Is Your Three Point Latch Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for three point latch

In today’s global marketplace, B2B buyers face the critical challenge of sourcing reliable and secure three-point latches that meet their diverse industrial needs. With applications ranging from electronic enclosures to heavy-duty truck doors, understanding the intricacies of three-point latching systems is essential for ensuring safety and efficiency. This comprehensive guide delves into the various types of three-point latches, their specific applications, and the factors to consider when selecting the right hardware for your operations.

Moreover, we will explore supplier vetting processes, pricing structures, and quality assurance measures that ensure you make informed purchasing decisions. For international buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe—including markets like Vietnam and Nigeria—this guide serves as a valuable resource. It empowers you to navigate the complexities of sourcing high-quality latching solutions, ultimately helping to enhance security and operational integrity within your business.

By equipping you with actionable insights and expert recommendations, this guide aims to streamline your procurement process, ensuring that your investments in three-point latches yield long-term benefits and peace of mind.

Understanding three point latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Three-Point Latch | Engages at three points: top, middle, and bottom of the door | Commercial doors, cabinets, and enclosures | Pros: Enhanced security; even pressure distribution. Cons: Higher cost than single-point latches. |

| Continuous Hinge Three-Point Latch | Integrated hinge and latch mechanism; watertight seal | NEMA enclosures, outdoor cabinets | Pros: Robust sealing; easy installation. Cons: May require specific installation conditions. |

| D-Ring Three-Point Latch | D-ring handle; cam mechanism holds door at center | Truck doors, trailers, and heavy-duty enclosures | Pros: Secure and user-friendly; versatile. Cons: Limited to specific door configurations. |

| Multipoint Locking System | Central handle with extending rods; multiple locking points | Industrial applications, electronic enclosures | Pros: Superior strength; protects against warping. Cons: Installation can be complex. |

| Keyed Three-Point Latch | Key locking mechanism for added security | High-security applications, storage units | Pros: Enhanced access control; theft deterrent. Cons: Key management can be cumbersome. |

What are the characteristics of a Standard Three-Point Latch?

Standard three-point latches are designed to lock doors at three distinct points: the top, middle, and bottom. This design ensures an even distribution of pressure across the door, enhancing security and preventing warping. They are commonly used in commercial settings for doors, cabinets, and enclosures. Buyers should consider the durability of materials and the latch mechanism’s ease of use, as these factors can significantly impact long-term performance.

How does a Continuous Hinge Three-Point Latch enhance security?

The continuous hinge three-point latch combines the hinge and latch into a single unit, creating a watertight seal that is ideal for outdoor applications. This design is particularly suited for NEMA enclosures, which require robust protection against environmental elements. When purchasing, businesses should evaluate the latch’s sealing capabilities and installation requirements, ensuring it meets their specific application needs.

What makes a D-Ring Three-Point Latch suitable for heavy-duty use?

D-ring three-point latches feature a central D-ring handle and a cam mechanism that secures the door at its center while locking both ends. This design is optimal for truck doors and heavy-duty enclosures, providing a secure yet user-friendly locking solution. Buyers should assess compatibility with their door configurations and consider the latch’s material strength, as these factors influence its effectiveness in demanding environments.

Why choose a Multipoint Locking System for industrial applications?

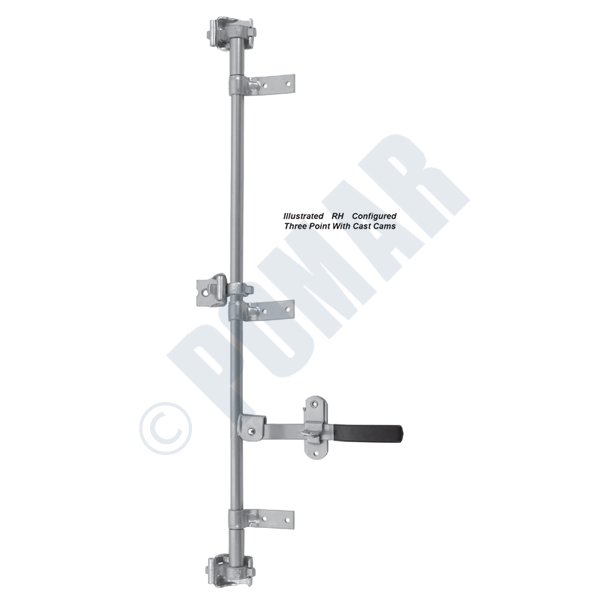

Multipoint locking systems utilize a central handle connected to rods that extend to multiple locking points, providing enhanced security and strength. This type of latch is particularly beneficial in industrial applications and electronic enclosures, where protecting contents from unauthorized access is crucial. Buyers should be aware of the complexity involved in installation and maintenance, as these systems may require specialized knowledge.

What advantages does a Keyed Three-Point Latch offer for security?

Keyed three-point latches integrate a key locking mechanism, providing an additional layer of security for storage units and high-security applications. They are designed to deter theft and unauthorized access, making them a preferred choice for businesses handling sensitive materials. However, potential buyers should consider the challenges of key management and the need for maintaining key security within their operations.

Key Industrial Applications of three point latch

| Industry/Sector | Specific Application of three point latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Securing semi-trailer doors | Enhanced security and protection against cargo theft | Material durability and resistance to weather elements |

| Manufacturing | Locking electronic enclosures for sensitive equipment | Safeguards valuable machinery and data from unauthorized access | Compliance with industry standards and custom solutions |

| Petrochemical | Enclosures for hazardous materials | Ensures safety and compliance with regulations | Fire resistance and robust sealing capabilities |

| Construction | Access control for job site storage containers | Protects tools and materials from theft and weather exposure | Customization options for various container sizes |

| Telecommunications | Securing network cabinets and data centers | Prevents tampering and ensures operational continuity | Compatibility with existing infrastructure and ease of installation |

How is a three point latch used in the transportation industry?

In the transportation sector, three point latches are crucial for securing semi-trailer doors. These latches engage at multiple points along the door, providing a tighter seal and enhanced security against theft and cargo damage. Given the high value of transported goods, businesses benefit from the peace of mind that comes with superior locking mechanisms. Buyers in this sector should prioritize materials that can withstand harsh weather conditions, as well as ensure that the latches meet relevant safety standards for transportation.

What role do three point latches play in manufacturing?

In manufacturing, three point latches are often employed to secure electronic enclosures housing sensitive equipment. These latches not only protect valuable machinery from theft but also prevent unauthorized access, thereby maintaining operational integrity. The need for compliance with industry standards is critical, so buyers should look for latches that are tested and certified for safety and reliability. Custom solutions may be necessary to accommodate specific machinery configurations, emphasizing the importance of working with manufacturers that can provide tailored products.

Why are three point latches essential in the petrochemical industry?

The petrochemical industry requires robust locking mechanisms for enclosures that store hazardous materials. Three point latches provide a reliable solution by ensuring that these enclosures are securely locked, reducing the risk of leaks and unauthorized access. Compliance with safety regulations is paramount, making it essential for buyers to source latches that offer fire resistance and effective sealing capabilities. The ability to withstand extreme conditions also plays a crucial role in selection, ensuring that the latches will perform reliably over time.

How do three point latches enhance security in construction?

In construction, three point latches are commonly used to secure storage containers on job sites. These latches protect valuable tools and materials from theft and the elements, contributing to overall project security. Buyers should consider customization options that fit various container sizes and configurations, as well as the durability of materials used in the latch construction. Ensuring that the latches provide effective weather resistance is also essential for maintaining the integrity of the stored items.

What benefits do three point latches offer in telecommunications?

In the telecommunications sector, three point latches secure network cabinets and data centers, protecting critical infrastructure from tampering and unauthorized access. This added security is vital for maintaining operational continuity and safeguarding sensitive data. Buyers should look for latches that are compatible with existing setups and provide ease of installation. The ability to customize latches for specific cabinet designs can also enhance security and functionality, making it a key consideration during the sourcing process.

3 Common User Pain Points for ‘three point latch’ & Their Solutions

Scenario 1: Security Compromises in Remote Areas

The Problem: Many B2B buyers in sectors like logistics and outdoor equipment storage face significant security challenges when using traditional locking mechanisms. In regions where theft and vandalism are prevalent, a single-point latch often proves inadequate, leaving doors vulnerable to forced entry. This insecurity can lead to substantial losses, especially for businesses that rely on the integrity of their storage systems, such as semi-trailers or outdoor enclosures.

The Solution: To enhance security, B2B buyers should invest in three-point latch systems that distribute locking force across multiple points, offering superior protection against break-ins. When sourcing three-point latches, look for high-quality materials such as stainless steel, which resist corrosion and wear, especially in harsh environments. Buyers should also ensure that the latches comply with international security standards, such as NEMA or UL certifications, to guarantee reliability. Collaborating with a reputable manufacturer that offers customizable solutions can also ensure that the latch fits specific applications, thus maximizing security.

Scenario 2: Installation Complexity and Operational Downtime

The Problem: Installation of locking mechanisms can be a significant pain point for B2B buyers, particularly when transitioning from single-point to three-point latching systems. Many users report that complex installation processes lead to operational downtime, impacting productivity and delaying project timelines. Additionally, inadequate installation can compromise the latch’s effectiveness, further risking security and functionality.

The Solution: To mitigate installation challenges, buyers should prioritize three-point latches that come with comprehensive installation guides and support from the manufacturer. Selecting systems that include all necessary mounting hardware and clear step-by-step instructions can simplify the process significantly. Furthermore, investing in latches designed for ease of installation—such as those with pre-drilled holes or adjustable components—can reduce setup time. Buyers should also consider training sessions or workshops offered by manufacturers to familiarize their teams with the installation process, ensuring a smooth transition with minimal disruption to operations.

Scenario 3: Maintenance and Longevity Concerns

The Problem: Another common issue for B2B buyers is the maintenance of locking systems, particularly in environments with heavy usage or exposure to the elements. Three-point latches that are not well-maintained can become stiff, leading to operational difficulties, increased wear, and eventually failure, which can necessitate costly replacements. Buyers often struggle to find solutions that ensure longevity without requiring excessive maintenance.

The Solution: To ensure the longevity of three-point latches, buyers should look for systems that feature durable, corrosion-resistant finishes and robust designs that withstand frequent use. Regular maintenance schedules should be established, including lubrication of moving parts and inspection for signs of wear or damage. Manufacturers often provide maintenance guidelines that detail the best practices for upkeep. Additionally, sourcing latches equipped with self-lubricating components can significantly reduce maintenance needs, allowing for smoother operation over time. Investing in high-quality latches from reputable manufacturers will also provide buyers with warranties and support, further safeguarding their investment and ensuring long-term reliability.

Strategic Material Selection Guide for three point latch

What Are the Key Materials Used in Three Point Latches?

When selecting materials for three point latches, it is crucial to consider properties such as strength, corrosion resistance, and manufacturing complexity. The choice of material can significantly impact the latch’s performance, durability, and suitability for specific applications. Below are analyses of four common materials used in the production of three point latches.

How Does Stainless Steel Perform in Three Point Latches?

Stainless steel is a popular choice for three point latches due to its excellent corrosion resistance and high strength. This material can withstand extreme temperatures and pressures, making it suitable for various environments, including marine and industrial applications.

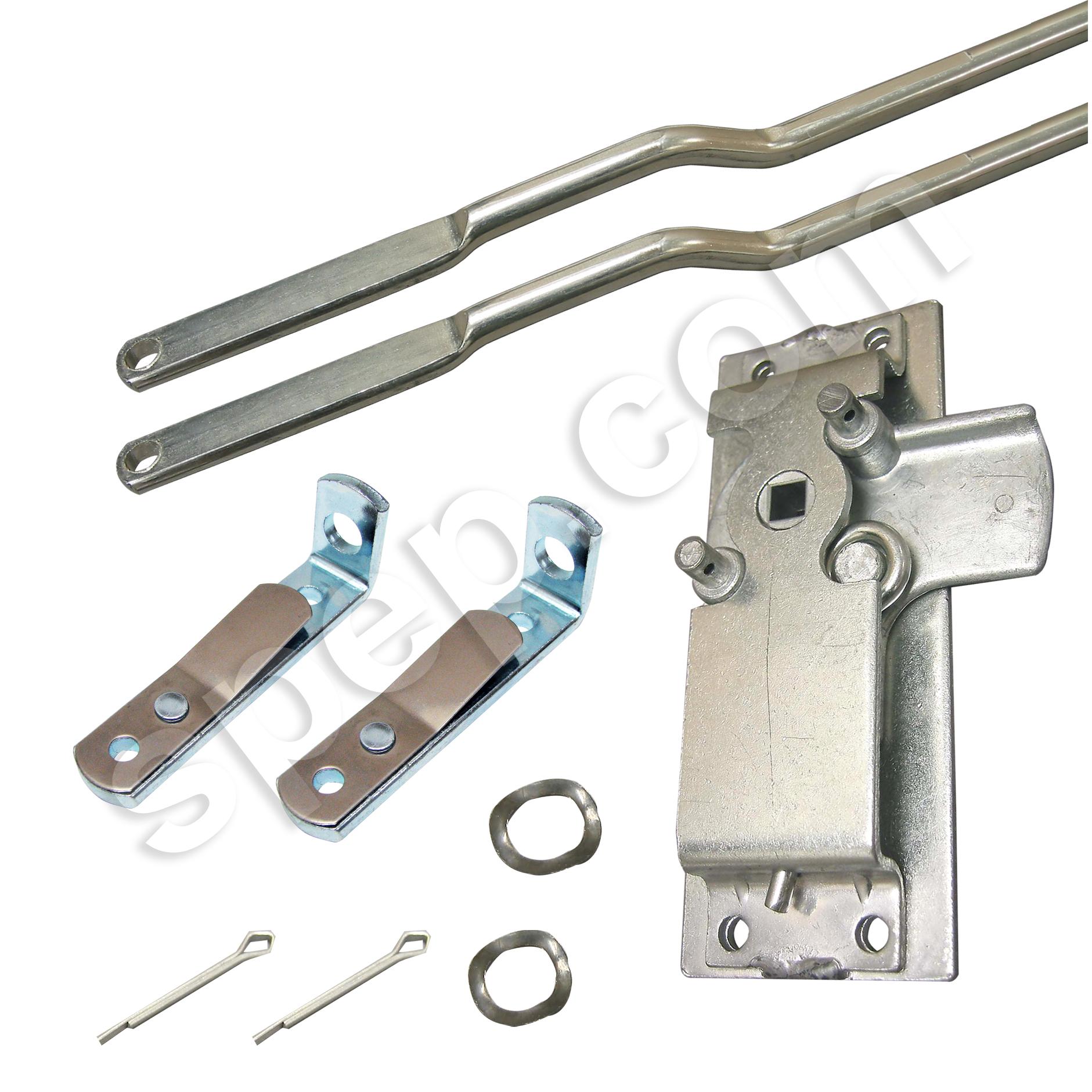

Illustrative image related to three point latch

Pros: Stainless steel latches are highly durable and can resist rust and corrosion, which is essential for outdoor or humid environments. They also offer a polished finish that enhances aesthetic appeal.

Cons: The primary drawback of stainless steel is its higher cost compared to other materials. Additionally, manufacturing processes can be more complex due to the hardness of the material, which may lead to longer lead times.

Impact on Application: Stainless steel latches are ideal for applications requiring robust security and longevity, such as in the transportation and energy sectors.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local corrosion resistance standards. For instance, ASTM standards for stainless steel can guide selection.

What Role Does Zinc-Plated Steel Play in Three Point Latches?

Zinc-plated steel is another common material used for three point latches, providing a balance between cost and performance. The zinc coating offers a level of corrosion resistance, making it suitable for many applications.

Pros: The primary advantage of zinc-plated steel is its lower cost compared to stainless steel, making it an economical choice for manufacturers. It also provides adequate strength for medium-duty applications.

Cons: However, zinc plating can wear off over time, exposing the underlying steel to corrosion. This makes it less suitable for harsh environments compared to stainless steel.

Impact on Application: Zinc-plated steel latches are often used in less demanding environments, such as residential or light commercial applications.

Illustrative image related to three point latch

Considerations for International Buyers: Buyers should be aware of the corrosion resistance requirements in their regions. Compliance with local standards such as JIS or DIN for plating thickness may also be necessary.

Why Choose Aluminum for Three Point Latches?

Aluminum is a lightweight alternative that offers good corrosion resistance and strength. It is particularly advantageous in applications where weight is a critical factor, such as in aerospace or automotive industries.

Pros: Aluminum latches are easy to manufacture and can be extruded into complex shapes, allowing for innovative designs. They are also resistant to corrosion, especially when anodized.

Cons: The main limitation of aluminum is its lower strength compared to stainless steel, which may not be suitable for high-security applications. Additionally, it can be more expensive than zinc-plated steel.

Impact on Application: Aluminum is best suited for applications where weight savings are essential, such as in mobile equipment or lightweight enclosures.

Considerations for International Buyers: Buyers should check for compliance with international aluminum standards, which can vary by region. In Europe, for example, EN standards for aluminum alloys may apply.

How Does Plastic Compare in Three Point Latch Applications?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is sometimes used in three point latches for specific applications, especially in environments where corrosion is a concern.

Pros: Plastic latches are lightweight, resistant to corrosion, and can be manufactured at a lower cost. They are also non-conductive, making them suitable for electrical enclosures.

Cons: The downside is that plastic latches may not provide the same level of security as metal counterparts, and their strength can be lower, making them unsuitable for heavy-duty applications.

Impact on Application: Plastic latches are ideal for applications in environments prone to corrosion, such as chemical processing or food handling.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and performance standards in their regions, such as FDA regulations for food applications.

Summary of Material Selection for Three Point Latches

| Material | Typical Use Case for three point latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and marine applications | Excellent corrosion resistance | Higher cost and complex mfg | High |

| Zinc-Plated Steel | Residential and light commercial use | Economical and adequate strength | Corrosion risk over time | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and easy to manufacture | Lower strength than steel | Medium |

| Plastic | Chemical processing and food handling | Corrosion-resistant and lightweight | Lower security and strength | Low |

This guide provides a comprehensive overview of the materials available for three point latches, helping B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for three point latch

What Are the Key Stages in the Manufacturing Process of Three Point Latches?

The manufacturing process for three point latches encompasses several critical stages, each designed to ensure the final product meets the highest standards of quality and durability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Three Point Latches?

The first step involves selecting high-quality raw materials, typically stainless steel, zinc-plated steel, or aluminum, known for their strength and resistance to corrosion. These materials undergo inspection to ensure they meet the specifications required for manufacturing. This initial quality check is essential, as it establishes a foundation for the entire production process.

Illustrative image related to three point latch

Once the materials are verified, they are cut to size using precision cutting tools. Advanced techniques such as laser cutting or CNC machining are often employed to achieve the necessary tolerances and shapes. This precision is crucial, as even minor discrepancies can affect the latch’s functionality and security.

What Forming Techniques Are Used in Three Point Latch Production?

After material preparation, the next stage is forming, where the cut materials are shaped into the various components of the latch. This process typically involves techniques like stamping, bending, or forging.

Stamping is widely used to create complex shapes and features in metal, while bending forms the rods and guides necessary for the latch mechanism. Forging may be employed for high-strength components to enhance durability. The choice of forming techniques depends on the specific design and performance requirements of the latch.

How Are Three Point Latches Assembled?

Once the individual components are formed, assembly begins. This stage involves fitting together the various parts, including rods, guides, and the locking mechanism. Automated assembly lines may be used to ensure consistency and efficiency, although manual assembly is also common for complex latches that require precision fitting.

During assembly, quality control checkpoints are established to ensure that each component fits correctly and functions as intended. This includes checking alignment, movement, and the locking mechanism’s responsiveness. Proper assembly is critical, as it directly impacts the latch’s performance and security.

What Finishing Processes Are Applied to Three Point Latches?

The final stage in the manufacturing process is finishing, which enhances the latch’s aesthetic appeal and protects it from environmental factors. Common finishing techniques include powder coating, plating, or anodizing, depending on the material used and the intended application.

For instance, zinc plating provides corrosion resistance for steel components, while powder coating offers a durable and visually appealing finish. Each finishing method has its own advantages and contributes to the overall lifespan and reliability of the latch.

What Quality Assurance Standards Are Relevant for Three Point Latches?

Quality assurance is a critical aspect of manufacturing three point latches, ensuring that products meet international standards and customer expectations. Key standards include ISO 9001, which focuses on effective quality management systems, and industry-specific certifications such as CE marking for compliance with European safety standards.

How Do International Standards Influence Quality Control?

ISO 9001 certification is a globally recognized standard that emphasizes quality management principles, including strong customer focus, the involvement of top management, and the process approach. Manufacturers of three point latches should be ISO 9001 certified to demonstrate their commitment to quality and continuous improvement.

In addition, CE marking indicates that the product meets EU safety, health, and environmental protection requirements. For B2B buyers, especially in Europe, verifying these certifications is crucial for ensuring that the latches will perform safely and effectively in their intended applications.

What Are the Critical Quality Control Checkpoints in Manufacturing?

Quality control throughout the manufacturing process involves several checkpoints, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards. Any substandard materials are rejected, preventing defects from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to monitor production processes. This includes checking tolerances during forming and verifying assembly accuracy.

-

Final Quality Control (FQC): Before products are shipped, a thorough inspection is performed to ensure each latch meets quality standards and functions correctly. This often includes testing the locking mechanism and verifying the finish quality.

What Testing Methods Are Commonly Used for Three Point Latches?

Manufacturers employ various testing methods to ensure that three point latches meet safety and performance standards. Common testing methods include:

- Functional Testing: Assessing the operation of the latch, including locking and unlocking mechanisms.

- Durability Testing: Subjecting latches to repeated cycles of use to evaluate their longevity.

- Environmental Testing: Exposing latches to different environmental conditions to ensure they perform under various circumstances.

These tests help ensure that the latches can withstand the rigors of their intended applications, especially in demanding environments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of their suppliers. Key strategies include:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards firsthand.

-

Reviewing Quality Reports: Requesting detailed quality reports from suppliers can provide transparency regarding their testing methods and results. This documentation is essential for understanding the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control practices. This is particularly beneficial for international buyers who may not have the resources to conduct audits themselves.

What Quality Control Nuances Should International Buyers Consider?

For international B2B buyers, understanding the nuances of quality control in different regions is critical. Buyers should be aware of local regulations, industry standards, and certification requirements that may vary significantly between countries.

Additionally, cultural differences may influence how quality control is perceived and implemented. Establishing clear communication with suppliers regarding quality expectations is essential for successful partnerships. By prioritizing quality assurance in the procurement process, buyers can ensure that they receive reliable, high-performance three point latches suited to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three point latch’

Introduction

Sourcing a three-point latch requires careful consideration of various factors to ensure that the chosen locking mechanism meets your specific security and operational needs. This guide provides a step-by-step checklist that will help you navigate the procurement process effectively, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline your technical requirements. Consider the type of application—industrial, commercial, or residential—and the specific environment in which the latch will be used.

– Material: Determine if you need stainless steel, zinc-plated, or another material based on corrosion resistance and strength.

– Size and Configuration: Specify dimensions and whether you need a left-hand or right-hand configuration.

Step 2: Research Market Options

Take time to explore the range of three-point latches available in the market. Utilize online resources and industry catalogs to understand what features different products offer.

– Types of Latches: Look into variations, such as continuous hinge latches or those with specific locking mechanisms.

– Performance Ratings: Check for compliance with industry standards, such as NEMA ratings, which indicate the suitability of the latch for specific environments.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform thorough due diligence. Request comprehensive company profiles, including their history, client base, and experience in your industry.

– References and Case Studies: Seek testimonials from existing clients, especially those in similar regions or industries, to gauge reliability and service quality.

– Customer Support: Assess the supplier’s commitment to post-purchase support, including installation assistance and warranty services.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications that demonstrate their adherence to quality standards.

– ISO Certification: Look for ISO 9001 or other relevant quality management certifications, which indicate a commitment to consistent quality.

– Testing Compliance: Confirm that products meet safety and performance standards, such as those set by Underwriters Laboratories (UL), ensuring reliability and safety.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare pricing structures and purchase terms.

– Total Cost of Ownership: Beyond the initial purchase price, consider installation costs, maintenance, and potential long-term savings from using higher-quality latches.

– Return Policies: Review the supplier’s return policy to understand the conditions under which you can return defective or unsuitable products.

Step 6: Conduct a Trial Order

Before making a bulk purchase, consider placing a smaller trial order to evaluate the latch’s performance and the supplier’s service.

– Performance Evaluation: Test the latch in real-world conditions to assess functionality, ease of installation, and security features.

– Supplier Interaction: Use this opportunity to assess responsiveness and support from the supplier during the ordering and delivery process.

Step 7: Finalize Your Purchase and Monitor Usage

After satisfactory evaluations, finalize your purchase and establish a monitoring plan for ongoing usage.

– Feedback Loop: Collect feedback from users on the latch’s performance to ensure it meets operational needs.

– Supplier Relationship: Maintain communication with the supplier for future needs and potential upgrades or custom solutions.

By following this checklist, you can ensure a strategic and informed approach to sourcing three-point latches that align with your business needs.

Illustrative image related to three point latch

Comprehensive Cost and Pricing Analysis for three point latch Sourcing

What Are the Key Cost Components Involved in Sourcing Three Point Latches?

When assessing the total cost of sourcing three point latches, it’s essential to break down the individual cost components. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly influences cost. For instance, stainless steel and zinc-plated steel are common in high-security latches. Premium materials typically command higher prices due to durability and corrosion resistance, which are critical in various industrial applications.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the manufacturing and assembly processes. Regions with lower labor costs may offer competitive pricing, but it’s crucial to ensure that quality is not compromised.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, leading to lower overall costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, these costs can be amortized over large production runs, making it essential to consider the volume when negotiating prices.

-

Quality Control: Ensuring that latches meet industry standards (like UL certification) involves costs related to testing and inspection. High-quality products may have a higher upfront cost but can lead to savings in the long run through reduced failure rates.

-

Logistics: Transportation and storage costs are vital components of the total cost. International shipments may incur additional fees, including customs duties and tariffs, which can vary significantly based on the shipping terms (Incoterms).

-

Margin: Suppliers typically include a margin to cover their costs and profit. Understanding the margin expectations can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Three Point Latches?

Several factors can influence the pricing of three point latches.

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding minimum order quantities (MOQs) and negotiating based on anticipated volume can lead to significant savings.

-

Specifications and Customization: Customized latches tailored to specific applications may come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs associated with changes during production.

-

Materials and Quality Certifications: Higher quality materials and certifications can increase costs but also enhance product reliability. Buyers should evaluate whether the added investment aligns with their operational needs.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can all affect pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind regarding product performance.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) impacts the final price, as they dictate who bears the risk and costs during shipping. Understanding these terms is crucial for international buyers to avoid unexpected expenses.

What Are Some Buyer Tips for Sourcing Three Point Latches Cost-Effectively?

To optimize sourcing costs for three point latches, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger volumes or longer-term contracts. Leverage competitive quotes to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, replacement, and operational costs over the product’s lifespan. Higher initial investments in quality latches may lead to lower TCO due to reduced failures and maintenance.

-

Pricing Nuances for International Buyers: Understand the specific market dynamics in your region. For example, buyers in Africa or South America may face different import duties and tariffs than those in Europe. Familiarize yourself with local regulations to ensure compliance and avoid additional costs.

-

Quality Assurance: Invest time in verifying supplier capabilities and product quality. Quality certifications and compliance with international standards can safeguard against future costs related to failures or recalls.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing influencers for three point latches can empower B2B buyers to make informed purchasing decisions. By strategically negotiating and focusing on total cost considerations, companies can achieve cost efficiencies while ensuring high-quality locking solutions for their applications.

Alternatives Analysis: Comparing three point latch With Other Solutions

Exploring Alternatives to the Three Point Latch System

In the realm of industrial security and access control, the three point latch system is often favored for its enhanced security and reliability. However, there are viable alternatives that may suit specific applications or preferences. This section will compare the three point latch with other locking mechanisms, specifically the single point latch and the multipoint lock, providing insights to help B2B buyers make informed decisions.

| Comparison Aspect | Three Point Latch | Single Point Latch | Multipoint Lock |

|---|---|---|---|

| Performance | High security; secures at three points for better force distribution | Moderate security; secures only at one point | Very high security; secures at multiple points, often more than three |

| Cost | Higher initial investment due to complexity | Lower cost, simpler design | Generally higher cost than three point latches due to advanced mechanism |

| Ease of Implementation | Requires precise installation; may need professional help | Easy to install; often a DIY solution | More complex installation; may require professional assistance |

| Maintenance | Low maintenance; durable materials reduce wear | Low maintenance; simple mechanics | Moderate maintenance; complexity may lead to more wear over time |

| Best Use Case | High-security environments like warehouses and sensitive data centers | General-purpose applications like residential doors | High-security settings such as commercial properties and electronic enclosures |

What Are the Advantages and Disadvantages of Each Alternative?

Single Point Latch

The single point latch is the simplest locking mechanism, engaging at just one point. This simplicity translates to lower costs and ease of installation, making it an ideal choice for residential applications or low-security environments. However, its primary drawback is the lack of security; it does not distribute force across the door, making it vulnerable to forced entry. For B2B buyers looking for cost-effective solutions for less critical applications, a single point latch may be adequate.

Multipoint Lock

Multipoint locks, like three point latches, secure doors at multiple points, offering superior security by distributing force evenly across the door frame. They are particularly effective for larger doors and high-security environments. However, they tend to be more expensive and can require professional installation due to their complexity. For businesses that prioritize security and are willing to invest more upfront, multipoint locks are a robust alternative that provides peace of mind.

How Can B2B Buyers Choose the Right Solution?

When selecting the right locking mechanism, B2B buyers should consider several factors, including the specific security needs of their application, budget constraints, and installation capabilities. For high-security environments, a three point latch or multipoint lock may be necessary despite the higher costs. Conversely, for more standard applications where cost is a priority, a single point latch may suffice. Ultimately, understanding the unique demands of each application will guide buyers toward the most suitable solution, ensuring both security and functionality are achieved.

Essential Technical Properties and Trade Terminology for three point latch

What Are the Key Technical Properties of a Three Point Latch?

Understanding the essential technical properties of a three point latch is crucial for B2B buyers looking for reliable and secure locking mechanisms. Below are critical specifications that should be considered:

1. Material Grade

The material used in the construction of three point latches significantly affects their performance and longevity. Common materials include stainless steel, zinc-plated steel, and aluminum. Stainless steel is favored for its corrosion resistance and durability, making it ideal for outdoor or harsh environments. Buyers should prioritize high-grade materials to ensure the latch can withstand environmental stressors and maintain its integrity over time.

2. Load Tolerance

Load tolerance refers to the maximum weight the latch can securely hold without failing. A three point latch’s load tolerance is vital for applications in industrial environments, where heavy doors or panels are common. Buyers must assess their specific application requirements to choose a latch with an appropriate load capacity, ensuring safety and reliability.

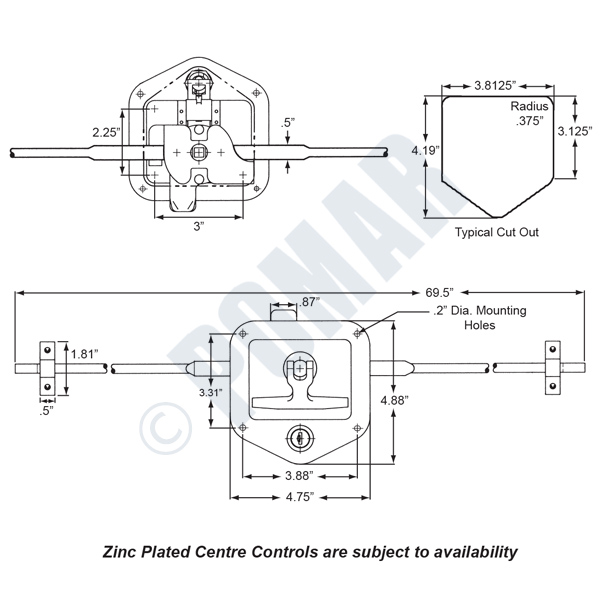

Illustrative image related to three point latch

3. Locking Mechanism

The locking mechanism design is pivotal in determining the latch’s security level. Three point latches utilize multiple locking points, typically at the top, middle, and bottom of the door, which enhances security by distributing force evenly. This feature minimizes the risk of door warping and unauthorized access. Buyers should look for latches with robust locking mechanisms, such as those certified by recognized safety standards.

4. Installation Type

Installation type includes how the latch is mounted and its compatibility with various door designs. Common types include surface-mounted and mortised latches. Understanding installation requirements is essential for ensuring the latch can be easily integrated into existing systems. Buyers should consider if they need additional accessories, such as mounting hardware or installation guides, to facilitate a smooth setup.

5. Weather Resistance Rating

For latches used in outdoor applications, a weather resistance rating, such as IP (Ingress Protection) ratings, is critical. A higher rating indicates better protection against dust and moisture, which can lead to corrosion and operational failure. Buyers should ensure that the three point latch chosen is rated appropriately for its intended use to guarantee durability and performance.

What Are Common Trade Terms Associated with Three Point Latches?

Familiarity with industry jargon is essential for effective communication and decision-making in B2B transactions. Here are several key terms associated with three point latches:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For three point latches, working with an OEM can ensure high-quality products that meet specific industry standards and requirements. Buyers often rely on OEMs for custom solutions tailored to their unique needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, particularly when sourcing three point latches, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their purchasing capabilities and project timelines.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. In the context of three point latches, submitting an RFQ allows buyers to compare offers and select suppliers that best meet their needs. Clarity in the RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in transactions. They clarify aspects like shipping, insurance, and risk. Understanding Incoterms is crucial for B2B buyers, especially in international markets, to avoid misunderstandings regarding shipping costs and responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. For three point latches, lead times can vary based on manufacturing processes and stock availability. Buyers should consider lead times when planning projects to ensure timely delivery and avoid potential delays.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the reliability and security of their locking mechanisms.

Navigating Market Dynamics and Sourcing Trends in the three point latch Sector

What Are the Key Trends Shaping the Three Point Latch Market?

The three point latch market is experiencing significant growth, driven by increasing demand for enhanced security solutions across various sectors, including construction, transportation, and industrial applications. One of the key trends is the integration of advanced technologies, such as smart locking systems and IoT capabilities, which allow for remote access and monitoring. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where the need for secure and efficient access control systems is paramount.

Moreover, manufacturers are focusing on customization and modular designs to cater to the specific needs of diverse industries. This adaptability is crucial for buyers looking for solutions that meet unique operational requirements. Additionally, the rising emphasis on sustainability is influencing sourcing decisions, with companies increasingly prioritizing eco-friendly materials and manufacturing processes.

Illustrative image related to three point latch

As global supply chains evolve, international buyers should also be aware of fluctuating material costs and logistics challenges, which can impact pricing and availability. Establishing strong relationships with reliable suppliers and leveraging technology for procurement processes can mitigate these challenges and enhance operational efficiency.

How Does Sustainability and Ethical Sourcing Impact the Three Point Latch Sector?

Sustainability and ethical sourcing are becoming integral to the three point latch sector, reflecting a broader shift towards responsible manufacturing practices. The environmental impact of production processes is under scrutiny, with stakeholders pushing for transparency in supply chains. For B2B buyers, this means selecting suppliers who prioritize sustainable materials and practices, which can include the use of recycled metals and eco-friendly coatings.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming increasingly important in the purchasing decision. Buyers should seek manufacturers who have these certifications, as they demonstrate a commitment to minimizing environmental footprints.

Moreover, ethical sourcing can enhance a company’s reputation and appeal to environmentally conscious consumers. By prioritizing suppliers that adhere to fair labor practices and ethical production standards, buyers can align their procurement strategies with corporate social responsibility goals, ultimately leading to increased brand loyalty and market competitiveness.

What is the Historical Context of Three Point Latch Development?

The evolution of the three point latch can be traced back to the growing need for enhanced security in various applications, particularly in the transportation and industrial sectors. Initially developed as a solution to improve the locking mechanisms of doors and enclosures, the three point latch has transformed significantly over the years.

In its early iterations, the focus was primarily on durability and basic functionality. However, advancements in materials science and engineering have led to the development of more sophisticated latching systems that provide greater security and ease of use. Modern three point latches are designed to distribute locking force evenly across a door, mitigating warping and enhancing protection against unauthorized access.

Illustrative image related to three point latch

As market demands evolve, the three point latch continues to adapt, incorporating technology and sustainable practices to meet the needs of international B2B buyers in an increasingly complex marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of three point latch

-

How do I ensure the three-point latch meets my security requirements?

To ensure a three-point latch meets your security needs, assess its material, construction, and locking mechanism. Opt for latches made from robust materials like stainless steel or zinc-plated steel for durability. Additionally, consider the latch’s certification, such as Underwriters Laboratories (UL) approval, which indicates that it has undergone rigorous testing for safety and performance. Consulting with suppliers about their product specifications and requesting samples can also help you evaluate their reliability and security features effectively. -

What are the advantages of using a three-point latch over a single-point latch?

Three-point latches offer enhanced security by locking at three different points along the door, which distributes force evenly and reduces the risk of forced entry. This mechanism creates a tighter seal, preventing warping and improving insulation against environmental factors. Moreover, three-point latches often come with added features like key locking systems, making them suitable for high-security applications in industrial settings, electronic enclosures, and transportation. -

What customization options are available for three-point latches?

Many manufacturers offer customization options for three-point latches to fit specific applications. These may include variations in size, material (such as stainless steel or aluminum), finishes (like powder coating), and additional features such as different locking mechanisms or handle designs. When discussing customization with suppliers, provide detailed specifications and requirements to ensure the final product meets your operational needs. -

What are the typical minimum order quantities (MOQ) for three-point latches in B2B transactions?

Minimum order quantities (MOQ) for three-point latches can vary significantly based on the supplier and the complexity of the product. Generally, MOQs can range from 50 to 500 units, with some manufacturers offering lower MOQs for standard products. When sourcing, inquire about MOQs early in the negotiation process, as this can impact your purchasing decisions and overall budget. -

How can I vet suppliers for three-point latches in international trade?

To vet suppliers effectively, start by researching their business credentials, including certifications like ISO 9001, which indicates a commitment to quality management. Request references and case studies from previous clients, especially those in your industry. Additionally, assess their production capabilities, lead times, and after-sales support. Using platforms like Alibaba or Global Sources can also provide insights into supplier ratings and reviews. -

What payment terms should I expect when purchasing three-point latches internationally?

Payment terms for international purchases can vary widely based on supplier policies and buyer negotiation. Common terms include payment upfront, a deposit with the balance due upon shipment, or letters of credit. It’s essential to clarify these terms before finalizing the order to avoid misunderstandings. Always consider using secure payment methods and check if the supplier offers buyer protection options. -

How do I ensure quality assurance for three-point latches?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Many manufacturers conduct rigorous testing to comply with industry standards, so ask for documentation that proves this. Additionally, consider visiting the manufacturing facility if possible, or request third-party inspections before shipment. Establishing a clear quality control process in your purchasing agreement will help mitigate risks. -

What logistics considerations should I keep in mind when sourcing three-point latches?

When sourcing three-point latches, consider shipping methods, lead times, and customs regulations in your region. Understand the total landed cost, which includes shipping, tariffs, and potential duties. Collaborate with your supplier to choose the most efficient shipping method, whether air or sea freight, based on urgency and budget. Additionally, ensure that your supplier can provide the necessary documentation for smooth customs clearance.

Top 3 Three Point Latch Manufacturers & Suppliers List

1. Industrial HWE – 3 Point Roller Lock Kit

Domain: industrialhwe.com

Registered: 1997 (28 years)

Introduction: Three Point Door Locks and Lock Kits available in medium duty or heavy duty construction. Options include inside release, override, spring loaded, with or without rods, rod end bolts, and rod guides. Key products include: 1. 3 POINT ROLLER LOCK KIT-48 IN. RODS-EBERHARD, SKU: EB1-2500U65, Price: $36.47, 3 In Stock. 2. 3-POINT LOCK KIT W/INSIDE RELEASE-POLAR, SKU: PL7011S-002, Price: $106.10, 19 In …

2. NEMA Enclosures – Continuous Hinge 3 Point Latch

Domain: nemaenclosures.com

Registered: 1999 (26 years)

Introduction: Continuous Hinge 3 Point Latch Electrical Enclosures are manufactured in Texas and are UL508A Listed. They are available in single-door and two-door configurations, suitable for wall-mount, floor-mount, and free-standing applications. The enclosures are made from materials such as carbon steel, 304 stainless steel, 316 stainless steel, and 5052 aluminum. They have safety ratings including NEMA Typ…

3. Allegis Corp – Left Hand 3-Point Locking D-Ring Latch

Domain: allegiscorp.com

Registered: 2001 (24 years)

Introduction: {“Part Number”: “2103S-50 SSL”, “Description”: “LEFT HAND 3-POINT LOCKING D-RING LATCH – KEYED 1250”, “Material”: “Zinc Plated Steel”, “Features”: [“Small left handed 4 7/8″ dia. D-ring”, “Cam holds door at center while rods secure door at each end”, “Cotters and washers for attaching rods included”, “Polished Stainless Steel handle”, “Key Locking”], “Specifications”: {“Weight”: “1.130000”, “Pack …

Strategic Sourcing Conclusion and Outlook for three point latch

In today’s competitive landscape, the strategic sourcing of three-point latches is crucial for businesses aiming to enhance security and operational efficiency. These advanced locking mechanisms not only provide superior protection through multiple contact points but also ensure durability and ease of access, making them ideal for various applications across industries. By investing in high-quality three-point latches, companies can mitigate risks associated with unauthorized access and improve the overall integrity of their enclosures.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize sourcing from reputable manufacturers who offer customizable solutions tailored to specific needs. This ensures that the latching systems meet industry standards and can withstand diverse environmental conditions.

As you consider your procurement strategies, focus on suppliers with a proven track record in quality assurance and customer support. The future of latching solutions lies in innovation and adaptability, and by aligning with forward-thinking manufacturers, you can secure not only your assets but also your competitive edge in the market. Embrace this opportunity to strengthen your sourcing strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.