Is Your Titanium Scrap Price Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for titanium scrap price

As global industries increasingly pivot towards sustainable practices, understanding the dynamics of titanium scrap prices becomes a vital concern for international B2B buyers. Sourcing titanium scrap, an essential component in various sectors including aerospace, automotive, and medical manufacturing, presents unique challenges. Fluctuating prices driven by market demand, geopolitical factors, and raw material costs can complicate procurement strategies. This guide aims to demystify the complexities surrounding titanium scrap pricing, offering a comprehensive exploration of types, applications, and market trends.

Throughout this resource, buyers will gain insights into the various grades of titanium scrap, their specific applications, and the critical factors influencing pricing fluctuations. Additionally, we will provide practical advice on vetting suppliers, ensuring quality assurance, and negotiating favorable terms. By equipping B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe—regions where the demand for titanium scrap is on the rise—with the knowledge to make informed purchasing decisions, this guide serves as a strategic tool for navigating the global marketplace.

In an era where material sourcing can significantly impact operational costs and sustainability efforts, understanding titanium scrap prices is not just beneficial; it is essential for competitive advantage. Engage with this guide to enhance your procurement strategies and secure the best value for your titanium scrap needs.

Understanding titanium scrap price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Alloy Scrap | Composed of titanium mixed with other metals; often requires sorting. | Aerospace, automotive, medical | Pros: High strength-to-weight ratio; valuable for recycling. Cons: Requires careful sorting and analysis. |

| Commercial Grade Scrap | Lower purity titanium scrap; may contain impurities. | General manufacturing, construction | Pros: More affordable; suitable for non-critical applications. Cons: Lower performance; limited use in high-stress environments. |

| Aerospace Grade Scrap | High-purity titanium scrap specifically from aerospace applications. | Aerospace manufacturing | Pros: High demand; excellent material properties. Cons: Higher cost; stringent quality requirements. |

| CP Titanium Scrap | Commercially pure titanium; minimal alloying elements. | Medical implants, chemical processing | Pros: Biocompatible; excellent corrosion resistance. Cons: Limited strength compared to alloys; higher price point. |

| Titanium Turnings | Small shavings or chips resulting from machining processes. | Metalworking, fabrication | Pros: Cost-effective; easy to handle. Cons: Lower value per pound; may require processing before use. |

What Are the Characteristics of Titanium Alloy Scrap?

Titanium alloy scrap is characterized by its combination of titanium with various alloying elements, enhancing its mechanical properties. This type of scrap is commonly found in aerospace and automotive industries due to its high strength-to-weight ratio and resistance to corrosion. When purchasing titanium alloy scrap, B2B buyers should consider the purity and composition, as these factors influence the scrap’s value and applicability in high-performance environments. Sorting and proper analysis are crucial to ensure the desired material characteristics are met.

Illustrative image related to titanium scrap price

How Does Commercial Grade Scrap Differ from Other Types?

Commercial grade titanium scrap features lower purity levels and may contain impurities from various manufacturing processes. It is typically more affordable and is suitable for general manufacturing and construction applications where high performance is not critical. Buyers should weigh the cost benefits against the potential limitations in performance when considering commercial grade scrap. This option is ideal for projects where budget constraints exist but still requires titanium’s inherent properties.

Why Choose Aerospace Grade Scrap for High-Performance Applications?

Aerospace grade titanium scrap is sourced specifically from aerospace applications, ensuring high purity and superior mechanical properties. This type of scrap is highly sought after in the aerospace manufacturing sector, where performance and reliability are paramount. B2B buyers must be prepared for a higher cost due to the stringent quality standards associated with this scrap type. The investment is justified by the material’s exceptional performance in demanding environments, making it a preferred choice for critical applications.

What Are the Benefits of CP Titanium Scrap?

Commercially pure (CP) titanium scrap is known for its minimal alloying elements, making it highly biocompatible and resistant to corrosion. This scrap type is primarily used in medical implants and chemical processing applications, where purity is essential. Buyers should consider the specific requirements of their applications, as the higher cost of CP titanium scrap is balanced by its excellent performance in sensitive environments. Understanding the end-use can help buyers make informed purchasing decisions.

How Are Titanium Turnings Used in Metalworking?

Titanium turnings are small chips or shavings generated during machining processes, representing a cost-effective option for metalworking and fabrication. While they may have a lower value per pound compared to other forms of titanium scrap, they are easy to handle and can be recycled efficiently. B2B buyers should assess the processing needs of turnings, as they may require additional treatment before being suitable for reuse in manufacturing. This type of scrap can be a practical choice for businesses looking to optimize costs while still utilizing titanium’s beneficial properties.

Key Industrial Applications of titanium scrap price

| Industry/Sector | Specific Application of titanium scrap price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of lightweight aircraft components | Reduces material costs while maintaining performance | Ensure compliance with aerospace standards and certifications |

| Medical Devices | Manufacturing of surgical instruments and implants | High biocompatibility and strength-to-weight ratio | Source from certified recyclers to guarantee material purity |

| Automotive | Development of high-performance vehicle parts | Enhances fuel efficiency and reduces overall weight | Consider regional supply chains and logistics for timely delivery |

| Marine Engineering | Construction of corrosion-resistant components | Increases durability and lifespan of marine equipment | Verify quality standards and resistance to seawater corrosion |

| 3D Printing | Supply of titanium powder for additive manufacturing | Enables innovative designs and rapid prototyping | Focus on particle size distribution and consistency for optimal results |

How is Titanium Scrap Price Used in Aerospace Applications?

In the aerospace industry, titanium scrap is primarily utilized in the production of lightweight aircraft components. This application is crucial as it allows manufacturers to reduce material costs without compromising performance or safety standards. International buyers, particularly from regions like Europe and the Middle East, must ensure that the titanium scrap they source meets stringent aerospace certifications and quality standards, which can vary significantly across different countries.

Illustrative image related to titanium scrap price

What are the Benefits of Titanium Scrap in Medical Devices?

Titanium scrap plays a vital role in the manufacturing of surgical instruments and implants due to its high biocompatibility and exceptional strength-to-weight ratio. This application not only enhances the performance of medical devices but also contributes to patient safety. Buyers in Africa and South America should prioritize sourcing from certified recyclers to ensure that the titanium scrap is free from contaminants and meets the regulatory requirements specific to the medical sector.

How Does Titanium Scrap Enhance Automotive Performance?

In the automotive sector, titanium scrap is increasingly used for developing high-performance vehicle parts. By incorporating titanium into their designs, manufacturers can significantly enhance fuel efficiency and reduce the overall weight of vehicles, leading to improved performance. For B2B buyers in regions like Brazil, it is essential to consider the regional supply chains and logistics, ensuring timely delivery to meet production schedules and maintain competitive pricing.

Why is Titanium Scrap Important for Marine Engineering?

Marine engineering benefits from titanium scrap as it is used in constructing corrosion-resistant components. The inherent properties of titanium make it ideal for environments exposed to seawater, increasing the durability and lifespan of marine equipment. Buyers should verify that the sourced titanium scrap adheres to quality standards for corrosion resistance, particularly if they are operating in harsh marine conditions, which is a common concern for companies in the Middle East.

How is Titanium Scrap Revolutionizing 3D Printing?

In the realm of 3D printing, titanium scrap is used to produce titanium powder, which is essential for additive manufacturing processes. This application allows for innovative designs and rapid prototyping, making it a game-changer in various industries. For international buyers, particularly in Europe, focusing on the particle size distribution and consistency of titanium powder is critical, as these factors directly impact the quality and performance of the final printed products.

3 Common User Pain Points for ‘titanium scrap price’ & Their Solutions

Scenario 1: Volatile Pricing Causing Budgeting Challenges

The Problem: B2B buyers often face significant difficulties in budgeting for titanium scrap purchases due to its inherent price volatility. Prices can fluctuate based on various factors such as global demand, geopolitical tensions, and changes in raw material costs. For example, a manufacturer in Brazil may find that the price of titanium scrap spikes unexpectedly due to increased demand in the aerospace sector, disrupting their financial forecasts and making it challenging to allocate resources effectively.

Illustrative image related to titanium scrap price

The Solution: To navigate this volatility, buyers should implement a strategic procurement plan that includes hedging strategies and long-term contracts. Establish relationships with multiple suppliers across different regions to diversify sourcing options and mitigate risks associated with price spikes. Additionally, staying informed about global market trends and political developments can provide early warnings about potential price fluctuations. Utilizing price alert services or subscribing to industry reports will allow buyers to make informed decisions and potentially lock in prices before they rise.

Scenario 2: Difficulty in Assessing Quality and Grade of Titanium Scrap

The Problem: Another common challenge faced by B2B buyers is accurately assessing the quality and grade of titanium scrap. The value of titanium scrap can vary significantly depending on its grade, and without proper testing or knowledge, buyers may end up overpaying for lower-quality materials or receiving scrap that does not meet their specifications. For instance, a buyer in Germany may receive titanium scrap that is contaminated with other metals, leading to costly production delays or rejected products.

The Solution: To ensure the quality of titanium scrap, buyers should invest in robust testing protocols. This includes using non-destructive testing methods such as X-ray fluorescence (XRF) analysis to determine the composition of the scrap before purchase. Establishing clear specifications and requirements for grade and quality with suppliers can also prevent misunderstandings. Additionally, consider working with reputable scrap dealers who provide certifications and detailed material reports. Regular training for procurement teams on material standards can further enhance the ability to assess scrap quality accurately.

Illustrative image related to titanium scrap price

Scenario 3: Navigating International Supply Chain Complexities

The Problem: B2B buyers often encounter complexities in navigating the international supply chain for titanium scrap, particularly when dealing with cross-border transactions. Issues such as import/export regulations, tariffs, and logistical challenges can create significant delays and additional costs. For example, a company in South Africa may face unexpected tariffs on imported titanium scrap from Europe, complicating their procurement strategy and impacting project timelines.

The Solution: To streamline international procurement processes, buyers should conduct thorough research on the regulatory landscape and establish a network of reliable logistics partners. Engaging with local experts who understand the nuances of international trade in metals can provide valuable insights. Additionally, leveraging technology such as supply chain management software can enhance visibility and tracking of shipments, helping to anticipate potential delays. Building strong relationships with customs brokers and freight forwarders can also facilitate smoother transactions and reduce the risk of compliance issues. By proactively addressing these logistical challenges, B2B buyers can enhance their procurement efficiency and maintain operational continuity.

Strategic Material Selection Guide for titanium scrap price

What Are the Key Properties of Common Titanium Scrap Materials?

When considering titanium scrap for B2B applications, understanding the specific materials and their properties is crucial. Here, we analyze four common titanium scrap materials: Commercially Pure Titanium, Titanium Alloys (like Ti-6Al-4V), Titanium Sponge, and Titanium Turnings. Each material has unique characteristics that influence its suitability for various applications.

What Are the Properties and Applications of Commercially Pure Titanium?

Commercially Pure Titanium (CPT) is known for its excellent corrosion resistance and biocompatibility, making it ideal for medical implants and aerospace applications. It maintains strength at elevated temperatures, with a melting point around 1,668°C (3,034°F). The material’s low density and high strength-to-weight ratio enhance its performance in applications requiring lightweight components.

Pros: CPT is highly durable and resistant to a wide range of corrosive environments, which is essential in industries like marine and chemical processing. Its biocompatibility is a significant advantage in medical applications.

Cons: The primary limitation of CPT is its relatively higher cost compared to other metals. Additionally, it can be more challenging to machine due to its toughness.

Illustrative image related to titanium scrap price

Impact on Application: CPT is particularly suitable for environments where exposure to corrosive media is a concern, such as in chemical processing and biomedical devices.

Considerations for International Buyers: Compliance with standards like ASTM F67 (for medical applications) is essential. Buyers from regions like Europe and the Middle East should also consider local regulations regarding material sourcing and environmental impact.

How Do Titanium Alloys Like Ti-6Al-4V Compare?

Titanium alloys, particularly Ti-6Al-4V, are among the most widely used in aerospace and automotive industries due to their superior mechanical properties. This alloy exhibits excellent strength, corrosion resistance, and weldability, with a melting point of approximately 1,600°C (2,912°F).

Illustrative image related to titanium scrap price

Pros: The primary advantage of Ti-6Al-4V is its high strength-to-weight ratio, which is crucial for aerospace applications. Its versatility allows it to be used in various environments, from high-stress aerospace components to medical devices.

Cons: The complexity of manufacturing and machining Ti-6Al-4V can lead to higher production costs. Additionally, its performance can be sensitive to heat treatment processes.

Impact on Application: Ti-6Al-4V is ideal for high-performance applications, including aircraft frames and engine components, where strength and weight are critical.

Considerations for International Buyers: Buyers should ensure compliance with ASTM B265 and other relevant standards. Understanding the specific alloy grades and their applications is vital for sourcing the right material.

What Role Does Titanium Sponge Play in Scrap Pricing?

Titanium sponge is an intermediate product in titanium processing, characterized by its high purity and low density. It serves as a raw material for producing titanium alloys and is crucial in applications requiring high-performance titanium.

Illustrative image related to titanium scrap price

Pros: Titanium sponge has excellent purity levels, making it suitable for high-end applications. Its lightweight nature contributes to overall material efficiency.

Cons: The production of titanium sponge is energy-intensive, leading to higher costs. Additionally, its availability can fluctuate based on mining operations and geopolitical factors.

Impact on Application: Titanium sponge is primarily used in the aerospace and defense sectors, where high purity and performance are non-negotiable.

Considerations for International Buyers: Compliance with international trade regulations and sourcing from stable geopolitical regions is crucial. Buyers should also be aware of the environmental impact of titanium sponge production.

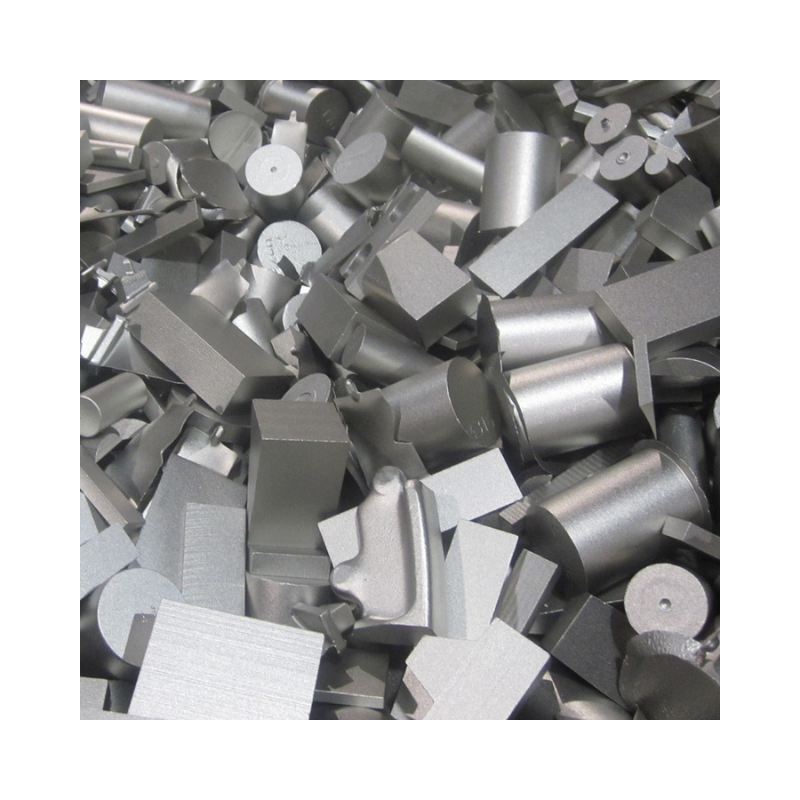

How Do Titanium Turnings Affect Scrap Value?

Titanium turnings are small metal shavings produced during machining processes. While they may seem less valuable than larger scrap pieces, they can still command high prices due to their titanium content.

Illustrative image related to titanium scrap price

Pros: The primary advantage of titanium turnings is their ability to be recycled efficiently, providing a cost-effective source of titanium for manufacturers. They are also easier to transport due to their smaller size.

Cons: The challenge with turnings lies in their lower density, which can affect shipping costs. Additionally, they may require additional processing to remove contaminants.

Impact on Application: Turnings are often used in the production of titanium powders for additive manufacturing, making them valuable in modern manufacturing processes.

Illustrative image related to titanium scrap price

Considerations for International Buyers: Buyers should ensure that turnings meet specific quality standards and are free from contaminants. Understanding local recycling regulations is also essential for compliance.

Summary Table of Titanium Scrap Materials

| Material | Typical Use Case for titanium scrap price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Commercially Pure Titanium | Medical implants, aerospace components | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Titanium Alloys (Ti-6Al-4V) | Aerospace, automotive applications | High strength-to-weight ratio | Complex manufacturing process | High |

| Titanium Sponge | Aerospace, defense applications | High purity and lightweight | Energy-intensive production | High |

| Titanium Turnings | Additive manufacturing, recycling | Cost-effective recycling option | Lower density affects shipping costs | Medium |

This analysis provides a comprehensive understanding of the various titanium scrap materials, their properties, and considerations for international B2B buyers. By aligning material selection with application requirements and compliance standards, buyers can make informed decisions that enhance their procurement strategies.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium scrap price

What Are the Main Stages of Manufacturing Titanium Scrap?

The manufacturing process for titanium scrap involves several critical stages to ensure the material is prepared and processed effectively for reuse in various applications. Understanding these stages can help B2B buyers evaluate the quality and reliability of their titanium scrap suppliers.

Material Preparation: How Is Titanium Scrap Processed Before Manufacturing?

The initial stage involves the collection and sorting of titanium scrap. This step is crucial as it determines the quality of the final product. Scrap titanium is typically categorized based on its grade and composition, which may include pure titanium, titanium alloys, or other titanium-containing materials.

Once sorted, the scrap undergoes cleaning to remove contaminants such as oils, paints, or other residues. This cleaning process may involve mechanical methods, such as shot blasting or grinding, to ensure the material is free from impurities. Following cleaning, the titanium scrap is often shredded or granulated to facilitate easier handling and processing in subsequent stages.

Illustrative image related to titanium scrap price

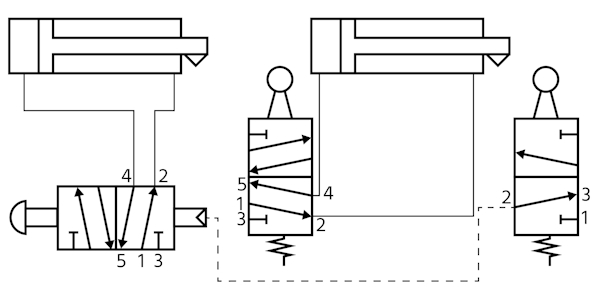

What Forming Techniques Are Used in Titanium Scrap Manufacturing?

Forming techniques play a pivotal role in the manufacturing of titanium scrap. Common methods include:

-

Hot and Cold Forging: These techniques involve shaping the titanium scrap at elevated temperatures or room temperature, respectively. Hot forging improves ductility, while cold forging enhances strength.

-

Casting: For certain applications, titanium scrap can be melted and cast into specific shapes or forms. This technique is particularly useful for producing complex geometries.

-

Powder Metallurgy: This innovative method involves compacting titanium powder (derived from scrap) and sintering it to create dense components. This technique is gaining traction due to its efficiency and ability to produce intricate designs.

How Does Finishing Impact the Quality of Titanium Scrap Products?

The finishing stage is critical for enhancing the surface quality and properties of titanium products. Common finishing techniques include:

-

Machining: Precision machining processes, such as turning and milling, are employed to achieve the desired dimensions and surface finish. This step is essential for applications requiring tight tolerances.

-

Anodizing: This electrochemical process enhances corrosion resistance and wear properties of titanium. Anodizing can also produce aesthetic finishes, making the material suitable for various applications.

-

Surface Treatments: Techniques such as shot peening or surface hardening may be applied to improve fatigue resistance and overall performance.

What Quality Control Standards Are Relevant for Titanium Scrap?

Quality assurance is paramount in the titanium scrap industry to ensure the material meets the necessary specifications and standards. B2B buyers should be aware of various international and industry-specific standards that govern quality control processes.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized international standard for quality management systems. Suppliers adhering to ISO 9001 demonstrate a commitment to quality assurance and continuous improvement. This standard requires documented processes for managing quality at all stages of production, from material procurement to final inspection.

Illustrative image related to titanium scrap price

Additionally, certifications such as CE marking and API (American Petroleum Institute) standards are relevant for suppliers targeting specific industries like aerospace and oil and gas. These certifications indicate compliance with industry regulations and ensure that the titanium scrap meets stringent performance criteria.

What Are the Key QC Checkpoints in Titanium Scrap Processing?

To ensure the quality of titanium scrap throughout the manufacturing process, several critical quality control checkpoints should be established:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting the incoming scrap materials for compliance with specifications. Key parameters assessed may include chemical composition, physical characteristics, and contamination levels.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures that operations adhere to established standards. This may involve regular sampling and testing of materials at various stages of production to identify any deviations early.

-

Final Quality Control (FQC): At this stage, finished titanium products undergo thorough inspections and testing. This may include dimensional checks, surface quality assessments, and mechanical property evaluations to confirm that the final product meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must implement strategies to verify the quality control processes of their titanium scrap suppliers. Here are several methods to ensure compliance and reliability:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting regular audits of suppliers can provide invaluable insights into their quality control processes. These audits should assess compliance with international standards, evaluate the effectiveness of quality management systems, and identify areas for improvement.

Furthermore, requesting quality assurance reports, including inspection results and certifications, can help buyers gauge the supplier’s commitment to maintaining quality standards. These documents should detail the methods used for testing and verification, providing a transparent view of the supplier’s processes.

Illustrative image related to titanium scrap price

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services is an effective way to validate a supplier’s quality control practices. Independent inspectors can conduct thorough assessments of materials, processes, and compliance with industry standards. This external validation adds a layer of assurance for B2B buyers, particularly those operating in regions with varying regulatory environments.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical.

How Do Regional Standards Affect Quality Assurance in Titanium Scrap?

Different regions may have specific standards and regulations governing the quality of titanium scrap. Buyers should familiarize themselves with local requirements to ensure compliance. For instance, European buyers may need to adhere to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations, while buyers in the Middle East may encounter different import standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, documented agreements on quality standards and expectations can help mitigate misunderstandings.

What Should Buyers Look for in Supplier Certifications?

When evaluating suppliers, international buyers should prioritize those with recognized certifications relevant to their industry. Certifications not only demonstrate compliance with quality standards but also indicate a supplier’s commitment to maintaining high production and quality assurance practices.

By thoroughly understanding the manufacturing processes and quality assurance protocols for titanium scrap, B2B buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium scrap price’

To effectively navigate the procurement of titanium scrap, it is essential for B2B buyers to follow a structured approach. This guide provides a step-by-step checklist that highlights the critical actions necessary to secure quality titanium scrap at competitive prices. By adhering to these steps, buyers can make informed decisions that align with their business needs.

Step 1: Understand Market Dynamics

Before initiating your sourcing process, familiarize yourself with the current market trends and pricing fluctuations for titanium scrap. Factors such as global demand, supply chain disruptions, and geopolitical influences can significantly impact prices. Monitoring industry reports and market analyses will help you anticipate price movements and negotiate better deals.

Step 2: Define Your Technical Specifications

Clearly outline the specifications for the titanium scrap you require, including grade, size, and quantity. Different grades of titanium scrap have varying applications and values, so it’s crucial to know exactly what you need. Consider factors like purity levels and any specific industry standards your product must meet.

Step 3: Evaluate Potential Suppliers

Assessing potential suppliers is vital to ensure you are working with reputable sources. Look for suppliers with a proven track record in the titanium scrap market. Request documentation such as company profiles, certifications, and references from other buyers to verify their credibility and reliability.

- Key Considerations:

- Supplier certifications (ISO, recycling standards)

- Customer reviews or testimonials

- History of consistent pricing and quality

Step 4: Request and Compare Quotes

Once you have identified potential suppliers, request detailed quotes that include pricing per pound, delivery options, and any additional fees. Comparing quotes allows you to identify the best value while ensuring that you are not compromising on quality. Pay attention to the terms of sale, including payment conditions and return policies.

Step 5: Conduct a Site Visit

If possible, visit the supplier’s facility to inspect their operations and materials firsthand. This step provides insight into their processing methods, quality control measures, and overall business practices. A site visit can also strengthen your relationship with the supplier, fostering trust and collaboration.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms that align with your procurement strategy. Discuss payment options, delivery schedules, and warranty conditions to ensure mutual satisfaction. Being transparent about your needs and expectations can lead to better terms and a stronger partnership.

Illustrative image related to titanium scrap price

Step 7: Finalize Purchase and Monitor Performance

After agreeing on terms, finalize the purchase and establish a system for monitoring the supplier’s performance. Regularly assess the quality of the titanium scrap received and the supplier’s adherence to agreed-upon terms. Maintaining open communication will help address any issues promptly and ensure ongoing satisfaction.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing titanium scrap effectively, ensuring they secure quality materials at competitive prices while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for titanium scrap price Sourcing

What Are the Key Cost Components in Titanium Scrap Pricing?

Understanding the cost structure of titanium scrap is crucial for B2B buyers looking to source efficiently. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The price of titanium scrap can fluctuate based on the quality and grade of the material. Higher-grade titanium scrap commands premium prices due to its enhanced properties and potential applications in industries like aerospace and medical devices.

-

Labor: Labor costs encompass the wages of workers involved in the collection, sorting, and processing of titanium scrap. Labor-intensive processes, especially in regions with higher wage standards, can significantly impact overall pricing.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment necessary for processing titanium scrap. Efficient operations can reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Investment in specialized tools and equipment for processing titanium scrap can affect pricing. Suppliers who invest in advanced technology may offer better quality but at a higher price point.

-

Quality Control (QC): Ensuring the quality of titanium scrap is essential for maintaining industry standards. Suppliers who implement rigorous QC measures may charge more, reflecting their commitment to quality assurance.

-

Logistics: Transportation and handling costs play a critical role, especially for international buyers. Factors such as distance, mode of transport, and local regulations can influence logistics costs significantly.

-

Margin: Suppliers will include a margin to ensure profitability. This margin can vary widely based on market conditions, competition, and the perceived value of the scrap.

How Do Price Influencers Impact Titanium Scrap Costs?

Several factors can influence the price of titanium scrap, making it vital for buyers to understand these dynamics:

-

Volume/MOQ: Larger orders typically attract discounts. Buyers should negotiate minimum order quantities (MOQs) to benefit from economies of scale.

-

Specifications and Customization: Tailored solutions or specific grade requirements can lead to increased costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Quality and Certifications: Titanium scrap with certifications (such as ISO or ASTM) may cost more due to the assurance of quality. Buyers should evaluate whether the added expense aligns with their application requirements.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers with proven track records may command higher prices due to perceived value.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, affecting overall costs.

What Tips Can Help Buyers Negotiate Better Titanium Scrap Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are key tips to enhance cost-efficiency and secure favorable pricing:

-

Research and Benchmarking: Familiarize yourself with current market prices and trends for titanium scrap. Use resources like scrap price tracking websites to benchmark against typical pricing.

-

Negotiate Terms: Be proactive in negotiations regarding payment terms, delivery schedules, and pricing structures. Flexibility in these areas can lead to cost savings.

-

Evaluate Total Cost of Ownership (TCO): Consider the TCO rather than just the purchase price. Factors such as shipping, handling, and potential tariffs can significantly affect overall expenses.

-

Build Relationships with Suppliers: Establish long-term relationships with reliable suppliers. A strong partnership can lead to better terms, priority during shortages, and favorable pricing adjustments.

-

Stay Informed on Market Dynamics: Monitor global events that could impact titanium scrap supply and demand. Understanding geopolitical issues, economic trends, and changes in regulations can give buyers a strategic advantage.

Conclusion: Navigating Titanium Scrap Pricing

While current prices for titanium scrap may vary, the complex interplay of cost components and pricing influencers means that buyers must approach sourcing strategically. Understanding these elements not only aids in negotiation but also helps in making informed purchasing decisions that align with business objectives. Always consider obtaining indicative prices from multiple suppliers to ensure competitive sourcing while keeping in mind that prices can fluctuate based on market conditions.

Alternatives Analysis: Comparing titanium scrap price With Other Solutions

In the competitive landscape of materials sourcing, B2B buyers must evaluate various options for titanium scrap procurement against alternative solutions. Understanding the nuances of these alternatives can aid in making informed decisions that align with operational needs and budget constraints.

| Comparison Aspect | Titanium Scrap Price | Additive Manufacturing (3D Printing) | Recycled Titanium Alloys |

|---|---|---|---|

| Performance | High strength-to-weight ratio; versatile applications in aerospace and medical fields. | Offers design flexibility and material efficiency; can produce complex geometries. | Comparable properties to virgin titanium; suitable for high-stress applications. |

| Cost | $7-$9 per pound (as of 2023); fluctuates based on demand and geopolitical factors. | Initial setup costs can be high; ongoing material costs depend on the technology used. | Typically lower than virgin titanium but higher than scrap; cost influenced by recycling processes. |

| Ease of Implementation | Requires sourcing from scrap yards; may require sorting and processing. | Requires specialized equipment and skilled labor; longer lead times for prototyping. | Can be integrated into existing supply chains; processing needs vary by alloy. |

| Maintenance | Low maintenance post-purchase; needs careful handling to preserve quality. | Equipment maintenance can be complex and costly; requires regular software updates. | Similar to titanium scrap; quality control is essential to ensure alloy consistency. |

| Best Use Case | Ideal for large-scale production where cost savings on raw materials are paramount. | Best for customized parts and low-volume production runs; excellent for prototyping. | Suitable for industries requiring high-performance materials with reduced environmental impact. |

What Are the Pros and Cons of Additive Manufacturing as an Alternative to Titanium Scrap?

Additive manufacturing, or 3D printing, presents a compelling alternative to titanium scrap, especially for businesses focused on innovation and customization. This technology enables the creation of complex geometries that are often impossible to achieve with traditional manufacturing methods. However, the initial investment in 3D printing equipment can be significant, and the materials used may be more costly than titanium scrap. Additionally, while the technology offers flexibility, it requires skilled personnel for operation and maintenance, which can add to overall costs.

Illustrative image related to titanium scrap price

How Does Recycled Titanium Alloys Compare to Titanium Scrap Prices?

Recycled titanium alloys serve as another viable alternative to titanium scrap. These alloys often retain comparable properties to virgin titanium, making them suitable for high-stress applications in aerospace and medical sectors. The cost of recycled alloys is typically lower than that of newly mined titanium but may still exceed the price of titanium scrap. This option allows for a more consistent material quality, reducing variability in performance. However, the recycling process can be labor-intensive, impacting the overall cost and supply chain logistics.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution depends largely on the specific requirements of your operation, including budget, production volume, and desired material properties. For businesses focused on cost-effective solutions for large-scale production, titanium scrap may be the best choice, particularly given its fluctuating market prices. Conversely, if customization and design flexibility are paramount, investing in additive manufacturing could provide significant long-term benefits. Lastly, if maintaining material consistency is crucial, recycled titanium alloys offer a reliable alternative that balances cost and performance. Evaluating these factors will enable B2B buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for titanium scrap price

What Are the Key Technical Properties of Titanium Scrap?

Understanding the essential technical properties of titanium scrap is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications:

1. Material Grade

Material grade indicates the quality and composition of titanium scrap. Common grades include commercially pure titanium (CP) and titanium alloys (e.g., Ti-6Al-4V). Each grade has different mechanical properties, making them suitable for various applications in industries like aerospace and medical. Buyers must ensure they are sourcing the correct grade to meet their specific project requirements, as this can significantly impact performance and cost.

2. Chemical Composition

The chemical composition of titanium scrap, including the presence of elements like aluminum, vanadium, and iron, plays a vital role in determining its properties. Different compositions can lead to variations in strength, corrosion resistance, and ductility. Buyers should request a material safety data sheet (MSDS) or certificate of analysis (COA) to verify the composition, ensuring that the scrap meets their specifications and compliance standards.

3. Size and Shape

The size and shape of titanium scrap can affect processing and recycling efficiency. For instance, larger pieces may require more extensive processing and could incur higher handling costs. Conversely, smaller, uniform pieces can streamline recycling processes. Buyers should specify their preferred dimensions to optimize their production or recycling operations and minimize costs.

4. Tolerance Levels

Tolerance refers to the permissible limit of variation in dimensions and properties of the titanium scrap. Tight tolerances may be necessary for applications requiring precision, such as aerospace components. Understanding the required tolerance levels helps buyers ensure that the scrap material will meet their application needs and reduce the risk of defects during manufacturing.

5. Contaminants and Impurities

The presence of contaminants, such as other metals or non-metallic materials, can negatively impact the quality of titanium scrap. Buyers need to ensure that the scrap is free from impurities, which can weaken the material and lead to failures in critical applications. Conducting a thorough inspection and analysis of the scrap before purchase is essential for maintaining quality standards.

What Are the Common Trade Terms Used in Titanium Scrap Pricing?

Familiarity with industry jargon is essential for effective communication and negotiation in the titanium scrap market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the titanium scrap industry, buyers often work with OEMs to source high-quality titanium components. Understanding OEM relationships can help buyers identify reliable suppliers and establish long-term partnerships.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. This term is critical in B2B transactions, as it affects inventory management and cost efficiency. Buyers should be aware of MOQs when negotiating contracts to ensure they can meet their production needs without incurring unnecessary costs.

Illustrative image related to titanium scrap price

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is crucial for B2B buyers to gather competitive offers and make informed purchasing decisions. A well-crafted RFQ can lead to better pricing and terms, making it a vital tool for procurement teams.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for buyers to clarify shipping, risk, and cost responsibilities. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which can significantly impact overall pricing and logistics.

5. Scrap Metal Recycling Rate

This term refers to the price paid for scrap metal based on its market value. The recycling rate for titanium scrap can fluctuate based on demand and supply dynamics. Buyers should keep abreast of current rates to negotiate favorable deals and maximize their purchasing power.

By grasping these technical properties and trade terms, B2B buyers can navigate the titanium scrap market more effectively, ensuring they make informed decisions that align with their operational needs and financial goals.

Illustrative image related to titanium scrap price

Navigating Market Dynamics and Sourcing Trends in the titanium scrap price Sector

What Are the Key Trends Influencing the Titanium Scrap Price Market?

The titanium scrap price sector is experiencing significant shifts driven by various global factors. Demand from industries such as aerospace, automotive, and medical technology is a primary driver. These sectors are increasingly relying on titanium due to its superior strength-to-weight ratio and corrosion resistance. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing strategies.

Emerging technologies, particularly in additive manufacturing (3D printing), are reshaping the market. The integration of titanium powders in manufacturing processes is expanding the applications for scrap titanium, leading to a surge in demand. Moreover, digital platforms are becoming essential for sourcing and price transparency, allowing buyers to access real-time data and historical trends that inform their purchasing decisions.

Market dynamics are also influenced by geopolitical factors, such as trade policies and political stability in titanium-producing regions. For example, supply chain disruptions due to sanctions or conflicts can lead to price spikes. Buyers should be vigilant about these external factors, as they can directly impact sourcing costs and availability.

How Is Sustainability and Ethical Sourcing Shaping the Titanium Scrap Price Landscape?

Sustainability is becoming a paramount concern in the titanium scrap industry, with increasing pressure on businesses to adopt ethical sourcing practices. The environmental impact of titanium mining and production has prompted a shift towards recycling as a more sustainable alternative. By sourcing titanium scrap, companies can significantly reduce their carbon footprint and contribute to circular economy principles.

Ethical supply chains are also gaining importance, with B2B buyers increasingly seeking suppliers who adhere to sustainable practices. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. Buyers should prioritize partnerships with suppliers who can demonstrate a responsible approach to sourcing and recycling titanium scrap.

Incorporating ‘green’ materials into procurement strategies not only aligns with corporate social responsibility (CSR) objectives but also enhances brand reputation in a competitive marketplace. As consumers and stakeholders demand greater accountability, companies that prioritize ethical sourcing will likely enjoy a competitive edge.

What Is the Brief Evolution of the Titanium Scrap Price Market?

The titanium scrap price market has evolved significantly over the last two decades, influenced by economic cycles, technological advancements, and industry demand. In the early 2000s, prices were relatively low, fluctuating between $2 to $3 per pound. However, as industries began to recognize the advantages of titanium, especially in aerospace applications, prices steadily increased, peaking around $6 to $7 per pound by 2006.

The 2008 financial crisis caused a notable dip in prices, but recovery in subsequent years, driven by rising economies and new applications, led to increased demand. The introduction of 3D printing technologies further transformed the landscape, creating new opportunities for titanium scrap usage. By 2023, the market saw regional disparities, with higher prices in Asia due to aggressive procurement strategies. Understanding this historical context helps B2B buyers navigate current market trends and forecast future pricing dynamics effectively.

Illustrative image related to titanium scrap price

Frequently Asked Questions (FAQs) for B2B Buyers of titanium scrap price

-

1. How do I determine the current market price for titanium scrap?

To determine the current market price for titanium scrap, start by checking reliable industry sources that provide daily updates on scrap metal prices. Websites of scrap recycling companies often list current prices alongside historical trends. Additionally, subscribing to industry newsletters and market analysis reports can provide valuable insights into price fluctuations influenced by supply and demand dynamics. Engage with local scrap dealers or recycling facilities to gather quotes and establish a baseline for pricing in your region. -

2. What factors influence the pricing of titanium scrap?

The pricing of titanium scrap is influenced by several key factors, including global demand from industries like aerospace and automotive, the cost of newly mined titanium, and overall economic conditions. Supply chain disruptions due to political instability or trade sanctions can also impact prices. Additionally, the costs associated with recycling titanium, such as labor and energy, can affect market rates. Understanding these dynamics will help you anticipate price changes and make informed purchasing decisions. -

3. How can I vet potential suppliers for titanium scrap?

Vetting suppliers for titanium scrap involves several steps. Start by researching their reputation through customer reviews and industry ratings. Verify their compliance with local and international regulations regarding metal recycling. Request certifications that demonstrate their commitment to quality and sustainability. Additionally, conducting site visits or audits can provide insights into their operational practices and material handling processes. Establishing clear communication and building relationships with suppliers can also enhance trust and reliability in your sourcing efforts. -

4. What are the typical payment terms for titanium scrap transactions?

Payment terms for titanium scrap transactions can vary widely among suppliers. Common arrangements include upfront payments, payment upon delivery, or net terms ranging from 30 to 90 days. It’s essential to clarify these terms before finalizing any agreements to avoid misunderstandings. Consider negotiating favorable terms based on your purchasing volume and relationship with the supplier. Always ensure that payment methods are secure and documented to protect both parties involved in the transaction. -

5. What is the minimum order quantity (MOQ) for titanium scrap purchases?

Minimum order quantities (MOQs) for titanium scrap can vary significantly depending on the supplier and the nature of the scrap. Some suppliers may have a MOQ of a few hundred pounds, while others may require several tons, especially for specialized grades. It’s important to communicate your needs and verify the MOQ before proceeding with an order. If your requirements are below a supplier’s MOQ, consider consolidating orders with other buyers or discussing custom arrangements that can work for both parties. -

6. How do logistics and shipping impact the cost of titanium scrap?

Logistics and shipping can substantially affect the overall cost of titanium scrap. Factors such as transportation distance, shipping method (air, sea, or land), and handling fees can add to the final price. When sourcing internationally, consider the implications of customs duties and tariffs, which can vary by country. To optimize costs, work with logistics providers experienced in scrap metal handling, and explore options for bulk shipping discounts or local sourcing to minimize transportation expenses. -

7. What quality assurance measures should I expect when purchasing titanium scrap?

When purchasing titanium scrap, expect suppliers to implement quality assurance measures that ensure the material meets industry standards. This may include material analysis reports, documentation of the scrap’s origin, and adherence to specifications for grades. Requesting samples or conducting your own tests can provide additional assurance of quality. Establishing clear quality criteria in your purchasing agreement will help mitigate risks associated with subpar materials and ensure you receive what you expect. -

8. How can I customize my titanium scrap orders to meet specific requirements?

To customize your titanium scrap orders, communicate your specific needs clearly with your supplier. This could include requests for certain grades, sizes, or forms of titanium scrap. Many suppliers are willing to accommodate custom orders, especially for repeat customers or larger volumes. Discuss potential adjustments in pricing based on customization and ensure that all specifications are documented in your purchase agreement to avoid discrepancies upon delivery.

Top 7 Titanium Scrap Price Manufacturers & Suppliers List

1. Rockaway Recycling – Titanium Scrap

Domain: rockawayrecycling.com

Registered: 2007 (18 years)

Introduction: {“current_price”:”$1.00/lb”,”description”:”Must be analyzed and be free of attachments. Titanium can be a very valuable scrap valued metal along with other types of rare alloys. If you aren’t sure what kind of material you have, be sure to perform a magnet test on it, the magnet should not stick if it is Titanium.”,”last_modified”:”September 12th, 2025, 10:44 am”}

2. Scrap Metal Buyers – Titanium Recycling

Domain: scrapmetalbuyers.com

Registered: 2018 (7 years)

Introduction: Titanium Recycling: We recycle all titanium grades and forms, including titanium alloy CP, titanium alloy 6-4, and titanium alloy 6-2. Solid titanium forms accepted: Titanium Bars, Titanium Turbine Blades and Disks, Titanium Plate Trimmings, Titanium Billets. Current Price: $0.35/lb. Titanium is strong as steel but less dense, used as an alloying agent in aircraft, spacecraft, and missiles due to …

3. Scrap Yards – Titanium Pricing Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Scrap yards may buy titanium. The going price for titanium is reported to be around $12-15 per ounce or approximately $52 for 1 kg. Reputable scrap yards typically pay 50-75% of the market spot price for titanium.

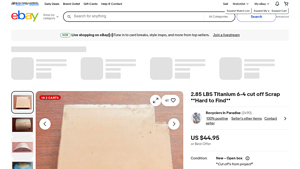

4. Recyclers In Paradise – Titanium 6-4 Cut Offs

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Weight”:”2.85 LBS”,”Material”:”Titanium 6-4″,”Condition”:”New – Open box”,”Description”:”Cut off’s from project”,”Seller”:”Recyclers In Paradise”,”Seller Feedback”:”100% positive”,”Price”:”US $44.95 or Best Offer”,”Shipping”:”Does not ship to Ukraine”,”Location”:”Santa Paula, California, United States”,”Returns”:”Seller does not accept returns”,”Quantity Available”:”More than 10 available”,”Sold…

5. XMake – Titanium Grades and Pricing

Domain: xmake.com

Registered: 2008 (17 years)

Introduction: Titanium is a strong, low-density metal known for its exceptional strength-to-weight ratio and outstanding corrosion resistance. It is commercially available in various grades and forms, with prices varying based on these factors. As of 2025, commercially pure titanium (Grades 1-4) ranges from $6 to $10 per pound, while titanium alloys like TiAl6V4 (Grade 5) range from $10 to $30 per pound. Titani…

6. JRS Advanced Recyclers – Scrap Metal Prices

Domain: jrsadvancedrecyclers.com

Registered: 2006 (19 years)

Introduction: {“Scrap_Metal_Prices”: {“Aluminum”: {“Auto_Rims”: “$1.00/lb”, “Breakage”: “$0.25/lb”, “Cast”: “$0.68/lb”, “Extruded”: “$0.88/lb”, “Pop_Cans”: “$0.70/lb”, “Semi_Rims”: “$0.65/lb”, “Sheet”: “$0.66/lb”, “Siding”: “$0.70/lb”, “Turnings”: “$0.25/lb”}, “Brass”: {“Red_Brass”: “$3.10/lb”, “Yellow_Brass_Clean”: “$2.40/lb”, “Yellow_Brass_Dirty”: “$1.10/lb”, “Cartridges”: “$2.40/lb”}, “Catalytic_Converters”:…

7. Trading Economics – Titanium Price Insights

Domain: tradingeconomics.com

Registered: 2006 (19 years)

Introduction: Titanium traded flat at 49 CNY/KG on September 12, 2025. The price has remained flat over the past month but is 11.36% higher than a year ago. Historically, Titanium reached an all-time high of 152.43 in May 2022. It is expected to trade at 49.24 CNY/KG by the end of the quarter and 49.97 CNY/KG in 12 months. Prices are based on over-the-counter (OTC) and contract for difference (CFD) financial in…

Strategic Sourcing Conclusion and Outlook for titanium scrap price

In navigating the dynamic landscape of titanium scrap pricing, strategic sourcing emerges as a crucial advantage for international B2B buyers. The interplay of supply and demand, coupled with geopolitical factors and economic fluctuations, significantly influences market prices. Buyers must be vigilant in tracking these trends, as the cost of newly mined titanium directly impacts the value of scrap, making timely procurement essential for maintaining competitive pricing.

Moreover, understanding the specific applications and grades of titanium scrap can enhance negotiation power and sourcing efficiency. For buyers in Africa, South America, the Middle East, and Europe, establishing reliable relationships with suppliers who can offer insights into market trends and pricing fluctuations will be invaluable.

As we look ahead, the demand for titanium scrap is poised to grow, driven by advancements in industries such as aerospace and medical technology. This presents a timely opportunity for B2B buyers to refine their sourcing strategies and capitalize on market conditions. Engage with suppliers now to secure favorable pricing and ensure a steady supply chain for your business needs in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.