ASTM or JIS. The material’s availability in these regions can also affect lead times.

What Role Does Steel Play in Claw Machine Construction?

Steel is often used for structural components and internal mechanisms due to its exceptional strength and longevity. It can withstand significant stress and pressure, making it ideal for the mechanical parts that operate the claw and the prize retrieval system.

Pros: Steel’s strength ensures that machines can endure heavy usage without compromising functionality. It also offers excellent corrosion resistance when treated or coated properly.

Cons: The primary drawback of steel is its weight, which can increase shipping costs and complicate installation. Additionally, it may require more complex manufacturing processes, such as welding.

International Considerations: Buyers should be aware of the different grades of steel and their compliance with international standards. In regions like the Middle East, where humidity can be high, selecting stainless steel or galvanized options may be necessary to prevent rust.

Illustrative image related to japanese claw machine

Why Is Glass Used in Japanese Claw Machines?

Glass is commonly employed for the viewing panels of claw machines, providing a clear view of the prizes inside. Tempered glass is typically used due to its strength and safety features, as it shatters into small pieces rather than sharp shards.

Pros: The aesthetic appeal of glass enhances the overall look of the claw machine, attracting customers. Its transparency allows players to see the prizes clearly, which can increase engagement.

Cons: Glass is heavier and more fragile than other materials, which can lead to higher shipping costs and potential breakage during transit.

International Considerations: Buyers should ensure that the glass used meets safety standards for public use, especially in regions with strict regulations on consumer safety.

How Does Plywood Contribute to the Design of Claw Machines?

Plywood is often used in the internal structure and base of claw machines. It is lightweight yet strong, making it an excellent choice for supporting the machine’s weight while remaining cost-effective.

Illustrative image related to japanese claw machine

Pros: Plywood is easy to work with and can be cut into various shapes, allowing for creative designs. It also provides good insulation against temperature fluctuations.

Cons: Plywood is less durable than metal or plastic and can be susceptible to moisture damage if not properly treated.

International Considerations: Buyers should look for plywood that meets international standards for sustainability and safety, particularly in regions where environmental regulations are stringent.

Summary Table of Material Selection for Japanese Claw Machines

| Material | Typical Use Case for Japanese Claw Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| ABS Plastic | Outer casing and internal components | Lightweight and cost-effective | Susceptible to chemical corrosion | Low |

| Steel | Structural components and mechanisms | Exceptional strength and longevity | Heavier and complex manufacturing | Medium |

| Glass | Viewing panels | Aesthetic appeal and transparency | Heavy and fragile | Medium |

| Plywood | Internal structure and base | Lightweight and easy to work with | Less durable and moisture-sensitive | Low |

This guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding material selection for Japanese claw machines, considering both performance and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for japanese claw machine

What Are the Key Manufacturing Stages for Japanese Claw Machines?

The manufacturing of Japanese claw machines involves several critical stages, each designed to ensure the final product meets the high standards expected in both domestic and international markets. Understanding these stages can help B2B buyers make informed purchasing decisions.

Illustrative image related to japanese claw machine

Material Preparation: What Materials Are Used?

The first step in manufacturing claw machines is material preparation. This typically involves sourcing high-quality metals, plastics, and electronic components. The metals used for the structure, such as steel or aluminum, are chosen for their durability and resistance to wear and tear. Plastics are often used for the exterior casing and internal mechanisms, and they must be lightweight yet sturdy.

In addition to traditional materials, suppliers may also use environmentally friendly options, which can be a key selling point in markets sensitive to sustainability. B2B buyers should inquire about the suppliers’ sourcing practices, particularly if they are aiming to align with eco-friendly initiatives.

How Are Claw Machines Formed and Assembled?

Once materials are prepared, the next stage is forming, which involves cutting, bending, and shaping metals and plastics to create the machine’s components. Advanced techniques such as CNC machining and laser cutting are often employed to ensure precision. This is critical, as any misalignment can affect the machine’s functionality.

Assembly follows forming, where components are brought together to create the finished product. This process may be manual or automated, depending on the scale of production. Automated assembly lines can increase efficiency and consistency, which are essential for maintaining quality across large production runs.

What Finishing Techniques Are Applied to Japanese Claw Machines?

The finishing stage involves applying coatings and treatments that enhance both aesthetics and durability. This may include powder coating for the exterior, which provides a smooth finish and protects against scratches and corrosion. Additionally, decals or printed designs are often added to enhance the visual appeal of the machines, especially since they are often located in entertainment venues.

Illustrative image related to japanese claw machine

Quality of finishing is crucial, as it impacts not only the machine’s lifespan but also its attractiveness to potential customers. B2B buyers should request samples of the finish and inquire about the durability of coatings used.

What Quality Assurance Standards Are Relevant for Claw Machines?

Quality assurance is a vital aspect of the manufacturing process for claw machines, especially for international buyers. Compliance with international standards such as ISO 9001 is essential, as it ensures that the manufacturer follows a systematic approach to quality management.

Moreover, industry-specific certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) are crucial for ensuring safety and reliability. These certifications can be particularly important for buyers in regions like Europe and North America, where regulatory compliance is strictly enforced.

Illustrative image related to japanese claw machine

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each component meets the required specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to verify that they meet quality standards before they enter production.

-

In-Process Quality Control (IPQC): During manufacturing, random samples of components are checked for adherence to specifications. This ensures that any deviations can be addressed promptly.

-

Final Quality Control (FQC): Before shipping, finished claw machines undergo comprehensive testing to ensure they operate correctly and meet all safety standards.

B2B buyers should inquire about these QC processes and request documentation of quality checks to verify compliance with standards.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for claw machines can vary, but some common techniques include:

-

Functional Testing: Machines are tested to ensure all components operate correctly, including the claw mechanism and electronic controls.

-

Safety Testing: This checks for electrical safety, ensuring that the machines meet required safety standards to prevent hazards.

-

Durability Testing: Machines are subjected to repeated use to evaluate their performance over time, simulating real-world usage conditions.

Buyers should look for suppliers that provide detailed testing reports as part of their quality assurance documentation.

Illustrative image related to japanese claw machine

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to high-quality standards, B2B buyers should consider implementing the following practices:

-

Audits: Regular audits of suppliers can help verify that they comply with quality standards and maintain effective quality management systems.

-

Documentation: Requesting detailed quality control reports and certifications can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality.

Buyers from regions such as Africa, South America, the Middle East, and Europe should pay special attention to these practices to mitigate risks associated with international sourcing.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers must be aware of specific nuances when it comes to quality control. Differences in regulatory requirements, cultural expectations, and communication styles can impact the quality assurance process.

Illustrative image related to japanese claw machine

For instance, buyers from Europe may have stricter compliance requirements compared to those in Africa or South America. It is essential for buyers to clearly communicate their expectations and understand the supplier’s capabilities in meeting these standards.

Additionally, language barriers can sometimes lead to misunderstandings regarding quality requirements. Employing local representatives or translation services can help facilitate clearer communication, ensuring that both parties are aligned on quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance practices for Japanese claw machines is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can ensure they source high-quality machines that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘japanese claw machine’

To facilitate the effective sourcing of Japanese claw machines, this guide offers a structured checklist tailored for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. This checklist will help streamline your procurement process and ensure that you make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating your search for suppliers, it’s essential to clearly outline your technical requirements. Determine the types of claw machines you need, including size, design, and functionality, such as whether they will feature digital interfaces or traditional mechanisms. This clarity will help you communicate effectively with suppliers and avoid potential mismatches in product offerings.

Illustrative image related to japanese claw machine

Step 2: Research Market Trends and Demand

Understanding current market trends is crucial for making a wise investment. Research popular themes and characters in the claw machine industry, as well as seasonal demand fluctuations. This knowledge will not only inform your purchasing decisions but also help in selecting machines that will attract customers in your target market.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request comprehensive company profiles, including their history in the industry, production capabilities, and client testimonials. Additionally, consider their experience with international shipping, especially if you are importing from Japan, as this can impact delivery timelines and costs.

Step 4: Verify Product Quality and Compliance

Quality assurance is paramount when sourcing claw machines. Ensure that the machines comply with relevant safety and quality standards in your region. Request product samples to evaluate the build quality, playability, and overall user experience. Look for certifications such as CE or ISO that confirm adherence to international standards.

Step 5: Assess After-Sales Support and Warranty Options

After-sales service is a critical factor in maintaining your claw machines. Confirm the level of support the supplier offers, including installation assistance, maintenance services, and troubleshooting. Inquire about warranty terms to protect your investment and ensure you have recourse in case of defects or malfunctions.

Illustrative image related to japanese claw machine

Step 6: Negotiate Pricing and Payment Terms

Once you’ve narrowed down your list of suppliers, initiate negotiations on pricing and payment terms. Be transparent about your budget and expectations, and don’t hesitate to ask for bulk purchase discounts or favorable payment schedules. Understanding the total cost, including shipping and customs duties, will help you make a financially sound decision.

Step 7: Finalize the Contract and Order Process

Before placing your order, review all terms and conditions carefully. Ensure that the contract covers all aspects of the transaction, including delivery timelines, payment schedules, and liability clauses. A well-drafted contract will protect both parties and set clear expectations for the entire procurement process.

By following this checklist, you can navigate the complexities of sourcing Japanese claw machines with confidence, ensuring a successful procurement that meets your business needs.

Comprehensive Cost and Pricing Analysis for japanese claw machine Sourcing

What are the key cost components involved in sourcing Japanese claw machines?

When evaluating the costs associated with sourcing Japanese claw machines, several key components come into play. These include:

-

Materials: The primary materials involved in manufacturing claw machines include high-quality plastics for the casing, electronic components for the control systems, and plush toys or other prizes. The choice of materials significantly influences the machine’s durability and overall aesthetic appeal.

-

Labor: Labor costs vary based on the location of the manufacturing facility. Skilled labor is often required for assembly and quality control processes, particularly in Japan, where craftsmanship is highly valued.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, facility maintenance, and administrative expenses. Efficient production facilities can help mitigate these costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or features. Buyers should consider these costs when evaluating their total investment.

-

Quality Control (QC): Ensuring that machines meet safety and performance standards is crucial. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs can vary greatly depending on the mode of transport, distance, and volume. International shipping also necessitates careful planning around customs duties and regulations.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on market conditions and competition.

How do price influencers affect the cost of Japanese claw machines?

Several factors influence the pricing of Japanese claw machines, which international B2B buyers should be aware of:

Illustrative image related to japanese claw machine

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Buyers should assess their sales forecasts to negotiate favorable minimum order quantities (MOQs).

-

Specifications and Customization: Customized machines with unique designs or features often come at a premium. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials Quality and Certifications: Machines made from higher-quality materials or those that meet international safety certifications (e.g., CE, UL) may carry higher price tags. However, these certifications can enhance marketability and reduce liability risks.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for pricing negotiations. These terms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, influencing the total landed cost.

What negotiation strategies can help international buyers achieve cost-efficiency?

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, can employ various strategies to ensure cost-efficiency when sourcing Japanese claw machines:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential resale value. This holistic approach can reveal the true value of a machine over its lifespan.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and terms. Frequent communication and transparency about your needs can foster trust and collaboration.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns. Discussing options such as staggered payments or longer payment periods can provide financial relief.

-

Stay Informed on Market Trends: Understanding market dynamics, such as seasonal demand fluctuations or emerging competitors, can empower buyers during negotiations. Knowledge of these trends can help justify pricing discussions and secure favorable deals.

-

Consider Alternative Suppliers: While Japanese suppliers are renowned for quality, exploring manufacturers in other regions can sometimes yield cost-effective alternatives without sacrificing quality.

Are there any pricing nuances specific to international B2B buyers?

Indeed, international buyers should be mindful of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact final costs. It’s prudent to lock in rates when negotiating contracts to mitigate this risk.

-

Import Duties and Taxes: Understanding local import regulations and associated taxes is essential. These can significantly affect the total cost and should be factored into pricing discussions.

-

Cultural Considerations: Different regions may have varying expectations regarding negotiation styles and pricing discussions. Being culturally aware can facilitate smoother negotiations.

Conclusion

Sourcing Japanese claw machines involves a complex interplay of costs and pricing factors. By understanding these components and employing strategic negotiation tactics, international B2B buyers can optimize their purchasing decisions and maximize value. It is important to approach this process with thorough research and a clear understanding of market dynamics to ensure a successful partnership with suppliers.

Alternatives Analysis: Comparing japanese claw machine With Other Solutions

Exploring Alternatives to the Japanese Claw Machine

In the realm of entertainment and gaming, the Japanese claw machine has carved out a significant niche. However, as the market evolves, exploring alternative solutions that provide similar engagement and revenue potential becomes essential for B2B buyers. This analysis will compare the Japanese claw machine against two viable alternatives: online claw machines and skill-based arcade games.

| Comparison Aspect | Japanese Claw Machine | Online Claw Machine | Skill-Based Arcade Games |

|---|---|---|---|

| Performance | High player engagement and repeat playability | Engages users remotely, allowing for global participation | High engagement through skill and competition |

| Cost | Higher initial investment (hardware, maintenance) | Lower operational costs, subscription-based models | Moderate investment; varies by game type and location |

| Ease of Implementation | Requires physical space and setup | Easy to implement with existing digital infrastructure | Requires arcade space, game licensing |

| Maintenance | Regular maintenance needed for physical machines | Minimal maintenance; software updates required | Regular maintenance for machines; can be intensive |

| Best Use Case | Ideal for entertainment venues, family centers | Great for online gaming platforms and e-commerce | Suitable for arcades, gaming lounges, and entertainment venues |

What Are the Pros and Cons of Online Claw Machines?

Online claw machines, such as those offered by platforms like Toreba, allow players to engage from the comfort of their homes. The appeal lies in their ability to cater to a global audience, providing 24/7 access to a variety of prizes. Players can win real items that are shipped directly to them, enhancing the experience. However, the downside includes the lack of physical interaction, which some players may find less thrilling than traditional machines. Additionally, operational costs can vary based on platform fees and shipping logistics.

How Do Skill-Based Arcade Games Compare?

Skill-based arcade games offer a different gaming experience, focusing on players’ abilities rather than chance. These games can attract a diverse audience, as they often involve competitive elements and leaderboards. While they require a moderate investment, they can generate high revenue through player engagement and repeat play. The challenges include the need for space in entertainment venues and potentially higher maintenance requirements, depending on the game type. However, their ability to cultivate a community and drive foot traffic can make them a worthwhile investment.

Conclusion: How Should B2B Buyers Decide on the Right Solution?

When choosing between the Japanese claw machine and its alternatives, B2B buyers should consider several factors: the target audience, location, and business model. If the goal is to create an engaging physical experience in a venue, the Japanese claw machine may be the right fit. Conversely, if the focus is on reaching a broader audience and reducing overhead costs, online claw machines could be more advantageous. Skill-based arcade games may serve as a compelling middle ground, appealing to those who value competition and skill. Ultimately, aligning the choice with business objectives and customer preferences will lead to the best outcomes.

Essential Technical Properties and Trade Terminology for japanese claw machine

What Are the Key Technical Properties of Japanese Claw Machines?

When considering the procurement of Japanese claw machines, it is essential to understand the critical technical specifications that can influence performance, durability, and overall customer satisfaction. Here are some of the most important properties:

-

Material Grade

The material used in claw machines directly affects their durability and aesthetic appeal. High-grade materials, such as stainless steel for the frame and high-impact plastics for the claw mechanism, ensure longevity and resistance to wear and tear. This is especially important for operators in high-traffic environments where machines are subjected to frequent use. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions of various components of the claw machine. Precise tolerances are crucial for the claw’s gripping mechanism to function effectively. A claw that is too loose may fail to grasp prizes, while one that is too tight can damage them. Ensuring that manufacturers adhere to tight tolerance levels can significantly enhance the user experience and reduce maintenance issues. -

Power Consumption

Understanding the power consumption specifications is vital for operational cost management. Machines that are energy efficient not only reduce electricity bills but also align with growing global sustainability efforts. B2B buyers should look for machines that offer lower power consumption without compromising performance. -

Weight Capacity

The weight capacity of a claw machine dictates the range of prizes that can be offered. Machines designed to handle heavier prizes can attract more players, particularly in markets where larger collectibles are popular. Buyers should assess the machine’s weight limits to ensure they align with their intended prize selection. -

Control System Type

Modern claw machines often incorporate advanced control systems that enhance user interaction. Options such as touch-screen interfaces or mobile app connectivity can significantly improve the customer experience. B2B buyers should consider the technology used in the control system, as this can influence both the machine’s appeal and its operational efficiency. -

Prize Dispensing Mechanism

The efficiency of the prize dispensing mechanism is a key technical property that can affect customer satisfaction. Machines with reliable dispensing systems minimize the chances of jams and ensure that prizes are delivered promptly after a successful grab. This reliability can lead to repeat business and higher customer retention rates.

What Are Common Trade Terms in the Japanese Claw Machine Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should know:

Illustrative image related to japanese claw machine

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the claw machine industry, understanding OEM relationships can help buyers ensure they are sourcing high-quality components and machines. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, especially those looking to enter the market with limited capital. This can affect inventory management and cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price offers for specific goods or services. This process allows B2B buyers to compare pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions. Understanding these terms can clarify shipping responsibilities, risk management, and cost allocations, which are crucial for international buyers in regions like Africa or South America. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is vital for planning inventory and ensuring that machines are available when needed. -

Warranty Period

The warranty period specifies the duration for which a manufacturer guarantees the machine against defects. A longer warranty can be indicative of a manufacturer’s confidence in their product and can be a significant factor in the purchasing decision for B2B buyers.

By understanding these technical properties and trade terms, international buyers can navigate the Japanese claw machine market more effectively, ensuring they make informed and strategic purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the japanese claw machine Sector

What are the Global Drivers and Key Trends in the Japanese Claw Machine Market?

The Japanese claw machine sector has witnessed significant transformation, driven by a blend of technological advancements and evolving consumer preferences. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly attracted to the unique offerings of Japanese claw machines. Key trends include the integration of online platforms that allow users to engage with claw machines remotely. This shift has opened new revenue streams for operators and broadened the market reach beyond traditional arcade settings.

Moreover, the demand for customized experiences, such as themed machines featuring popular anime and gaming franchises, has surged. Buyers are keen on sourcing machines that not only entertain but also resonate with cultural trends. Additionally, the rise of mobile gaming and social media engagement has influenced claw machine design, encouraging operators to adopt innovative marketing strategies that enhance user interaction and retention.

Emerging technologies such as augmented reality (AR) and machine learning are also making their mark in the sector. These technologies can enhance gameplay experiences, providing players with real-time feedback and personalized gaming options. As a result, international buyers are looking for suppliers who can offer these cutting-edge features, ensuring that their claw machines remain competitive in a rapidly evolving market landscape.

How is Sustainability and Ethical Sourcing Impacting the Japanese Claw Machine Industry?

Sustainability is becoming a crucial consideration for international B2B buyers in the Japanese claw machine sector. The environmental impact of production processes and the materials used in these machines is under increasing scrutiny. Buyers are more inclined to partner with manufacturers that prioritize eco-friendly practices and materials. For instance, sourcing machines made from recyclable plastics and sustainably sourced wood can significantly reduce the carbon footprint associated with production.

Ethical supply chains are also gaining prominence. Buyers are increasingly interested in understanding the labor practices of suppliers, ensuring that workers are treated fairly and that operations comply with international labor standards. Certifications related to environmental sustainability and social responsibility, such as ISO 14001 and Fair Trade, are becoming essential criteria in the sourcing process.

Furthermore, the demand for ‘green’ certifications is leading manufacturers to innovate in their production methods, integrating sustainable practices throughout their supply chains. This not only helps in building a positive brand image but also attracts a growing segment of environmentally conscious consumers. B2B buyers should prioritize these factors when sourcing claw machines to align with global sustainability trends and meet the expectations of their clientele.

What is the Brief Evolution and History of the Japanese Claw Machine?

The Japanese claw machine, or “UFO catcher,” has evolved significantly since its inception in the late 20th century. Initially introduced as simple arcade games, these machines have transformed into complex entertainment devices that reflect contemporary culture. The rise of anime and gaming in Japan contributed to the popularity of claw machines, with operators beginning to stock them with plush toys and figures from beloved franchises.

By the early 2000s, claw machines began incorporating technology that allowed for improved gameplay and user engagement. The introduction of online platforms in recent years has further revolutionized the sector, allowing players worldwide to participate remotely. This evolution has positioned Japanese claw machines not just as arcade staples but as versatile entertainment options that appeal to a global audience. As international markets continue to embrace these machines, understanding their evolution can provide B2B buyers with insights into consumer preferences and market opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of japanese claw machine

1. How do I choose the right Japanese claw machine for my business?

Choosing the right claw machine involves assessing several factors such as target audience, location, and budget. Identify the types of prizes that appeal to your customer base, whether they are plush toys, collectibles, or branded merchandise. Consider the machine’s size and design to ensure it fits well in your intended location. Additionally, evaluate the machine’s features, such as electronic payment options and remote management capabilities, which can enhance user experience and operational efficiency.

2. What are the minimum order quantities (MOQ) for Japanese claw machines?

Minimum order quantities vary by supplier and can depend on the specific model and customization options. Generally, MOQs for claw machines can range from one unit for standard models to larger quantities for customized machines. When negotiating with suppliers, inquire about bulk purchase discounts and flexible ordering options, particularly if you’re looking to test the market with fewer units initially.

3. What customization options are available for Japanese claw machines?

Customization options often include machine design, branding elements, and prize selection. Many manufacturers offer the ability to create unique graphics or themes to align with your brand identity. Additionally, you can select specific features such as lighting, sound effects, and control systems. Discuss your vision with potential suppliers to ensure they can accommodate your customization needs effectively.

4. How do I verify the credibility of a supplier for Japanese claw machines?

To verify a supplier’s credibility, conduct thorough research by checking their business licenses, certifications, and customer reviews. Request references from previous clients and inquire about their experience with the supplier. Additionally, consider visiting their manufacturing facility if possible or utilizing third-party inspection services to assess product quality and operational standards. Engaging in direct communication can also provide insights into their reliability and customer service.

5. What payment terms are typically offered by suppliers of Japanese claw machines?

Payment terms can vary widely depending on the supplier and the scale of your order. Common options include upfront payments, partial payments during production, and payment upon delivery. Some suppliers may offer financing options or payment through letters of credit, especially for larger orders. Always clarify payment terms upfront and ensure they align with your cash flow needs before finalizing any agreements.

6. What quality assurance processes should I expect from suppliers of Japanese claw machines?

Reputable suppliers should have stringent quality assurance processes in place, including pre-production inspections, in-process quality checks, and final product evaluations. Request detailed information about their QA protocols and certifications, such as ISO standards. It’s also beneficial to inquire about warranty options and after-sales support to ensure you’re covered in case of any defects or operational issues.

7. How can I manage logistics and shipping for Japanese claw machines?

Effective logistics management involves coordinating with suppliers regarding shipping methods, timelines, and costs. Discuss options such as air freight for quicker delivery or sea freight for cost-effective bulk shipments. Ensure that your supplier provides necessary documentation for customs clearance and understand any import regulations specific to your country. Partnering with a reliable freight forwarder can streamline the shipping process and minimize potential delays.

8. What are common challenges faced when sourcing Japanese claw machines internationally?

Common challenges include navigating import regulations, language barriers, and potential delays in shipping. Cultural differences can also impact negotiations and communication. To mitigate these issues, conduct thorough research on trade laws and establish clear communication channels with suppliers. It’s advisable to work with local partners or consultants who understand the market dynamics and can facilitate smoother transactions.

Illustrative image related to japanese claw machine

Top 1 Japanese Claw Machine Manufacturers & Suppliers List

1. Otakuhouse – Live Claw Machine Games

Domain: shop.otakuhouse.com

Registered: 2009 (16 years)

Introduction: Online Claw Machine Game – Play Live 24/7 in the USA. Enjoy the thrill of the game from home without waiting in lines. Prizes include a variety of anime merchandise such as plush toys, anime figurines, and rare items from popular series like Demon Slayer, My Hero Academia, Pokémon, and Jujutsu Kaisen. Free plays daily, no app download needed.

Strategic Sourcing Conclusion and Outlook for japanese claw machine

In summary, the strategic sourcing of Japanese claw machines offers significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding market dynamics and consumer preferences, businesses can effectively tap into the growing demand for these engaging entertainment products. Key takeaways include the importance of sourcing high-quality machines that feature popular themes, as well as the value of partnering with reputable suppliers who can ensure consistent product availability and innovative designs.

Moreover, the rise of online claw machine platforms illustrates a shift in consumer behavior, highlighting the potential for digital integration in traditional gaming experiences. Buyers should consider how these trends can enhance their offerings and engage a broader audience.

As the market evolves, it is essential for buyers to stay informed about emerging trends and technologies within the claw machine sector. By doing so, they can position themselves strategically to leverage new opportunities and drive growth. We encourage international buyers to explore partnerships with Japanese manufacturers and distributors to capitalize on this unique market niche and bring the excitement of claw machines to their regions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.