Is Your Wall Transformer Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for wall transformer

In an increasingly interconnected world, sourcing reliable wall transformers poses significant challenges for B2B buyers across various global markets. Ensuring compatibility with local voltage standards, understanding diverse applications, and navigating the complexities of supplier vetting are just a few hurdles that can complicate the purchasing process. This comprehensive guide serves as a vital resource for international buyers from regions such as Africa, South America, the Middle East, and Europe—specifically targeting countries like Vietnam and Germany.

Within these pages, we delve into the diverse types of wall transformers available, from encapsulated non-ventilated units to specialized isolation transformers. Each section is designed to illuminate their specific applications, enabling buyers to make informed decisions tailored to their operational needs. Additionally, we offer insights into supplier vetting processes, ensuring that you partner with trustworthy manufacturers and distributors.

Cost considerations are also a key focus, with detailed pricing structures and potential tariffs highlighted to help you navigate the financial aspects of your purchase. By equipping you with this knowledge, this guide empowers you to make confident, strategic decisions when sourcing wall transformers, ultimately enhancing your business’s efficiency and reliability in an ever-evolving market landscape.

Understanding wall transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Encapsulated Non-Ventilated | Sealed design prevents dust and moisture ingress | Industrial machinery, HVAC systems | Pros: Low maintenance, durable. Cons: Limited cooling, may require higher initial investment. |

| Encapsulated Isolation | Provides electrical isolation for safety | Medical equipment, sensitive electronics | Pros: Enhanced safety, reduces noise. Cons: Higher cost, larger footprint. |

| Buck-Boost Transformers | Adjusts voltage levels up or down | Lighting systems, motor control | Pros: Versatile voltage management. Cons: Complexity in installation, potential for overheating. |

| Dry Type Distribution | No liquid insulation, safer in various environments | Commercial buildings, schools | Pros: Environmentally friendly, maintenance-free. Cons: Lower efficiency at high loads. |

| Safety Isolating Transformers | Protects sensitive equipment from surges and faults | Telecommunications, data centers | Pros: Protects against electrical hazards. Cons: Typically higher price point, may require specialized installation. |

What Are the Characteristics of Encapsulated Non-Ventilated Transformers?

Encapsulated non-ventilated transformers are designed for environments where dust and moisture can pose risks to electrical components. Their sealed casing provides protection, making them suitable for industrial machinery and HVAC systems. Buyers should consider the initial investment versus long-term maintenance costs, as these transformers require minimal upkeep while providing reliable performance.

How Do Encapsulated Isolation Transformers Ensure Safety?

Encapsulated isolation transformers are engineered to provide electrical isolation, which is crucial for applications involving sensitive equipment like medical devices and precision electronics. They mitigate electrical noise and enhance safety by reducing the risk of electric shock. Buyers must weigh the advantages of increased safety against the typically higher costs and larger footprint of these transformers.

In What Scenarios Are Buck-Boost Transformers Most Effective?

Buck-boost transformers are unique in their ability to adjust voltage levels, making them particularly effective for applications such as lighting systems and motor control. They are ideal for businesses that experience fluctuating voltage levels, as they can stabilize power supply. However, buyers should be aware of the complexity involved in installation and the potential for overheating if not properly managed.

Why Choose Dry Type Distribution Transformers?

Dry type distribution transformers are notable for their lack of liquid insulation, making them safer for various environments, including commercial buildings and schools. They are environmentally friendly and require little maintenance, appealing to businesses concerned about sustainability. However, they may exhibit lower efficiency when operating at high loads, which is a consideration for buyers focused on performance.

What Benefits Do Safety Isolating Transformers Provide?

Safety isolating transformers are critical for protecting sensitive equipment from electrical surges and faults, making them a staple in telecommunications and data centers. Their design minimizes electrical hazards, providing peace of mind for businesses relying on sensitive technology. While they offer significant safety benefits, buyers should be prepared for a higher price point and the possibility of needing specialized installation services.

Key Industrial Applications of wall transformer

| Industry/Sector | Specific Application of wall transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering CNC machines and automation systems | Ensures stable power supply, enhancing operational efficiency | Voltage compatibility, power rating, and thermal management |

| Telecommunications | Supporting telecom equipment and data centers | Provides reliable power for continuous operation | Size, weight, and electromagnetic interference (EMI) shielding |

| Healthcare | Supplying power to medical imaging devices | Vital for patient safety and equipment reliability | Compliance with safety standards and certifications |

| Hospitality | Powering HVAC systems and lighting in hotels | Enhances guest comfort and energy efficiency | Energy efficiency ratings and scalability |

| Construction | Providing power to tools and equipment on job sites | Ensures operational continuity and worker safety | Portability, ruggedness, and environmental resistance |

How are Wall Transformers Used in Manufacturing?

In the manufacturing sector, wall transformers are integral to powering CNC machines and automation systems. These transformers convert high-voltage electricity to lower voltages suitable for sensitive equipment. This ensures a stable power supply, reducing the risk of downtime due to power fluctuations. For international buyers, particularly in regions like Africa and South America, sourcing transformers that meet local voltage requirements and thermal management standards is crucial for operational efficiency.

What Role Do Wall Transformers Play in Telecommunications?

Wall transformers are essential in telecommunications for powering equipment in data centers and telecom facilities. They provide a reliable power source, ensuring continuous operation of critical systems. Businesses benefit from enhanced uptime and reduced maintenance costs. Buyers should consider factors such as size, weight, and electromagnetic interference (EMI) shielding when sourcing these transformers, especially in regions with stringent regulatory requirements, like Europe and the Middle East.

Why are Wall Transformers Important in Healthcare?

In the healthcare sector, wall transformers supply power to vital medical imaging devices such as MRI and CT scanners. The reliability of these transformers is crucial for patient safety and the consistent performance of medical equipment. Buyers must ensure that the transformers comply with safety standards and certifications, particularly in markets like Germany, where regulatory compliance is paramount. This guarantees not only operational efficiency but also adherence to health and safety regulations.

How Do Wall Transformers Benefit the Hospitality Industry?

In the hospitality industry, wall transformers power HVAC systems and lighting in hotels, significantly enhancing guest comfort. A reliable power supply leads to improved energy efficiency and lower operational costs. When sourcing transformers for hospitality applications, businesses should prioritize energy efficiency ratings and scalability, ensuring that the units can accommodate future growth and changes in energy consumption patterns.

What is the Role of Wall Transformers in Construction?

Wall transformers are increasingly used in construction to provide power to tools and equipment on job sites. They ensure operational continuity and worker safety by delivering a stable power supply. For international buyers, key considerations include portability, ruggedness, and environmental resistance, especially in challenging job site conditions. This ensures that the transformers can withstand the rigors of construction environments while maintaining performance reliability.

3 Common User Pain Points for ‘wall transformer’ & Their Solutions

Scenario 1: Voltage Compatibility Issues in Diverse Markets

The Problem: Many B2B buyers, especially those operating in regions like Africa and South America, face challenges when dealing with voltage compatibility. They often find that the wall transformers available do not align with the local voltage standards. This misalignment can lead to equipment malfunction, increased operational costs, and safety hazards, ultimately affecting business operations and customer satisfaction.

The Solution: To address voltage compatibility issues, it’s crucial for buyers to conduct thorough research on local voltage standards before procurement. When sourcing wall transformers, opt for manufacturers that provide a wide range of primary and secondary voltage options. This can include transformers that cater to both 50Hz and 60Hz frequency requirements. Buyers should also consider products with adjustable voltage settings or models designed specifically for buck-boost applications. Engaging with suppliers who offer detailed specifications and technical support can further ensure that the selected transformers meet local requirements, minimizing operational risks and enhancing reliability.

Scenario 2: Inefficient Space Utilization in Facilities

The Problem: In many commercial and industrial settings, space is at a premium. B2B buyers often struggle with bulky transformer units that occupy valuable floor space, making it difficult to optimize their facility layout. This issue is particularly pronounced in urban areas or smaller operations where maximizing every square meter is essential for efficiency and productivity.

The Solution: To combat space inefficiencies, buyers should explore wall-mounted transformers designed for compact installations. These units can be installed directly on walls, freeing up floor space for other essential equipment or storage. When selecting a wall transformer, look for encapsulated designs that reduce the need for additional ventilation and can withstand varying environmental conditions. Additionally, consider consulting with manufacturers about custom solutions tailored to specific spatial constraints, ensuring that the transformer not only fits the physical space but also integrates seamlessly with existing systems.

Scenario 3: Lack of Technical Support and Guidance

The Problem: B2B buyers often find themselves overwhelmed by the technical specifications and installation requirements of wall transformers. The complexity of electrical systems, coupled with insufficient technical support from suppliers, can lead to misapplications or improper installations. This can result in costly downtime, safety violations, and equipment failures, creating frustration for buyers who are trying to ensure operational continuity.

The Solution: To mitigate these challenges, buyers should prioritize partnerships with suppliers who offer comprehensive technical support throughout the purchasing and installation process. Look for vendors that provide in-depth product documentation, installation guides, and ongoing customer service. Additionally, investing in training sessions or workshops offered by manufacturers can equip technical staff with the necessary skills to handle installation and maintenance effectively. By fostering a collaborative relationship with suppliers, buyers can ensure that they receive not only the right product but also the expertise needed to optimize its performance, ultimately contributing to smoother operations and long-term success.

Strategic Material Selection Guide for wall transformer

What are the Common Materials Used in Wall Transformers?

When selecting materials for wall transformers, several options are commonly utilized, each with distinct properties that affect performance, durability, and application suitability. Below, we analyze four prevalent materials: silicon steel, copper, aluminum, and plastic.

How Does Silicon Steel Perform in Wall Transformers?

Silicon steel is widely used in the core of wall transformers due to its excellent magnetic properties. It has a high permeability, which enhances the efficiency of the transformer by reducing energy losses during operation. Silicon steel can withstand high temperatures and has good mechanical strength, making it suitable for various industrial applications.

Pros: The primary advantage of silicon steel is its magnetic efficiency, which leads to lower operational costs. Additionally, it is relatively durable and can handle high-temperature environments.

Cons: However, silicon steel is more expensive than other materials, and its manufacturing process can be complex, requiring precise control of the silicon content to maintain performance standards.

Impact on Application: Silicon steel is compatible with high-frequency applications, making it ideal for transformers used in electronic devices and industrial machinery.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local standards for electrical components, as silicon steel must comply with ASTM and ISO standards to ensure safety and performance.

What Role Does Copper Play in Wall Transformers?

Copper is another critical material used in wall transformers, particularly for windings. Its high electrical conductivity ensures minimal energy loss, which is essential for efficient transformer operation. Copper also has excellent thermal conductivity, allowing for effective heat dissipation.

Pros: The primary advantage of copper is its superior conductivity, which enhances the efficiency of the transformer. It is also highly durable and resistant to corrosion.

Cons: On the downside, copper is relatively expensive compared to aluminum and can be subject to price volatility in international markets. Additionally, its weight can be a disadvantage in applications where weight reduction is crucial.

Impact on Application: Copper is particularly suitable for applications requiring high efficiency and reliability, such as in renewable energy systems and high-performance electrical devices.

Considerations for International Buyers: Buyers should consider the implications of copper’s price fluctuations and ensure compliance with international standards, such as DIN and JIS, particularly in European markets.

Why is Aluminum Considered for Wall Transformers?

Aluminum is often chosen as an alternative to copper for windings due to its lower cost and lighter weight. While it has lower conductivity than copper, advancements in alloy technology have improved its performance significantly.

Pros: The key advantages of aluminum include its cost-effectiveness and reduced weight, which can be beneficial in applications where weight is a critical factor.

Illustrative image related to wall transformer

Cons: However, aluminum has a lower conductivity, which can lead to higher energy losses compared to copper. Additionally, it is more susceptible to corrosion, which may require protective coatings in certain environments.

Impact on Application: Aluminum is suitable for applications where cost is a primary concern, such as in budget-sensitive projects or in regions with lower material costs.

Considerations for International Buyers: Buyers should be aware of the need for proper corrosion protection and compliance with standards, especially in humid climates prevalent in parts of Africa and the Middle East.

How is Plastic Used in Wall Transformers?

Plastic materials, particularly thermoplastics, are often used for insulation and casing in wall transformers. They provide excellent electrical insulation and can be molded into various shapes for specific applications.

Illustrative image related to wall transformer

Pros: The main advantages of plastic include its lightweight nature, corrosion resistance, and flexibility in design. It is also generally less expensive than metals.

Cons: However, plastics may not withstand high temperatures as effectively as metals, which can limit their use in high-power applications. Additionally, they may degrade over time when exposed to certain environmental conditions.

Impact on Application: Plastic is ideal for low-power transformers or applications where weight and corrosion resistance are more critical than high thermal performance.

Considerations for International Buyers: Buyers should ensure that the plastics used meet international safety and environmental standards, particularly in regions with stringent regulations.

Summary Table of Material Properties for Wall Transformers

| Material | Typical Use Case for wall transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Transformer cores | High magnetic efficiency | High cost, complex manufacturing | High |

| Copper | Windings | Superior conductivity | Expensive, weight | High |

| Aluminum | Windings | Cost-effective, lightweight | Lower conductivity, corrosion prone | Medium |

| Plastic | Insulation and casing | Lightweight, corrosion resistant | Limited thermal resistance | Low |

This guide provides essential insights for B2B buyers, enabling informed decisions on material selection for wall transformers based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for wall transformer

What Are the Key Stages in the Manufacturing Process of Wall Transformers?

The manufacturing process of wall transformers involves several critical stages that ensure the final product meets the necessary performance and safety standards. Each stage is designed to optimize efficiency, minimize waste, and ensure the quality of the end product.

1. Material Preparation

The first step in manufacturing wall transformers is material preparation. This involves sourcing high-quality raw materials, such as copper for windings, silicon steel for cores, and insulation materials. Suppliers should ensure that these materials meet international standards such as RoHS (Restriction of Hazardous Substances) to guarantee safety and environmental compliance.

Once the materials are sourced, they undergo inspection and testing to confirm their specifications. This initial quality check is crucial in preventing defects in the final product, as poor material quality can lead to failures in performance and safety.

2. Forming and Core Assembly

After material preparation, the next stage is forming and core assembly. This involves the following key processes:

Illustrative image related to wall transformer

-

Winding: Copper wire is wound around the magnetic core to create the primary and secondary coils. This can be done using automated winding machines that ensure precision and consistency.

-

Core Lamination: The core is constructed using laminated sheets of silicon steel to reduce energy losses due to eddy currents. This step is essential for enhancing efficiency, especially in high-power transformers.

-

Assembly: The assembled core and windings are then placed into a housing, which is often encapsulated to provide protection from environmental factors. This process may involve techniques such as potting or encapsulation to ensure durability and reliability.

3. Finishing Processes

Finishing processes include applying coatings and insulation to protect the transformer from moisture, dust, and other contaminants. These processes can also involve:

-

Painting: A protective layer of paint is often applied to the exterior for aesthetic purposes and additional corrosion resistance.

-

Testing and Calibration: After assembly, transformers undergo electrical testing to ensure they operate within specified parameters. This may include applying voltage tests and measuring output currents to verify performance.

How Is Quality Assurance Implemented in Wall Transformer Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for wall transformers. It encompasses various standards and checkpoints to ensure that products meet both regulatory and customer expectations.

International and Industry-Specific Standards

Manufacturers of wall transformers often adhere to several international and industry-specific standards to ensure product quality and safety. Key standards include:

-

ISO 9001: This is a globally recognized quality management standard that outlines a framework for consistent quality assurance. Compliance demonstrates a commitment to quality and customer satisfaction.

-

CE Marking: In Europe, CE marking indicates that the transformer meets essential safety requirements outlined in relevant directives, such as the Low Voltage Directive (LVD).

-

API Standards: For transformers used in specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards may be required.

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and address potential issues. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials and components meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): This involves ongoing inspections during the manufacturing process to detect any deviations from quality standards. Techniques such as statistical process control (SPC) may be utilized to monitor processes in real-time.

-

Final Quality Control (FQC): The final checkpoint occurs after assembly and testing, where the entire product is evaluated against quality standards before shipment. This may include rigorous electrical testing and visual inspections.

What Testing Methods Are Commonly Used for Wall Transformers?

Testing is a crucial aspect of ensuring the reliability and safety of wall transformers. Manufacturers typically employ several testing methods, including:

-

Electrical Testing: This includes insulation resistance tests, power factor testing, and load testing to verify that the transformer performs as expected under operational conditions.

-

Thermal Imaging: This method allows manufacturers to identify potential hot spots in the transformer that could indicate issues such as inadequate cooling or component failure.

-

Vibration Testing: For transformers intended for use in dynamic environments, vibration testing ensures that the product can withstand mechanical stresses without compromising functionality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must ensure that their suppliers maintain robust quality control processes. Here are several methods to verify supplier QC:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. These audits should assess compliance with international standards and the effectiveness of their quality control measures.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the testing methods used and the results obtained. This transparency is crucial for establishing trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct tests and provide certifications that validate the supplier’s claims.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various nuances in quality control and certification to ensure compliance with local regulations and standards. Key considerations include:

-

Regulatory Compliance: Understanding the specific regulations in target markets is essential. For example, products sold in Europe must comply with CE marking requirements, while those in the United States may need to meet UL standards.

-

Cultural and Regional Differences: Different regions may have varying expectations regarding quality and safety. B2B buyers should be aware of these differences to effectively communicate their requirements to suppliers.

-

Documentation and Traceability: Maintaining thorough documentation of quality control processes and certifications is vital. This not only facilitates compliance but also aids in resolving any potential disputes that may arise regarding product quality.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting wall transformer suppliers, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wall transformer’

Introduction

Navigating the procurement of wall transformers can be complex, particularly for international B2B buyers. This guide offers a structured checklist to help you make informed purchasing decisions. By following these steps, you can ensure that you select the right transformer to meet your operational needs while also optimizing your supply chain.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider parameters such as voltage requirements, power ratings, and frequency compatibility.

– Voltage Requirements: Identify the primary and secondary voltage levels that are compatible with your existing systems.

– Power Ratings: Determine the necessary kVA rating based on your load requirements to prevent underperformance or overload.

Step 2: Research Compliance Standards

Understanding the relevant compliance standards is crucial for ensuring safety and performance. Different regions have specific regulations that your wall transformers must meet.

– RoHS Compliance: Ensure the products comply with the Restriction of Hazardous Substances directive, particularly if you are operating in the European market.

– Local Regulations: Investigate any additional local standards that may apply in your target market, such as IEC or UL certifications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Experience: Look for suppliers with a proven track record in manufacturing wall transformers for your specific application.

– Quality Assurance: Assess their quality control processes to ensure consistent product quality.

Step 4: Request Detailed Quotations

Obtaining detailed quotations is essential for comparing options effectively. Ensure that each quotation includes comprehensive information about the product specifications, pricing, and terms.

– Breakdown of Costs: Look for a clear breakdown of costs, including shipping, tariffs, and any applicable taxes.

– Lead Times: Confirm lead times for production and shipping to avoid delays in your project timelines.

Step 5: Review Warranty and After-Sales Support

A robust warranty and reliable after-sales support can save you significant costs in the long run.

– Warranty Terms: Ensure you understand the warranty terms, including duration and coverage for parts and labor.

– Technical Support: Verify the availability of technical support for installation and troubleshooting, especially if your team lacks expertise.

Step 6: Assess Payment and Shipping Options

Understanding payment terms and shipping options is vital for cash flow management and logistics planning.

– Payment Terms: Negotiate favorable payment terms that align with your budget and cash flow.

– Shipping Methods: Choose reliable shipping methods that can accommodate your timelines while ensuring the safe delivery of products.

Step 7: Conduct a Final Review and Approval

Before finalizing the purchase, conduct a comprehensive review of all gathered information.

– Cross-Check Specifications: Ensure all specifications match your original requirements.

– Stakeholder Approval: Obtain necessary approvals from stakeholders in your organization to facilitate a smooth purchasing process.

By following this checklist, you can streamline your procurement process for wall transformers, ensuring that you select the right products from reliable suppliers while adhering to compliance and budgetary constraints.

Comprehensive Cost and Pricing Analysis for wall transformer Sourcing

What Are the Key Cost Components in Wall Transformer Sourcing?

When sourcing wall transformers, understanding the cost structure is vital for B2B buyers aiming for cost-efficiency. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to wall transformer

- Materials: The quality and type of materials used significantly impact the cost. For instance, encapsulated non-ventilated transformers often utilize high-grade insulation materials, which can increase prices.

- Labor: Labor costs vary based on the region and complexity of manufacturing. Countries with lower labor costs may offer competitive pricing, but this can affect quality.

- Manufacturing Overhead: This includes expenses related to the operation of production facilities, such as utilities and equipment maintenance. Efficient production processes can reduce these overheads, leading to lower prices for buyers.

- Tooling: Initial setup costs for specialized tooling can be substantial, particularly for custom transformers. These costs are usually amortized over large production runs, making larger orders more economical.

- Quality Control: Ensuring compliance with industry standards and certifications can add to the cost. Buyers should consider suppliers with robust QC processes to avoid future expenses related to product failures.

- Logistics: Shipping and handling costs can vary greatly, especially for international orders. Understanding Incoterms can help buyers manage these costs effectively.

- Margin: Supplier margins can vary based on market conditions and competition. Buyers should evaluate different suppliers to find the best balance between price and quality.

What Influences Pricing for Wall Transformers?

Several factors influence pricing in wall transformer sourcing, including volume or minimum order quantity (MOQ), specifications and customization, materials, quality certifications, supplier characteristics, and Incoterms.

- Volume/MOQ: Larger orders often attract better pricing due to economies of scale. Suppliers may offer tiered pricing structures where the unit cost decreases with higher quantities.

- Specifications and Customization: Custom designs or specific voltage requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected charges.

- Materials: The choice of materials, particularly for high-performance or specialized transformers, can lead to significant price fluctuations. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

- Quality and Certifications: Transformers that meet international standards and certifications typically command higher prices. However, investing in certified products can lead to lower maintenance costs and enhanced reliability.

- Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with proven track records may charge more but offer better warranties and support.

- Incoterms: Understanding Incoterms is crucial for international buyers. Different terms can shift responsibilities and costs, impacting the overall price.

What Negotiation Strategies Can Enhance Cost-Efficiency for Buyers?

B2B buyers can employ several strategies to negotiate better pricing and improve cost-efficiency in wall transformer sourcing.

- Leverage Volume Discounts: If your business anticipates recurring needs, negotiating for bulk purchasing can lead to significant savings. Establishing a long-term relationship with suppliers can also yield better pricing and terms.

- Assess Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the upfront price but the TCO, which includes installation, maintenance, and operational costs. A slightly higher initial cost may lead to lower long-term expenses.

- Be Informed About Market Conditions: Awareness of current market trends, material costs, and supply chain issues can provide leverage during negotiations. This knowledge enables buyers to make informed decisions and justify their pricing expectations.

- Request Samples: Before committing to large orders, request samples to evaluate the quality and suitability of the transformers. This practice can help avoid costly mistakes associated with poor-quality products.

- Explore Alternative Suppliers: Diversifying your supplier base can enhance competition and lead to better pricing. However, ensure that any new supplier meets your quality and service standards.

Conclusion

Sourcing wall transformers involves navigating a complex landscape of costs and pricing factors. By understanding these components and employing strategic negotiation tactics, B2B buyers can optimize their purchasing decisions, ensuring quality and cost-effectiveness in their operations. Keep in mind that prices can vary widely based on the factors discussed, and it’s essential to approach sourcing with a comprehensive understanding of your needs and the market.

Alternatives Analysis: Comparing wall transformer With Other Solutions

Introduction to Alternative Solutions for Power Transformation

In the landscape of electrical systems, wall transformers play a critical role in converting voltage levels to meet various operational requirements. However, several alternative solutions exist that can also achieve similar objectives. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and specific application needs.

Comparison Table

| Comparison Aspect | Wall Transformer | Buck-Boost Transformer | Variable Frequency Drive (VFD) |

|---|---|---|---|

| Performance | Reliable voltage conversion; handles multiple voltages | Efficient for adjusting voltage levels; best for fluctuating loads | Controls motor speed and torque; ideal for variable loads |

| Cost | Moderate upfront cost; varies with capacity | Generally lower cost; economical for specific applications | Higher initial investment; offers long-term savings through energy efficiency |

| Ease of Implementation | Simple installation; requires basic electrical knowledge | Straightforward setup; minimal adjustments needed | Complex installation; may require specialized knowledge |

| Maintenance | Low maintenance; periodic inspections recommended | Low maintenance; robust design | Moderate maintenance; requires regular monitoring and software updates |

| Best Use Case | General-purpose voltage conversion in commercial settings | Adjusting voltage in applications with fluctuating loads | Applications requiring precise motor control and energy efficiency |

Detailed Breakdown of Alternatives

Buck-Boost Transformer

Buck-boost transformers are specifically designed to adjust voltage levels within a circuit. They are highly efficient and cost-effective for applications where voltage fluctuations occur frequently. Their simplicity in installation makes them a popular choice for smaller operations or projects with limited budgets. However, they are not as versatile as wall transformers, which can handle a broader range of voltage conversions.

Variable Frequency Drive (VFD)

Variable Frequency Drives are advanced devices that control the speed and torque of electric motors by varying the frequency and voltage of the power supplied to them. VFDs are particularly beneficial in applications that require adjustable speeds, such as HVAC systems or conveyor belts. While they offer significant energy savings and enhanced control, VFDs come with a higher initial investment and more complex installation requirements compared to wall transformers. Additionally, they may require ongoing maintenance to ensure optimal performance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a power transformation solution, B2B buyers should consider specific operational needs, budget constraints, and long-term goals. Wall transformers provide reliable voltage conversion across various applications, while alternatives like buck-boost transformers and variable frequency drives offer specialized benefits. By evaluating the performance, cost, and implementation ease of each option, buyers can make informed decisions that align with their operational requirements and financial plans. Ultimately, the right choice will depend on the specific application context, highlighting the importance of thorough analysis and understanding of each solution’s advantages and limitations.

Essential Technical Properties and Trade Terminology for wall transformer

What Are the Key Technical Specifications of Wall Transformers?

Understanding the essential technical specifications of wall transformers is crucial for B2B buyers, as these properties directly impact the performance, reliability, and compatibility of the transformers in various applications. Below are some critical specifications to consider:

Illustrative image related to wall transformer

-

Power Rating (kVA)

This specification indicates the transformer’s capacity to handle electrical power, measured in kilovolt-amperes (kVA). It is essential for determining whether a transformer can support the electrical load of specific equipment. A higher power rating means the transformer can manage greater loads, making it vital for industries with high energy demands. -

Primary and Secondary Voltages

These values define the input and output voltage levels of the transformer. For example, a transformer may have a primary voltage of 240V and a secondary voltage of 120V. Buyers must match these voltage specifications with their electrical systems to ensure proper functionality and prevent equipment damage. -

Frequency Range (Hz)

The frequency range, typically expressed in hertz (Hz), indicates the operational frequency of the transformer. Common frequencies include 50Hz and 60Hz. Selecting a transformer with the correct frequency is crucial for ensuring compatibility with the local electrical grid and avoiding operational issues. -

Type of Cooling

Transformers can be ventilated or non-ventilated. Non-ventilated transformers are designed for quieter operations and are typically used in indoor applications where noise levels need to be minimized. Understanding the cooling type helps buyers choose transformers suited to their operational environments. -

Compliance Standards (RoHS, SVHC)

Compliance with regulations such as RoHS (Restriction of Hazardous Substances) ensures that the transformer is manufactured without harmful substances. For buyers, this is particularly important in regions with strict environmental regulations, ensuring that products meet legal requirements and promote sustainability. -

Isolation Type

Transformers can be categorized into isolation types, such as encapsulated isolation transformers. These are designed to provide electrical isolation between the input and output, enhancing safety and reducing the risk of electrical shock. This specification is vital for applications requiring high safety standards.

What Are Common Trade Terms in the Wall Transformer Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common trade terms related to wall transformers:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that manufactures products that are used as components in another company’s product. In the context of wall transformers, OEMs provide specialized transformers that meet specific requirements for various industries, allowing buyers to ensure compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage their inventory and budget effectively. It also affects the negotiation process, as larger orders may lead to lower per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ for wall transformers allows them to compare offerings from multiple vendors, ensuring they make informed purchasing decisions. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding Incoterms is critical for B2B buyers to manage risks and costs associated with international shipments. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. For buyers, understanding lead times for wall transformers is essential for project planning and ensuring that equipment is available when needed. -

Warranty Period

This specification indicates the duration for which the manufacturer guarantees the performance and reliability of the transformer. A longer warranty period can provide buyers with peace of mind, knowing they are covered in case of defects or failures.

By grasping these technical properties and trade terminology, B2B buyers can make more informed decisions when sourcing wall transformers, ensuring that they select the right products for their applications and navigate the complexities of international procurement effectively.

Navigating Market Dynamics and Sourcing Trends in the wall transformer Sector

What Are the Current Market Dynamics and Key Trends Influencing the Wall Transformer Sector?

The wall transformer market is witnessing significant growth, driven by the increasing demand for energy-efficient power solutions across various industries. Key global drivers include the rapid expansion of renewable energy sources and the rising need for reliable power supply in emerging markets, particularly in Africa, South America, the Middle East, and Europe. These regions are investing heavily in infrastructure development, creating a robust demand for wall transformers that can cater to diverse voltage requirements and power ratings.

Emerging B2B technology trends are reshaping the sourcing landscape. For instance, manufacturers are increasingly adopting smart technology, integrating IoT capabilities into transformers to enable real-time monitoring and predictive maintenance. This trend not only enhances operational efficiency but also reduces downtime, which is critical for businesses that rely on continuous power supply. Furthermore, the push for sustainability is prompting buyers to seek products with higher energy efficiency ratings, compelling suppliers to innovate and produce more environmentally friendly options.

Market dynamics are also influenced by fluctuating raw material prices and geopolitical factors. Buyers must stay abreast of these fluctuations, as they can impact pricing structures and availability. Strategic sourcing partnerships, especially with manufacturers that offer competitive pricing and reliable lead times, are essential for securing a consistent supply chain. For international B2B buyers, understanding local regulations and compliance requirements is crucial, as these can vary significantly across regions such as Vietnam and Germany.

How Is Sustainability and Ethical Sourcing Shaping the Wall Transformer Industry?

Sustainability is no longer a mere trend but a fundamental aspect of business strategy, particularly in the wall transformer sector. As industries strive to reduce their carbon footprints, the focus on environmentally friendly materials and processes has intensified. Manufacturers are increasingly adopting eco-design principles, which consider the environmental impact of transformers throughout their lifecycle, from production to disposal.

Ethical sourcing is also gaining traction among B2B buyers. Companies are now prioritizing suppliers that demonstrate a commitment to social responsibility, ensuring that their products are manufactured under fair labor conditions and with minimal environmental impact. Certifications such as RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management) are becoming essential credentials for suppliers, as they provide assurance that products meet stringent environmental standards.

The emphasis on ‘green’ certifications is particularly relevant for wall transformers. Buyers are encouraged to evaluate products that utilize recyclable materials or innovative designs that minimize energy loss. By selecting transformers that align with sustainability goals, companies not only contribute to environmental conservation but also enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

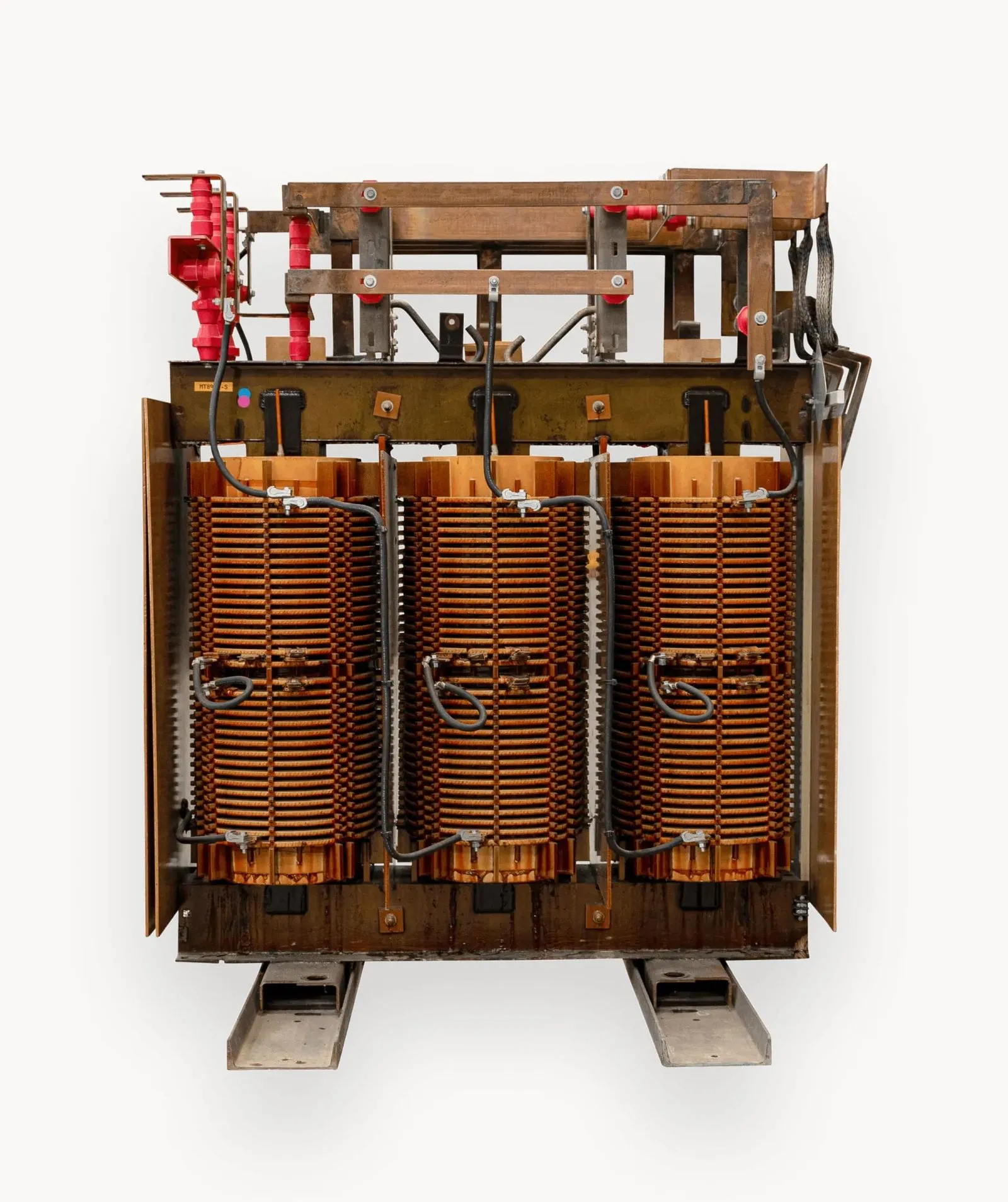

What Is the Historical Context of Wall Transformers in the B2B Marketplace?

The evolution of wall transformers traces back to the early 20th century, when electrical systems began to standardize. Initially, these devices were essential for converting high-voltage electricity from power lines to usable levels for residential and commercial applications. Over the decades, advancements in technology have led to significant improvements in efficiency, reliability, and safety standards.

Illustrative image related to wall transformer

The introduction of encapsulated designs and enhanced thermal management solutions marked a pivotal point in the development of wall transformers. These innovations have allowed for more compact and versatile installations, catering to the diverse needs of modern businesses. As industries continue to evolve, wall transformers have adapted, integrating smarter technologies and sustainability practices that resonate with the current B2B landscape. This historical context underscores the importance of innovation in meeting the growing demands of international markets, particularly in developing regions where reliable power is critical.

Frequently Asked Questions (FAQs) for B2B Buyers of wall transformer

-

How do I choose the right wall transformer for my application?

When selecting a wall transformer, consider the primary and secondary voltage requirements of your devices, the power rating (kVA or VA), and the frequency (50Hz or 60Hz). Evaluate the environment where the transformer will be installed—ventilated or non-ventilated options are available. Additionally, assess any specific regulatory compliance needs, such as RoHS certification. If customization is required, communicate your specifications to suppliers early in the process. -

What is the best wall transformer for industrial applications?

For industrial applications, encapsulated wall transformers with higher power ratings (5 kVA and above) are often recommended due to their durability and ability to handle increased loads. Brands like Hammond Power Solutions and Square D offer robust options with multiple primary and secondary voltage configurations. Ensure the transformer you choose can handle the specific environmental conditions of your facility, such as temperature variations or humidity levels. -

What are the typical minimum order quantities (MOQs) for wall transformers?

MOQs can vary significantly by supplier and product type. Generally, for wall transformers, MOQs might range from 1 to several units, depending on the manufacturer and the customization required. Large manufacturers may offer lower MOQs, while specialized suppliers could require larger orders to justify production runs. Always confirm MOQs with your supplier before finalizing your order to avoid unexpected costs. -

How can I vet suppliers when sourcing wall transformers internationally?

To vet international suppliers, start by checking their certifications, such as ISO compliance and RoHS certifications. Look for customer reviews and testimonials, and request references from previous clients. Conduct a factory audit if possible, or utilize third-party inspection services to ensure quality control. Additionally, consider suppliers who are members of industry associations, which can be a sign of reliability. -

What payment terms should I expect when purchasing wall transformers?

Payment terms will vary by supplier and region, but common practices include partial upfront payments (e.g., 30-50%) with the balance due upon delivery or after inspection. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always negotiate terms that fit your financial capabilities and ensure clarity in the contract to avoid misunderstandings. -

Are there customization options available for wall transformers?

Yes, many manufacturers offer customization options for wall transformers. This can include modifications to voltage ratings, power capacity, and form factors to suit specific applications. When discussing customization with suppliers, provide detailed specifications and requirements. Be aware that customized products may have longer lead times and higher costs, so plan accordingly. -

What quality assurance measures should I look for in wall transformers?

Quality assurance measures may include compliance with international standards such as IEC or UL certifications. Request documentation that confirms testing and quality control processes, including insulation resistance tests and thermal performance evaluations. Suppliers should provide data sheets with detailed specifications and testing results to ensure the product meets your requirements. -

How do logistics and shipping impact the procurement of wall transformers?

Logistics and shipping can significantly affect the overall cost and delivery timeline of wall transformers. Consider factors such as shipping methods (air vs. sea), customs duties, and local regulations that may impact import procedures. Collaborate with your supplier to understand their shipping policies and timelines, and factor in potential delays when planning your project. Establishing a reliable logistics partner can also help streamline the process and reduce risks.

Top 8 Wall Transformer Manufacturers & Suppliers List

1. Hillrom – Welch Allyn Green Series 777 Wall Transformer

Domain: hillrom.com

Registered: 1997 (28 years)

Introduction: The Welch Allyn Green Series 777 Wall Transformer powers your physical exam tools. It features a wall-mounted otoscope.

2. Square D – Buck-Boost

Domain: newark.com

Registered: 1994 (31 years)

Introduction: {“total_products”: 291, “manufacturers”: [“Square D By Schneider Electric”, “Hammond Power Solutions”, “Solahd”, “Eaton Tripp Lite”, “Schneider Electric”, “Acme Electric”], “types”: [“Buck-Boost”, “Encapsulated Buck-Boost”, “Encapsulated Dry Type Distribution”, “Encapsulated Industrial Control”, “Encapsulated Isolation”, “Encapsulated Non-Ventilated”], “primary_voltages”: [“120 X 240V”, “120V”, “1…

3. Squishy Circuits – Power Adapter

Domain: squishycircuits.com

Registered: 2011 (14 years)

Introduction: This company, Squishy Circuits – Power Adapter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Redding Medical – Green Series Wall Transformers

Domain: reddingmedical.com

Registered: 1997 (28 years)

Introduction: The Green Series Wall Transformers are designed for medical diagnostic use, featuring a compact design for easy installation. They provide reliable power for various medical devices and are compliant with safety standards. The transformers are equipped with multiple output options and are energy-efficient, contributing to lower operational costs. Additionally, they offer advanced features such as …

5. McKesson – Multi-Function Wall Transformers

Domain: mms.mckesson.com

Registered: 1994 (31 years)

Introduction: Multi-Function Wall Transformers from McKesson include various models such as Integrated Wall Systems featuring LED Coaxial Ophthalmoscopes, LED MacroView™ Basic Otoscopes, BP Aneroid, Specula Dispensers, Thermometers, and Transformers. Models include McKesson Brand #156-4L, #156-4PM3, #156-4PM2, and #156-3L. These products are designed for use in clinical settings and are available for order thro…

6. Medline – Wall Transformer Sets GS-777

Domain: medline.com

Registered: 1998 (27 years)

Introduction: Wall Transformer Sets, Model: GS-777, Product Code: Z05-PF44019

7. Light-O-Rama – 12 Volt Wall Transformer

Domain: store.lightorama.com

Registered: 2002 (23 years)

Introduction: {“name”:”12 Volt Wall Transformer”,”sku”:”Transformer-12V”,”price”:”$9.95″,”description”:”This transformer can power a variety of Light-O-Rama devices including the DC-MP3 director card, Gen4 Mini Director, N2-G4-MP3, N4-G4-MP3, Pixielink or iDMX-1000. It can supply constant power and/or add an external timer. The transformer package includes multiple plug adapters for various voltages and locatio…

8. Jameco – AC-to-AC Wall Transformers

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: AC-to-AC Wall Transformers available at Jameco Electronics. Features include well-regulated, user-adjustable designs, low-noise power supplies, and a variety of sizes and configurations. Jameco offers a 30-day return policy and a 90-day general warranty. Jameco has over 50 years of experience and carries over 70,000 electronic components.

Strategic Sourcing Conclusion and Outlook for wall transformer

What Are the Key Takeaways for Sourcing Wall Transformers?

In the dynamic landscape of wall transformer procurement, strategic sourcing emerges as a pivotal approach for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Engaging with reputable manufacturers like Schneider Electric and Hammond Power Solutions ensures access to high-quality products that meet regional voltage and frequency requirements. Buyers should prioritize compliance with RoHS standards and consider encapsulated designs for enhanced safety and durability.

How Can Buyers Enhance Their Sourcing Strategy?

Investing in a comprehensive sourcing strategy not only mitigates risks associated with supply chain disruptions but also leverages bulk purchasing opportunities for cost savings. By cultivating relationships with suppliers and staying informed about market trends, businesses can enhance their operational efficiency and ensure they remain competitive in their respective industries.

What Does the Future Hold for Wall Transformer Sourcing?

Looking ahead, the demand for wall transformers is expected to grow as industries increasingly prioritize energy efficiency and safety in electrical installations. B2B buyers should remain proactive in exploring innovative solutions and technologies that align with sustainable practices. Now is the time to engage suppliers, assess your current needs, and position your organization for success in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.