Is Your Sunwest Containers Phoenix Arizona Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for sunwest containers phoenix arizona

In today’s dynamic global marketplace, sourcing high-quality packaging solutions, such as Sunwest containers from Phoenix, Arizona, presents a significant challenge for international B2B buyers. Companies must navigate a myriad of options while ensuring that their chosen containers meet stringent industry standards and align with their specific operational needs. This comprehensive guide serves as an essential resource, offering insights into the diverse types of containers available, their applications across various industries, and the critical aspects of supplier vetting.

Within these pages, you will find detailed information on the range of products offered by Sunwest Container Co., including plastic containers, steel plastic fiber drums, and customizable options tailored to unique business requirements. We will also delve into cost considerations, sustainability practices, and logistical solutions, all designed to empower you to make informed purchasing decisions.

By focusing on the needs of international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Nigeria—this guide aims to bridge the gap between global sourcing challenges and effective packaging solutions. Our objective is to equip you with the knowledge and tools necessary to select reliable suppliers and optimize your packaging strategy, ensuring that your products are protected and presented effectively in the marketplace.

Understanding sunwest containers phoenix arizona Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Bottles | Lightweight, customizable sizes and shapes | Beverage, pharmaceuticals, cosmetics | Pros: Versatile, cost-effective. Cons: Limited durability compared to rigid containers. |

| Plastic Jugs | Larger capacity, ergonomic design for pouring | Household cleaning products, chemicals | Pros: Easy to handle, ideal for bulk storage. Cons: May not be suitable for high-viscosity liquids. |

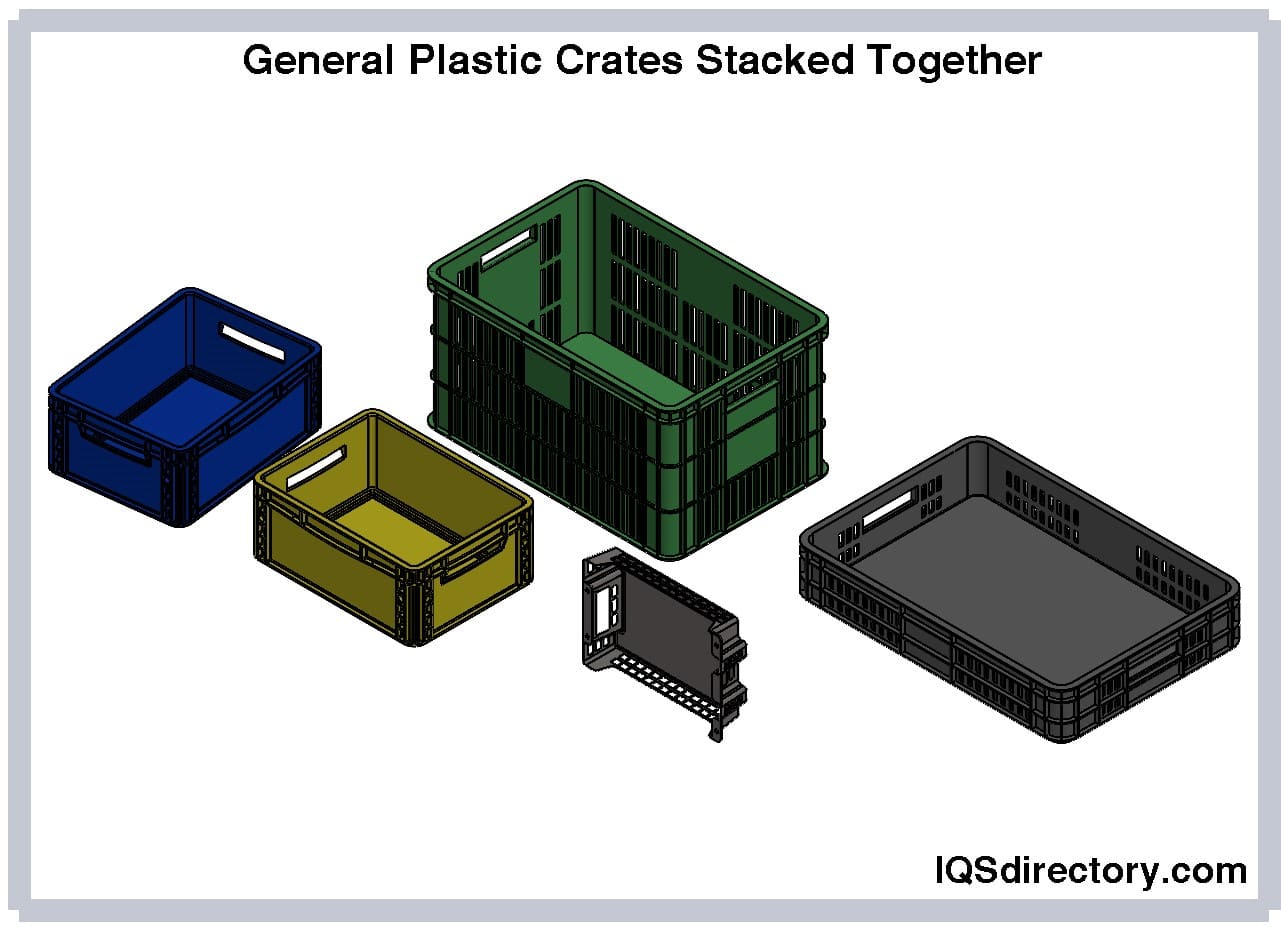

| Plastic Crates | Stackable, durable, often made from recycled materials | Logistics, warehousing, agriculture | Pros: Space-efficient, reusable. Cons: Initial investment can be high. |

| Steel Plastic Fibre Drums | Robust construction, suitable for hazardous materials | Industrial chemicals, lubricants | Pros: Excellent durability, compliant with safety standards. Cons: Heavier and more expensive than plastic alternatives. |

| Plastic Tanks | Large volume, customizable configurations | Water storage, agricultural applications | Pros: Long-lasting, resistant to weathering. Cons: Requires careful handling during transport. |

What Are the Characteristics of Plastic Bottles and Their Suitability for B2B Buyers?

Plastic bottles are lightweight containers that can be customized in various sizes and shapes, making them ideal for diverse applications in industries such as beverages, pharmaceuticals, and cosmetics. Their versatility allows businesses to tailor the design to fit branding needs, including color and labeling options. When purchasing, B2B buyers should consider the specific material used, as some plastics may offer better chemical resistance than others, ensuring product integrity during storage and transport.

How Do Plastic Jugs Meet the Needs of Different Industries?

Plastic jugs are characterized by their larger capacities and ergonomic designs, making them easy to pour and handle. They are commonly used in sectors such as household cleaning and chemicals. B2B buyers should evaluate the jug’s compatibility with the product it will contain, particularly for high-viscosity liquids, as some jug designs may not be suited for thicker formulations. Additionally, customization options can enhance branding efforts while maintaining functionality.

What Advantages Do Plastic Crates Offer for Logistics and Warehousing?

Plastic crates are designed for stackability and durability, often made from recycled materials, which makes them an environmentally friendly choice. They are widely used in logistics, warehousing, and agricultural applications due to their space-efficient design and reusability. Buyers should consider the initial investment against long-term savings from reduced waste and the ability to reuse crates multiple times. The choice of crate size and design should align with the specific storage and transport needs of the business.

Why Are Steel Plastic Fibre Drums Considered a Reliable Choice for Industrial Packaging?

Steel plastic fibre drums are engineered for strength and durability, making them suitable for storing hazardous materials and industrial chemicals. Their robust construction ensures compliance with safety standards, providing peace of mind for businesses handling sensitive products. Buyers should be aware of the weight and cost implications, as these drums tend to be heavier and more expensive than their plastic counterparts. However, their long-term reliability often justifies the initial investment.

What Should B2B Buyers Consider When Selecting Plastic Tanks?

Plastic tanks are large-volume storage solutions customizable for various applications, including water storage and agricultural use. Their resistance to weathering and durability make them an excellent choice for long-term storage. When purchasing, buyers should assess the tank’s size, configuration, and material compatibility with the intended contents. Additionally, considerations regarding installation and transport logistics are crucial to ensure the tanks meet operational needs effectively.

Key Industrial Applications of sunwest containers phoenix arizona

| Industry/Sector | Specific Application of Sunwest Containers Phoenix Arizona | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Bulk storage and transportation of ingredients | Ensures product integrity and compliance with safety standards | Need for food-grade materials, temperature control, and certifications |

| Chemical Manufacturing | Packaging of hazardous materials | Provides secure containment and prevents leaks during transport | Compliance with international safety regulations and durability |

| Agriculture and Horticulture | Storage and transport of seeds and fertilizers | Protects products from moisture and pests, ensuring quality | Customization options for size and shape to fit specific needs |

| Pharmaceuticals | Packaging for medical supplies and drugs | Ensures sterility and safety, crucial for patient health | Regulatory compliance, traceability, and tamper-evident features |

| Retail and E-commerce | Branded packaging for consumer goods | Enhances brand visibility and customer appeal | Customization options for branding and quick turnaround times |

How Are Sunwest Containers Used in the Food and Beverage Industry?

In the food and beverage sector, Sunwest containers are essential for the bulk storage and transportation of ingredients such as grains, liquids, and other perishable items. These containers are designed to meet stringent food safety standards, ensuring that products remain uncontaminated during transit. For international buyers, particularly from regions like Africa and South America, sourcing containers that comply with local regulations is critical. Additionally, the ability to customize sizes and shapes allows businesses to optimize storage space and streamline their supply chain.

What Role Do Sunwest Containers Play in Chemical Manufacturing?

Sunwest containers are widely used in chemical manufacturing for the packaging of hazardous materials. These robust containers are engineered to withstand harsh conditions and prevent leaks, ensuring safe transport and storage. For international B2B buyers, especially in the Middle East, it is vital to consider compliance with international safety standards and regulations governing the transport of hazardous substances. Sunwest’s commitment to quality and durability provides peace of mind for businesses needing reliable packaging solutions.

Why Are Sunwest Containers Important for Agriculture and Horticulture?

In agriculture and horticulture, Sunwest containers facilitate the storage and transport of seeds, fertilizers, and other agricultural inputs. These containers are designed to protect products from moisture and pests, which is crucial for maintaining quality. For buyers in regions like Nigeria and Brazil, sourcing containers that can withstand varying climates and environmental conditions is essential. Customization options, such as specific sizes and shapes, help farmers and distributors optimize their logistics and storage processes.

How Do Sunwest Containers Support the Pharmaceutical Industry?

In the pharmaceutical sector, Sunwest containers are vital for packaging medical supplies and drugs. These containers ensure sterility and safety, which are paramount for patient health. International buyers must prioritize suppliers that offer compliance with strict regulatory requirements, including traceability and tamper-evident features. Sunwest’s expertise in creating customized solutions allows pharmaceutical companies to maintain product integrity while enhancing their branding efforts.

What Benefits Do Sunwest Containers Offer to Retail and E-commerce Businesses?

For retail and e-commerce businesses, Sunwest containers provide an effective solution for branded packaging of consumer goods. The ability to customize containers with logos and designs enhances brand visibility and customer appeal. Quick turnaround times are essential for businesses looking to meet market demands, especially in fast-paced environments. For international buyers, understanding the logistics of sourcing and shipping these containers is crucial for maintaining competitive advantage in the global marketplace.

3 Common User Pain Points for ‘sunwest containers phoenix arizona’ & Their Solutions

Scenario 1: Supply Chain Disruptions in Container Procurement

The Problem:

B2B buyers often face significant challenges when procuring containers, especially in times of global supply chain disruptions. For instance, a manufacturer in Brazil may experience delays due to shipping bottlenecks, leading to an inability to secure essential packaging from Sunwest Containers in Phoenix, Arizona. This can result in halted production lines, missed deadlines, and ultimately, financial losses. The lack of clear communication regarding order status and shipping timelines can further exacerbate buyer frustration.

The Solution:

To mitigate supply chain disruptions, it is crucial for buyers to establish a robust communication channel with Sunwest Containers. Buyers should initiate regular check-ins to monitor the status of their orders and discuss potential delays. Utilizing Sunwest’s quick turnaround capabilities can also provide a buffer against unforeseen circumstances. Additionally, buyers should consider diversifying their sourcing strategy by establishing relationships with multiple suppliers, thereby reducing dependency on a single source. Engaging in proactive planning, such as placing orders well in advance of peak seasons, can also ensure that critical containers are available when needed.

Scenario 2: Inadequate Customization Options for Unique Products

The Problem:

Many B2B buyers require specific container designs to meet their branding or functional needs. A company in Nigeria, for example, may need custom-sized containers with specific printing for its unique product line. If Sunwest Containers does not offer adequate customization options or if the process is too complex, it can lead to a mismatch between the container and the product, ultimately affecting the product’s marketability.

The Solution:

Buyers should leverage Sunwest’s expertise in customization by clearly outlining their specific requirements during the initial consultations. It’s beneficial to provide detailed specifications, including size, color, and branding elements. Buyers can also request samples of customized containers to ensure they meet expectations before placing a larger order. Additionally, taking advantage of Sunwest’s knowledgeable sales team can guide buyers through the customization process and help them explore innovative solutions that align with their branding strategy.

Scenario 3: Environmental Concerns and Sustainability Requirements

The Problem:

As global awareness of environmental issues rises, many B2B buyers are under pressure to source sustainable packaging solutions. A company in South America may find that its customers are increasingly demanding eco-friendly packaging options, yet they are uncertain whether Sunwest Containers offers compliant products that meet these sustainability standards. The challenge lies in navigating the myriad of options and ensuring that the chosen containers are genuinely environmentally responsible.

The Solution:

To address these sustainability concerns, B2B buyers should engage directly with Sunwest Containers to inquire about their eco-friendly product offerings. Buyers can request detailed information on materials used, such as recycled plastics or biodegradable options, to ensure compliance with their sustainability goals. Furthermore, attending industry trade shows or webinars where Sunwest presents its latest innovations can provide valuable insights into sustainable practices. Buyers should also consider incorporating sustainability criteria into their procurement process, ensuring that all future container purchases align with their environmental commitments.

Strategic Material Selection Guide for sunwest containers phoenix arizona

What Are the Key Materials Used in Sunwest Containers, Phoenix Arizona?

In the manufacturing of containers at Sunwest Containers, several materials are commonly utilized, each with distinct properties, advantages, and disadvantages. Understanding these materials can aid international B2B buyers in making informed decisions based on their specific needs.

How Do Polypropylene Containers Perform in Various Applications?

Polypropylene (PP) is a widely used thermoplastic polymer known for its versatility and resilience. Its key properties include excellent chemical resistance, a high melting point (around 160°C), and good impact resistance, making it suitable for a variety of applications, including food and chemical storage.

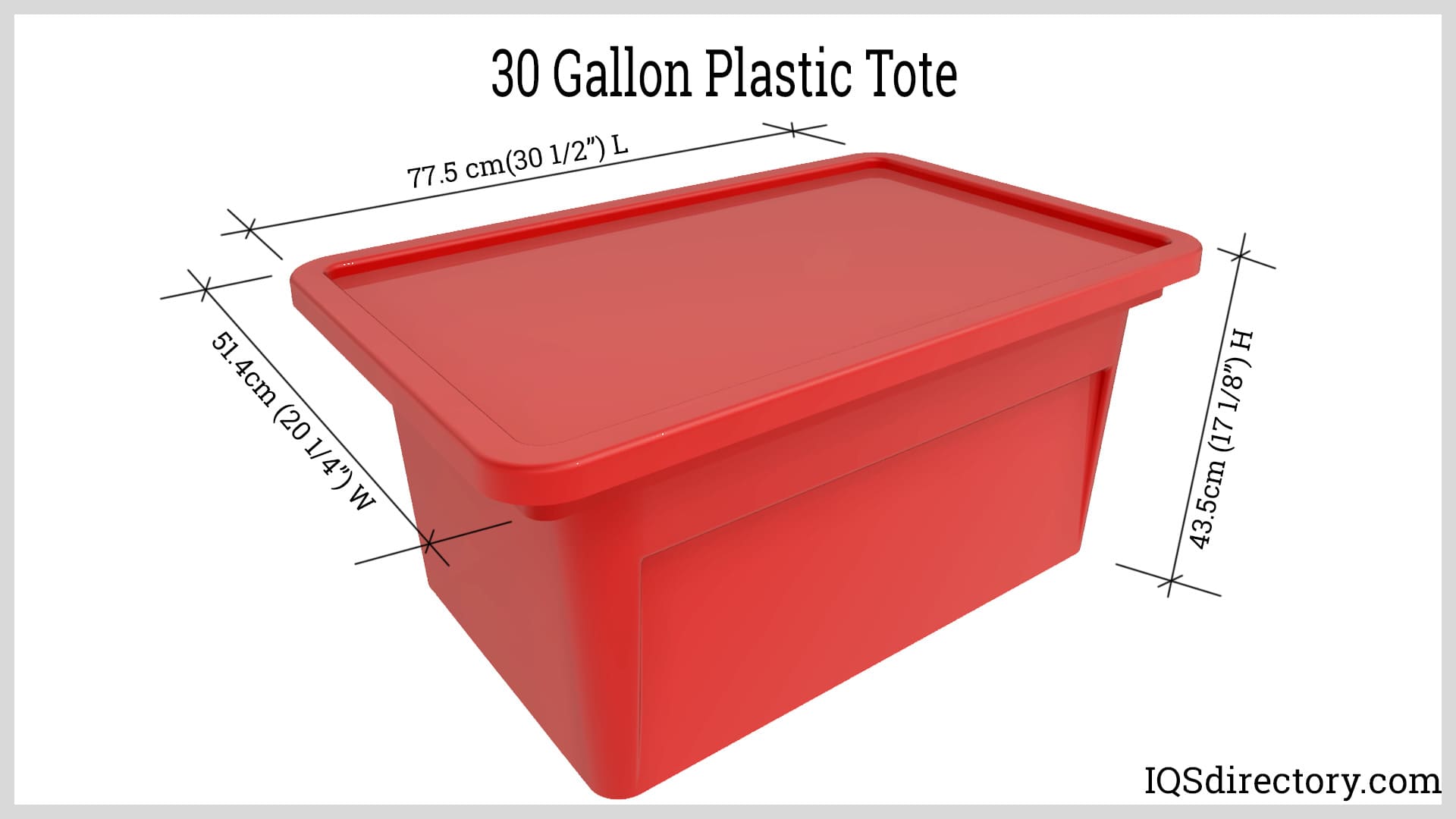

Illustrative image related to sunwest containers phoenix arizona

Pros: Polypropylene containers are lightweight, cost-effective, and resistant to moisture, which enhances their durability. They can also be easily molded into various shapes and sizes, allowing for customization.

Cons: However, polypropylene may not be suitable for applications involving extreme temperatures or prolonged exposure to UV light, which can lead to degradation over time. Additionally, while it is recyclable, the recycling process can be complex.

Impact on Application: Polypropylene is compatible with a wide range of media, including food products and non-hazardous chemicals, making it a popular choice for industries such as food and beverage, pharmaceuticals, and consumer goods.

Considerations for International Buyers: Buyers from regions like Africa, South America, and the Middle East should ensure that polypropylene containers meet local food safety and environmental regulations, such as those outlined by ASTM or DIN standards.

What Are the Benefits of Using High-Density Polyethylene (HDPE) Containers?

High-Density Polyethylene (HDPE) is another prevalent material in container manufacturing. Known for its high strength-to-density ratio, HDPE offers excellent resistance to impact and chemicals, with a melting point of approximately 120°C.

Pros: HDPE containers are durable, lightweight, and resistant to moisture and chemicals, making them ideal for storing hazardous materials and liquids. They are also recyclable, which appeals to environmentally conscious businesses.

Cons: The main drawback of HDPE is its susceptibility to UV degradation if not treated, which can limit its outdoor applications. Additionally, while HDPE is generally cost-effective, the initial manufacturing costs can be higher compared to other plastics.

Impact on Application: HDPE is particularly well-suited for applications involving chemicals, detergents, and food products, due to its non-reactive nature.

Illustrative image related to sunwest containers phoenix arizona

Considerations for International Buyers: Companies in regions such as Europe and the Middle East should verify that HDPE containers comply with relevant safety and environmental standards, including those set by the European Union.

Why Choose Steel Plastic Fibre Drums for Heavy-Duty Applications?

Steel Plastic Fibre Drums combine the strength of steel with the lightweight properties of plastic and fiber, making them ideal for heavy-duty applications. These drums are designed to withstand high pressures and temperatures, with a typical pressure rating of up to 10 bar.

Pros: The primary advantage of these drums is their durability and ability to protect contents from external factors. They are also customizable in terms of size and closure options, which enhances their versatility.

Cons: The manufacturing complexity of Steel Plastic Fibre Drums can lead to higher costs compared to single-material containers. Additionally, they may require more careful handling due to their weight.

Illustrative image related to sunwest containers phoenix arizona

Impact on Application: These drums are suitable for transporting hazardous materials, chemicals, and heavy industrial goods, ensuring safety and compliance during transit.

Considerations for International Buyers: Buyers should ensure that these drums meet international shipping and safety regulations, particularly for hazardous materials, which can vary significantly across regions.

Summary of Material Options for Sunwest Containers

| Material | Typical Use Case for sunwest containers phoenix arizona | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Food and chemical storage | Lightweight and cost-effective | Not suitable for extreme temperatures | Low |

| High-Density Polyethylene (HDPE) | Storing hazardous materials and liquids | Excellent chemical resistance | Susceptible to UV degradation | Medium |

| Steel Plastic Fibre Drums | Transporting hazardous materials and industrial goods | Durable and customizable | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of material options available at Sunwest Containers, enabling international B2B buyers to make informed choices based on their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sunwest containers phoenix arizona

What Are the Main Stages of Manufacturing at Sunwest Containers in Phoenix, Arizona?

Sunwest Containers employs a systematic approach to manufacturing plastic containers, ensuring each product meets stringent quality standards. The manufacturing process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality raw materials, typically involving various types of plastics, including polyethylene and polypropylene. These materials are sourced from reputable suppliers who adhere to industry standards. The materials undergo rigorous testing to ensure they meet specifications for strength and durability before they are approved for use in production.

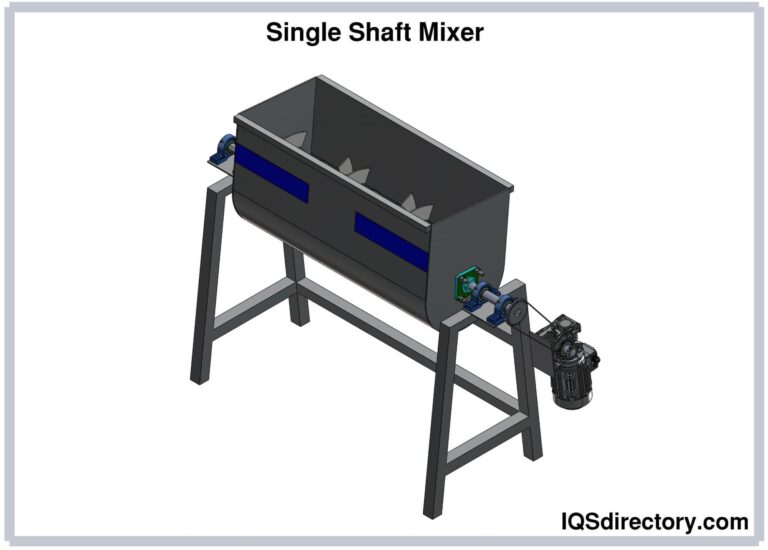

Illustrative image related to sunwest containers phoenix arizona

Forming Techniques

Once the materials are prepared, they move to the forming stage. Sunwest utilizes advanced manufacturing techniques such as injection molding and blow molding. Injection molding allows for the production of intricate shapes and designs, ideal for containers with specific branding requirements. Blow molding, on the other hand, is employed for creating hollow containers, such as bottles and jugs, providing a lightweight yet sturdy solution for packaging needs.

Assembly

After forming, the components are assembled. This stage may involve attaching lids, labels, or additional features tailored to customer specifications. Automation plays a significant role here, improving efficiency and consistency. Skilled technicians oversee the assembly process to ensure all components fit correctly and meet the design criteria.

Finishing Processes

The final stage involves finishing processes, which may include surface treatments, labeling, and packaging. Containers are often treated to enhance their appearance and performance, such as UV protection or anti-static coatings. Custom branding options, including color matching and printed logos, are also available to help businesses establish their product identity.

How Does Sunwest Containers Ensure Quality Control Throughout Manufacturing?

Quality assurance at Sunwest Containers is integral to its manufacturing process, incorporating various international standards and industry-specific certifications. This commitment to quality is reflected in their adherence to ISO 9001 standards, which provide a framework for consistent quality management practices.

Key Quality Control Checkpoints

Quality control is embedded at multiple checkpoints during the manufacturing process, including:

-

Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet the required specifications. This step is critical to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the production process. This includes monitoring temperature, pressure, and material flow in real-time to catch any deviations early.

-

Final Quality Control (FQC): After production, finished products undergo rigorous testing. This includes visual inspections, dimensional checks, and functionality tests to ensure they meet both internal standards and customer requirements.

Common Testing Methods

Testing methods include tensile strength tests, impact resistance tests, and leak tests, ensuring that the containers can withstand the rigors of transportation and usage. Sunwest Containers also conducts environmental testing to evaluate how products perform under varying temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of suppliers like Sunwest Containers. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s operational practices. This can include reviewing quality control documentation, observing manufacturing processes, and interviewing key personnel.

-

Requesting Quality Reports: B2B buyers should request detailed quality reports that outline the results of testing and inspections conducted throughout the manufacturing process. These reports should include data on defect rates, compliance with standards, and corrective actions taken for any issues identified.

-

Third-Party Inspections: Engaging independent third-party inspection services can help validate the quality claims made by suppliers. These services can conduct on-site inspections and testing to ensure compliance with international standards and customer specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is essential for international B2B buyers. Different regions may have varying regulatory requirements and standards. For instance, buyers from Europe may be particularly concerned with CE marking, which indicates compliance with European safety, health, and environmental protection legislation.

Additionally, buyers should be aware of specific industry standards that may apply based on the intended use of the containers. For example, containers intended for food and beverage applications must comply with regulations set forth by organizations such as the FDA in the United States or EFSA in Europe.

Illustrative image related to sunwest containers phoenix arizona

It is also crucial to build strong communication channels with suppliers. Establishing clear expectations regarding quality standards and compliance can help mitigate risks associated with international procurement. Regular updates on production schedules, quality issues, and corrective actions taken can foster trust and transparency between buyers and suppliers.

Conclusion

Sunwest Containers in Phoenix, Arizona, exemplifies a commitment to high-quality manufacturing processes and robust quality assurance practices. By understanding the manufacturing stages and quality control measures in place, international B2B buyers can make informed decisions when sourcing plastic containers. Emphasizing thorough verification processes, compliance with international standards, and open communication will enable buyers to establish reliable partnerships with suppliers, ensuring their packaging needs are met effectively and efficiently.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sunwest containers phoenix arizona’

Introduction

Sourcing plastic containers from Sun West Container Co. in Phoenix, Arizona, can be a strategic move for businesses seeking reliable packaging solutions. This guide provides a comprehensive checklist to help international B2B buyers effectively navigate the procurement process, ensuring they select the right containers tailored to their specific needs.

Illustrative image related to sunwest containers phoenix arizona

-

Step 1: Define Your Technical Specifications

Clearly articulating your container requirements is essential. Consider the type of products you will store or transport and the necessary material properties, such as durability, resistance to chemicals, and weight capacity. Specify dimensions, closure types, and any regulatory compliance needed for your industry. -

Step 2: Research Supplier Capabilities

Investigate Sun West Container Co.’s range of products and services. Look for detailed descriptions of their plastic containers, including customization options like color and branding. Understanding their manufacturing capabilities can help you determine if they can meet your specific needs and production volumes. -

Step 3: Evaluate Potential Suppliers

It’s crucial to thoroughly vet suppliers before making a commitment. Request company profiles, case studies, and references from buyers in a similar industry or region. Investigate their reputation for quality and customer service to ensure they align with your standards. -

Step 4: Verify Certifications and Compliance

Ensure that Sun West Container Co. complies with industry standards and regulations. Ask for certifications related to quality management (e.g., ISO certifications) and environmental practices. This step is vital to mitigate risks associated with product safety and sustainability. -

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the containers you intend to purchase. Testing the samples for durability, usability, and compatibility with your products can help you avoid costly mistakes. Assessing the quality firsthand allows for informed decision-making. -

Step 6: Discuss Customization Options

Engage with the sales team at Sun West Container Co. to explore customization possibilities. Discuss your specific branding requirements, such as logos and color schemes, which can enhance your product’s marketability. Customization can also help differentiate your offerings in competitive markets. -

Step 7: Establish Clear Communication Channels

Building a strong communication framework with your chosen supplier is essential for a successful partnership. Discuss lead times, order tracking, and support for any questions or concerns that may arise during the procurement process. Clear communication can help prevent misunderstandings and ensure timely delivery.

By following this practical sourcing checklist, B2B buyers can effectively navigate the procurement landscape for Sun West Container Co. in Phoenix, Arizona, ensuring they select the right containers for their business needs.

Comprehensive Cost and Pricing Analysis for sunwest containers phoenix arizona Sourcing

What Are the Key Cost Components in Sourcing Sunwest Containers in Phoenix, Arizona?

When considering sourcing from Sunwest Container Co. in Phoenix, Arizona, it is essential to understand the various cost components that contribute to the overall pricing structure. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts cost. Sunwest specializes in high-quality plastics and eco-friendly options, which may carry a premium compared to standard materials. Buyers should assess their specific needs, as opting for recycled or biodegradable materials can affect both price and sustainability credentials.

-

Labor: Labor costs in Phoenix are influenced by local wage standards and the complexity of the manufacturing process. Skilled labor is essential for ensuring quality and efficiency, particularly for customized solutions. Understanding labor rates and productivity levels in the region can provide insights into potential pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Sunwest’s commitment to quality and sustainability may result in higher overhead, but this often translates to better product quality and reliability.

-

Tooling: For customized orders, tooling costs can be a significant factor. These are one-time costs for creating molds or specialized equipment necessary for specific container designs. Buyers should consider whether the investment in tooling aligns with their production volume and long-term needs.

-

Quality Control (QC): Sunwest places a strong emphasis on QC, which is essential for maintaining product standards. The costs associated with rigorous testing and compliance with industry certifications can impact pricing but are crucial for ensuring safety and reliability, especially for international shipments.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) can significantly affect logistics expenses. Understanding the total logistics cost is vital for accurate budgeting.

-

Margin: Suppliers typically include a margin that reflects their costs and desired profit. This margin can vary based on competition, demand, and the perceived value of the product.

How Do Price Influencers Affect Sourcing Decisions for Sunwest Containers?

Several factors can influence the pricing of containers from Sunwest. Understanding these can help B2B buyers make informed decisions.

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders may qualify for bulk discounts, while smaller orders might incur higher per-unit costs. Buyers should assess their needs and potential for future orders to negotiate better terms.

-

Specifications and Customization: Custom containers with specific dimensions, colors, or branding will generally cost more due to additional tooling and production requirements. Buyers should weigh the benefits of customization against the added costs.

-

Materials and Quality Certifications: The choice of materials can affect both the price and the perceived quality of the product. Certifications for food safety, chemical resistance, or environmental standards may also influence costs, as compliant materials often command higher prices.

-

Supplier Factors: The reputation and reliability of Sunwest Container Co. can impact pricing. Established suppliers with a track record of quality and service may charge more, but they also reduce risks associated with sourcing.

-

Incoterms: Understanding Incoterms is critical for international buyers, as they define the responsibilities of buyers and sellers in shipping and delivery. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect total costs.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing?

-

Negotiation: Always approach negotiations with a clear understanding of your requirements and budget. Building a strong relationship with the supplier can lead to better pricing and terms.

-

Total Cost of Ownership: Consider the total cost of ownership rather than just the initial price. This includes logistics, potential custom duties, and long-term durability of the containers.

-

Research Market Trends: Stay informed about market trends, material costs, and technological advancements in container manufacturing. This knowledge can empower buyers to make strategic purchasing decisions.

-

Leverage Relationships: Cultivating long-term relationships with suppliers can lead to favorable pricing and priority service. Regular communication and feedback can also help suppliers better understand your needs.

-

Be Aware of Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and local regulations, which can all influence pricing. Developing a comprehensive understanding of these factors will help in forecasting costs more accurately.

Disclaimer

Prices and costs mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. It is advisable for buyers to conduct their own due diligence and obtain quotes tailored to their unique needs.

Alternatives Analysis: Comparing sunwest containers phoenix arizona With Other Solutions

Understanding Alternatives in Container Solutions

When evaluating packaging solutions, it is essential to consider alternatives that might meet your business needs more effectively or affordably. This analysis compares Sunwest Containers in Phoenix, Arizona, with other viable options available in the market. The goal is to provide international B2B buyers with insights that help them make informed decisions based on performance, cost, and specific use cases.

Illustrative image related to sunwest containers phoenix arizona

Comparison Table

| Comparison Aspect | Sunwest Containers Phoenix Arizona | Alternative 1: U.S. Plastic Corp. | Alternative 2: Greif Inc. |

|---|---|---|---|

| Performance | High durability and customization options | Wide range of materials; robust performance | Strong focus on industrial applications; high strength |

| Cost | Competitive pricing with customization | Generally lower base prices; additional costs for customizations | Premium pricing for specialized containers |

| Ease of Implementation | Quick turnaround and local support | Easy ordering process; extensive online resources | Complex supply chain for international orders |

| Maintenance | Low maintenance; eco-friendly options | Requires adherence to specific storage guidelines | Durable but may need specialized handling for hazardous materials |

| Best Use Case | Versatile applications across industries | Ideal for general-purpose storage | Best for hazardous materials and bulk storage |

Detailed Breakdown of Alternatives

U.S. Plastic Corp.

U.S. Plastic Corp. offers a comprehensive selection of plastic containers and packaging solutions. One of its primary advantages is its competitive pricing, particularly for standard products. The ordering process is straightforward, with extensive online resources that facilitate easy product selection. However, while their base prices are lower, additional costs may arise for customizations. U.S. Plastic Corp. is best suited for businesses looking for general-purpose storage solutions without extensive customization needs.

Greif Inc.

Greif Inc. specializes in industrial packaging solutions, particularly for hazardous materials. Their containers are known for their high strength and durability, making them suitable for demanding applications. However, Greif’s focus on specialized containers leads to a higher price point, which may not be justifiable for all businesses. Additionally, their complex supply chain can pose challenges for international buyers, especially in terms of lead times and logistics. Greif is ideal for companies requiring robust packaging for hazardous materials, but may not be the most cost-effective option for standard needs.

Conclusion: Choosing the Right Container Solution

Selecting the right packaging solution requires a careful assessment of your specific needs, including performance, cost, and ease of implementation. While Sunwest Containers in Phoenix, Arizona, offers a strong balance of customization and competitive pricing, alternatives like U.S. Plastic Corp. and Greif Inc. may provide specific advantages depending on your requirements. Consider your industry, the nature of the products being packaged, and your budget constraints when making a decision. Engaging with suppliers to discuss your unique challenges can further help tailor the solution that best fits your business objectives.

Essential Technical Properties and Trade Terminology for sunwest containers phoenix arizona

What Are the Key Technical Properties of Sunwest Containers in Phoenix, Arizona?

When considering packaging solutions from Sunwest Containers in Phoenix, understanding the technical properties of their products is crucial for making informed purchasing decisions. Here are some essential specifications:

Illustrative image related to sunwest containers phoenix arizona

1. Material Grade

Sunwest Containers utilize high-quality plastics, such as HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate). These materials are known for their durability, chemical resistance, and recyclability. Selecting the right material grade ensures that the containers can withstand the rigors of transportation and storage, which is vital for maintaining product integrity during shipping.

2. Capacity and Size Options

Sunwest offers a variety of container sizes, ranging from small jars to large tanks. Understanding the capacity you need is crucial for inventory management and supply chain efficiency. Having the right size container can minimize waste and optimize storage space, leading to cost savings in logistics and handling.

3. Tolerance Levels

Tolerance refers to the allowable variation in the dimensions and weight of containers. Sunwest Containers maintains stringent tolerance levels to ensure consistency and reliability in their products. This is particularly important for B2B buyers who require precise measurements for compatibility with existing equipment or packaging lines.

4. Closure Systems

The type of closure system used can significantly affect the usability and safety of containers. Sunwest provides various closure options, including screw caps, snap-on lids, and tamper-evident seals. Selecting the right closure system is essential for product protection and compliance with safety regulations, especially when packaging hazardous materials.

5. Customization Capabilities

Sunwest Containers offers extensive customization options, including color, size, and branding. This flexibility is crucial for businesses looking to establish a unique market identity. Customization can enhance brand visibility and consumer trust, making it a valuable aspect of packaging strategy.

Illustrative image related to sunwest containers phoenix arizona

What Are Common Trade Terms Used in the Container Industry?

Familiarity with industry jargon can streamline communication and negotiation processes for B2B buyers. Here are some common terms related to Sunwest Containers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of Sunwest Containers, they may work with OEMs to provide customized packaging solutions that meet specific manufacturing requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding the MOQ is essential for businesses to manage their budget and inventory effectively. Sunwest Containers may have different MOQs based on product type or customization options.

3. RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers. When engaging with Sunwest Containers, submitting an RFQ can help businesses get accurate quotes based on their specific needs, including quantity, customization, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Knowing these terms is crucial for B2B buyers from regions like Africa or South America, as it clarifies who bears the risk and costs at different stages of the shipping process.

Illustrative image related to sunwest containers phoenix arizona

5. Sustainability Practices

This term encompasses the eco-friendly initiatives that Sunwest Containers employs, such as using recycled materials and biodegradable options. Businesses increasingly prioritize sustainability in their supply chains, making it an essential consideration when selecting packaging partners.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing packaging solutions from Sunwest Containers in Phoenix, Arizona. This knowledge not only aids in selecting the right products but also facilitates smoother negotiations and stronger supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the sunwest containers phoenix arizona Sector

What Are the Key Market Dynamics and Trends Affecting International Buyers of Sunwest Containers in Phoenix, Arizona?

The market for plastic containers, particularly in Phoenix, Arizona, is shaped by several global drivers, including the increasing demand for sustainable packaging solutions and the need for cost-effective storage options. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that can provide high-quality, durable products while also adhering to stringent environmental regulations. Emerging trends such as automation in manufacturing processes and the use of advanced materials are also gaining traction, making it imperative for buyers to stay updated on technological advancements.

Additionally, the rise of e-commerce has led to a surge in demand for versatile packaging solutions that can cater to a variety of industries, from food and beverage to chemicals and pharmaceuticals. This shift is prompting manufacturers like Sunwest Container Co. to innovate their product lines, offering customizable and eco-friendly options. As international trade grows, buyers need to consider logistics and supply chain efficiency, ensuring that their sourcing partners can deliver products in a timely manner without compromising on quality.

How Are Sustainability and Ethical Sourcing Influencing the B2B Landscape for Packaging?

Sustainability has become a critical consideration for international B2B buyers in the packaging sector. With increasing awareness of environmental issues, companies are prioritizing sustainable practices in their supply chains. Sunwest Container Co. stands out by offering eco-friendly options, such as containers made from recycled materials and biodegradable plastics. This commitment not only reduces environmental impact but also enhances brand image for buyers who are keen on promoting their sustainability initiatives.

The importance of ethical sourcing cannot be overstated. Buyers are increasingly demanding transparency in their supply chains, seeking suppliers who prioritize responsible practices. Certifications such as ISO 14001 for environmental management and other “green” credentials are becoming essential for manufacturers to prove their commitment to sustainability. By partnering with suppliers that adhere to these standards, international buyers can ensure they are contributing to a more sustainable future while meeting regulatory requirements in their respective markets.

What Is the Evolution of Sunwest Containers in the Context of B2B Sourcing?

Sunwest Container Co. has evolved significantly since its inception over 25 years ago. Initially focused on producing basic plastic containers, the company has expanded its offerings to include a diverse range of packaging solutions tailored to various industries. This evolution is marked by a commitment to quality and innovation, resulting in a robust product line that includes customizable options for branding and specific industry needs.

As the market dynamics shifted towards sustainability, Sunwest Container adapted by incorporating eco-friendly materials and practices into its production processes. Today, the company is recognized not just for its high-quality products but also for its dedication to customer service and sustainability, making it a trusted partner for international B2B buyers looking for reliable and responsible packaging solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of sunwest containers phoenix arizona

-

1. How do I select the right plastic container for my business needs?

To select the appropriate plastic container, first assess the specific requirements of your products, including size, shape, and storage conditions. Consider the material properties, such as durability and chemical resistance, especially if you are storing hazardous materials. Evaluate customization options that can enhance branding, like color and labeling. Lastly, consult with a knowledgeable sales representative from Sun West Container Co. to gain insights tailored to your unique needs, ensuring you make an informed decision. -

2. What customization options are available for Sun West containers?

Sun West Container Co. offers a variety of customization options for their containers, including sizes, colors, and printing capabilities. Businesses can request custom logos, product information, and unique designs that align with their branding. Additionally, there are choices for different closure systems to ensure product integrity. Discussing your specific requirements with their sales team can help you navigate the available options and find the best fit for your packaging needs. -

3. What are the minimum order quantities (MOQs) for containers?

Minimum order quantities at Sun West Container Co. can vary depending on the type of container and customization requested. Typically, MOQs are set to ensure cost-effectiveness in production. It’s advisable to reach out directly to their sales team to discuss your project and inquire about specific MOQs for your desired products, as they may also offer flexibility for large-scale orders or long-term partnerships. -

4. How do I ensure quality assurance when sourcing containers internationally?

To ensure quality assurance when sourcing containers from Sun West Container Co., request samples before placing a bulk order. This allows you to evaluate the container’s durability and functionality. Additionally, inquire about their quality control processes and certifications, which demonstrate their commitment to meeting industry standards. Establishing open communication with their team can also help address any concerns and ensure your specifications are met. -

5. What payment terms are available for international buyers?

Sun West Container Co. typically offers various payment terms tailored to meet the needs of international buyers. Common options include upfront payments, letters of credit, and installment plans based on order size and customer relationship. It’s crucial to discuss payment terms during the negotiation phase to ensure clarity and mutual agreement. Their finance team can provide detailed information and support throughout the payment process. -

6. What logistics support does Sun West Container Co. provide for international shipping?

Sun West Container Co. offers comprehensive logistics support for international shipping, ensuring timely and efficient delivery of your orders. They can assist with coordinating shipping options, including freight forwarding and customs clearance. Additionally, you can expect updates on shipment status and tracking information to keep you informed. Collaborating with their logistics team can help navigate any complexities associated with international trade. -

7. How does Sun West Container Co. address environmental sustainability?

Sun West Container Co. is committed to sustainability by offering eco-friendly packaging solutions. They utilize recycled materials and develop biodegradable options to reduce environmental impact. Businesses seeking sustainable packaging can discuss their specific needs with the sales team to explore available options. This commitment not only aligns with global sustainability goals but can also enhance your brand image in environmentally conscious markets. -

8. What industries does Sun West Container Co. serve?

Sun West Container Co. serves a diverse range of industries, including food and beverage, chemicals, pharmaceuticals, and industrial applications. Their extensive product line includes containers suitable for various uses, from storage to transportation. Understanding your industry’s specific requirements can help the sales team recommend the most suitable packaging solutions for your business, ensuring compliance with relevant regulations and standards.

Top 4 Sunwest Containers Phoenix Arizona Manufacturers & Suppliers List

1. Sun West Container Co. – Plastic Containers

Domain: plastic-containers.net

Registered: 2002 (23 years)

Introduction: Sun West Container Co. is a leading manufacturer and distributor of plastic containers with over 25 years of experience. They produce high-quality, durable, versatile, and cost-effective plastic containers including bottles, jars, jugs, and canisters. Their products are made from materials that meet industry standards for strength and durability, available in various sizes, shapes, and colors. Cus…

2. Sun West Container Co. – Steel Plastic Fibre Drums

Domain: steel-plastic-fibre-drums.com

Registered: 2015 (10 years)

Introduction: Sun West Container Co. specializes in Steel Plastic Fibre Drums, offering high-quality packaging solutions for various industries. Their drums are engineered using steel, plastic, and fiber materials, ensuring strength, durability, and protection for products like chemicals and hazardous materials. The company emphasizes innovation, reliability, and customer satisfaction, maintaining stringent qua…

3. Sun West Container Co. – Plastic Containers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Sun West Container Co. supplies a variety of plastic containers including 55-gallon drums, pails, lids, bottles, totes, and more for industries such as petroleum, chemical, paint, environmental, and food.

4. PitchBook – Plastic Containers & Spill Products

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: Manufacturer of plastic containers, drums and containment products including metal cans, spill containers, plastic pails and lids, totes, plastic bottles, fiber drums and absorbent products.

Strategic Sourcing Conclusion and Outlook for sunwest containers phoenix arizona

As businesses increasingly recognize the importance of strategic sourcing, Sunwest Container Co. stands out as a premier partner for high-quality plastic containers. With over 25 years of experience, their commitment to durability, customization, and environmental sustainability positions them as a reliable supplier in the packaging industry. International buyers from Africa, South America, the Middle East, and Europe can leverage Sunwest’s extensive product range, including bottles, jugs, and innovative Steel Plastic Fibre Drums, to meet diverse operational needs.

The ability to customize packaging solutions not only enhances branding but also ensures that specific market requirements are met efficiently. Sunwest’s focus on exceptional customer service, quick turnaround times, and eco-friendly options further underscores their value proposition. By prioritizing strategic sourcing from a trusted manufacturer like Sunwest, businesses can optimize their supply chain, reduce costs, and enhance their market competitiveness.

Looking ahead, the demand for high-quality, sustainable packaging solutions will continue to grow. Now is the time for international B2B buyers to engage with Sunwest Container Co. to secure reliable, innovative, and tailored packaging solutions that will support their business objectives and sustainability goals. Embrace the opportunity to partner with a leader in the industry—your packaging solution awaits.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.