Is Your Types Of Ac Electric Motors Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for types of ac electric motors

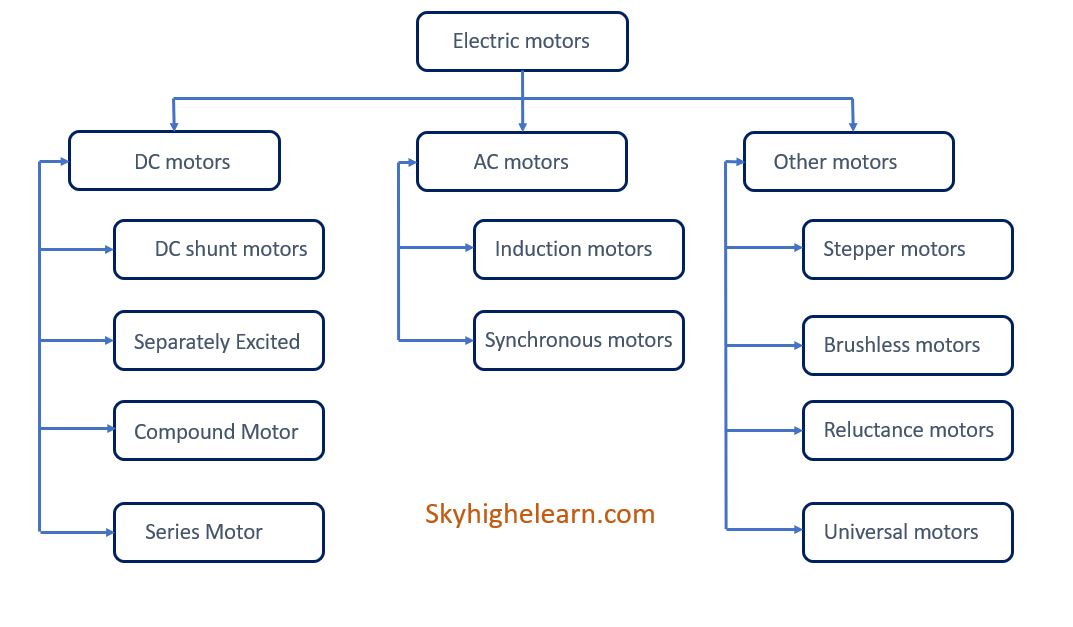

In the rapidly evolving landscape of industrial automation, sourcing the right types of AC electric motors poses a significant challenge for international B2B buyers. Whether you are operating in the bustling markets of Africa, the diverse economies of South America, or the industrial hubs of the Middle East and Europe, understanding the nuances of AC motor technologies is crucial for enhancing operational efficiency and competitiveness. This comprehensive guide delves into various types of AC electric motors, including synchronous and induction motors, while highlighting their specific applications across industries such as manufacturing, energy, and transportation.

Our exploration will also cover essential aspects of supplier vetting, cost considerations, and best practices for integrating these motors into your operations. By providing actionable insights and detailed comparisons, this guide empowers buyers to make informed purchasing decisions that align with their strategic goals.

As you navigate the complexities of the global market, this resource will serve as your roadmap, helping you identify the most suitable AC electric motor solutions tailored to your unique requirements. From understanding technical specifications to evaluating supplier reliability, you will be equipped with the knowledge needed to optimize your procurement process and drive your business forward.

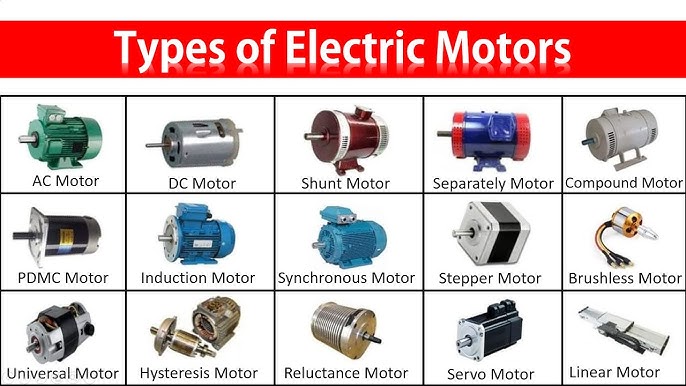

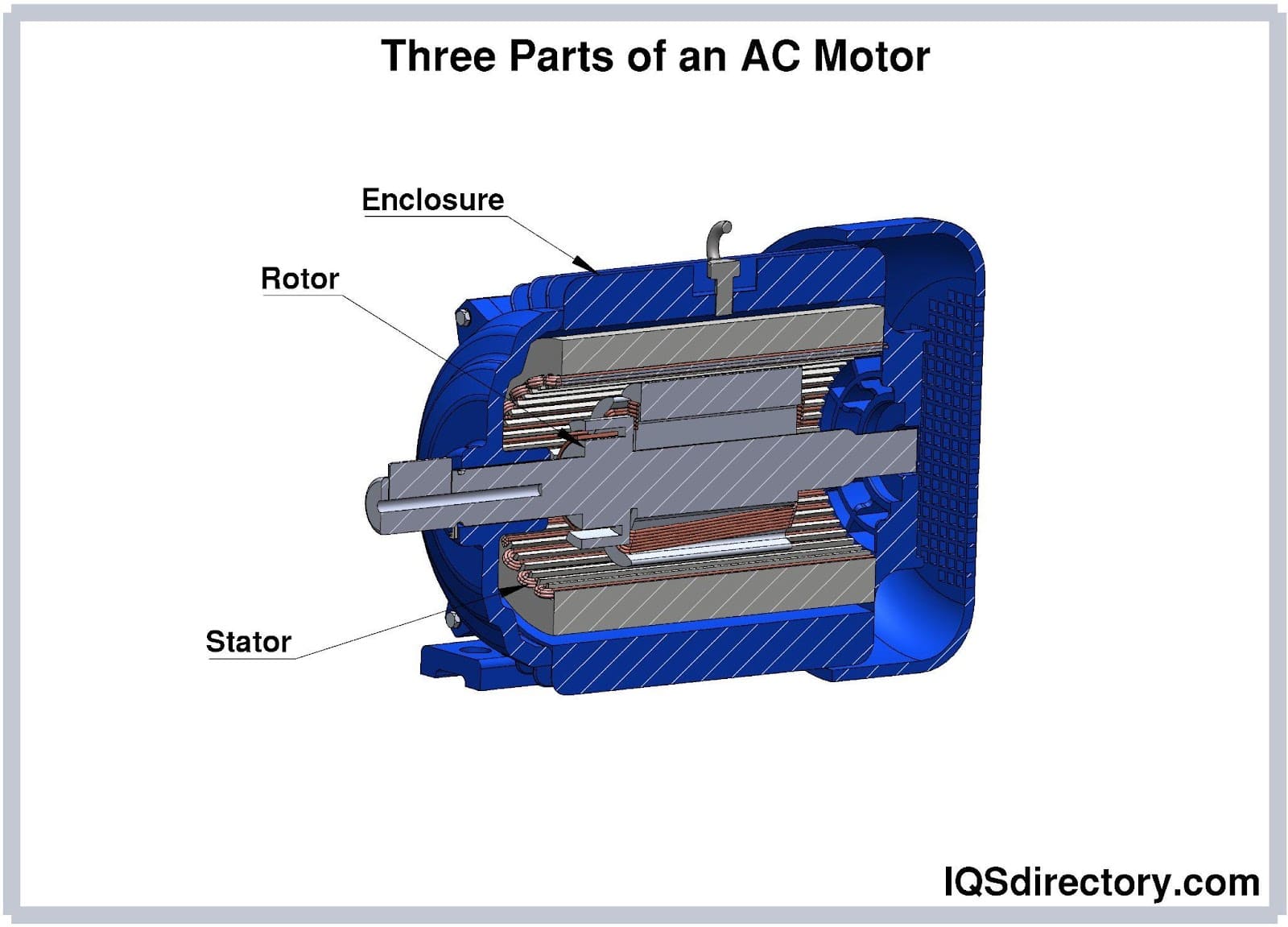

Understanding types of ac electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Synchronous Motors | Operate at constant speed; rotor speed synchronized with supply frequency | Pumps, fans, compressors, precision machinery | Pros: High efficiency, precise speed control. Cons: Higher initial cost, complex maintenance. |

| Induction Motors | Asynchronous operation; rotor speed lags behind magnetic field | General industrial applications, HVAC systems | Pros: Cost-effective, robust design. Cons: Lower efficiency at variable loads. |

| Wound Rotor Motors | Feature windings on the rotor; can control speed and torque | Cranes, lifts, and applications requiring high starting torque | Pros: Adjustable speed and torque. Cons: More complex and costly than squirrel-cage motors. |

| Permanent Magnet Motors | Utilize permanent magnets for rotor; high efficiency and compact design | Electric vehicles, robotics, and high-performance applications | Pros: High efficiency, compact size. Cons: Higher material costs, limited by magnet temperature. |

| Universal Motors | Operate on AC or DC; high speed and torque | Power tools, household appliances, and small machinery | Pros: Versatile, lightweight. Cons: Shorter lifespan, higher maintenance needs. |

What are the Key Characteristics of Synchronous Motors for B2B Buyers?

Synchronous motors are characterized by their ability to maintain a constant speed regardless of load variations, as their rotor speed is synchronized with the supply frequency. This feature makes them ideal for applications requiring precise speed control, such as pumps and compressors. B2B buyers should consider their higher initial costs and the complexity of maintenance, particularly for models with slip rings. However, their operational efficiency and power factor correction capabilities can lead to long-term savings in energy costs.

How Do Induction Motors Stand Out in Industrial Applications?

Induction motors, or asynchronous motors, are widely recognized for their reliability and cost-effectiveness. They operate under the principle that the rotor speed lags behind the magnetic field generated by the stator. This makes them suitable for a broad range of applications, including HVAC systems and general industrial machinery. Buyers should note that while induction motors are typically less expensive and easier to maintain, they may exhibit reduced efficiency under variable load conditions.

Why Choose Wound Rotor Motors for Heavy-Duty Applications?

Wound rotor motors are distinguished by their rotor windings, which provide the ability to control speed and torque effectively. This makes them particularly suitable for heavy-duty applications such as cranes and lifts, where high starting torque is essential. While they offer enhanced performance and adaptability, buyers must weigh the complexity and cost against the operational benefits, especially in environments that demand high torque at startup.

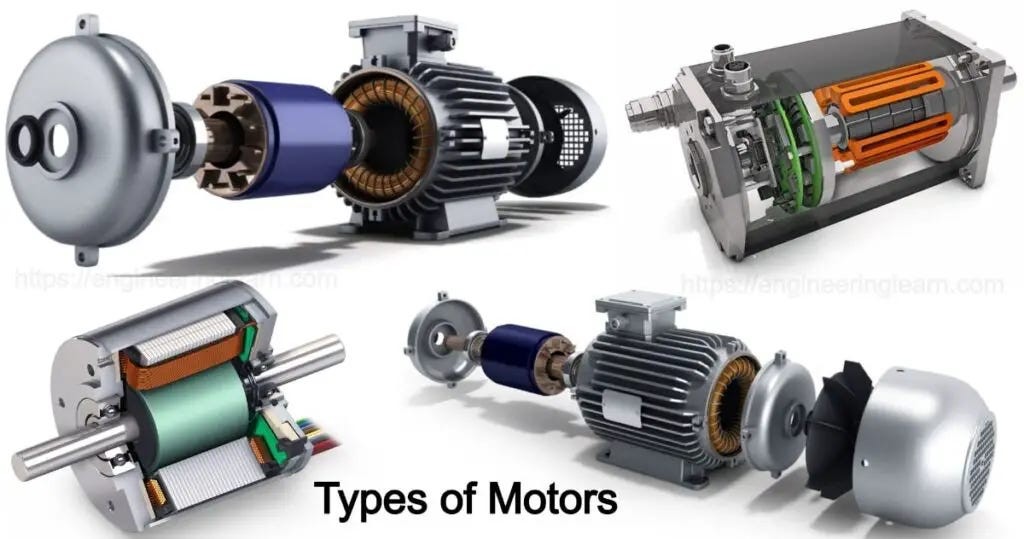

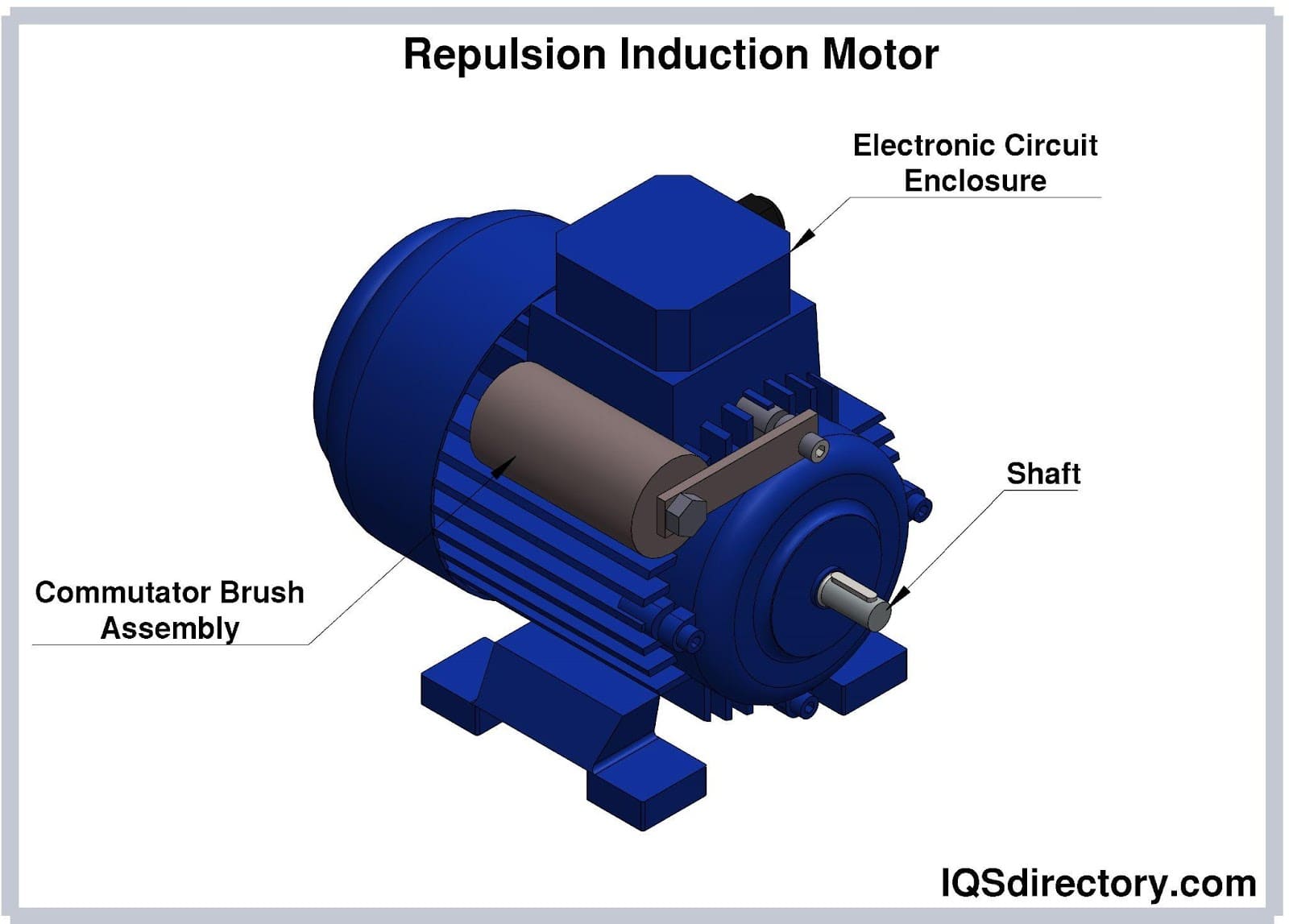

Illustrative image related to types of ac electric motors

What Advantages Do Permanent Magnet Motors Offer?

Permanent magnet motors are known for their compact design and high efficiency, thanks to the use of permanent magnets in the rotor. They are increasingly used in electric vehicles and advanced robotics due to their excellent power-to-weight ratio. However, buyers should be aware of the higher costs associated with the materials used in these motors, as well as potential limitations related to temperature and magnet degradation over time.

How Versatile are Universal Motors for Various Applications?

Universal motors are unique in their ability to operate on both AC and DC power, providing high speed and torque, which makes them popular in power tools and household appliances. Their versatility is a significant advantage for businesses looking for adaptable solutions. However, B2B buyers should consider the potential downsides, including a shorter lifespan and higher maintenance requirements compared to other motor types.

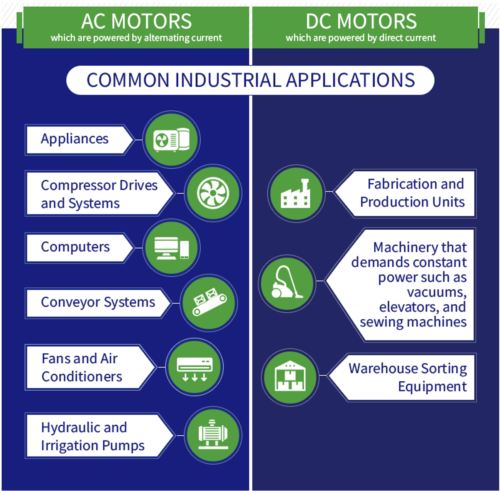

Key Industrial Applications of types of ac electric motors

| Industry/Sector | Specific Application of types of ac electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Improved efficiency and reduced downtime in production | Reliability, energy efficiency, and compatibility with existing systems |

| Agriculture | Irrigation Pumps | Enhanced water management and crop yield optimization | Durability, resistance to environmental conditions, and power requirements |

| Mining and Minerals | Crushers and Grinders | Increased productivity and reduced operational costs | Robust design, maintenance support, and adaptability to harsh environments |

| HVAC Systems | Fans and Compressors | Energy savings and improved climate control | Energy efficiency ratings, noise levels, and serviceability |

| Automotive | Electric Vehicle Charging Stations | Support for growing EV market and infrastructure needs | Compatibility with various charging technologies and power ratings |

How Are AC Electric Motors Used in Manufacturing?

In manufacturing, AC electric motors are integral to conveyor systems, where they drive the movement of materials and products along production lines. By providing consistent speed and torque, these motors enhance operational efficiency and minimize downtime due to mechanical failures. For international buyers, especially those in regions like Africa and South America, sourcing motors that are reliable and energy-efficient is critical to maintaining a competitive edge in production costs.

What Role Do AC Electric Motors Play in Agriculture?

In the agricultural sector, AC electric motors power irrigation pumps that are essential for effective water management. These motors help ensure that crops receive the necessary water supply, directly impacting yield and quality. Buyers in developing regions, such as Nigeria and Vietnam, should consider the motors’ durability and resistance to environmental factors like dust and moisture, which can affect performance in outdoor settings.

How Do AC Electric Motors Enhance Mining Operations?

AC electric motors are widely used in mining applications, particularly in crushers and grinders that process raw materials. These motors provide the necessary power to handle tough materials while ensuring reliability and efficiency. For B2B buyers in the mining industry, sourcing robust motors that can withstand harsh conditions and offer maintenance support is crucial for minimizing operational costs and maximizing productivity.

What Benefits Do AC Electric Motors Offer HVAC Systems?

In HVAC systems, AC electric motors drive fans and compressors that regulate air flow and temperature. By utilizing energy-efficient motors, businesses can achieve significant energy savings while ensuring optimal climate control within buildings. Buyers from Europe and the Middle East must focus on energy efficiency ratings and noise levels when sourcing these motors to meet regulatory standards and customer expectations.

How Are AC Electric Motors Transforming the Automotive Industry?

The automotive industry increasingly relies on AC electric motors for electric vehicle (EV) charging stations. These motors support the growing demand for EV infrastructure by providing reliable power for charging operations. For international buyers, it is vital to consider compatibility with various charging technologies and the power ratings required to meet diverse consumer needs, especially in rapidly expanding markets.

3 Common User Pain Points for ‘types of ac electric motors’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right AC Motor for Specific Applications

The Problem: B2B buyers often face the challenge of selecting the appropriate type of AC electric motor for their specific industrial applications. With various options like induction, synchronous, and universal motors available, the decision can become overwhelming. Buyers may struggle to understand the technical specifications, such as torque requirements, speed, and efficiency, which can lead to selecting a motor that does not meet operational needs. This misalignment can result in inefficient operations, increased costs, and even equipment failures.

The Solution: To effectively address this challenge, buyers should begin by conducting a thorough needs assessment that includes understanding the application requirements, load characteristics, and environmental conditions. Collaborating with motor manufacturers or experienced distributors can provide insights into the best motor type for specific applications. For instance, if precision speed control is crucial, a synchronous motor may be the best choice due to its ability to maintain a constant speed under varying loads. Buyers should also utilize online tools and calculators provided by manufacturers to compare the specifications of different motor types. Engaging in detailed discussions with technical support teams can further clarify the best options based on real-world usage scenarios.

Scenario 2: High Operational Costs Due to Inefficient Motor Performance

The Problem: Many businesses experience high operational costs stemming from the inefficient performance of their AC motors. Over time, motors may consume more energy than anticipated, especially if they are not properly matched to the application or if they are outdated models. This inefficiency can lead to increased electricity bills and higher maintenance costs, ultimately affecting the bottom line.

The Solution: To combat high operational costs, companies should consider upgrading to energy-efficient AC motors, such as those compliant with the IE3 or IE4 efficiency standards. Conducting an energy audit can help identify the motors that are underperforming and provide data on their energy consumption. Additionally, retrofitting existing motors with variable frequency drives (VFDs) can optimize their performance by allowing for speed adjustments based on real-time demand. Buyers should consult with energy management experts to analyze potential savings and return on investment when upgrading to more efficient motor technologies. By making informed choices, businesses can significantly reduce operational costs over time.

Scenario 3: Frequent Motor Failures Leading to Downtime

The Problem: Frequent failures of AC motors can lead to significant downtime in production environments, creating a ripple effect that impacts overall productivity and profitability. B2B buyers often find themselves struggling with understanding the root causes of these failures, which could be due to poor maintenance practices, incorrect installation, or unsuitable motor selection for the application.

The Solution: Implementing a proactive maintenance strategy is essential in minimizing motor failures. Buyers should invest in a comprehensive maintenance program that includes regular inspections, vibration analysis, and thermal imaging to monitor the condition of the motors. Additionally, ensuring proper installation and alignment during the initial setup can greatly reduce the risk of premature failures. Providing training for staff on the importance of maintenance and operational best practices can also enhance longevity. Furthermore, engaging with suppliers that offer warranties and after-sales support can provide peace of mind and assistance in case of unexpected failures. By fostering a culture of preventive maintenance and selecting motors suited for their specific applications, companies can significantly reduce downtime and enhance operational efficiency.

Strategic Material Selection Guide for types of ac electric motors

What Are the Key Materials Used in AC Electric Motors?

When selecting materials for AC electric motors, understanding the properties, advantages, and limitations of various materials is crucial for optimizing performance and ensuring reliability. Here, we analyze four common materials used in the construction of AC electric motors: copper, aluminum, steel, and plastic composites.

How Does Copper Influence AC Electric Motor Performance?

Copper is widely regarded for its excellent electrical conductivity, which is essential for efficient motor operation. It boasts a high melting point, making it suitable for high-temperature applications. Copper’s resistance to corrosion also enhances its longevity in various environments.

Pros: Copper’s superior conductivity leads to lower energy losses, making it ideal for high-performance motors. Its durability and resistance to wear contribute to a longer lifespan.

Cons: The primary drawback of copper is its cost, which is higher than many alternatives. Additionally, its weight may be a concern in applications where weight reduction is critical.

Impact on Application: Copper is particularly effective in environments where high efficiency is paramount, such as in industrial machinery and high-speed applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability and cost fluctuations of copper. Compliance with international standards such as ASTM B187 is also essential to ensure quality.

What Role Does Aluminum Play in AC Electric Motors?

Aluminum is increasingly used in AC motors due to its lightweight nature and good conductivity, although it is less efficient than copper. It has a lower melting point, which can limit its use in high-temperature applications.

Pros: Aluminum’s lightweight properties make it ideal for portable applications. It is also more cost-effective than copper, making it a popular choice for budget-conscious projects.

Cons: While aluminum is resistant to corrosion, it can be less durable than copper, especially under high-stress conditions. Its lower conductivity can lead to higher energy losses.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in automotive and aerospace industries.

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards like ASTM B221 to guarantee quality. Additionally, understanding local market conditions can help in sourcing aluminum at competitive prices.

How Does Steel Contribute to AC Electric Motor Durability?

Steel is primarily used for the stator and rotor cores in AC motors due to its magnetic properties and strength. It can withstand high temperatures and mechanical stress, making it suitable for demanding applications.

Pros: Steel’s durability and high tensile strength make it ideal for heavy-duty applications. It also provides good magnetic performance, which is crucial for efficient motor operation.

Cons: The weight of steel can be a disadvantage in applications requiring lightweight components. Additionally, it is prone to corrosion unless treated or coated.

Illustrative image related to types of ac electric motors

Impact on Application: Steel is commonly used in industrial motors where robustness is essential, such as in pumps and compressors.

Considerations for International Buyers: Buyers should be aware of corrosion resistance standards and ensure compliance with international specifications like DIN 17100 for steel quality.

What Advantages Do Plastic Composites Offer in AC Electric Motors?

Plastic composites are increasingly used in non-structural components of AC motors, such as housings and insulation. They offer a unique combination of lightweight and corrosion resistance.

Pros: The primary advantage of plastic composites is their resistance to corrosion and chemicals, making them suitable for harsh environments. They also reduce weight, which can improve energy efficiency.

Cons: Plastic composites may not withstand high temperatures as effectively as metals, which can limit their application in high-performance motors. Additionally, their mechanical strength can be inferior to metals.

Impact on Application: These materials are ideal for applications in corrosive environments, such as marine or chemical processing industries.

Illustrative image related to types of ac electric motors

Considerations for International Buyers: Buyers should verify that plastic composites meet relevant standards, such as ISO 9001, to ensure quality and performance.

Summary Table of Material Selection for AC Electric Motors

| Material | Typical Use Case for types of ac electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance industrial machinery | Superior electrical conductivity | High cost and weight | High |

| Aluminum | Portable applications, automotive | Lightweight and cost-effective | Lower conductivity and durability | Medium |

| Steel | Heavy-duty industrial motors | High strength and magnetic properties | Heavy and prone to corrosion | Medium |

| Plastic Composites | Non-structural components in harsh environments | Corrosion resistance and lightweight | Limited temperature tolerance | Low |

This strategic material selection guide provides actionable insights for B2B buyers looking to optimize their AC electric motor applications while considering regional compliance and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for types of ac electric motors

What Are the Key Stages in the Manufacturing Process of AC Electric Motors?

The manufacturing process of AC electric motors involves several critical stages that ensure quality and performance. Understanding these stages helps B2B buyers identify reliable suppliers and make informed purchasing decisions.

How Is Material Prepared for AC Electric Motors?

Material preparation is the first step in manufacturing AC electric motors. High-quality raw materials such as electrical steel for laminations, copper for windings, and various alloys for rotor and stator components are sourced. Suppliers should provide certifications for these materials to confirm they meet industry standards. The selection of materials directly impacts the motor’s efficiency, durability, and performance.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the prepared materials into components like the stator and rotor. Techniques such as stamping, machining, and die-casting are commonly employed. Stamping is used to create laminated cores from electrical steel, while precision machining shapes components to exact specifications. It is crucial for manufacturers to utilize CNC (Computer Numerical Control) machines for high precision, ensuring that tolerances are adhered to, which is vital for performance.

How Are AC Electric Motors Assembled?

The assembly stage is where individual components come together to form the complete motor. This process often involves:

- Winding the Stator: Coils of wire are wound around the stator slots, with attention paid to the number of turns and winding patterns to ensure optimal electromagnetic performance.

- Rotor Assembly: Depending on the motor type, either a squirrel cage or wound rotor is assembled. This includes securely attaching rotor bars or windings to ensure reliable operation.

- Integration of Components: The stator and rotor are then fitted together, along with bearings and end shields. Proper alignment is crucial to minimize friction and wear during operation.

What Finishing Processes Are Important for Quality?

Finishing processes include painting or coating the motor to enhance corrosion resistance and aesthetic appeal. Additionally, balancing the rotor is essential to reduce vibrations during operation. Quality control measures during this stage ensure that all components meet design specifications and performance standards.

What International Standards Guide Quality Assurance in AC Motor Manufacturing?

Quality assurance is paramount in the manufacturing of AC electric motors. International standards such as ISO 9001 provide frameworks for quality management systems. Adherence to these standards ensures that manufacturers implement consistent processes and maintain high-quality outputs.

Illustrative image related to types of ac electric motors

Industry-specific certifications, such as CE for safety compliance in the European market and API for pumps and motors used in oil and gas applications, are also critical. B2B buyers should inquire about these certifications when evaluating suppliers.

What Are the QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet required specifications before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to verify that components are being produced according to specifications. This includes measuring dimensions and performing functional tests.

- Final Quality Control (FQC): Before the finished motors are shipped, a final inspection is performed. This includes testing electrical performance, insulation resistance, and mechanical integrity.

What Common Testing Methods Are Employed?

Testing methods vary based on the motor type and application but typically include:

- Electrical Testing: Insulation resistance tests and power factor tests are conducted to ensure electrical integrity.

- Performance Testing: Motors are subjected to load tests to evaluate their performance under operational conditions.

- Vibration Analysis: This helps identify potential mechanical issues that could lead to premature failure.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can verify a supplier’s quality control processes through several means:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturer’s quality control practices and adherence to standards.

-

Quality Reports: Requesting detailed quality reports, including inspection and testing results, can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and finished products.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding QC and certification:

-

Regional Standards: Different regions may have varying standards and regulations. Understanding these can help buyers ensure compliance and avoid costly setbacks.

-

Documentation Requirements: Comprehensive documentation, including certificates of conformity and test reports, is often required for customs clearance and regulatory compliance.

-

Cultural Considerations: Communication styles and business practices may differ significantly across cultures. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings.

Conclusion

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for AC electric motors is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with stringent quality control protocols, buyers can ensure they are procuring reliable and efficient motors. Additionally, being aware of international standards and verification methods can facilitate smoother transactions and foster long-term supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of ac electric motors’

In the dynamic world of industrial operations, selecting the right type of AC electric motor is critical for efficiency and performance. This guide provides a comprehensive checklist for B2B buyers to streamline their procurement process, ensuring they make informed decisions tailored to their specific needs.

Illustrative image related to types of ac electric motors

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it’s essential to articulate your requirements clearly. Consider the operational environment, load characteristics, and required speed control.

– Key Specifications: Identify if you need synchronous or induction motors based on the application. For instance, synchronous motors are preferred for high precision, while induction motors are favored for their reliability and cost-effectiveness.

Step 2: Research Motor Types and Applications

Understanding the different types of AC motors and their applications will help you make an informed decision. Each motor type has unique characteristics suitable for various tasks.

– Application Suitability: Evaluate where each motor type excels; for example, synchronous motors are ideal for constant-speed applications, while induction motors are versatile for many industrial settings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Background: Look for suppliers with a proven track record and expertise in your required motor type. Checking their history with similar applications can provide insight into their reliability and performance.

Step 4: Verify Quality Certifications

Confirm that potential suppliers hold relevant industry certifications, such as ISO 9001 or IEC standards. This ensures that the motors meet quality and safety standards.

– Importance of Certification: Certified products are generally more reliable and efficient, which can lead to lower maintenance costs and better overall performance in your operations.

Step 5: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, delivery times, and terms of service.

– Comparative Analysis: Look beyond just the price; analyze the total cost of ownership, including installation, maintenance, and potential energy savings over time.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales service offered by suppliers, including warranties and technical support. A strong support system can significantly impact the long-term success of your motor application.

– Support Availability: Ensure that the supplier can provide timely maintenance and troubleshooting assistance, which is crucial for minimizing downtime in your operations.

Step 7: Finalize the Contract Terms

Before finalizing your purchase, review the contract terms carefully. Ensure that they align with your business objectives and cover all aspects of the procurement, including delivery schedules and payment terms.

– Contract Clarity: Clarity in terms can prevent future disputes and ensure that both parties have a mutual understanding of expectations and responsibilities.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing AC electric motors effectively, leading to informed decisions that enhance operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for types of ac electric motors Sourcing

What Are the Key Cost Components in AC Electric Motors?

When sourcing AC electric motors, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw materials, including copper, aluminum, and steel, can fluctuate based on global market trends. Higher-quality materials typically result in better motor performance and longevity, but they also increase the initial cost.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer competitive pricing but could compromise on quality. Skilled labor is essential for ensuring the precision required in motor assembly and testing.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses related to production. Efficient manufacturing processes can help minimize these costs, impacting the final price.

-

Tooling: The initial setup for manufacturing AC motors involves tooling costs. These can be substantial for custom designs, as specialized tools may be required.

-

Quality Control: Rigorous QC processes are essential to ensure that motors meet specifications and safety standards. This may involve additional testing and certification costs, which can be significant but are crucial for reliability.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and the complexity of the supply chain. For international buyers, understanding Incoterms is essential to calculate total logistics costs accurately.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary depending on the supplier’s market position, reputation, and the competitive landscape.

What Influences the Pricing of AC Electric Motors?

Several factors can influence the pricing of AC electric motors, particularly for B2B buyers in diverse markets.

-

Volume and Minimum Order Quantities (MOQ): Higher volume orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom motors that meet specific application requirements can significantly impact pricing. Standard motors are usually more cost-effective, but customization may be necessary for unique applications.

-

Quality and Certifications: Motors that meet international quality standards (e.g., ISO, CE) often command higher prices. Buyers should weigh the importance of certifications against potential cost savings from non-certified alternatives.

-

Supplier Factors: The reputation, location, and production capabilities of suppliers can affect pricing. Established suppliers may charge a premium but typically offer better reliability and support.

-

Incoterms: Understanding delivery terms is crucial for calculating total costs. Incoterms dictate who bears the cost and risk during shipping, which can significantly impact the final price.

How Can Buyers Optimize Costs When Sourcing AC Electric Motors?

To achieve cost-efficiency in sourcing AC electric motors, B2B buyers should consider the following strategies:

-

Negotiate Effectively: Use market research to negotiate better pricing. Understanding competitor pricing can provide leverage in discussions with suppliers.

-

Assess Total Cost of Ownership (TCO): Beyond initial purchase price, consider factors like energy efficiency, maintenance costs, and lifespan. A lower upfront cost may lead to higher TCO if the motor is less efficient or requires frequent repairs.

-

Explore Diverse Suppliers: Engaging multiple suppliers can foster competition, leading to better pricing. Consider suppliers from emerging markets, as they may offer competitive rates without compromising quality.

-

Stay Informed About Pricing Trends: Keeping abreast of market trends related to materials and labor in different regions can help buyers time their purchases strategically, potentially reducing costs.

-

Understand Regional Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional economic conditions that can influence pricing and supply chain dynamics. Tailoring sourcing strategies to local contexts can yield significant savings.

Disclaimer on Indicative Prices

Pricing for AC electric motors can vary widely based on the factors mentioned above. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing types of ac electric motors With Other Solutions

Exploring Alternatives to AC Electric Motors: A Comparative Analysis

In today’s industrial landscape, selecting the right motor technology is crucial for operational efficiency and cost-effectiveness. While AC electric motors, including induction and synchronous types, are widely used due to their reliability and performance, various alternative solutions can also meet specific application needs. This analysis will compare AC electric motors with two prominent alternatives: DC electric motors and hydraulic systems, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Types Of AC Electric Motors | DC Electric Motors | Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency, consistent speed under load | High torque at low speeds, variable speed control | High power density, excellent for heavy loads |

| Cost | Higher initial cost; lower operating costs | Moderate initial cost; variable operating costs | High initial investment; maintenance-intensive |

| Ease of Implementation | Moderate complexity; requires electrical infrastructure | Simple installation; often modular | Complex setup; requires hydraulic infrastructure |

| Maintenance | Regular maintenance needed, especially for synchronous motors | Low maintenance; wear on brushes in brushed models | High maintenance; fluid leaks and component wear |

| Best Use Case | Ideal for constant-speed applications like fans and pumps | Suitable for applications requiring precise speed control | Best for heavy lifting and machinery requiring high force |

Analyzing DC Electric Motors as an Alternative

DC electric motors are known for their simplicity and versatility, making them a popular choice in various applications. Their ability to provide high torque at low speeds and variable speed control makes them particularly suitable for tasks requiring precise motion, such as in robotics and conveyor systems. However, while they offer ease of implementation and low maintenance, brushed DC motors can experience wear over time, necessitating periodic replacements of brushes. Overall, DC motors are ideal for applications where precise speed control is paramount, but they may not match the efficiency of AC motors in high-load scenarios.

Evaluating Hydraulic Systems as a Competing Solution

Hydraulic systems leverage fluid power to generate high force and torque, making them indispensable in heavy machinery applications, such as construction and manufacturing. They excel in environments where high power density is required, providing substantial force with relatively compact designs. However, hydraulic systems come with a higher initial investment and can be maintenance-intensive due to potential fluid leaks and the need for regular inspections of components. While their complexity may deter some users, they are unmatched in scenarios demanding significant lifting capacity and force, making them a strong alternative to electric motors in specific contexts.

How Should B2B Buyers Choose the Right Motor Solution?

When selecting between AC electric motors and alternative technologies like DC motors or hydraulic systems, B2B buyers should consider several key factors. The nature of the application—whether it requires precise speed control, high torque, or the ability to handle heavy loads—will significantly influence the decision. Additionally, assessing the total cost of ownership, including initial investment and maintenance requirements, will help ensure that the chosen solution aligns with budget constraints and operational goals. By thoroughly evaluating these elements, businesses can make informed decisions that enhance operational efficiency and productivity.

Essential Technical Properties and Trade Terminology for types of ac electric motors

What Are the Key Technical Properties of AC Electric Motors?

When considering the procurement of AC electric motors, understanding their technical properties is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should be aware of:

-

Efficiency Rating

Efficiency ratings, typically expressed as a percentage, indicate how effectively a motor converts electrical energy into mechanical energy. Higher efficiency ratings translate to lower operational costs and reduced energy consumption, which is vital for industries focused on sustainability and cost reduction. For buyers, ensuring that the selected motor meets specific efficiency standards can impact long-term operational budgets. -

Power Rating

This specification, measured in kilowatts (kW) or horsepower (HP), indicates the motor’s output capability. Understanding the power rating is essential for matching the motor to the application’s demands. Selecting a motor with an inadequate power rating can lead to performance issues, while oversizing can result in unnecessary costs and energy waste. -

Synchronous Speed

Defined by the formula (N_s = \frac{120f}{P}), synchronous speed is the speed at which the motor’s magnetic field rotates, determined by the frequency of the power supply and the number of poles in the motor. Buyers should consider synchronous speed in applications requiring precise speed control, as it directly affects performance in machinery like pumps and fans. -

Torque Characteristics

Torque is the rotational force produced by the motor, critical for applications requiring specific load handling. Understanding the starting torque and the motor’s torque-speed curve helps buyers select motors that can handle varying loads effectively, ensuring operational reliability. -

Insulation Class

The insulation class indicates the motor’s thermal endurance, with classes ranging from A (low) to H (high). Choosing the correct insulation class is vital for ensuring the longevity and reliability of the motor in different environmental conditions, particularly in industrial settings with varying temperature extremes. -

Vibration and Noise Levels

The operational noise and vibration levels of a motor can impact both worker safety and compliance with industry standards. Monitoring these levels is essential for maintaining a conducive working environment. Buyers should seek specifications that detail acceptable noise and vibration limits, especially for applications in sensitive environments.

What Are Common Trade Terms Related to AC Electric Motors?

Familiarity with trade terminology is equally important for effective communication and negotiation in the procurement process. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is critical for B2B buyers to ensure they are sourcing quality components that meet industry standards, which can affect overall product performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for budget-conscious buyers who need to manage inventory levels while ensuring that they meet production requirements. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to potential suppliers to solicit pricing and terms for specific products. Crafting a detailed RFQ helps buyers compare options effectively, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for buyers to navigate shipping costs, risk allocation, and delivery responsibilities, which can vary significantly across regions. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is essential for planning production schedules and maintaining operational efficiency. -

Warranty Period

The warranty period indicates the duration during which the manufacturer is responsible for repairing or replacing defective products. Buyers should carefully consider warranty terms to protect their investment and ensure support during the motor’s operational life.

By grasping these technical properties and trade terms, B2B buyers can enhance their decision-making process, leading to more strategic procurement of AC electric motors tailored to their operational needs.

Navigating Market Dynamics and Sourcing Trends in the types of ac electric motors Sector

What Are the Key Market Dynamics for AC Electric Motors?

The AC electric motors market is undergoing significant transformations driven by technological advancements and shifting industrial demands. Globally, the push for energy efficiency and sustainable practices is propelling the adoption of high-efficiency motors, particularly synchronous and induction types. In regions like Africa, South America, and parts of Europe, infrastructure development and industrialization are key drivers, with countries such as Nigeria and Vietnam increasingly focusing on upgrading their manufacturing capabilities.

Emerging B2B trends include the integration of IoT (Internet of Things) technologies in motor systems, enhancing real-time monitoring and predictive maintenance capabilities. This trend is particularly relevant for industries looking to minimize downtime and optimize performance. Additionally, the rise of automation in manufacturing processes is increasing the demand for versatile motor types, capable of adapting to various operational needs. International buyers must remain vigilant about these trends to leverage opportunities for cost savings and operational efficiencies.

How Can Sustainability and Ethical Sourcing Impact AC Electric Motor Procurement?

Sustainability has become a pivotal consideration in the procurement of AC electric motors. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are encouraged to seek suppliers who adhere to sustainable practices, such as using recycled materials or low-impact manufacturing techniques.

Illustrative image related to types of ac electric motors

Ethical sourcing is equally important. Companies are increasingly prioritizing suppliers who can demonstrate commitment to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for ensuring that suppliers meet ethical standards. B2B buyers should also consider motors that have ‘green’ certifications, which indicate compliance with environmental regulations and performance standards. Choosing sustainably sourced motors not only enhances corporate social responsibility but also aligns with the growing consumer demand for eco-friendly products.

What Is the Historical Context of AC Electric Motors for Today’s Market?

The evolution of AC electric motors dates back to the late 19th century, with significant advancements in design and technology over the decades. Initially, induction motors dominated due to their simplicity and reliability. However, as industrial applications grew more complex, synchronous motors emerged, offering better performance and efficiency for specific applications.

In recent years, the introduction of advanced materials and smart technologies has revolutionized the sector. The transition from traditional manufacturing methods to automated production lines has also impacted sourcing strategies. Today, buyers are not only looking for high-performance motors but also for suppliers who can provide innovative solutions that align with modern manufacturing demands. Understanding this historical context enables B2B buyers to make informed decisions based on the evolution of technologies and market needs.

Conclusion

In summary, navigating the AC electric motors market requires an understanding of current trends, sustainability practices, and historical context. International B2B buyers must engage with suppliers who are not only meeting performance expectations but are also committed to ethical and sustainable practices. By staying informed and proactive, businesses can position themselves for success in a rapidly evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of types of ac electric motors

-

1. How do I choose the right type of AC electric motor for my application?

Choosing the right AC electric motor involves assessing your specific application requirements, such as torque, speed, and load characteristics. For high precision and constant speed, synchronous motors are ideal. In contrast, induction motors are preferred for general-purpose applications due to their reliability and cost-effectiveness. Additionally, consider factors like environmental conditions, available power supply, and maintenance needs. Collaborating with a knowledgeable supplier can also help ensure that you select a motor that meets your technical specifications and operational demands. -

2. What is the best AC motor for high-efficiency applications?

For high-efficiency applications, synchronous motors are often the best choice due to their ability to maintain a constant speed and high power factor. They are particularly suitable for processes requiring precise speed control, such as in manufacturing or pumping systems. While they may come with a higher initial cost and complexity, their operational efficiency can lead to significant energy savings in the long run. Assess your operational requirements and consult with suppliers who specialize in high-efficiency motors to find the best fit. -

3. What should I look for when vetting suppliers of AC electric motors?

When vetting suppliers, consider their industry reputation, experience, and certifications. Look for suppliers with a proven track record in manufacturing AC motors, as well as those who can provide references from similar industries. Additionally, evaluate their quality assurance processes, lead times, and customer service responsiveness. It’s also beneficial to inquire about their ability to provide custom solutions tailored to your specific application needs, which can enhance the overall value of your procurement. -

4. Are there minimum order quantities (MOQs) for AC electric motors?

Minimum order quantities (MOQs) for AC electric motors can vary significantly among suppliers. Some manufacturers may have low MOQs for standard models, while custom or specialized motors often come with higher MOQs due to the complexity of production. It’s essential to clarify MOQs with potential suppliers during initial discussions to ensure they align with your purchasing needs. Additionally, consider the potential for negotiating MOQs based on your long-term partnership with the supplier. -

5. What payment terms are typically offered for international orders of AC electric motors?

Payment terms for international orders of AC electric motors can vary widely based on the supplier and the buyer’s relationship. Common terms include upfront payments, partial payments, or letters of credit. Negotiating favorable terms is crucial, especially for larger orders, as it can impact cash flow. Ensure that you understand the currency used, payment methods accepted, and any associated transaction fees. Consulting with your financial institution may also provide insights into the best practices for international transactions. -

6. How can I ensure the quality of AC electric motors sourced internationally?

To ensure quality, request certifications and compliance documentation from suppliers, such as ISO standards or specific industry certifications. Conducting pre-shipment inspections through third-party agencies can also help verify that the motors meet your specifications before they leave the manufacturer. Establishing a clear quality assurance process, including performance testing and warranty agreements, can further protect your investment and ensure that the motors operate reliably in your applications. -

7. What logistics considerations should I keep in mind when importing AC electric motors?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Evaluate the most efficient transportation options based on your location and the supplier’s capabilities. Ensure that you understand import regulations, tariffs, and taxes that may apply to your shipment. Engaging a reliable logistics partner can facilitate smoother customs processes and help manage any potential delays. Planning for contingencies in delivery timelines is also advisable, especially for critical projects. -

8. Can AC electric motors be customized to fit specific application needs?

Yes, many manufacturers offer customization options for AC electric motors to meet specific application requirements. Customizations can include modifications to size, power ratings, speed configurations, and mounting options. When discussing your needs with suppliers, provide detailed specifications and any unique operational challenges your application may present. Collaborating closely with the manufacturer during the design phase can lead to a motor that perfectly aligns with your operational goals, enhancing efficiency and performance.

Top 4 Types Of Ac Electric Motors Manufacturers & Suppliers List

1. Monolithic Power – Synchronous Motors

Domain: monolithicpower.com

Registered: 1998 (27 years)

Introduction: Synchronous Motors are a type of AC motor where the rotation of the shaft is synchronized with the frequency of the supply current. Key features include: 1. Components: Rotor and stator; stator produces a revolving magnetic field. 2. Rotor Types: Salient pole (with steel laminations) and non-salient (cylindrical, smooth cylinder). 3. Excitation Methods: Slip rings or brushless exciters generate ro…

2. IQS Directory – AC Motors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: AC Motors are electrical devices that transform electrical energy into mechanical movement, consisting of a stationary stator and a rotating rotor. They are categorized into single-phase and three-phase types, with synchronous and induction motors as the primary categories. Synchronous motors rotate in sync with the current frequency, while induction motors operate with excitation only in the stat…

3. Oriental Motor – AC Motors

Domain: orientalmotor.com

Registered: 1997 (28 years)

Introduction: AC motors are electric motors that operate using power from a commercial AC power supply. They are easy to handle and low-cost, making them widely used for various devices. Key features include: 1. Easy to Use: Connects directly to AC power supply; low-cost start-up possible. 2. Structure: Includes components like a die cast aluminum flange bracket, stator with electromagnetic steel plates and cop…

4. Ennovi – AC Motors for Electric Vehicles

Domain: ennovi.com

Registered: 2015 (10 years)

Introduction: Types of AC Motors for Electric Vehicles (EVs): 1. Asynchronous (Induction) Motors – rely on electromagnetic induction to generate torque. 2. Synchronous Motors – operate based on different principles than asynchronous motors. Key features of AC motors include: – Efficiency – Performance – Adaptability – Ability to handle varying power demands – Smooth and efficient operation over a wide range of …

Strategic Sourcing Conclusion and Outlook for types of ac electric motors

In conclusion, the strategic sourcing of AC electric motors—whether synchronous or induction—presents significant opportunities for international B2B buyers. Understanding the operational characteristics and applications of these motors allows companies to align their sourcing strategies with their specific needs. Synchronous motors, with their precise speed control and efficiency, are ideal for high-performance applications, while induction motors offer a reliable and cost-effective solution for a wide range of industrial uses.

Illustrative image related to types of ac electric motors

As businesses navigate the complexities of sourcing in diverse markets such as Africa, South America, the Middle East, and Europe, it is crucial to prioritize quality, reliability, and supplier partnerships. By leveraging strategic sourcing practices, companies can enhance operational efficiencies and maintain a competitive edge in their respective industries.

Looking ahead, the demand for advanced AC motor technologies will continue to grow. B2B buyers are encouraged to stay informed about emerging trends and innovations in motor design and application. Engaging with trusted suppliers and investing in quality solutions will be paramount for future success. Embrace this opportunity to optimize your sourcing strategies and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to types of ac electric motors