Is Your Supplement Warehouse Racking System Sourcing Strategy Flawed? Read This 2025…

Introduction: Navigating the Global Market for supplement warehouse racking system

Navigating the complexities of sourcing a supplement warehouse racking system can be a daunting task for international B2B buyers. With the growing demand for efficient storage solutions in warehouses across Africa, South America, the Middle East, and Europe, businesses must prioritize maximizing their space while ensuring cost-effectiveness and durability. This guide offers a comprehensive overview of the various types of racking systems available, their applications in diverse industries, and crucial insights into supplier vetting processes.

From mobile compact pallet racks that optimize floor space to traditional static systems, understanding the nuances of each option is vital for making informed purchasing decisions. Additionally, we delve into the factors influencing costs, helping you balance budget constraints with quality requirements.

Designed specifically for B2B buyers in regions like Nigeria and Vietnam, this guide equips you with actionable insights that enable you to navigate the global market confidently. By addressing key challenges such as space management, inventory control, and supplier reliability, you will be empowered to select the most suitable racking solutions for your warehouse operations. With this knowledge, you can enhance your logistical efficiency, ultimately driving productivity and profitability in your business.

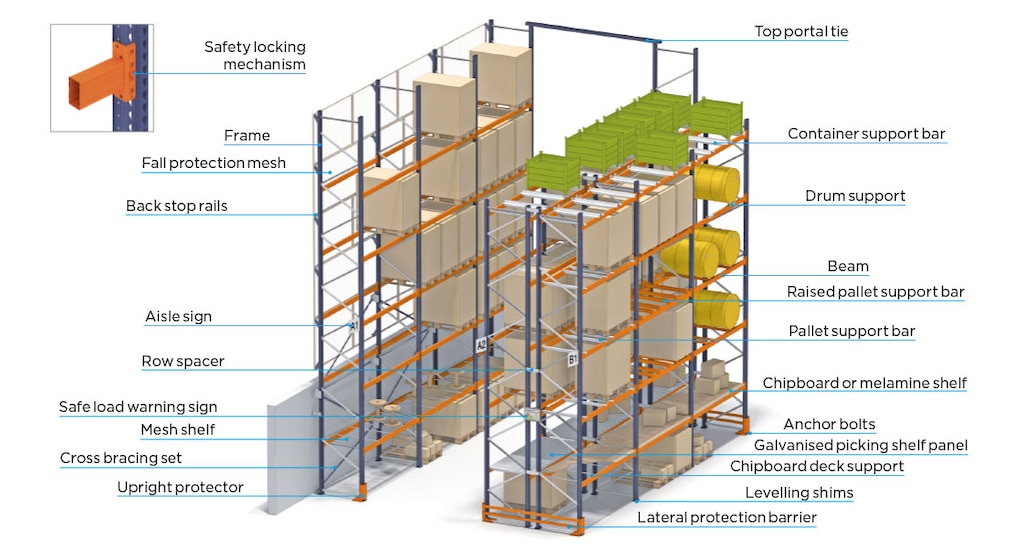

Understanding supplement warehouse racking system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Selective Pallet Racking | Adjustable shelves for easy access; versatile layout | General storage, retail, and distribution | Pros: Flexible, easy to install; Cons: Requires more floor space, limited height capacity. |

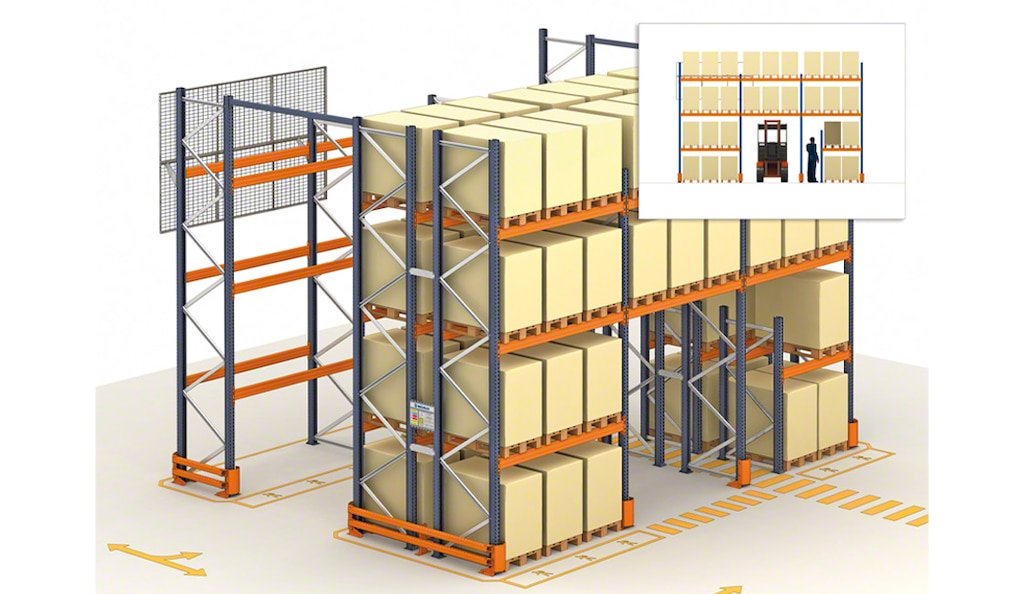

| Drive-In Racking | High-density storage; allows for multiple pallets deep | Cold storage, bulk storage, and warehouses | Pros: Maximizes space; Cons: Limited selectivity, requires specialized forklifts. |

| Mobile Racking Systems | Racks on tracks; compact and movable | High-volume operations, retail environments | Pros: Doubles storage capacity; Cons: Higher initial investment, maintenance required. |

| Cantilever Racking | Open design for long or bulky items | Lumber yards, furniture stores, and warehouses | Pros: Easy loading/unloading; Cons: Limited height adjustment, may require more floor space. |

| Automated Storage Systems | Mechanized retrieval and storage; high efficiency | E-commerce, manufacturing, and distribution | Pros: Reduces labor costs, increases speed; Cons: High upfront costs, complex maintenance. |

What Are the Key Characteristics of Selective Pallet Racking?

Selective pallet racking is widely recognized for its adjustable shelves and straightforward installation, making it a go-to solution for many businesses. This type of racking allows easy access to individual pallets, enhancing operational efficiency. It is particularly suitable for general storage needs in retail and distribution centers where flexibility is paramount. Buyers should consider the layout of their warehouse, as selective racking requires more floor space compared to other systems.

How Does Drive-In Racking Maximize Storage Efficiency?

Drive-in racking is designed for high-density storage, allowing pallets to be stored multiple units deep. This system is ideal for businesses with large inventories, such as cold storage facilities and warehouses, where maximizing vertical space is crucial. While it offers significant space savings, buyers must evaluate their operational needs, as the limited selectivity may slow down retrieval times and requires specific handling equipment.

What Are the Benefits of Mobile Racking Systems?

Mobile racking systems utilize tracks to enable racks to move, creating adjustable aisles based on current storage needs. This innovative design is perfect for high-volume operations and retail spaces where floor space is at a premium. While mobile racking can effectively double storage capacity, potential buyers should weigh the higher initial investment and ongoing maintenance against the benefits of increased efficiency and space utilization.

Illustrative image related to supplement warehouse racking system

Why Choose Cantilever Racking for Bulky Items?

Cantilever racking features an open design that is particularly beneficial for storing long or bulky items, such as lumber or furniture. This type of racking allows for easy loading and unloading, making it suitable for lumber yards and warehouses that handle oversized products. However, businesses should consider that cantilever racking may require more floor space and offers limited height adjustment options.

What Makes Automated Storage Systems Attractive?

Automated storage systems utilize mechanized solutions for efficient retrieval and storage of goods, significantly improving operational speed and reducing labor costs. This type of racking is particularly beneficial for e-commerce and manufacturing environments where quick access to inventory is essential. Despite the advantages, potential buyers should be mindful of the high upfront costs and the complexity of maintenance involved in these systems.

Key Industrial Applications of supplement warehouse racking system

| Industry/Sector | Specific Application of supplement warehouse racking system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Storage of raw materials and finished products | Maximizes space utilization, ensuring efficient inventory management and compliance with safety standards | Durability, ease of cleaning, and temperature control capabilities |

| Pharmaceuticals | Storing temperature-sensitive products | Ensures product integrity and compliance with regulatory standards | Temperature control features, tracking systems, and modular designs |

| E-commerce and Retail | Centralized storage for diverse product ranges | Streamlines order fulfillment processes and enhances inventory visibility | Flexibility in design, scalability, and integration with existing systems |

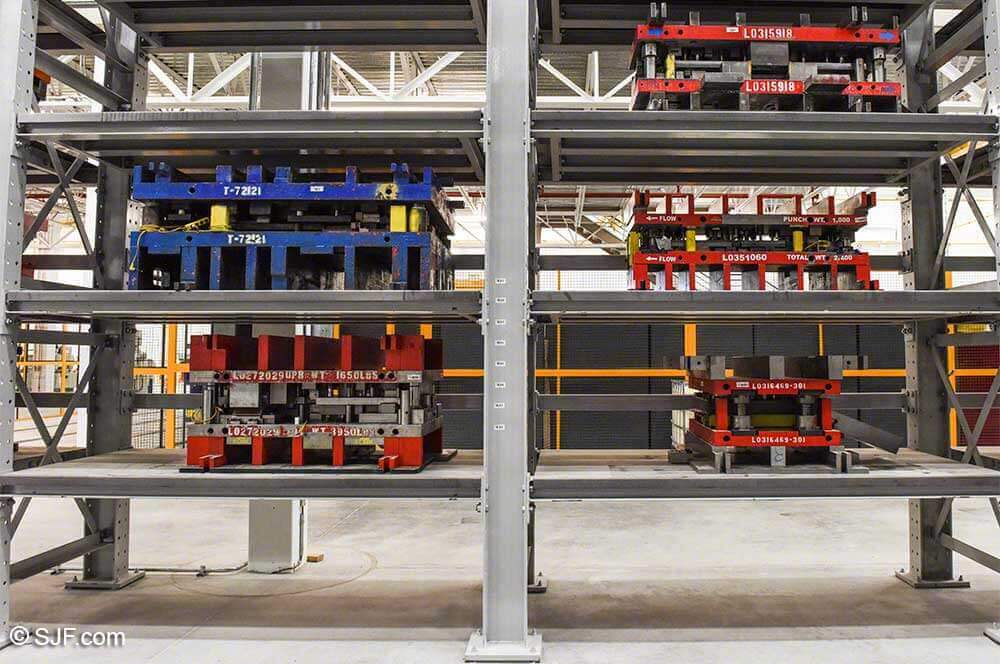

| Automotive Parts | Storage of various components and assemblies | Reduces retrieval times and improves inventory accuracy | Heavy-duty construction, load capacity, and accessibility |

| Electronics | Organization of delicate components and finished goods | Protects sensitive items while maximizing storage density | Anti-static features, customization options, and ease of access |

How is the Supplement Warehouse Racking System Used in the Food and Beverage Industry?

In the food and beverage sector, supplement warehouse racking systems are crucial for storing both raw materials and finished products. These systems help businesses optimize their storage capacity while ensuring compliance with food safety regulations. For international buyers, especially in regions like Africa and South America, it’s important to consider racking systems that are durable and easy to clean, which can withstand the rigorous demands of this industry. Additionally, integrating temperature control capabilities can further enhance product preservation.

What Role Does the Supplement Warehouse Racking System Play in Pharmaceuticals?

Pharmaceutical companies rely heavily on supplement warehouse racking systems to store temperature-sensitive medications and raw materials. These systems help maintain product integrity and compliance with strict regulatory standards. Buyers in the Middle East and Europe should prioritize racking solutions that offer temperature control features and robust tracking systems. Modular designs can also be beneficial, allowing for adjustments as inventory needs change, ensuring that all products are easily accessible and organized.

Illustrative image related to supplement warehouse racking system

How Do Supplement Warehouse Racking Systems Improve E-commerce and Retail Operations?

In the fast-paced world of e-commerce and retail, supplement warehouse racking systems are essential for centralizing storage of diverse product ranges. By maximizing space utilization and enhancing inventory visibility, these systems streamline order fulfillment processes, leading to quicker delivery times. International B2B buyers, particularly from regions like Nigeria and Vietnam, should focus on sourcing flexible and scalable racking solutions that can adapt to the evolving needs of their businesses. Integration with existing inventory management systems is also a key consideration.

Why are Supplement Warehouse Racking Systems Vital for Automotive Parts Storage?

The automotive industry benefits significantly from supplement warehouse racking systems, which are designed to store various components and assemblies efficiently. These systems reduce retrieval times and improve inventory accuracy, which is critical in a sector that requires precise tracking of parts. Buyers from Europe and South America should consider heavy-duty construction options that can support substantial weight and provide easy access to stored items. Customizable designs can also cater to specific storage needs.

How Do Supplement Warehouse Racking Systems Support Electronics Storage?

In the electronics sector, supplement warehouse racking systems are vital for organizing delicate components and finished goods. These systems help protect sensitive items while maximizing storage density, which is essential in a space-constrained environment. International buyers, particularly from Africa and the Middle East, should look for racking solutions with anti-static features to prevent damage to electronic components. Customization options can further enhance usability, ensuring that the racking system meets specific operational requirements.

Illustrative image related to supplement warehouse racking system

3 Common User Pain Points for ‘supplement warehouse racking system’ & Their Solutions

Scenario 1: Inefficient Space Utilization in Supplement Warehouses

The Problem: Many B2B buyers face significant challenges with maximizing storage capacity in their supplement warehouses. The traditional static racking systems often lead to wasted space due to fixed aisles and limited accessibility. This inefficiency can result in overstocking in some areas while underutilizing others, ultimately increasing operational costs and complicating inventory management. For companies dealing with varying product sizes and seasonal demand fluctuations, the inability to adapt their storage solutions can lead to serious logistical headaches.

The Solution: To overcome space utilization challenges, consider implementing compact rolling pallet racks. These systems allow for adjustable aisles that can be compressed or expanded based on current needs, effectively doubling storage capacity without the need for additional floor space. When sourcing these racking systems, collaborate with suppliers who offer customizable solutions tailored to your specific product types and warehouse layout. It’s essential to conduct a thorough assessment of your current inventory and projected growth to determine the optimal racking configuration. Additionally, integrate inventory management software that syncs with your racking system to streamline operations and ensure that you can easily adapt to changing storage needs.

Scenario 2: Difficulty in Managing Inventory Fluctuations

The Problem: For many supplement distributors, inventory fluctuations due to seasonal demand or new product launches can create chaos in warehouse management. Traditional racking systems can hinder quick access to high-turnover products, leading to delays in order fulfillment and customer dissatisfaction. This situation is particularly challenging in regions with rapid market changes, such as Africa and South America, where emerging trends can drastically alter inventory needs.

Illustrative image related to supplement warehouse racking system

The Solution: Implementing a dynamic racking system, such as adjustable shelving and flow racks, can significantly improve inventory management. These systems allow for quick reconfiguration to accommodate new products or changes in demand. When selecting a racking system, prioritize solutions that offer easy reconfiguration and modular designs. Additionally, invest in training for warehouse staff on best practices for utilizing these systems effectively. Leveraging data analytics to monitor inventory levels and turnover rates can further enhance your ability to make informed decisions about stock placement, ensuring that high-demand products are always readily accessible.

Scenario 3: Safety Concerns in Supplement Warehousing

The Problem: Safety is a paramount concern in any warehouse setting, and supplement warehouses are no exception. The improper use of racking systems can lead to accidents, injuries, and damage to products, especially when heavy loads are involved. Inadequate safety measures can result in costly liabilities and disruptions in operations, particularly in regions where regulatory compliance is strictly enforced.

The Solution: To address safety concerns, it is crucial to select racking systems that adhere to international safety standards and are designed for the specific loads they will bear. Invest in heavy-duty racking systems with features such as anti-tip mechanisms and load indicators to enhance safety. Conduct regular safety audits and training sessions for employees to ensure they understand the proper handling techniques and the importance of maintaining clear access to aisles. Additionally, consider installing safety barriers and signage around racking areas to further mitigate risks. By prioritizing safety in your racking solutions, you can create a safer work environment while maintaining efficiency in your operations.

Strategic Material Selection Guide for supplement warehouse racking system

What Are the Key Materials for Supplement Warehouse Racking Systems?

When selecting materials for supplement warehouse racking systems, it is crucial to consider their properties, advantages, disadvantages, and specific applications. The following analysis examines four common materials: steel, aluminum, wood, and plastic, focusing on their suitability for international B2B buyers.

How Does Steel Perform in Supplement Warehouse Racking Systems?

Steel is the most widely used material for warehouse racking systems due to its exceptional strength and durability. It typically has a high load-bearing capacity and can withstand significant pressure, making it ideal for heavy-duty applications. Steel racks can also be treated for corrosion resistance, which is particularly important in humid or chemically active environments.

Illustrative image related to supplement warehouse racking system

Pros: Steel is highly durable and can support heavy loads, making it suitable for various supplement products. Additionally, it is relatively cost-effective for large-scale operations.

Cons: The primary downside of steel is its susceptibility to corrosion if not properly treated. Moreover, the manufacturing complexity can increase costs if customized designs are required.

Impact on Application: Steel racks are compatible with various media, including heavy boxes and pallets of supplements. They are often compliant with international standards such as ASTM and ISO, which is beneficial for B2B buyers in different regions.

What Are the Benefits of Aluminum in Racking Systems?

Aluminum is another popular choice for warehouse racking systems, especially in environments where weight and mobility are critical. It is lightweight yet strong, making it easier to handle and install.

Pros: The primary advantage of aluminum is its resistance to corrosion, which makes it suitable for warehouses with high humidity or exposure to chemicals. Additionally, its lightweight nature allows for easy reconfiguration of storage layouts.

Illustrative image related to supplement warehouse racking system

Cons: Aluminum is generally more expensive than steel and may not support as heavy a load, which could limit its use in certain applications.

Impact on Application: Aluminum racks are ideal for lighter supplements and can be easily moved or adjusted. International buyers should ensure compliance with local standards, as aluminum products may have different regulations in various regions.

Why Choose Wood for Supplement Warehouse Racking Systems?

Wood is less common in modern warehouse racking systems but can still be a viable option for specific applications. It offers a rustic aesthetic and is often used for lighter loads or in retail environments.

Pros: Wood is readily available and can be cost-effective, especially for smaller operations. It is also easy to work with, allowing for custom designs.

Illustrative image related to supplement warehouse racking system

Cons: Wood is less durable than metal options and can be susceptible to pests, moisture, and warping. This limits its longevity and suitability for heavy-duty applications.

Impact on Application: Wooden racks are best suited for lighter, non-perishable supplements. Buyers in humid climates should consider treatments to enhance durability and compliance with local regulations.

What Role Does Plastic Play in Warehouse Racking Systems?

Plastic racking systems are gaining popularity due to their lightweight and corrosion-resistant properties. They are often used in environments where hygiene is paramount, such as food and supplement storage.

Pros: Plastic racks are resistant to moisture, chemicals, and corrosion, making them suitable for various applications. They are also lightweight, which facilitates easy handling and installation.

Cons: The main limitation of plastic is its lower load-bearing capacity compared to metal options. This can restrict its use in heavy-duty applications.

Illustrative image related to supplement warehouse racking system

Impact on Application: Plastic racks are ideal for storing lightweight supplements and can be compliant with food safety standards. International buyers should verify that the materials meet local health and safety regulations.

Summary of Material Selection for Supplement Warehouse Racking Systems

| Material | Typical Use Case for supplement warehouse racking system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty storage of bulk supplements | High load capacity and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight storage solutions | Corrosion-resistant and easy to handle | Higher cost and lower load capacity | High |

| Wood | Retail display or lighter load storage | Cost-effective and customizable | Less durable and moisture-sensitive | Low |

| Plastic | Hygienic storage for lightweight supplements | Moisture and corrosion-resistant | Lower load capacity | Medium |

In summary, selecting the right material for a supplement warehouse racking system involves assessing each option’s properties, advantages, and limitations. International B2B buyers should consider local regulations and standards to ensure compliance and suitability for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for supplement warehouse racking system

What Are the Main Stages in the Manufacturing Process of Supplement Warehouse Racking Systems?

Manufacturing a supplement warehouse racking system involves several critical stages, each designed to ensure the final product meets operational efficiency and safety standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Warehouse Racking Systems?

Material preparation is the first step in the manufacturing process. Typically, high-strength steel is used due to its durability and load-bearing capacity. The steel is sourced from reputable suppliers and undergoes quality checks to ensure it meets specific standards.

Once the steel is procured, it is cut into standardized sizes using precision cutting machines. This stage may also involve the application of protective coatings to prevent corrosion, especially important for warehouses in humid or variable climates. Suppliers often opt for galvanized or powder-coated finishes to enhance longevity.

What Forming Techniques Are Used in Racking System Manufacturing?

After material preparation, the forming process begins. This stage involves shaping the steel into the desired configurations for the racking system. Common techniques include:

- Roll Forming: A continuous bending operation in which a long strip of metal is passed through a series of rollers to create various shapes.

- Welding: Used to join different components, ensuring structural integrity. Automated welding machines enhance precision and speed.

- Punching: Creating holes for bolts and other fasteners, which is crucial for assembly later on.

These techniques are chosen based on the design specifications and load requirements of the racking systems, ensuring that they can withstand the intended weight and usage.

How Are Warehouse Racking Systems Assembled?

The assembly stage involves combining the formed components into complete racking units. This is typically done in a systematic manner to ensure efficiency. Key steps include:

- Fitting: Components are fitted together using bolts and nuts. The use of high-tensile fasteners is common to ensure strength.

- Quality Checks: At this stage, initial quality checks are performed to ensure that all parts are correctly assembled and meet design specifications.

For larger systems, modular assembly techniques may be employed, allowing for easier transport and installation at the final site. This is particularly beneficial for international buyers who may face shipping and logistics challenges.

What Finishing Processes Are Applied to Warehouse Racking Systems?

Finishing processes are critical for enhancing the durability and aesthetics of racking systems. These processes typically include:

- Surface Treatment: Coatings such as powder coating or galvanization are applied to prevent rust and wear.

- Final Inspection: A thorough inspection is conducted to identify any defects or inconsistencies before the product is packaged and shipped.

The finishing stage not only improves the visual appeal of the racking systems but also ensures they can withstand harsh warehouse conditions.

What International Standards Govern Quality Assurance in Racking System Manufacturing?

Quality assurance in the manufacturing of supplement warehouse racking systems is governed by several international and industry-specific standards. Key among these is ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, other certifications like CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) standards for certain industrial applications may also apply. These certifications demonstrate compliance with safety and quality standards relevant to specific markets and industries.

Illustrative image related to supplement warehouse racking system

What Quality Control Checkpoints Are Critical in the Manufacturing Process?

Quality control (QC) is an essential aspect of the manufacturing process, typically segmented into various checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor compliance with design specifications. This includes checking welds, dimensions, and coatings.

- Final Quality Control (FQC): Before shipment, a comprehensive evaluation is conducted to ensure the finished product meets all quality criteria and standards.

These checkpoints help identify defects early, reducing the risk of costly recalls or rework.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical. Here are some actionable steps:

- Supplier Audits: Conducting onsite audits can provide insights into the manufacturing processes and quality control measures in place. This allows buyers to evaluate the supplier’s adherence to quality standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC stages.

- Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is especially useful for buyers who may not have the resources to conduct in-depth audits.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers must be aware of specific nuances in quality control that may affect their purchasing decisions. These include:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding these can prevent compliance issues post-purchase.

- Logistics and Handling: Consideration of how products are packaged and shipped is crucial, as improper handling can lead to damage before the product even reaches the buyer.

- Cultural and Communication Barriers: Effective communication regarding quality expectations is essential, especially when dealing with suppliers from different cultural backgrounds.

By understanding these aspects, B2B buyers can make informed decisions and ensure that their chosen suppliers meet the necessary quality standards for supplement warehouse racking systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘supplement warehouse racking system’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure an effective supplement warehouse racking system. As businesses expand and inventory needs grow, optimizing storage solutions becomes critical. This checklist will help you navigate the procurement process, ensuring you choose a system that maximizes efficiency and aligns with your operational requirements.

Step 1: Assess Your Warehouse Space

Understanding your available space is the first step in selecting the right racking system. Measure the dimensions of your warehouse, including ceiling height and floor area, to determine how much storage you can realistically accommodate. Consider factors such as aisle width and access points for forklifts or other machinery, which will impact your layout.

Step 2: Define Your Inventory Types and Volume

Identify the types of supplements you will store and their expected volumes. Different products may require different racking configurations; for instance, bulk items might benefit from pallet racking, while smaller items could be better suited for shelving systems. This step is crucial as it influences the design and capacity of your racking solution.

Step 3: Determine Technical Specifications

Establish the technical requirements for your racking system, including load capacity, materials, and safety features. Ensure that the racking can support the weight of your products and is constructed from durable materials that withstand your warehouse environment. This will prevent costly damage and ensure the longevity of your investment.

Illustrative image related to supplement warehouse racking system

Step 4: Research and Evaluate Suppliers

Conduct thorough research on potential suppliers of warehouse racking systems. Look for companies with a proven track record in your industry and request case studies or testimonials from other B2B clients. A reputable supplier should provide detailed product information and be willing to discuss your specific needs to tailor a solution.

Step 5: Verify Compliance and Certifications

Before making a purchase, verify that the racking systems meet relevant safety and industry standards. Certifications such as ISO or local safety regulations are indicators of a supplier’s commitment to quality. Compliance ensures that your racking system will not only perform effectively but also adhere to safety guidelines, minimizing risks in your warehouse.

Step 6: Request a Detailed Quotation

Ask for a comprehensive quotation that includes all costs associated with the racking system, including delivery, installation, and any additional accessories. A transparent quotation allows for better budget planning and helps you avoid hidden costs down the line. Make sure to compare quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to supplement warehouse racking system

Step 7: Plan for Installation and Training

Finally, consider the logistics of installation and any training required for your staff. A well-planned installation minimizes downtime and disruptions in your operations. Ensure that the supplier offers support during the setup phase and provides training on how to use the racking system effectively and safely.

By following this checklist, you can confidently procure a supplement warehouse racking system that meets your business needs while maximizing efficiency and safety in your storage operations.

Comprehensive Cost and Pricing Analysis for supplement warehouse racking system Sourcing

What Are the Key Cost Components of a Supplement Warehouse Racking System?

When evaluating the cost structure of a supplement warehouse racking system, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the cost. Steel is commonly used for its durability, while lighter materials may reduce costs but could compromise strength. For international buyers, it’s crucial to consider local material availability to minimize transportation costs.

-

Labor: Labor costs vary by region. In countries with higher labor costs, such as those in Europe, the overall expense may be elevated compared to regions in Africa or South America. Understanding local labor markets can help buyers negotiate better rates or consider suppliers who can provide installation services at competitive prices.

-

Manufacturing Overhead: This encompasses costs associated with production facilities, equipment maintenance, and utilities. Buyers should inquire about a supplier’s production capabilities and how these may affect pricing.

-

Tooling: Customization often requires specialized tools, which can increase upfront costs. However, investing in the right tooling can lead to long-term savings through improved efficiency and reduced downtime.

-

Quality Control (QC): Rigorous QC processes ensure that the racking systems meet industry standards and certifications. While this may add to the cost, it is essential for long-term reliability and safety.

-

Logistics: Shipping and handling can be significant factors, particularly for international transactions. Understanding Incoterms (International Commercial Terms) is vital as they define responsibilities for shipping costs, insurance, and tariffs.

-

Margin: Supplier margins can vary widely based on competition and market demand. Buyers should conduct market research to understand typical margins in their region to ensure they receive fair pricing.

How Do Price Influencers Affect the Sourcing of Racking Systems?

Several factors influence the pricing of supplement warehouse racking systems, and recognizing these can aid buyers in making informed decisions.

Illustrative image related to supplement warehouse racking system

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Suppliers may offer better pricing for larger orders, so buyers should assess their current and future needs to leverage volume pricing.

-

Specifications and Customization: Customized racking systems tailored to specific needs can incur higher costs. Buyers should balance customization against standard options to achieve cost efficiency.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO) typically lead to increased costs. However, investing in certified products can minimize risks associated with safety and compliance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to perceived value, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the implications of different Incoterms is crucial. They dictate who is responsible for shipping costs and risks, affecting overall pricing. Buyers should negotiate terms that align with their logistics capabilities.

What Are the Best Buyer Tips for Sourcing Supplement Warehouse Racking Systems?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize sourcing and ensure cost efficiency.

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility that can lead to significant savings.

-

Consider Total Cost of Ownership (TCO): Beyond initial costs, consider maintenance, operational efficiency, and potential downtime. A higher upfront investment might yield lower long-term costs through durability and reduced maintenance.

-

Understand Pricing Nuances: Be aware that international pricing can be affected by currency fluctuations, tariffs, and trade agreements. Staying informed about these factors can help in forecasting costs accurately.

-

Leverage Local Knowledge: Utilize local representatives or consultants who understand regional market dynamics. They can provide valuable insights into supplier capabilities and pricing strategies.

-

Request Multiple Quotes: Always obtain quotes from multiple suppliers to ensure competitive pricing. This also allows for comparison of quality and service levels.

By considering these cost components, price influencers, and buyer tips, B2B buyers can make well-informed decisions in sourcing supplement warehouse racking systems that best meet their operational needs while optimizing costs.

Alternatives Analysis: Comparing supplement warehouse racking system With Other Solutions

Exploring Viable Alternatives to the Supplement Warehouse Racking System

In the quest for efficient warehouse management, businesses often explore various racking systems to optimize space and improve operations. The supplement warehouse racking system is just one option among several alternatives that can enhance storage capabilities. Below, we compare this system with two other viable solutions: Compact Rolling Pallet Racks and Automated Storage Systems. This comparison aims to help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Supplement Warehouse Racking System | Compact Rolling Pallet Racks | Automated Storage Systems |

|---|---|---|---|

| Performance | High density storage with static access | High density with dynamic access | Variable performance based on automation level |

| Cost | Moderate initial investment; variable operational costs | Moderate to high initial investment; lower operational costs | High initial investment; potential for high ROI |

| Ease of Implementation | Relatively easy to install | Requires professional installation | Complex installation and setup |

| Maintenance | Low maintenance; periodic checks needed | Low maintenance; check tracks regularly | High maintenance; requires technical expertise |

| Best Use Case | Ideal for stable inventory with predictable turnover | Best for dynamic inventory and limited space | Suitable for high-volume operations requiring automation |

What are the Benefits and Drawbacks of Compact Rolling Pallet Racks?

Compact Rolling Pallet Racks are designed to maximize storage efficiency by allowing racks to move along tracks, creating adjustable aisles as needed. This system can effectively double storage capacity in the same footprint, making it an excellent choice for businesses facing space constraints. The primary advantage lies in its ability to adapt to changing inventory needs without requiring additional square footage. However, the installation can be more complex and might necessitate professional assistance, leading to higher upfront costs.

Illustrative image related to supplement warehouse racking system

How do Automated Storage Systems Compare?

Automated Storage Systems leverage robotics and technology to manage inventory, providing high-density storage solutions that can drastically reduce picking times and labor costs. These systems offer significant advantages in terms of speed and efficiency, especially for high-volume warehouses. However, they come with a substantial initial investment and ongoing maintenance costs, as they require specialized knowledge for upkeep. Furthermore, the complexity of the installation process may not be suitable for all businesses, particularly smaller operations with limited budgets.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate racking solution, B2B buyers should evaluate their specific operational requirements, including storage capacity, inventory turnover rates, and budget constraints. The supplement warehouse racking system is well-suited for businesses with stable inventory needs, whereas Compact Rolling Pallet Racks are ideal for those requiring flexibility in storage arrangements. For high-volume operations, Automated Storage Systems may offer the best long-term ROI despite their higher initial costs. Ultimately, understanding these factors will empower buyers to choose a solution that aligns with their operational goals and financial resources, ensuring optimal warehouse efficiency.

Essential Technical Properties and Trade Terminology for supplement warehouse racking system

What Are the Critical Technical Properties of Supplement Warehouse Racking Systems?

When considering a supplement warehouse racking system, understanding its technical properties is essential for optimizing storage efficiency and safety. Here are some critical specifications to consider:

-

Material Grade

– Racking systems are typically constructed from steel, which offers strength and durability. The material grade, such as structural steel (e.g., ASTM A36), indicates its load-bearing capacity and resistance to corrosion. Higher-grade materials ensure longevity and reduce replacement costs, making them a wise investment for B2B buyers. -

Load Capacity

– This specification refers to the maximum weight each shelf or rack can support. Load capacities vary widely, with some racks supporting thousands of kilograms. Understanding load capacity is vital for ensuring safety and compliance with local regulations, preventing overloading that could lead to structural failure. -

Tolerance Levels

– Tolerance levels indicate the permissible deviation from specified dimensions in the racking system. High precision in manufacturing tolerances (e.g., ±1 mm) ensures that racks fit together correctly and operate smoothly, which is crucial for mobile or dynamic systems. This precision is particularly important for automated warehouses, where even minor errors can lead to significant operational inefficiencies. -

Adjustability

– Many racking systems feature adjustable shelving heights to accommodate various product sizes. This flexibility allows businesses to adapt their storage solutions as inventory needs change, maximizing storage efficiency. Adjustable racking systems can also enhance accessibility, making it easier for warehouse staff to retrieve items. -

Safety Standards Compliance

– Compliance with industry safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the International Organization for Standardization (ISO), is critical. These standards ensure that racking systems are designed and installed to minimize risks, protecting both employees and inventory.

What Trade Terminology Should B2B Buyers Know When Purchasing Racking Systems?

Familiarity with industry jargon can streamline the purchasing process and improve communication with suppliers. Here are some common terms used in the context of warehouse racking systems:

Illustrative image related to supplement warehouse racking system

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a racking system is OEM or aftermarket can influence decisions regarding warranty, support, and compatibility. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for international buyers who may need to consider shipping costs and storage capabilities. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and other details for specific products. Utilizing RFQs can help buyers compare offers effectively, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping contracts. They clarify who is responsible for shipping costs, insurance, and risk management during transportation, which is crucial for international transactions. -

Pallet Positioning

– This term refers to the specific arrangement of pallets within a racking system. Efficient pallet positioning can optimize warehouse space and improve access to inventory, which is particularly important for managing perishable or fast-moving goods. -

Dynamic Racking

– Dynamic racking systems, such as pallet flow or push-back racks, utilize gravity to facilitate the movement of goods. This term is essential for buyers looking to enhance their warehouse efficiency, as dynamic systems often reduce picking times and increase inventory turnover.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when investing in supplement warehouse racking systems, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the supplement warehouse racking system Sector

What Are the Key Market Dynamics and Trends Influencing the Supplement Warehouse Racking System Sector?

The global supplement warehouse racking system sector is witnessing a transformative phase driven by various market dynamics and emerging technologies. One of the significant drivers is the increasing demand for health and wellness products, particularly in regions like Africa and South America, where dietary supplements are gaining popularity. As e-commerce continues to expand, B2B buyers are looking for innovative storage solutions that optimize space and improve operational efficiency. Mobile storage systems, such as compact rolling pallet racks, are emerging as a preferred choice due to their ability to maximize warehouse space while ensuring easy access to products.

Moreover, the rise of automation and smart technology in warehouse management is reshaping sourcing trends. Technologies like RFID for inventory tracking and automated pallet systems are becoming essential for businesses aiming to streamline their operations. This shift is particularly relevant for international buyers who seek to enhance their logistical capabilities and reduce overhead costs. Sustainable practices are also gaining traction, with many businesses prioritizing eco-friendly materials and energy-efficient systems. This trend is essential for buyers in Europe and the Middle East, where regulations regarding sustainability are becoming increasingly stringent.

How Are Sustainability and Ethical Sourcing Impacting the Supplement Warehouse Racking System Sector?

The importance of sustainability in the warehouse racking system sector cannot be overstated, especially for B2B buyers who are increasingly conscious of their environmental footprint. The manufacturing and disposal of racking systems can significantly impact the environment, prompting businesses to adopt more sustainable practices. Ethical sourcing of materials is becoming a priority, with suppliers focusing on using recycled or sustainably sourced steel and other materials for their products.

Moreover, obtaining green certifications is gaining relevance, as many international buyers prefer suppliers who can demonstrate compliance with environmental standards. Certifications such as ISO 14001 for environmental management and sustainable sourcing certifications can enhance a company’s reputation and marketability. This trend is particularly relevant for buyers in regions like Europe, where consumers and businesses alike are demanding more transparency and accountability in supply chains.

Illustrative image related to supplement warehouse racking system

What Is the Historical Context of the Supplement Warehouse Racking System Sector?

The supplement warehouse racking system sector has evolved significantly over the past few decades. Initially, traditional static racking systems dominated the market, limiting flexibility and efficiency. However, as the health supplement industry grew and e-commerce began to thrive, the demand for more dynamic and space-efficient solutions emerged. Innovations such as mobile racking systems and automated storage solutions began to take center stage, allowing businesses to adapt to changing demands and optimize their storage capabilities.

Today, the sector is characterized by a blend of traditional and advanced storage solutions, catering to a diverse range of businesses across various markets. This evolution reflects the broader trends in logistics and supply chain management, where efficiency, sustainability, and technology integration are paramount for success in the competitive landscape. For B2B buyers, understanding this historical context is crucial for making informed sourcing decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of supplement warehouse racking system

-

How do I solve space constraints in my warehouse?

To address space constraints in your warehouse, consider implementing a compact racking system, such as mobile pallet racks on tracks. This system allows for efficient use of floor space by enabling racks to roll and create movable aisles, effectively doubling storage capacity without expanding the warehouse footprint. Evaluate your current inventory levels and layout to identify the best configuration for your needs. Consult with storage solution experts to design a tailored system that maximizes both storage and operational efficiency. -

What is the best racking system for supplement storage?

The optimal racking system for supplement storage is typically a combination of adjustable pallet racks and mobile shelving units. Adjustable racks provide flexibility for various supplement sizes, while mobile systems enhance accessibility and maximize storage density. Consider factors like weight capacity, ease of access, and the specific types of supplements you store. It’s essential to work with suppliers who understand the unique requirements of supplement warehousing to ensure compliance with safety and regulatory standards. -

How can I vet international suppliers for racking systems?

To vet international suppliers, start by researching their reputation and customer reviews. Look for certifications and compliance with international standards such as ISO or local regulations. Request references from previous clients and assess their experience with similar projects. Conduct a financial health check to ensure stability, and consider visiting their facilities if possible. Establishing clear communication channels and understanding their manufacturing processes will also help ensure they can meet your quality and delivery expectations. -

What customization options are available for warehouse racking systems?

Customization options for warehouse racking systems can include adjustable heights, widths, and depths to accommodate different supplement sizes. You can also choose between static and mobile systems based on your operational needs. Additional features may include specialized coatings for humidity resistance or built-in safety mechanisms. Discuss your specific requirements with potential suppliers to explore tailored solutions that enhance the functionality and efficiency of your storage space. -

What is the minimum order quantity (MOQ) for warehouse racking systems?

Minimum order quantities (MOQ) for warehouse racking systems vary by supplier and can depend on factors such as manufacturing processes and inventory levels. Generally, MOQs can range from a few units to several dozen. If you have specific needs or a smaller operation, discuss your requirements with suppliers; many are willing to accommodate smaller orders, especially for customized solutions. Understanding the MOQ can help you budget effectively and ensure you receive the right equipment for your warehouse. -

What payment terms should I expect when sourcing racking systems?

Payment terms for sourcing racking systems can vary significantly among suppliers. Common terms include a deposit upon order confirmation, followed by the balance due before shipment or on delivery. Some suppliers may offer financing options or extended payment plans for larger orders. Always clarify payment terms upfront and ensure they align with your budget and cash flow. Additionally, consider negotiating terms that provide flexibility, especially if your order size or delivery timeline changes. -

How do I ensure quality assurance for my racking systems?

To ensure quality assurance for your racking systems, request product samples and detailed specifications before finalizing your order. Verify that the supplier adheres to quality control standards and has a robust inspection process in place. Look for third-party certifications that validate the quality of materials used in their racking systems. Establish a clear agreement regarding warranty terms and after-sales support to address any potential issues that may arise post-installation. -

What logistics considerations should I keep in mind when importing racking systems?

When importing racking systems, consider shipping methods, customs regulations, and potential duties or taxes that may apply. Work with a logistics provider experienced in international shipping to navigate these complexities. Ensure that the racking systems are properly packaged to avoid damage during transit. Additionally, plan for lead times and coordinate with your supplier for timely delivery to avoid disruptions in your operations. Having a clear logistics strategy will help streamline the process and reduce costs.

Top 10 Supplement Warehouse Racking System Manufacturers & Suppliers List

1. Coast Label – Warehouse Storage Systems

Domain: coastlabel.com

Registered: 1997 (28 years)

Introduction: Warehouse Storage Systems: A combination of methods and equipment to organize, store, and manage products in a warehouse. Benefits include optimized space use, better inventory management, and increased productivity. Types of systems discussed include: 1. Supplement Warehouse Racking System: Specialized for dietary supplements with types like selective pallet racking, flow racking, and temperature…

2. Nationwide Shelving – Heavy-Duty Rack for Supplement Storage

Domain: nationwideshelving.com

Registered: 2004 (21 years)

Introduction: Rack for Supplement Storage: Designed for Inno-Vita to store vitamin supplements in a warehouse. Features include roll formed columns and beams with fully welded base plates for heavy-duty bracing, available in various sizes and weight capacities. Adaptable to different storage weights and sizes, suitable for bulk packages of vitamin supplements. Wire decking requested for easier loading/unloading…

3. Lyon Workspace – Heavy-Duty Pallet Racking

Domain: lyonworkspace.com

Registered: 2000 (25 years)

Introduction: Industrial pallet racking designed for heavy-duty warehouse use. Features include:

– Roll formed industrial pallet racking uprights with a strong strength-to-weight ratio.

– 100% MIG welded with precision k-braces and heavy-duty cross channel reinforcements.

– Tapered keyhole slots on 2-inch centers for easy beam adjustment.

– Teardrop design compatible with all major teardrop style products.

– Du…

4. NAI – Supplement Warehousing Solutions

Domain: nai-online.com

Registered: 1996 (29 years)

Introduction: Supplement Warehousing is essential for preserving the quality and potency of dietary supplements. NAI addresses unique challenges in supplement storage and packaging by managing physical and chemical factors, as well as storage time. Key challenges include: 1. Physical Factors: Different forms of supplements (tablets, powders) have distinct storage requirements. 2. Chemical Factors: pH levels, tr…

5. Southwest Solutions – Compact Rolling Pallet Racks

Domain: southwestsolutions.com

Registered: 1997 (28 years)

Introduction: Compact Rolling Pallet Racks on Tracks are motorized pallet racks designed to optimize warehouse floor space. They allow for the rolling and compacting of pallet storage areas, effectively reducing the required space by half. The racks are mounted on rolling structures and placed on floor tracks, enabling them to move sideways to create access aisles. This system can help centralize storage, elimi…

6. KPI Solutions – Warehouse Storage & Pallet Racking

Domain: kpisolutions.com

Registered: 2006 (19 years)

Introduction: Warehouse Storage and Pallet Racking solutions by KPI Solutions include traditional and modern storage options designed to optimize warehouse space and enhance efficiency. Key offerings include: 1. Twinlode Racking: Innovative dual-pallet storage system maximizing storage density and product accessibility, suitable for high-volume products. 2. Static Warehouse Storage: Includes selective pallet ra…

7. Rackson Tracks – High Density Mobile Storage Solutions

Domain: racksontracks.com

Registered: 2010 (15 years)

Introduction: Rolling Warehouse Racking, Compact Pallet Racks on Tracks, Mobile Storage, High Density Shelving, Sliding Bi-file & Tri-files, Rotary Cabinets, Stationary Shelving, Mailroom Furniture, Industrial Storage Equipment, Automated Storage Carousels, Box Shelving, Weapons Racks, Modular Casework, Demountable Walls, Art Storage Racks. Features include: rolling pallet racks that can be compacted to save sp…

8. SJF Material Handling – Warehouse Racking Systems

Domain: sjf.com

Registered: 1996 (29 years)

Introduction: SJF Material Handling offers a variety of warehouse racking systems including:

1. **Pallet Racks Systems**:

– **Teardrop Pallet Racking**: Versatile shelving system for efficient, high-capacity storage of palletized goods with forklift access.

– **Drive-In Racking**: High-density system for bulk storage of uniform products, allowing forklifts to drive directly into rack bays.

– **Struct…

9. MHE – Pallet Racking Systems

Domain: m-h-e.com

Registered: 1997 (28 years)

Introduction: Pallet Racking Systems include various components such as Pallet Rack Beams, Pallet Rack Uprights, Structural Pallet Racking, Pallet Rack Supports, Cantilever Racks, and Wire Decks. The product offerings feature both new and used pallet racks, including starter kits and adder kits in multiple sizes and configurations. Specific products include MHE Teardrop Pallet Rack Starter Kits and Adder Kits i…

10. Mecalux – Mobile Racking (Movirack)

Domain: mecalux.com

Registered: 1996 (29 years)

Introduction: Mobile Racking (Movirack) is a high-density storage solution that increases storage capacity by 80 to 120% compared to conventional pallet racking while allowing direct access to all pallets. The system consists of racks mounted on motorised mobile bases that move laterally along rails, optimising the volume occupied by the storage system. Key advantages include: increased storage capacity, direct…

Strategic Sourcing Conclusion and Outlook for supplement warehouse racking system

In conclusion, the effective strategic sourcing of supplement warehouse racking systems is pivotal for optimizing operational efficiency and maximizing storage capabilities. By investing in advanced solutions such as compact rolling pallet racks, businesses can not only enhance space utilization but also streamline workflow processes. The case study of Donald’s company illustrates the tangible benefits, including significant cost savings from reduced auxiliary warehouse needs and the ability to repurpose space for additional workstations.

Illustrative image related to supplement warehouse racking system

For international B2B buyers, particularly those in emerging markets across Africa, South America, the Middle East, and Europe, the opportunity to leverage innovative storage solutions is immense. As your operations grow, so does the necessity for adaptable and efficient storage systems that cater to diverse product lines and fluctuating inventory levels.

Moving forward, we encourage you to explore tailored warehouse racking solutions that align with your specific business needs. Embrace the potential for increased productivity and cost efficiency by reaching out to suppliers who can offer expert guidance and support in your strategic sourcing journey. The right investment today can lay the groundwork for sustainable growth tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to supplement warehouse racking system

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.