Is Your Vertical Conveyor Belt Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for vertical conveyor belt

In the fast-paced world of manufacturing and logistics, sourcing the right vertical conveyor belt can significantly enhance operational efficiency and product handling. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Germany—the challenge lies not just in identifying suitable products but in navigating a complex landscape of suppliers, applications, and costs. This guide aims to demystify the vertical conveyor belt market by providing a comprehensive overview of various types of conveyor systems, their specific applications across industries, and essential criteria for vetting suppliers.

We will explore the diverse configurations of vertical conveyors, from bucket elevators to belt systems, and their roles in optimizing material handling processes. Additionally, we will address the critical factors affecting costs, including installation, maintenance, and operational efficiency, ensuring that you can make informed purchasing decisions. By leveraging this guide, B2B buyers will be equipped with actionable insights to streamline their sourcing process, enhance productivity, and ultimately improve their bottom line. Whether you are looking to elevate your operational capabilities or expand your product offerings, understanding the nuances of vertical conveyor belts is key to your success in today’s global market.

Understanding vertical conveyor belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Conveyors | Continuous belt system for smooth transport | Manufacturing, Warehousing, Food Processing | Pros: Versatile, efficient; Cons: Limited incline angles |

| Bucket Elevators | Vertical lifting with buckets for bulk materials | Agriculture, Mining, Food Production | Pros: High capacity; Cons: Requires more space |

| Vibratory Conveyors | Uses vibration for movement of bulk materials | Recycling, Mining, Food Processing | Pros: Gentle handling; Cons: Limited to specific materials |

| Positive Drive Conveyors | Self-tracking belts with minimal product waste | Food Processing, Packaging | Pros: Sanitary, efficient; Cons: Higher initial cost |

| Screw Conveyors | Spiral design for moving granular and semi-solid materials | Agriculture, Chemical Processing | Pros: Compact; Cons: Potential for material degradation |

What Are the Characteristics of Belt Conveyors and Their Suitability for B2B Applications?

Belt conveyors are one of the most widely recognized types of vertical conveyor systems, characterized by their continuous belt that facilitates the smooth transport of goods. They are suitable for various applications, including manufacturing, warehousing, and food processing, where efficient movement of products is essential. When considering belt conveyors, buyers should evaluate the incline angles, load capacity, and the types of materials being transported to ensure optimal integration into their operations.

How Do Bucket Elevators Operate and What Are Their Key B2B Applications?

Bucket elevators are designed to lift bulk materials vertically using a series of attached buckets. Commonly used in agriculture, mining, and food production, they excel in handling granular or powdered materials. Buyers should consider the height requirements, bucket design, and material compatibility when purchasing bucket elevators, as these factors can significantly influence performance and efficiency in their specific applications.

Why Choose Vibratory Conveyors for Specific Material Handling Needs?

Vibratory conveyors utilize vibration to move bulk materials gently across their surface. This type of conveyor is particularly effective in recycling, mining, and food processing industries, where delicate handling of materials is crucial. Buyers should assess the types of materials they intend to transport and the required throughput rates, as vibratory conveyors may not be suitable for all material types due to their specific operational characteristics.

What Makes Positive Drive Conveyors a Preferred Choice in Food Processing?

Positive drive conveyors are known for their self-tracking belts that minimize product waste and ensure consistent flow, making them ideal for food processing and packaging applications. Their sanitary design and efficient operation make them a popular choice among B2B buyers, particularly in sectors where cleanliness and product integrity are paramount. Buyers should consider the initial investment and the potential for long-term savings due to reduced waste and maintenance needs.

In What Scenarios Are Screw Conveyors Most Effective for B2B Buyers?

Screw conveyors feature a spiral design that effectively transports granular and semi-solid materials. They are commonly used in agriculture and chemical processing industries. Their compact design makes them suitable for operations with limited space. When evaluating screw conveyors, buyers should consider factors such as material flow characteristics, potential for degradation, and maintenance requirements to ensure they choose the right solution for their specific needs.

Key Industrial Applications of vertical conveyor belt

| Industry/Sector | Specific Application of Vertical Conveyor Belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Elevating sticky products like dough or meat for processing | Minimizes waste and optimizes space utilization | Sanitary design, easy maintenance, and product integrity |

| Mining | Transporting mined materials vertically in confined spaces | Increases efficiency and reduces operational costs | Durability, load capacity, and resistance to harsh conditions |

| Pharmaceuticals | Vertical transport of bulk drugs in production lines | Ensures product integrity and reduces contamination | Compliance with health regulations and cleanroom standards |

| Manufacturing | Moving components between different production levels | Streamlines operations and reduces manual handling | Customization options and integration with existing systems |

| Agriculture | Elevating bulk grains or fertilizers for processing | Enhances productivity and reduces handling time | Capacity for bulk handling and resistance to environmental factors |

How is Vertical Conveyor Belt Used in Food Processing?

In the food processing industry, vertical conveyor belts are essential for elevating sticky products like dough, peanut butter, or meat during production. These systems minimize product waste, ensuring that even viscous materials are efficiently transported without spillage. For international buyers, particularly in regions like the Middle East and Africa, it’s crucial to consider the sanitary design of these conveyors, which should facilitate easy cleaning and maintenance to comply with food safety standards.

What Role Does Vertical Conveyor Belt Play in Mining?

In mining applications, vertical conveyor belts are employed to transport mined materials vertically, especially in confined spaces where horizontal movement is limited. This technology enhances operational efficiency by reducing the need for extensive horizontal transportation systems, ultimately lowering operational costs. Buyers in regions like South America and Europe should prioritize sourcing durable conveyor systems that can withstand harsh environmental conditions and heavy loads.

How is Vertical Conveyor Belt Critical in Pharmaceuticals?

In the pharmaceutical sector, vertical conveyor belts are utilized to transport bulk drugs throughout production lines, ensuring product integrity and minimizing contamination risks. These systems are designed to meet stringent health regulations, making it essential for buyers to prioritize compliance with cleanroom standards. Buyers from Europe and the Middle East should focus on sourcing conveyors that offer precision and reliability to maintain the high quality of pharmaceutical products.

Why is Vertical Conveyor Belt Important in Manufacturing?

Vertical conveyor belts streamline operations in manufacturing by moving components between different production levels, significantly reducing manual handling and improving overall efficiency. This application is vital for international buyers looking to enhance their production lines, particularly in the automotive and electronics sectors. When sourcing these systems, consider customization options that allow integration with existing machinery and processes for optimal workflow.

How Does Vertical Conveyor Belt Benefit Agriculture?

In agriculture, vertical conveyor belts are used for elevating bulk grains or fertilizers during processing. This application enhances productivity by reducing handling time and ensuring efficient transportation of materials. Buyers, especially in regions like Africa where agriculture is a key industry, should seek out conveyors that can handle large volumes while being resistant to environmental factors such as moisture and dust.

3 Common User Pain Points for ‘vertical conveyor belt’ & Their Solutions

Scenario 1: Limited Space in Manufacturing Facilities

The Problem: Many manufacturers face the challenge of optimizing space in their facilities, particularly in areas where horizontal movement is limited. Vertical conveyor belts can be a great solution, but often they are not utilized effectively due to concerns about installation and operational efficiency. Buyers may worry about how to integrate these systems into existing workflows without causing disruptions or requiring extensive redesigns of their facility layouts.

The Solution: To address this issue, it’s crucial to conduct a thorough assessment of your facility’s layout and workflow before purchasing a vertical conveyor belt. Engage with experienced suppliers who can provide customized solutions that fit your specific space constraints. Look for models that offer a compact design and can be integrated seamlessly into your existing operations. Ensure that the supplier provides installation support and training for your team, as this will help facilitate a smoother transition and minimize downtime. Additionally, consider adjustable models that can accommodate various product sizes and weights, providing the flexibility needed for different operational demands.

Scenario 2: Product Damage During Transport

The Problem: In industries such as food processing or pharmaceuticals, maintaining product integrity during transportation is critical. Vertical conveyors can sometimes lead to product damage due to abrupt movements or improper handling of materials. B2B buyers in these sectors often express concerns about how to prevent waste and ensure that their products arrive at their destination in perfect condition.

The Solution: To mitigate the risk of product damage, it’s essential to select a vertical conveyor belt designed with gentle handling features. Look for systems that include positive drive mechanisms, which ensure stable and consistent product movement. Furthermore, consider conveyor belts equipped with adjustable speed settings, allowing you to customize the pace based on the type of product being transported. This adaptability can significantly reduce the risk of jostling or dropping items. Regular maintenance and monitoring of the conveyor system are also vital; establish a routine to check for wear and tear, and ensure that all components are functioning correctly. Partnering with a supplier that offers ongoing support and service can help maintain the integrity of your conveyor system and your products.

Scenario 3: Compliance with Sanitation Standards

The Problem: For businesses in the food and pharmaceutical industries, adhering to strict sanitation and hygiene regulations is non-negotiable. However, traditional conveyor systems can be difficult to clean and maintain, leading to potential compliance issues. B2B buyers often find themselves grappling with how to ensure their vertical conveyor systems meet regulatory standards while remaining efficient and operationally viable.

The Solution: When sourcing a vertical conveyor belt, prioritize systems specifically designed for easy sanitation. Look for models that feature an open-frame design, which allows for better access during cleaning. Ensure that the conveyor belt materials are compliant with food safety standards, such as FDA-approved materials that can withstand frequent washdowns. Additionally, choose systems that have tool-less belt adjustments and easy access points for cleaning, as this can save significant time and labor costs during maintenance. Regular training for staff on proper cleaning protocols can further enhance compliance and operational efficiency. Engaging with suppliers who understand the regulatory landscape can also provide valuable insights into best practices for maintaining sanitation standards in your operations.

Strategic Material Selection Guide for vertical conveyor belt

What Are the Key Materials Used for Vertical Conveyor Belts?

When selecting materials for vertical conveyor belts, it is essential to consider the specific properties and performance requirements of each option. This guide analyzes four common materials—rubber, PVC, metal, and polyurethane—highlighting their advantages, disadvantages, and implications for international B2B buyers.

How Does Rubber Perform in Vertical Conveyor Belt Applications?

Rubber is a widely used material for vertical conveyor belts due to its excellent flexibility and grip. It typically has a high-temperature rating, making it suitable for environments that experience variable temperatures. Rubber also exhibits good abrasion resistance, which is vital for applications involving heavy loads or rough materials.

Pros: Rubber belts are durable and can handle a wide range of materials, making them versatile. They are also cost-effective, which is attractive for companies looking to minimize operational costs.

Cons: However, rubber can degrade under certain chemical exposures and may not be suitable for high-pressure applications. Additionally, its manufacturing complexity can lead to longer lead times.

Impact on Application: Rubber belts are particularly effective for transporting bulk materials in industries like agriculture and mining, where durability and flexibility are paramount.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, especially in regions like Europe and the Middle East, where regulatory frameworks are stringent.

What Are the Benefits of Using PVC for Vertical Conveyor Belts?

Polyvinyl chloride (PVC) is another popular choice for vertical conveyor belts, especially in food processing and packaging industries. PVC belts are known for their chemical resistance and can handle a variety of media, including oils and fats.

Pros: PVC belts are lightweight and easy to install, which can reduce labor costs. They also offer good resistance to moisture and are available in various thicknesses to suit different applications.

Cons: On the downside, PVC belts may not perform well in extreme temperatures and can become brittle over time. Their lifespan may be shorter compared to rubber, particularly in high-stress environments.

Impact on Application: PVC is ideal for applications involving food products or other materials that require a clean and hygienic transport solution.

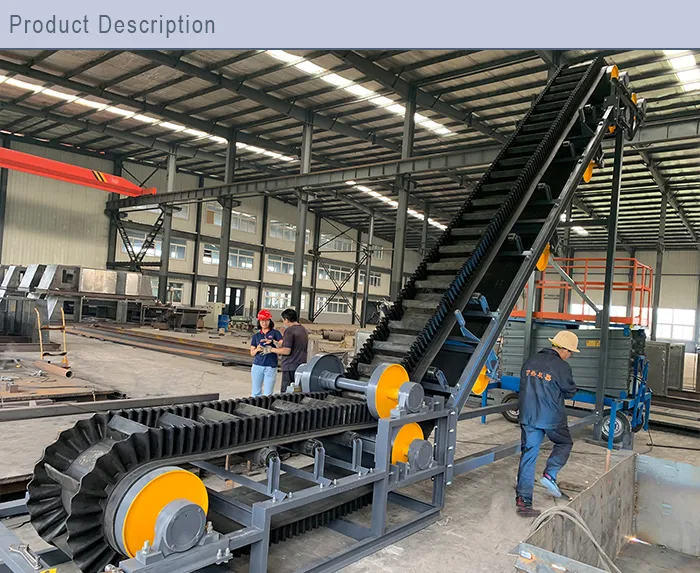

Illustrative image related to vertical conveyor belt

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EFSA, is crucial for buyers in the food industry. Buyers should also check for certifications that meet local regulations in their respective regions.

Why Choose Metal for Vertical Conveyor Belts?

Metal conveyor belts, often made from stainless steel or other alloys, are known for their strength and durability. They can withstand high temperatures and heavy loads, making them suitable for demanding industrial applications.

Pros: The primary advantage of metal belts is their longevity and resistance to wear and tear. They are also easy to clean, making them ideal for food processing and pharmaceutical applications.

Cons: However, metal belts can be more expensive than their rubber or PVC counterparts. They may also require more complex installation and maintenance procedures.

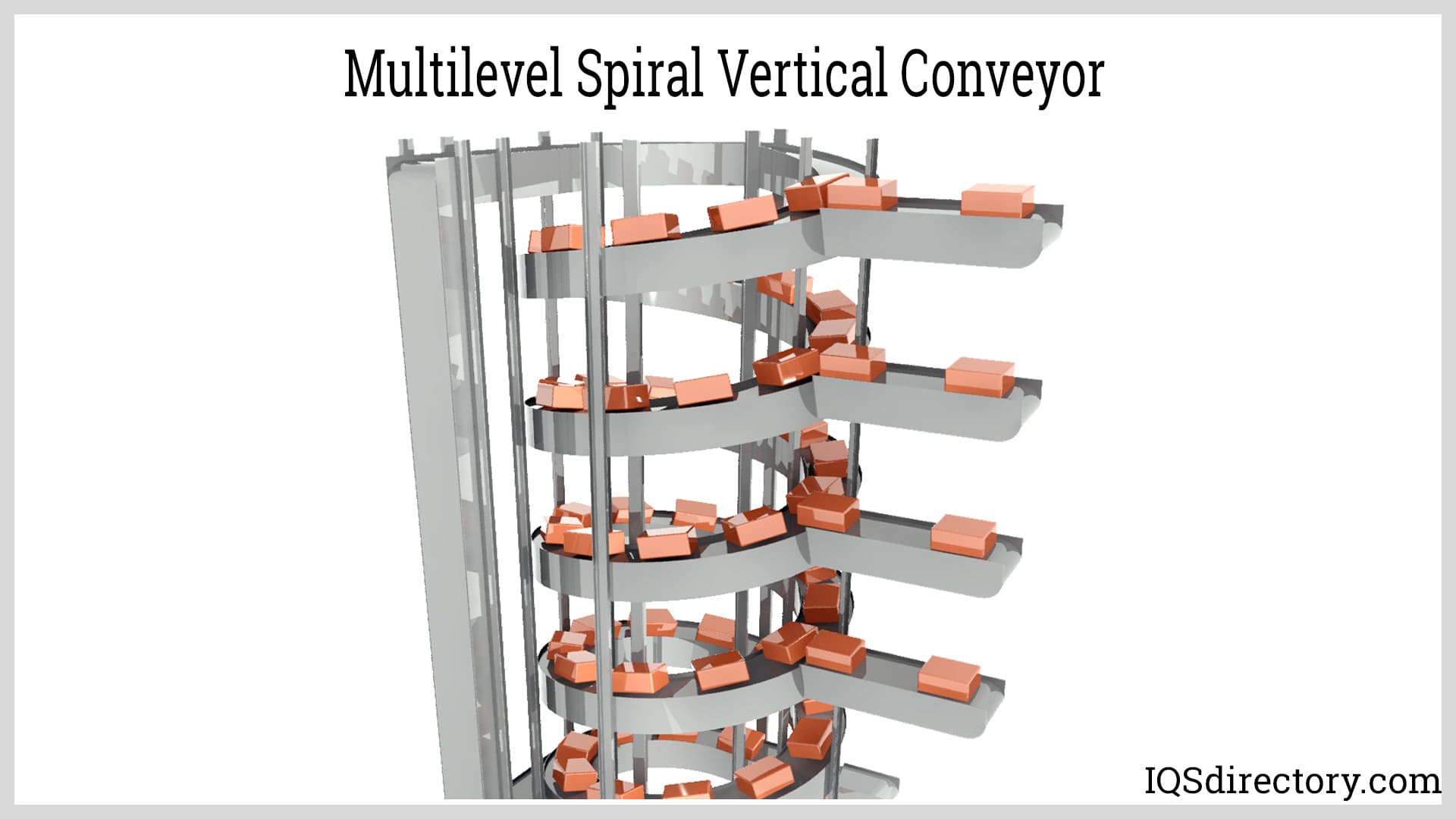

Illustrative image related to vertical conveyor belt

Impact on Application: Metal belts excel in environments where high hygiene standards are required, such as in meat processing or chemical manufacturing.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades that comply with international standards, such as JIS for Japan or ASTM for the U.S. This is particularly important in regions like Europe, where compliance with environmental and safety regulations is strictly enforced.

What Advantages Does Polyurethane Offer for Vertical Conveyor Belts?

Polyurethane is gaining popularity for vertical conveyor belts due to its flexibility and resistance to abrasion and chemicals. It can operate effectively in a wide range of temperatures and is often used in specialized applications.

Pros: Polyurethane belts are highly durable and can handle heavy loads with ease. They also offer excellent grip, reducing the risk of slippage during operation.

Cons: The main drawback is that polyurethane can be more expensive than rubber or PVC. Additionally, its manufacturing process can be complex, leading to longer production times.

Impact on Application: These belts are particularly useful in industries that require precise handling of materials, such as electronics or pharmaceuticals.

Considerations for International Buyers: Buyers should assess the availability of polyurethane belts that meet specific international standards, especially in regions like Africa and South America, where local suppliers may have different product offerings.

Summary of Material Selection for Vertical Conveyor Belts

| Material | Typical Use Case for vertical conveyor belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Bulk material transport in agriculture | High durability and flexibility | Degrades under certain chemicals | Medium |

| PVC | Food processing and packaging | Lightweight and easy to install | Brittle under extreme temperatures | Low |

| Metal | Heavy-duty industrial applications | Long-lasting and hygienic | Higher cost and complex maintenance | High |

| Polyurethane | Precise handling in electronics | Excellent grip and durability | Higher initial cost | High |

By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vertical conveyor belt

What Are the Main Stages in the Manufacturing Process of Vertical Conveyor Belts?

The manufacturing process for vertical conveyor belts involves several critical stages that ensure the final product meets both performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage of manufacturing vertical conveyor belts begins with material selection. Common materials used include rubber, PVC, metal, and synthetic composites, each chosen for their durability and suitability for specific applications. The materials undergo rigorous quality checks to ensure they meet industry standards and specifications.

Once selected, the materials are cut into appropriate sizes and shapes for further processing. This stage may also involve treating materials to enhance their properties, such as increasing resistance to wear or improving adhesion for belt surfaces. Effective material preparation is critical as it directly impacts the performance and longevity of the conveyor system.

What Techniques Are Used for Forming Vertical Conveyor Belts?

The forming process is where the prepared materials are shaped into the desired configuration. This typically involves several techniques:

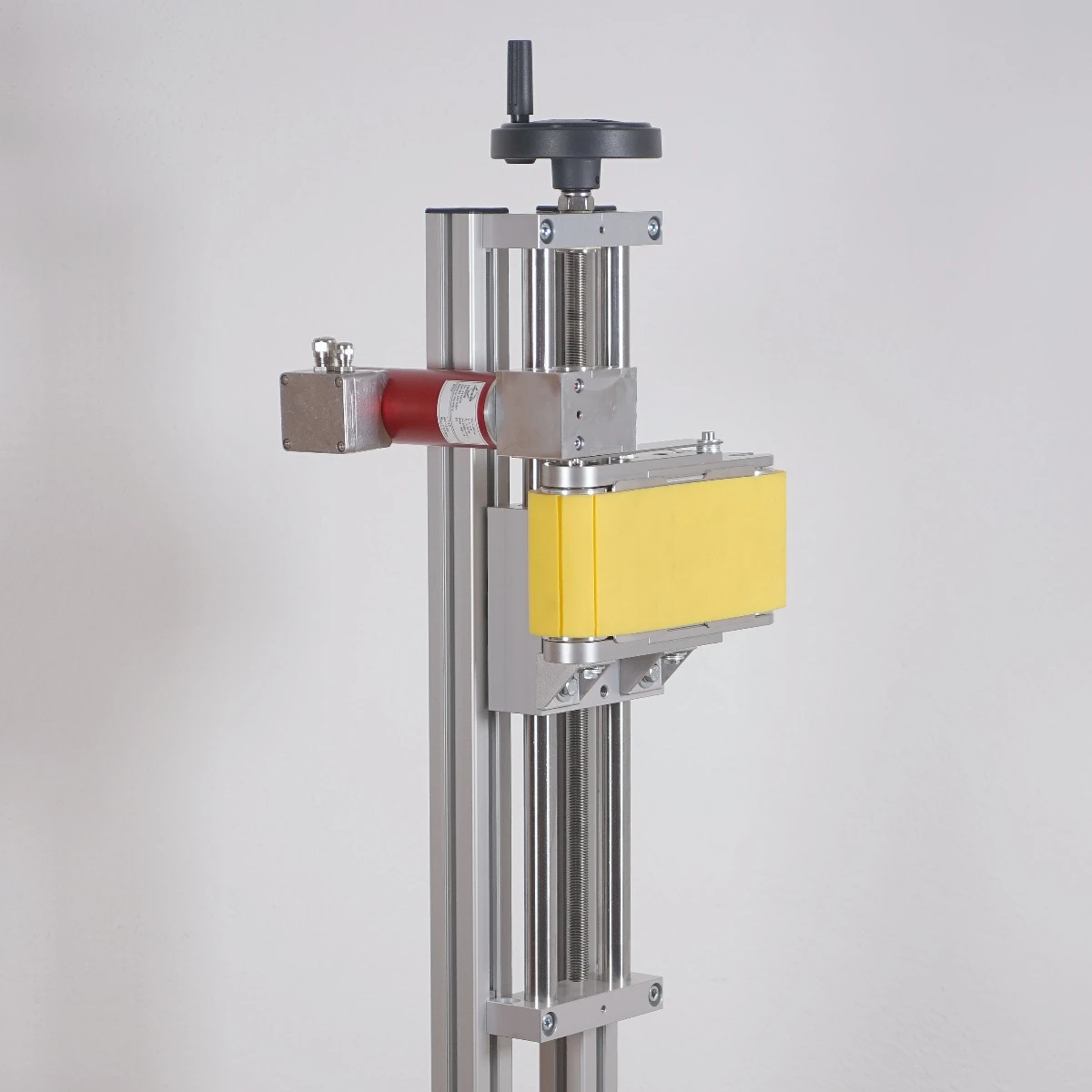

Illustrative image related to vertical conveyor belt

-

Extrusion: For rubber or plastic belts, extrusion is a common technique. The material is heated and forced through a die to create continuous lengths of belt material.

-

Welding: Metal conveyor belts often undergo welding processes to join sections together, ensuring strength and durability. Techniques like spot welding or continuous welding are employed based on the design requirements.

-

Molding: In some cases, especially for custom belts, molding techniques may be used. This involves placing material into a mold that shapes it into a specific form, which is particularly useful for specialized applications.

These forming techniques must be carefully controlled to ensure the belts are produced to precise dimensions and tolerances, which are crucial for proper operation.

How Is the Assembly Process Conducted for Vertical Conveyor Belts?

Assembly is the stage where individual components are combined to create the complete conveyor belt system. This process can vary significantly based on the type of conveyor system being manufactured but generally includes:

-

Joining Components: Various parts, such as pulleys, frames, and belts, are assembled. The joining process may involve mechanical fasteners, welding, or adhesive bonding, depending on the materials and design.

-

Integration of Drive Systems: The motor and drive systems are integrated, ensuring that the belt operates smoothly and efficiently. This is crucial for vertical applications where elevation and stability are key.

-

Quality Checks: During assembly, multiple quality checks are conducted to ensure that the components fit correctly and function as intended. These checks help to identify any issues early in the manufacturing process, reducing costs associated with rework.

What Finishing Techniques Are Used in Vertical Conveyor Belt Manufacturing?

The finishing stage enhances the belt’s performance and appearance. This includes:

-

Surface Treatment: Techniques such as coating or texturing may be applied to improve grip, reduce friction, or enhance resistance to environmental factors.

-

Inspection and Testing: Final inspections are conducted to ensure that all dimensions and specifications are met. Testing methods may include load testing, wear testing, and performance evaluations to simulate operational conditions.

-

Packaging: Once finished, the conveyor belts are packaged carefully to prevent damage during transport, which is essential for maintaining quality upon arrival at the buyer’s facility.

What Are the Quality Assurance Measures for Vertical Conveyor Belts?

Quality assurance (QA) is critical in the manufacturing of vertical conveyor belts to ensure that they meet international and industry-specific standards. This process includes implementing various checkpoints and following rigorous testing protocols.

Which International Standards Are Relevant for Vertical Conveyor Belt Quality Assurance?

Manufacturers of vertical conveyor belts often adhere to internationally recognized standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality throughout their processes.

In addition to ISO standards, specific industry certifications such as CE marking (for European markets) and API standards (for petroleum and gas industries) may be applicable. These certifications demonstrate compliance with safety and performance regulations, which is particularly important for B2B buyers in sectors such as food processing, mining, and manufacturing.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential for ensuring that the manufacturing process produces reliable products. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection assesses raw materials and components upon arrival to ensure they meet specified standards before manufacturing begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC involves regular inspections and testing at various stages (e.g., during material preparation, forming, and assembly) to catch defects early.

-

Final Quality Control (FQC): After assembly and finishing, the final product undergoes comprehensive testing and inspection to verify that it meets all specifications and quality standards before it is shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Buyers can employ several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facility, review quality control processes, and ensure compliance with relevant standards.

-

Reviewing Quality Reports: Requesting detailed quality assurance reports and testing results from suppliers can provide insights into their QC practices and product reliability.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing processes and product quality.

What Nuances Should International B2B Buyers Consider Regarding Quality Control Certifications?

When engaging with international suppliers, B2B buyers must be aware of the nuances surrounding quality control certifications. Different countries may have varying requirements and standards, which can affect compliance and product performance.

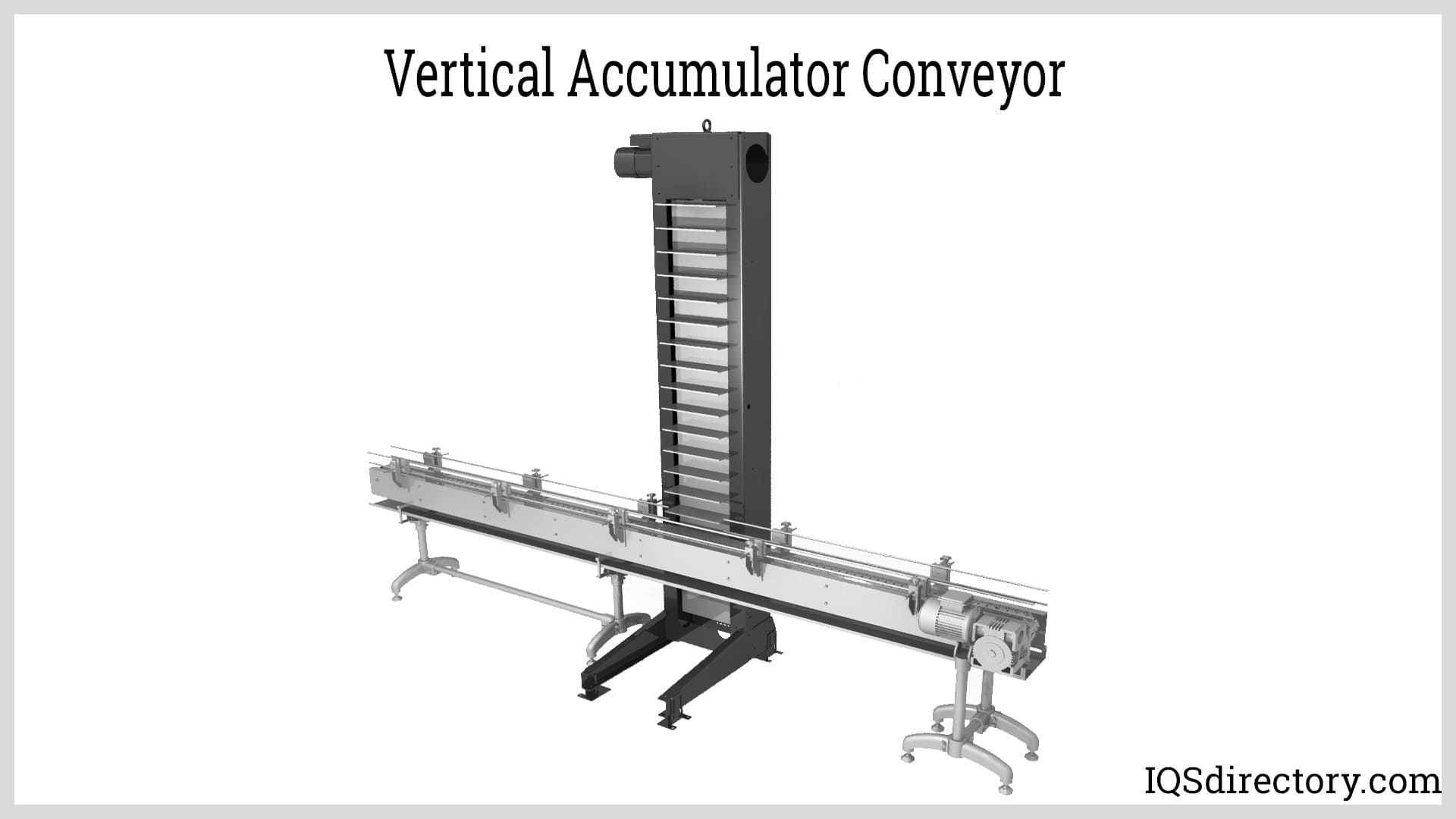

Illustrative image related to vertical conveyor belt

For instance, while ISO 9001 is a widely accepted standard, specific industries might require additional certifications. Buyers should ensure that their suppliers not only hold necessary certifications but also understand the implications of these standards in their respective markets.

Furthermore, cultural differences in manufacturing practices and quality expectations can impact the final product. Buyers should maintain open communication with suppliers to clarify quality expectations and ensure alignment with international standards.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and select suppliers that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vertical conveyor belt’

In the competitive landscape of manufacturing and logistics, selecting the right vertical conveyor belt is essential for optimizing operations and ensuring efficiency. This guide provides a structured checklist to assist B2B buyers in making informed decisions when sourcing vertical conveyor systems.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes understanding the types of materials you will be handling, the maximum load capacity, height, and speed requirements. Defining these specifications early ensures that you target suppliers who can meet your operational needs effectively.

- Material Compatibility: Ensure the conveyor is suitable for the products you intend to transport (e.g., food-grade materials for food processing).

- Space Constraints: Measure the physical space to determine the required dimensions and layout of the conveyor system.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the market. Look for manufacturers with extensive experience in producing vertical conveyor belts tailored to your industry.

- Industry Experience: Focus on suppliers who have successfully delivered solutions in your sector, whether it’s food processing, packaging, or manufacturing.

- Client Reviews: Check online reviews and testimonials to gauge customer satisfaction and product reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Verification of supplier certifications is critical to ensuring product quality and safety. Look for compliance with international standards, such as ISO certifications, which indicate a commitment to quality management.

- Safety Standards: Ensure that the conveyor systems meet local and international safety regulations to prevent workplace accidents.

- Quality Assurance: Suppliers should provide details on their quality control processes and certifications.

Step 4: Request Customization Options

Different applications may require specific customizations in vertical conveyor belts. Discuss potential modifications with your shortlisted suppliers to ensure the conveyor can be tailored to your unique operational needs.

- Belt Material and Design: Inquire about various belt materials suitable for different loads and environments.

- Automation Features: Consider options for automated controls or integration with existing systems to enhance efficiency.

Step 5: Analyze Total Cost of Ownership (TCO)

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, energy consumption, and potential downtime. A more expensive system may offer long-term savings through efficiency and lower maintenance costs.

- Energy Efficiency: Look for energy-efficient models that can reduce operational costs over time.

- Maintenance Requirements: Assess how easy it is to maintain the conveyor and the availability of spare parts.

Step 6: Negotiate Terms and Conditions

Once you’ve narrowed down your options, engage in negotiations with suppliers regarding pricing, payment terms, and delivery schedules. Ensure clarity on warranties and after-sales support, which are critical for long-term partnerships.

- Warranty Coverage: Understand what is covered under warranty and for how long, as this can protect your investment.

- Delivery Timelines: Agree on realistic timelines for delivery and installation to avoid disruptions in your operations.

Step 7: Conduct a Final Review and Make Your Selection

Before finalizing your purchase, conduct a comprehensive review of all gathered information. Compare suppliers based on performance, pricing, and alignment with your operational needs.

- Supplier Visit: If feasible, visit the supplier’s facility to see their operations and products firsthand.

- Decision Matrix: Create a decision matrix to objectively evaluate each supplier based on your predetermined criteria.

By following this checklist, B2B buyers can effectively navigate the procurement process for vertical conveyor belts, ensuring that they select a solution that enhances their operational efficiency and supports their business goals.

Comprehensive Cost and Pricing Analysis for vertical conveyor belt Sourcing

What Are the Key Cost Components for Vertical Conveyor Belts?

When sourcing vertical conveyor belts, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

Illustrative image related to vertical conveyor belt

-

Materials: The choice of materials significantly affects pricing. Options range from rubber and synthetic composites for standard belts to specialized materials like metal or food-grade components for specific applications. Higher-quality materials typically yield better durability and performance but come at a premium.

-

Labor: Labor costs encompass not only the manufacturing workforce but also the skilled technicians involved in installation and maintenance. Regions with higher labor costs will naturally influence the final price, making it essential to consider the geographical location of the supplier.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can reduce these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: Depending on the complexity of the conveyor design, tooling costs can vary. Custom tooling for specialized applications can add to the initial investment but may be justified by enhanced performance and longevity.

-

Quality Control (QC): Rigorous QC processes ensure that products meet necessary standards and certifications, impacting the overall cost. Buyers should consider whether the added expense of stringent QC measures aligns with their quality requirements.

-

Logistics: Transportation costs play a significant role, particularly for international shipments. Factors such as distance, shipping method, and Incoterms (which define the responsibilities of buyers and sellers) can drastically affect logistics expenses.

-

Margin: Supplier profit margins vary widely based on market demand, competition, and the uniqueness of their offering. Understanding the average margins in the industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Impact Vertical Conveyor Belt Costs?

Several factors can influence the pricing of vertical conveyor belts, which B2B buyers should carefully evaluate:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide price breaks at higher order volumes. Negotiating favorable terms for larger quantities can lead to significant savings.

-

Specifications and Customization: Custom solutions tailored to specific operational needs may incur higher costs. Buyers should assess whether the benefits of customization justify the additional expense.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., ISO, HACCP for food safety) usually command a higher price. Buyers should evaluate the necessity of these certifications based on their end-use and regulatory requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to attract business.

What Buyer Tips Can Help Optimize Costs?

International B2B buyers can benefit from several strategies to optimize costs when sourcing vertical conveyor belts:

-

Effective Negotiation: Engaging in open discussions with suppliers about pricing, quality, and lead times can lead to better terms. Establishing a long-term relationship may also enable more favorable pricing.

-

Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, consider the TCO, which includes maintenance, operational efficiency, and potential downtime. A slightly higher initial investment in a durable and reliable conveyor system can lead to lower long-term costs.

-

Understanding Pricing Nuances in Different Markets: Pricing can vary significantly across regions due to local economic conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should research local market trends and supplier landscapes to make informed decisions.

-

Disclaimer on Indicative Prices: Prices for vertical conveyor belts can fluctuate based on market conditions, material costs, and supplier pricing strategies. It’s advisable to request current quotes and conduct thorough comparisons before making purchasing decisions.

By understanding these cost components, price influencers, and strategic buyer tips, B2B buyers can navigate the complexities of vertical conveyor belt sourcing more effectively, ensuring they secure the best value for their investments.

Alternatives Analysis: Comparing vertical conveyor belt With Other Solutions

Exploring Alternatives to Vertical Conveyor Belts

In the world of material handling, vertical conveyor belts are often a preferred choice for elevating products efficiently within tight spaces. However, various alternative solutions exist, each offering unique advantages and potential drawbacks. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs.

| Comparison Aspect | Vertical Conveyor Belt | Bucket Elevators | Pneumatic Conveying |

|---|---|---|---|

| Performance | High efficiency for vertical transport with minimal footprint | Excellent for bulk materials, high volume | Effective for fine powders and granules, continuous flow |

| Cost | Moderate initial investment; long-term savings on labor | Higher upfront cost; lower operational costs | Variable costs depending on system complexity and material type |

| Ease of Implementation | Requires space for installation and alignment; can be complex | Installation can be straightforward with proper planning | Can require significant infrastructure changes for piping |

| Maintenance | Moderate; needs regular checks for belt wear | Low; generally requires less frequent maintenance | Higher; involves regular checks on air supply and seals |

| Best Use Case | Ideal for food processing, pharmaceuticals, and warehousing | Best for agricultural and mining industries | Suitable for food, chemicals, and bulk materials where dust control is critical |

Detailed Breakdown of Alternatives

Bucket Elevators

Bucket elevators are designed to lift bulk materials vertically using a series of buckets attached to a belt or chain. These systems are particularly effective in industries such as agriculture and mining, where high volumes of granular materials need to be moved. The main advantage of bucket elevators is their ability to handle a wide range of materials, including grains, fertilizers, and even some types of waste. However, they can require a higher initial investment compared to vertical conveyor belts and are typically less flexible in terms of product handling.

Pneumatic Conveying

Pneumatic conveying systems utilize air pressure to transport materials through enclosed pipelines. This method is particularly effective for moving fine powders and granular materials, making it popular in the food and chemical industries. One of the key advantages of pneumatic systems is their ability to minimize dust and spillage, which can enhance workplace safety and cleanliness. However, the complexity of installation and the need for regular maintenance on air supply systems can lead to higher operational costs over time.

Illustrative image related to vertical conveyor belt

Conclusion: How to Choose the Right Solution

When selecting between a vertical conveyor belt and its alternatives, B2B buyers should consider several factors, including the type of material being handled, the required throughput, and the specific operational environment. Each solution has its unique strengths and weaknesses, making it essential to assess operational needs carefully. By evaluating performance metrics, cost implications, and maintenance requirements, buyers can make informed decisions that not only enhance productivity but also align with their long-term business strategies.

Essential Technical Properties and Trade Terminology for vertical conveyor belt

What Are the Essential Technical Properties of Vertical Conveyor Belts?

When considering vertical conveyor belts, understanding key technical specifications is crucial for ensuring optimal performance and reliability. Here are some essential properties that B2B buyers should evaluate:

-

Material Grade

The material used in conveyor belts typically includes rubber, PVC, polyurethane, and metal. Each material has its own strengths: rubber offers excellent flexibility and durability, while metal provides superior strength and heat resistance. Selecting the right material is vital based on the specific application, such as food processing or heavy-duty industrial use, to ensure compliance with industry standards and longevity. -

Belt Width and Length

The dimensions of the conveyor belt directly affect its capacity and efficiency. Standard widths range from 12 inches to 48 inches, while lengths can vary significantly based on installation needs. Proper sizing is essential to accommodate the volume of materials being transported and to fit within the spatial constraints of the facility, preventing bottlenecks and optimizing workflow. -

Load Capacity

This specification indicates the maximum weight the conveyor can handle per unit length. Load capacities can range from a few hundred pounds to several tons, depending on the design and material. Understanding load capacity is critical for ensuring safety and performance, as exceeding this limit can lead to equipment failure and operational disruptions. -

Speed

Conveyors operate at various speeds, typically measured in feet per minute (FPM). The appropriate speed depends on the material being transported and the desired throughput. Adjusting speed settings can enhance efficiency, but it’s important to balance speed with product integrity, especially when handling delicate items. -

Tensioning System

A reliable tensioning system ensures that the belt remains taut during operation, which is crucial for maintaining consistent movement and reducing wear. Pneumatic or mechanical tensioning systems are common, and the choice can impact maintenance requirements and operational efficiency. A well-designed tensioning system minimizes downtime and extends the life of the conveyor. -

Sanitary Design Features

Particularly important in food processing, sanitary design features like open-frame construction and easy-access components facilitate thorough cleaning and maintenance. Compliance with health regulations is essential for businesses in sectors such as food production, where contamination risks must be minimized.

What Are Common Trade Terminology and Jargon Used in Vertical Conveyor Belt Procurement?

Navigating the procurement landscape for vertical conveyor belts requires familiarity with industry-specific terminology. Here are some key terms:

Illustrative image related to vertical conveyor belt

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures that buyers are sourcing high-quality components that are compatible with existing systems. -

MOQ (Minimum Order Quantity)

This term defines the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for businesses operating on tight margins. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document is essential for comparing offers and ensuring that the procurement team can make informed purchasing decisions based on detailed specifications and pricing. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers involved in global trade to avoid misunderstandings and ensure compliance with international regulations. -

Lead Time

The amount of time it takes from placing an order until delivery is made. Understanding lead times is essential for effective project planning and ensuring that production schedules are met without delays. -

Service Level Agreement (SLA)

An SLA outlines the expected service standards between a supplier and a buyer, including performance metrics and accountability measures. Having a clear SLA helps establish expectations and ensures that both parties are aligned on service delivery.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making process and ensure that their investments in vertical conveyor belts meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the vertical conveyor belt Sector

What Are the Current Market Dynamics and Key Trends in the Vertical Conveyor Belt Sector?

The global vertical conveyor belt market is experiencing significant growth, driven by increasing automation and the demand for efficient material handling solutions across various industries, including food processing, mining, and logistics. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek to optimize their operations, several key trends are emerging.

One notable trend is the adoption of smart technology within conveyor systems. Innovations such as IoT-enabled sensors and predictive maintenance tools are enhancing operational efficiency and reducing downtime. This shift towards Industry 4.0 is essential for businesses looking to maintain competitiveness in an increasingly automated landscape. Additionally, the demand for modular conveyor systems is rising, allowing for customizable solutions that can be easily integrated into existing operations, thereby minimizing disruption during upgrades.

Moreover, sustainability has become a focal point in sourcing decisions. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to environmentally friendly practices, including the use of recyclable materials and energy-efficient technologies. This trend is particularly pronounced in regions like Europe, where regulatory frameworks are pushing for greener manufacturing processes.

In emerging markets, such as those in Africa and South America, there is a growing need for cost-effective solutions that do not compromise quality. This has led to increased collaboration between local manufacturers and international suppliers, aiming to leverage regional knowledge while integrating global best practices.

Illustrative image related to vertical conveyor belt

How Does Sustainability and Ethical Sourcing Impact the Vertical Conveyor Belt Market?

The environmental impact of conveyor systems is a critical concern for modern businesses. As industries strive to reduce their carbon footprints, the sourcing of vertical conveyor belts is increasingly influenced by sustainability considerations. B2B buyers are now evaluating suppliers based on their environmental policies and the sustainability of their manufacturing processes.

Ethical sourcing is gaining traction as companies seek to ensure that their supply chains are not only environmentally responsible but also socially conscious. This includes assessing the labor practices of suppliers and ensuring compliance with international labor standards. The emphasis on transparency and traceability in supply chains has prompted buyers to demand certifications such as ISO 14001, which focuses on effective environmental management systems.

Moreover, the use of ‘green’ materials in the production of conveyor belts is becoming more prevalent. Buyers are looking for options such as recycled plastics and sustainably sourced rubber. These materials not only contribute to reducing environmental impact but also resonate with consumers who prefer to support eco-friendly brands.

As sustainability becomes a key differentiator in the marketplace, B2B buyers must prioritize partnerships with suppliers who align with their ethical and environmental values. This not only enhances corporate reputation but also meets the growing consumer demand for sustainable practices.

What Is the Evolution of Vertical Conveyor Systems and Their Relevance Today?

The evolution of vertical conveyor systems dates back to the early 20th century, when they were primarily used in mining operations to transport materials from underground to the surface. Over the decades, advancements in technology and materials have transformed these systems into sophisticated solutions used across various industries.

The introduction of belt conveyors revolutionized material handling, allowing for efficient transportation of goods in manufacturing and warehousing. Innovations such as modular designs and automated control systems have further enhanced their functionality, making them essential for modern supply chains.

Today, vertical conveyors are not only vital for logistics and manufacturing but have also found applications in sectors such as food processing, where hygiene and efficiency are paramount. With ongoing advancements in technology and a heightened focus on sustainability, the vertical conveyor belt sector continues to evolve, catering to the dynamic needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of vertical conveyor belt

-

1. How do I select the right vertical conveyor belt for my industry?

Choosing the right vertical conveyor belt involves assessing your specific application needs. Consider factors like the type of materials you will be transporting (e.g., food products, bulk materials), the required load capacity, and the vertical height to be achieved. Additionally, evaluate the environment where the conveyor will operate—factors such as temperature, humidity, and the presence of contaminants can impact material selection. Engaging with suppliers who offer customization options can ensure the conveyor meets your operational requirements. -

2. What is the best vertical conveyor belt for food processing applications?

For food processing, the best vertical conveyor belts are those designed with sanitation and efficiency in mind. Look for models like positive drive systems that minimize product waste and maintain product integrity, especially for sticky items like dough or meat. Sanitary design features, such as easy-to-clean surfaces and tool-less maintenance capabilities, are crucial. Ensure the conveyor complies with food safety standards and can withstand frequent washdowns, which are common in food processing environments. -

3. What are the common materials used in vertical conveyor belts?

Vertical conveyor belts are typically made from a variety of materials, including rubber, plastic, and metal. Rubber belts are favored for their flexibility and grip, while plastic belts can offer lightweight options with easier maintenance. Metal belts are durable and suitable for heavy loads or extreme conditions. The choice of material should align with the specific applications, including the type of products being conveyed, environmental conditions, and regulatory compliance requirements. -

4. How do I vet suppliers when sourcing vertical conveyor belts internationally?

To vet suppliers for vertical conveyor belts, start by reviewing their experience and expertise in your specific industry. Request references or case studies from existing clients, particularly those in your geographic region. Verify certifications that demonstrate compliance with international standards, such as ISO or food safety regulations. Additionally, assess their manufacturing capabilities, lead times, and after-sales support. Engaging in direct communication and possibly visiting their facilities can provide valuable insights into their operations. -

5. What are the typical minimum order quantities (MOQs) for vertical conveyor belts?

Minimum order quantities (MOQs) for vertical conveyor belts can vary significantly by supplier and the complexity of the design. Generally, MOQs can range from a few units for standard models to larger quantities for customized solutions. It’s essential to discuss your requirements with potential suppliers to understand their policies. Some suppliers may offer flexibility in MOQs for first-time buyers or ongoing contracts, allowing you to better manage inventory and costs. -

6. What payment terms should I expect when purchasing vertical conveyor belts?

Payment terms for vertical conveyor belts can vary depending on the supplier’s policies and the scale of the order. Common terms include partial payment upfront (typically 30-50%) with the balance due upon delivery or installation. For large orders or international transactions, suppliers may offer letters of credit or escrow services to ensure security for both parties. Always clarify payment terms upfront and consider negotiating terms that align with your cash flow and procurement processes. -

7. How can I ensure quality assurance (QA) when sourcing vertical conveyor belts?

To ensure quality assurance when sourcing vertical conveyor belts, request detailed specifications and compliance documentation from suppliers. Ask about their QA processes, including testing for material durability, performance under load, and safety standards. Many reputable suppliers will provide certification for their products, such as ISO 9001. Additionally, consider conducting on-site inspections or third-party audits to verify the manufacturing processes and quality control measures in place. -

8. What logistics considerations should I keep in mind when importing vertical conveyor belts?

When importing vertical conveyor belts, consider logistics factors such as shipping methods, lead times, and customs regulations. Collaborate with suppliers to understand their shipping options and potential costs associated with freight forwarding. Ensure all necessary documentation, including customs declarations and compliance certificates, are prepared to avoid delays. Additionally, factor in the delivery schedule to align with your production timelines, and consider warehousing solutions if you anticipate longer lead times.

Top 5 Vertical Conveyor Belt Manufacturers & Suppliers List

1. IQS Directory – Vertical Conveyors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Vertical conveyors, also known as vertical reciprocating conveyors (VRCs), are mechanical systems designed for elevating items between various height levels, enhancing efficiency in material handling. They are classified under ASME B20.1 safety standards and are used for transporting goods in warehouses, manufacturing plants, and multi-story facilities. Types of vertical conveyors include: 1. Spir…

2. PFI Conveyors – PURlift Positive Drive Vertical Lift Conveyor

Domain: pficonveyors.com

Registered: 2022 (3 years)

Introduction: PURlift Positive Drive Vertical Lift Conveyor features a dual “sandwich” lift design for vertical product elevation, optimal product integrity with a self-tracking positive drive belt, and pneumatic belt tensioning for dependable operation. It is designed for easy maintenance with an open-frame structure and tool-less adjustments. Key specifications include:

– Lifts products up to 90 degrees verti…

3. Frontier Kemper – Corrugated Sidewall Conveyors

Domain: frontierkemper.com

Registered: 2000 (25 years)

Introduction: {“Type”:”Corrugated Sidewall”,”Max Lift”:”2,600 ft. (800m)”,”Max Tonnage”:”Up to 6,000 TPH (varies by depth & density)”,”Belt Construction”:”Fabric & Steel Cord Base Belts”,”Braking”:”External Backstops & Spring-Applied Caliper Brakes/Hydraulic Release”,”Controls”:”Soft-Start or VFD”}

4. Conveyor Systems – Vertical Conveyors

Domain: conveyor-systems.biz

Registered: 2002 (23 years)

Introduction: Vertical conveyors are essential equipment used in various industries to transport materials and products vertically and horizontally. They are designed to move products or materials up or down between multi-levels, commonly used in intermittent flow operations and environments with limited horizontal space. Key components include a drive unit, conveyor belt, pulleys, supports, and safety features…

5. TCE Conveyors – Vertical Reciprocating Conveyors

Domain: tceconveyors.com

Registered: 2001 (24 years)

Introduction: Vertical Reciprocating Conveyors (VRCs) provide a safe, easy, and cost-effective solution for transporting staff and products between elevations. They are safer than forklifts, can handle heavier loads, and offer flexibility in carriage size, capacity, and traffic patterns. VRCs are classified as material conveyors, eliminating the need for OSHA forklift training. They are manufactured in the USA …

Strategic Sourcing Conclusion and Outlook for vertical conveyor belt

Why is Strategic Sourcing Essential for Vertical Conveyor Belt Procurement?

As the global marketplace continues to evolve, strategic sourcing for vertical conveyor belts emerges as a critical component for international businesses, particularly those in Africa, South America, the Middle East, and Europe. By focusing on quality and efficiency, companies can enhance their operational capabilities while reducing costs. Vertical conveyor belts are instrumental in optimizing space and improving workflow in various industries, including food processing, manufacturing, and logistics.

How Can Businesses Benefit from Understanding Vertical Conveyor Belt Options?

Understanding the diverse types of vertical conveyor systems—such as positive drive belts and bucket elevators—enables buyers to make informed decisions tailored to their specific applications. Investing in technology that aligns with operational needs not only boosts productivity but also minimizes product waste, enhancing overall process integrity. Moreover, leveraging relationships with suppliers ensures access to the latest innovations and maintenance support, leading to long-term operational success.

What’s Next for International B2B Buyers?

Looking ahead, businesses must prioritize partnerships with reliable manufacturers and suppliers to navigate the complexities of sourcing vertical conveyor belts. By fostering these relationships, companies can ensure they remain competitive in a rapidly changing landscape. Now is the time for international B2B buyers to explore tailored solutions and elevate their operations—take the next step towards optimizing your supply chain by engaging with trusted conveyor belt suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.