Is Your Three Way Solenoid Valve Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for three way solenoid valve

In the dynamic landscape of industrial automation, sourcing the right three-way solenoid valve can be a critical challenge for B2B buyers across various sectors. These valves are essential for controlling the flow of liquids and gases in applications ranging from HVAC systems to chemical processing, making their selection pivotal for operational efficiency and safety. This guide aims to demystify the complexities of the three-way solenoid valve market, providing international buyers—particularly those in Africa, South America, the Middle East, and Europe, including Nigeria and Saudi Arabia—with the insights needed to make informed purchasing decisions.

Throughout this comprehensive resource, you will discover detailed information on the different types of three-way solenoid valves, their applications, and the factors that influence their cost. We will delve into best practices for supplier vetting, ensuring you partner with manufacturers that meet your quality standards and operational needs. Additionally, this guide will equip you with essential knowledge about the technical specifications and compatibility considerations crucial for your specific use case.

By the end of this guide, you will be empowered to navigate the global market with confidence, facilitating not only the selection of the right products but also the optimization of your procurement strategy. With the right information at your fingertips, you can enhance your operational capabilities and drive greater value for your business.

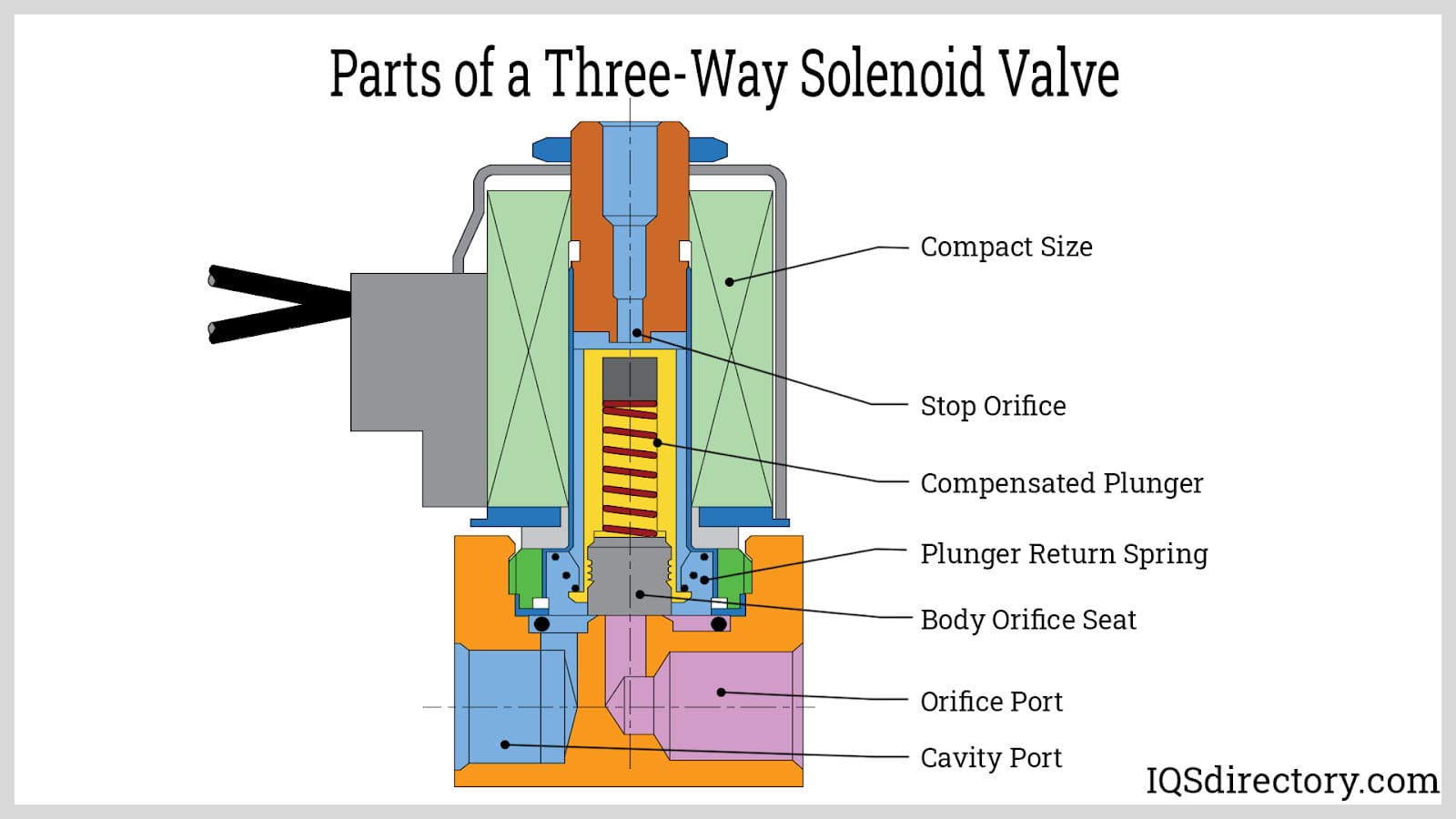

Understanding three way solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Normally Closed 3-Way Solenoid Valve | Remains closed until energized, allowing for pressure release | HVAC, Chemical Processing | Pros: Prevents fluid buildup, energy-efficient. Cons: Requires power to operate. |

| Normally Open 3-Way Solenoid Valve | Stays open until energized, facilitating immediate flow | Irrigation, Automotive | Pros: Quick response, ideal for continuous flow. Cons: May lead to unintended flow without power. |

| Universal 3-Way Solenoid Valve | Can be configured as normally open or closed | Food Processing, Pharmaceutical | Pros: Versatile for different applications. Cons: May require customization for specific needs. |

| Direct-Acting 3-Way Solenoid Valve | Operates directly via solenoid action without pilot pressure | Industrial Automation, Water Treatment | Pros: Fast response time, compact design. Cons: Limited to lower flow rates. |

| Quick-Exhaust 3-Way Solenoid Valve | Features a built-in exhaust for rapid pressure release | Pneumatic Systems, Robotics | Pros: Reduces cycle times, improves efficiency. Cons: Can be more complex to install. |

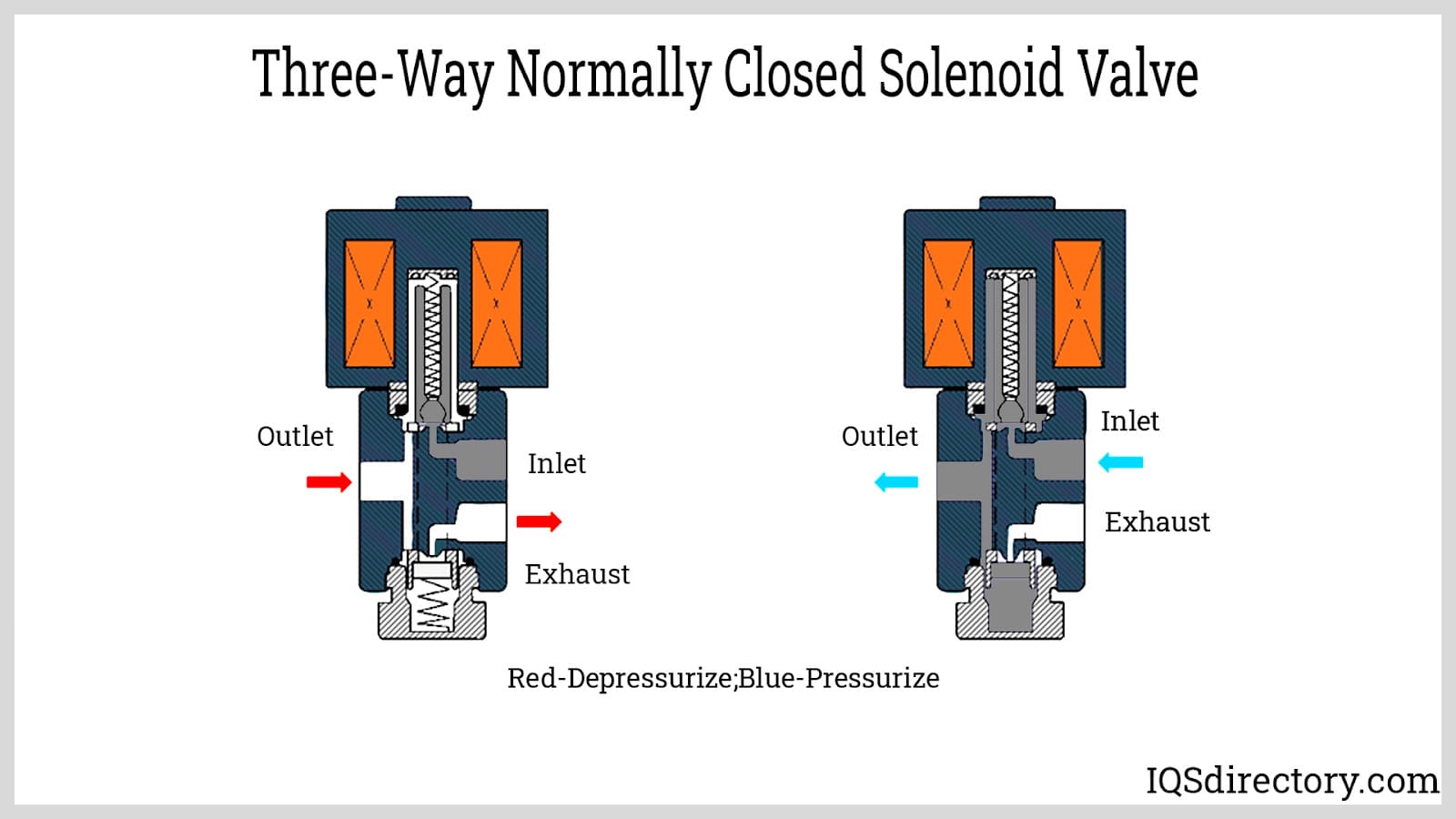

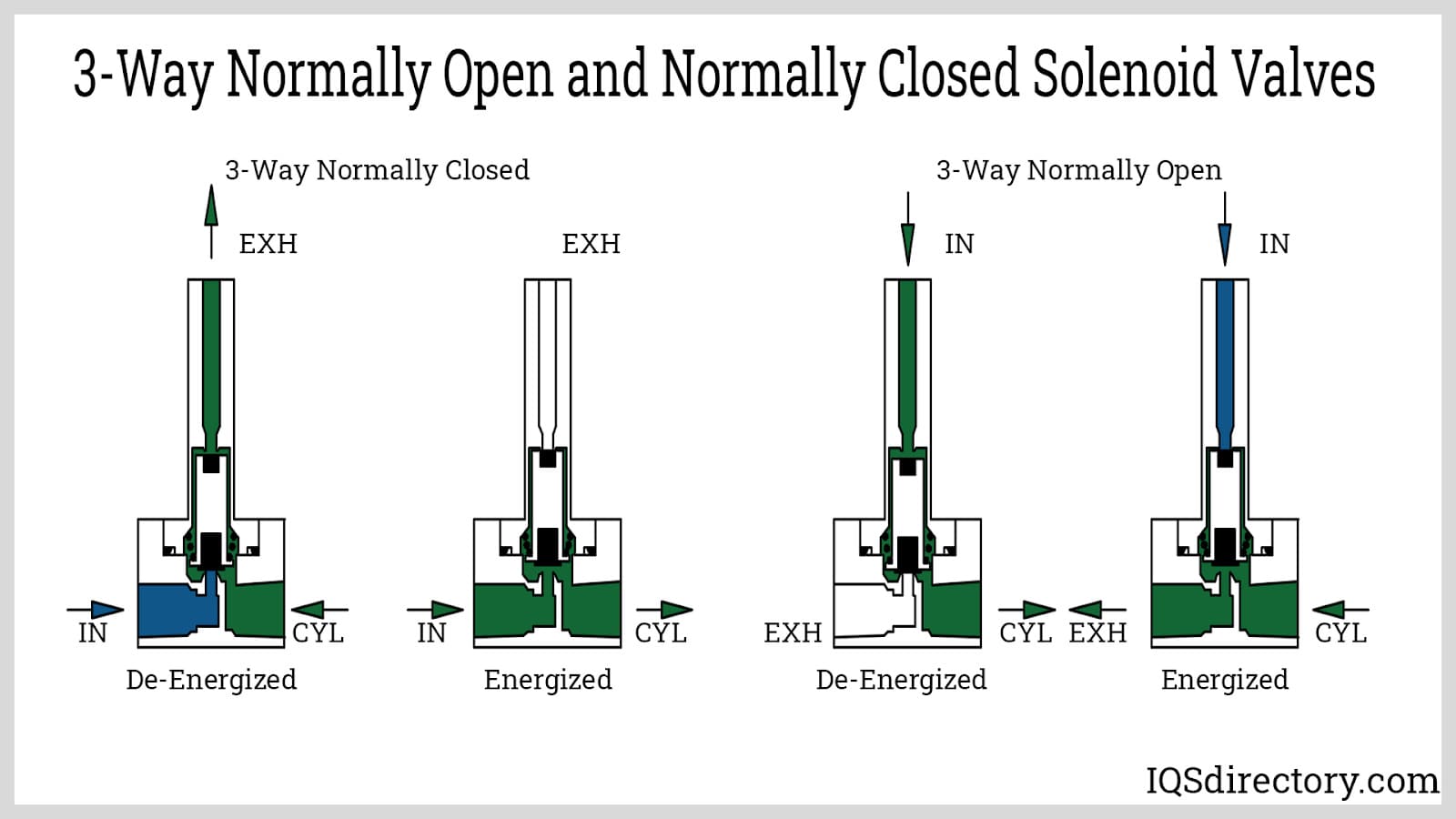

What Are the Characteristics of Normally Closed 3-Way Solenoid Valves?

Normally closed 3-way solenoid valves are designed to remain shut until activated. This feature is critical in applications where fluid or pressure control is essential, as it prevents unwanted leaks or fluid buildup. They are commonly used in HVAC systems and chemical processing, where maintaining system integrity is paramount. Buyers should consider the valve’s pressure rating and compatibility with the controlled media to ensure optimal performance.

How Do Normally Open 3-Way Solenoid Valves Work?

Normally open 3-way solenoid valves are designed to allow flow until they are energized, making them ideal for applications requiring continuous fluid movement, such as irrigation and automotive systems. Their quick response time enables immediate action, which is beneficial in dynamic environments. When purchasing, businesses should evaluate the power requirements and flow characteristics to match their specific operational needs.

What Makes Universal 3-Way Solenoid Valves Unique?

Universal 3-way solenoid valves can be configured to operate as either normally open or normally closed, providing flexibility in various applications, including food processing and pharmaceuticals. This adaptability allows for tailored solutions that can change with operational demands. Buyers should assess the valve’s customization options and compatibility with existing systems to maximize its utility.

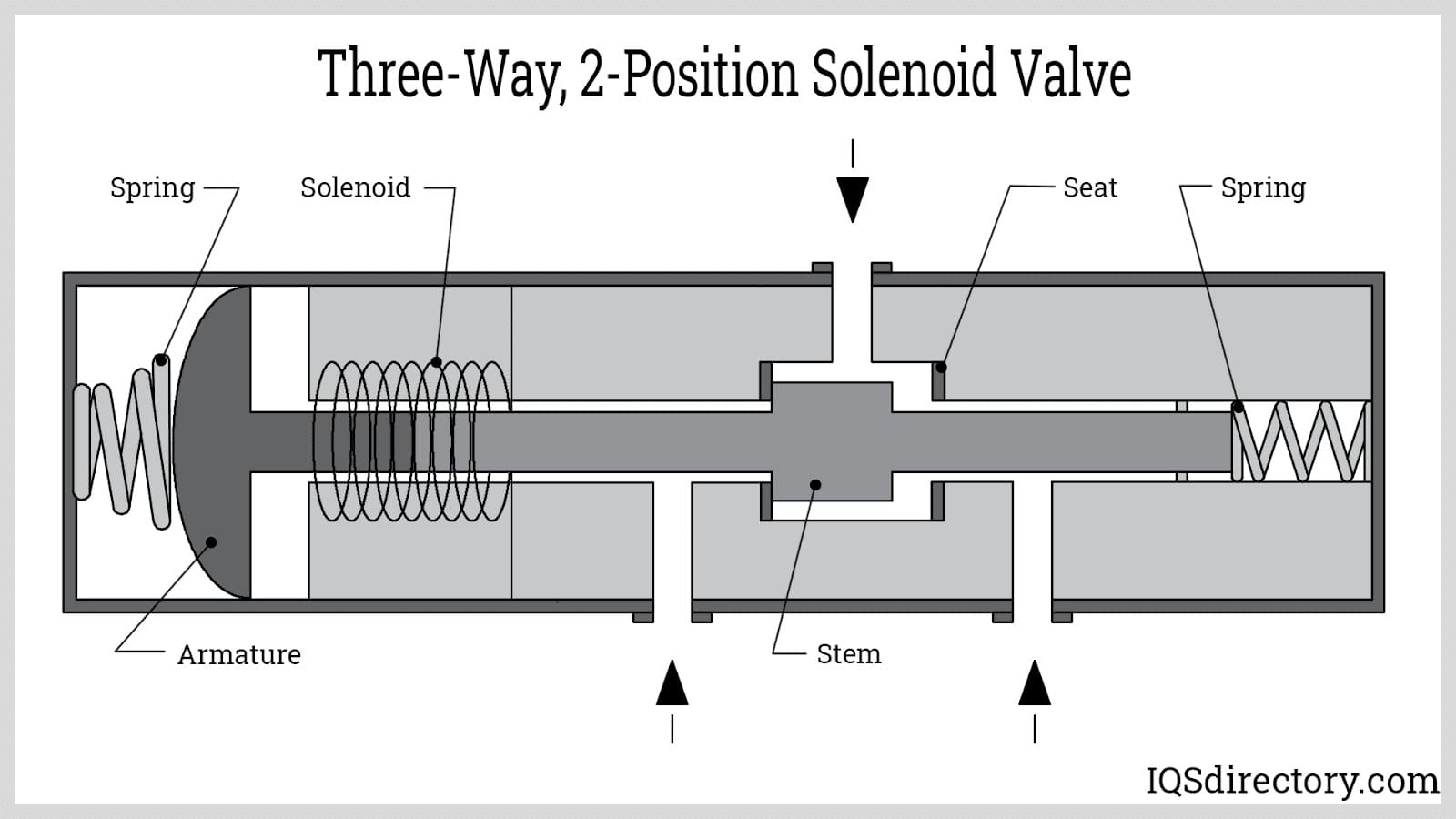

Why Choose Direct-Acting 3-Way Solenoid Valves?

Direct-acting 3-way solenoid valves utilize the solenoid’s action directly to control fluid flow, making them suitable for applications where space is limited, such as industrial automation and water treatment. These valves offer fast response times but may be limited to lower flow rates. Buyers should consider the specific requirements of their systems, including flow rate and pressure, to ensure the valve meets their application needs.

What Are the Advantages of Quick-Exhaust 3-Way Solenoid Valves?

Quick-exhaust 3-way solenoid valves are designed with built-in exhaust features that facilitate rapid pressure release, significantly enhancing cycle times in pneumatic systems and robotics. While they improve efficiency, their installation may be more complex compared to standard models. Buyers should weigh the benefits of increased operational speed against potential installation challenges to determine the best fit for their processes.

Key Industrial Applications of three way solenoid valve

| Industry/Sector | Specific Application of three way solenoid valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Temperature control in heating and cooling systems | Enhanced energy efficiency and precise temperature control | Compatibility with existing systems and energy ratings |

| Agriculture | Automated irrigation systems | Optimized water usage and reduced labor costs | Durability in outdoor conditions and chemical compatibility |

| Automotive | Coolant flow control in engines | Improved engine performance and reliability | Temperature and pressure ratings for specific engines |

| Chemical Processing | Flow control of different chemicals | Safe and accurate mixing of chemicals | Material compatibility with various chemicals |

| Food Processing | Control of liquid ingredients in processing lines | Improved food safety and consistency | Compliance with food safety standards and regulations |

How is a Three Way Solenoid Valve Used in HVAC Systems?

In HVAC applications, three way solenoid valves are critical for controlling the flow of hot and cold water, allowing for efficient temperature regulation. These valves can quickly switch between water sources, enabling systems to respond dynamically to temperature changes. International buyers, especially in regions with extreme temperatures, must consider valves that can withstand high pressures and temperatures while ensuring energy efficiency. Proper selection leads to enhanced system performance and reduced operational costs.

What Role Does a Three Way Solenoid Valve Play in Agriculture?

In agricultural settings, three way solenoid valves automate irrigation systems by controlling water flow to different areas. This automation reduces labor costs and optimizes water usage, which is especially crucial in regions facing water scarcity. Buyers from Africa and South America should prioritize valves that are durable against harsh environmental conditions and compatible with various water sources. Effective irrigation management can significantly improve crop yields and sustainability.

How is a Three Way Solenoid Valve Essential in the Automotive Industry?

Three way solenoid valves are employed in automotive applications to regulate coolant flow in engines. By managing the flow of coolant, these valves help maintain optimal engine temperatures, enhancing performance and reliability. Buyers in the automotive sector, particularly in the Middle East and Europe, must ensure that the valves meet specific temperature and pressure ratings relevant to their engine designs. This attention to detail can prevent engine overheating and extend vehicle lifespan.

In What Ways are Three Way Solenoid Valves Used in Chemical Processing?

In chemical processing, three way solenoid valves are vital for controlling the flow of various chemicals, allowing for safe and accurate mixing. These valves can switch between different chemical tanks, minimizing the risk of contamination and ensuring precision in formulations. Buyers must consider material compatibility with the chemicals involved, especially in regions with diverse chemical industries like South America. Investing in high-quality valves can enhance operational safety and efficiency.

How Do Three Way Solenoid Valves Benefit Food Processing?

In food processing, three way solenoid valves are used to control the flow of liquid ingredients, ensuring consistent quality and safety in food production. These valves help maintain hygienic conditions and are essential for meeting food safety regulations. International buyers, particularly in Europe, should focus on sourcing valves that comply with stringent food safety standards. Proper valve selection can lead to improved product quality and operational efficiency in food processing plants.

3 Common User Pain Points for ‘three way solenoid valve’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Specifications

The Problem: B2B buyers often struggle with selecting the appropriate specifications for three-way solenoid valves that meet their specific operational requirements. This challenge can stem from a lack of understanding of flow rates, pressure ratings, and the types of media being controlled. For instance, an HVAC company in Nigeria may need a valve that can handle both high and low-pressure water systems but lacks the technical expertise to determine the right valve specifications. Misselection can lead to system inefficiencies, increased costs, and even failures that disrupt operations.

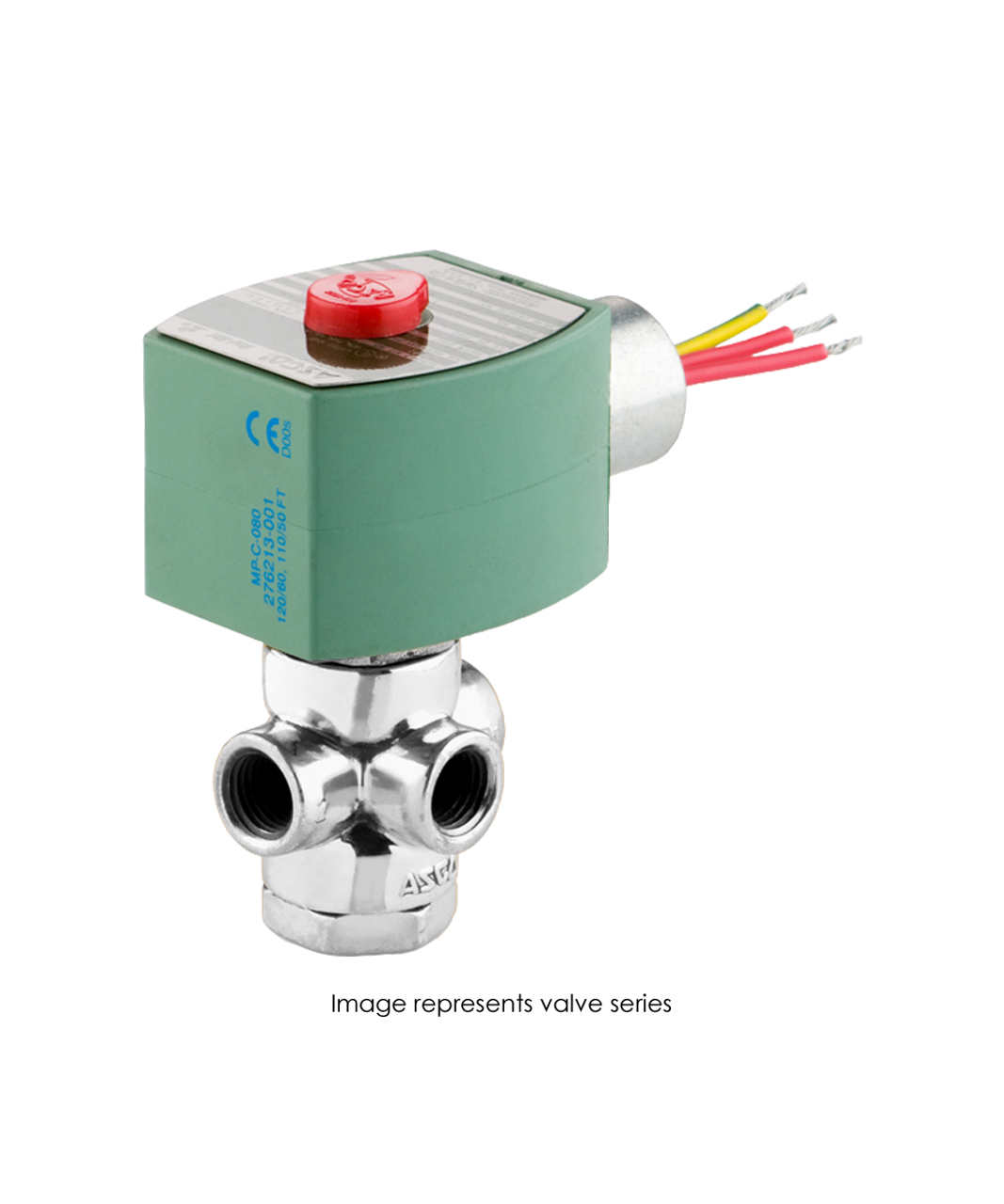

Illustrative image related to three way solenoid valve

The Solution: To overcome this challenge, buyers should prioritize collaboration with valve manufacturers or suppliers who offer expert guidance. When sourcing a three-way solenoid valve, it is essential to request detailed specifications and application examples that align with your operational needs. Utilize compatibility databases provided by suppliers to ensure that the valve material is suitable for the media it will control, whether it is water, gas, or chemicals. Conduct thorough testing in a controlled environment before full deployment to confirm that the selected valve operates effectively under expected conditions. Additionally, investing in simulation software can help visualize how different valves perform under varying operational scenarios, aiding in informed decision-making.

Scenario 2: Concerns Over Reliability and Maintenance

The Problem: Many businesses experience significant downtime due to the failure of solenoid valves, which can be attributed to poor reliability or inadequate maintenance practices. For instance, a food processing company in Brazil might rely heavily on three-way solenoid valves for controlling ingredient flow. If these valves frequently malfunction, it can lead to production delays and increased operational costs. The challenge is further compounded by the fact that maintenance teams may lack clear protocols or training on proper valve upkeep.

The Solution: To enhance reliability and reduce maintenance-related downtime, businesses should implement a proactive maintenance strategy that includes regular inspections and timely replacements of solenoid valves. Partnering with manufacturers that offer robust warranties and support can provide peace of mind. Create a maintenance schedule that incorporates training for staff on best practices for valve operation and troubleshooting. Utilize smart valve technology that includes diagnostic features to predict failures before they occur, allowing for preemptive action. Additionally, consider investing in valves made from durable materials that require less frequent replacements, thus saving costs over time.

Scenario 3: Inadequate Response to System Changes

The Problem: In dynamic industrial environments, businesses often face the challenge of adapting their fluid control systems to changing operational demands. For instance, a chemical processing plant in Saudi Arabia may require rapid adjustments to fluid flow during batch processes. If the three-way solenoid valves in use cannot respond quickly or accurately to these changes, it can result in production inefficiencies, safety risks, and potential regulatory issues.

The Solution: To ensure that three-way solenoid valves can adapt effectively to varying system demands, it is crucial to select models with fast response times and adjustable settings. Investing in valves that feature advanced control options, such as proportional or pulse-width modulation, can provide the flexibility needed for precise flow adjustments. Additionally, integrating valves with automation systems allows for real-time monitoring and control, enabling operators to make swift adjustments based on production needs. Regularly reviewing and updating system configurations as operational demands evolve can help maintain optimal performance and compliance with industry regulations. Lastly, seeking feedback from operators on valve performance during varying conditions can inform future purchasing decisions, ensuring that the right technology is in place for evolving requirements.

Strategic Material Selection Guide for three way solenoid valve

What Are the Common Materials Used in Three Way Solenoid Valves?

When selecting materials for three way solenoid valves, it’s essential to consider their properties in relation to the specific applications they will serve. The choice of material can significantly impact performance, durability, and compatibility with various media. Below, we analyze four common materials used in the construction of three way solenoid valves: brass, stainless steel, plastic, and aluminum.

How Does Brass Perform in Three Way Solenoid Valves?

Brass is a widely used material in solenoid valves due to its excellent machinability and corrosion resistance. It typically offers a temperature rating of up to 180°C (356°F) and can handle pressures up to 16 bar (232 psi).

Pros: Brass valves are durable and have a long lifespan, making them suitable for various applications, including water and gas control. They are also relatively cost-effective compared to other metals.

Illustrative image related to three way solenoid valve

Cons: However, brass may not be suitable for aggressive chemicals, as it can corrode over time. Additionally, the manufacturing complexity can be higher due to the need for precise machining.

Impact on Application: Brass is often used in HVAC systems and water applications, but buyers should ensure compatibility with the specific media they intend to use.

Considerations for International Buyers: Compliance with standards such as ASTM B16 and DIN 50930-6 is crucial. Buyers from regions like Nigeria and Saudi Arabia should also consider local regulations regarding material use in plumbing and HVAC systems.

What Are the Advantages of Stainless Steel in Solenoid Valves?

Stainless steel is another popular choice for three way solenoid valves, known for its exceptional corrosion resistance and strength. It can withstand temperatures up to 250°C (482°F) and pressures exceeding 20 bar (290 psi).

Pros: The durability of stainless steel makes it suitable for harsh environments and aggressive media, including chemicals and high-temperature applications. Its hygienic properties also make it ideal for food and pharmaceutical industries.

Cons: The main drawback is its higher cost compared to brass and plastic. Additionally, it can be more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel valves are commonly used in chemical processing and food manufacturing, where media compatibility and cleanliness are paramount.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM A276 and JIS G4303. In regions like Europe, adherence to EU regulations regarding food safety is critical.

Illustrative image related to three way solenoid valve

How Do Plastic Materials Compare for Three Way Solenoid Valves?

Plastic solenoid valves, typically made from materials like PVC or polypropylene, offer excellent corrosion resistance and are lightweight. They generally have a temperature rating of up to 60°C (140°F) and can handle pressures around 10 bar (145 psi).

Pros: The primary advantage of plastic valves is their low cost and ease of manufacturing. They are also resistant to a wide range of chemicals, making them suitable for various applications.

Cons: However, plastic valves may not be suitable for high-temperature or high-pressure applications. Their durability can also be a concern in demanding environments.

Impact on Application: Plastic valves are ideal for irrigation systems and low-pressure water applications, but buyers should ensure they avoid using them with high-temperature fluids.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is important. Buyers in South America and Africa should also consider local availability and sourcing options for plastic materials.

What Role Does Aluminum Play in Three Way Solenoid Valves?

Aluminum is sometimes used in solenoid valve construction due to its lightweight and good corrosion resistance. It typically has a temperature rating of up to 150°C (302°F) and can handle pressures around 15 bar (217 psi).

Pros: Aluminum valves are easy to install and maintain, making them a convenient choice for various applications. They are also more affordable than stainless steel.

Cons: However, aluminum can be less durable than brass or stainless steel and may not perform well in highly corrosive environments.

Impact on Application: Aluminum is often used in automotive applications and pneumatic systems where weight savings are essential.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM B211 and JIS H4000. In regions like the Middle East, local environmental conditions may also influence material choice.

Summary Table of Material Selection for Three Way Solenoid Valves

| Material | Typical Use Case for three way solenoid valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | HVAC systems, water applications | Durable and cost-effective | Corrosion with aggressive chemicals | Medium |

| Stainless Steel | Chemical processing, food manufacturing | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Irrigation systems, low-pressure applications | Low cost and lightweight | Not suitable for high temperatures | Low |

| Aluminum | Automotive applications, pneumatic systems | Lightweight and easy to maintain | Less durable in corrosive environments | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for three way solenoid valve

What Are the Key Stages in the Manufacturing Process of a Three-Way Solenoid Valve?

The manufacturing of three-way solenoid valves involves several critical stages, each designed to ensure high quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Three-Way Solenoid Valves?

The manufacturing process begins with the selection of high-quality materials, typically brass, stainless steel, or plastic, depending on the application requirements. The chosen materials undergo rigorous inspection to ensure they meet specified standards for durability and corrosion resistance. Material preparation may involve cutting, machining, and surface treatment to enhance performance characteristics, such as wear resistance and flow efficiency.

What Techniques Are Used in Forming Three-Way Solenoid Valves?

In the forming stage, various techniques are employed, including precision machining and injection molding. For metal valves, CNC (Computer Numerical Control) machining is common, allowing for exact dimensions and tolerances. Injection molding is often used for plastic components, ensuring that intricate designs can be produced efficiently. This stage is crucial as it defines the valve’s operational capabilities, such as pressure ratings and flow paths.

How Is Assembly Conducted for Three-Way Solenoid Valves?

Once individual components are formed, they proceed to the assembly stage. This involves the careful integration of the solenoid, valve body, and actuator mechanism. Automated assembly lines are often utilized to enhance efficiency and maintain consistency, but skilled technicians may also conduct manual assembly for complex components. Quality checks are performed at this stage to ensure that each assembly meets design specifications before moving on to the finishing process.

What Finishing Processes Are Applied to Three-Way Solenoid Valves?

The finishing stage includes surface treatments and coatings that improve the valve’s durability and functionality. Techniques such as anodizing, plating, or applying protective coatings are common to prevent corrosion and enhance aesthetic appeal. This stage may also involve the application of seals and gaskets, ensuring that the valve can operate under the required pressure without leaks.

What Quality Assurance Measures Are Essential for Three-Way Solenoid Valves?

Quality assurance is a cornerstone of the manufacturing process, ensuring that three-way solenoid valves meet international standards and customer expectations.

Which International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that comply with recognized international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking for European markets or API standards for oil and gas applications provide assurance of product reliability and safety. Understanding these standards can help buyers assess supplier capabilities.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints play a crucial role in maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this stage verifies that each step adheres to quality standards.

- Final Quality Control (FQC): At this stage, finished products are subjected to rigorous testing to ensure they meet performance specifications before shipment.

What Testing Methods Are Commonly Used for Three-Way Solenoid Valves?

Testing is an integral part of the quality assurance process. Common testing methods include:

- Functional Testing: Ensuring the valve operates correctly under specified conditions.

- Pressure Testing: Validating the valve’s ability to withstand operational pressures without leaking.

- Electrical Testing: For solenoid components, verifying that electrical connections and actuations function reliably.

- Leak Testing: This ensures that no fluid escapes during operation, critical for maintaining system integrity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can be achieved through:

- Supplier Audits: Conducting audits allows buyers to assess manufacturing processes, quality control systems, and adherence to international standards.

- Quality Assurance Reports: Requesting documentation related to quality assurance practices, including testing results and certifications, can provide insight into supplier reliability.

- Third-Party Inspections: Engaging independent inspection agencies can validate the quality of the products before they are shipped, providing an added layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from different regions, it’s essential to understand the nuances in quality control practices. For instance, the regulatory environment in Europe may be more stringent compared to suppliers in Africa or South America. B2B buyers should familiarize themselves with local standards and ensure that their suppliers are compliant. Additionally, language barriers and differences in business practices can affect communication regarding quality expectations.

By understanding the manufacturing processes and quality assurance measures associated with three-way solenoid valves, international B2B buyers can make informed purchasing decisions, ensuring they source reliable and high-quality products suited to their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three way solenoid valve’

This guide serves as a comprehensive checklist for B2B buyers looking to procure three-way solenoid valves. The selection process can be intricate, involving various technical specifications and supplier evaluations. By following this step-by-step checklist, you can ensure that you select the right valve for your specific application while mitigating risks associated with procurement.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your technical requirements. This includes flow rate, pressure ratings, temperature ranges, and the type of media (liquid or gas) the valve will control. Clearly defined specifications will help you identify suitable products and avoid costly mispurchases.

- Flow Rate: Determine the required flow rate for your application to ensure the valve can handle the necessary volume.

- Pressure and Temperature: Specify the maximum pressure and temperature conditions the valve will face in operation.

Step 2: Identify Application Requirements

Different applications demand specific functionalities from solenoid valves. Understanding the context in which the valve will be used—such as HVAC systems, chemical processing, or automotive applications—will guide your selection.

- Functionality: Decide if you need a normally closed or normally open valve based on your application’s needs.

- Compatibility: Ensure the valve material is compatible with the media to prevent corrosion or degradation.

Step 3: Evaluate Potential Suppliers

Assessing suppliers is a critical step in the procurement process. A reliable supplier can significantly affect the performance and longevity of your valves.

- Experience and Reputation: Look for suppliers with a proven track record in your industry. Check customer reviews and case studies for insights.

- Certifications: Verify that the supplier complies with relevant industry standards and holds necessary certifications (e.g., ISO, CE).

Step 4: Request Samples or Prototypes

Before making a bulk purchase, request samples or prototypes of the three-way solenoid valves. This will allow you to test their performance and compatibility within your system.

- Testing: Evaluate the valve under actual operating conditions to ensure it meets your specifications.

- Feedback Loop: Gather feedback from your engineering team on the valve’s performance to make informed decisions.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and tested their products, it’s time to discuss pricing and contractual terms. Effective negotiation can lead to significant cost savings and favorable conditions.

Illustrative image related to three way solenoid valve

- Bulk Discounts: Inquire about discounts for large orders or long-term contracts.

- Warranty and Support: Ensure that warranty terms are clear and that the supplier offers adequate post-purchase support.

Step 6: Finalize Your Order and Monitor Delivery

After finalizing the terms, place your order and establish a monitoring system for delivery. Delays in procurement can impact your operations, so maintaining communication with the supplier is key.

- Tracking: Use tracking systems to monitor the shipment and ensure timely delivery.

- Quality Checks: Plan for quality inspections upon receipt to ensure the valves meet your specifications.

Step 7: Plan for Installation and Maintenance

Once the valves are delivered, prepare for installation and ongoing maintenance. Proper installation and regular maintenance will enhance the longevity and reliability of your solenoid valves.

- Installation Guidelines: Follow manufacturer guidelines for installation to avoid operational issues.

- Maintenance Schedule: Create a maintenance schedule to routinely check for wear and tear, ensuring optimal performance.

By diligently following this checklist, you can streamline your procurement process for three-way solenoid valves and ensure that you are making informed, strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for three way solenoid valve Sourcing

What Are the Key Cost Components in Sourcing Three Way Solenoid Valves?

When sourcing three way solenoid valves, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to three way solenoid valve

-

Materials: The quality and type of materials used, such as brass, stainless steel, or plastic, directly influence the price. High-grade materials that offer durability and corrosion resistance may incur higher costs but can reduce maintenance needs over time.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with higher labor costs may result in increased pricing for the valves. Conversely, manufacturers in regions with lower labor costs might offer more competitive pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help keep these costs lower.

-

Tooling: The initial setup for production can be a significant upfront cost, especially for custom designs. The more complex the valve, the higher the tooling costs are likely to be.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring that the valves meet industry standards and specifications. While this may add to the cost, it significantly reduces the risk of failures and associated liabilities.

-

Logistics: Shipping costs vary based on distance, mode of transport, and the Incoterms agreed upon. International shipping can add considerable expenses, especially if expedited delivery is required.

-

Margin: Suppliers typically add a profit margin to their base costs. Understanding the market standard for margins can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Three Way Solenoid Valves?

Several factors can influence the pricing of three way solenoid valves:

-

Volume/MOQ: Purchasing in bulk can often lead to discounts. Suppliers typically offer lower prices for larger orders, which can significantly affect overall costs.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling and manufacturing processes. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials: The choice of materials not only impacts the valve’s durability but also its price. Specialty materials or high-performance options will come at a premium.

-

Quality and Certifications: Valves that meet specific industry certifications (e.g., ISO, API) may carry a higher price tag due to the rigorous testing and quality assurance processes involved.

-

Supplier Factors: Established suppliers with a reputation for reliability may charge more than lesser-known manufacturers. However, the long-term reliability and service can justify the higher cost.

-

Incoterms: The terms of shipping and delivery can greatly affect the final price. Understanding Incoterms helps buyers evaluate total costs, including insurance, tariffs, and responsibilities during transit.

What Are Some Tips for Buyers to Achieve Cost-Efficiency in Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate: Always engage in negotiations with suppliers. Understanding the cost structure allows buyers to pinpoint areas where discounts can be applied without compromising quality.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also the long-term costs associated with maintenance, energy efficiency, and potential downtime. A slightly higher upfront cost may yield savings over time.

-

Understand Pricing Nuances: Be aware that currency fluctuations and local economic conditions can affect pricing. Establishing contracts in stable currencies or using hedging strategies can mitigate risks.

-

Research Suppliers: Investigate multiple suppliers and request quotes to compare prices and service offerings. This helps in making informed decisions and securing the best deal.

-

Plan for Lead Times: Account for potential delays in production or shipping, especially when sourcing from different continents. Planning ahead can prevent rushed orders that may incur additional costs.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always consult with multiple suppliers and consider comprehensive cost factors before making purchasing decisions.

Alternatives Analysis: Comparing three way solenoid valve With Other Solutions

Exploring Alternatives to Three Way Solenoid Valves

In industrial applications, selecting the right valve technology is crucial for optimizing system performance and efficiency. While three way solenoid valves are widely used for controlling fluid and gas flow, various alternative solutions can also achieve similar objectives. This analysis compares three way solenoid valves against two viable alternatives: pneumatic actuated valves and manual valves, providing insights for B2B buyers in diverse industries.

| Comparison Aspect | Three Way Solenoid Valve | Pneumatic Actuated Valve | Manual Valve |

|---|---|---|---|

| Performance | Fast response time; ideal for automation | Moderate response time; good for high flow | Slow; dependent on operator |

| Cost | Generally cost-effective | Higher initial investment due to actuator cost | Low initial cost, but may require more labor |

| Ease of Implementation | Straightforward installation; minimal maintenance | Requires compressed air setup; more complex | Simple installation but labor-intensive |

| Maintenance | Low maintenance; few moving parts | Moderate; requires regular checks on air supply | High; frequent checks needed for wear and tear |

| Best Use Case | Automated systems needing quick fluid control | High flow applications in continuous processes | Manual operations or low-frequency use cases |

What are the Advantages and Disadvantages of Pneumatic Actuated Valves?

Pneumatic actuated valves utilize compressed air to operate, offering a reliable alternative to solenoid valves in certain applications. Pros include their ability to handle higher flow rates and their suitability for systems requiring robust operation in harsh environments. However, they can be more expensive to implement initially, as they require a compressed air source and additional components, which can complicate the setup. Their moderate response time may also not be suitable for applications requiring rapid actuation.

How Do Manual Valves Compare?

Manual valves are a traditional solution for fluid control, operated directly by an operator. Pros include low initial costs and simplicity in design, making them easy to install. They are often preferred in applications where flow control does not require automation. However, manual valves can be labor-intensive, as they rely on human operation. This can lead to inconsistencies in flow control and increased downtime if an operator is unavailable. Their slower response time also makes them less suited for dynamic applications.

Making the Right Choice for Your Application

When selecting between a three way solenoid valve and its alternatives, B2B buyers must consider the specific requirements of their application. For environments demanding rapid and automated fluid control, three way solenoid valves are often the best choice due to their quick response times and energy efficiency. Conversely, for high flow situations where automation is less critical, pneumatic actuated valves may offer better performance. Manual valves can serve effectively in low-frequency or less critical operations where cost is a significant factor.

Ultimately, understanding the unique demands of your system—such as the required flow rate, response time, and installation complexity—will guide you to the most effective solution for your business needs.

Essential Technical Properties and Trade Terminology for three way solenoid valve

What Are the Essential Technical Properties of Three-Way Solenoid Valves?

When evaluating three-way solenoid valves for industrial applications, several critical specifications must be considered to ensure optimal performance and compatibility with specific systems. Here are key properties to focus on:

1. Material Grade

The material of the valve body significantly impacts its durability and suitability for different media. Common materials include brass, stainless steel, and plastic. Brass is often used for water and air applications, while stainless steel is preferable for corrosive environments. Selecting the right material is essential for minimizing maintenance costs and ensuring longevity.

2. Flow Rate

Flow rate, typically measured in liters per minute (L/min) or gallons per minute (GPM), indicates how much fluid can pass through the valve in a specified time. This specification is crucial for applications that require precise flow control, such as in HVAC systems or chemical processing. Understanding flow rate helps buyers select a valve that meets system demands without causing pressure drops or inefficiencies.

3. Pressure Rating

The pressure rating defines the maximum pressure the valve can withstand without failure. It is expressed in pounds per square inch (PSI) or bar. This specification is vital for safety and operational efficiency, especially in high-pressure applications like automotive cooling systems or industrial automation. Ensuring compatibility with existing system pressure levels can prevent costly failures.

4. Electrical Specifications

Three-way solenoid valves operate using electrical signals, so understanding their electrical specifications—such as voltage (e.g., 24V AC/DC or 110V AC) and power consumption—is essential. Proper voltage matching ensures the valve operates efficiently and reduces the risk of electrical malfunctions. This is particularly important in automated systems where reliability is paramount.

5. Temperature Range

The temperature range indicates the operational limits of the valve, usually specified in degrees Celsius or Fahrenheit. This property is critical for applications involving hot fluids or environments with significant temperature fluctuations. Choosing a valve with an appropriate temperature rating ensures consistent performance and prevents thermal-related failures.

Illustrative image related to three way solenoid valve

What Common Trade Terminology Should B2B Buyers Know Regarding Three-Way Solenoid Valves?

Understanding industry jargon can enhance communication and negotiation with suppliers. Here are some common terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of solenoid valves, knowing whether a supplier is an OEM can provide insights into product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for budgeting and inventory management. Buyers should ensure that the MOQ aligns with their operational needs to avoid excess stock or unmet demand.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. Understanding how to craft an effective RFQ can lead to better pricing and terms, ensuring that the buyer receives competitive offers for three-way solenoid valves.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and logistics. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are critical when sourcing products from international suppliers.

Illustrative image related to three way solenoid valve

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is essential for planning and inventory management. Buyers should inquire about lead times to ensure that their projects stay on schedule.

Incorporating these technical properties and trade terms into your procurement strategy can significantly enhance decision-making and streamline the sourcing process for three-way solenoid valves.

Navigating Market Dynamics and Sourcing Trends in the three way solenoid valve Sector

What Are the Current Market Dynamics and Key Trends in the Three Way Solenoid Valve Sector?

The global market for three-way solenoid valves is experiencing significant growth, driven by increasing demand across various sectors, including automotive, HVAC, and industrial automation. Key trends include the rise of automation technologies, where these valves play a crucial role in controlling fluid dynamics efficiently. As industries in regions like Africa, South America, the Middle East, and Europe modernize their operations, the need for reliable and energy-efficient solutions is paramount. For instance, in the Middle East, the push for sustainable energy practices is leading to increased adoption of advanced fluid control systems, including three-way solenoid valves.

Moreover, the shift toward Industry 4.0 is influencing sourcing trends, with manufacturers increasingly seeking smart valves that can integrate with IoT devices for real-time monitoring and control. This technological evolution is not only enhancing operational efficiency but also providing valuable data analytics capabilities, which are critical for making informed business decisions. Additionally, as global supply chains become more complex, buyers are focusing on sourcing from suppliers that offer flexibility and rapid response times to ensure continuity in production.

How Can Sustainability and Ethical Sourcing Impact the Three Way Solenoid Valve Sector?

Sustainability is becoming a pivotal factor in sourcing decisions for three-way solenoid valves. The environmental impact of manufacturing processes, particularly concerning resource consumption and waste generation, is under scrutiny. B2B buyers are increasingly favoring suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing energy consumption during production.

Illustrative image related to three way solenoid valve

Ethical sourcing is also gaining traction, with companies prioritizing suppliers that uphold labor rights and fair trade practices. Certifications like ISO 14001, which focuses on effective environmental management systems, and other “green” certifications can serve as benchmarks for buyers when evaluating potential suppliers. Furthermore, the use of environmentally friendly materials in the construction of solenoid valves is becoming more common, aligning with the global push towards reducing carbon footprints. For international buyers, particularly those in emerging markets, aligning procurement strategies with sustainable practices not only enhances brand reputation but also meets the growing regulatory demands for environmental stewardship.

What Is the Evolution of the Three Way Solenoid Valve and Its Relevance to Today’s Market?

The evolution of three-way solenoid valves can be traced back to the early 20th century when pneumatic and hydraulic systems began to dominate industrial applications. Initially, these valves were primarily mechanical, relying on manual operation. However, with advancements in electromagnetic technology, the introduction of solenoid-actuated valves revolutionized the industry by allowing for automated control of fluid flow.

Today, three-way solenoid valves are essential components in diverse applications, from controlling temperature in HVAC systems to managing fluid transfer in chemical processing. Their versatility and reliability have made them a staple in modern automation solutions. As industries continue to embrace digital transformation, the integration of smart technologies into these valves is expected to further enhance their functionality and market demand. This historical context underscores the importance of understanding both the technological advancements and the evolving market landscape for effective sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of three way solenoid valve

-

How do I select the right three-way solenoid valve for my application?

Choosing the right three-way solenoid valve involves assessing several key factors. First, consider the type of media being controlled—whether it’s gas, water, or chemicals—as compatibility is crucial. Next, evaluate the flow rate, pressure, and temperature requirements specific to your application. Electrical specifications, such as voltage and power consumption, also play a significant role in selection. Lastly, consulting with manufacturers or using a chemical compatibility database can provide additional insights tailored to your unique needs. -

What are the common applications for three-way solenoid valves?

Three-way solenoid valves are versatile components used across various industries. Common applications include HVAC systems, where they control the flow of hot and cold water; irrigation systems for automated water distribution; and the automotive industry for managing coolant or air flow. They are also widely used in chemical processing to facilitate the mixing of different fluids or the switching between chemical tanks. Understanding your application will help determine the best valve configuration. -

What customization options are available for three-way solenoid valves?

Many manufacturers offer customization options to meet specific operational needs. Customizations may include variations in size, material, port configurations, and electrical specifications. Some suppliers may also provide options for specific coatings or seals to enhance chemical compatibility or environmental resistance. When discussing customization, clearly communicate your requirements and any industry standards to ensure the valve meets your operational demands. -

What is the minimum order quantity (MOQ) for three-way solenoid valves?

Minimum order quantities (MOQ) for three-way solenoid valves can vary significantly between suppliers. Some manufacturers may have a low MOQ, while others may require larger orders for specific models or customizations. It’s essential to inquire directly with your chosen supplier about their MOQ policies. If you’re concerned about inventory costs, consider negotiating terms or exploring suppliers that offer flexible order options to accommodate your purchasing needs. -

What payment terms should I expect when sourcing three-way solenoid valves?

Payment terms can vary by supplier and region. Common terms may include upfront payment, net 30 or net 60 days, or a letter of credit for larger orders. It’s advisable to establish clear payment terms before finalizing your order to avoid any misunderstandings. Additionally, consider the currency exchange rates and transaction fees, especially when dealing with international suppliers. Always verify the supplier’s credibility before proceeding with payment to mitigate risks. -

How do I vet suppliers for three-way solenoid valves?

Vetting suppliers is critical for ensuring quality and reliability. Start by researching the supplier’s reputation through online reviews and industry forums. Request references from previous clients to assess their experience. Additionally, verify certifications such as ISO standards that indicate quality management. It’s also beneficial to inquire about their manufacturing processes, quality assurance protocols, and after-sales support to ensure they can meet your specific needs. -

What quality assurance measures should I look for in three-way solenoid valves?

Quality assurance is vital in the manufacturing of three-way solenoid valves. Look for suppliers that adhere to recognized industry standards, such as ISO 9001, which ensures consistent quality. Inquire about their testing protocols, including pressure tests and performance evaluations, to confirm that their products meet your specifications. Additionally, consider suppliers who offer warranties or guarantees on their products, which can serve as an assurance of quality and reliability. -

What logistics considerations should I keep in mind when importing three-way solenoid valves?

When importing three-way solenoid valves, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate the cost of freight and potential tariffs that may apply. It’s also crucial to ensure that your supplier can provide the necessary documentation, such as certificates of origin and compliance, to facilitate a smooth customs process. Collaborating with a logistics provider experienced in international trade can help navigate these complexities effectively.

Top 10 Three Way Solenoid Valve Manufacturers & Suppliers List

1. Electric Solenoid Valves – 3 Way Solenoid Valves

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: 3 Way Solenoid Valves are used for controlling the flow of water, air, vacuum, or other low viscosity fluids. They have three ports: an inlet port, an outlet port, and an exhaust port. The exhaust port vents or releases pressure or fluid, preventing buildup. Key features include flexibility in configuration, energy efficiency, reliability, versatility for various applications (HVAC, irrigation, au…

2. McMaster – Three-Way Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Emerson – Three-Way Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Three-Way Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – 3-Way Solenoid Valve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 3-way solenoid valve: solves issues like soupy puck, portafilter sneezing, and dripping after stopping brew; drawbacks include potential blockage, being an electrical failure point, and requiring maintenance like back-flushing or valve cleaning. Non-solenoid designs lack meaningful pressure control, often running at max pump pressure (about 15 bar), which is undesirable for espresso. Solenoids all…

5. Bezzera / Pasquini – 3-Way Solenoid Valve 110V

Domain: pasquini.com

Registered: 1997 (28 years)

Introduction: {“name”:”3-Way Solenoid Valve – 110V”,”sku”:”8806108″,”price”:”149.00″,”brand”:”Bezzera / Pasquini”,”factory_number”:”7702416R”,”item_detail”:”SOLENOID VALVE 3 WAY SIRAI 110/120V”,”weight”:”318 grams”,”inventory_quantity”:6,”final_sale”:”All parts are final sale and non-refundable. Unauthorized repairs are undertaken at your own risk, and any damage to your machine resulting from improper installa…

6. Solenoid Solutions Inc – 3-Way Valves

Domain: solenoidsolutionsinc.com

Registered: 2006 (19 years)

Introduction: Different Types of 3-Way Valves: 3-way normally open solenoid valves, 3-way normally closed solenoid valves, 3-way directional control solenoid valves, 3-way multipurpose valves. Key features include: 3 pipe connections (cavity port, body orifice port, stop port), 2 orifices (body orifice and stop orifice), flow control capabilities, and applications in various industries. Solenoid valves availabl…

7. SMC – 3-Port Double Solenoid Valve

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC – 3-Port Double Solenoid Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Tameson – 3/2-Way Pneumatic Solenoid Valves

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: 3/2-way pneumatic solenoid valves are essential for regulating air flow in applications such as single-acting cylinders, pneumatic actuators, blow-off, pressure release, and vacuum operations. They have three connection ports: Inlet (P, 1), Outlet (A, 2), and Exhaust (R, 3), and two states: open and closed. The valve can be normally closed (NC) or normally open (NO). There are two types of operati…

9. AGBind – 3-Way Normally Closed Solenoid Valve

Domain: agbind.com

Registered: 2018 (7 years)

Introduction: {“Product Type”: “3-Way Normally Closed Solenoid Valve”, “Applications”: [“Air”, “Water”, “Steam”, “Compressed Air”, “Food and Beverage”], “Features”: {“No Minimum Pressure Required”: true, “Mountable in Any Position”: true, “Seal Material Options”: true}, “Part Number”: “Series — Reset Selection — D Series”, “Body Material Options”: [“Brass”, “PVC”, “Stainless Steel”, “Lead Free Brass”], “Volta…

10. Dntlworks – 3 Way Solenoid 120V

Strategic Sourcing Conclusion and Outlook for three way solenoid valve

In conclusion, the strategic sourcing of three-way solenoid valves is essential for optimizing fluid control applications across diverse industries. These valves offer significant advantages, including energy efficiency, reliability, and versatility, making them suitable for automotive, HVAC, chemical processing, and irrigation systems. By carefully considering factors such as flow rate, pressure, temperature, and media compatibility, international buyers can ensure they select the right products to meet their specific operational needs.

Investing in high-quality three-way solenoid valves not only enhances operational efficiency but also reduces maintenance costs and downtime, ultimately leading to improved productivity. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing opportunity for businesses to leverage advanced fluid control technologies.

We encourage B2B buyers to engage with suppliers that offer expert guidance and comprehensive product support. As you navigate the sourcing landscape, prioritize partnerships that align with your operational goals and sustainability commitments. Together, let’s drive innovation and efficiency in fluid control systems for a better tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to three way solenoid valve

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.