Is Your Types Of Force Sensors Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for types of force sensors

In the fast-evolving landscape of industrial technology, sourcing the right types of force sensors can present significant challenges for B2B buyers. As organizations increasingly rely on precision measurement for automation, quality control, and safety applications, understanding the nuances of various force sensor technologies becomes critical. This comprehensive guide delves into the myriad types of force sensors available in the global market, exploring their unique applications, operational principles, and benefits across diverse industries.

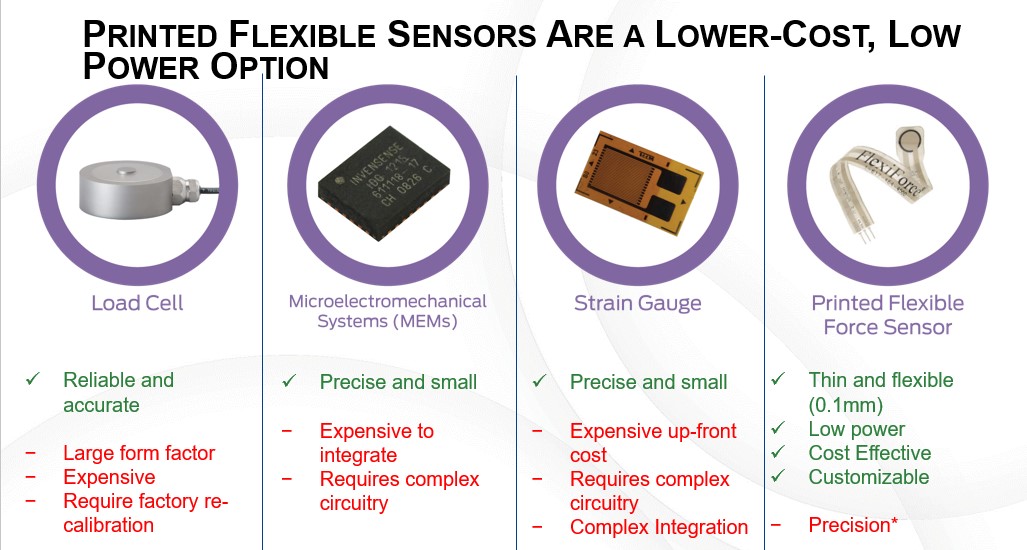

From strain gauges and load cells to piezoelectric and optical sensors, each type offers distinct advantages tailored to specific operational needs. Additionally, we will cover essential aspects such as supplier vetting, cost considerations, and the importance of calibration in ensuring accuracy and reliability.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, this guide serves as an invaluable resource. It empowers decision-makers to navigate the complexities of force sensor procurement with confidence, ensuring that they select the best solutions to meet their operational requirements. By equipping buyers with the knowledge needed to make informed purchasing decisions, this guide not only enhances operational efficiency but also contributes to the overall success of their businesses in a competitive global marketplace.

Understanding types of force sensors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

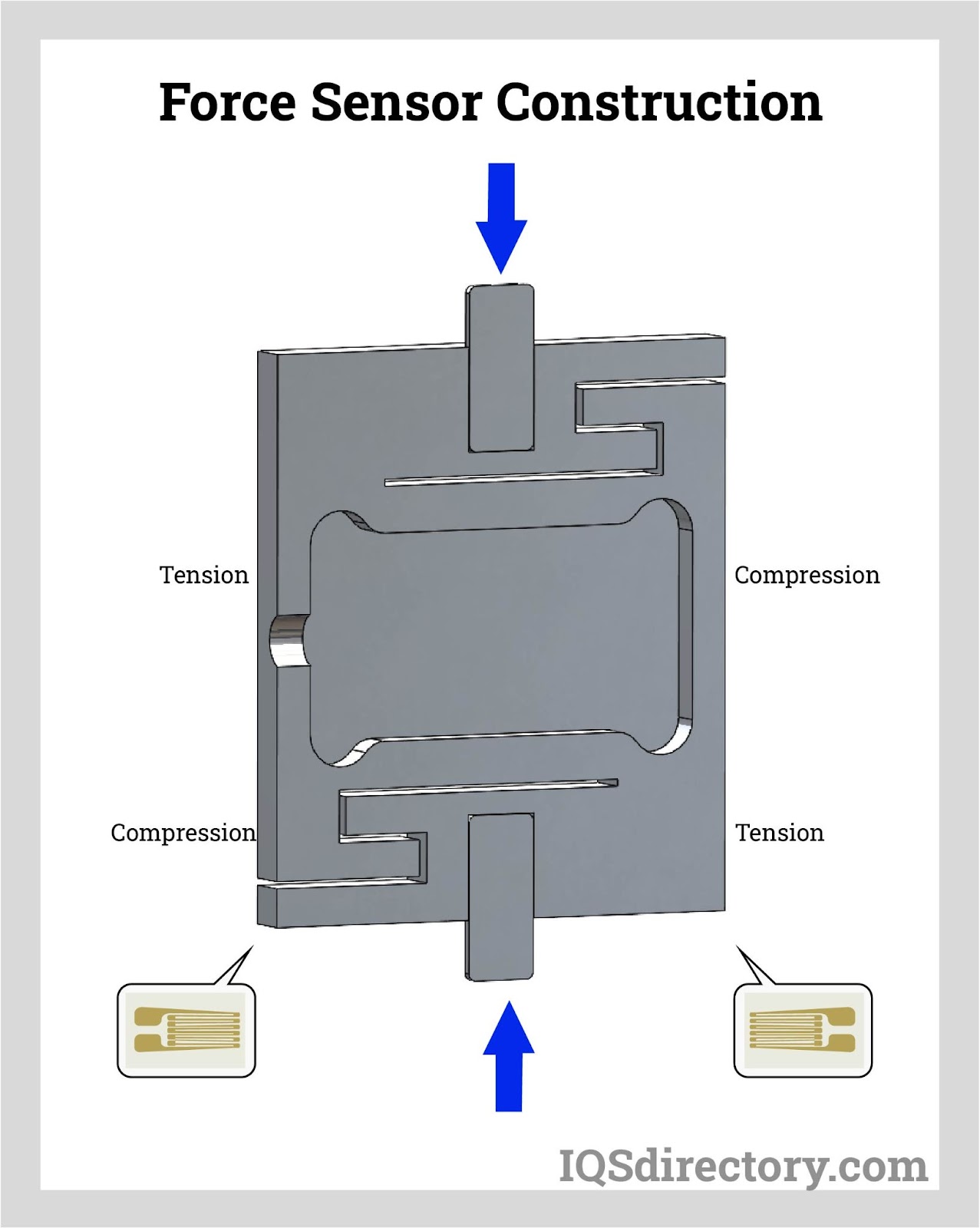

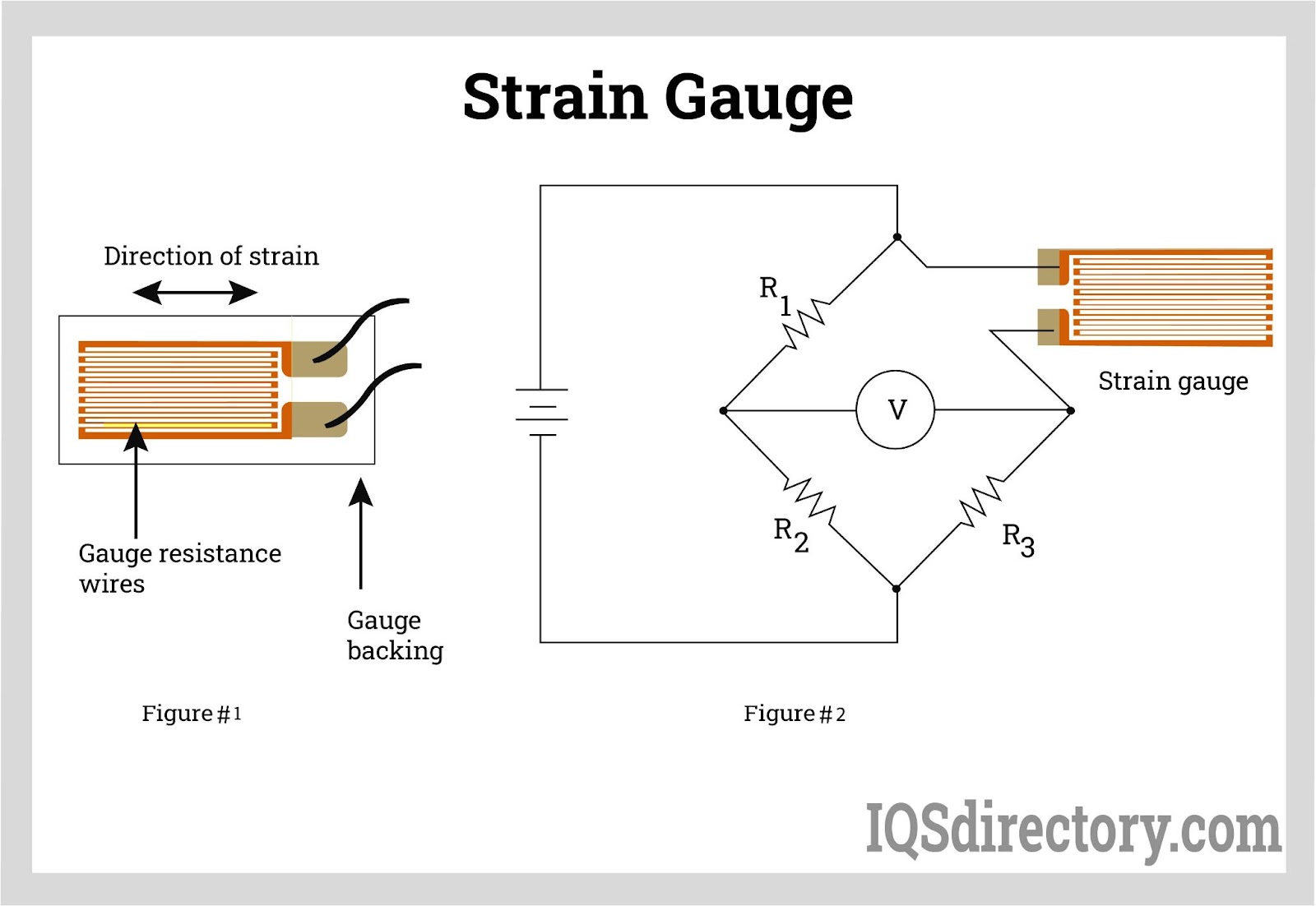

| Strain Gauge Sensor | Measures deformation via electrical resistance changes. | Manufacturing, medical devices, aerospace | Pros: High accuracy, versatile. Cons: Sensitive to temperature changes. |

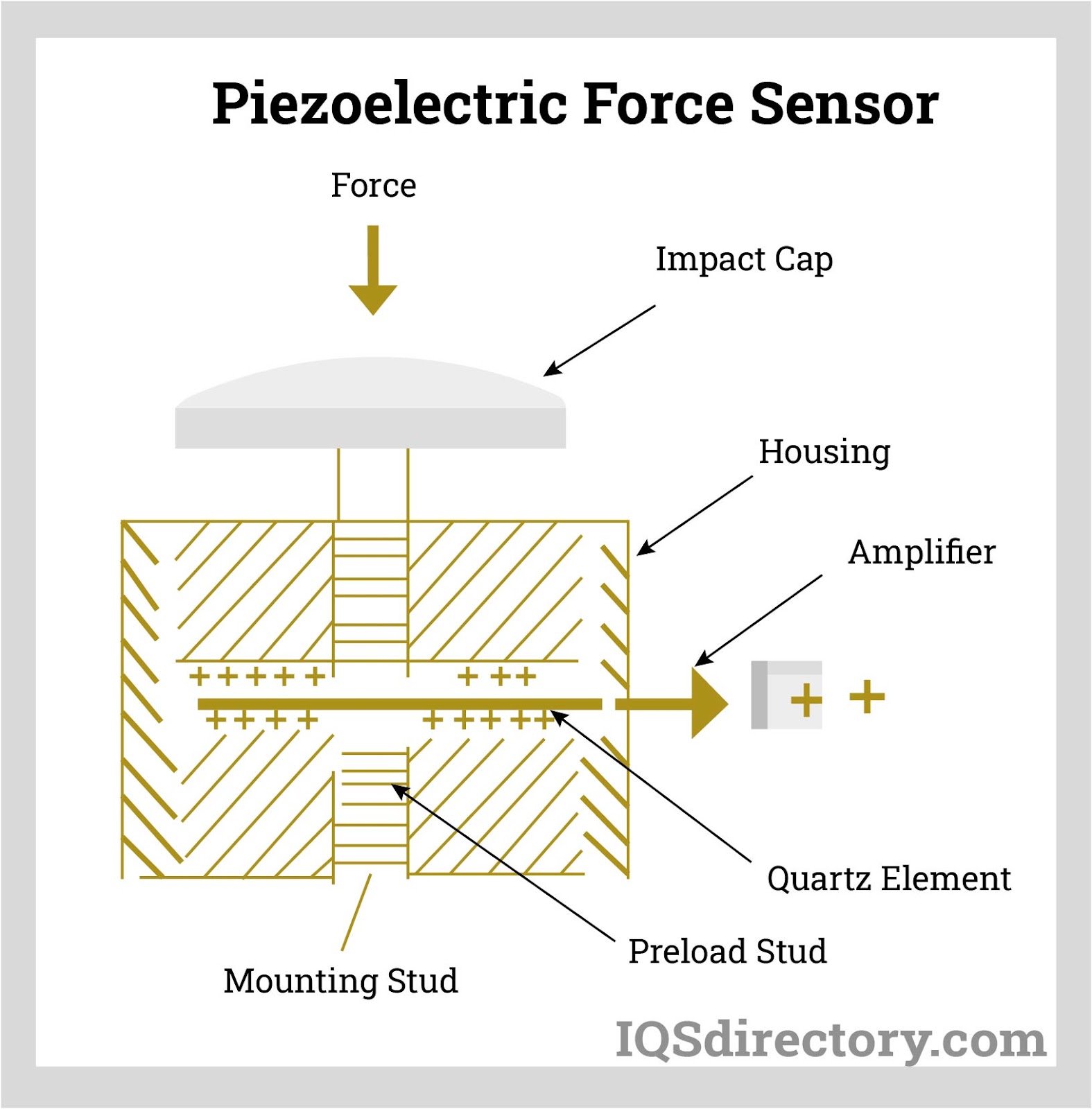

| Piezoelectric Sensor | Generates electrical charge in response to applied force. | Dynamic force measurement in robotics and automotive | Pros: Fast response time, suitable for dynamic loads. Cons: Limited to dynamic measurements. |

| Capacitive Sensor | Measures changes in capacitance due to deformation. | Touchscreens, consumer electronics | Pros: High sensitivity, compact design. Cons: Affected by environmental factors like humidity. |

| Optical Force Sensor | Utilizes light intensity changes to measure force. | High-precision applications in research and labs | Pros: Excellent precision, immune to electromagnetic interference. Cons: Higher cost, complex setup. |

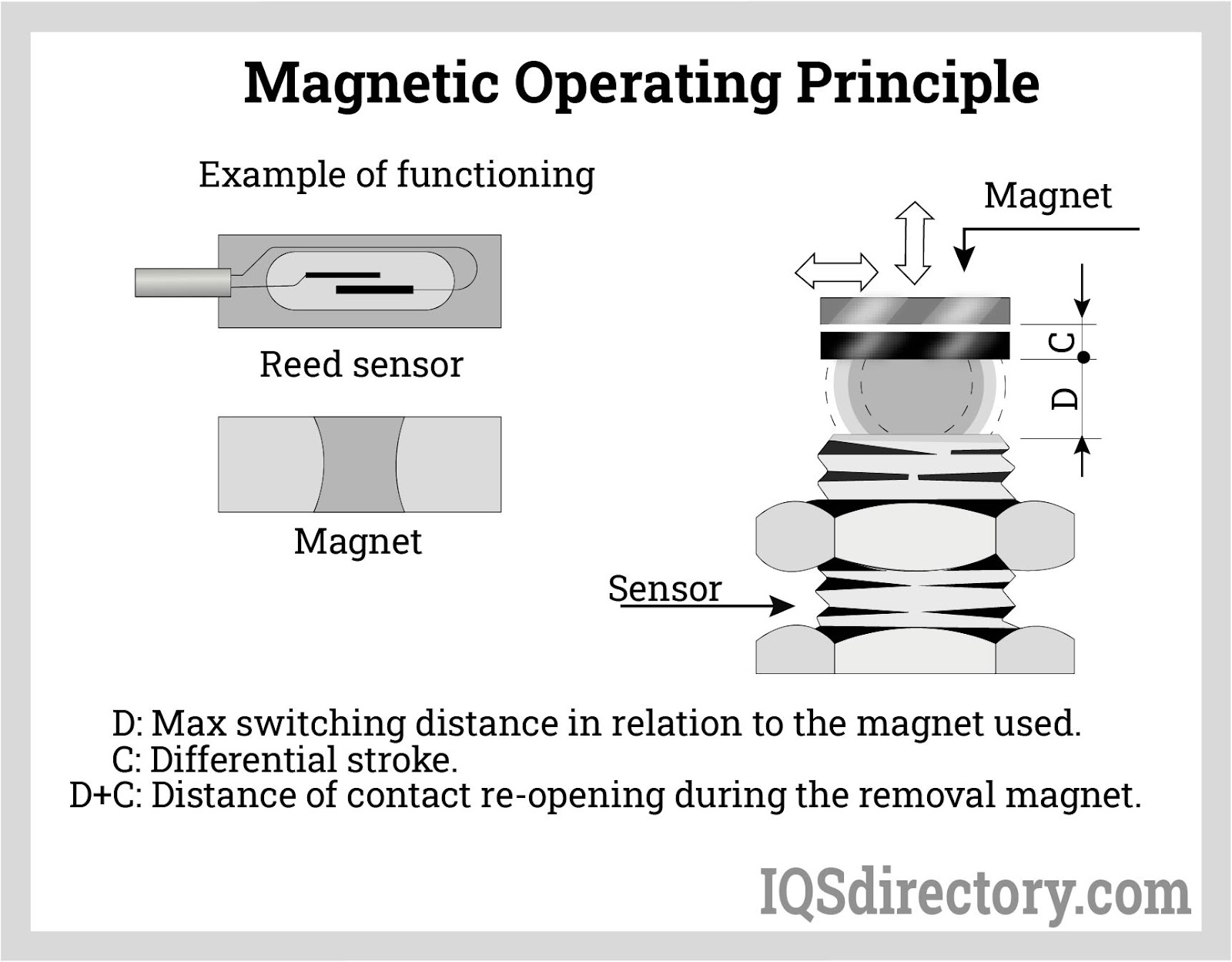

| Magnetic Force Sensor | Measures variations in magnetic fields due to applied force. | Industrial automation, aerospace | Pros: Robust in harsh environments, immune to external noise. Cons: Requires careful calibration. |

What are the characteristics and suitability of Strain Gauge Sensors for B2B applications?

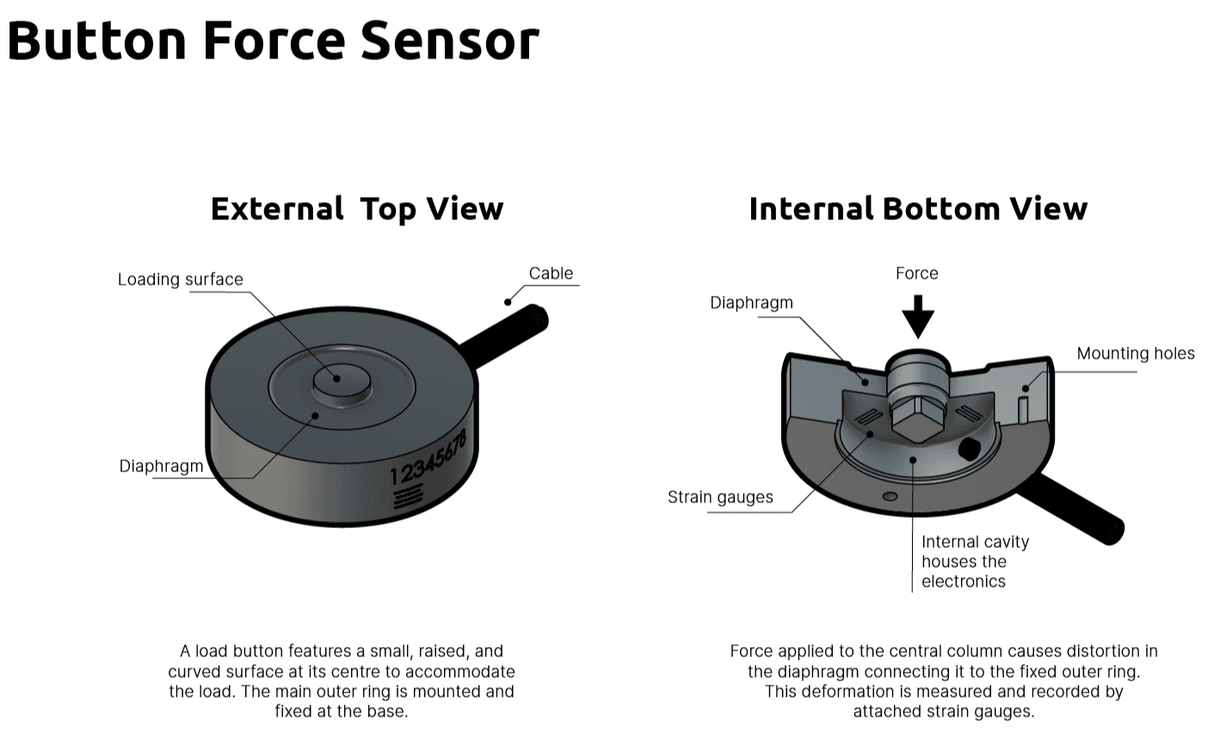

Strain gauge sensors are widely recognized for their ability to accurately measure force through deformation, which is translated into an electrical signal. They are particularly suited for applications in manufacturing, medical devices, and aerospace due to their reliability and versatility. B2B buyers should consider the environment where the sensor will be used, as strain gauges can be sensitive to temperature fluctuations, potentially affecting their accuracy. Additionally, their integration into existing systems is generally straightforward, making them a popular choice for various industrial applications.

How do Piezoelectric Sensors stand out in dynamic force measurement?

Piezoelectric sensors are unique in their capability to generate an electrical charge in response to applied force, making them ideal for dynamic force measurements. This feature is especially beneficial in industries such as robotics and automotive, where rapid changes in force are common. Buyers should note that while piezoelectric sensors excel in dynamic environments, they may not be suitable for static force measurements. Their quick response time and durability are significant advantages, but understanding the specific application needs is crucial for effective deployment.

In what scenarios are Capacitive Sensors most effective?

Capacitive sensors function by measuring changes in capacitance due to applied force, making them highly sensitive and compact. They are often used in touchscreens and consumer electronics, where precision is essential. However, environmental factors such as humidity can impact their performance. B2B buyers should evaluate the operational environment and ensure that capacitive sensors align with their specific application requirements. Their small size and high sensitivity can be advantageous in applications where space is limited.

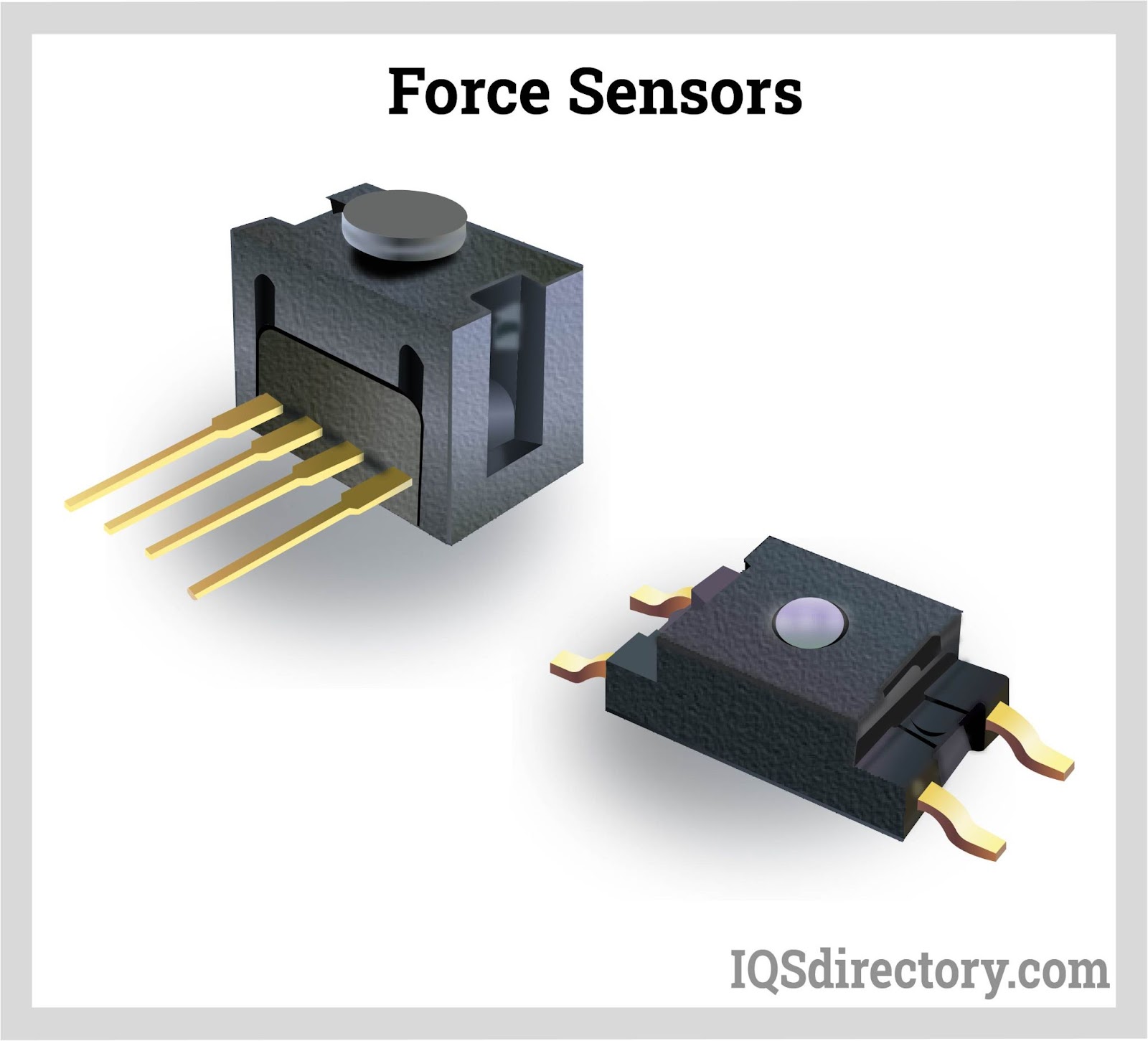

Illustrative image related to types of force sensors

What are the advantages of Optical Force Sensors in high-precision applications?

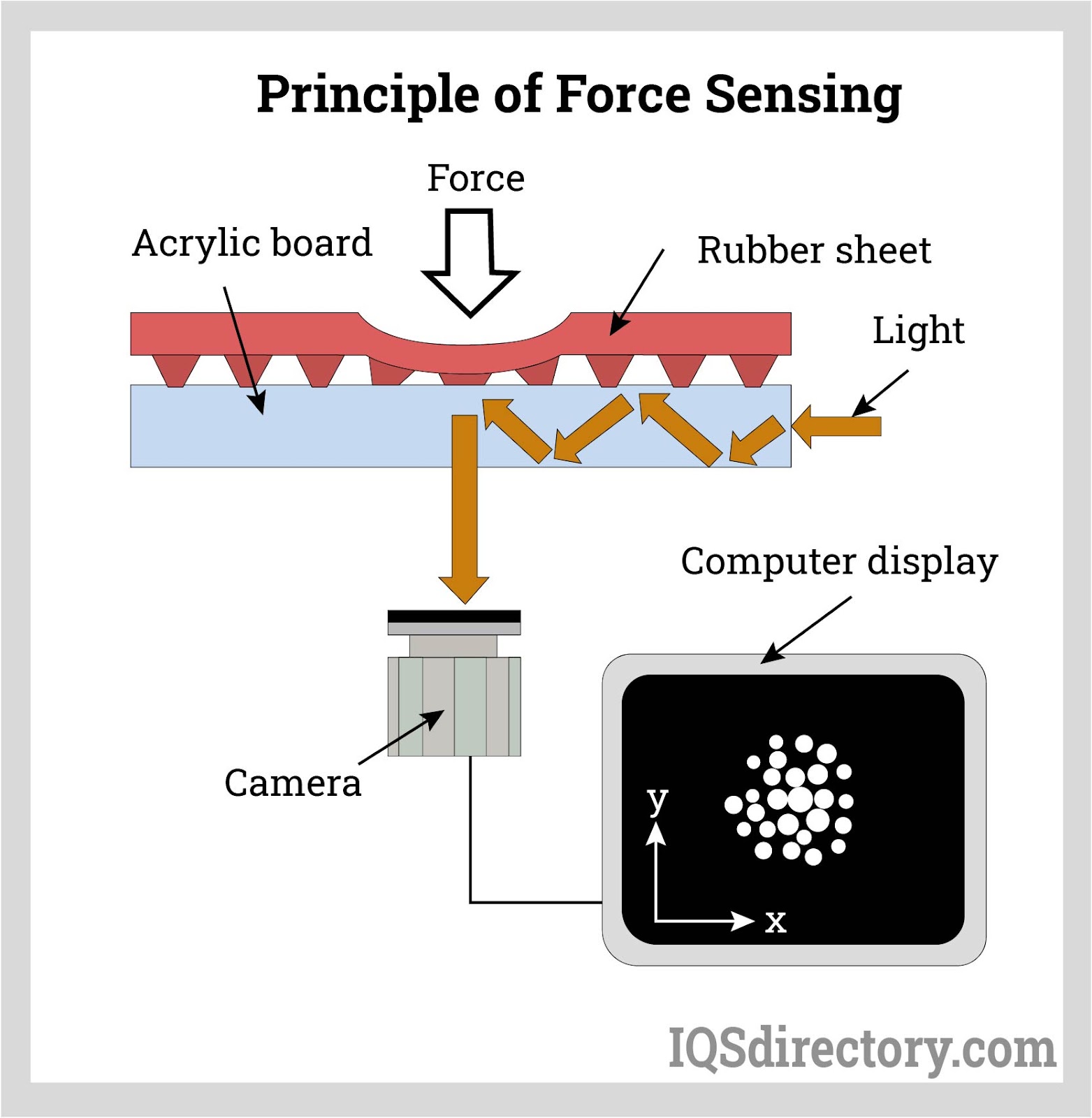

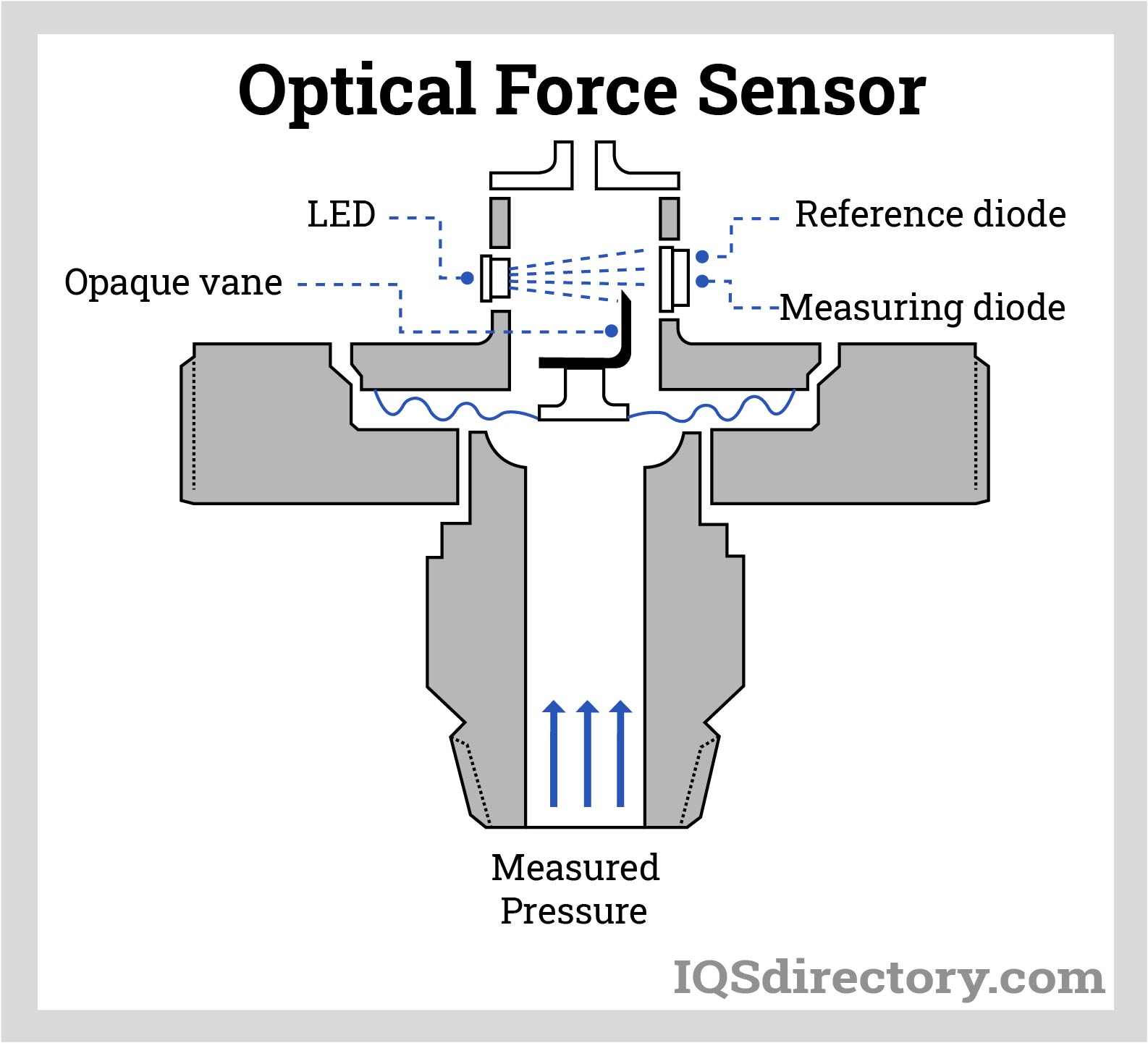

Optical force sensors utilize changes in light intensity to measure force, offering exceptional precision. They are particularly suited for high-precision applications in research and laboratory settings. While they provide excellent accuracy and are immune to electromagnetic interference, their higher cost and complex setup may deter some buyers. Companies looking for cutting-edge solutions for precision measurement will find optical sensors a worthy investment, provided they are prepared to manage the associated setup complexities.

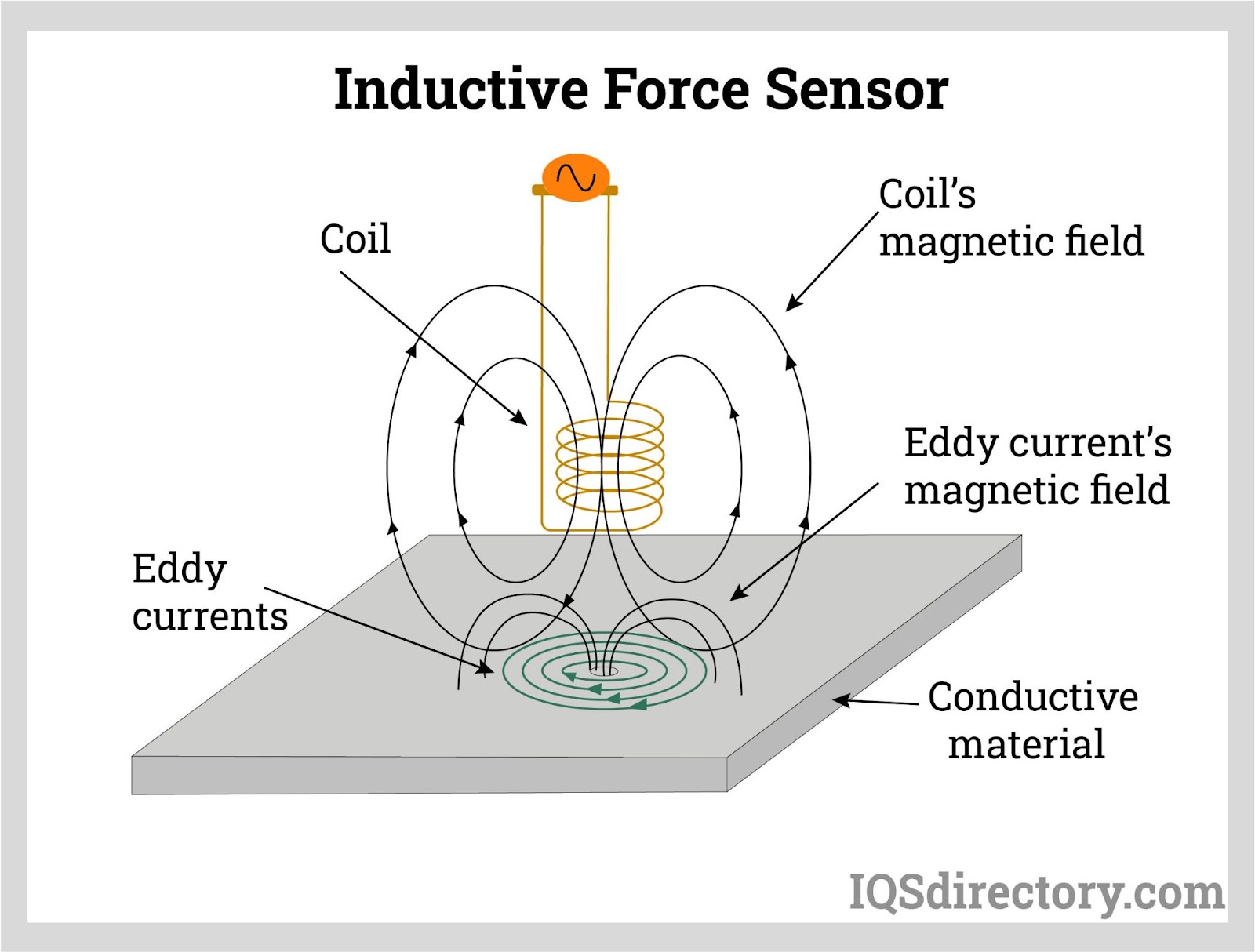

Why choose Magnetic Force Sensors for harsh environments?

Magnetic force sensors measure changes in magnetic fields caused by applied force, making them robust and reliable in harsh industrial environments. They are commonly used in aerospace and automation sectors, where external noise and interference can pose challenges. B2B buyers should consider the need for careful calibration when using magnetic sensors, as this ensures accurate measurements. Their resilience against environmental factors makes them a strong candidate for demanding applications, though buyers should weigh their calibration requirements against operational needs.

Key Industrial Applications of types of force sensors

| Industry/Sector | Specific Application of types of force sensors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Quality control in assembly lines for airbag systems | Ensures safety and compliance with regulations, reducing liability | Need for high precision sensors capable of rapid response times |

| Medical Devices | Force measurement in robotic surgery | Enhances surgical precision and patient safety | Requirements for miniaturization and biocompatibility |

| Aerospace | Load monitoring in aircraft components | Improves safety and performance of critical components | Must withstand extreme environmental conditions |

| Industrial Automation | Force feedback in robotic arms | Increases efficiency and adaptability in manufacturing processes | Sensors must be durable and capable of continuous operation |

| Consumer Electronics | Testing pressure sensitivity in touchscreens | Improves user experience and product quality | Need for compact sensors with high sensitivity and accuracy |

How Are Force Sensors Used in the Automotive Industry?

In the automotive sector, force sensors play a crucial role in quality control, particularly in airbag systems. These sensors ensure that airbags deploy correctly by measuring the force applied during a collision. This application not only enhances safety but also ensures compliance with stringent automotive regulations, thereby reducing liability for manufacturers. For international buyers, sourcing high-precision sensors that can respond rapidly to force changes is essential, particularly in markets like Brazil and South Africa, where safety standards are increasingly being enforced.

What Role Do Force Sensors Play in Medical Devices?

In the medical field, force sensors are integral to robotic surgery systems, where they measure the forces applied during surgical procedures. This capability allows for enhanced precision, which is critical for patient safety and successful outcomes. Buyers in this sector must prioritize miniaturization and biocompatibility when sourcing these sensors, especially in regions like Europe and the Middle East, where regulatory standards for medical devices are high.

How Are Force Sensors Applied in Aerospace?

Force sensors are vital in the aerospace industry for load monitoring in aircraft components. They provide real-time data on the forces acting on critical parts, thereby improving the safety and performance of these components. For businesses sourcing sensors in this sector, it is crucial to select devices that can withstand extreme environmental conditions, such as temperature fluctuations and vibrations, particularly in regions with varying climates.

Illustrative image related to types of force sensors

Why Are Force Sensors Important in Industrial Automation?

In industrial automation, force sensors are used for providing feedback in robotic arms. This feedback is essential for enhancing the efficiency and adaptability of manufacturing processes, enabling robots to handle various tasks with precision. Buyers should look for durable sensors capable of continuous operation, particularly in high-demand markets like South America and Africa, where industrial growth is rapidly evolving.

How Do Force Sensors Enhance Consumer Electronics?

Force sensors are also employed in consumer electronics to test the pressure sensitivity of touchscreens. By measuring the force applied to screens, manufacturers can improve user experience and product quality. For international buyers, sourcing compact sensors that offer high sensitivity and accuracy is vital, especially in competitive markets such as Europe and Vietnam, where consumer expectations are high.

3 Common User Pain Points for ‘types of force sensors’ & Their Solutions

Scenario 1: Calibration Challenges in Manufacturing Processes

The Problem: A manufacturing company in South America relies heavily on force sensors to ensure the quality of their production line. However, they often encounter issues with sensor calibration, leading to inaccurate measurements and costly production errors. The sensors may drift over time due to environmental factors like temperature fluctuations or mechanical stress, resulting in discrepancies that can compromise product quality and safety. This not only affects operational efficiency but also jeopardizes compliance with industry standards.

The Solution: To tackle calibration challenges, it is essential for the company to implement a regular maintenance and recalibration schedule. This can be achieved by investing in high-quality force sensors equipped with self-calibration features or built-in diagnostics that can alert operators when recalibration is needed. Additionally, partnering with a reputable supplier who offers training on calibration procedures can empower the team to perform these checks efficiently. Using a mobile calibration test bench can also facilitate on-site calibration, minimizing downtime. By integrating these practices, the company can maintain accuracy in their measurements and improve overall production reliability.

Scenario 2: Selecting the Right Force Sensor for Diverse Applications

The Problem: A European robotics firm is experiencing difficulties in choosing the appropriate force sensor for different applications in their robotic systems. With a variety of sensors available—such as strain gauges, piezoelectric, and capacitive sensors—the decision-making process is overwhelming. Each application has specific requirements for force measurement, and using the wrong type can lead to suboptimal performance or even failure in critical tasks, such as precision gripping or pressure sensing.

Illustrative image related to types of force sensors

The Solution: The key to resolving this issue lies in conducting a thorough needs assessment for each application. The firm should define the specific force measurement requirements, including the type of force (tension, compression, shear), the expected range, and the environmental conditions (such as humidity and temperature) the sensor will face. Collaborating with manufacturers to understand the unique strengths and limitations of each type of sensor can also provide valuable insights. Additionally, engaging in pilot testing with selected sensors can help validate their performance before full-scale implementation. This strategic approach will ensure that the firm selects the most suitable force sensors, enhancing the effectiveness of their robotic systems.

Scenario 3: Dealing with Environmental Interference in Sensor Performance

The Problem: An African automotive manufacturer faces challenges with their force sensors due to electromagnetic interference (EMI) in their production facility. This interference affects the accuracy of measurements, leading to inconsistencies in quality control processes for critical components like airbags and braking systems. These issues not only increase the risk of product failures but also escalate operational costs and delay production schedules.

The Solution: To combat environmental interference, the manufacturer should consider using magnetic force sensors, which are inherently immune to EMI. Additionally, implementing shielding techniques, such as using grounded enclosures or twisted-pair wiring, can further protect the sensors from external disturbances. It is also beneficial to conduct a comprehensive audit of the facility to identify sources of interference and mitigate them through better layout planning or by relocating sensitive equipment. Furthermore, investing in advanced data filtering and signal processing technologies can enhance the reliability of sensor outputs. By adopting these measures, the manufacturer can improve the reliability of their force measurements, ensuring higher product quality and safety.

Strategic Material Selection Guide for types of force sensors

What Are the Key Materials Used in Force Sensors?

When selecting force sensors, the choice of material plays a crucial role in determining the sensor’s performance, durability, and suitability for specific applications. Below, we analyze four common materials used in force sensors, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Strain Gauges Made from Metal Influence Force Sensor Performance?

Key Properties: Metal strain gauges, often made from alloys like constantan or nickel, exhibit excellent conductivity and mechanical strength. They can operate effectively in a wide temperature range, typically from -50°C to 150°C, and withstand significant pressure.

Pros & Cons: The durability of metal strain gauges makes them suitable for high-stress applications, but they can be susceptible to corrosion if not properly coated. While they are relatively cost-effective, the manufacturing complexity increases when creating precise configurations for specific applications.

Impact on Application: Metal strain gauges are ideal for dynamic applications in automotive and aerospace industries, where reliability under varying loads is essential. However, they may not perform well in corrosive environments unless treated.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure that suppliers can provide corrosion-resistant coatings, especially for applications in humid or saline environments.

Illustrative image related to types of force sensors

What Role Do Polymer-Based Sensors Play in Force Measurement?

Key Properties: Polymer-based force sensors are lightweight and flexible, often made from materials like polyimide or silicone. They can operate in temperatures ranging from -40°C to 120°C and are resistant to many chemicals.

Pros & Cons: The flexibility of polymer sensors allows for integration into compact spaces, making them suitable for applications in wearable technology. However, they may not offer the same level of accuracy as metal sensors and can be more expensive due to specialized manufacturing processes.

Impact on Application: These sensors are particularly useful in medical devices, where conformability and sensitivity to low forces are crucial. However, their limited temperature range can restrict usage in extreme environments.

Considerations for International Buyers: When sourcing polymer-based sensors, buyers should verify compliance with medical device regulations in their respective countries, as well as ensure that the materials used are biocompatible.

Illustrative image related to types of force sensors

How Do Piezoelectric Materials Enhance Force Sensor Functionality?

Key Properties: Piezoelectric materials, such as quartz or certain ceramics, generate an electrical charge in response to mechanical stress. They are capable of measuring rapid force changes and can operate effectively in a wide temperature range.

Pros & Cons: The primary advantage of piezoelectric sensors is their high sensitivity and fast response time, making them ideal for dynamic measurements. However, they can be more expensive and require specialized electronics for signal processing.

Impact on Application: These sensors are widely used in industrial automation and robotics, where quick feedback is necessary. Their sensitivity to environmental conditions, such as humidity and temperature, can affect performance, necessitating careful application design.

Illustrative image related to types of force sensors

Considerations for International Buyers: Buyers should ensure that piezoelectric sensors meet international standards for accuracy and reliability, particularly in high-precision applications. Regions with stringent regulations, like Europe, may require additional certifications.

What Advantages Do Optical Force Sensors Offer in Precision Applications?

Key Properties: Optical force sensors utilize light to measure force changes, offering high precision and immunity to electromagnetic interference. They can function effectively in a range of temperatures, typically from -20°C to 80°C.

Pros & Cons: The primary advantage is their precision, making them suitable for applications requiring exact measurements. However, they can be more complex and costly to manufacture, and their performance can be affected by environmental factors such as dust or moisture.

Impact on Application: Optical sensors are ideal for high-precision applications in laboratories and research settings. Their sensitivity to environmental conditions may limit their use in harsh industrial environments.

Illustrative image related to types of force sensors

Considerations for International Buyers: Buyers should consider the installation requirements and environmental conditions when selecting optical sensors. Compliance with international standards for optical measurements is also essential.

Summary Table of Material Selection for Force Sensors

| Material | Typical Use Case for types of force sensors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal (Strain Gauges) | Automotive, Aerospace | High durability and reliability | Susceptible to corrosion | Medium |

| Polymer | Medical devices, Wearable technology | Lightweight and flexible | Limited accuracy | High |

| Piezoelectric | Industrial automation, Robotics | High sensitivity and fast response | Requires specialized electronics | High |

| Optical | Laboratory research, Precision applications | High precision | Affected by environmental factors | High |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of force sensors

What Are the Main Stages in the Manufacturing Process of Force Sensors?

The manufacturing process of force sensors involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages helps B2B buyers ensure they are sourcing from reliable manufacturers.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing of force sensors is material preparation. The primary materials used include metals like stainless steel and aluminum for their strength and durability, along with specialized polymer materials for certain types of sensors. The selection of materials is crucial as they must withstand various environmental conditions and mechanical stresses. Manufacturers typically perform quality checks on raw materials to ensure they meet specified standards before moving on to the next stage.

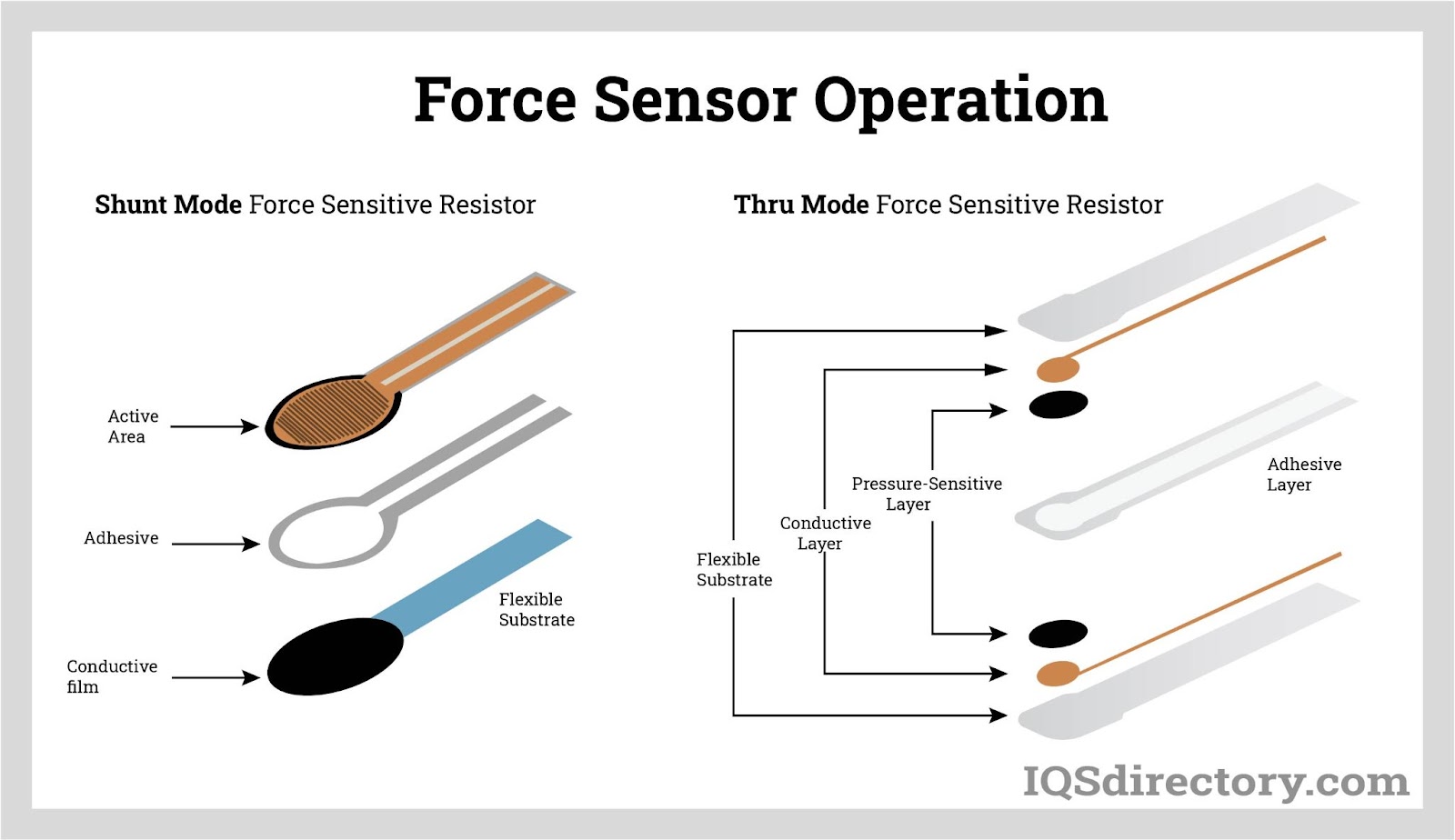

How Are Force Sensors Formed?

After preparing the materials, the next step is forming. This involves machining processes such as cutting, bending, and shaping the metal components that will house the sensor. Techniques like CNC (Computer Numerical Control) machining are often employed for precision and consistency. For strain gauge sensors, the strain gauges themselves are also fabricated during this stage, involving the bonding of conductive materials to flexible substrates. This precision is vital, as even minor deviations can affect measurement accuracy.

What Does the Assembly Process Entail?

The assembly process is where various components are brought together to create the final force sensor. This includes integrating the strain gauges, load cells, and other electronic components into a cohesive unit. Automated assembly lines may be utilized to enhance efficiency, though skilled technicians often oversee critical assembly tasks to ensure proper alignment and functionality. During assembly, it is essential to maintain a clean environment to prevent contamination that could lead to sensor failure.

How Is the Finishing Process Conducted?

Finishing is the final stage of manufacturing, which includes processes like painting, coating, or anodizing to enhance the sensor’s durability and corrosion resistance. This stage may also involve final calibrations to ensure the sensor provides accurate measurements. The finishing process not only improves the aesthetic appeal of the sensors but also extends their lifespan, making them suitable for various applications across different industries.

What Quality Assurance Measures Are Applied in Force Sensor Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for force sensors. Adhering to international standards and implementing robust QA measures ensures that the sensors meet the required performance criteria.

Which International Standards Are Relevant for Force Sensors?

Manufacturers of force sensors are often required to comply with international standards such as ISO 9001, which outlines quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications play a significant role in assuring product quality. These certifications indicate that the products have undergone rigorous testing and meet safety and performance standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch any defects early. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring and testing are performed to ensure that the assembly and forming processes are executed correctly.

- Final Quality Control (FQC): Before shipping, the final products undergo rigorous testing to verify their performance against specifications. This may include load testing, calibration checks, and electrical signal assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must have a clear strategy for verifying the quality control measures of their suppliers. This verification process can significantly impact their sourcing decisions and the reliability of the products they receive.

What Audit Processes Should Be Considered?

Conducting supplier audits is one of the most effective methods for verifying quality control practices. B2B buyers should consider both announced and unannounced audits to assess the supplier’s adherence to quality standards. During an audit, buyers should look for documentation of processes, certifications, and records of past inspections and tests.

Illustrative image related to types of force sensors

How Can Reports and Third-party Inspections Enhance Transparency?

Requesting detailed quality reports from suppliers can provide insight into their QA processes. These reports should include data on material certifications, testing outcomes, and compliance with relevant standards. Engaging third-party inspection services can also add an extra layer of credibility. Independent inspectors can evaluate the manufacturing process and provide unbiased reports on quality adherence.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Differences in regulatory standards and market expectations can impact sourcing decisions.

How Do Regional Standards Affect Sourcing Decisions?

Different regions may have varying standards and certifications that affect product acceptance. For instance, while CE marking is critical for products sold in Europe, other regions may prioritize different certifications. Buyers must ensure that their suppliers are compliant with the relevant standards for their target markets to avoid regulatory issues.

What Are the Challenges in Ensuring Quality Across Borders?

Cross-border sourcing can introduce challenges such as language barriers, differing regulatory environments, and varying quality expectations. To mitigate these challenges, B2B buyers should establish clear communication channels with suppliers, utilize technology for real-time updates, and consider local partners who understand the regional market dynamics.

Conclusion: Ensuring Quality in Force Sensors Manufacturing

In summary, the manufacturing processes and quality assurance measures for force sensors are intricate and require careful attention to detail. B2B buyers should prioritize suppliers that adhere to rigorous quality standards, utilize advanced manufacturing techniques, and demonstrate transparency through audits and certifications. By understanding these processes, buyers can make informed decisions that enhance their operations and ensure the reliability of the force sensors they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of force sensors’

In the evolving landscape of industrial applications, sourcing the right force sensors is essential for ensuring accurate measurements and operational efficiency. This practical guide provides a systematic approach to help B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effectively procure the appropriate types of force sensors for their needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before beginning your search for force sensors. Consider the types of forces you need to measure—tension, compression, or shear—and the required measurement range. This clarity will help you narrow down your options and ensure that the sensors you select are tailored to your specific applications.

Step 2: Identify Your Application Requirements

Different industries and applications may have distinct requirements for force sensors. For example, sensors used in medical devices must meet stringent safety and accuracy standards, while those in industrial automation may prioritize durability and resistance to environmental factors. Understanding these nuances will guide you in selecting sensors that not only perform well but also comply with industry regulations.

Illustrative image related to types of force sensors

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is necessary. Investigate company profiles, look for case studies, and request references from other buyers in similar industries or regions. Consider their experience with specific types of force sensors and their ability to provide technical support post-purchase, which is vital for effective implementation and troubleshooting.

Step 4: Assess Sensor Technology Types

Familiarize yourself with the various technologies available in force sensors, such as strain gauges, piezoelectric sensors, and capacitive sensors. Each technology has its advantages and limitations:

– Strain Gauges: Excellent for static measurements and offer high accuracy.

– Piezoelectric Sensors: Ideal for dynamic force measurements due to their rapid response times.

– Capacitive Sensors: Best suited for low-force applications and flexible installations.

Step 5: Verify Supplier Certifications and Standards

Ensure that potential suppliers adhere to relevant industry standards and possess necessary certifications, such as ISO 9001 or CE marking. These certifications indicate that the supplier maintains high-quality manufacturing processes and compliance with safety regulations, which is critical for minimizing risks in your operations.

Step 6: Request Samples and Conduct Testing

Before finalizing your purchase, request samples of the force sensors for testing in your specific environment. Evaluate their performance under real operational conditions to assess accuracy, durability, and ease of integration into your existing systems. This step can prevent costly mistakes and ensure the sensors meet your expectations.

Step 7: Review Pricing and Total Cost of Ownership

Finally, compare pricing among suppliers while considering the total cost of ownership. This includes not just the initial purchase price but also maintenance costs, expected lifespan, and potential downtime. A lower upfront cost might not always equate to the best long-term value, so it’s crucial to weigh these factors carefully.

By following this checklist, B2B buyers can systematically approach the sourcing of force sensors, ensuring they choose the right products that align with their operational needs and industry standards.

Comprehensive Cost and Pricing Analysis for types of force sensors Sourcing

When sourcing force sensors, understanding the comprehensive cost structure is crucial for making informed purchasing decisions. The cost components of force sensors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins. Each of these elements plays a significant role in the final pricing of force sensors.

Illustrative image related to types of force sensors

What Are the Key Cost Components in Force Sensor Manufacturing?

-

Materials: The choice of materials directly affects the cost of force sensors. High-quality components such as strain gauges, piezoelectric elements, and durable casings can increase initial costs but often result in better performance and longevity. For instance, stainless steel or specialized alloys may be preferred for their durability in harsh environments, driving up material costs.

-

Labor: Labor costs vary significantly based on the region and the level of expertise required for assembly and testing. In regions with higher labor costs, such as parts of Europe, the overall price of force sensors may be elevated. Conversely, sourcing from regions with lower labor costs can provide savings, but may come with trade-offs in quality or lead times.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs, which are typically factored into the pricing of force sensors. Manufacturers may pass these costs onto buyers, making it essential to understand the production environment of your supplier.

-

Tooling: Custom tooling can be necessary for producing specialized sensors. This upfront investment can lead to higher costs initially, but is often amortized over larger production runs, making it more cost-effective in high-volume scenarios.

-

Quality Control (QC): Rigorous testing and certification processes ensure that force sensors meet industry standards. These QC measures are vital for maintaining reliability and safety, especially in critical applications like aerospace and medical devices. However, they can add to the overall cost.

-

Logistics: Transporting sensors from manufacturers to buyers involves shipping costs, customs duties, and potential tariffs, especially for international transactions. Understanding these logistics costs is vital, as they can significantly impact total acquisition costs.

-

Margin: Suppliers typically apply a margin to cover their operating expenses and profit. This margin can vary based on market competition and the supplier’s position within the supply chain.

How Do Price Influencers Affect Force Sensor Costs?

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Buyers should negotiate to achieve favorable MOQs that balance inventory needs with cost savings.

-

Specifications/Customization: Custom specifications may increase costs due to the need for specialized manufacturing processes. Buyers should carefully consider their requirements to avoid unnecessary expenditures.

-

Materials and Quality Certifications: The level of certification required for specific applications, such as ISO or CE compliance, can influence pricing. High-quality materials and certifications may be more expensive but are essential for certain industries.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may command higher prices, but they often provide better assurance of product reliability.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for managing costs. Options such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final price and the responsibilities of buyers and sellers.

What Are Effective Buyer Tips for Sourcing Force Sensors?

Negotiating with suppliers can lead to significant cost savings. Buyers should be transparent about their budget and volume expectations to leverage better pricing. Additionally, consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs over the sensor’s lifespan.

For international buyers, especially those in Africa, South America, the Middle East, and Europe, understanding pricing nuances is essential. Currency fluctuations, import duties, and local market conditions can all affect the final cost. Therefore, it is advisable to conduct thorough market research and engage with multiple suppliers to gain insights into competitive pricing.

In conclusion, sourcing force sensors requires a comprehensive understanding of the cost structure and price influencers to ensure optimal purchasing decisions. Buyers should approach this process with diligence, leveraging the insights shared to achieve cost-effective and reliable solutions for their specific needs.

Alternatives Analysis: Comparing types of force sensors With Other Solutions

Introduction: What Are the Alternatives to Force Sensors?

When evaluating the best solutions for force measurement, B2B buyers must consider various technologies beyond traditional force sensors. While force sensors like load cells and strain gauges offer precise measurement capabilities, alternative methods exist that can also fulfill similar roles in specific contexts. This analysis aims to provide a comparative overview of force sensors against two viable alternatives: pressure sensors and mechanical switches, enabling buyers to make informed decisions based on their unique requirements.

Comparison Table

| Comparison Aspect | Types Of Force Sensors | Pressure Sensors | Mechanical Switches |

|---|---|---|---|

| Performance | High accuracy in measuring force (tension, compression, shear) | Good for static pressure measurement but limited in dynamic applications | Reliable in binary state detection (on/off) but lacks precision |

| Cost | Moderate to high cost depending on type and specifications | Generally lower cost, depending on technology (e.g., piezoresistive, capacitive) | Low cost and widely available |

| Ease of Implementation | Requires calibration and installation expertise | Easier to install with minimal calibration | Straightforward installation with simple wiring |

| Maintenance | Moderate; periodic calibration needed | Low maintenance; typically requires infrequent checks | Minimal; durable with long service life |

| Best Use Case | Precision applications in robotics, healthcare, and manufacturing | Suitable for monitoring fluid pressures in industrial systems | Ideal for simple on/off applications like control panels |

Detailed Breakdown of Alternatives

Pressure Sensors

Pressure sensors are devices that measure the pressure of gases or liquids within a system. They are typically less expensive than force sensors and easier to implement, making them attractive for projects with budget constraints. However, pressure sensors are often limited to static pressure measurements and may not perform well in dynamic or rapidly changing environments. Their primary use cases include HVAC systems, automotive applications, and fluid monitoring, where precision in force measurement is not as critical.

Illustrative image related to types of force sensors

Mechanical Switches

Mechanical switches serve as simple devices that detect the presence or absence of force, providing a binary output. They are cost-effective and easily integrated into control systems for applications like machinery operation and simple safety mechanisms. While they excel in simplicity and durability, mechanical switches lack the precision and versatility of force sensors. Their best use cases are in basic control panels or situations where precise force measurement is not required, making them ideal for straightforward applications.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate technology for force measurement depends on several factors, including the nature of the application, budget constraints, and required precision. Force sensors offer unparalleled accuracy and versatility, making them ideal for advanced applications in various industries. However, for projects with simpler requirements or tighter budgets, pressure sensors and mechanical switches can provide adequate solutions. B2B buyers should carefully assess their specific needs, considering performance, cost, ease of implementation, and maintenance to make the best choice for their operational goals.

Essential Technical Properties and Trade Terminology for types of force sensors

What Are the Essential Technical Properties of Force Sensors?

When evaluating force sensors, understanding their technical properties is crucial for B2B buyers. Here are some critical specifications that can impact performance and suitability for various applications:

1. Material Grade

The material used in force sensors significantly affects their durability, accuracy, and operational environment. Common materials include stainless steel and aluminum, chosen for their strength and resistance to corrosion. Selecting the right material ensures that the sensor can withstand environmental conditions such as humidity or chemical exposure, which is vital for industries such as automotive and pharmaceuticals.

Illustrative image related to types of force sensors

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. High tolerance levels are crucial in applications requiring precision, such as medical devices or aerospace components. A sensor with low tolerance can lead to inaccuracies, affecting product quality and safety. Therefore, understanding the required tolerance for a specific application helps in selecting the right sensor.

3. Measurement Range

This specification indicates the minimum and maximum force that a sensor can accurately measure. Understanding the required measurement range is essential for ensuring that the sensor can handle expected loads without risk of damage. For instance, in industrial applications, sensors must be capable of measuring high forces, while delicate tasks may only require low-force measurements.

4. Sensitivity

Sensitivity refers to a sensor’s ability to detect small changes in force. A highly sensitive sensor can provide valuable data in applications requiring fine measurements, such as robotics and quality control. Sensitivity is often expressed in terms of millivolts per volt (mV/V) or as a ratio, and it plays a significant role in the accuracy of force measurements.

5. Output Type

Force sensors can provide various output types, including analog voltage, digital signals, or frequency outputs. The choice of output type affects how the sensor integrates with existing systems. Understanding the output type is essential for ensuring compatibility with data acquisition systems and facilitating seamless operation in automated environments.

6. Operating Temperature Range

This specification denotes the range of temperatures within which the sensor can operate effectively. Force sensors used in extreme environments must be able to function reliably under varying temperatures. Selecting a sensor with the appropriate operating temperature range is critical for applications in sectors such as manufacturing and aerospace.

What Are Common Trade Terms in Force Sensor Procurement?

Navigating the procurement process for force sensors involves familiarizing oneself with industry-specific terminology. Here are some key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of force sensors, OEMs often provide specialized sensors that meet specific requirements for various applications, making them essential partners for businesses seeking tailored solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory and budget effectively. For instance, suppliers may have high MOQs for specialized force sensors, impacting the buyer’s purchasing strategy and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers to provide pricing for specific products or services. Issuing an RFQ for force sensors allows buyers to compare costs and terms from different vendors, facilitating informed decision-making and budget management.

Illustrative image related to types of force sensors

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is crucial for B2B transactions involving force sensors, as they dictate who is responsible for shipping, insurance, and tariffs, thereby influencing overall costs and logistics.

5. Calibration

Calibration is the process of configuring a sensor to provide accurate measurements. It is essential for maintaining the integrity of force sensors, particularly in industries where precision is critical. Regular calibration ensures that sensors continue to perform within specified tolerances, thus safeguarding product quality.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting force sensors that best suit their operational needs.

Navigating Market Dynamics and Sourcing Trends in the types of force sensors Sector

What Are the Current Market Trends Influencing Force Sensors?

The global force sensor market is witnessing significant growth, driven by advancements in technology and increasing demand across various industries such as automotive, aerospace, and healthcare. The integration of IoT and Industry 4.0 principles is revolutionizing force measurement by enabling real-time data collection and analysis, enhancing operational efficiencies for international B2B buyers. In regions like Africa and South America, the growing emphasis on automation in manufacturing is propelling the adoption of force sensors, with applications extending into robotics and smart devices.

Emerging trends such as miniaturization and the development of multifunctional sensors are catering to the needs of diverse applications, allowing companies to optimize space and improve accuracy. Additionally, the rise of electric vehicles in Europe and the Middle East is increasing the demand for force sensors in battery management systems and vehicle dynamics control, further fueling market growth. Buyers in these regions should also keep an eye on the trend towards customization, as manufacturers increasingly offer tailored solutions to meet specific operational requirements.

How Can Sustainability and Ethical Sourcing Impact the Force Sensor Market?

Sustainability is becoming a critical focus for B2B buyers in the force sensor sector, particularly as environmental regulations tighten globally. The manufacturing of force sensors can have a significant environmental impact, from the extraction of raw materials to energy consumption during production. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through eco-friendly practices and materials.

Ethical sourcing is gaining traction, with companies looking to ensure that their supply chains are free from exploitation and environmentally harmful practices. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances are becoming vital for suppliers seeking to establish credibility in the market. Moreover, the use of recyclable or biodegradable materials in sensor production is emerging as a preferred choice among environmentally-conscious buyers.

By aligning procurement strategies with sustainability goals, companies can not only enhance their brand image but also improve long-term profitability by reducing waste and operational costs. This shift towards responsible sourcing is likely to shape the landscape of force sensor procurement significantly.

How Have Force Sensors Evolved Over Time?

The evolution of force sensors dates back to the early 20th century, when basic mechanical devices were employed to measure force. Over the decades, technological advancements have transformed these simple devices into sophisticated sensors capable of high precision and versatility. The introduction of strain gauge technology in the 1950s marked a significant milestone, allowing for more accurate force measurement through electrical signals.

Today, force sensors utilize various technologies, including piezoelectric, capacitive, and optical sensing methods, each suited to specific applications. The continuous development of these technologies has led to the emergence of compact, lightweight sensors that can be integrated into a wide range of devices, from industrial machinery to medical equipment. As industries evolve, the demand for innovative force measurement solutions continues to rise, making it essential for B2B buyers to stay informed about the latest advancements in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of types of force sensors

-

How do I select the right type of force sensor for my application?

Selecting the appropriate force sensor involves evaluating several factors including the type of force you need to measure (tension, compression, shear), the required accuracy, the environmental conditions (temperature, humidity, vibration), and the physical space available for installation. Additionally, consider the sensor’s output type (analog or digital) and compatibility with your existing systems. Engaging with suppliers for expert guidance and conducting thorough product testing can further ensure you choose a sensor that meets your specific operational needs. -

What are the main types of force sensors available in the market?

The primary types of force sensors include strain gauge sensors, piezoelectric sensors, capacitive sensors, optical sensors, and magnetic sensors. Strain gauge sensors are widely used for their accuracy and reliability. Piezoelectric sensors excel in dynamic measurements, while capacitive sensors are ideal for low-force applications. Optical sensors offer high precision, and magnetic sensors are effective in environments with electromagnetic interference. Understanding these types will help you select the best sensor for your specific application. -

What customization options are available for force sensors?

Many manufacturers offer customization options for force sensors to meet specific requirements. Customizations may include alterations in size, shape, force range, output type, and environmental protections. Additionally, you can often request specific calibration settings or integrate sensors into existing systems. It’s essential to communicate your exact needs with potential suppliers to explore available options and ensure the sensor meets your operational standards. -

What are the minimum order quantities (MOQ) for force sensors?

Minimum order quantities for force sensors can vary widely among suppliers, ranging from a single unit for specialized applications to hundreds or thousands for bulk orders. It’s crucial to discuss your volume needs with potential suppliers to negotiate favorable terms. Some manufacturers may offer flexibility in MOQs for first-time buyers or smaller businesses, so it’s beneficial to explore multiple suppliers to find the best fit for your purchasing strategy. -

How can I ensure the quality of the force sensors I purchase?

To ensure quality, start by sourcing from reputable manufacturers with a proven track record in force sensor production. Request certifications such as ISO 9001 or other relevant quality management certifications. Additionally, ask for product specifications, performance data, and customer testimonials. It’s also advisable to conduct a quality assurance check upon receipt of the sensors, including testing their performance under your specific operating conditions. -

What payment terms are typically offered by force sensor suppliers?

Payment terms can vary significantly between suppliers, typically including options like upfront payment, net 30 or net 60 days, and even letter of credit for larger orders. Some suppliers may offer discounts for early payments or bulk orders. It’s essential to clarify payment terms during negotiation to avoid any misunderstandings. Establishing a good rapport with suppliers may also lead to more favorable terms. -

What logistics considerations should I keep in mind when sourcing force sensors internationally?

When sourcing force sensors internationally, consider shipping costs, customs duties, and lead times, which can vary based on the origin and destination. Ensure you understand the supplier’s shipping policies and whether they provide tracking information. Additionally, familiarize yourself with local regulations regarding imports to avoid delays. Partnering with a logistics provider experienced in international trade can streamline the process and mitigate potential issues. -

How do I vet suppliers for force sensors effectively?

Vetting suppliers involves assessing their credentials, manufacturing capabilities, and customer service reputation. Start by checking their certifications, production processes, and quality control measures. Request references from past clients, especially those in your industry, and consider visiting their facilities if possible. Online platforms and trade shows can also provide insights into supplier reliability. Conducting thorough research will help ensure you partner with a trustworthy supplier that meets your quality and service expectations.

Top 9 Types Of Force Sensors Manufacturers & Suppliers List

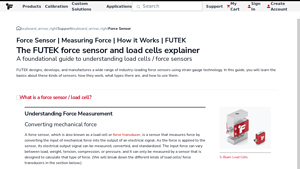

1. IQS Directory – Force Sensors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Force sensors are instruments that convert mechanical forces into electrical signals, measuring forces from grams to tons. They are used in various applications, including bathroom scales, medical devices, and industrial automation. Key factors to consider when selecting a force sensor include cost, repeatability, accuracy, environmental conditions, durability, response time, sensitivity, and form…

2. DSM Messtechnik – Force Sensors and Control Systems

Domain: dsm-messtechnik.de

Introduction: Different Types of Force Sensors: 1. Tightening Technique: Handheld Nutrunners – DSH Series, Built-In Nutrunners – DS Series. 2. Press-In Technique: Press-In Units – QMP Series, SMP Series, XMP Series. 3. Control Systems: MultiPro 3G, QS Box, QS Components. 4. Handling Systems: HST Series, HSA Series, POSI Series. 5. Accessories: IO Extension, I/O Expander, ToolControl, Linear Module, Workstations…

3. Flintec – Force Sensors

Domain: flintec.com

Registered: 2001 (24 years)

Introduction: Force Sensor: A device that measures applied force on an object and translates it into an electrical signal. Types include Strain Gauge, Piezoelectric, Capacitive, Optical, and Magnetic Force Sensors. Applications span robotics, healthcare, automotive, electronics, manufacturing, aerospace, and defense. Key features include measuring tension, compression, and shear forces, with considerations for …

4. FUTEK – Force Sensors

Domain: futek.com

Registered: 1996 (29 years)

Introduction: FUTEK designs, develops, and manufactures a wide range of industry-leading force sensors using strain gauge technology. A force sensor, also known as a load cell or force transducer, measures force by converting mechanical force into an electrical signal. Key features include:

– Types: S-Beam Load Cells, Nano Force Sensors, Torque Sensors, Multi-Axis Sensors, Pressure Sensors, Custom & Special Mod…

5. Robots Done Right – Robotic Force Sensors

Domain: robotsdoneright.com

Registered: 2015 (10 years)

Introduction: Robotic force sensors are becoming mainstream in robotic technology, enhancing manufacturing capabilities by providing robots with a sense of touch. Key types of robotic force sensors include: 1. Pressure Sensors: Basic and affordable, detecting force in one direction but not suitable for complex applications due to higher error margins. 2. Strain Gauge Force Sensors: Most common in industrial rob…

6. Phoeintl – Force Sensors

Domain: phoeintl.com

Registered: 2019 (6 years)

Introduction: Force sensors are devices used to measure the force or load applied to them, commonly used in industrial, automotive, robotics, and medical fields. Types of force sensors include: Strain Gauge Load Cells (measure strain and convert it to an electrical signal, available in beam, shear, and S-type configurations), Piezoelectric Force Sensors (generate electrical output proportional to force using th…

7. RobotShop – Sensor Solutions

Domain: robotshop.com

Registered: 2004 (21 years)

Introduction: This company, RobotShop – Sensor Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Digi-Key – Force Sensors

Domain: forum.digikey.com

Registered: 1995 (30 years)

Introduction: {“Force Sensors”: {“Description”: “Devices that detect and respond to pressure changes on actuators such as buttons, membranes, or plungers.”, “Sensor Types”: [“Force Sensing Resistor”, “Load Cell”, “Resistive”], “Operating Force Range”: {“Newtons”: “0 to 1500 N”, “Kilograms Force”: “0 to 22680 kgf”, “Pounds”: “0 to 50000 lbs”}, “Output Options”: [“Analog Voltage”, “Resistive”, “Ratiometric”, “Vol…

9. Lorenz Messtechnik – Force Sensors

Domain: lorenz-messtechnik.de

Introduction: Force Sensors by Lorenz Messtechnik GmbH are robust, reliable, and durable for measuring static, quasi-static, and dynamic tension and compression forces. Key types include: 1. Tension Force Sensors – Compact design, external threads or connecting straps, analog output in mV/V, optional extended temperature range (-40°C to 150°C). Applications: rope/spring force measurement, operating forces, belt…

Strategic Sourcing Conclusion and Outlook for types of force sensors

In summary, the selection of the right type of force sensor is pivotal for enhancing operational efficiency and accuracy across various industries. Understanding the distinct characteristics and applications of sensors such as strain gauges, load pins, and piezoelectric devices enables businesses to make informed procurement decisions. Strategic sourcing not only ensures the acquisition of high-quality sensors but also fosters strong supplier relationships, leading to better negotiation power and reduced costs.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe, it is crucial to consider factors such as environmental conditions, application specificity, and technological advancements when sourcing force sensors. The evolving landscape of force measurement technology presents opportunities for innovation, particularly in sectors like robotics and automation.

Engaging with trusted suppliers who understand your unique requirements can streamline your sourcing process and elevate your operational capabilities. Now is the time to invest in cutting-edge force sensor technologies that align with your business goals and drive future growth. Explore the vast potential of force sensors to transform your operations today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to types of force sensors

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.