Is Your Slide Mechanism Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for slide mechanism

In today’s competitive landscape, sourcing reliable slide mechanisms can be a daunting challenge for international B2B buyers, particularly those in emerging markets like Nigeria and Vietnam. The diversity of slide mechanisms—ranging from electric and hydraulic systems to cable and rack-and-pinion designs—can complicate purchasing decisions. This comprehensive guide aims to demystify the global market for slide mechanisms, offering insights into various types, their applications across industries, and critical factors for supplier vetting.

Understanding the nuances of slide mechanism technology is essential for making informed purchasing decisions that align with your business needs and operational requirements. This guide will cover essential topics, including cost considerations, maintenance protocols, and best practices for sourcing high-quality components from reputable suppliers. By equipping buyers with the knowledge needed to navigate this complex landscape, we empower businesses to optimize their procurement strategies, reduce operational risks, and ensure long-term satisfaction with their slide mechanisms.

Whether you are expanding your manufacturing capabilities or enhancing product offerings, this guide serves as a vital resource for B2B buyers from Africa, South America, the Middle East, and Europe, ensuring you can confidently invest in the right solutions for your specific needs.

Understanding slide mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Slide | Utilizes electric motors with gear and rack systems. | RVs, mobile homes, modular buildings | Pros: Easy to operate, lower maintenance. Cons: Requires reliable power source, potential for motor failure. |

| Hydraulic Slide | Operates via hydraulic pumps and cylinders. | Commercial vehicles, heavy machinery | Pros: High lifting capacity, smooth operation. Cons: More complex maintenance, potential for hydraulic leaks. |

| Cable Slide | Features cables and pulleys driven by electric motors. | RVs, trailers, and larger mobile units | Pros: Lightweight, suitable for longer slides. Cons: Requires regular tension adjustments, potential cable wear. |

| Schwintek Slide | Identified by external aluminum guides and worm tracks. | Lightweight RVs and trailers | Pros: Compact design, easy installation. Cons: Limited to lighter applications, may require precise alignment. |

| Rack and Pinion Slide | Uses rotating gears and linear tracks for movement. | Various vehicles, including RVs | Pros: Affordable, easy adjustability. Cons: Mechanical wear over time, may need frequent maintenance. |

What Are the Key Characteristics of Electric Slide Mechanisms?

Electric slide mechanisms are characterized by their use of electric motors coupled with gear and rack systems to extend and retract slide-outs. They are prevalent in RVs and mobile homes due to their straightforward operation, typically activated by a wall switch. For B2B buyers, the ease of use and lower maintenance requirements make electric slides appealing. However, ensuring a reliable power source is essential, as failure to provide adequate voltage can hinder performance.

How Do Hydraulic Slide Mechanisms Operate?

Hydraulic slide mechanisms utilize hydraulic pumps and cylinders to facilitate movement. This type is commonly found in commercial vehicles and heavy machinery, where the need for high lifting capacities is paramount. The smooth operation and robust power provided by hydraulic systems are significant advantages. However, B2B purchasers must consider the complexity of maintenance and the risks associated with hydraulic leaks, which can lead to costly repairs.

What Are the Benefits of Cable Slide Mechanisms?

Cable slide mechanisms incorporate a system of cables and pulleys powered by electric motors, making them lightweight and capable of managing longer slide-outs. They are often used in RVs and trailers, providing a balance of strength and weight efficiency. For buyers, the primary consideration is the need for regular tension adjustments to maintain functionality, as wear on cables can lead to performance issues.

Why Choose Schwintek Slide Mechanisms for Lightweight Applications?

Schwintek slide mechanisms are recognized for their external aluminum guides and worm tracks, designed specifically for lightweight RVs and trailers. Their compact design allows for easy installation in spaces where weight savings are crucial. While they offer advantages in terms of space efficiency, B2B buyers should be aware of the limitations regarding the weight capacity and the need for precise alignment during installation.

What Advantages Do Rack and Pinion Slide Mechanisms Offer?

Rack and pinion slide mechanisms employ rotating gears to move along a linear track, making them a common choice in various vehicles, including RVs. These systems are known for their affordability and ease of adjustability, which can be advantageous for businesses looking to minimize costs. However, potential mechanical wear over time necessitates a commitment to regular maintenance, which is a critical consideration for B2B buyers aiming for long-term reliability.

Key Industrial Applications of slide mechanism

| Industry/Sector | Specific Application of slide mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Adjustable seating and dashboard components | Enhanced user comfort and vehicle adaptability | Durability under varying temperatures and conditions |

| Construction | Sliding doors and windows in modular buildings | Space optimization and improved accessibility | Compliance with local building regulations |

| Electronics | Retractable screens and panels in devices | Improved design aesthetics and functionality | Precision engineering and compatibility with devices |

| Marine | Slide-out compartments in yachts and boats | Maximized storage and living space in confined areas | Resistance to corrosion and water damage |

| Hospitality | Slide-out furniture in hotels and resorts | Versatile space usage for events and guest comfort | Aesthetic appeal and durability for high-traffic use |

How is Slide Mechanism Utilized in the Automotive Industry?

In the automotive sector, slide mechanisms are often employed in adjustable seating and dashboard components. These mechanisms allow for easy customization of seating positions, catering to different driver preferences and enhancing overall comfort. For international buyers, particularly from regions like Africa and South America, sourcing durable materials that can withstand diverse climates is crucial. Additionally, compliance with safety standards is essential to ensure the longevity and reliability of these components.

What Role Does Slide Mechanism Play in Construction?

In construction, slide mechanisms are integral to the functionality of sliding doors and windows in modular buildings. These applications not only facilitate space optimization but also enhance accessibility, making them ideal for both residential and commercial projects. Buyers in the Middle East and Europe should prioritize suppliers who adhere to local building regulations and standards, ensuring that the mechanisms are both functional and compliant. Additionally, considering the materials used is vital for durability and insulation.

How Are Slide Mechanisms Used in Electronics?

The electronics industry leverages slide mechanisms for retractable screens and panels in various devices, such as smartphones and tablets. This innovation not only improves the design aesthetics but also enhances device functionality by allowing for larger screens in compact formats. Buyers from regions like Vietnam and Nigeria should seek suppliers with expertise in precision engineering to ensure compatibility with existing technologies. The ability to integrate seamlessly with other components is a key consideration in this sector.

Why Are Slide Mechanisms Important in Marine Applications?

In the marine industry, slide-out compartments in yachts and boats utilize slide mechanisms to maximize storage and living space in confined areas. This is particularly valuable in luxury vessels where space is at a premium. International buyers should focus on sourcing materials that are resistant to corrosion and water damage, as these factors significantly affect the longevity and performance of marine applications. Additionally, ensuring that these mechanisms can operate smoothly in harsh marine environments is crucial for reliability.

How Do Slide Mechanisms Enhance Hospitality Solutions?

In the hospitality industry, slide-out furniture is increasingly used in hotels and resorts to create versatile spaces for events and guest comfort. These mechanisms allow for quick reconfiguration of spaces, adapting to various needs and maximizing usability. For B2B buyers in Africa and South America, it’s essential to consider the aesthetic appeal and durability of these solutions, as they must withstand high traffic while maintaining a welcoming atmosphere for guests. Sourcing from manufacturers who specialize in high-quality, visually appealing designs can significantly enhance the customer experience.

3 Common User Pain Points for ‘slide mechanism’ & Their Solutions

Scenario 1: Difficulty in Identifying Slide Mechanism Types

The Problem:

B2B buyers often face significant challenges when it comes to identifying the type of slide mechanism used in their vehicles or equipment. This is particularly true for manufacturers and fleet operators who may be dealing with various models and brands. Without clear identification, it becomes nearly impossible to source the right replacement parts or to conduct appropriate maintenance. Misidentifying the slide mechanism can lead to costly downtime, wasted resources, and even damage to the equipment.

The Solution:

To effectively identify the slide mechanism, buyers should implement a systematic approach. First, they should consult the manufacturer’s specifications or user manuals when available. If manuals are not accessible, a visual inspection of the mechanism is essential. Look for distinguishing features such as hydraulic lines for hydraulic systems or electric motors and gear systems for electric mechanisms. Creating a standardized checklist for each vehicle or equipment can aid in rapid identification. Additionally, investing in training for maintenance personnel on different slide-out types—like cable systems, rack and pinion, and Schwintek—can enhance their ability to quickly and accurately identify mechanisms. This proactive measure can save time and resources in the long run.

Scenario 2: Voltage Issues Leading to Slide Malfunction

The Problem:

One common issue B2B buyers encounter is the malfunctioning of slide mechanisms due to inadequate voltage supply. Slides are heavy components requiring significant power to operate. When battery maintenance is neglected, or if the electrical system is not properly designed, the slide may fail to extend or retract smoothly. This can cause operational delays and create a frustrating experience for users, particularly in sectors that rely on mobile or expandable units, such as RV manufacturers and fleet operators.

The Solution:

To prevent voltage-related issues, it is crucial for buyers to invest in robust battery maintenance protocols. Regularly check battery health and ensure connections are clean and free of corrosion. Consider integrating a battery monitoring system to keep tabs on the charge levels and overall health of the electrical system. For new purchases, buyers should specify high-quality, heavy-duty batteries that can handle the demands of slide mechanisms. Additionally, a thorough electrical system assessment during the design or procurement phase can ensure that the system is capable of providing the necessary voltage consistently. Implementing these measures will enhance the reliability of slide mechanisms and reduce the likelihood of operational interruptions.

Scenario 3: Maintenance Complexity Leading to Increased Downtime

The Problem:

Many B2B buyers in the RV and mobile equipment industries find that the maintenance of slide mechanisms can be overly complex and time-consuming. This complexity often leads to increased downtime, which is particularly detrimental in competitive markets where efficiency is key. Without a clear understanding of the maintenance requirements for different slide types, companies may struggle to keep their equipment in optimal working condition, resulting in lost business opportunities.

The Solution:

To address maintenance complexities, buyers should develop a comprehensive maintenance plan tailored to the specific slide mechanisms in use. This plan should include scheduled inspections, lubrication routines, and troubleshooting guides tailored to the type of slide mechanism. Engaging with manufacturers for training sessions on specific slide-out systems can empower maintenance teams with the knowledge they need to perform upkeep efficiently. Additionally, leveraging technology such as maintenance management software can help track service schedules and maintenance histories, ensuring that no critical tasks are overlooked. By streamlining maintenance processes, companies can significantly reduce downtime and enhance the longevity and reliability of their slide mechanisms.

Strategic Material Selection Guide for slide mechanism

What Are the Key Materials Used in Slide Mechanisms?

When selecting materials for slide mechanisms, it is essential to consider the specific requirements of the application, including environmental conditions, load capacities, and operational longevity. Here, we analyze four common materials used in slide mechanisms: aluminum, steel, plastic composites, and stainless steel. Each material presents unique properties, advantages, and limitations that must be understood by B2B buyers, especially in diverse international markets.

How Does Aluminum Perform in Slide Mechanisms?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels.

Pros: Aluminum is durable and resistant to rust, making it suitable for outdoor applications. Its lightweight nature facilitates easier installation and operation of slide mechanisms, which is particularly beneficial in mobile applications like RVs or trailers.

Cons: While aluminum is cost-effective, it may not withstand extreme loads as well as other metals. Additionally, its manufacturing processes can be complex, especially when precision machining is required.

Impact on Application: Aluminum is compatible with various media, including water and air, but may not be suitable for applications involving harsh chemicals.

Considerations for Buyers: International buyers should ensure compliance with material standards such as ASTM B221 for extruded aluminum shapes. In regions like Africa and South America, sourcing aluminum from local suppliers can reduce costs and lead times.

What Are the Benefits of Steel in Slide Mechanisms?

Steel is renowned for its high strength and durability, making it a popular choice for heavy-duty slide mechanisms. It has a higher temperature rating than aluminum, often exceeding 300°C, and can handle substantial pressure.

Pros: Steel’s robust nature allows it to support heavier loads, making it ideal for industrial applications. It is also more cost-effective than aluminum for larger components.

Cons: Steel is heavier than aluminum and is susceptible to corrosion if not properly treated. This can lead to increased maintenance costs over time.

Impact on Application: Steel is compatible with various media, including oil and gas, but may require protective coatings for corrosive environments.

Considerations for Buyers: Buyers in Europe and the Middle East should be aware of compliance with EN standards for steel products. In regions with high humidity, such as parts of Africa, corrosion-resistant coatings are essential.

How Do Plastic Composites Enhance Slide Mechanisms?

Plastic composites are increasingly used in slide mechanisms due to their lightweight and corrosion-resistant properties. They can typically withstand temperatures up to 100°C and moderate pressure.

Pros: Composites are highly resistant to chemicals and moisture, making them suitable for diverse environments. They also reduce noise and vibration during operation.

Cons: While they are cost-effective for smaller components, their strength may not match that of metals, limiting their use in heavy-duty applications.

Impact on Application: Plastic composites are ideal for applications involving water or mild chemicals but may not be suitable for high-temperature or high-pressure situations.

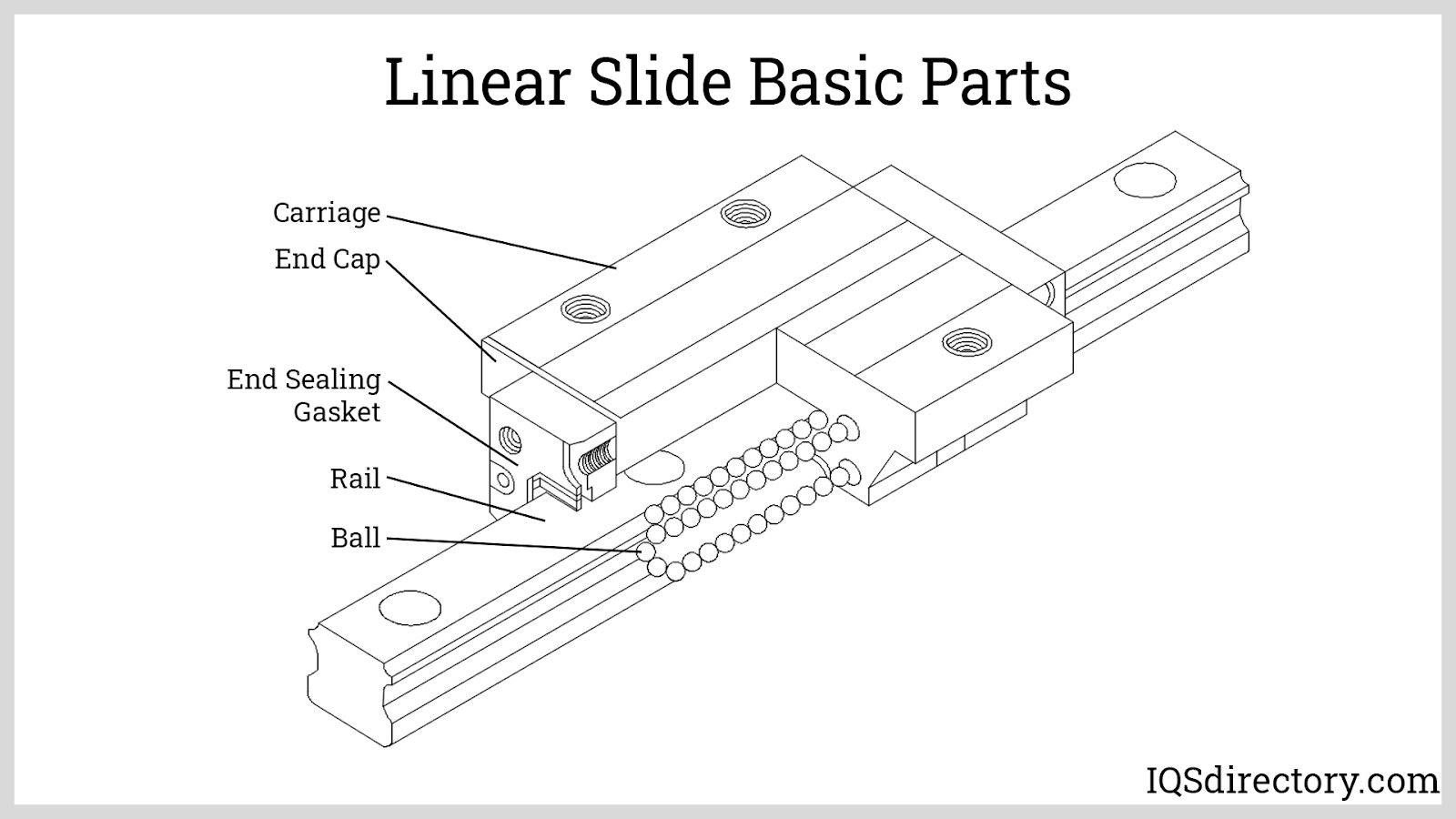

Illustrative image related to slide mechanism

Considerations for Buyers: International buyers should check for compliance with standards such as ASTM D638 for tensile properties. In regions like Vietnam, where humidity is high, the moisture resistance of composites can be a significant advantage.

What Role Does Stainless Steel Play in Slide Mechanisms?

Stainless steel is known for its exceptional corrosion resistance and durability, making it an excellent choice for slide mechanisms exposed to harsh environments. It can withstand high temperatures and pressures, often exceeding 400°C.

Pros: Its strength and resistance to rust make stainless steel ideal for demanding applications, including marine and industrial environments. It also requires minimal maintenance.

Cons: The primary drawback is its cost, which is typically higher than other materials. The manufacturing process can also be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including corrosive substances, making it suitable for chemical processing applications.

Considerations for Buyers: Buyers in regions with stringent environmental regulations, such as Europe, should ensure compliance with EN 10088 standards for stainless steel. Additionally, sourcing options may vary, with local suppliers potentially offering better pricing.

Summary Table of Material Selection for Slide Mechanisms

| Material | Typical Use Case for slide mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | RV and trailer slide mechanisms | Lightweight and corrosion-resistant | Less load capacity compared to steel | Medium |

| Steel | Industrial heavy-duty applications | High strength and load-bearing capacity | Susceptible to corrosion | Low |

| Plastic Composites | Lightweight consumer products | Chemical resistance and noise reduction | Limited strength for heavy applications | Low |

| Stainless Steel | Marine and chemical processing | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

This guide serves as a foundational resource for international B2B buyers looking to make informed decisions regarding material selection for slide mechanisms. Understanding the properties, advantages, and limitations of each material will enable buyers to choose the best option for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for slide mechanism

The manufacturing process and quality assurance of slide mechanisms are critical aspects for B2B buyers, especially in international markets. Understanding these processes can help buyers select reliable suppliers and ensure they receive products that meet their specific requirements.

What are the Main Stages of Manufacturing Slide Mechanisms?

The manufacturing of slide mechanisms typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is essential in creating a robust and reliable product.

How is Material Prepared for Slide Mechanisms?

Material preparation is the first step, involving the selection of high-quality materials that meet the necessary specifications for durability and performance. Common materials include aluminum, steel, and high-strength plastics. The chosen materials undergo rigorous inspection to ensure they conform to industry standards. This may involve checking for defects, measuring thickness, and verifying chemical compositions.

What Forming Techniques are Used in Slide Mechanism Production?

Forming techniques play a crucial role in shaping the materials into components for slide mechanisms. Techniques such as extrusion, stamping, and machining are commonly employed. For instance, aluminum components might be extruded to create the desired profiles, while steel parts may be stamped for precision. These processes require specialized machinery and skilled operators to ensure accuracy and efficiency.

How is Assembly Conducted in Slide Mechanism Manufacturing?

Assembly is where individual components come together to form the final slide mechanism. This stage may involve manual assembly or the use of automated systems. Precision is critical; components must align perfectly to ensure smooth operation. Quality control checkpoints are integrated into the assembly process, where workers or machines verify tolerances and functionality before moving to the next stage.

What Finishing Processes Are Applied to Slide Mechanisms?

Finishing processes enhance the aesthetic appeal and functional performance of slide mechanisms. Common techniques include anodizing, powder coating, and surface treatments that improve corrosion resistance. These finishing processes not only extend the lifespan of the product but also ensure that it meets industry-specific aesthetic requirements. The final products undergo comprehensive inspections to confirm that they meet quality standards before packaging.

What Quality Control Measures are Essential in Slide Mechanism Manufacturing?

Quality control is paramount in ensuring that slide mechanisms meet international standards and customer expectations. There are several relevant standards and checkpoints throughout the manufacturing process.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 serve as benchmarks for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality. Additionally, industry-specific certifications such as CE (for European markets) and API (for oil and gas applications) may be relevant depending on the application of the slide mechanism.

What are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify that they meet specified standards. Defective materials are rejected to prevent downstream issues.

- In-Process Quality Control (IPQC): This stage includes monitoring the manufacturing processes to catch defects early. Regular checks are conducted to ensure that machinery is operating correctly and that components are within tolerance.

- Final Quality Control (FQC): The final inspection occurs before products are packaged and shipped. This includes functional testing, dimensional checks, and visual inspections to ensure that each slide mechanism meets quality standards.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods vary depending on the specific requirements of the slide mechanism but often include:

- Functional Testing: Ensures that the slide mechanism operates as intended under load conditions.

- Durability Testing: Involves subjecting the mechanism to repeated use to simulate long-term performance.

- Corrosion Resistance Testing: Assesses the materials’ ability to withstand environmental factors, especially for mechanisms used in outdoor or harsh conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures employed by suppliers. Here are some effective strategies:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is an essential step. Buyers can request audits to review a supplier’s manufacturing processes, quality control measures, and compliance with international standards. This can include on-site visits or third-party audits conducted by recognized organizations.

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers can provide insights into their adherence to quality standards. These reports should detail the results of IQC, IPQC, and FQC, along with any corrective actions taken for non-conformities.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an additional layer of assurance. These services conduct independent evaluations of the manufacturing process and final products, ensuring that they meet specified standards and requirements.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, there are specific nuances to consider. Understanding regional regulations and standards is crucial, as compliance may differ significantly across markets.

How Do Cultural and Regulatory Differences Affect Quality Control?

Cultural differences can impact quality expectations and communication with suppliers. Buyers should be aware of these differences and ensure that expectations regarding quality standards are clearly communicated. Additionally, understanding regional regulations, such as those pertaining to safety and environmental impacts, is essential for compliance and successful market entry.

Conclusion

Manufacturing processes and quality assurance for slide mechanisms are complex but critical areas for B2B buyers. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, buyers can make informed decisions that enhance their procurement strategies and ultimately lead to successful partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slide mechanism’

Introduction

This practical sourcing guide provides a structured approach for B2B buyers interested in procuring slide mechanisms. Understanding the various types and specifications of slide mechanisms is critical for ensuring compatibility, reliability, and efficiency in your applications. This checklist will help you navigate the procurement process effectively.

1. Identify Your Application Requirements

Before sourcing slide mechanisms, clearly define the application in which they will be used. Consider factors such as load capacity, space constraints, and the type of environment (e.g., outdoor, industrial). This understanding will guide your selection process and help you communicate your needs to potential suppliers.

2. Define Your Technical Specifications

Establish the technical specifications that the slide mechanism must meet. This includes dimensions, material preferences (e.g., aluminum, steel), and operational mechanisms (electric, hydraulic, or manual). Detailed specifications will aid in evaluating product offerings and ensuring they align with your operational requirements.

3. Research Different Slide Mechanism Types

Familiarize yourself with the various types of slide mechanisms available in the market. Key types include:

– Electric Slide-Outs: Ideal for ease of use and quick operation, but require adequate power supply.

– Hydraulic Slide-Outs: Suitable for heavier applications, offering robust performance but may necessitate additional maintenance.

– Cable Systems: Lightweight and efficient for longer slides, but ensure proper alignment and tensioning.

Understanding these types will enable you to choose the best fit for your needs.

4. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your needs. Request company profiles, product catalogs, and case studies that illustrate their experience in your industry. It’s also beneficial to seek references from other businesses that have sourced similar products to gauge reliability and service quality.

5. Verify Supplier Certifications and Compliance

Ensure that suppliers have the necessary certifications and compliance with international standards (e.g., ISO, CE). This verification is crucial for ensuring product quality and safety, especially if the slide mechanisms will be used in regulated environments or industries.

6. Request Samples or Prototypes

Before finalizing your order, request samples or prototypes of the slide mechanisms. Testing these samples in your specific application will help you assess their performance and compatibility. This step can prevent costly mistakes and ensure you are satisfied with the product before committing to a larger purchase.

7. Negotiate Terms and Conditions

Once you’ve identified a suitable supplier and confirmed product specifications, engage in negotiations regarding pricing, delivery timelines, and after-sales support. Clear communication during this phase is vital for establishing a long-term partnership and ensuring that both parties are aligned on expectations.

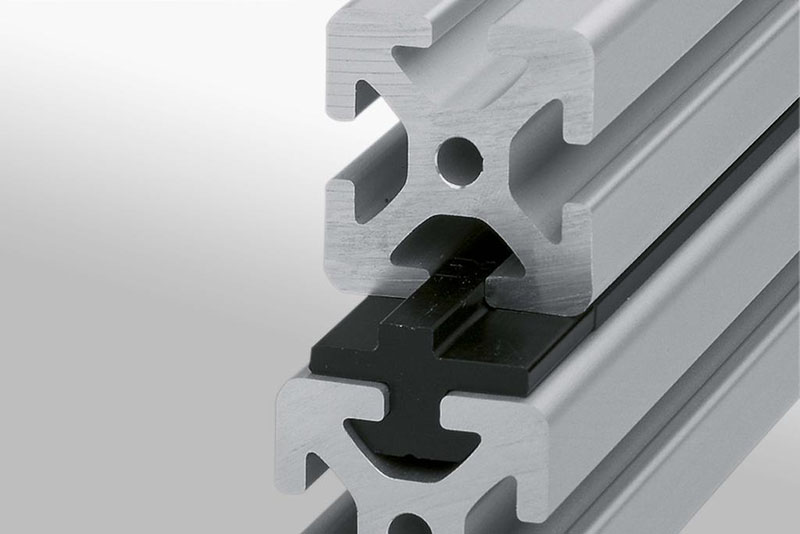

Illustrative image related to slide mechanism

By following this checklist, B2B buyers can navigate the complexities of procuring slide mechanisms effectively, ensuring that their selections meet both operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for slide mechanism Sourcing

What Are the Key Cost Components in Slide Mechanism Sourcing?

When sourcing slide mechanisms, understanding the cost structure is essential for making informed purchasing decisions. The main cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Common materials include aluminum, steel, and high-strength plastics. The quality and sourcing of these materials can vary widely, impacting price.

-

Labor: Labor costs depend on the manufacturing location and the complexity of the slide mechanism. Regions with higher labor costs may lead to increased pricing, while more automated manufacturing processes can mitigate labor expenses.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as facility maintenance, utilities, and administrative expenses. Efficient operations can help keep these costs down.

-

Tooling: Custom tooling for specific slide mechanisms can be a substantial upfront investment. The complexity of the design and the materials used will determine tooling costs.

-

Quality Control (QC): Ensuring product reliability and compliance with international standards may involve additional QC expenses. Certifications such as ISO can add to the cost but are crucial for maintaining quality assurance.

-

Logistics: Transportation and shipping costs vary based on distance, weight, and volume. For international buyers, understanding Incoterms can help in estimating these logistics costs accurately.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and demand.

How Do Pricing Influencers Affect Slide Mechanism Costs?

Several factors influence the pricing of slide mechanisms, impacting the overall cost structure for buyers:

Illustrative image related to slide mechanism

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes can lead to significant discounts. Suppliers often have a MOQ, and meeting these thresholds can provide better pricing.

-

Specifications and Customization: Customized slide mechanisms, tailored to specific needs, may incur additional costs. Standard products are generally more cost-effective than bespoke solutions.

-

Materials and Quality Certifications: Higher quality materials and compliance with specific certifications can drive up costs. Buyers must balance quality requirements with budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery is critical for cost estimation. Different Incoterms can shift the burden of shipping costs and risk between the buyer and seller.

What Tips Can Help Buyers Negotiate Better Prices for Slide Mechanisms?

To optimize sourcing costs, buyers should consider the following strategies:

-

Negotiate Volume Discounts: Engaging in discussions about bulk purchases can yield favorable pricing. Suppliers are often willing to negotiate on larger orders.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial purchase prices, consider the TCO, which includes maintenance, operational efficiency, and durability over time. This broader perspective can lead to more cost-effective decisions.

-

Research Pricing Nuances in Different Markets: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of regional pricing variations. Factors such as import duties, local competition, and currency fluctuations can impact costs.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and ensure competitive pricing.

-

Understand Local Market Trends: Being informed about local market trends can help buyers anticipate pricing shifts and make timely purchasing decisions.

Conclusion

In conclusion, navigating the cost and pricing landscape for slide mechanisms requires a comprehensive understanding of the various cost components and influencers. By leveraging negotiation tactics and considering the Total Cost of Ownership, international B2B buyers can make more informed purchasing decisions that align with their operational goals. It’s essential to approach sourcing with a strategic mindset to optimize costs effectively.

Alternatives Analysis: Comparing slide mechanism With Other Solutions

In the pursuit of optimizing space and functionality in vehicles or structures, various mechanisms exist beyond the traditional slide mechanism. Understanding the alternatives available can empower B2B buyers to make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Slide Mechanism | Alternative 1: Folding Mechanism | Alternative 2: Telescoping Mechanism |

|---|---|---|---|

| Performance | High efficiency in expanding space | Moderate efficiency; space-saving | Excellent for compact spaces |

| Cost | Moderate to high initial investment | Generally lower cost | Higher cost due to complexity |

| Ease of Implementation | Requires specialized installation | Easier to install | More complex installation process |

| Maintenance | Regular maintenance needed | Low maintenance requirements | Moderate maintenance needed |

| Best Use Case | RVs, mobile homes, and trailers | Compact living spaces, urban settings | Heavy-duty applications, cranes, and lifts |

How Does a Folding Mechanism Compare to Slide Mechanisms?

Folding mechanisms are an alternative that allows for significant space savings by collapsing or folding into a smaller profile. This system is generally more affordable and easier to install than slide mechanisms, making it ideal for smaller applications like compact living spaces or urban environments. However, the performance may not match that of slide mechanisms in terms of efficiency and ease of use. Maintenance requirements are also minimal, making it a good option for cost-conscious buyers.

What Are the Advantages of a Telescoping Mechanism?

Telescoping mechanisms utilize a series of interlocking sections that slide within one another, allowing for excellent space efficiency. This method is particularly advantageous in heavy-duty applications, such as cranes or lifts, where maximizing lifting capacity and stability is crucial. However, the complexity of the system can lead to higher initial costs and more intricate installation processes. Maintenance is moderate, requiring periodic checks to ensure smooth operation, making it essential for B2B buyers in demanding environments to weigh these factors carefully.

Conclusion: Which Mechanism Should You Choose for Your Needs?

When evaluating which mechanism to adopt, B2B buyers must assess their specific application requirements, budget constraints, and maintenance capabilities. If space optimization and ease of access are paramount, slide mechanisms may offer the best performance. Conversely, for projects with budget limitations or simpler operational demands, folding mechanisms could provide adequate functionality at a lower cost. Telescoping mechanisms serve specialized needs and may justify their investment in heavy-duty scenarios. Ultimately, the right choice hinges on aligning the mechanism’s strengths with the operational goals of the business.

Essential Technical Properties and Trade Terminology for slide mechanism

What Are the Key Technical Properties of Slide Mechanisms?

In the B2B landscape of slide mechanisms, understanding critical specifications is essential for making informed purchasing decisions. Here are several key properties that buyers should consider:

1. Material Grade

The material used in slide mechanisms significantly impacts durability and performance. Common materials include aluminum, steel, and high-strength plastics. For instance, aluminum offers a good balance of weight and strength, making it ideal for applications where weight is a concern, such as RVs. Buyers should assess the material grade to ensure it meets the specific environmental and operational demands of their application.

2. Load Capacity

Load capacity defines the maximum weight a slide mechanism can support without compromising functionality. It is crucial for applications such as RVs or modular buildings where slide-outs expand living spaces. Understanding load capacity helps businesses choose the right system, ensuring it can handle the intended use without failure, which could lead to costly downtime or repairs.

3. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions of the slide components. It is critical for ensuring proper fit and function, especially in systems that must align precisely for optimal performance. Tight tolerances are essential in high-precision applications, while looser tolerances may suffice for less demanding environments. Buyers should specify tolerance levels to ensure compatibility with existing systems and components.

4. Actuation Type

Slide mechanisms can be actuated either electrically or hydraulically. Understanding the difference is vital for maintenance and operational efficiency. Electric systems often offer easier installation and lower maintenance costs, while hydraulic systems can provide greater force and smoother operation for larger slides. Buyers must consider their specific use cases when choosing the actuation type.

5. Maintenance Requirements

Different slide mechanisms come with varying maintenance needs, which can impact operational costs. For example, hydraulic systems may require regular fluid checks and potential leaks monitoring, while electric systems may need periodic electrical inspections. Understanding these requirements helps businesses plan for long-term maintenance and avoid unexpected costs.

6. Compatibility with Automation

As technology evolves, many slide mechanisms are now compatible with automation systems. This feature allows for remote operation and integration with smart home technologies, enhancing user experience and convenience. Businesses looking to future-proof their investments should consider the compatibility of slide mechanisms with automation technologies.

What Are Common Trade Terms Related to Slide Mechanisms?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation. Here are some common terms used in the slide mechanism trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can help buyers gauge the quality and reliability of the components being sourced, as OEM products often adhere to strict quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and financial planning. Understanding MOQ helps businesses balance their purchasing needs with supplier requirements.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is essential for obtaining competitive pricing and ensuring that buyers receive the best value for their investments in slide mechanisms.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms helps businesses understand shipping logistics, risk management, and cost implications during international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead time is crucial for project planning and inventory management. Buyers should factor in lead time when scheduling deliveries to avoid disruptions in operations.

Illustrative image related to slide mechanism

6. Certification Standards

Certification standards, such as ISO or CE, indicate that a product meets specific safety and quality benchmarks. Knowing whether a slide mechanism is certified can provide buyers with confidence in its reliability and performance, especially in regulated industries.

In conclusion, a clear understanding of technical properties and trade terminology is vital for B2B buyers in the slide mechanism market. By focusing on these aspects, businesses can make informed decisions that enhance operational efficiency and reduce costs.

Navigating Market Dynamics and Sourcing Trends in the slide mechanism Sector

What Are the Key Drivers Influencing the Slide Mechanism Market?

The slide mechanism sector is witnessing significant transformations driven by technological advancements and changing consumer preferences. Globally, the demand for recreational vehicles (RVs) and modular living spaces is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe. This surge is propelled by an increase in disposable income, a growing interest in outdoor activities, and a trend towards more compact living solutions. For B2B buyers in emerging markets, understanding these dynamics is crucial for aligning their sourcing strategies with market demands.

Emerging technologies such as smart slide-out systems equipped with IoT capabilities are gaining traction. These innovations enhance user experience by allowing remote operation and monitoring of slide mechanisms through mobile applications. Additionally, the demand for energy-efficient solutions is influencing the development of lighter and more durable materials, which can lead to cost savings in shipping and maintenance. Buyers should be aware of these trends to source products that not only meet current standards but also anticipate future requirements.

How Can Sustainability and Ethical Sourcing Impact Slide Mechanism Sourcing?

Sustainability is becoming increasingly important in the slide mechanism sector. B2B buyers are now prioritizing suppliers who demonstrate a commitment to reducing environmental impact. This includes sourcing materials that are recyclable or made from renewable resources, as well as minimizing waste during production. For instance, manufacturers are exploring eco-friendly composites and lightweight metals that reduce the overall carbon footprint of slide mechanisms.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should seek suppliers that adhere to ethical labor practices and ensure fair treatment of workers throughout the supply chain. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for sustainable wood sourcing can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with these credentials, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products.

What Is the Evolution of Slide Mechanisms in the B2B Context?

The evolution of slide mechanisms dates back several decades, initially gaining popularity in the RV industry. Early systems were primarily manual, requiring significant physical effort to operate. However, advancements in hydraulic and electric technologies have revolutionized the sector, making slide mechanisms more efficient and user-friendly. Today, systems like the Schwintek and Lippert designs illustrate the shift towards automated solutions that offer reliability and ease of use.

This progression has allowed manufacturers to cater to a broader audience, including not just RVs but also modular buildings and mobile homes. As the market continues to evolve, B2B buyers must stay informed about these technological advancements to ensure they are sourcing the most up-to-date and efficient slide mechanisms for their needs. Understanding the historical context also provides valuable insights into future trends and innovations that may emerge in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of slide mechanism

-

1. How do I identify the right slide mechanism for my application?

Identifying the right slide mechanism involves evaluating your specific needs, such as the weight and dimensions of the items to be moved, the frequency of use, and the environment in which the mechanism will operate. Consider the two primary types: electric and hydraulic systems. Electric mechanisms are generally more straightforward to install and maintain, while hydraulic systems can handle heavier loads. Additionally, consult with suppliers about customization options to ensure compatibility with your existing infrastructure. -

2. What factors should I consider when sourcing slide mechanisms internationally?

When sourcing slide mechanisms internationally, consider quality certifications, supplier reliability, and the availability of spare parts. Assess the supplier’s experience in your industry and their ability to meet your technical specifications. Additionally, understanding local regulations and import duties in your region can help avoid unexpected costs. It’s also wise to request samples or prototypes before committing to larger orders. -

3. How can I ensure the quality of slide mechanisms from suppliers?

To ensure the quality of slide mechanisms, request detailed product specifications and certifications from suppliers. Conduct factory audits or quality assurance checks to verify manufacturing processes. Establish clear quality criteria and performance benchmarks in your purchase agreement. It’s also beneficial to read reviews or seek testimonials from other B2B clients who have previously worked with the supplier. -

4. What is the minimum order quantity (MOQ) for slide mechanisms?

Minimum order quantities (MOQ) for slide mechanisms can vary significantly between suppliers and depend on the complexity of the product. Typically, standard items may have an MOQ of 50-100 units, while custom designs could require larger orders. Discuss your needs with potential suppliers to negotiate favorable terms that align with your inventory strategy and cash flow considerations. -

5. Are there customization options available for slide mechanisms?

Yes, many suppliers offer customization options for slide mechanisms to meet specific application requirements. Customization may include size adjustments, material selection, and modifications to mechanical components. When discussing your needs with suppliers, provide detailed specifications and performance expectations to facilitate the design process. This ensures the final product aligns with your operational demands. -

6. What payment terms are typically offered for international orders?

Payment terms for international orders can vary widely, but common practices include letters of credit, advance payments, and net payment terms after delivery. Suppliers may request a deposit upfront, especially for custom orders. Always negotiate terms that balance risk and cash flow while ensuring that you have sufficient recourse in case of non-compliance or quality issues. -

7. How do I handle logistics and shipping for slide mechanisms?

Handling logistics and shipping for slide mechanisms involves selecting a reliable freight forwarder and understanding the shipping terms (Incoterms) applicable to your order. Consider the most efficient shipping methods based on cost, delivery time, and the nature of the product. Be aware of any customs regulations and tariffs in your country to avoid delays. Additionally, tracking shipments and maintaining communication with your supplier can help resolve any potential issues quickly. -

8. What are the common maintenance practices for slide mechanisms?

Regular maintenance of slide mechanisms is crucial for longevity and performance. Common practices include inspecting mechanical components for wear, checking hydraulic fluid levels for hydraulic systems, and ensuring electrical connections are secure for electric mechanisms. Lubricating moving parts and cleaning tracks can prevent operational issues. Establishing a maintenance schedule based on the manufacturer’s recommendations can help identify problems early and reduce downtime.

Top 1 Slide Mechanism Manufacturers & Suppliers List

1. BBC – Slider Mechanism

Domain: bbc.co.uk

Registered: 1996 (29 years)

Introduction: A slider mechanism is a set of moving parts that work together to allow motion in two directions, typically forwards and backwards or side to side. It consists of a rigid bar or rod that moves within a guide, which can be a rail, slot, bracket, or groove. Slider mechanisms are commonly found in door latches, sliding drawers, sound mixing desks, and puzzles. They ensure smooth motion and are used i…

Strategic Sourcing Conclusion and Outlook for slide mechanism

In conclusion, the landscape of slide mechanisms offers a diverse range of options, each with unique advantages and maintenance considerations. Understanding the distinctions between electric, hydraulic, and cable-driven systems is crucial for international B2B buyers, as it informs both procurement decisions and ongoing maintenance strategies. A strategic sourcing approach not only enhances operational efficiency but also ensures that buyers are equipped with the most reliable and suitable slide mechanisms for their needs.

For businesses operating in regions such as Africa, South America, the Middle East, and Europe, the importance of sourcing high-quality components cannot be overstated. As these markets continue to grow, leveraging local suppliers and manufacturers can foster sustainable partnerships and optimize supply chains.

Looking ahead, the demand for innovative slide mechanisms will likely rise, driven by advancements in technology and increased consumer expectations. By prioritizing strategic sourcing, international B2B buyers can position themselves to take advantage of emerging opportunities and ensure they remain competitive in this evolving market. Engage with suppliers today to explore the latest offerings and secure the best solutions for your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.