Is Your What Is Forged Aluminum Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for what is forged aluminum

In the competitive landscape of global manufacturing, sourcing high-quality forged aluminum can present a significant challenge for B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Forged aluminum, known for its superior strength and durability compared to other aluminum forms, is a critical material for industries ranging from aerospace to automotive. This guide aims to demystify the complexities of forged aluminum, providing essential insights into its various types, applications, and the benefits it offers over casting and billet forms.

Buyers will find comprehensive information on how to effectively vet suppliers, assess costs, and understand the metallurgical advantages that forged aluminum provides. With a focus on practical applications and market trends, this guide empowers international buyers to make informed purchasing decisions that align with their operational needs and budget constraints. By addressing common pitfalls and offering actionable strategies, we ensure that your sourcing process is streamlined and efficient, enabling you to leverage the full potential of forged aluminum in your projects. Whether you are looking to enhance product performance or reduce overall costs, this guide serves as a valuable resource tailored to meet the unique challenges faced by B2B buyers in diverse markets.

Understanding what is forged aluminum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Die Forging | Utilizes flat or simple dies; allows for large parts. | Aerospace, automotive, heavy machinery | Pros: Cost-effective for large parts. Cons: Limited complexity in shapes. |

| Closed Die Forging | Involves more intricate dies; produces precise shapes. | Medical devices, automotive components | Pros: High precision and better surface finish. Cons: Higher tooling costs. |

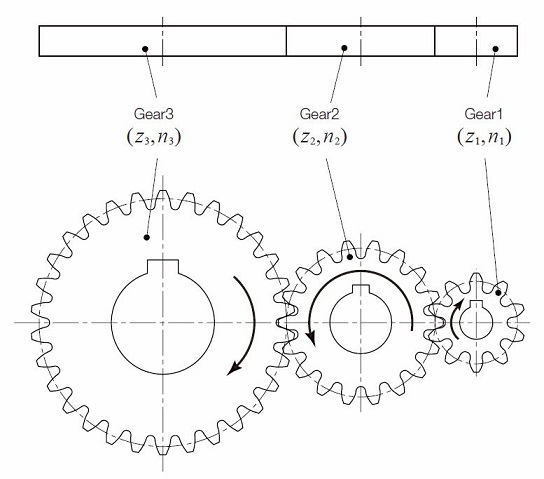

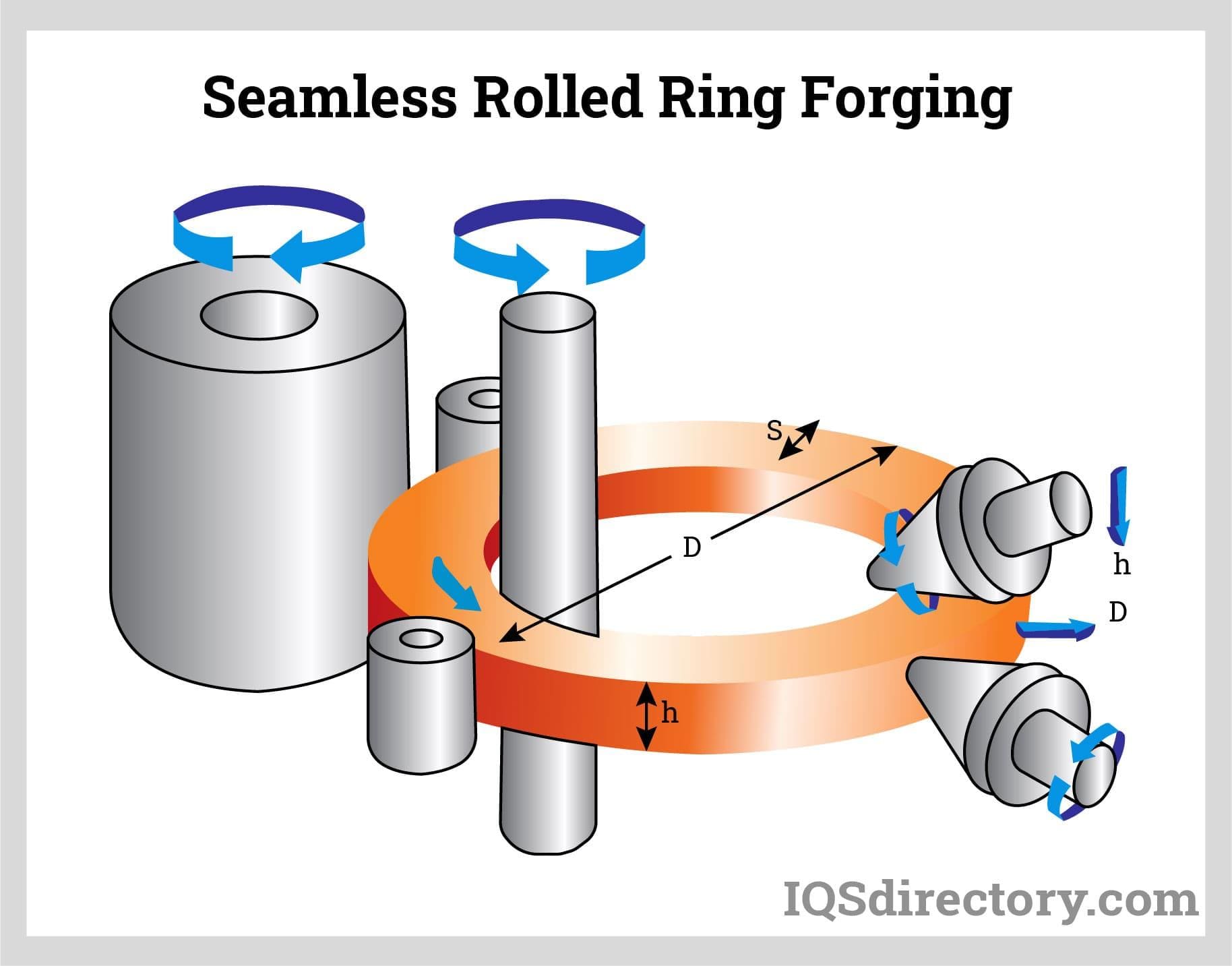

| Roll Forging | Uses rotating rolls to shape the metal; continuous process. | Construction, rail, and automotive parts | Pros: Efficient for long parts; less waste. Cons: Limited to simpler geometries. |

| Precision Forging | High accuracy and tight tolerances; often uses CNC machines. | Electronics, aerospace, and military | Pros: Exceptional dimensional accuracy. Cons: More expensive due to complexity. |

| Isothermal Forging | Maintains temperature during forging; reduces defects. | Aerospace, high-performance applications | Pros: Improved material properties. Cons: Specialized equipment required. |

What Are the Characteristics of Open Die Forging in B2B Applications?

Open die forging is characterized by the use of flat or simple dies, allowing for the production of large parts without intricate shapes. This method is particularly suited for industries such as aerospace and heavy machinery, where large components are common. B2B buyers should consider the cost-effectiveness of this process for large-scale production, though they must also weigh the limitations in complexity, which may necessitate additional machining for certain applications.

How Does Closed Die Forging Offer Precision for Specialized Industries?

Closed die forging employs intricate dies to create components with precise shapes and dimensions, making it ideal for applications in medical devices and automotive components. The high precision and superior surface finish are significant advantages for B2B buyers, especially when reliability is paramount. However, the initial tooling costs can be higher, which may affect budget considerations for smaller production runs.

Why Choose Roll Forging for Efficiency in Manufacturing?

Roll forging is a continuous process that shapes metal using rotating rolls, making it highly efficient for producing long parts, such as those used in construction and automotive industries. This method reduces material waste and can be a cost-effective solution for high-volume production. Buyers should be mindful that while roll forging is efficient, it is best suited for simpler geometries, which may limit design flexibility.

What Benefits Does Precision Forging Provide for High-Tech Applications?

Precision forging is known for its exceptional dimensional accuracy and tight tolerances, often utilizing advanced CNC machinery. This method is essential in sectors like electronics, aerospace, and military applications, where component reliability is critical. While the benefits of precision forging are significant, B2B buyers must consider the higher costs associated with this intricate process and assess whether the enhanced accuracy justifies the investment.

How Does Isothermal Forging Improve Material Properties for Advanced Uses?

Isothermal forging maintains a consistent temperature throughout the forging process, significantly reducing defects and enhancing the material properties of the final product. This technique is particularly beneficial in aerospace and high-performance applications, where durability and reliability are non-negotiable. However, the requirement for specialized equipment can lead to increased costs, making it essential for B2B buyers to evaluate the long-term benefits against initial investments.

Key Industrial Applications of what is forged aluminum

| Industry/Sector | Specific Application of what is forged aluminum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components like landing gear and structural frames | Enhanced strength-to-weight ratio, crucial for performance and fuel efficiency | Certification standards (e.g., AS9100), supplier reliability, and material traceability |

| Automotive | Engine components and suspension systems | Improved durability and safety, reducing the risk of failure under stress | Compliance with automotive industry standards, cost-effectiveness, and lead times |

| Oil & Gas | Drill bits and components for downhole equipment | High resistance to corrosion and wear, essential for harsh environments | Material certification, sourcing from specialized suppliers, and performance testing |

| Defense & Military | Armor plating and structural components | High strength and reliability, critical for mission success | Compliance with military specifications, sourcing from certified manufacturers, and geopolitical stability |

| Consumer Electronics | Chassis and frames for high-performance devices | Lightweight and thermal conductivity, enhancing device performance | Cost considerations, customization options, and supplier innovation capabilities |

How is Forged Aluminum Used in Aerospace Applications?

In the aerospace industry, forged aluminum is critical for manufacturing aircraft components such as landing gear and structural frames. These components require materials that can withstand extreme stress while minimizing weight to enhance fuel efficiency. Forged aluminum’s superior strength-to-weight ratio addresses these demands, ensuring safety and performance in flight. International buyers must consider suppliers that meet stringent certification standards, like AS9100, and ensure material traceability to guarantee compliance with industry regulations.

What Role Does Forged Aluminum Play in Automotive Manufacturing?

The automotive sector utilizes forged aluminum for engine components and suspension systems, where durability and safety are paramount. The forging process enhances the material’s mechanical properties, providing a robust solution that reduces the risk of failure under high stress. Buyers in this field should focus on suppliers that comply with automotive industry standards and can offer competitive pricing and reliable lead times, especially in emerging markets in Africa and South America, where cost and efficiency are critical.

Why is Forged Aluminum Essential for Oil & Gas Industries?

In the oil and gas sector, forged aluminum is employed in the production of drill bits and downhole equipment components. The material’s high resistance to corrosion and wear is vital for performance in harsh environments, such as deep-sea drilling. For B2B buyers, sourcing considerations include ensuring material certification and partnering with specialized suppliers who can provide performance testing data, which is crucial for operational reliability in challenging conditions.

How is Forged Aluminum Utilized in Defense & Military Applications?

The defense and military industries rely on forged aluminum for applications such as armor plating and structural components in military vehicles. The high strength and reliability of forged aluminum are critical for mission success and personnel safety. Buyers in this sector must prioritize suppliers that comply with military specifications and are capable of providing materials from stable geopolitical regions to mitigate supply chain risks.

What Advantages Does Forged Aluminum Offer in Consumer Electronics?

In consumer electronics, forged aluminum is used for manufacturing chassis and frames of high-performance devices. The lightweight nature of forged aluminum, combined with its excellent thermal conductivity, enhances device performance and user experience. B2B buyers should focus on cost considerations, customization options, and the ability of suppliers to innovate, which is particularly important in competitive markets in Europe and Southeast Asia.

Illustrative image related to what is forged aluminum

3 Common User Pain Points for ‘what is forged aluminum’ & Their Solutions

Scenario 1: Understanding Material Specifications for Forged Aluminum Components

The Problem: B2B buyers often struggle with understanding the specific material properties and specifications required for forged aluminum components. This confusion can lead to misalignment between project requirements and the actual materials sourced, resulting in product failures or increased costs due to redesigns. For instance, a manufacturer in the automotive sector might need forged aluminum parts with specific tensile strength and ductility, but without clear specifications, they risk sourcing materials that do not meet safety and performance standards.

The Solution: To address this challenge, buyers should invest time in developing a comprehensive understanding of the mechanical properties of forged aluminum relevant to their applications. Collaborate closely with suppliers to obtain detailed material data sheets and certifications, which outline the alloy composition and mechanical properties. Establish a clear communication channel with your forging partner to specify the exact requirements, including tensile strength, yield strength, and elongation. Using standardized tests, such as ASTM or ISO, can also help ensure that the materials meet industry standards. Additionally, consider conducting preliminary tests on sample components to validate performance before committing to large-scale production.

Scenario 2: Cost Management in Forged Aluminum Procurement

The Problem: Another common issue faced by B2B buyers is the high cost associated with procuring forged aluminum parts, which can be significantly higher than cast or billet aluminum alternatives. This cost factor can strain budgets, especially for projects with tight margins. Buyers may find themselves in a dilemma between choosing lower-cost materials that could compromise quality and safety or investing in higher-quality forged components that align with performance specifications.

The Solution: To effectively manage costs while ensuring quality, buyers should adopt a strategic sourcing approach. Begin by conducting a thorough cost-benefit analysis of different aluminum processing methods, including forged, cast, and billet options, to determine the best fit for your project. Engage multiple suppliers to compare pricing and negotiate terms, ensuring you communicate your volume and long-term partnership potential to secure better rates. Additionally, consider exploring the possibility of bulk purchasing agreements or long-term contracts that can lead to discounts. It’s also beneficial to evaluate the lifecycle costs of components; while forged aluminum may be more expensive initially, its enhanced durability can result in lower maintenance and replacement costs over time.

Scenario 3: Navigating Lead Times and Supply Chain Challenges

The Problem: B2B buyers frequently encounter issues with long lead times and unpredictable supply chain disruptions when sourcing forged aluminum components. Factors such as global material shortages, transportation delays, and fluctuating demand can significantly impact production schedules and project timelines. A company in the aerospace industry, for example, may face delays that jeopardize compliance with strict delivery schedules and project milestones, resulting in financial penalties or lost contracts.

Illustrative image related to what is forged aluminum

The Solution: To mitigate these risks, buyers should develop a proactive supply chain strategy that emphasizes flexibility and responsiveness. Start by building strong relationships with multiple suppliers across different regions to diversify your sourcing options. This not only helps in securing alternate supply routes but also provides leverage in negotiating lead times. Implement a robust inventory management system that allows for better forecasting of demand, enabling you to maintain safety stock levels of critical components. Additionally, consider investing in technology that offers real-time tracking of orders and materials, which can enhance visibility throughout the supply chain. By being prepared and adaptable, you can significantly reduce the impact of supply chain challenges on your projects.

Strategic Material Selection Guide for what is forged aluminum

What Are the Key Properties of Common Forged Aluminum Materials?

When selecting forged aluminum for various applications, it is essential to understand the properties of different aluminum alloys. Here, we analyze several commonly used materials in the forging process, focusing on their performance characteristics, advantages, disadvantages, and considerations for international buyers.

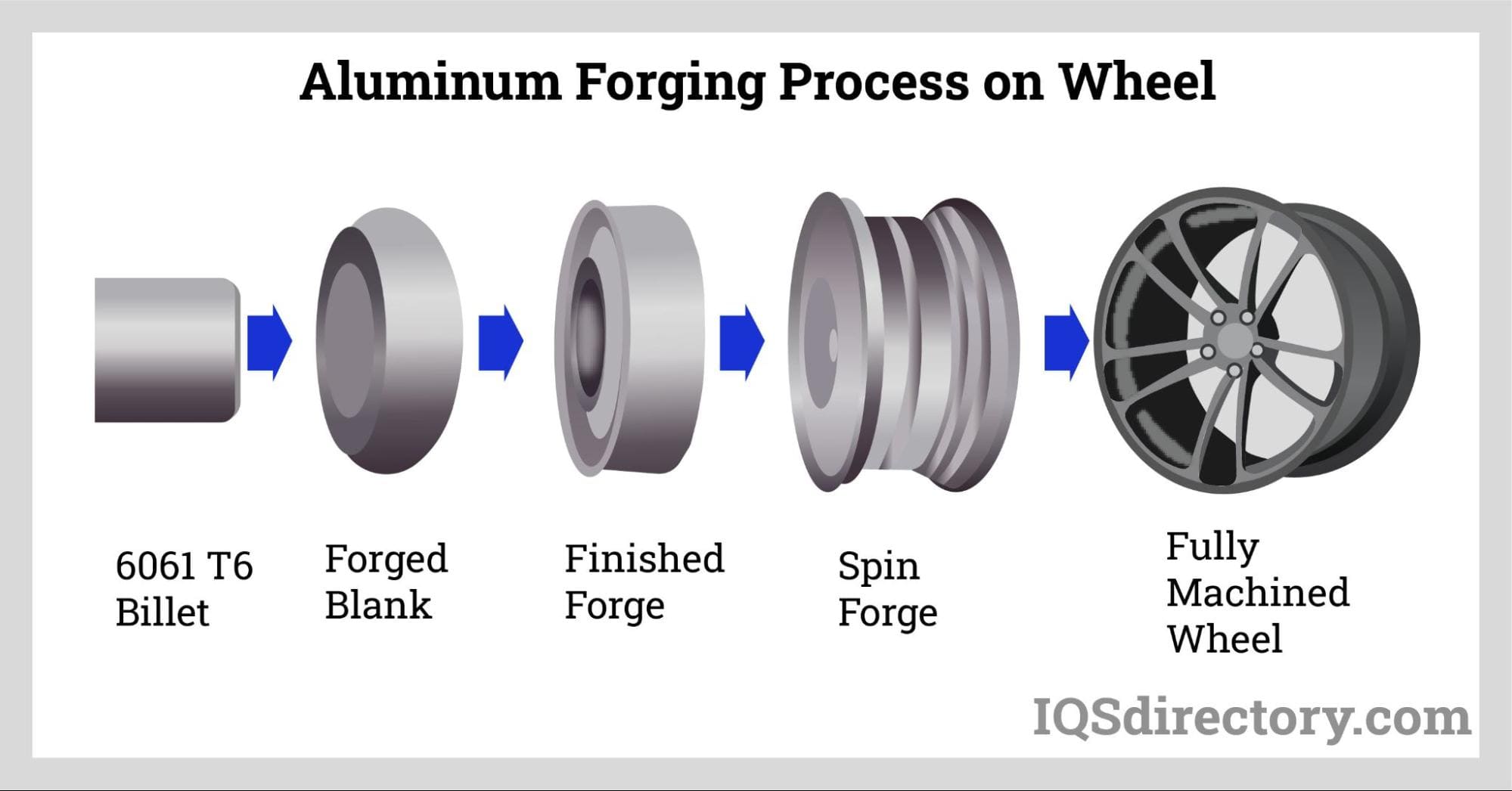

What Are the Key Properties of 6061 Aluminum Alloy for Forging?

6061 aluminum alloy is one of the most widely used materials in the forging industry. It boasts excellent mechanical properties, including good corrosion resistance, weldability, and medium to high strength. This alloy performs well at temperatures up to 200°C (392°F) and exhibits good machinability.

Pros: Its versatility makes it suitable for various applications, including automotive parts, marine components, and structural applications. The alloy’s ability to be heat-treated enhances its strength.

Illustrative image related to what is forged aluminum

Cons: While 6061 is durable, it is not as strong as some other aluminum alloys, such as 7075. Its cost can also be higher compared to lower-grade alloys.

Impact on Application: 6061 is compatible with various media, including water and mild chemicals, making it ideal for marine and automotive applications.

Considerations for International Buyers: Compliance with ASTM standards is vital, especially for buyers in Europe and the Middle East. Buyers should also ensure that suppliers can provide certifications to meet local regulations.

What Are the Key Properties of 7075 Aluminum Alloy for Forging?

7075 aluminum alloy is known for its high strength-to-weight ratio, making it an excellent choice for applications requiring maximum durability. This alloy can withstand higher temperatures, with a performance threshold of up to 300°C (572°F), and offers good resistance to stress corrosion.

Pros: Its strength makes it suitable for aerospace components, military applications, and high-stress structural components. The alloy also has excellent fatigue resistance.

Illustrative image related to what is forged aluminum

Cons: 7075 is more expensive than 6061 and can be challenging to weld due to its high zinc content. Additionally, it has lower corrosion resistance compared to other aluminum alloys.

Impact on Application: This alloy is ideal for applications that require lightweight yet strong materials, such as aircraft frames and high-performance automotive parts.

Considerations for International Buyers: Buyers must be aware of compliance with military and aerospace standards, particularly in Europe and the Middle East. Certifications for quality assurance are crucial.

What Are the Key Properties of 2024 Aluminum Alloy for Forging?

2024 aluminum alloy is another high-strength material often used in aerospace applications. It has excellent fatigue resistance and can perform well at elevated temperatures, with a maximum service temperature of around 200°C (392°F).

Pros: Its high strength makes it suitable for critical structural applications, including aircraft skins and fuselage components. The alloy also has good machinability.

Cons: 2024 has lower corrosion resistance, requiring protective coatings in many applications. It is also more expensive than lower-strength alloys.

Impact on Application: The alloy’s high strength makes it ideal for applications where weight savings are critical, but it may not be suitable for environments with high corrosion potential.

Illustrative image related to what is forged aluminum

Considerations for International Buyers: Compliance with aerospace standards such as ASTM and JIS is essential for buyers in the aerospace sector. Buyers should also consider the availability of protective coatings.

What Are the Key Properties of 7050 Aluminum Alloy for Forging?

7050 aluminum alloy is designed for high-strength applications and offers excellent resistance to stress corrosion cracking. It can withstand temperatures up to 200°C (392°F) and is known for its toughness.

Pros: This alloy is suitable for aerospace and military applications, providing a good balance of strength and weight. Its corrosion resistance is superior to that of 7075.

Cons: 7050 is more expensive than other aluminum alloys and can be difficult to machine due to its high strength.

Impact on Application: The alloy is ideal for parts subjected to high stress, such as aircraft components, where failure is not an option.

Considerations for International Buyers: Buyers should ensure compliance with international aerospace standards and consider the need for specialized machining capabilities.

Summary Table of Forged Aluminum Materials

| Material | Typical Use Case for what is forged aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum Alloy | Automotive and marine components | Good corrosion resistance and weldability | Lower strength compared to other alloys | Medium |

| 7075 Aluminum Alloy | Aerospace and military applications | High strength-to-weight ratio | More expensive and difficult to weld | High |

| 2024 Aluminum Alloy | Aircraft skins and fuselage components | Excellent fatigue resistance | Lower corrosion resistance | High |

| 7050 Aluminum Alloy | High-stress aerospace components | Superior toughness and corrosion resistance | High cost and machining difficulty | High |

This strategic material selection guide provides a comprehensive overview of the key properties and considerations for various forged aluminum alloys, helping B2B buyers make informed decisions based on their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for what is forged aluminum

What Are the Key Stages in the Manufacturing Process of Forged Aluminum?

The manufacturing process of forged aluminum involves several critical stages that ensure the material’s integrity and performance. The main stages are material preparation, forming, assembly, and finishing.

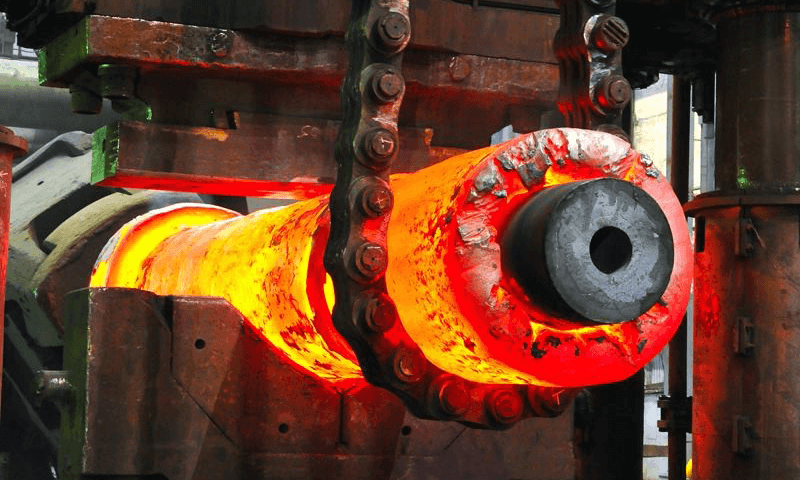

Material Preparation

The first step in the manufacturing process is the preparation of aluminum ingots or billets. High-quality raw materials are essential, as the properties of the final product depend significantly on the quality of the starting material. Manufacturers typically begin by heating the aluminum to a specific temperature, making it malleable and easier to work with. The ingots are then cut into manageable sizes, ensuring they are appropriate for the desired forging process.

Forming Techniques

Once the material is prepared, the forming stage begins. This can involve various techniques, including:

-

Hot Forging: The aluminum is heated above its recrystallization temperature, allowing for significant deformation. This process improves the material’s strength and ductility.

-

Cold Forging: Conducted at or near room temperature, this technique increases the material’s yield strength and hardness through strain hardening. It is less common for aluminum but can be used for specific applications.

-

Impact Forging: This method uses rapid blows to deform the aluminum, which can help in achieving intricate shapes while enhancing the material’s properties.

Each technique has its advantages and is chosen based on the specific requirements of the final product.

Assembly and Finishing Processes

After forging, the components may require assembly, especially if they are part of a larger assembly. Common assembly processes include welding, riveting, or bolting, depending on the design requirements.

The finishing stage involves processes such as machining, heat treatment, and surface treatment. Machining is used to achieve precise dimensions and surface finishes, while heat treatment can enhance mechanical properties. Surface treatments, like anodizing or painting, improve corrosion resistance and aesthetics.

What Quality Assurance Measures Are Essential for Forged Aluminum?

Quality assurance (QA) is crucial in ensuring that forged aluminum products meet international standards and customer expectations. The following outlines relevant international standards, quality control checkpoints, common testing methods, and best practices for B2B buyers in various regions.

Illustrative image related to what is forged aluminum

Relevant International Standards

Manufacturers of forged aluminum must comply with several international standards, including:

-

ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality and customer satisfaction.

-

CE Marking: Particularly relevant in Europe, this certification indicates that the product meets EU safety, health, and environmental protection standards.

-

API Standards: For suppliers in the oil and gas industry, adhering to American Petroleum Institute (API) standards ensures that products meet industry-specific quality requirements.

Quality Control Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials upon arrival. Ensuring the materials meet specified standards is critical for the integrity of the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. This includes checking temperature, pressure, and deformation rates to ensure that the forging process adheres to established parameters.

-

Final Quality Control (FQC): Once the products are completed, they undergo rigorous testing for dimensional accuracy, mechanical properties, and surface finish.

Common Testing Methods for Forged Aluminum

Several testing methods are commonly employed to verify the quality of forged aluminum:

-

Tensile Testing: This assesses the material’s strength and ductility by measuring how much it elongates under tension.

-

Hardness Testing: Techniques like Rockwell or Brinell hardness tests determine the material’s resistance to deformation.

-

Non-Destructive Testing (NDT): Methods such as ultrasonic testing or radiographic inspection help identify internal defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure reliability and performance. Here are some actionable steps:

Conduct Audits

Regular audits of suppliers can help verify their compliance with international standards and internal QA processes. An audit should assess everything from material sourcing to manufacturing practices and final product inspections.

Request Documentation and Reports

Buyers should ask for detailed quality control reports, including IQC, IPQC, and FQC data. This documentation should outline inspection results, testing methods used, and any corrective actions taken for non-conforming products.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and quality assurance measures. This can be particularly beneficial for international transactions, where direct oversight may be challenging.

Illustrative image related to what is forged aluminum

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of several nuances related to quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding material standards and safety. Understanding these regulations is crucial for ensuring compliance.

-

Cultural Differences: Communication styles and business practices can differ significantly across regions. Establishing clear expectations and maintaining open lines of communication can help bridge these gaps.

-

Supply Chain Considerations: Factors such as logistics, lead times, and geopolitical issues can affect quality assurance processes. Buyers should consider these elements when selecting suppliers to mitigate potential risks.

In conclusion, understanding the manufacturing processes and quality assurance measures for forged aluminum is vital for B2B buyers. By focusing on material preparation, forming techniques, and stringent quality control measures, businesses can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is forged aluminum’

When sourcing forged aluminum, it’s essential for B2B buyers to have a structured approach. This guide offers a step-by-step checklist to help you navigate the procurement process efficiently, ensuring you select the right materials for your applications.

Step 1: Define Your Technical Specifications

Before starting the sourcing process, clearly outline your technical requirements for forged aluminum. This includes dimensions, tolerances, and specific alloy compositions that meet your application needs. A well-defined specification helps suppliers understand your needs and reduces the risk of receiving substandard materials.

- Consider application requirements: Different industries may have unique demands, such as weight constraints or resistance to corrosion.

- Identify performance criteria: Include factors like strength, ductility, and fatigue resistance that are critical for your use case.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers of forged aluminum. Look for companies with a strong reputation in the industry and experience in your specific application.

- Check industry certifications: Ensure suppliers have relevant certifications, such as ISO 9001, which indicates quality management practices.

- Review case studies: Analyze their previous work to determine if they have successfully delivered similar projects.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of shortlisted suppliers to ensure they can meet your production requirements. This includes evaluating their forging techniques, machinery, and quality control processes.

- Inspect production methods: Understand the types of forging processes they utilize, such as open-die or closed-die forging, and how these impact the final product.

- Analyze quality assurance practices: Look for suppliers that implement rigorous testing and inspection protocols to ensure product integrity.

Step 4: Request Samples and Prototypes

Before placing a large order, request samples or prototypes of the forged aluminum components. This allows you to evaluate the quality and suitability of the materials for your specific needs.

- Assess physical properties: Examine factors like surface finish, dimensional accuracy, and mechanical properties.

- Conduct performance testing: If applicable, test the samples under real-world conditions to ensure they meet your performance criteria.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds necessary certifications and adheres to industry standards. This verification is crucial for maintaining quality and compliance in your supply chain.

- Request documentation: Ask for copies of certifications and quality management system documentation.

- Check for compliance: Ensure they comply with international standards relevant to your industry, especially if operating in regulated markets.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to finalize terms, pricing, and delivery schedules. This step is essential for establishing a mutually beneficial partnership.

- Discuss bulk pricing: Inquire about pricing tiers based on order volume and payment terms.

- Clarify delivery timelines: Ensure that both parties agree on realistic timelines to avoid disruptions in your production schedule.

Step 7: Establish a Communication Plan

Set up a clear communication plan to facilitate ongoing dialogue with your supplier. This ensures that any issues can be addressed promptly and helps maintain a strong working relationship.

- Designate points of contact: Identify key personnel on both sides for effective communication.

- Schedule regular check-ins: Plan periodic updates to review project status and address any concerns proactively.

By following these steps, B2B buyers can confidently navigate the sourcing process for forged aluminum, ensuring they select the right materials and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for what is forged aluminum Sourcing

What are the Key Cost Components in Sourcing Forged Aluminum?

When sourcing forged aluminum, several cost components contribute to the overall price structure. Understanding these elements can help international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, make informed decisions.

Illustrative image related to what is forged aluminum

-

Materials: The primary cost driver in forged aluminum sourcing is the raw material itself. Aluminum alloy prices fluctuate based on global market conditions, availability, and quality. Buyers should consider the specific alloy requirements for their applications, as premium alloys may incur higher costs.

-

Labor: Labor costs vary significantly depending on the region and the complexity of the forging process. Skilled labor is essential for quality assurance in forging operations, and wages can differ based on local economic conditions. It’s crucial to assess whether the supplier employs skilled artisans or automated systems, as this impacts labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Suppliers with efficient production processes may offer lower overhead costs, which can be beneficial for buyers seeking competitive pricing.

-

Tooling: Forging often requires specialized tooling, which can represent a substantial upfront investment. The cost of molds, dies, and other equipment needs to be factored into the pricing. Buyers should inquire about tooling longevity and the potential for reusability to optimize this cost.

-

Quality Control (QC): Quality assurance processes, including testing and inspection, are vital in ensuring that the forged aluminum meets industry standards. These QC measures can add to the overall cost, but they are essential for preventing defects and ensuring product reliability.

-

Logistics: Transportation and handling costs are critical components, especially for international shipments. Factors such as shipping distance, mode of transport, and customs duties can significantly impact the final price. Buyers should evaluate logistics to ensure cost-effectiveness.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure business sustainability. Understanding the expected margin can help buyers negotiate better pricing.

What Factors Influence the Pricing of Forged Aluminum?

Several key influencers can affect the pricing of forged aluminum components:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to better pricing due to economies of scale. Buyers should negotiate MOQs with suppliers to achieve cost savings.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should balance their specific needs with the potential for cost-effective standard solutions.

-

Material Quality and Certifications: Premium materials with certifications (e.g., ISO, ASTM) tend to be priced higher. Buyers should assess the necessity of these certifications against their application requirements.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence costs. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for calculating total costs. Different shipping terms (e.g., FOB, CIF) can affect the overall pricing by shifting responsibility for shipping and insurance between buyer and seller.

What Tips Should Buyers Consider for Cost-Efficient Forged Aluminum Sourcing?

For international B2B buyers, particularly from developing regions, several strategies can enhance cost-efficiency in sourcing forged aluminum:

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Highlighting potential for larger orders or long-term partnerships can lead to favorable terms.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront price. This includes factoring in logistics, potential downtime due to quality issues, and maintenance costs associated with the components.

-

Pricing Nuances: Be aware of regional pricing variations and how currency fluctuations can impact costs. Buyers should also consider the political and economic stability of supplier countries, as these factors can affect pricing and supply continuity.

-

Supplier Diversification: Establish relationships with multiple suppliers to mitigate risks related to pricing and supply chain disruptions. This approach can also foster competitive pricing.

Disclaimer on Indicative Prices

Prices for forged aluminum can vary widely based on the factors mentioned above. Buyers are encouraged to obtain multiple quotes and conduct thorough market research to ensure they are getting competitive pricing aligned with their requirements.

Alternatives Analysis: Comparing what is forged aluminum With Other Solutions

Exploring Alternatives to Forged Aluminum: A Comparative Analysis

When evaluating material options for manufacturing components, B2B buyers often seek alternatives to forged aluminum. Understanding the distinctions between various methods can help businesses make informed decisions that align with their operational needs and project specifications. This section compares forged aluminum with cast aluminum and billet aluminum, two viable alternatives that serve similar purposes.

Illustrative image related to what is forged aluminum

Comparison Table

| Comparison Aspect | What Is Forged Aluminum | Cast Aluminum | Billet Aluminum |

|---|---|---|---|

| Performance | High strength, toughness, and durability due to refined microstructure | Good for complex shapes but lower mechanical properties | Offers good strength and machinability but less structural integrity than forged aluminum |

| Cost | Higher initial cost due to processing complexity | Generally lower cost due to simpler production | Moderate cost, dependent on machining processes |

| Ease of Implementation | Requires specialized tooling and equipment | Easier to implement with existing casting facilities | Requires CNC machining, adding complexity |

| Maintenance | Lower maintenance due to high durability | Moderate maintenance; can be prone to defects | Higher maintenance if precision is critical post-machining |

| Best Use Case | Aerospace, automotive, and applications where safety is paramount | Decorative items, housings, and less critical structural components | Components needing precise tolerances and custom shapes |

Detailed Breakdown of Alternatives

What Is Cast Aluminum?

Cast aluminum is produced by melting aluminum and pouring it into molds. This process allows manufacturers to create complex shapes economically. While cast aluminum excels in producing intricate designs with internal features, it often suffers from lower mechanical properties compared to forged aluminum. The potential for defects such as voids and inclusions can compromise its strength, making it less suitable for high-stress applications.

What Is Billet Aluminum?

Billet aluminum refers to solid aluminum bars or rods that can be further processed through methods like CNC machining. This material offers good machinability and can achieve precise dimensions, making it ideal for custom components. However, it typically does not match the strength and durability of forged aluminum. Billet aluminum is best suited for applications that require fine tolerances and where the cost of machining can be justified.

Conclusion: Choosing the Right Solution for Your Needs

In the decision-making process for selecting the right aluminum solution, B2B buyers should carefully assess their specific requirements. If maximum strength and reliability are paramount, forged aluminum is the best choice despite its higher cost and complexity. For projects that prioritize intricate designs and lower costs, cast aluminum may be more appropriate. Alternatively, if precision and custom machining are essential, billet aluminum could be the ideal solution. Ultimately, understanding the pros and cons of each option will enable buyers to align their material choices with their operational goals and project demands.

Essential Technical Properties and Trade Terminology for what is forged aluminum

What Are the Key Technical Properties of Forged Aluminum?

Forged aluminum is known for its superior mechanical properties and structural integrity, making it an ideal choice for demanding applications. Below are some critical specifications that B2B buyers should consider when evaluating forged aluminum products:

1. Material Grade

Material grades, such as 6061 or 7075, indicate the alloy composition and its corresponding mechanical properties. For instance, 6061 aluminum is known for its good weldability and corrosion resistance, while 7075 offers higher strength, making it preferable for aerospace applications. Selecting the right grade is crucial for ensuring that the forged part meets performance requirements in specific environments.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In forging, maintaining tight tolerances (often within ±0.005 inches) is essential for parts that require precise fit and function, such as in automotive or aerospace components. Understanding tolerance specifications helps buyers ensure that their products will perform reliably and reduce the need for costly rework.

3. Yield Strength

Yield strength measures the maximum stress that a material can withstand without permanent deformation. For forged aluminum, higher yield strength values indicate better performance under load. This is particularly important in industries where failure can result in catastrophic outcomes, making it vital for buyers to consider yield strength in their material selection.

4. Elongation Percentage

Elongation percentage indicates the ductility of the material, or how much it can stretch before breaking. Higher elongation percentages in forged aluminum signify better ductility, which is essential for applications requiring complex shapes or those subject to dynamic loading conditions. This property can influence the reliability and longevity of the forged components.

5. Hardness

Hardness is a measure of a material’s resistance to deformation. It is particularly relevant in applications where wear resistance is crucial, such as tooling and industrial equipment. The hardness of forged aluminum can be enhanced through heat treatment, allowing B2B buyers to specify the required hardness based on their application needs.

Illustrative image related to what is forged aluminum

What Are Common Trade Terms Used in Forged Aluminum?

Understanding industry jargon is essential for effective communication and negotiation in the B2B sector. Here are some commonly used terms in the forged aluminum market:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of forged aluminum, OEMs often specify stringent requirements for quality and performance, making it essential for suppliers to understand these specifications to meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the forged aluminum market, MOQs can vary significantly based on the complexity of the component and the manufacturing process. Understanding MOQs helps buyers plan their purchases effectively and manage inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This is crucial for B2B buyers looking to compare costs, lead times, and terms of service, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps B2B buyers navigate logistics and understand their liabilities, ensuring smoother transactions across international borders.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the forged aluminum industry, understanding lead times is essential for supply chain management and project planning, as delays can significantly impact production schedules.

6. Heat Treatment

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of a material. This is especially relevant for forged aluminum, where heat treatment can enhance strength and toughness. Buyers should be aware of different heat treatment processes to select materials that meet their specific performance requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing forged aluminum, ensuring that their products meet industry standards and performance requirements.

Illustrative image related to what is forged aluminum

Navigating Market Dynamics and Sourcing Trends in the what is forged aluminum Sector

What Are the Current Market Dynamics in the Forged Aluminum Sector?

The forged aluminum market is experiencing notable growth, driven by increasing demand across various industries, including automotive, aerospace, and construction. Key market drivers include the need for lightweight materials that enhance fuel efficiency and reduce emissions. Additionally, the rise in electric vehicle production is propelling the demand for high-strength, lightweight components, where forged aluminum excels due to its superior mechanical properties compared to cast aluminum.

Emerging B2B technology trends are reshaping sourcing strategies, with a shift towards automation and Industry 4.0 practices. Companies are leveraging data analytics and AI to optimize supply chains, improve quality control, and enhance product development timelines. This digital transformation is particularly beneficial for international buyers from regions like Africa and South America, where efficient sourcing can mitigate logistical challenges and reduce costs.

Market dynamics are also influenced by geopolitical factors, including trade regulations and tariffs, which can affect pricing and availability. Buyers must navigate these complexities, ensuring they establish reliable partnerships with suppliers who can deliver consistent quality and adhere to international standards. Establishing long-term relationships with local manufacturers in emerging markets can be advantageous, providing both cost savings and a more responsive supply chain.

How Is Sustainability and Ethical Sourcing Impacting the Forged Aluminum Market?

Sustainability has become a critical consideration for B2B buyers in the forged aluminum sector. The environmental impact of aluminum production, particularly in terms of energy consumption and greenhouse gas emissions, is prompting companies to seek out sustainable practices. Sourcing from suppliers that utilize renewable energy and efficient production methods is increasingly important.

Illustrative image related to what is forged aluminum

Ethical supply chains are gaining traction, with buyers prioritizing suppliers that adhere to fair labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management systems and the Aluminium Stewardship Initiative (ASI) certification are becoming essential criteria for selecting suppliers. These certifications assure buyers that their materials are sourced responsibly, aligning with corporate sustainability goals.

Moreover, the use of recycled aluminum in forging processes is a growing trend, significantly reducing the carbon footprint associated with raw material extraction. B2B buyers are encouraged to consider suppliers who incorporate recycled materials into their offerings, thereby enhancing their own sustainability credentials while supporting a circular economy.

What Is the Historical Context of Forged Aluminum in B2B Applications?

The history of forged aluminum dates back to the mid-20th century when advancements in metallurgy and manufacturing techniques began to unlock the material’s potential. Initially used primarily in aerospace applications due to its lightweight and strength properties, forged aluminum quickly gained traction in the automotive industry as manufacturers sought to improve vehicle efficiency.

Illustrative image related to what is forged aluminum

Over the decades, innovations in forging techniques, such as closed-die forging and precision forging, have expanded the capabilities and applications of forged aluminum. This evolution has enabled manufacturers to produce increasingly complex shapes while maintaining the integrity of the material. As a result, forged aluminum has become a cornerstone in high-performance applications, satisfying the growing demands for durability and safety in modern engineering.

In conclusion, understanding these dynamics, sustainability imperatives, and historical developments is crucial for international B2B buyers looking to navigate the forged aluminum sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of what is forged aluminum

-

How do I determine if forged aluminum is suitable for my application?

Assessing the suitability of forged aluminum involves understanding your application’s requirements. Consider factors such as the mechanical properties needed, the environmental conditions the components will face, and any weight restrictions. Forged aluminum typically offers enhanced strength, durability, and resistance to fatigue compared to cast aluminum, making it ideal for high-stress applications. Engage with suppliers to discuss your specifications and get material samples to evaluate performance under your specific conditions. -

What are the advantages of forged aluminum over other aluminum types?

Forged aluminum provides superior mechanical properties, including enhanced strength and toughness, due to its solid-state processing. Unlike cast aluminum, which can contain voids and impurities, forging refines the internal structure, improving overall integrity. This makes forged aluminum ideal for applications where reliability is critical, such as aerospace and automotive industries. Additionally, forged components often have a longer lifespan, reducing the total cost of ownership in the long term. -

What should I consider when sourcing forged aluminum suppliers internationally?

When sourcing suppliers, prioritize their experience in forging aluminum and their reputation in the industry. Check for certifications that indicate quality assurance standards, such as ISO certifications. Evaluate their production capabilities, lead times, and past client references. Consider logistical factors such as shipping costs, customs regulations, and delivery timelines to ensure a smooth procurement process. Establish clear communication channels to facilitate ongoing support and collaboration. -

What is the typical minimum order quantity (MOQ) for forged aluminum parts?

Minimum order quantities for forged aluminum can vary significantly based on the supplier and the complexity of the parts. Generally, MOQs can range from a few hundred to several thousand units. Discuss your specific needs with potential suppliers; many are willing to accommodate smaller orders for prototype runs or custom projects. However, be aware that lower MOQs may lead to higher per-unit costs due to setup and tooling expenses. -

How can I ensure quality assurance for forged aluminum components?

Quality assurance can be ensured by selecting suppliers who implement rigorous testing protocols throughout the manufacturing process. Look for suppliers that conduct non-destructive testing (NDT), mechanical property testing, and dimensional inspections. Request documentation of these tests, as well as certification of compliance with industry standards. Establish a quality agreement outlining your expectations for product performance and testing methods before commencing production. -

What payment terms are typically offered for international forged aluminum orders?

Payment terms can vary widely based on the supplier and the specifics of the order. Common arrangements include upfront deposits (often 30-50%) with the balance due upon delivery or before shipment. Some suppliers may offer letters of credit or payment against documents to ensure security for both parties. Discuss and negotiate terms upfront to avoid misunderstandings, and consider using escrow services for large transactions to protect your investment. -

What logistics considerations should I be aware of when importing forged aluminum?

Importing forged aluminum requires careful planning regarding shipping methods, customs clearance, and compliance with local regulations. Be aware of tariffs, import duties, and the documentation required for international shipping, including bills of lading and certificates of origin. Collaborate with logistics partners experienced in handling aluminum products to streamline the process. Ensure that the supplier provides adequate packaging to prevent damage during transit. -

Can I customize forged aluminum parts for my specific needs?

Yes, many suppliers offer customization options for forged aluminum parts, including specific dimensions, shapes, and surface finishes. When discussing your requirements, provide detailed specifications and any relevant design drawings. Collaborate with the supplier’s engineering team to optimize the design for manufacturing. Customization may involve longer lead times and additional costs, so it’s advisable to plan ahead and discuss potential impacts on pricing and timelines.

Top 7 What Is Forged Aluminum Manufacturers & Suppliers List

1. QC Forge – Forged vs. Cast Aluminum

Domain: qcforge.com

Registered: 1995 (30 years)

Introduction: Forged Aluminum vs. Cast Aluminum: The key differences include the manufacturing processes where forging involves solid-state deformation without melting the material, while casting involves melting metal and pouring it into molds. Cast aluminum allows for complex shapes and internal features but risks contamination and defects like voids and inconsistent properties. Forged aluminum benefits from …

2. Wayken RM – Billet and Cast Aluminum Solutions

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Billet Aluminum: Produced through extrusion or roll forging; uniform grain structure; high density; requires further processing (e.g., CNC machining); advantages include precision and customization, tensile strength and structural integrity, better heat dissipation.

Cast Aluminum: Produced through metal casting; less dense; prone to gas porosity; advantages include cost-effectiveness for mass pr…

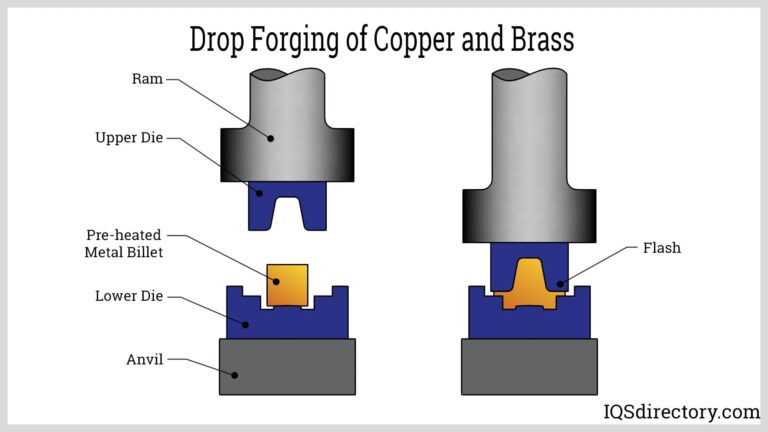

3. IQS Directory – Aluminum Forging Techniques

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Aluminum forging is a method to process aluminum alloys by applying pressure and heat to create strong and durable parts. Key types of aluminum forging include hot forging and cold forging, with advanced techniques such as drop forging, press forging, upset forging, roll forging, rolled ring forging, isothermal forging, open die forging, and closed die forging. Aluminum alloys like 6061, 7075, and…

4. LinkedIn – Aluminum Process Comparison

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: The article discusses the differences between die cast, press, and forged aluminum processes. Key details include:

1. **Aluminum Advantages**: Lightweight, stable, impact resistant, strong, fully recyclable, vapor impermeable, UV resistant, hygienic, excellent heat conductor, and energy-efficient.

2. **Die Cast Aluminum Process**: Involves pouring molten aluminum alloy into steel molds. The al…

5. JC Forged Wheels – Aftermarket Wheel Types

Domain: jcforgedwheels.com

Registered: 2022 (3 years)

Introduction: The text discusses three types of aftermarket wheels: cast wheels, rotary formed wheels, and forged wheels.

1. **Cast Wheels**:

– Most common type, accounting for 90% of OE wheels.

– Made by pouring molten aluminum into a mold using gravity or low-pressure casting.

– Gravity casting is cost-effective but results in heavier wheels due to porosity.

– Low-pressure casting offers den…

6. Reddit – Forged vs. Cast Aluminum Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cast aluminum has non-uniform microstructures due to the casting process, while forged aluminum has a more uniform microstructure due to recrystallization during forging. Forging typically results in refined grain size, leading to increased yield strength and fatigue life compared to cast aluminum. Cast parts may achieve similar yield strength to forged parts, but their ultimate tensile strength (…

7. VMT CNC – Cast Aluminum Solutions

Domain: vmtcnc.com

Registered: 2019 (6 years)

Introduction: Cast Aluminum:

– Process: Melting aluminum or aluminum alloy ingots, pouring into molds, cooling to form parts.

– Properties: Good fluidity, shrinkage during solidification, high air tightness.

– Advantages: Low cost (suitable for mass production), good corrosion resistance (enhanced by surface treatments), lightweight (reduces overall weight and improves energy efficiency).

Forged Aluminum: …

Strategic Sourcing Conclusion and Outlook for what is forged aluminum

Forged aluminum stands out in the competitive landscape of materials due to its superior mechanical properties and resilience. Key takeaways for international B2B buyers include the understanding that while forging may involve higher upfront costs compared to casting, the long-term benefits—such as enhanced durability, reduced maintenance, and lower failure rates—make it a wise investment for critical applications. This is particularly important in industries where safety and reliability are paramount, such as aerospace, automotive, and heavy machinery.

Illustrative image related to what is forged aluminum

Strategic sourcing of forged aluminum is essential for optimizing supply chain efficiency and ensuring access to high-quality materials that meet specific project requirements. By partnering with trusted suppliers who specialize in forged products, businesses can leverage their expertise to achieve better pricing, timely delivery, and custom solutions tailored to their needs.

Looking ahead, the demand for forged aluminum is expected to grow as industries increasingly prioritize sustainability and performance. Buyers from Africa, South America, the Middle East, and Europe should act now to secure reliable sources and capitalize on this trend. Engage with experts in the field to explore opportunities that will enhance your product offerings and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is forged aluminum

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.