Is Your Types Of Cleaning Brushes Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for types of cleaning brushes

In the competitive landscape of international business, sourcing the right types of cleaning brushes is critical for maintaining operational efficiency and hygiene standards. As B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate diverse markets, they face the challenge of identifying cleaning tools that not only meet their specific needs but also align with local regulations and cultural expectations. This comprehensive guide delves into the multifaceted world of cleaning brushes, exploring various types and their applications, such as janitorial, industrial, and specialized brushes for food service and healthcare.

Throughout this guide, buyers will gain valuable insights into the different bristle types and materials, allowing them to make informed choices based on durability and effectiveness. We will also cover essential factors for supplier vetting, cost considerations, and the importance of selecting brushes tailored to specific tasks, which can significantly impact operational success. By understanding these elements, B2B buyers can streamline their purchasing processes and ensure they invest in high-quality cleaning solutions that enhance cleanliness and safety in their operations.

Equipped with this knowledge, buyers will be empowered to navigate the global market confidently, ensuring they select the right cleaning brushes that meet their unique requirements while fostering a clean, inviting environment for their customers and employees alike.

Understanding types of cleaning brushes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Duster | Soft bristles for dust removal | Offices, restaurants, and retail spaces | Pros: Gentle on surfaces, effective dust removal. Cons: Not suitable for heavy grime. |

| Floor and Wall Brush | Sturdy bristles for scrubbing hard surfaces | Commercial kitchens, warehouses | Pros: Durable, effective for heavy-duty cleaning. Cons: May require additional scrubbing effort. |

| Grout Brush | Narrow, stiff bristles for tight spaces | Tile and grout cleaning in bathrooms | Pros: Excellent for deep cleaning grout lines. Cons: Labor-intensive for large areas. |

| Toilet Brush | Long handle with stiff bristles | Restroom sanitation | Pros: Promotes hygiene, easy to use. Cons: Limited to toilet cleaning only. |

| Bottle Brush | Flexible bristles on a long handle | Cleaning bottles and narrow containers | Pros: Versatile for various container shapes. Cons: May not be effective for larger surfaces. |

What Are the Key Characteristics of Dusters in B2B Cleaning?

Dusters are designed with soft bristles, making them ideal for removing dust from delicate surfaces without causing scratches. They are commonly used in offices, retail spaces, and restaurants to maintain a clean appearance. When purchasing dusters, B2B buyers should consider the bristle material, handle length, and ease of cleaning. A quality duster can enhance the visual appeal of a space, which is crucial for customer retention.

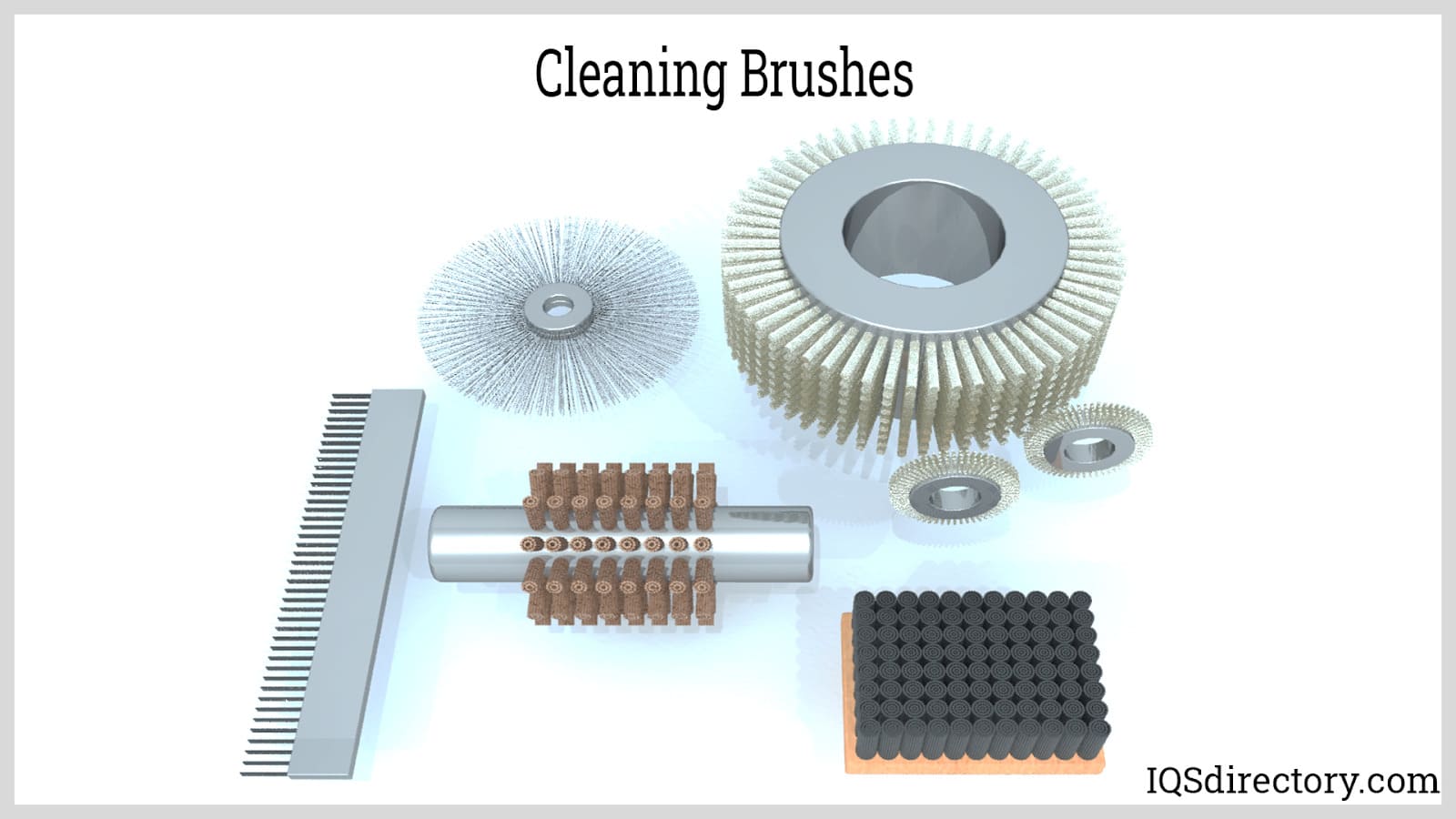

Illustrative image related to types of cleaning brushes

How Do Floor and Wall Brushes Support Heavy-Duty Cleaning?

Floor and wall brushes feature sturdy bristles specifically designed for scrubbing hard surfaces. These brushes are essential in commercial kitchens and warehouses where grease and grime accumulate. Buyers should look for brushes with durable construction and ergonomic handles for ease of use. While they are effective for heavy-duty cleaning, they may require more effort to achieve desired results, especially in high-traffic areas.

Why Are Grout Brushes Important for Maintaining Hygiene?

Grout brushes are characterized by their narrow, stiff bristles that excel in reaching tight spaces, making them perfect for cleaning tile grout. They are commonly used in bathrooms and kitchens to prevent mold and mildew buildup. B2B buyers should consider the brush’s size and bristle stiffness when selecting a grout brush, as these factors influence cleaning efficiency. While highly effective, using grout brushes can be labor-intensive, particularly in larger areas.

What Makes Toilet Brushes Essential in Restroom Sanitation?

Toilet brushes come equipped with stiff bristles and a long handle, facilitating thorough cleaning of toilet bowls. They are essential tools for maintaining restroom hygiene in any commercial setting. Buyers should prioritize the quality of bristles and handle design to ensure effective cleaning and ease of use. Although they are limited to toilet sanitation, investing in a good toilet brush is crucial for promoting overall cleanliness and customer satisfaction.

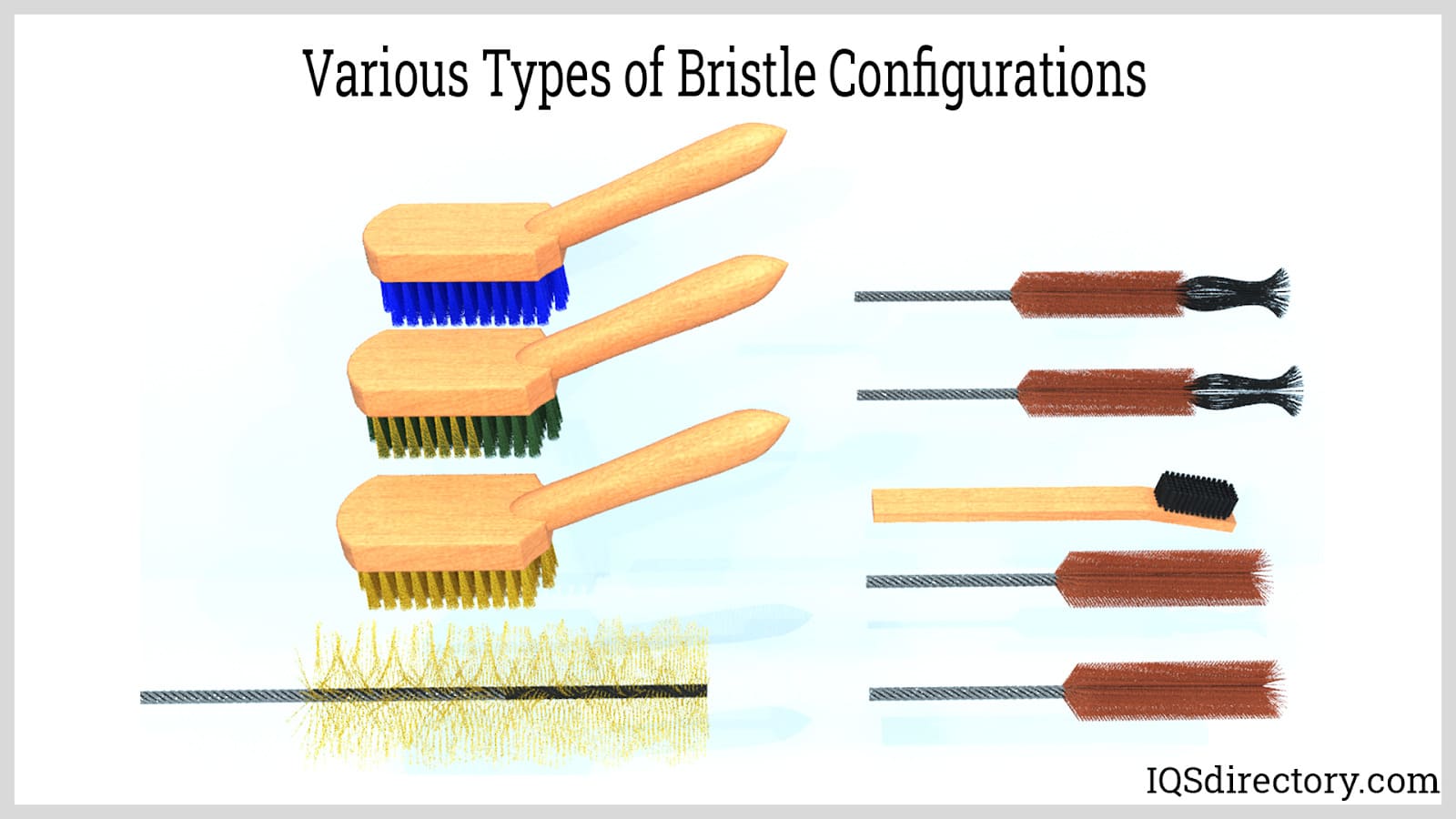

Illustrative image related to types of cleaning brushes

How Do Bottle Brushes Enhance Cleaning Versatility?

Bottle brushes feature flexible bristles on a long handle, making them suitable for cleaning various container shapes, particularly narrow bottles. They are valuable in food service and laboratory settings, where cleanliness of containers is paramount. When purchasing bottle brushes, B2B buyers should consider the flexibility of bristles and the length of the handle to ensure they can reach all areas. While versatile, bottle brushes are less effective for larger surface areas, requiring additional tools for comprehensive cleaning.

Key Industrial Applications of types of cleaning brushes

| Industry/Sector | Specific Application of types of cleaning brushes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Janitorial brushes for kitchens and dining areas | Enhances hygiene and customer satisfaction | Durability, bristle type for specific surfaces, compliance with food safety regulations |

| Manufacturing | Wire brushes for surface preparation and deburring | Improves product quality and reduces rework costs | Material strength, compatibility with machinery, brush size and shape |

| Healthcare | Specialized cleaning brushes for medical instruments | Ensures sanitation and compliance with health standards | Anti-microbial properties, ease of cleaning, size for instrument types |

| Hospitality | Toilet and restroom cleaning brushes | Maintains cleanliness and enhances guest experience | Material resistance to chemicals, ergonomic design, ease of use |

| Automotive | Cylinder brushes for engine parts cleaning | Increases operational efficiency and reduces downtime | Brush flexibility, compatibility with various engine designs, durability under harsh conditions |

How Are Janitorial Brushes Used in the Food Service Industry?

In the food service sector, janitorial brushes are essential for maintaining cleanliness in kitchens and dining areas. They help remove dirt, grease, and food particles, thus ensuring compliance with health regulations. Buyers need to consider the durability and type of bristles to match various surfaces, as well as compliance with food safety standards, especially in regions like Europe and South America where regulations are strict.

What Role Do Wire Brushes Play in Manufacturing?

Wire brushes are critical in manufacturing for surface preparation, deburring, and finishing processes. They effectively remove rust, paint, and other contaminants from metal surfaces, enhancing product quality. For international buyers, sourcing wire brushes requires attention to material strength and compatibility with specific machinery, particularly in high-demand markets like Germany and Brazil, where production efficiency is paramount.

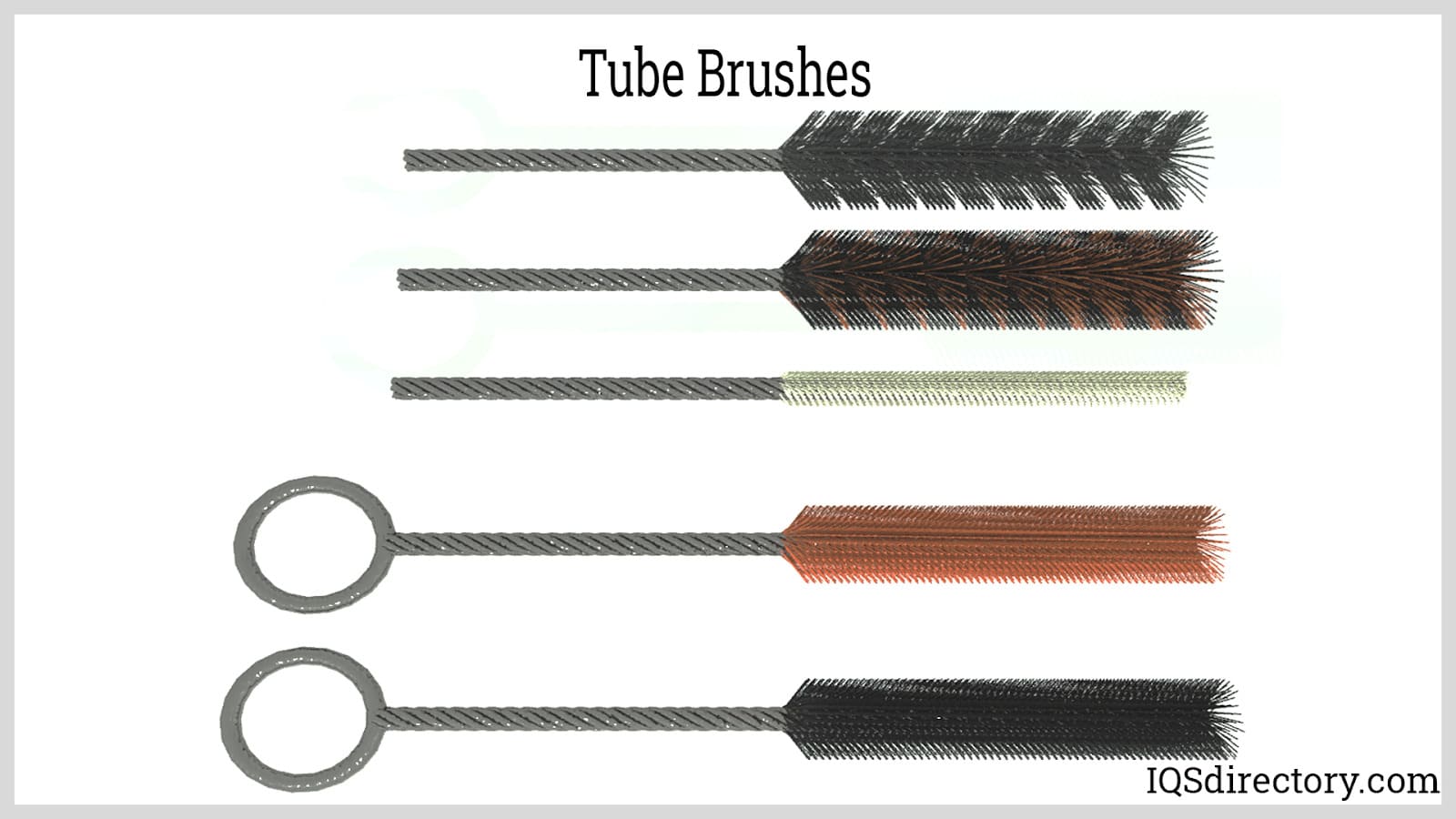

Illustrative image related to types of cleaning brushes

How Are Specialized Cleaning Brushes Used in Healthcare?

In healthcare settings, specialized cleaning brushes are vital for sanitizing medical instruments and surfaces. They help prevent cross-contamination and maintain a sterile environment, crucial for patient safety. Buyers in this sector must prioritize brushes with anti-microbial properties and ease of cleaning, ensuring compliance with strict health standards prevalent in regions such as the Middle East and Europe.

Why Are Toilet Cleaning Brushes Important in Hospitality?

Toilet cleaning brushes are essential in the hospitality industry for maintaining restroom hygiene. They facilitate thorough cleaning and sanitation, which is vital for guest satisfaction and overall reputation. Buyers should consider the material’s resistance to harsh chemicals and ergonomic designs for ease of use, particularly in high-traffic areas. This is especially relevant in regions with diverse customer expectations, such as Africa and South America.

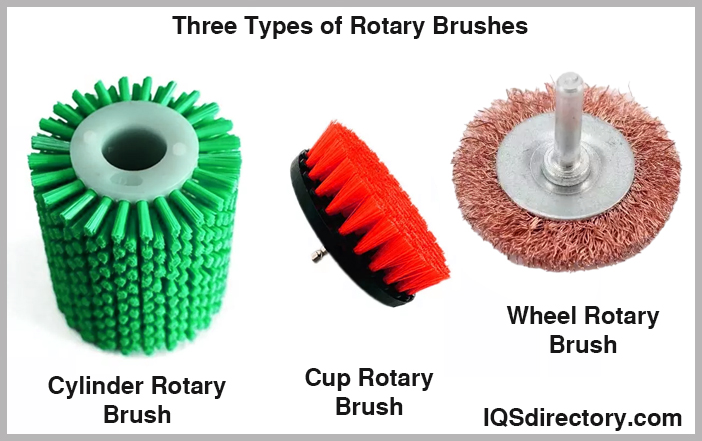

What Benefits Do Cylinder Brushes Provide in Automotive Cleaning?

Cylinder brushes are used extensively in the automotive industry for cleaning engine parts and other components. Their flexibility allows them to reach intricate areas, ensuring thorough cleaning without damaging surfaces. When sourcing these brushes, buyers should consider their durability under harsh conditions and compatibility with various engine designs, especially in rapidly growing markets like Brazil and the Middle East.

Illustrative image related to types of cleaning brushes

3 Common User Pain Points for ‘types of cleaning brushes’ & Their Solutions

Scenario 1: Inadequate Brush Selection for Specific Cleaning Tasks

The Problem: Many B2B buyers struggle with selecting the right cleaning brushes for specific applications within their facilities. For example, a restaurant manager may purchase a standard scrub brush, believing it will suffice for all surfaces. However, this brush might be too harsh for delicate surfaces like glass or too soft for heavily soiled kitchen floors. This misalignment can lead to ineffective cleaning, increased labor costs, and ultimately, unsatisfactory hygiene standards that could jeopardize the establishment’s reputation.

The Solution: To address this issue, buyers should conduct a thorough needs assessment before making purchases. Start by categorizing the surfaces that require cleaning—identify materials such as tile, stainless steel, and wood. Then, research specific brush types tailored to these surfaces. For instance, use nylon brushes for stainless steel due to their durability and resistance to corrosion, while opting for softer bristle brushes for delicate glass surfaces. Additionally, consider consulting with suppliers who can provide samples or demonstrations of the brushes to ensure they meet the required specifications.

Scenario 2: Brush Maintenance and Longevity Challenges

The Problem: B2B buyers often face the challenge of maintaining cleaning brushes to ensure their longevity and effectiveness. Over time, bristles can become worn or contaminated, leading to reduced cleaning performance. For example, a commercial kitchen that neglects regular brush maintenance may find that its grout brushes are ineffective at removing dirt and grime, resulting in unsanitary conditions and increased risk of cross-contamination.

The Solution: Implementing a structured maintenance routine is crucial for preserving the effectiveness of cleaning brushes. Buyers should establish a cleaning protocol that includes regular inspections of brush bristles for wear and tear. Brushes that show signs of damage should be replaced immediately to prevent ineffective cleaning. Additionally, designate specific brushes for particular tasks and clean them appropriately after each use. For instance, after using a grout brush, rinse it under hot water and use dish detergent to remove any residue, ensuring that it remains sanitary for future use. Educating staff on proper brush care can significantly extend the lifespan of the tools and maintain high hygiene standards.

Scenario 3: Overlooking the Importance of Brush Materials

The Problem: A common oversight among B2B buyers is not considering the material composition of cleaning brushes, which can greatly affect their performance and suitability for different environments. For instance, a facility manager might choose a brush with natural bristles for a high-heat environment, leading to quick degradation and the need for frequent replacements. This not only incurs additional costs but also disrupts operations due to the need for constant replenishment of cleaning supplies.

Illustrative image related to types of cleaning brushes

The Solution: Buyers should prioritize understanding the materials used in cleaning brushes and their appropriate applications. Synthetic bristles, for example, are often more suitable for environments exposed to heat, chemicals, or moisture, making them ideal for kitchens and industrial settings. In contrast, natural bristles may be more appropriate for delicate tasks, such as cleaning painted surfaces. When sourcing brushes, inquire about the specific properties of the bristles—such as heat resistance, flexibility, and durability— to ensure that they align with the intended use. This knowledge will empower buyers to make informed decisions, optimizing their cleaning processes and reducing overall costs associated with brush replacements.

Strategic Material Selection Guide for types of cleaning brushes

What Are the Key Properties of Common Materials Used in Cleaning Brushes?

When selecting cleaning brushes for various applications, understanding the materials used is crucial for optimizing performance and ensuring compliance with industry standards. Here, we analyze four common materials: nylon, polypropylene, boar bristles, and wire.

How Does Nylon Contribute to Brush Performance?

Nylon is a synthetic material known for its durability and versatility. It exhibits excellent abrasion resistance, making it suitable for tough cleaning tasks. Nylon brushes can withstand temperatures up to 200°C, which is beneficial for applications involving hot surfaces. However, while nylon is resistant to many chemicals, it may not be suitable for highly acidic or alkaline environments.

Pros: Highly durable, resistant to chemicals, and heat tolerant.

Cons: Can be more expensive than natural fibers and may not be biodegradable.

Impact on Application: Ideal for industrial and commercial settings where rigorous cleaning is required, such as food processing plants.

Considerations for International Buyers: Ensure compliance with ASTM standards for durability and chemical resistance.

What Advantages Does Polypropylene Offer for Cleaning Brushes?

Polypropylene is another synthetic option that provides flexibility and resilience. It is particularly effective in environments where moisture is prevalent, as it resists water absorption. Polypropylene brushes can endure temperatures up to 90°C. However, they may not be as durable as nylon in high-abrasion applications.

Illustrative image related to types of cleaning brushes

Pros: Cost-effective, lightweight, and resistant to moisture.

Cons: Lower heat resistance compared to nylon, and less durable under heavy use.

Impact on Application: Suitable for general cleaning tasks in both indoor and outdoor settings.

Considerations for International Buyers: Check for compliance with local standards, particularly in regions with strict environmental regulations.

Why Are Boar Bristles Considered a Premium Choice?

Boar bristles are a natural option favored for their soft, absorbent qualities. They are particularly effective on delicate surfaces, making them suitable for applications where scratching is a concern. However, boar bristles have a lower temperature tolerance, typically around 70°C, which limits their use in high-heat environments.

Pros: Gentle on surfaces, highly absorbent, and biodegradable.

Cons: More expensive and less durable than synthetic options.

Impact on Application: Best suited for cleaning delicate items, such as glassware or fine china.

Considerations for International Buyers: Ensure that the sourcing of natural fibers complies with environmental sustainability standards.

What Role Do Wire Brushes Play in Heavy-Duty Cleaning?

Wire brushes are constructed with stiff bristles made from various metals, making them ideal for abrasive cleaning tasks, such as removing rust or paint. They can withstand high temperatures and heavy pressure, which is advantageous in industrial applications. However, their rigidity can damage softer surfaces, making them less versatile.

Pros: Extremely durable and effective for heavy-duty applications.

Cons: Can cause surface damage and are not suitable for delicate cleaning tasks.

Impact on Application: Commonly used in metalworking and automotive industries for surface preparation.

Considerations for International Buyers: Verify compliance with safety standards to prevent injuries during use.

Illustrative image related to types of cleaning brushes

Summary of Material Selection for Cleaning Brushes

| Material | Typical Use Case for types of cleaning brushes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Industrial cleaning in food processing | Highly durable and heat resistant | More expensive than natural fibers | Medium |

| Polypropylene | General cleaning tasks indoors and outdoors | Cost-effective and moisture resistant | Lower heat resistance | Low |

| Boar Bristles | Cleaning delicate items like glassware | Gentle and biodegradable | Less durable and higher cost | High |

| Wire | Heavy-duty applications like rust removal | Extremely durable for tough tasks | Can damage softer surfaces | Medium |

Understanding these materials and their properties allows international B2B buyers to make informed decisions tailored to their specific cleaning needs, ensuring compliance with local standards and enhancing operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for types of cleaning brushes

What Are the Key Stages in the Manufacturing Process of Cleaning Brushes?

The manufacturing of cleaning brushes involves several critical stages that ensure the final product meets quality and performance standards. Understanding these processes allows B2B buyers to appreciate the craftsmanship and reliability of the products they are purchasing.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing cleaning brushes is the selection and preparation of raw materials. Common materials include various types of bristles (such as nylon, polypropylene, and natural fibers), handles made from plastic, wood, or metal, and adhesives used to bond bristles to handles. Each material is chosen based on the intended use of the brush. For instance, nylon bristles are favored for their durability and resistance to chemicals, while natural fibers may be chosen for their absorbent properties.

Once the materials are selected, they undergo quality checks to ensure they meet industry standards. This includes verifying the strength and flexibility of the bristles and ensuring the handles are free from defects.

How Are Cleaning Brushes Formed?

The forming stage involves shaping the materials into the desired brush design. Different techniques are employed depending on the type of brush being produced. For example:

- Injection Molding: Often used for plastic handles, this technique allows for mass production of uniform shapes and sizes.

- Tufting: In this process, bristles are inserted into holes in the brush head and secured with adhesive. This method is commonly used for various types of janitorial brushes.

- Wire Binding: For wire brushes, metal filaments are wound around a core to create a dense bristle pack, which is ideal for heavy-duty cleaning tasks.

These techniques ensure that brushes are not only functional but also ergonomically designed for user comfort and efficiency.

What Does the Assembly Process Involve?

Once the components are formed, they move to the assembly stage. Here, bristles are attached to handles, and any additional features (like ergonomic grips or hanging holes) are incorporated. Assembly can be automated or manual, depending on the scale of production and the complexity of the brush design.

Quality control is integrated into this stage, with inspections to ensure that bristles are securely attached and that the final product meets the required specifications for weight, balance, and usability.

What Finishing Techniques Are Applied to Cleaning Brushes?

The finishing stage enhances the brush’s aesthetic appeal and functionality. This can include:

- Surface Treatment: Handles may undergo treatments such as sanding or coating to improve grip and appearance.

- Quality Coating: Some brushes receive a protective coating to enhance durability against chemicals and wear.

- Labeling and Packaging: Final packaging is designed to protect the brushes during transport and provide information to consumers regarding usage and care.

How Is Quality Assurance Implemented in Cleaning Brush Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of cleaning brushes, particularly for B2B buyers who require consistent performance and reliability.

What International Standards Are Relevant for Quality Assurance?

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications like CE marking (for compliance with European health, safety, and environmental protection standards) and API standards (for brushes used in industrial applications) are crucial indicators of quality.

What Quality Control Checkpoints Are Commonly Used?

Quality control checkpoints in the manufacturing process typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they are used in production to ensure they meet predefined standards.

- In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor the manufacturing process and ensure that each stage adheres to quality specifications.

- Final Quality Control (FQC): After assembly, finished brushes undergo rigorous testing to assess their performance, durability, and safety.

Common testing methods may include:

- Functional Testing: Assessing the brush’s cleaning efficacy and durability.

- Material Testing: Evaluating the strength and flexibility of bristles and handles.

- Chemical Resistance Testing: Ensuring materials can withstand exposure to various cleaning agents.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure they are investing in reliable products. Here are several ways to conduct this verification:

What Steps Should Be Taken for Supplier Audits?

- On-Site Audits: Conducting on-site visits to the manufacturing facility allows buyers to evaluate production processes, quality control measures, and overall working conditions.

- Requesting Quality Reports: Suppliers should provide documentation of their quality assurance processes, including results from IQC, IPQC, and FQC assessments.

How Important Are Third-Party Inspections?

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality practices. These organizations often have established protocols for assessing compliance with international standards and can offer insights into areas for improvement.

What Nuances Should International Buyers Consider Regarding Quality Control?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control practices. For instance:

- Regional Standards: Different countries may have varying regulations regarding product safety and environmental impact, so it is crucial to ensure that suppliers are compliant with local laws.

- Cultural Expectations: Understanding cultural differences in business practices can enhance communication and expectations regarding quality and delivery timelines.

- Logistics and Supply Chain Factors: Buyers must consider the logistics of sourcing materials and the implications for quality, particularly in regions with less consistent supply chains.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring that they source high-quality cleaning brushes that meet their operational needs and standards.

Illustrative image related to types of cleaning brushes

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of cleaning brushes’

Introduction

When it comes to maintaining cleanliness in a commercial setting, selecting the right cleaning brushes is essential. This guide offers a step-by-step checklist to help B2B buyers effectively source various types of cleaning brushes, ensuring optimal hygiene standards, efficiency, and suitability for specific cleaning tasks.

Step 1: Identify Your Cleaning Needs

Understanding the specific cleaning tasks your business requires is the first step in sourcing the right brushes. Assess areas that need regular cleaning, such as kitchen floors, equipment, or restrooms. Different brushes serve distinct purposes, such as grout brushes for tiles or toilet brushes for restroom maintenance.

Step 2: Define Your Technical Specifications

Clearly outline the specifications needed for each type of brush you intend to procure. Consider the materials, bristle types, and dimensions that will best suit your cleaning applications. For instance, synthetic bristles are ideal for durability and resistance to chemicals, while softer bristles are necessary for delicate surfaces to avoid scratches.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in cleaning brushes. Look for companies with a strong track record in the industry and positive customer reviews. Evaluate their product range to ensure they offer the specific types of brushes you need.

- Tip: Use trade directories and industry forums to find suppliers with experience in your region, particularly in Africa, South America, the Middle East, and Europe.

Step 4: Verify Supplier Certifications

Before finalizing any purchase, confirm that your chosen suppliers meet industry standards and certifications. This can include ISO certifications or adherence to local health and safety regulations. Certified suppliers are more likely to provide high-quality products that meet your operational standards.

Illustrative image related to types of cleaning brushes

Step 5: Request Samples and Conduct Quality Checks

Always request samples of the brushes to evaluate their quality before making a bulk purchase. Assess the bristle quality, handle durability, and overall construction. Conducting a quality check ensures that the brushes will perform well in your specific cleaning environments and withstand regular use.

Step 6: Evaluate Pricing and Payment Terms

Compare pricing from different suppliers while considering the quality of the brushes. Look for bulk purchase discounts or flexible payment terms that can benefit your budget. Remember, the cheapest option may not always be the best in terms of durability and performance.

Step 7: Establish a Reliable Supply Chain

Once you’ve selected your suppliers, work on building a reliable supply chain. Discuss lead times, delivery schedules, and inventory management practices to ensure that you can maintain adequate stock levels without interruptions. A dependable supply chain is crucial for consistent cleanliness and operational efficiency.

Illustrative image related to types of cleaning brushes

By following these steps, B2B buyers can effectively source the right types of cleaning brushes tailored to their specific needs, ensuring a clean and hygienic environment for their operations.

Comprehensive Cost and Pricing Analysis for types of cleaning brushes Sourcing

What Are the Key Cost Components in Cleaning Brush Manufacturing?

When sourcing cleaning brushes, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of bristles (e.g., nylon, polypropylene, natural fibers) significantly impacts the cost. Synthetic bristles are typically more cost-effective and durable, while natural fibers can be more expensive due to their sourcing challenges.

-

Labor: Labor costs can vary based on the region where manufacturing occurs. Countries with lower labor costs may offer competitive pricing but might compromise on quality. It’s crucial to evaluate the skill level and training of the workforce involved in the production process.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, equipment depreciation, and utilities. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial investment in specialized tools for brush production can be significant. This is especially relevant for custom brush designs, where the tooling costs need to be amortized over the expected production volume.

-

Quality Control (QC): Ensuring that brushes meet quality standards requires investment in testing and inspection processes. This is particularly important for brushes intended for food service or medical applications, where hygiene and safety are paramount.

-

Logistics: Shipping costs can vary widely depending on the distance and mode of transport. International buyers should consider the implications of tariffs and customs duties, which can affect the overall cost.

-

Margin: Suppliers typically mark up prices to ensure profitability. Understanding the typical margins in the industry can help buyers negotiate better prices.

What Influences Pricing for Cleaning Brushes in B2B Transactions?

Several factors can influence the pricing of cleaning brushes, particularly for international buyers.

Illustrative image related to types of cleaning brushes

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and consider bulk purchasing to maximize savings.

-

Specifications and Customization: Custom brushes designed for specific applications may incur higher costs due to the need for specialized materials and tooling. Clear communication about requirements can help manage expectations and costs.

-

Material Quality and Certifications: Brushes that meet specific industry standards (e.g., FDA approval for food service) may be priced higher. Buyers should weigh the benefits of certified products against their cost.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms used in international shipping is crucial. They dictate responsibilities for shipping costs, insurance, and liability, which can influence the overall pricing structure.

How Can Buyers Negotiate Effectively for Cleaning Brushes?

To achieve cost-efficiency in sourcing cleaning brushes, buyers should consider several negotiation strategies:

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, evaluate the TCO, which includes maintenance, longevity, and disposal costs. This approach can justify a higher initial investment in quality brushes.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage during negotiations. It also allows buyers to compare quality and service levels.

-

Discuss Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options such as extended payment periods or discounts for early payments.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and service over time. Suppliers may be more willing to offer discounts or favorable terms to loyal customers.

-

Stay Informed About Market Trends: Understanding market dynamics, such as material availability and production costs, can empower buyers to negotiate more effectively.

Conclusion

In the competitive landscape of cleaning brush sourcing, a thorough understanding of cost components and pricing influencers is essential for making informed purchasing decisions. By leveraging negotiation strategies and considering the total cost of ownership, international B2B buyers can achieve significant savings while ensuring they acquire high-quality cleaning brushes that meet their operational needs. Always remember that prices can vary widely, and it is advisable to seek multiple quotations and conduct thorough due diligence before finalizing any agreements.

Alternatives Analysis: Comparing types of cleaning brushes With Other Solutions

Understanding Alternatives to Cleaning Brushes in Professional Settings

In the realm of professional cleaning, businesses often face the challenge of selecting the most effective tools and methods. While cleaning brushes are a staple in janitorial practices, several alternative solutions exist that can achieve similar goals. Understanding the pros and cons of these alternatives helps B2B buyers make informed decisions tailored to their specific operational needs.

Comparison of Cleaning Brushes with Alternative Solutions

| Comparison Aspect | Types Of Cleaning Brushes | Electric Pressure Washers | Microfiber Cloths |

|---|---|---|---|

| Performance | Highly effective for targeted cleaning; versatile across surfaces | Excellent for deep cleaning and removing tough grime quickly | Good for dusting and light cleaning; may require multiple passes for deep stains |

| Cost | Moderate initial investment; long-term savings with durability | Higher upfront cost; potential savings on labor | Low cost; requires frequent replacement |

| Ease of Implementation | Requires training for specific brushes and techniques | Can be complex; requires setup and understanding of equipment | Very easy to use; minimal training needed |

| Maintenance | Requires periodic cleaning and replacement of bristles | Requires regular maintenance and occasional repairs | Low maintenance; replace when worn out |

| Best Use Case | Ideal for detailed cleaning in kitchens and restrooms | Best for exterior cleaning and large surfaces | Perfect for light cleaning and dusting in various environments |

Detailed Breakdown of Alternatives

Electric Pressure Washers

Electric pressure washers are powerful tools that utilize high-pressure water jets to remove dirt, grime, and stains. They excel in situations requiring deep cleaning, such as outdoor surfaces, large floors, and heavy machinery. However, their higher upfront cost can be a barrier for smaller businesses, and they may require specialized training for proper operation. Additionally, while effective, they might not be suitable for delicate surfaces where brushes can provide a gentler touch.

Microfiber Cloths

Microfiber cloths have gained popularity due to their versatility and efficiency in cleaning. They are excellent for capturing dust and dirt without the need for harsh chemicals, making them an eco-friendly choice. Their low cost is appealing, but they do have a shorter lifespan compared to brushes, requiring frequent replacements. Microfiber cloths are particularly suited for light cleaning tasks and maintaining surfaces, but they may not be effective for heavy-duty scrubbing or deep cleaning needs.

Illustrative image related to types of cleaning brushes

Conclusion: How to Choose the Right Cleaning Solution

When selecting a cleaning solution, B2B buyers should consider factors such as the specific cleaning tasks at hand, budget constraints, and the operational environment. Cleaning brushes remain a reliable option for targeted cleaning in various settings, particularly in foodservice and sanitation contexts. However, electric pressure washers and microfiber cloths can provide effective alternatives depending on the scale and nature of the cleaning required. By carefully assessing these aspects, businesses can invest in the most appropriate cleaning tools that align with their operational goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for types of cleaning brushes

What Are the Key Technical Properties of Cleaning Brushes in B2B Markets?

In the realm of cleaning brushes, understanding specific technical properties is crucial for B2B buyers. Selecting the right brush can significantly impact cleaning efficiency, hygiene standards, and overall operational effectiveness. Here are several essential specifications to consider:

-

Material Composition

– The material of the bristles and the handle affects durability and cleaning efficacy. Common materials include synthetic fibers, nylon, polypropylene, and natural fibers like boar bristles. Synthetic fibers are often preferred for their resistance to chemicals and moisture, making them suitable for various cleaning tasks in commercial settings. -

Bristle Hardness

– Bristle hardness varies from soft to hard, impacting the brush’s ability to clean different surfaces. Soft bristles are ideal for delicate surfaces, preventing scratches, while hard bristles are effective for tough grime and grease removal. Understanding this property allows buyers to choose brushes that align with their specific cleaning requirements. -

Handle Design and Ergonomics

– The design of the brush handle plays a vital role in user comfort and effectiveness. Ergonomic handles reduce strain during prolonged use, which is particularly important in high-volume environments. Buyers should consider handle length, grip design, and overall weight to enhance user experience and productivity. -

Resistance to Wear and Chemical Exposure

– Brushes used in industrial settings often encounter harsh chemicals and abrasive materials. Selecting brushes with high resistance to wear and chemical exposure can extend their lifespan and reduce replacement frequency. This property is particularly crucial for businesses in sectors like food service and manufacturing. -

Compatibility with Cleaning Systems

– Certain brushes are designed to be compatible with specific cleaning machines or systems. Understanding the compatibility of brushes with existing equipment ensures seamless integration and optimized cleaning processes. This factor can influence purchasing decisions, especially for large-scale operations. -

Bristle Recovery Strength

– This refers to a bristle’s ability to maintain its shape after use. Brushes with high recovery strength are less likely to splay or break, leading to longer-lasting performance. This property is essential for maintaining consistent cleaning standards over time.

What Are the Common Trade Terms Related to Cleaning Brushes?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the cleaning brush industry, OEMs can provide customized brushes tailored to specific business needs, ensuring quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and ensure they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. It allows buyers to gather competitive bids and make informed purchasing decisions based on cost, quality, and service. -

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping, insurance, and delivery obligations. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for effective inventory management and ensuring that cleaning operations remain uninterrupted. -

Bulk Packaging

– This term describes the packaging of large quantities of products, often used to reduce costs and improve shipping efficiency. Buyers should consider bulk packaging options to optimize their supply chain and reduce per-unit costs.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right cleaning brushes for their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the types of cleaning brushes Sector

What Are the Current Market Dynamics and Trends in the Cleaning Brushes Sector?

The global cleaning brushes market is experiencing significant growth, driven by increasing awareness of hygiene standards across various industries, including food service, healthcare, and manufacturing. The demand for specialized cleaning tools is rising as businesses aim to meet stringent sanitation regulations and enhance customer experiences. This is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where B2B buyers are seeking reliable, high-quality cleaning brushes that can withstand rigorous use. Technological advancements are also shaping the sector, with innovations in bristle materials and ergonomic handle designs improving efficiency and user comfort.

Emerging trends indicate a shift towards multifunctional cleaning brushes that can tackle a variety of surfaces and materials, reducing the need for multiple tools. For instance, brushes with interchangeable heads or adjustable handles are gaining traction, appealing to businesses that prioritize space and cost efficiency. Moreover, the rise of e-commerce platforms has simplified sourcing for international buyers, enabling them to compare products and prices easily, thus fostering competitive pricing and better deals.

How is Sustainability Impacting the Sourcing of Cleaning Brushes?

Sustainability is becoming a crucial factor in the sourcing of cleaning brushes, with many companies looking to reduce their environmental footprint. The production of cleaning brushes often involves plastic and synthetic materials that can contribute to pollution and waste. As a result, there is a growing emphasis on ethical sourcing practices and the adoption of eco-friendly materials.

B2B buyers are increasingly prioritizing suppliers that offer brushes made from recycled or biodegradable materials, such as bamboo or natural fibers. Certifications such as FSC (Forest Stewardship Council) or Cradle to Cradle demonstrate a commitment to sustainability and can influence purchasing decisions. In addition, the demand for brushes that are designed for durability—thus reducing the frequency of replacement—aligns with a broader trend toward sustainable consumption.

By integrating sustainable practices into their supply chains, businesses not only contribute to environmental conservation but also enhance their brand image, appealing to a growing segment of environmentally-conscious consumers.

How Have Cleaning Brushes Evolved Over Time?

The evolution of cleaning brushes reflects the changing needs of various industries. Initially, brushes were simplistic in design, primarily made from natural bristles and wood. However, as cleaning standards became more rigorous, especially in commercial settings, the design and materials of cleaning brushes began to evolve significantly.

The introduction of synthetic materials, such as nylon and polypropylene, has allowed for greater durability and versatility. Today, brushes are specifically engineered for different applications, from food service to industrial cleaning, ensuring that each brush is optimized for its intended use. This evolution not only enhances cleaning efficiency but also addresses hygiene concerns, particularly in sectors where cross-contamination is a critical issue.

Illustrative image related to types of cleaning brushes

As the market continues to innovate, the future will likely see even more specialized brushes designed to meet emerging challenges in cleanliness and sanitation across diverse industries.

Frequently Asked Questions (FAQs) for B2B Buyers of types of cleaning brushes

-

How do I choose the right cleaning brush for my specific needs?

Selecting the appropriate cleaning brush involves understanding the surfaces you need to clean and the type of debris you are dealing with. For example, use soft-bristled brushes for delicate surfaces to avoid scratches, while stiff bristles are ideal for tough grime. Consider the brush’s material; synthetic bristles are versatile and resistant to chemicals, making them suitable for various environments. Additionally, assess the size and shape of the brush to ensure it fits your cleaning tasks effectively. -

What types of bristles are best for different cleaning tasks?

The choice of bristle type depends on the cleaning application. Soft bristles are best for sensitive surfaces, such as glass or polished wood, while stiff bristles are effective for heavy-duty cleaning on concrete or tile floors. Synthetic bristles are resistant to heat and chemicals, making them versatile for both wet and dry applications. For specialized tasks, such as grout cleaning, use brushes specifically designed with the right bristle stiffness and shape to ensure thorough cleaning without damage. -

What are the minimum order quantities (MOQ) for cleaning brushes?

Minimum order quantities can vary significantly by supplier and the type of cleaning brush. Generally, MOQs range from 50 to 500 units, depending on the material and customization options. For bulk orders, suppliers may offer discounts or flexible terms. It’s advisable to discuss your specific requirements with potential suppliers to negotiate MOQs that align with your purchasing strategy and budget. -

How can I ensure the quality of cleaning brushes from international suppliers?

To ensure quality, conduct thorough research on potential suppliers by checking their certifications, customer reviews, and production processes. Request samples to evaluate the brushes firsthand, focusing on materials, bristle durability, and overall construction. Establish clear quality assurance protocols, including inspections upon delivery and adherence to international standards. Building strong relationships with suppliers can also facilitate better quality control and responsiveness to your needs. -

What payment terms are typically offered by suppliers for cleaning brushes?

Payment terms can vary widely among suppliers, often influenced by the buyer’s location and relationship with the supplier. Common terms include upfront payment, net 30, or net 60 days, where payment is due within 30 or 60 days after delivery. Discussing terms upfront is crucial, especially for international transactions, as factors like currency fluctuations and transfer fees can impact overall costs. Using secure payment methods can also help mitigate risks. -

What logistics considerations should I keep in mind when importing cleaning brushes?

Logistics play a critical role in the timely and cost-effective delivery of cleaning brushes. Consider factors such as shipping methods (air vs. sea), customs clearance processes, and potential tariffs or duties based on the brush materials. Collaborating with experienced freight forwarders can simplify the import process. Additionally, ensure that the supplier provides all necessary documentation for customs to avoid delays and ensure compliance with local regulations. -

Can cleaning brushes be customized to meet specific needs?

Many suppliers offer customization options for cleaning brushes, including bristle stiffness, handle length, and brush shape. Customizing brushes can enhance their effectiveness for specific tasks or industries. When discussing customization, provide detailed specifications and any branding requirements. Keep in mind that customization may affect lead times and minimum order quantities, so plan accordingly to meet your operational needs. -

What should I look for in a supplier when sourcing cleaning brushes internationally?

When sourcing cleaning brushes internationally, prioritize suppliers with a proven track record and positive reputation. Evaluate their manufacturing capabilities, certifications, and adherence to quality standards. Communication is key; ensure the supplier is responsive and transparent regarding production timelines and pricing. Additionally, consider their logistics capabilities and ability to handle international shipping. Building a strong partnership can lead to better service and more favorable terms over time.

Top 4 Types Of Cleaning Brushes Manufacturers & Suppliers List

1. Webstaurant Store – Types of Cleaning Brushes

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Types of Cleaning Brushes: 1. Duster – For use on all surfaces, removes dust particles. 2. Floor and Wall Brush – For non-carpet floors and walls, removes grease and grime. 3. Grout Brush – For tile floors, clears heavy dirt and grime from between tiles. 4. Hand and Nail Brush – Promotes hygiene next to sinks. 5. Push Broom – Clears dirt and dust before scrubbing and mopping. 6. Toilet Brush – Pro…

2. IQS Directory – Brushes for Various Applications

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: A brush consists of bristles made from materials like hair, wire, metal, synthetic fibers, or natural elements, affixed to a handle made of wood, plastic, metal, or wire. Brushes are designed for various applications, including industrial cleaning, paint removal, and precision tasks. Key types include cylindrical brushes for conveyor belts, sanding brushes for wood preparation, and micro brushes f…

3. Yewlee – Cobweb & Iron Brushes

Domain: yewlee.com.my

Registered: 2003 (22 years)

Introduction: 1. Cobweb Brush: Rounded brush head for removing cobwebs and dust from ceiling corners; some variants have extendable grip poles. Versatile for dusting window frames, lampshades, and furniture.

2. Iron Brush: Compact with an ergonomic plastic handle; nylon bristles for washing dishes, sinks, and household items. Waterproof, flexible, and strong bristles that resist bending from moisture. Available…

4. Reddit – Versatile Cleaning Brushes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Various cleaning brushes including a skinny brush for grout, a larger brush for scrubbing bathtubs, a long handle brush for cleaning sneakers, and a grey pad for scrubbing surfaces. The brushes come in different shapes and sizes for various cleaning tasks.

Strategic Sourcing Conclusion and Outlook for types of cleaning brushes

In the realm of cleaning brushes, strategic sourcing is vital for B2B buyers aiming to enhance operational efficiency and hygiene standards. Understanding the various types of brushes, from duster and floor brushes to specialized options like bottle and cylinder brushes, allows businesses to choose the right tools tailored to their specific needs. Prioritizing the selection of quality bristles—such as synthetic, nylon, or boar hair—can significantly impact the effectiveness and durability of cleaning tools, ultimately leading to better sanitation outcomes.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should focus on establishing reliable supply chains. This ensures access to high-quality cleaning brushes that meet local compliance and performance standards. By investing in the right tools, businesses not only foster a cleaner environment but also enhance customer satisfaction and retention.

Looking ahead, the demand for innovative and sustainable cleaning solutions will grow. B2B buyers are encouraged to stay informed on emerging trends and technologies in cleaning tools. This proactive approach will not only optimize operations but also position companies as leaders in hygiene and cleanliness within their respective industries.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.