Is Your Stretcher Bed Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for stretcher bed

The global market for stretcher beds is evolving rapidly, presenting unique challenges for B2B buyers seeking reliable solutions. Sourcing high-quality stretcher beds that prioritize patient comfort and caregiver efficiency can be daunting, particularly for those operating in diverse environments across Africa, South America, the Middle East, and Europe. This comprehensive guide addresses these challenges by exploring various types of stretcher beds, their applications in healthcare and emergency services, and essential considerations for supplier vetting.

In this guide, you will find valuable insights into the latest innovations in stretcher bed technology, including motorized options that enhance mobility and safety during patient transfers. We will also delve into critical factors such as cost analysis, compliance with international safety standards, and the importance of ergonomic design. By providing detailed information on the specifications and functionalities of different stretcher beds, this guide empowers international B2B buyers to make informed purchasing decisions that align with their operational needs.

Whether you are a procurement officer in Brazil looking to equip a new medical facility or a logistics manager in Nigeria sourcing equipment for emergency response teams, this guide serves as a crucial resource. By understanding the intricacies of the stretcher bed market, you can ensure that you select products that not only meet regulatory requirements but also enhance patient care and operational efficiency.

Understanding stretcher bed Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Stretcher Bed | Durable construction, universal fit, easy to clean | Emergency services, hospitals, funeral homes | Pros: Cost-effective, versatile. Cons: Limited customization options. |

| Motorized Stretcher Bed | Electric lift, adjustable height, powered by lithium-ion battery | Surgical centers, outpatient clinics | Pros: Reduces manual labor, enhances patient comfort. Cons: Higher initial cost, maintenance required. |

| Bariatric Stretcher Bed | Increased weight capacity, wider design, reinforced structure | Specialized care facilities, hospitals | Pros: Supports heavier patients, durable. Cons: Bulkier, may require larger transport vehicles. |

| Folding Stretcher Bed | Compact design, lightweight, portable | Outdoor medical services, disaster response | Pros: Easy to transport, space-saving. Cons: Less stability, not ideal for long-term use. |

| Pediatric Stretcher Bed | Smaller dimensions, designed for children, safety features | Pediatric hospitals, emergency medical services | Pros: Tailored for young patients, enhances safety. Cons: Limited to specific age group, may not be suitable for adults. |

What are the Characteristics of Standard Stretcher Beds?

Standard stretcher beds are characterized by their durable construction and universal fit, making them suitable for a variety of applications such as emergency services and funeral homes. Their easy-to-clean surfaces are particularly beneficial for environments where hygiene is paramount. Buyers should consider the cost-effectiveness and versatility of these beds, but they may find limitations in customization options, which could impact specific operational needs.

How Do Motorized Stretcher Beds Enhance Workflow?

Motorized stretcher beds are equipped with electric lifts and adjustable heights, powered by lithium-ion batteries. This design is ideal for surgical centers and outpatient clinics, as it minimizes the need for manual lifting and enhances patient comfort. While the initial investment is higher, the reduction in physical strain on caregivers and the improved patient experience make these beds an attractive option for healthcare facilities looking to streamline their operations.

What Makes Bariatric Stretcher Beds Essential for Specialized Care?

Bariatric stretcher beds are specifically designed to support heavier patients, featuring reinforced structures and increased weight capacities. These beds are vital in specialized care facilities and hospitals that cater to diverse patient populations. While they offer durability and stability, buyers should be aware of their bulkier design, which may necessitate larger transport vehicles, potentially increasing logistical considerations.

Why Choose Folding Stretcher Beds for Portability?

Folding stretcher beds are lightweight and compact, making them ideal for outdoor medical services and disaster response scenarios. Their portability allows for easy transportation and storage, which is crucial in emergency situations. However, buyers should weigh the benefits of ease of transport against the potential drawbacks of stability and long-term use, as these beds are not typically designed for prolonged patient care.

What are the Safety Features of Pediatric Stretcher Beds?

Pediatric stretcher beds are tailored for children’s needs, incorporating safety features and smaller dimensions. These beds are essential in pediatric hospitals and emergency medical services, as they provide a secure environment for young patients. While they enhance safety and comfort for children, buyers must consider that their limited size may restrict usage to specific age groups, making them less versatile for adult patients.

Key Industrial Applications of stretcher bed

| Industry/Sector | Specific Application of Stretcher Bed | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient Transport within Hospitals | Enhances patient safety and comfort during transport | Compliance with local health regulations and safety standards |

| Emergency Services | Rapid Response in Ambulances | Quick and efficient patient handling in emergencies | Durability and ease of cleaning for frequent use |

| Funeral Services | Transportation of Deceased Bodies | Streamlined process for dignified handling | Customization options and materials suited for long-term use |

| Military & Defense | Field Medical Units and Casualty Evacuation | Reliable and portable solution for battlefield care | Lightweight design and adaptability to various terrains |

| Home Healthcare | In-home Patient Care and Mobility | Facilitates safe patient transfers and comfort | Compact design for residential spaces and ease of storage |

How is a Stretcher Bed Used in Healthcare Settings?

In healthcare facilities, stretcher beds are essential for patient transport, ensuring safe transitions between different departments like surgery, radiology, and recovery. They minimize the risk of patient injury during movement, which is critical in high-pressure environments. International buyers should prioritize compliance with regional health regulations and safety standards, ensuring that the equipment meets the specific needs of their healthcare systems, especially in regions with varying infrastructure capabilities.

What Role Do Stretcher Beds Play in Emergency Services?

In emergency services, stretcher beds are critical for rapid patient transport in ambulances. Their design allows for quick loading and unloading, enabling first responders to act swiftly in life-threatening situations. Buyers in this sector must consider the durability of materials, ease of cleaning, and the ability to withstand harsh conditions, particularly in regions where emergency services are often stretched thin.

Why Are Stretcher Beds Important for Funeral Services?

In the funeral industry, stretcher beds facilitate the respectful transportation of deceased bodies. These beds streamline the logistics involved in moving bodies from various locations to funeral homes or cemeteries. Buyers should seek customization options that allow for personalization and ensure that the materials used can endure extended use while maintaining a dignified appearance, especially in culturally sensitive regions.

How Do Stretcher Beds Benefit Military and Defense Operations?

In military settings, stretcher beds are vital for field medical units and casualty evacuation. They provide a reliable and portable solution for transporting injured personnel from the battlefield to medical facilities. Sourcing considerations should include lightweight designs that can be easily maneuvered in various terrains, ensuring that military operations can maintain a high level of medical readiness even in challenging environments.

What Are the Advantages of Stretcher Beds in Home Healthcare?

For home healthcare providers, stretcher beds offer a practical solution for in-home patient care, allowing caregivers to transport patients safely and comfortably. They help reduce the physical strain on caregivers while ensuring that patients receive the necessary support during transfers. Buyers must consider the compact design of stretcher beds to fit residential spaces while also ensuring they are easy to store when not in use, catering to the unique needs of home healthcare environments.

3 Common User Pain Points for ‘stretcher bed’ & Their Solutions

Scenario 1: The Challenge of Versatile Use in Diverse Environments

The Problem: B2B buyers often struggle with selecting stretcher beds that can adapt to varying operational needs within their facilities. For instance, hospitals may require a stretcher bed suitable for surgical transport, while funeral homes need beds that can handle heavier loads and be used in removal vehicles. The lack of versatility can lead to inefficient operations, increased costs, and potential safety risks for patients and caregivers. Additionally, buyers may face difficulties in finding equipment that complies with local regulations, especially in regions where standards vary widely.

The Solution: To address these challenges, buyers should prioritize sourcing stretcher beds with customizable features and universal compatibility. Invest in models like the MTI 840 Stretcher Bed, which offers multiple functionalities suitable for various medical specialties, enhancing flexibility and workflow. When purchasing, ensure that the stretcher can accommodate the specific weight and size requirements of your patient demographic. Additionally, verify that the supplier can provide customization options, such as different sizes or configurations, to meet the diverse needs of your operations. Engaging with suppliers who understand local regulations and can provide compliant solutions will also streamline the purchasing process and ensure safety and efficiency.

Scenario 2: Managing Maintenance and Durability Concerns

The Problem: A significant pain point for B2B buyers is the ongoing maintenance and durability of stretcher beds. Frequent repairs and replacements not only incur additional costs but can also disrupt patient care. Many buyers find that low-quality materials lead to wear and tear, resulting in unreliable equipment that can jeopardize patient safety. In regions with limited access to spare parts or service technicians, this issue is compounded, making it crucial to invest in long-lasting solutions.

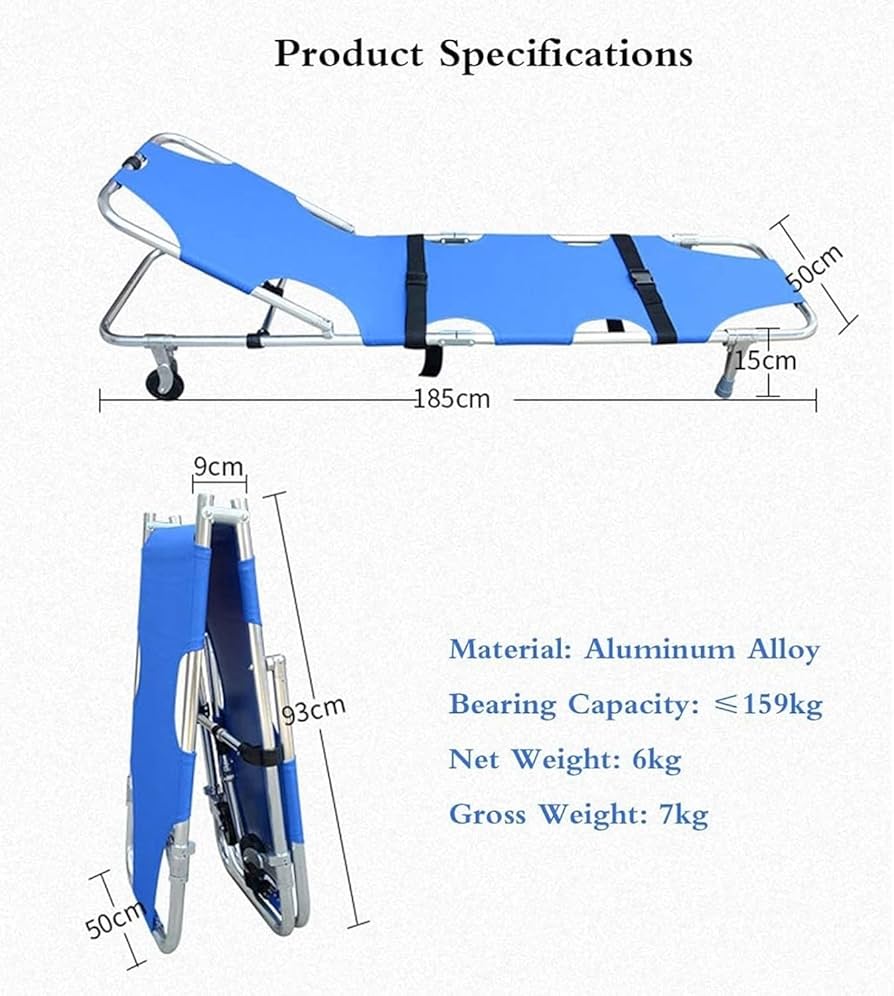

The Solution: To mitigate these concerns, buyers should focus on acquiring stretcher beds constructed from high-quality, durable materials, such as aluminum alloy, which is lightweight yet robust. Look for models that offer maintenance-free joints and easy-to-clean surfaces, reducing the need for frequent upkeep. It’s advisable to establish a relationship with reputable manufacturers who provide warranties and after-sales support, ensuring that you have access to parts and service when needed. Additionally, consider training staff on proper usage and maintenance practices to prolong the lifespan of the equipment and enhance safety protocols.

Scenario 3: Ensuring Safe and Efficient Patient Transfers

The Problem: Efficient and safe patient transfers are critical in healthcare settings, yet many buyers find that standard stretcher beds do not facilitate smooth transitions. This inefficiency can lead to increased risk of patient injury and stress for both patients and caregivers. In emergency situations, the inability to quickly and safely transport patients can have serious consequences, underscoring the need for reliable equipment.

The Solution: To enhance patient transfer processes, buyers should seek stretcher beds equipped with features that promote safety and ease of use. Look for beds with powered lift capabilities, such as the MTI 840, which minimizes the physical strain on caregivers and reduces the risk of injury. Furthermore, consider models that offer programmable height adjustments and ergonomic design to accommodate a range of patient needs. Investing in beds with smooth-rolling casters and easy maneuverability will also facilitate safe transfers through tight spaces in medical facilities. By prioritizing these features, buyers can create a more efficient workflow that ultimately improves patient care and safety outcomes.

Strategic Material Selection Guide for stretcher bed

When selecting materials for stretcher beds, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of stretcher beds, highlighting their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Aluminum in Stretcher Beds?

Aluminum is a popular choice for stretcher beds due to its lightweight nature and excellent corrosion resistance. It can withstand a range of temperatures and is generally resistant to rust, making it suitable for various environments, including humid climates. Aluminum’s strength-to-weight ratio is particularly advantageous, allowing for easy maneuverability without compromising structural integrity.

Pros: Aluminum is durable, lightweight, and easy to clean, which is crucial for hygiene in medical settings. Its manufacturing process is relatively straightforward, allowing for customization in design.

Cons: While aluminum is strong, it may not support extreme weight loads as effectively as other materials like steel. Additionally, it can be more expensive than some alternatives, which may be a consideration for budget-conscious buyers.

Impact on Application: Aluminum’s compatibility with various cleaning agents and disinfectants makes it ideal for healthcare environments. Its lightweight nature is beneficial for transport and handling.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with local regulations regarding material safety and durability. Familiarity with standards like ASTM or ISO can aid in selecting the right product.

How Does Steel Compare as a Material for Stretcher Beds?

Steel, particularly stainless steel, is another common material for stretcher beds. Known for its exceptional strength and durability, steel can handle heavy loads and is resistant to deformation under stress. Stainless steel also offers corrosion resistance, making it suitable for environments where sanitation is critical.

Pros: Steel’s robustness ensures longevity, making it a wise investment for facilities expecting high usage. It can be manufactured to meet specific safety standards, enhancing its appeal to B2B buyers.

Cons: The weight of steel can be a disadvantage, making it less portable than aluminum. Additionally, the manufacturing process can be more complex and costly, which may affect overall pricing.

Impact on Application: Steel’s ability to withstand heavy loads makes it ideal for emergency services and hospitals that require reliable equipment for patient transport.

Considerations for International Buyers: Buyers should verify compliance with international safety standards and certifications, especially in regions with stringent regulations, such as Europe.

What Are the Benefits of Using Plastic Composites in Stretcher Beds?

Plastic composites are increasingly being used in stretcher beds due to their lightweight and versatile properties. These materials often incorporate fiberglass or other reinforcements to enhance strength while maintaining a low weight.

Pros: The primary advantage of plastic composites is their resistance to chemicals and moisture, making them easy to clean and maintain. They are also typically more affordable than metal options.

Cons: Plastic composites may not offer the same load-bearing capacity as metals, which could limit their use in certain applications. Additionally, they may have a shorter lifespan compared to aluminum or steel.

Impact on Application: Their chemical resistance makes plastic composites suitable for environments where exposure to disinfectants is common.

Considerations for International Buyers: Buyers should consider the environmental impact of plastics and ensure that the materials comply with local regulations regarding waste management and recycling.

Illustrative image related to stretcher bed

How Do Fabric and Upholstery Materials Affect Stretcher Bed Performance?

The choice of fabric and upholstery materials for stretcher beds is crucial for comfort and hygiene. Common materials include vinyl and specialized medical-grade fabrics that are resistant to stains and easy to clean.

Pros: High-quality upholstery can enhance patient comfort and is often designed to withstand harsh cleaning agents, ensuring longevity.

Cons: While fabric options can be cost-effective, they may require more maintenance and have a shorter lifespan than metal components.

Impact on Application: The right upholstery can significantly improve the patient experience during transport, which is vital in healthcare settings.

Considerations for International Buyers: Buyers should ensure that upholstery materials comply with local health regulations and are suitable for the intended climate and usage conditions.

Summary Table of Material Selection for Stretcher Beds

| Material | Typical Use Case for stretcher bed | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General healthcare transport | Lightweight and corrosion-resistant | Limited weight capacity | Medium |

| Steel | Emergency services, hospitals | High strength and durability | Heavier and more expensive | High |

| Plastic Composites | Lightweight transport solutions | Chemical resistance and affordability | Lower load capacity | Low |

| Upholstery Fabrics | Patient comfort in transport | Enhanced comfort and hygiene | Requires maintenance | Medium |

This guide provides B2B buyers with critical insights into material selection for stretcher beds, ensuring that their choices align with operational needs and compliance standards in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for stretcher bed

What Are the Main Stages in the Manufacturing Process of Stretcher Beds?

The manufacturing process of stretcher beds involves several critical stages that ensure the final product meets safety and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with the selection of high-quality materials, such as durable aluminum alloy or high-strength steel, known for their lightweight and resilience. Materials are sourced from certified suppliers to ensure compliance with international standards. After procurement, materials undergo inspection to verify their integrity and suitability for the production of stretcher beds.

-

Forming: This stage involves shaping the raw materials into the required components of the stretcher bed. Techniques such as CNC machining, welding, and bending are commonly used. CNC machining allows for precision cutting and shaping of components, while welding ensures strong joints between parts. The forming process must adhere to strict tolerances to guarantee compatibility and structural integrity.

-

Assembly: Once individual components are formed, they are assembled into the final product. This phase may involve manual assembly or the use of automated systems, depending on the manufacturer’s capabilities. Key considerations during assembly include ergonomic design and the integration of features such as adjustable height, removable arms, and safety locks. Each assembly line worker is typically trained to perform specific tasks to minimize errors and optimize efficiency.

-

Finishing: The final stage of production includes surface treatment and finishing processes. This may involve powder coating or painting to enhance durability and aesthetics. Additionally, upholstery is applied to provide comfort and facilitate easy cleaning. Quality checks during this phase ensure that the product meets the desired specifications before moving on to the quality assurance process.

How Is Quality Assurance Implemented in Stretcher Bed Manufacturing?

Quality assurance (QA) is integral to the manufacturing of stretcher beds, ensuring that the final products are safe, durable, and compliant with industry standards. The QA process typically adheres to both international and industry-specific standards.

-

Relevant International Standards: Manufacturers often seek certification for ISO 9001, which focuses on quality management systems. This certification demonstrates a commitment to consistent quality and continuous improvement. Additionally, industry-specific standards such as CE marking in Europe and API certification may apply, indicating compliance with safety and performance requirements.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the facility. Suppliers must provide documentation to verify compliance with specifications.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs at various stages to detect any deviations from established standards. This includes checking dimensions, functionality, and safety features.

– Final Quality Control (FQC): After assembly, each stretcher bed undergoes a thorough inspection. This includes functional testing, load capacity assessments, and checks for any surface imperfections or assembly errors. -

Common Testing Methods: Testing methods used in quality assurance include mechanical testing for load-bearing capacity, electrical safety testing (for motorized beds), and usability assessments to ensure ergonomic design. Manufacturers may also conduct simulated usage scenarios to evaluate performance under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. This may involve site visits to observe operations and review documentation related to quality management systems.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers, including results from IQC, IPQC, and FQC. These reports should outline any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of a supplier’s quality control measures. These agencies can perform inspections at various stages of production and provide certification that the products meet relevant standards.

-

Certifications and Compliance Documentation: Verify that suppliers possess relevant certifications, such as ISO 9001, CE marking, or other applicable industry-specific certifications. Documentation should be readily available and current.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances when dealing with quality control in different regions. Understanding these factors can enhance procurement strategies and ensure compliance with local regulations.

-

Regional Standards and Regulations: Different regions may have varying standards for medical equipment, which can affect compliance. For example, the CE mark is crucial for selling in Europe, while local regulations in African countries may differ significantly. Buyers should familiarize themselves with the specific requirements of the target market.

-

Cultural Considerations: Cultural factors can influence manufacturing practices and quality perceptions. Buyers should be aware of these nuances and engage in open communication with suppliers to address any concerns.

-

Supply Chain Transparency: Establishing transparency in the supply chain is vital. Buyers should inquire about the sourcing of materials and the sustainability practices of suppliers, as these factors can impact product quality.

-

Building Long-Term Relationships: Developing strong relationships with suppliers can enhance quality assurance processes. Regular communication, feedback, and collaboration on quality improvement initiatives can lead to better outcomes for both parties.

By understanding the manufacturing processes and quality assurance measures associated with stretcher beds, B2B buyers can make informed decisions that ensure the procurement of high-quality products that meet their specific needs.

Illustrative image related to stretcher bed

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stretcher bed’

To effectively procure a stretcher bed, it’s essential to follow a structured approach that ensures you select a product that meets your specific needs while also considering supplier reliability and regulatory compliance. This guide outlines the key steps to facilitate your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as the stretcher bed’s dimensions, weight capacity, and mobility features. Ensure that the specifications align with the intended use, whether for emergency medical services, hospitals, or specialized clinics.

- Size and Weight Capacity: Look for options that accommodate the maximum patient weight and dimensions suitable for your facility.

- Mobility Features: Evaluate if the stretcher bed requires manual handling or if it features powered mobility for ease of transport.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in stretcher beds. Utilize online marketplaces, industry forums, and trade shows to compile a list of potential vendors.

Illustrative image related to stretcher bed

- Industry Reputation: Look for suppliers with a strong reputation in the medical equipment sector, particularly those with experience in your geographic region.

- Product Range: Ensure the suppliers offer a variety of stretcher beds, including specialized models that may be necessary for specific medical procedures.

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with any supplier, verify their certifications and compliance with relevant medical standards. This ensures that the products meet safety and quality benchmarks.

- ISO and CE Certifications: Check for certifications that validate the quality management systems and compliance with European health regulations.

- Local Regulations: Be aware of any regional certifications required in your target market, especially if you are sourcing from different continents.

Step 4: Request Product Samples or Demonstrations

Once you have shortlisted potential suppliers, request samples or arrange demonstrations of the stretcher beds. This step allows you to assess the quality and functionality first-hand.

- Hands-On Evaluation: Testing the product will give you insight into its ease of use, durability, and comfort for patients.

- Feedback from Staff: Involve your medical staff in the evaluation process to gather feedback on usability and features that are important for their workflow.

Step 5: Analyze Pricing and Payment Terms

Carefully review the pricing structures and payment terms offered by suppliers. Ensure that the costs align with your budget while also considering the long-term value of the product.

Illustrative image related to stretcher bed

- Total Cost of Ownership: Factor in additional costs such as shipping, installation, and maintenance when evaluating pricing.

- Flexible Payment Options: Look for suppliers who offer favorable payment terms that can ease cash flow, especially for larger orders.

Step 6: Assess After-Sales Support and Warranty Options

Ensure that the supplier provides robust after-sales support and warranty options. This is crucial for minimizing downtime in case of product issues.

- Technical Support: Verify if the supplier offers technical assistance and training for your staff on using the stretcher bed.

- Warranty Coverage: Understand the warranty terms, including what is covered and the duration, to safeguard your investment.

Step 7: Finalize the Contract and Place Your Order

Once you have completed your evaluations and are satisfied with your chosen supplier, proceed to finalize the contract. Ensure all terms are clearly outlined to prevent misunderstandings.

- Contract Clarity: Include delivery timelines, payment schedules, and penalties for non-compliance to protect your interests.

- Confirmation of Specifications: Reconfirm that the order matches your initial specifications to avoid discrepancies upon delivery.

Following this checklist will help you make informed decisions when sourcing stretcher beds, ensuring that you acquire high-quality products that meet your operational needs.

Comprehensive Cost and Pricing Analysis for stretcher bed Sourcing

What Are the Key Cost Components in Stretcher Bed Manufacturing?

When sourcing stretcher beds, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly influences the overall cost. Stretcher beds made from durable aluminum alloy or high-quality steel tend to be more expensive due to their longevity and robustness. Additionally, upholstery materials, such as Ultraleather, can add to the cost but enhance patient comfort and ease of cleaning.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. Skilled labor is essential, especially for beds with advanced features like motorized adjustments or safety mechanisms.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and general operational expenses. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in the final price of the stretcher beds.

-

Tooling: The initial investment in tooling for specialized stretcher bed designs can be significant. Customization options, such as specific dimensions or additional features, may require unique tooling, impacting overall production costs.

-

Quality Control (QC): Ensuring that each stretcher bed meets safety and quality standards incurs additional costs. This is particularly important for international buyers who must comply with stringent regulations in their home countries.

-

Logistics: Shipping and handling costs should not be overlooked. These costs can vary significantly based on the shipping method, distance, and whether the supplier covers these in the pricing.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the typical margins in the stretcher bed market can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Stretcher Bed Costs?

Several factors influence the pricing of stretcher beds, including order volume, specifications, materials used, quality certifications, supplier reputation, and Incoterms.

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often lead to reduced per-unit costs. Negotiating for bulk purchases may yield better pricing. Conversely, smaller orders may face higher costs due to lower economies of scale.

-

Specifications and Customization: Customized stretcher beds, designed for specific medical applications or unique patient needs, tend to be more expensive. Buyers should weigh the importance of customization against budget constraints.

-

Material Quality and Certifications: Beds that comply with international safety and quality standards (like ISO or CE certifications) might carry a premium but offer peace of mind regarding safety and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a track record of quality may charge more but can save buyers from potential issues down the line.

-

Incoterms: Understanding the shipping terms under Incoterms is vital. Costs related to customs, insurance, and freight can vary depending on whether the buyer or seller is responsible for these elements.

What Buyer Tips Can Enhance Cost-Efficiency for Stretcher Beds?

To maximize value when sourcing stretcher beds, international buyers should consider the following strategies:

-

Negotiation: Engage suppliers in negotiations to explore discounts, especially for larger orders. Building a relationship with suppliers can also lead to better terms over time.

-

Total Cost of Ownership (TCO): Assess the TCO by considering not only the purchase price but also maintenance, potential repairs, and operational costs over the bed’s lifecycle. Higher upfront costs can sometimes lead to lower TCO if the product has superior durability.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and additional costs related to importing goods, such as tariffs and taxes, which can impact overall pricing. Understanding local regulations regarding medical equipment can also prevent unexpected expenses.

-

Research and Compare: Conduct thorough market research to compare prices and features across different suppliers. This will help identify fair pricing and value for money.

Conclusion

Sourcing stretcher beds involves a nuanced understanding of costs and pricing influencers. By focusing on the key components and employing strategic purchasing tactics, international buyers can optimize their procurement processes, ensuring they acquire high-quality products at competitive prices. Always remember that indicative prices may vary based on changing market conditions and individual supplier practices.

Alternatives Analysis: Comparing stretcher bed With Other Solutions

Understanding Alternatives to Stretcher Beds

In the healthcare and emergency transport sectors, the choice of patient handling equipment can significantly impact operational efficiency and patient safety. Stretcher beds are widely used for their versatility in transporting patients, but there are alternative solutions that may better meet specific needs depending on the context. This section explores viable alternatives to stretcher beds, providing insights into their respective advantages and disadvantages for B2B buyers.

Comparison of Stretcher Bed and Alternatives

| Comparison Aspect | Stretcher Bed | Motorized Patient Transport Chair | Flexible Stretchers |

|---|---|---|---|

| Performance | High; suitable for various patient types | Moderate; best for stable patients | Variable; ideal for uneven terrain |

| Cost | $749 and up | $1,500 – $3,000 | $200 – $800 |

| Ease of Implementation | Moderate; requires training for use | High; easy to maneuver and use | Low; lightweight and portable |

| Maintenance | Moderate; regular checks needed | Low; minimal upkeep required | Low; easy to clean and store |

| Best Use Case | Hospital transport and surgeries | Outpatient procedures and transfers | Emergency situations, uneven surfaces |

Detailed Breakdown of Alternatives

Motorized Patient Transport Chair

Motorized patient transport chairs provide a powered solution for moving patients within healthcare facilities. They are designed for ease of use, enabling caregivers to transport patients without excessive physical strain. The primary advantages of these chairs include their maneuverability and reduced risk of injury for caregivers. However, they may not be suitable for patients with significant mobility issues or for transporting patients over long distances, as their design typically limits the load capacity and comfort for extended periods.

Flexible Stretchers

Flexible stretchers are lightweight, portable alternatives designed for emergency situations. They can be easily folded and stored, making them ideal for first responders and in environments where space is limited. Their versatility allows for transport over uneven terrain, which is crucial in outdoor or disaster scenarios. While they are cost-effective and easy to deploy, flexible stretchers may not provide the same level of comfort or support as stretcher beds, making them less suitable for prolonged patient transport in stable environments.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate patient transport solution, B2B buyers should consider the specific requirements of their operations, including the nature of patient conditions, transport distances, and available budget. Stretcher beds offer robust performance and versatility, making them suitable for a wide range of medical scenarios. However, for settings where mobility and ease of use are paramount, motorized transport chairs may provide a more efficient option. In emergency contexts, flexible stretchers can offer the portability and adaptability needed for rapid response. Ultimately, understanding the unique advantages and limitations of each option will enable buyers to make informed decisions that enhance patient care and operational efficiency.

Illustrative image related to stretcher bed

Essential Technical Properties and Trade Terminology for stretcher bed

What Are the Key Technical Properties of a Stretcher Bed?

When evaluating stretcher beds, several critical specifications should be considered to ensure they meet your operational needs. Here are the essential technical properties to focus on:

-

Material Composition

Stretcher beds are typically constructed from durable materials such as aluminum alloy or stainless steel. These materials provide a robust framework that ensures longevity and resistance to corrosion, particularly important in environments like hospitals or funeral homes where sanitation is paramount. A high-grade material not only enhances the bed’s durability but also impacts weight capacity and ease of maneuverability. -

Weight Capacity

The weight capacity of a stretcher bed is a vital specification that determines its usability in various scenarios. Most stretcher beds can accommodate patients weighing between 450 to 725 pounds. Understanding the weight capacity is crucial for ensuring patient safety and compliance with healthcare regulations, especially in regions with diverse patient demographics. -

Dimensions and Adjustability

Standard dimensions for stretcher beds typically range around 90 inches in length and 26 to 30 inches in width. However, adjustable features, such as height and angle, enhance patient comfort and accessibility. Beds with a motorized lift feature allow for seamless transitions between different positions, reducing the risk of caregiver injury and improving the overall workflow in medical environments. -

Power Source

Stretcher beds may operate using various power sources, including electric, battery, or manual mechanisms. Battery-powered models, like those utilizing lithium-ion technology, offer the advantage of portability without being tethered to an electrical outlet. This feature is particularly useful in emergency situations or during transport across facilities, ensuring uninterrupted service. -

Safety Standards Compliance

It’s essential to verify that the stretcher bed complies with international safety standards, such as IEC 60601-1 or AAMI ES60601-1. Compliance guarantees that the product has undergone rigorous testing for electrical safety, mechanical integrity, and patient protection. This factor is critical for B2B buyers in ensuring that their investment meets regulatory requirements in their respective markets.

What Are Common Trade Terms Used in the Stretcher Bed Industry?

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are sold under another company’s brand name. For stretcher beds, knowing the OEM can help buyers assess product quality and reliability, as well as potential warranty and service options. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory planning. Suppliers often set MOQs to ensure production efficiency, which can influence pricing structures. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. When procuring stretcher beds, submitting an RFQ allows buyers to compare pricing, specifications, and terms from multiple vendors, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

These are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risk transfer, and delivery obligations, ensuring smooth logistics and compliance with international trade laws. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is vital for planning and inventory management, especially in urgent situations where timely access to stretcher beds can impact patient care or operational efficiency. -

Warranty Period

This term indicates the duration during which a product is covered for repairs or replacements due to defects. A comprehensive warranty period can provide peace of mind for buyers, indicating the manufacturer’s confidence in their product’s quality and durability.

By familiarizing yourself with these technical properties and trade terms, you can make informed purchasing decisions that align with your operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the stretcher bed Sector

What Are the Key Trends Driving the Stretcher Bed Market?

The stretcher bed market is witnessing robust growth, fueled by several global drivers. The increasing demand for advanced healthcare facilities, particularly in emerging markets such as Africa and South America, is leading to greater investments in medical infrastructure. Furthermore, the ongoing global health crises have highlighted the importance of efficient patient transport systems, spurring the adoption of innovative stretcher bed technologies.

Current trends indicate a shift toward motorized and multifunctional stretcher beds that enhance workflow efficiency and patient safety. For instance, products like the MTI 840 series not only facilitate seamless transitions between different healthcare settings but also minimize the risk of injuries to both patients and caregivers. Additionally, the integration of smart technologies, such as remote battery charging and programmable settings, is becoming increasingly prevalent, appealing to B2B buyers seeking operational efficiency.

Illustrative image related to stretcher bed

International buyers are also focusing on sourcing from manufacturers that offer customization options to meet specific regional needs, such as size variations and compliance with local health regulations. This demand for tailored solutions is particularly significant in regions like the Middle East and Europe, where diverse healthcare requirements necessitate adaptable products.

How Is Sustainability and Ethical Sourcing Influencing the Stretcher Bed Industry?

Sustainability is becoming a pivotal factor in the stretcher bed sector, with B2B buyers increasingly prioritizing environmentally friendly products. The environmental impact of manufacturing processes, coupled with the rising awareness of climate change, is driving demand for sustainable materials. Manufacturers are responding by incorporating recycled materials and eco-friendly certifications into their product lines, making it essential for buyers to verify the sustainability credentials of suppliers.

Ethical sourcing is also gaining traction, with companies seeking to ensure that their supply chains adhere to fair labor practices and environmental standards. Buyers are encouraged to look for suppliers who are transparent about their sourcing methods and can demonstrate compliance with international ethical standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Incorporating ‘green’ materials not only aligns with corporate social responsibility goals but can also enhance brand reputation, making sustainable stretcher beds an attractive choice for B2B buyers in regions with stringent regulations on healthcare waste and environmental impact.

What Is the Evolution of Stretcher Beds in the Healthcare Sector?

The evolution of stretcher beds has been marked by significant technological advancements and a growing focus on patient safety. Initially designed as simple transport devices, modern stretcher beds now incorporate features such as motorized adjustments, lightweight materials, and ergonomic designs aimed at enhancing patient comfort and caregiver efficiency.

In recent years, the shift toward multifunctionality has transformed stretcher beds into critical components of patient care, facilitating seamless transitions between various stages of treatment. This evolution reflects broader trends in healthcare toward improved patient outcomes and operational efficiency, making the stretcher bed a vital investment for B2B buyers in the healthcare sector.

As the market continues to innovate, staying informed about the latest developments and sourcing trends will be essential for buyers looking to make strategic purchasing decisions in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of stretcher bed

-

How do I choose the right stretcher bed for my healthcare facility?

Selecting the right stretcher bed involves assessing your facility’s specific needs. Consider factors such as patient load capacity, mobility requirements, and the types of procedures performed. Evaluate features like powered adjustments for height and tilt, which enhance patient comfort and caregiver efficiency. Additionally, review the dimensions to ensure compatibility with your transport vehicles and storage areas. Collaborating with suppliers who offer customization options can further ensure the stretcher bed aligns with your operational workflow. -

What are the key features to look for in a stretcher bed?

When sourcing a stretcher bed, prioritize features that enhance functionality and safety. Look for beds with adjustable heights, powered controls for easy maneuverability, and durable materials that withstand heavy use. Safety features such as locking casters and side rails are essential for patient security. Additional considerations include battery life for mobile units, ease of cleaning, and compatibility with medical equipment. Understanding these features will help you select a product that meets both patient care standards and operational efficiency. -

What is the typical lead time for ordering stretcher beds?

Lead times for stretcher bed orders can vary significantly based on supplier location, customization requirements, and current stock levels. Generally, you can expect delivery within 4 to 12 weeks. For customized orders, it may take longer due to manufacturing processes. It’s advisable to discuss lead times during the procurement process to align your order with your facility’s needs. Ensuring clear communication with the supplier can help avoid delays and ensure timely delivery. -

What are the minimum order quantities (MOQ) for stretcher beds?

Minimum order quantities (MOQ) can differ among suppliers based on their production capabilities and inventory policies. Typically, MOQs range from 1 to 10 units for standard models, while custom orders may require higher quantities. When planning your purchase, consider your facility’s demand and budget. Engaging with suppliers for bulk discounts or flexible ordering options can also be beneficial, particularly for international buyers looking to optimize logistics and costs. -

How can I ensure the quality and safety of the stretcher beds I purchase?

To ensure quality and safety, verify that the stretcher beds comply with relevant international standards such as IEC 60601 for medical devices. Request certifications and product specifications from suppliers. Conducting a thorough supplier vetting process, including checking reviews and asking for references, can also provide insights into their reliability. Consider arranging a demonstration or trial period to assess the product’s performance in real-world conditions before finalizing your purchase. -

What payment terms are typically offered for B2B stretcher bed purchases?

Payment terms for stretcher bed purchases can vary widely among suppliers. Common options include upfront payment, payment upon delivery, or net payment terms (e.g., net 30 or net 60 days). International buyers may also encounter additional considerations such as currency exchange rates and import duties. It’s important to negotiate favorable terms that align with your cash flow and financial policies. Clarifying payment methods accepted (bank transfer, credit terms, etc.) is also crucial for smooth transactions. -

What logistics considerations should I keep in mind when sourcing stretcher beds internationally?

When sourcing stretcher beds internationally, logistics considerations include shipping methods, customs regulations, and delivery timelines. Evaluate whether air freight or sea freight is more suitable based on urgency and cost. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. Additionally, consider using a freight forwarder to navigate complex international shipping processes, which can streamline delivery and mitigate potential delays. -

Can stretcher beds be customized to meet specific healthcare needs?

Yes, many suppliers offer customization options for stretcher beds to cater to specific healthcare requirements. Customizations may include size adjustments, specialized features like integrated monitoring systems, or tailored upholstery for infection control. When discussing your needs with suppliers, provide detailed specifications and any regulatory requirements that must be met. This collaborative approach will ensure you receive a product that is not only functional but also compliant with local healthcare standards.

Top 6 Stretcher Bed Manufacturers & Suppliers List

1. MTI – 840 Stretcher Bed

Domain: mti.net

Registered: 1996 (29 years)

Introduction: Product Name: MTI 840 Stretcher Bed

Type: Medical Furniture

Key Features:

– Motorized bed for seamless transitions from pre-op to transport, surgery, and recovery

– No patient transfers required, minimizing injury risk

– Powered by a smart lithium-ion battery for mobility without electrical connection

– Extra battery can be inserted for uninterrupted operation

– Charges remotely, maintaining full …

2. MOBI Medical – Stretcher Bed & Ramp

Domain: vischerfuneralsupplies.com

Registered: 2000 (25 years)

Introduction: {“name”:”Stretcher Bed & Ramp”,”SKU”:”1234-X”,”price”:”From $749.00″,”sizes”:[“Oversize Stretcher Base”,”Standard Stretcher Base”],”brand”:”MOBI Medical”,”features”:[“Durable Aluminum Alloy Construction”,”Universal, Easy to Clean”,”Can be used in any removal vehicle”,”Designed for convenient loading/unloading of any cot or stretcher”,”Flip down ramp protects bumper”,”Customized Sizing Available”],…

3. Stretcher Bed – Medical & Therapeutic Options

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Stretcher Bed listings on eBay include various types of medical and therapeutic beds, primarily designed for spinal traction and lumbar relief. Key features include:

– Condition: New and Used options available

– Price Range: Typically from $20.00 to over $350.00

– Shipping: Free delivery in 2-4 days for many items, with options for local pickup

– Seller Ratings: Many listings from Top Rated Pl…

4. Darche – Stretcher Beds

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Stretcher beds discussed include options with and without center bars. Users mention brands like Darche and Oztent. Concerns include sagging when two people use a stretcher without a center bar, and discomfort from center bars. Recommendations include using stretchers with end bars for less sag and considering single stretchers for individual comfort. Users also mention the importance of a fully b…

5. PZWiki – Stretcher Bed

Domain: pzwiki.net

Registered: 2011 (14 years)

Introduction: {‘name’: ‘Stretcher Bed’, ‘category’: ‘Furniture’, ‘encumbrance_per_tile’: 6.0, ‘total_encumbrance’: 12, ‘size’: ‘2 tiles’, ‘properties’: {‘bed_type’: ‘Average’, ‘is_low’: True, ‘moveable’: False}, ‘pickup_tool’: None, ‘disassemble_skill_level’: ‘Carpentry’, ‘disassemble_tools’: [‘Claw Hammer’], ‘technical_item_id’: ‘Base.Mov_Cot’, ‘sprite_ids’: [{‘id’: 137056, ‘sprite’: ‘furniture_bedding_01_56’}…

6. Zempire – W Leg V2 Camp Cot Stretcher

Domain: zempirecamping.com

Registered: 2014 (11 years)

Introduction: {“products”:[{“name”:”W Leg V2 Camp Cot Stretcher”,”price”:80.00},{“name”:”Z Leg Twin Camp Cot Stretcher”,”price”:150.00},{“name”:”Z Leg King Single Camp Cot Stretcher”,”price”:140.00},{“name”:”Z Leg Single Camp Cot Stretcher”,”price”:120.00}],”features”:”Designed for portability, comfort, and quick set-up. Provides extra storage underneath. Comes with durable carry bags for easy transportation an…

Strategic Sourcing Conclusion and Outlook for stretcher bed

In navigating the complex landscape of stretcher bed procurement, international B2B buyers must prioritize strategic sourcing to enhance operational efficiency and patient safety. Key takeaways from this guide emphasize the importance of selecting high-quality, durable stretcher beds that cater to various medical specialties and environments. The integration of innovative features, such as motorized systems and lithium-ion battery operation, not only streamlines workflows but also mitigates risks associated with patient transfers.

Strategic sourcing enables buyers to leverage competitive pricing and ensure compliance with safety standards, which is crucial in regions such as Africa, South America, the Middle East, and Europe. By establishing strong relationships with reliable suppliers, organizations can secure customized solutions that meet their specific needs, ultimately enhancing service delivery.

As healthcare demands continue to evolve, staying ahead of market trends and investing in advanced stretcher bed solutions will be vital. International buyers are encouraged to actively engage with suppliers, participate in product demonstrations, and explore customizable options that align with their operational requirements. Embrace the opportunity to elevate your healthcare services through strategic sourcing of high-quality stretcher beds.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to stretcher bed

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.