Is Your Wire Rope Assembly Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for wire rope assembly

Navigating the complexities of sourcing wire rope assembly can present significant challenges for international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe. The demand for high-quality, durable, and customized wire rope assemblies is on the rise, as industries such as construction, marine, and energy increasingly rely on these essential components for their operations. This guide aims to illuminate the intricacies of the wire rope assembly market, providing insights into the various types available, their diverse applications, and critical factors to consider when vetting suppliers.

In the pages that follow, we delve into the essential aspects of wire rope assembly, including material specifications, manufacturing processes, and compliance standards that vary by region. We also explore cost considerations and provide actionable tips on how to evaluate potential suppliers effectively. By equipping buyers with this knowledge, the guide empowers informed purchasing decisions, ensuring that businesses can secure reliable wire rope assemblies tailored to their specific operational needs. Whether you’re sourcing for heavy machinery in Nigeria or offshore platforms in Vietnam, understanding the global landscape of wire rope assemblies is vital for maintaining competitive advantage and operational efficiency.

Understanding wire rope assembly Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Cable Assemblies | Designed for mechanical load applications; includes end fittings for connection. | Lifting, pulling, and supporting machinery. | Pros: High strength, customizable. Cons: May require specific engineering input for design. |

| Electrical Cable Assemblies | Includes conductors and insulation for electrical transmission; often used for signal transfer. | Industrial automation, robotics, and energy sectors. | Pros: Efficient signal transmission, ready-to-install. Cons: Limited to electrical applications only. |

| Custom Wire Rope Assemblies | Tailored to specific requirements regarding length, diameter, and fittings. | Aerospace, automotive, and specialized machinery. | Pros: Meets unique specifications, high versatility. Cons: Typically higher cost and longer lead times. |

| Marine Cable Assemblies | Corrosion-resistant materials; designed for harsh marine environments. | Offshore oil rigs, shipping, and fishing industries. | Pros: Durability in extreme conditions. Cons: Specialized materials can increase costs. |

| Multi-strand Wire Rope Assemblies | Composed of multiple strands twisted together for enhanced flexibility and strength. | Construction, mining, and heavy lifting. | Pros: Excellent load distribution and flexibility. Cons: More complex manufacturing process may lead to longer delivery times. |

What Are the Key Characteristics of Mechanical Cable Assemblies?

Mechanical cable assemblies are engineered for high-load applications, featuring robust end fittings that connect to machinery or equipment. They are commonly used in various industries for tasks such as lifting, pulling, and supporting. When purchasing, buyers should consider the specific load requirements, environmental conditions, and the need for customization based on their operational needs. The ability to tailor these assemblies ensures they can withstand the rigors of industrial use while providing reliable performance.

How Do Electrical Cable Assemblies Function in Industrial Settings?

Electrical cable assemblies are crucial for transmitting electrical power and signals. They typically consist of conductors, insulation, and connectors, designed for plug-and-play usability. These assemblies are widely used in industrial automation and robotics, providing efficient communication and power delivery. Buyers should evaluate the electrical specifications, such as voltage and current ratings, as well as compatibility with existing systems to ensure optimal performance and safety in their applications.

Why Choose Custom Wire Rope Assemblies for Unique Applications?

Custom wire rope assemblies are tailored to meet specific operational requirements, including dimensions, material types, and end fittings. This customization is particularly beneficial for industries like aerospace and automotive, where precision and reliability are paramount. Buyers should consider the complexity of their requirements, as custom solutions may involve longer lead times and increased costs. However, the investment can yield significant benefits in terms of performance and longevity.

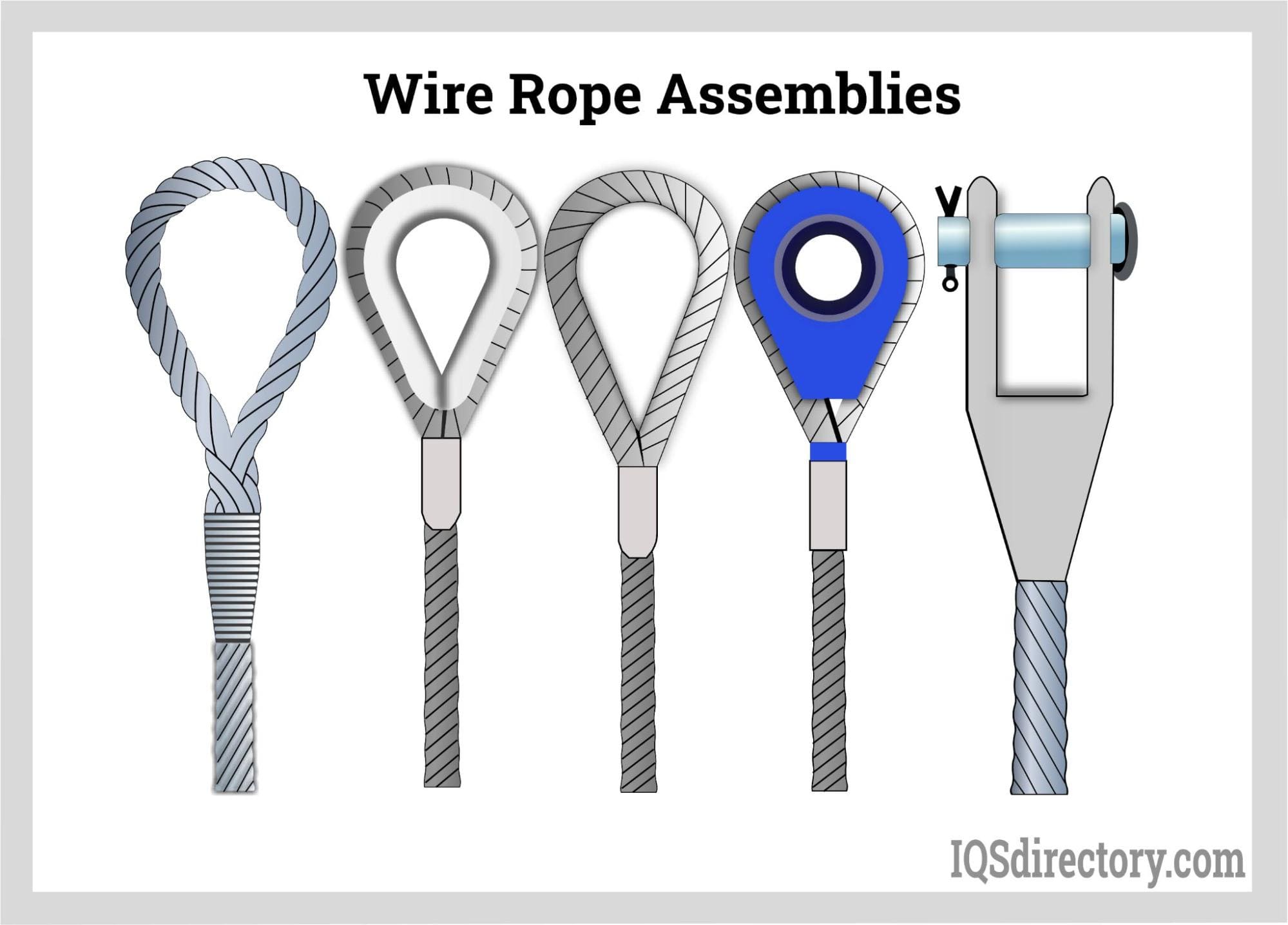

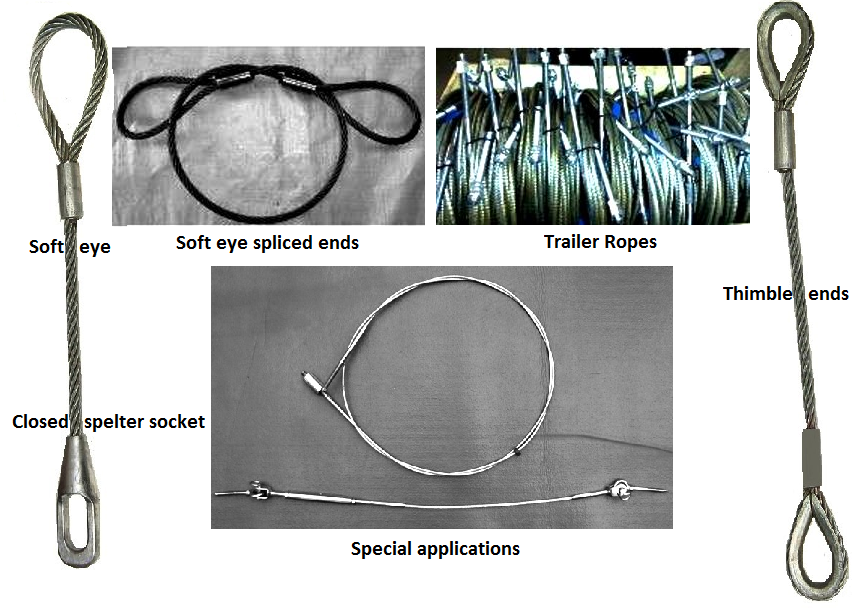

Illustrative image related to wire rope assembly

What Advantages Do Marine Cable Assemblies Offer in Harsh Environments?

Marine cable assemblies are specifically designed to withstand the corrosive effects of saltwater and extreme weather conditions. Utilizing specialized materials, these assemblies are essential for offshore operations, shipping, and fishing industries. Buyers must assess the environmental conditions of their applications and ensure that the selected assemblies meet relevant industry standards for durability and safety. While these assemblies offer enhanced performance, the specialized materials may result in higher upfront costs.

How Do Multi-strand Wire Rope Assemblies Enhance Performance?

Multi-strand wire rope assemblies consist of several strands twisted together, providing superior flexibility and strength. They are particularly effective in heavy lifting and construction applications, where load distribution is critical. When considering these assemblies, buyers should take into account the specific load capacities and flexibility requirements of their projects. Although they may involve a more complex manufacturing process, the resulting performance benefits can justify the investment in demanding industrial environments.

Key Industrial Applications of wire rope assembly

| Industry/Sector | Specific Application of wire rope assembly | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and hoisting equipment | Increases operational efficiency and safety | Strength, durability, and compliance with local regulations |

| Oil & Gas | Tensioning systems for drilling rigs | Enhances reliability in harsh environments | Corrosion resistance and load capacity |

| Marine | Mooring and anchoring systems | Improves vessel stability and safety | Weather resistance and custom lengths |

| Mining | Cable assemblies for material handling | Increases productivity and reduces downtime | High tensile strength and adaptability |

| Aerospace | Control systems in aircraft manufacturing | Ensures precision and reliability in operations | Lightweight materials and compliance with aviation standards |

How is Wire Rope Assembly Used in Construction Projects?

In the construction industry, wire rope assemblies are critical for lifting and hoisting equipment. They enable cranes and other lifting devices to handle heavy loads efficiently and safely. The use of high-strength wire ropes minimizes the risk of failures during operations, ensuring worker safety and project timelines are met. International buyers should consider local regulations regarding load capacities and safety standards when sourcing these assemblies, ensuring compliance and reliability in their operations.

What Role Does Wire Rope Assembly Play in the Oil & Gas Sector?

In the oil and gas sector, wire rope assemblies are vital for tensioning systems used in drilling rigs. These assemblies must withstand extreme conditions, including high tension and corrosive environments. The reliability of these systems is paramount, as any failure can lead to costly downtime and safety hazards. Buyers should prioritize sourcing assemblies with high corrosion resistance and the ability to handle significant load capacities, as these factors are essential for maintaining operational integrity in this challenging industry.

How is Wire Rope Assembly Essential for Marine Applications?

Marine applications utilize wire rope assemblies for mooring and anchoring systems, providing stability and safety for vessels. These assemblies must be designed to endure harsh marine environments, including saltwater exposure and extreme weather conditions. Selecting the right wire rope assembly ensures that vessels remain secure during docking and at sea. Buyers in this sector should focus on sourcing weather-resistant materials and custom lengths to meet specific operational needs, enhancing safety and efficiency.

In What Ways Do Mining Operations Benefit from Wire Rope Assemblies?

In the mining industry, wire rope assemblies are employed in material handling systems, including conveyor belts and hoisting mechanisms. These assemblies improve productivity by ensuring materials are moved efficiently and safely, reducing downtime caused by equipment failures. Buyers should look for assemblies with high tensile strength and adaptability to various environments, as mining operations often involve rugged conditions that demand robust solutions.

Why is Wire Rope Assembly Important in Aerospace Manufacturing?

In aerospace manufacturing, wire rope assemblies play a crucial role in control systems for aircraft. They provide the precision and reliability needed for critical operations, such as controlling flaps and landing gear. The aerospace sector requires lightweight materials that meet strict compliance standards for safety and performance. Buyers should prioritize sourcing wire rope assemblies that adhere to aviation regulations while ensuring they meet the specific performance requirements of their applications.

3 Common User Pain Points for ‘wire rope assembly’ & Their Solutions

Scenario 1: Inconsistent Performance Due to Quality Variability

The Problem:

B2B buyers often face the challenge of inconsistent performance from wire rope assemblies, particularly when sourcing from multiple suppliers. This inconsistency can stem from variations in manufacturing quality, material specifications, or assembly techniques. For example, a construction company may experience unexpected failures in lifting equipment due to subpar wire rope assemblies that do not meet required safety standards. Such failures can lead to costly downtime, safety hazards, and damage to equipment, which can ultimately affect project timelines and budgets.

The Solution:

To mitigate quality variability, buyers should prioritize working with established manufacturers that adhere to industry standards and certifications. When sourcing wire rope assemblies, request detailed product specifications and quality assurance documentation. Additionally, consider implementing a supplier audit process to evaluate the manufacturing capabilities and quality control measures of potential suppliers. Establishing a close partnership with a single reliable manufacturer can also lead to better control over the quality of the assemblies, as ongoing communication allows for immediate feedback and adjustments based on performance metrics.

Illustrative image related to wire rope assembly

Scenario 2: Difficulty in Customization for Specific Applications

The Problem:

Many businesses struggle with finding wire rope assemblies that are tailored to their unique operational needs. Standard products may not provide the necessary specifications, such as length, diameter, or type of fittings, which can lead to inefficiencies in operations. For instance, an oil and gas company may require wire rope assemblies that can withstand extreme environmental conditions, yet find only generic options that do not meet their durability or flexibility requirements.

The Solution:

Buyers should engage manufacturers that offer custom wire rope assembly solutions and have in-house engineering capabilities. By collaborating closely with the manufacturer’s design team, businesses can develop assemblies that meet their specific application needs. Providing detailed operational parameters and performance expectations during the design phase will ensure that the final product is optimized for durability and functionality. Furthermore, consider conducting prototype testing to validate the custom assembly under real-world conditions before full-scale production, reducing the risk of costly modifications later.

Scenario 3: Challenges with Assembly and Installation Processes

The Problem:

Another significant pain point for B2B buyers is the complexity of assembly and installation processes associated with wire rope assemblies. Inadequate training or understanding of assembly techniques can lead to improper installation, which can compromise safety and functionality. A manufacturer in the mining sector may face operational disruptions if their team is not adequately trained to install the wire rope assemblies correctly, resulting in increased labor costs and potential accidents.

The Solution:

To address these challenges, companies should invest in comprehensive training programs for their staff, focusing on best practices for assembly and installation of wire rope assemblies. Collaborating with the manufacturer to provide on-site training or access to detailed instructional materials can significantly enhance the team’s understanding. Additionally, establishing a clear protocol for installation that includes checklists and regular inspections will help ensure that the assemblies are installed correctly and maintained over time. This proactive approach not only improves safety but also maximizes the operational lifespan of the wire rope assemblies.

By addressing these common pain points with targeted solutions, B2B buyers can enhance their procurement processes and ensure that their wire rope assemblies meet the high standards required for their specific applications.

Strategic Material Selection Guide for wire rope assembly

When selecting materials for wire rope assemblies, understanding the properties, advantages, and limitations of each option is crucial for ensuring optimal performance and compliance with industry standards. Below, we analyze four common materials used in wire rope assemblies, focusing on their key properties, pros and cons, and considerations for international buyers.

What Are the Key Properties of Steel Wire Rope Assemblies?

Steel is the most commonly used material for wire rope assemblies due to its high tensile strength and durability. Steel wire ropes can withstand extreme loads and harsh environmental conditions, making them suitable for applications in construction, mining, and marine industries.

Illustrative image related to wire rope assembly

- Key Properties: Steel wire ropes exhibit excellent tensile strength, with breaking strengths ranging from 270 lbs to over 14,000 lbs. They also have good resistance to abrasion and fatigue.

- Pros: Steel is cost-effective and widely available, making it a preferred choice for many applications. Its strength allows for thinner cables, reducing weight without sacrificing performance.

- Cons: Steel is susceptible to corrosion, particularly in marine or humid environments, which can compromise its integrity over time. Protective coatings or galvanization may be necessary, increasing manufacturing complexity.

- Impact on Application: Steel wire ropes are ideal for lifting and pulling applications, but they require careful handling to prevent rust and degradation in corrosive environments.

How Does Stainless Steel Compare in Wire Rope Assemblies?

Stainless Steel is an alloy known for its corrosion resistance, making it suitable for applications in environments where exposure to moisture or chemicals is a concern.

- Key Properties: Stainless steel wire ropes maintain high tensile strength while offering superior resistance to rust and corrosion, especially in saline or acidic environments.

- Pros: The primary advantage of stainless steel is its longevity and reduced maintenance needs, making it ideal for applications in the marine, food processing, and chemical industries.

- Cons: Stainless steel is generally more expensive than carbon steel, which can impact budget considerations. Additionally, it may not perform as well under extreme temperatures compared to specialized alloys.

- Impact on Application: Stainless steel wire ropes are essential for applications requiring high hygiene standards, such as in food processing or pharmaceuticals, where corrosion could lead to contamination.

What Are the Benefits of Synthetic Materials in Wire Rope Assemblies?

Synthetic materials, such as nylon or polyester, are increasingly used in wire rope assemblies, particularly in applications where weight and flexibility are critical.

- Key Properties: Synthetic ropes are lightweight, flexible, and resistant to UV degradation. They also provide good shock absorption, which can be beneficial in dynamic applications.

- Pros: The primary advantage of synthetic materials is their weight, which makes them easier to handle and install. They are also resistant to corrosion and do not conduct electricity, making them suitable for various applications.

- Cons: Synthetic ropes generally have lower tensile strength compared to steel and may not be suitable for heavy lifting applications. They can also be more expensive than traditional wire ropes.

- Impact on Application: Synthetic wire ropes are ideal for applications in leisure (e.g., boating) and certain industrial settings where weight and flexibility are more critical than maximum load capacity.

How Do Composite Materials Enhance Wire Rope Assemblies?

Composite materials, which combine fibers with resin, are gaining traction in specialized applications where traditional materials may fall short.

- Key Properties: Composites can be engineered to provide specific performance characteristics, such as enhanced strength-to-weight ratios and resistance to environmental factors.

- Pros: The versatility of composites allows for tailored solutions that can meet specific application needs, including high-temperature resistance or enhanced fatigue life.

- Cons: The manufacturing process for composite materials can be complex and costly, which may deter some buyers. Additionally, they may not be as widely available as traditional materials.

- Impact on Application: Composites are increasingly used in aerospace and advanced engineering applications, where performance under extreme conditions is essential.

Summary Table of Material Selection for Wire Rope Assemblies

| Material | Typical Use Case for wire rope assembly | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, mining, marine | High tensile strength and durability | Susceptible to corrosion | Low |

| Stainless Steel | Marine, food processing, chemical | Excellent corrosion resistance | Higher cost than carbon steel | Medium |

| Synthetic | Leisure (boating), industrial | Lightweight and flexible | Lower tensile strength | Medium |

| Composite | Aerospace, advanced engineering | Tailored performance characteristics | Complex and costly to manufacture | High |

This guide provides a comprehensive overview of material selection for wire rope assemblies, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

Illustrative image related to wire rope assembly

In-depth Look: Manufacturing Processes and Quality Assurance for wire rope assembly

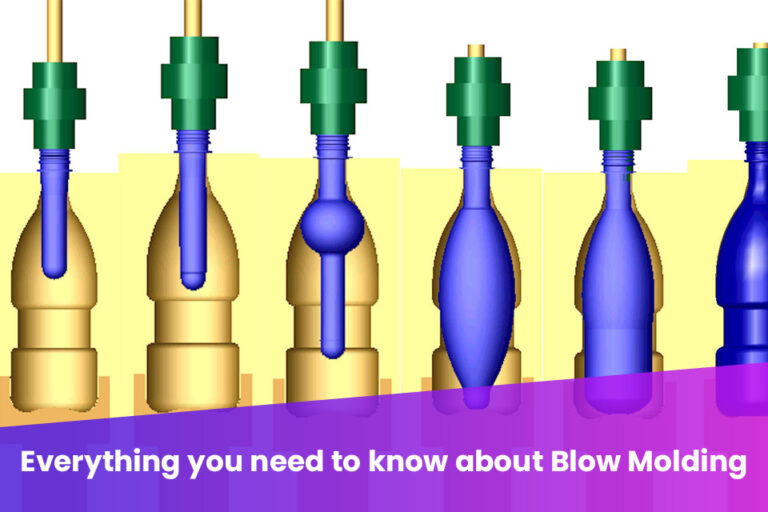

What Are the Main Stages in the Manufacturing Process of Wire Rope Assemblies?

The manufacturing of wire rope assemblies is a meticulous process that involves several key stages, each crucial for ensuring the final product meets the required specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is the Raw Material Processed?

The first step in manufacturing wire rope assemblies is material preparation, where high-quality steel wires are sourced. These wires undergo a series of treatments, such as cleaning and coating, to enhance their durability and resistance to corrosion. Quality control begins here, with inspections to verify the material’s tensile strength and other mechanical properties. This stage ensures that only the best materials are used, setting a solid foundation for the assembly process.

How Is Wire Rope Formed and Assembled?

Once the materials are prepared, the next step is forming. This involves twisting the steel wires together to create strands, which are then twisted into larger groups to form the wire rope. The lay of the rope—whether right or left—affects its flexibility and strength, and must be chosen according to the intended application.

The assembly phase follows, where the wire rope is cut to specific lengths, and end fittings or connectors are attached. This is where the assembly can be customized to meet specific client needs, whether for lifting, pulling, or other mechanical applications. Each assembly is crafted to adhere to the precise engineering specifications provided by the client.

What Finishing Techniques Are Commonly Used?

Finishing is the final stage of the manufacturing process, which includes several treatments to enhance the wire rope’s performance and longevity. Common finishing techniques involve coating the wire rope with protective layers to prevent rust and corrosion. Final inspections are conducted to ensure that the assembly meets both visual and functional standards before being packaged for shipment.

What Quality Control Measures Are Implemented During Manufacturing?

Quality assurance is a critical aspect of wire rope assembly manufacturing. Several international standards, such as ISO 9001, guide the quality management processes. Compliance with these standards demonstrates a commitment to maintaining high-quality production processes.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Specifications for tensile strength, diameter, and surface finish are checked to ensure they meet the required standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are performed to monitor the production line. This includes checks during the forming and assembly phases to ensure that the wire rope is being constructed correctly and that the specifications are adhered to.

-

Final Quality Control (FQC): The final inspection assesses the finished product for overall quality, functionality, and compliance with the specified requirements. Testing methods such as load testing, continuity testing, and visual inspections are conducted to ensure that the wire rope assemblies are safe and reliable.

What Testing Methods Are Used in Wire Rope Assembly Quality Assurance?

Testing methods play a pivotal role in the quality assurance of wire rope assemblies. Here are some common tests conducted:

-

Tensile Testing: This method evaluates the strength of the wire rope by applying a load until it breaks. This helps to ascertain whether the assembly can withstand the required operational loads.

-

Continuity Testing: Used to ensure that electrical connections are intact in wire rope cable assemblies designed for electrical transmission.

-

Insulation Resistance Testing: This assesses the effectiveness of insulation materials, ensuring that they provide adequate protection against environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers. Here are several methods to achieve this:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards. This firsthand evaluation helps establish trust and reliability.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports and certifications from suppliers, demonstrating compliance with standards such as ISO 9001 and other industry-specific certifications like CE or API. These documents provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product reliability. These inspections can be particularly valuable for buyers in regions where local oversight may be limited.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of specific nuances in quality control. Different regions may have varying standards and practices, which can affect the quality of wire rope assemblies. For instance, suppliers in Europe might adhere to stricter regulations compared to those in other regions.

Illustrative image related to wire rope assembly

Additionally, cultural differences in business practices can influence communication and expectations regarding quality. Understanding these nuances is crucial for establishing effective partnerships and ensuring that the supplied products meet the necessary standards.

Conclusion

The manufacturing processes and quality assurance practices for wire rope assemblies are critical to delivering reliable and high-performance products. By understanding the stages of production, quality control checkpoints, and testing methods, B2B buyers can make informed decisions when selecting suppliers. Verifying quality control practices through audits, reports, and third-party inspections further enhances confidence in the supplier’s ability to deliver products that meet international standards. This comprehensive approach not only safeguards investments but also ensures that the wire rope assemblies perform effectively in their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire rope assembly’

In today’s competitive industrial landscape, sourcing wire rope assemblies requires careful consideration and strategic planning. This guide provides a step-by-step checklist to assist B2B buyers in procuring high-quality wire rope assemblies that meet their specific operational needs.

Illustrative image related to wire rope assembly

Step 1: Define Your Technical Specifications

Before starting the sourcing process, clearly outline your technical requirements. This includes specifications such as length, diameter, breaking strength, and type of fittings. Precise definitions help ensure that the final product meets your operational demands and can withstand the intended load and environmental conditions.

- Considerations:

- Identify industry standards relevant to your application.

- Document any unique requirements based on your machinery or operational environment.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers who specialize in wire rope assemblies. Look for manufacturers with a proven track record in your industry. Reliable suppliers often provide case studies or testimonials from satisfied clients, which can give you insight into their capabilities.

- Tips:

- Utilize industry directories and online platforms to find reputable suppliers.

- Attend industry trade shows to meet potential suppliers face-to-face.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of your potential suppliers. Certifications such as ISO 9001 indicate that the manufacturer adheres to rigorous quality management principles. This step is crucial to ensure that the wire rope assemblies you purchase are safe, reliable, and compliant with relevant regulations.

Illustrative image related to wire rope assembly

- Checklist:

- Request copies of certifications.

- Inquire about their quality control processes.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the wire rope assemblies. Testing samples will allow you to evaluate their performance under real-world conditions, ensuring they meet your specifications. This step helps mitigate risks associated with bulk purchases.

- Important Tests:

- Perform load testing to verify breaking strength.

- Assess flexibility and durability based on your operational requirements.

Step 5: Discuss Customization Options

If your application requires specific features, discuss customization options with your supplier. Many manufacturers offer tailored solutions to meet unique needs, such as specialized fittings or materials. Customization can enhance the performance and longevity of the wire rope assemblies.

- Key Points:

- Clarify any additional costs associated with customization.

- Ensure that the supplier has the engineering capabilities to deliver what you need.

Step 6: Review Pricing and Payment Terms

Once you have shortlisted suppliers, review their pricing structures and payment terms. Ensure that the pricing aligns with your budget while considering the quality of the product. Transparent payment terms can facilitate smoother transactions and help build a long-term relationship.

- Considerations:

- Look for volume discounts or long-term contract benefits.

- Clarify shipping costs and timelines to avoid unexpected expenses.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the procurement process. Establish a clear communication plan with your supplier to ensure that both parties are aligned on expectations, timelines, and any potential issues that may arise. A proactive communication strategy can prevent misunderstandings and delays.

- Best Practices:

- Schedule regular check-ins during the production phase.

- Use project management tools to track progress and address concerns.

By following this checklist, B2B buyers can streamline the sourcing process for wire rope assemblies, ensuring they select the right suppliers and products to meet their operational requirements efficiently.

Illustrative image related to wire rope assembly

Comprehensive Cost and Pricing Analysis for wire rope assembly Sourcing

What Are the Key Cost Components in Wire Rope Assembly Sourcing?

When sourcing wire rope assemblies, understanding the various cost components is crucial for effective budgeting and pricing negotiations. The primary cost elements include:

-

Materials: The raw materials for wire rope assemblies typically consist of high-strength steel, aluminum, or specialized alloys. The choice of material significantly impacts the cost. Premium materials may enhance durability and performance but will also raise the price.

-

Labor: Labor costs encompass the wages for skilled workers involved in cutting, assembling, and testing the wire rope assemblies. Skilled labor is essential for ensuring high-quality production, particularly for custom assemblies.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thus reducing the overall cost of production.

-

Tooling: Specialized tools and machinery are often required to produce wire rope assemblies, particularly custom designs. The amortization of tooling costs can influence pricing, especially for low-volume orders.

-

Quality Control (QC): Rigorous quality checks are essential to ensure the safety and reliability of wire rope assemblies. QC processes may involve testing for tensile strength and durability, which can add to the overall cost but are critical for compliance with industry standards.

-

Logistics: Shipping costs can vary widely based on the distance, method of transportation, and volume of the order. Import duties and taxes may also apply, particularly for international shipments, affecting the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing to cover risk and ensure business sustainability. This margin can vary based on market competition and the supplier’s business model.

How Do Price Influencers Affect Wire Rope Assembly Costs?

Several factors can influence the pricing of wire rope assemblies:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Negotiating MOQs with suppliers can significantly impact pricing, particularly for businesses looking to reduce costs.

-

Specifications and Customization: Custom designs or specific specifications will generally increase costs. Providing detailed requirements upfront can help suppliers give more accurate quotes.

-

Material Quality and Certifications: Higher quality materials and compliance with international standards or certifications (e.g., ISO) can elevate costs but also provide assurance of reliability and performance.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Suppliers with advanced technology or a strong track record may command higher prices.

-

Incoterms: Understanding the terms of delivery (Incoterms) is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can influence the overall cost by determining who bears the shipping and insurance costs.

What Tips Can Buyers Use for Negotiating Wire Rope Assembly Prices?

Effective negotiation strategies can lead to significant cost savings:

-

Research and Benchmarking: Understanding market prices and competitor offerings can empower buyers during negotiations. Gathering quotes from multiple suppliers can provide leverage.

-

Emphasizing Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also the long-term costs associated with maintenance, reliability, and potential downtime. A higher initial investment in quality may yield better long-term savings.

-

Flexibility in Specifications: If possible, consider flexibility in design or specifications, as this can open up options for cost savings.

-

Building Relationships: Establishing a long-term relationship with suppliers can lead to better pricing and more favorable terms over time. Frequent communication and collaboration can foster trust and reliability.

-

Understanding Pricing Nuances for International Sourcing: International buyers should be aware of currency fluctuations, local tariffs, and compliance regulations that may affect pricing. Utilizing local representatives or sourcing agents can help navigate these complexities.

Disclaimer on Indicative Prices

Prices for wire rope assemblies can vary significantly based on the aforementioned factors. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing wire rope assembly With Other Solutions

Introduction to Alternative Solutions for Wire Rope Assembly

In the realm of industrial applications, wire rope assemblies are often a go-to solution for tasks requiring strength and reliability. However, various alternatives exist that may better suit specific operational needs, budgets, or environmental conditions. This section delves into a comparison of wire rope assemblies with two viable alternatives: synthetic rope and chain assemblies. Understanding these options helps B2B buyers make informed decisions tailored to their unique requirements.

Comparison of Wire Rope Assembly with Alternatives

| Comparison Aspect | Wire Rope Assembly | Synthetic Rope | Chain Assembly |

|---|---|---|---|

| Performance | High tensile strength, flexible | Lightweight, high strength-to-weight ratio | Extremely durable, high load capacity |

| Cost | Moderate to high | Generally lower initial cost | Higher initial investment but long lifespan |

| Ease of Implementation | Requires specialized fittings and installation | Easy to handle and install | Complex installation requiring more tools |

| Maintenance | Moderate; regular inspections needed | Minimal; resistant to abrasion | High; requires lubrication and inspection |

| Best Use Case | Heavy lifting in harsh environments | Marine applications, lightweight lifting | Permanent installations, heavy-duty lifting |

Pros and Cons of Each Alternative

Synthetic Rope

Synthetic ropes, often made from materials such as nylon or polyester, provide a lightweight alternative to wire rope assemblies. Their high strength-to-weight ratio makes them ideal for marine and recreational applications, where ease of handling is paramount. However, while they offer excellent resistance to abrasion and UV degradation, they can be susceptible to damage from sharp edges or extreme temperatures. For industries focused on reducing weight while maintaining strength, synthetic ropes are a compelling option, especially in environments where reduced weight translates to enhanced efficiency.

Chain Assembly

Chain assemblies are another alternative that excels in durability and strength. They are particularly well-suited for permanent installations and heavy-duty lifting applications, such as in construction and manufacturing. Chains can handle extreme loads without risk of stretching or snapping, making them a reliable choice for high-tension applications. However, they tend to be heavier and require more complex installation processes, including the need for specialized tools. Maintenance can also be demanding, as chains need regular lubrication and inspection to prevent wear and rust, which can increase overall operational costs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between wire rope assemblies, synthetic ropes, and chain assemblies, B2B buyers should carefully consider their specific operational requirements, including load capacity, environmental conditions, and maintenance capabilities. Each alternative presents unique advantages and challenges that may align differently with business objectives. By assessing these factors and understanding the nuances of each solution, buyers can make informed choices that optimize performance and cost-efficiency in their applications.

Essential Technical Properties and Trade Terminology for wire rope assembly

What Are the Key Technical Properties of Wire Rope Assembly?

Understanding the technical properties of wire rope assembly is crucial for B2B buyers, especially when selecting products that meet specific operational requirements. Here are some essential specifications to consider:

1. Material Grade

Wire ropes are typically made from various materials, including steel, stainless steel, and synthetic fibers. The material grade affects the wire rope’s tensile strength, flexibility, and resistance to environmental factors like corrosion. For B2B buyers, selecting the right material grade is critical to ensure the assembly can withstand the operational demands of its intended application, such as heavy lifting or exposure to harsh conditions.

2. Breaking Strength

Breaking strength refers to the maximum load that a wire rope assembly can support before failure. It is measured in pounds or kilograms and is a vital specification for industries that rely on high-load applications, such as construction and manufacturing. Buyers must consider the breaking strength to ensure safety and operational efficiency, avoiding potential failures that could lead to costly downtime or accidents.

3. Diameter

The diameter of the wire rope influences its strength, flexibility, and compatibility with other equipment. Typically measured in inches or millimeters, the diameter must match the specifications of the machinery it will be used with. B2B buyers should be aware that selecting the appropriate diameter is essential for ensuring proper fit and functionality in various applications.

4. Lay Direction

Lay direction refers to the way the wires and strands are twisted together, which can be either right lay or left lay. This specification impacts the rope’s flexibility and its performance in specific applications. Understanding lay direction helps buyers select the right wire rope assembly for their needs, especially in dynamic applications where movement is involved.

5. End Fittings

End fittings are components attached to the ends of wire ropes, such as hooks, loops, or connectors, which allow for secure attachment to machinery or loads. The type and quality of end fittings are critical for ensuring safe and reliable connections. Buyers must evaluate the compatibility of end fittings with their equipment to prevent failures during operation.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can streamline communication and negotiations. Here are several essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For wire rope assembly, understanding OEM relationships helps buyers identify quality manufacturers whose products meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it can impact inventory management and cost-effectiveness. Knowing the MOQ can help buyers plan their purchases and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other relevant details for a specific product or service. For wire rope assemblies, issuing an RFQ can help buyers compare options from various suppliers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is crucial for B2B buyers engaged in international transactions, as it clarifies who is responsible for shipping costs, risks, and insurance during transport.

5. Tolerance

Tolerance refers to the allowable deviation from specified dimensions and performance criteria in wire rope assemblies. Understanding tolerance is vital for ensuring that the products meet the necessary specifications for functionality and safety, particularly in high-stakes applications.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure product reliability in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the wire rope assembly Sector

What Are the Key Drivers and Trends in the Global Wire Rope Assembly Market?

The wire rope assembly market is experiencing significant growth driven by various global factors. Key industries such as construction, mining, and marine equipment are expanding, particularly in emerging markets like Africa and South America. These regions are investing heavily in infrastructure development, which increases the demand for reliable lifting and pulling solutions provided by wire rope assemblies. Additionally, the rise of automation in manufacturing is leading to an increased need for customized wire rope solutions, integrating advanced technologies such as IoT and AI for enhanced functionality.

Emerging sourcing trends also reflect a shift towards digitalization. B2B buyers are increasingly utilizing online platforms for procurement, allowing for better price comparisons and supplier evaluations. This trend is particularly evident in Europe and the Middle East, where e-commerce solutions are streamlining supply chain processes. Moreover, the demand for custom cable assemblies is on the rise, as businesses seek to optimize operations and improve efficiencies through tailored solutions.

Lastly, the focus on product quality and reliability remains paramount, with buyers prioritizing suppliers that can demonstrate a proven track record. As competition intensifies, international buyers must be vigilant in sourcing from manufacturers that offer high tensile strength and durability, ensuring that the wire rope assemblies can withstand harsh operational conditions.

Illustrative image related to wire rope assembly

How Does Sustainability and Ethical Sourcing Impact Wire Rope Assembly Procurement?

Sustainability is becoming increasingly critical in the wire rope assembly sector, influencing purchasing decisions among B2B buyers. The environmental impact of manufacturing processes, particularly in terms of carbon emissions and waste generation, has prompted buyers to seek suppliers who prioritize eco-friendly practices. This is especially relevant in regions like Europe, where stringent regulations are in place regarding environmental standards.

Ethical sourcing is equally important, as international buyers are now more aware of the social implications of their procurement decisions. Companies are expected to ensure that their supply chains are free from exploitation and that workers are treated fairly. This has led to a growing emphasis on certifications such as ISO 14001 for environmental management and Fair Trade accreditation, which assures buyers of ethical practices in the production of wire rope assemblies.

Moreover, the use of ‘green’ materials is gaining traction. Manufacturers that utilize recyclable materials or sustainable practices in their production processes are becoming more attractive to buyers. The trend towards sustainability not only helps companies mitigate risks associated with environmental regulations but also enhances their brand reputation in the eyes of increasingly eco-conscious consumers.

What Is the Historical Context of Wire Rope Assembly Development?

The wire rope assembly industry has evolved significantly since its inception in the 19th century, primarily driven by advancements in metallurgy and engineering. Initially developed for lifting heavy loads in mining and construction, wire rope technology has progressed to meet the demands of various applications across multiple sectors, including aerospace and marine industries.

Over the decades, innovations such as improved wire coating and the introduction of synthetic materials have enhanced the durability and performance of wire rope assemblies. These advancements have allowed manufacturers to create more flexible and stronger products, capable of withstanding extreme conditions. As industries continue to innovate, the wire rope assembly sector is poised for further growth, adapting to the changing needs of international B2B buyers while maintaining a focus on quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of wire rope assembly

1. How do I choose the right wire rope assembly for my application?

Choosing the right wire rope assembly involves assessing your specific application requirements, such as load capacity, environmental conditions, and flexibility. Consider factors like the diameter and material of the wire, as well as the type of end fittings required for connection. Consulting with a manufacturer or supplier can provide insights based on their expertise and experience, ensuring you select an assembly that meets your operational demands.

2. What are the typical lead times for custom wire rope assemblies?

Lead times for custom wire rope assemblies can vary significantly based on complexity, materials, and production capacity. Generally, expect anywhere from 2 to 6 weeks for standard orders. If your project requires specific customization or large quantities, it’s advisable to communicate your timeline with suppliers early on. This can help ensure that production aligns with your project schedule and avoid potential delays.

3. What quality assurance measures should I look for in wire rope assembly suppliers?

When vetting suppliers, inquire about their quality assurance processes, such as certifications (ISO, ASTM), testing methods, and inspection protocols. A reputable supplier should conduct rigorous testing on their assemblies, including load testing and material inspections. Request documentation of past quality audits and customer feedback to gauge reliability and service quality.

4. What are the minimum order quantities (MOQs) for wire rope assemblies?

Minimum order quantities for wire rope assemblies can vary based on the supplier and the complexity of the assembly. Generally, MOQs can range from as low as 100 units to several thousand. It’s essential to discuss your needs with suppliers upfront, as many are willing to accommodate smaller orders, especially for custom assemblies, to build long-term relationships.

5. How can I ensure the wire rope assembly will perform in harsh environments?

To ensure performance in harsh environments, specify the materials and coatings needed for corrosion resistance and durability. Factors such as environmental temperature, exposure to chemicals, and mechanical stress should be communicated to the supplier. Additionally, consider assemblies with enhanced shielding and insulation to protect against environmental factors, ensuring longevity and reliability.

6. What payment terms are typically offered by wire rope assembly suppliers?

Payment terms can vary widely among suppliers, but common arrangements include 30% upfront and 70% upon delivery or net 30 days after invoicing. For international transactions, be aware of currency fluctuations and additional fees. Discussing payment terms in advance can help establish trust and clarity in the business relationship.

7. How do I manage logistics and shipping for international orders of wire rope assemblies?

Managing logistics for international orders requires careful planning. Collaborate with your supplier to determine the best shipping method based on cost, speed, and reliability. Ensure compliance with import regulations in your country and consider working with a freight forwarder experienced in handling industrial components. This can streamline the process and mitigate potential customs delays.

8. What should I include in a request for quotation (RFQ) for wire rope assemblies?

When preparing an RFQ for wire rope assemblies, be detailed about your requirements, including specifications for dimensions, load capacity, material types, and any customization needed. Provide information on the intended application, environmental conditions, and desired lead times. Clear communication of expectations helps suppliers provide accurate quotes and enhances the efficiency of the procurement process.

Top 6 Wire Rope Assembly Manufacturers & Suppliers List

1. McMaster – Wire Rope Assemblies

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Wire Rope Assemblies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Thern – 3/16 Stainless Steel Wire Rope Assemblies

Domain: liftingequipmentstore.us

Registered: 2018 (7 years)

Introduction: Product Name: Thern 3/16″ Stainless Steel Wire Rope Assemblies

Diameter: 3/16″

Material: Stainless Steel

Lengths Available: 20ft, 28ft, 36ft, 45ft, 60ft, 75ft

End Configuration: One end plain, other end with stainless steel swivel hook

Compatibility: Fits both powered and manual Thern winches

Price: $243.00

Contact: +1-713-489-5335, [email protected]

3. Union Rope – Wire Rope Products

Domain: unionrope.com

Registered: 2008 (17 years)

Introduction: Wire Rope Products: 19×7, 6×19 & 6×36 Class Ropes, 7 Flex & 7 Flex PFV, 8×19 & 8×25 Resistwist Crane Pendants, Flattened Strand IWRC, Flex-X 19, Flex-X 6, Flex-X 7, CC Flex-X 9, Oil & Gas 3×7 Swaged, 5×7-SFC, 6×19 & 6×26 Drill Lines, 6x26WS Tubing Lines, 6×31 Swaged, 6×19 & 6×36 IWRC, 6×7 SFC Bright/Galvanized Mast Raising Lines, TUF-FLEX DL & DLX, TUF-KOTE Drill Line, Mining 6 Strand & 6 Strand P…

4. Arlington Scale – Custom Wire Rope Assemblies

Domain: arlingtonscale.com

Registered: 2002 (23 years)

Introduction: Wire rope assemblies improve load cell alignment and repeatability, and serve as natural vibration dampeners. Custom wire ropes are available for specific applications. Product models include:

– Part #17760: Wire Rope, 1/4-20NCx1/4-28 NFx4L, 400 lb, Steel, Galvanized, Jam Nut included.

– Part #17762: Wire Rope, 3/8-16NCx3/8-24 NFx5L, 850 lb, Steel, Galvanized, Jam Nut included.

– Part #17766: W…

5. Tractel – Heavy-Duty Wire Rope Assembly

Domain: tractel.com

Registered: 1996 (29 years)

Introduction: 10,000 lbs. load capacity; 5/16 in. diameter; available in 5×19 or 5×26 wire rope assembly; includes hook and welded tip.

6. Rice Lake – Cardinal Wire Rope Assemblies

Domain: ricelake.com

Registered: 1997 (28 years)

Introduction: Wire Rope Assemblies provide better alignment and increase load cell repeatability, acting as natural vibration dampeners. Key products include: 1. Cardinal Wire Rope Assemblies: EL208 (7,500 lb capacity FH model, 8,000 lb capacity EP model), EL209 (20,000 lb capacity FH and EP models, also for 15,000 lb capacity). 2. Custom Wire Ropes: Requires Custom Wire Rope Definition form, sample, tension ra…

Strategic Sourcing Conclusion and Outlook for wire rope assembly

What Are the Key Takeaways for B2B Buyers of Wire Rope Assemblies?

In conclusion, strategic sourcing of wire rope assemblies offers significant advantages for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers that not only provide high-quality, customizable solutions but also possess the engineering expertise to meet specific application requirements. Understanding the manufacturing process, from design to testing, is crucial for ensuring product reliability and performance in demanding environments.

How Can Strategic Sourcing Enhance Your Supply Chain?

Engaging with manufacturers who emphasize quality control and have a track record in various industries—such as aerospace, mining, and construction—can lead to improved operational efficiency and reduced long-term costs. By leveraging local partnerships and global networks, businesses can enhance their supply chain resilience while accessing innovative technologies and materials.

What Does the Future Hold for Wire Rope Assembly Sourcing?

As the demand for robust wire rope assemblies continues to rise, particularly in sectors driven by automation and infrastructure development, now is the ideal time for B2B buyers to reassess their sourcing strategies. By focusing on reliable partnerships and investing in quality products, companies can position themselves for growth. Embrace the opportunity to optimize your sourcing today and ensure your operations are equipped for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to wire rope assembly

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.