Is Your Silicon Tubing Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for silicon tubing

In the ever-evolving global market, sourcing high-quality silicone tubing can pose significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexity arises from the need to navigate varying standards, applications, and supplier capabilities, which can lead to critical mistakes in procurement. This guide aims to demystify the process of selecting silicone tubing, offering insights into the various types available, their specific applications across industries, and key considerations for supplier vetting.

From medical-grade options that meet stringent purity standards to industrial-grade tubing designed for high-temperature applications, understanding the breadth of available products is essential for making informed purchasing decisions. Additionally, we delve into cost factors, helping buyers evaluate the total cost of ownership rather than just the upfront price.

Equipped with this comprehensive knowledge, international B2B buyers can confidently engage with suppliers and negotiate favorable terms, ensuring that their operations are supported by reliable, high-performance silicone tubing solutions. Whether you are a buyer in Nigeria looking to source for medical applications or a procurement officer in Germany seeking industrial-grade solutions, this guide is designed to empower your decision-making process and streamline your purchasing efforts.

Understanding silicon tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Platinum-Cured Silicone Tubing | High purity, biocompatibility, autoclavable | Medical, pharmaceutical, food and beverage | Pros: Excellent for sensitive applications; Cons: Higher cost compared to other types. |

| High-Temperature Silicone Tubing | Resistant to extreme temperatures, flexible | Aerospace, automotive, industrial machinery | Pros: Durable under heat; Cons: Limited flexibility at high temperatures. |

| Food-Grade Silicone Tubing | Compliant with food safety regulations, non-toxic | Food processing, packaging, beverage dispensing | Pros: Safe for food contact; Cons: May require specific certifications. |

| Reinforced Silicone Hose | Added durability, pressure resistance | Chemical transfer, pneumatic controls, industrial applications | Pros: Enhanced strength; Cons: Heavier and less flexible than standard tubing. |

| Medical-Grade Silicone Tubing | Designed for biopharmaceutical and medical applications | Infusion pumps, laboratory environments, medical devices | Pros: High reliability; Cons: More expensive due to regulatory compliance. |

What Are the Characteristics of Platinum-Cured Silicone Tubing?

Platinum-cured silicone tubing is known for its high purity and biocompatibility, making it ideal for critical applications in the medical and food industries. Its autoclavable properties ensure that it can be sterilized without compromising integrity. Buyers should consider the higher cost associated with this type, but the investment is justified for applications requiring stringent safety standards.

Why Choose High-Temperature Silicone Tubing?

High-temperature silicone tubing is engineered to withstand extreme heat, making it suitable for aerospace and automotive applications. Its flexibility allows for easy installation, but buyers should be aware that flexibility may diminish at elevated temperatures. This tubing is a reliable choice for industries where thermal resistance is paramount.

What Makes Food-Grade Silicone Tubing Unique?

Food-grade silicone tubing is specifically designed to meet food safety regulations, ensuring non-toxicity and compliance with health standards. It is widely used in food processing and beverage dispensing applications. While it offers safety for food contact, businesses must ensure that their specific applications meet the necessary certifications to avoid compliance issues.

How Does Reinforced Silicone Hose Benefit Industrial Applications?

Reinforced silicone hose features added strength and pressure resistance, making it suitable for demanding industrial applications such as chemical transfer and pneumatic controls. While it offers enhanced durability, buyers should note that this type tends to be heavier and less flexible than standard silicone tubing. This trade-off can impact installation and operational efficiency.

What Are the Advantages of Medical-Grade Silicone Tubing?

Medical-grade silicone tubing is tailored for biopharmaceutical and medical applications, providing high reliability and compliance with industry standards. Its design accommodates critical uses such as infusion pumps and laboratory environments. Although the cost is generally higher due to regulatory requirements, the assurance of quality and safety makes it a worthwhile investment for healthcare applications.

Key Industrial Applications of silicon tubing

| Industry/Sector | Specific Application of Silicon Tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical & Pharmaceutical | Medical device manufacturing, including infusion pumps | Ensures biocompatibility and precision in dosage delivery | Compliance with medical standards, purity, and temperature ratings |

| Food & Beverage | Food processing and packaging | Maintains hygiene and prevents contamination | Certification for food safety, flexibility, and temperature tolerance |

| Chemical Processing | Chemical transfer in laboratories | High resistance to chemicals and temperature variations | Compatibility with specific chemicals, durability under pressure |

| Automotive | Fuel and oil transfer systems | Reliable performance under varying temperatures and pressures | Resistance to degradation, compliance with automotive standards |

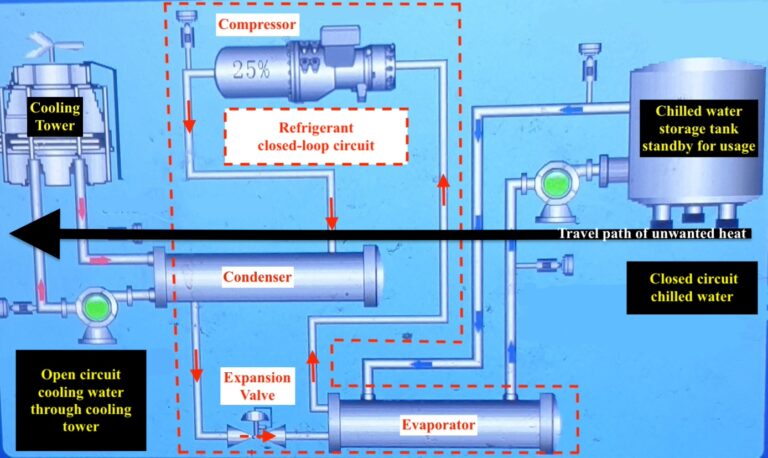

| HVAC | Air conditioning and refrigeration systems | Enhances energy efficiency and durability | Resistance to UV and ozone, compatibility with refrigerants |

How Is Silicone Tubing Used in Medical & Pharmaceutical Industries?

In the medical and pharmaceutical sectors, silicone tubing is vital for manufacturing medical devices such as infusion pumps and catheters. Its biocompatibility ensures that it does not react with bodily fluids, thus maintaining the integrity of the medication being administered. Furthermore, its low compression set allows for precise dosage delivery, which is crucial in medical applications. International buyers must ensure that the tubing meets rigorous medical standards and is available in various sizes and lengths to fit specific device requirements.

与silicon tubing相关的说明性图片

What Role Does Silicone Tubing Play in Food & Beverage Processing?

Silicone tubing is extensively used in food processing and packaging due to its non-toxic properties and ability to withstand high temperatures. This tubing prevents contamination and ensures that food products maintain their quality during processing. The flexibility of silicone allows for easy installation and routing in complex systems. Buyers in this sector must prioritize certifications for food safety and ensure that the tubing can withstand the specific temperature ranges required for their processes.

How Is Silicone Tubing Applied in Chemical Processing?

In chemical processing, silicone tubing is essential for transferring various chemicals safely. Its high resistance to a wide range of chemicals and temperature variations makes it ideal for laboratory environments. Silicone tubing can handle harsh conditions without degrading, ensuring that chemical integrity is maintained. For international buyers, it is crucial to confirm the tubing’s compatibility with specific chemicals and its durability under pressure to prevent leaks and spills.

Why Is Silicone Tubing Important for Automotive Fuel Systems?

Silicone tubing is increasingly used in automotive applications, particularly for fuel and oil transfer systems. Its ability to withstand extreme temperatures and pressures ensures reliable performance in demanding environments. Silicone’s resistance to degradation and flexibility makes it suitable for routing in tight spaces. Buyers from the automotive sector should focus on sourcing tubing that complies with industry standards and can handle various fuel types without compromising safety.

How Does Silicone Tubing Enhance HVAC Systems?

In HVAC applications, silicone tubing plays a crucial role in air conditioning and refrigeration systems. Its durability and resistance to UV radiation enhance the overall efficiency and longevity of these systems. The smooth inner surface of silicone tubing minimizes friction loss, thereby improving energy efficiency. Buyers should consider the tubing’s compatibility with refrigerants and its ability to withstand varying environmental conditions to ensure optimal performance in their systems.

3 Common User Pain Points for ‘silicon tubing’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Silicone Tubing for Medical Applications

The Problem: B2B buyers in the medical sector often face challenges in sourcing silicone tubing that meets stringent health and safety regulations. With the increasing demand for biocompatibility and purity, finding suppliers who provide certified medical-grade silicone tubing can be daunting. Buyers may experience delays due to inadequate inventory or inconsistent quality, leading to potential production halts and compliance issues.

The Solution: To overcome sourcing challenges, B2B buyers should prioritize suppliers that specialize in medical-grade silicone tubing and have certifications such as ISO 13485 or FDA compliance. Conduct thorough research to identify manufacturers with a proven track record in the medical field. Request product samples to evaluate the material quality, flexibility, and performance under different conditions. Additionally, establishing long-term partnerships with reliable suppliers can ensure a steady flow of high-quality products and reduce lead times.

Scenario 2: Incompatibility of Silicone Tubing with Various Chemicals

The Problem: Many B2B buyers in industries such as chemical processing or food and beverage face issues with silicone tubing becoming degraded when exposed to certain chemicals. This incompatibility can lead to leaks, contamination, and costly downtime. Buyers may struggle to find the right type of silicone tubing that can withstand specific chemical interactions without compromising performance.

The Solution: It is critical for buyers to assess the chemical compatibility of silicone tubing before making a purchase. Suppliers often provide detailed compatibility charts that indicate which substances the tubing can safely handle. Buyers should consult these resources and communicate their specific application requirements to suppliers. Opting for platinum-cured silicone tubing can provide enhanced resistance to chemicals and higher thermal stability. Moreover, consider conducting compatibility tests within controlled environments to ensure the selected tubing will perform as needed in real-world applications.

Scenario 3: Challenges in Customizing Silicone Tubing Dimensions

The Problem: B2B buyers frequently encounter issues with standard silicone tubing not meeting their unique specifications regarding diameter, length, or wall thickness. This can lead to inefficiencies, as custom solutions may require longer lead times and higher costs. Additionally, the lack of customization can result in compatibility issues with existing equipment and systems.

The Solution: To address customization challenges, buyers should seek suppliers that offer flexible manufacturing options, including the ability to produce silicone tubing to precise specifications. When placing orders, clearly communicate the required dimensions and any additional features, such as color or reinforcement needs. Engaging in a consultative approach with suppliers can lead to tailored solutions that meet specific project demands. Furthermore, consider leveraging technology such as 3D modeling to visualize how the custom tubing will integrate with existing systems, ensuring compatibility and functionality before production begins.

Strategic Material Selection Guide for silicon tubing

When selecting silicone tubing for various applications, it is essential for international B2B buyers to understand the key materials available, their properties, and how they align with specific operational needs. Below is an analysis of four common materials used in silicone tubing, with insights tailored for buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Platinum-Cured Silicone Tubing?

Platinum-cured silicone tubing is renowned for its exceptional purity and biocompatibility, making it a preferred choice for medical and food applications. It can withstand temperatures ranging from -60°C to 260°C and has excellent resistance to UV radiation and oxidation. This material also exhibits a low compression set, which is crucial for applications requiring precise fluid delivery, such as in infusion pumps.

Pros & Cons: The primary advantage of platinum-cured silicone is its high purity and flexibility, which enhance its usability across sensitive applications. However, it tends to be more expensive than other silicone options, which may be a consideration for budget-sensitive projects.

Impact on Application: This material is particularly suitable for applications involving food processing, pharmaceuticals, and biopharmaceuticals, where contamination risks must be minimized.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as FDA regulations for food applications and ISO standards for medical use. In regions like Germany, adherence to DIN standards is also critical.

How Does Peroxide-Cured Silicone Tubing Compare?

Peroxide-cured silicone tubing is another common option, known for its durability and cost-effectiveness. It typically operates within a temperature range of -50°C to 200°C and offers good resistance to various chemicals. However, it may not match the purity levels of platinum-cured options.

Pros & Cons: The main advantage of peroxide-cured silicone is its lower cost, making it suitable for applications where high purity is not the primary concern. However, its performance in extreme temperatures and exposure to certain chemicals may be limited compared to platinum-cured silicone.

Impact on Application: This tubing is often used in industrial applications, such as chemical transfer and general manufacturing processes, where the risk of contamination is lower.

与silicon tubing相关的说明性图片

Considerations for International Buyers: Buyers should verify that the tubing meets local regulations and standards, such as ASTM or JIS, especially in regions with stringent compliance requirements.

What Advantages Does High-Temperature Silicone Tubing Offer?

High-temperature silicone tubing is designed to withstand extreme thermal conditions, with ratings often exceeding 300°C. It is particularly useful in applications involving steam or hot fluids, such as in food processing and industrial machinery.

Pros & Cons: The key advantage of high-temperature silicone is its ability to maintain structural integrity under extreme conditions. However, it can be more expensive and may require specialized manufacturing processes.

Impact on Application: This material is ideal for applications that involve high heat, such as steam lines in food processing or high-performance automotive applications.

Considerations for International Buyers: Ensure that the tubing complies with local thermal and safety standards, particularly in industries where high temperatures are common.

How Does Medical-Grade Silicone Tubing Perform?

Medical-grade silicone tubing is specifically designed for applications in healthcare settings. It is typically platinum-cured and meets rigorous biocompatibility standards, making it suitable for use in medical devices and laboratory settings.

Pros & Cons: The primary advantage is its safety and reliability in critical applications. However, the cost can be significantly higher than standard silicone tubing.

Impact on Application: This tubing is essential for applications in hospitals, laboratories, and pharmaceutical manufacturing, where patient safety and product integrity are paramount.

Considerations for International Buyers: Compliance with medical device regulations, such as the EU MDR or FDA guidelines in the U.S., is crucial for buyers in the healthcare sector.

| Material | Typical Use Case for Silicone Tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Platinum-Cured Silicone | Medical and food applications | High purity and biocompatibility | Higher cost | High |

| Peroxide-Cured Silicone | Industrial applications | Cost-effective | Limited chemical resistance | Med |

| High-Temperature Silicone | Food processing, automotive | Excellent thermal stability | Higher manufacturing complexity | High |

| Medical-Grade Silicone | Healthcare and laboratory settings | Safety and reliability | Significantly higher cost | High |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding silicone tubing, ensuring they choose the right material for their specific applications while adhering to international standards and regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for silicon tubing

What Are the Main Stages of Manufacturing Silicone Tubing?

The manufacturing process of silicone tubing involves several crucial stages that ensure product quality and performance. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

与silicon tubing相关的说明性图片

Material Preparation

The first step in manufacturing silicone tubing is material preparation. Silicone rubber, either in liquid silicone rubber (LSR) or solid silicone form, is sourced based on the intended application—medical, food-grade, or industrial. High-quality raw materials are essential, as they impact the tubing’s durability, flexibility, and temperature resistance. Suppliers often conduct thorough assessments of their materials, including checking for contaminants and ensuring compliance with international standards.

Forming Techniques

Once the raw materials are prepared, they undergo forming techniques to create the desired tubing shape. Common methods include extrusion and molding.

-

Extrusion: In this process, the silicone is heated and forced through a die to create long lengths of tubing. This method is highly efficient for producing uniform diameters and wall thicknesses.

-

Molding: For specific shapes or custom designs, silicone can be molded using various techniques, including compression and injection molding. This is particularly useful for creating tubing with complex geometries or integrated features.

Assembly and Finishing

After forming, the tubing may require additional assembly or finishing processes. This could include cutting the tubing to specific lengths, adding fittings, or applying surface treatments to enhance performance characteristics. The finishing stage is critical as it directly influences the product’s usability in different applications, from medical devices to food processing systems.

What Quality Control Measures Are Essential for Silicone Tubing?

Quality assurance is a pivotal aspect of silicone tubing manufacturing, ensuring that the final product meets all required specifications and standards. Various international and industry-specific standards govern this process.

International Standards for Quality Assurance

B2B buyers should be familiar with key quality standards such as:

-

ISO 9001: This standard outlines requirements for a quality management system (QMS) that organizations can use to enhance customer satisfaction through effective system implementation.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API (American Petroleum Institute): Relevant for tubing used in the oil and gas industry, ensuring compliance with safety and performance specifications.

These certifications not only enhance product credibility but also ensure that manufacturers adhere to strict quality protocols.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are crucial throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards and requirements.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor production processes, ensuring that any issues are identified and rectified promptly.

-

Final Quality Control (FQC): After production, the finished tubing undergoes comprehensive testing to verify compliance with specifications. This may include dimensional checks, tensile strength testing, and thermal stability assessments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for minimizing risks. Here are strategies to ensure supplier compliance:

Audits and On-Site Inspections

Conducting regular audits and on-site inspections of suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should assess the supplier’s QMS, check for certifications, and evaluate their adherence to established standards.

Quality Reports and Documentation

Requesting quality reports and documentation is another effective way to verify supplier claims. This includes certificates of compliance, test reports, and records of quality inspections. Reliable suppliers should be transparent and willing to provide this information upon request.

Third-Party Inspections

Engaging third-party inspection services can further enhance quality assurance. These independent entities can conduct thorough assessments of suppliers’ facilities and processes, ensuring compliance with international standards and providing unbiased evaluations of product quality.

What Are Common Testing Methods for Silicone Tubing?

Testing methods are integral to ensuring that silicone tubing meets necessary performance and safety standards. Common methods include:

-

Tensile Testing: Measures the strength of the silicone material by determining how much force it can withstand before breaking. This is crucial for applications requiring high durability.

-

Compression Set Testing: Evaluates the material’s ability to return to its original shape after being compressed. This is particularly important for tubing used in dynamic applications like pumps.

-

Thermal Stability Testing: Assesses the tubing’s performance under extreme temperatures, ensuring it can withstand the operational conditions it will encounter in service.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various nuances in quality control to ensure compliance with local regulations and market demands. Understanding these nuances is vital for successful procurement.

Regional Regulations and Compliance

Different regions may have specific regulations regarding silicone tubing, particularly in industries such as food and pharmaceuticals. Buyers should familiarize themselves with local compliance requirements to avoid costly mistakes.

Language and Cultural Barriers

Communication can be a challenge when dealing with international suppliers. Buyers should ensure that language barriers do not impede understanding of quality standards and specifications. Utilizing clear documentation and possibly hiring local representatives can help mitigate this issue.

Relationship Building with Suppliers

Establishing strong relationships with suppliers can enhance transparency and trust. Regular communication about quality expectations and performance can lead to improved outcomes and a more streamlined procurement process.

In summary, understanding the manufacturing processes and quality assurance measures for silicone tubing is essential for B2B buyers. By focusing on material preparation, forming techniques, quality control standards, and effective verification methods, buyers can ensure they source high-quality products that meet their specific needs.

与silicon tubing相关的说明性图片

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silicon tubing’

Introduction

Sourcing silicone tubing for industrial applications requires a strategic approach to ensure quality, compliance, and suitability for specific needs. This guide provides a step-by-step checklist to help B2B buyers effectively navigate the procurement process, whether for medical, food, or industrial applications. By following these steps, buyers can make informed decisions that align with their operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline the technical specifications of the silicone tubing you require. Consider factors such as:

– Diameter and Length: Specify the inner and outer diameters, as well as the total length needed for your applications.

– Temperature Resistance: Identify the temperature range the tubing must withstand, particularly for high-temperature applications.

Defining these specifications upfront will streamline your search and help you communicate effectively with potential suppliers.

Step 2: Research Supplier Options

Conduct thorough research to identify reputable suppliers who specialize in silicone tubing. Look for:

– Industry Experience: Suppliers with a proven track record in your specific industry can offer tailored solutions.

– Product Range: Ensure the supplier has a variety of options, including medical-grade and food-safe silicone tubing.

A well-researched supplier list will provide you with choices that meet your quality and compliance standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to vet them thoroughly. Consider the following:

– Certifications and Compliance: Verify that the supplier adheres to industry standards, such as ISO certifications or FDA compliance for food-related applications.

– References and Reviews: Request case studies or testimonials from other B2B buyers in similar sectors to gauge reliability and performance.

This evaluation process can help mitigate risks associated with supplier reliability and product quality.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the silicone tubing. This step is vital to:

– Assess Quality: Evaluate the physical properties, such as flexibility, tensile strength, and temperature resistance.

– Test Compatibility: Ensure the tubing is suitable for your specific applications, including any chemical resistance requirements.

Testing samples helps confirm that the product meets your standards before placing a bulk order.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your selected suppliers to negotiate pricing and terms. Consider:

– Volume Discounts: Inquire about pricing tiers based on order quantity to optimize your budget.

– Payment Terms: Clarify payment schedules and any financing options available to maintain cash flow.

Effective negotiation can lead to significant cost savings and favorable terms that benefit your procurement process.

Step 6: Confirm Delivery and Logistics

After finalizing your order, confirm the logistics surrounding delivery. Important considerations include:

– Lead Times: Understand the expected delivery timeframe and any potential delays based on your location.

– Shipping Options: Discuss shipping methods and costs, particularly for international orders, to ensure timely and cost-effective delivery.

Clear communication about logistics will help you manage your inventory and production schedules effectively.

与silicon tubing相关的说明性图片

Step 7: Monitor Quality Upon Receipt

Once you receive the silicone tubing, conduct a thorough inspection to ensure it meets the agreed-upon specifications. Look for:

– Physical Damage: Check for any signs of damage or defects during transit.

– Compliance Documentation: Ensure that all necessary certifications and compliance documents are included with the shipment.

Monitoring quality upon receipt is crucial to maintaining operational integrity and preventing future issues in your applications.

Comprehensive Cost and Pricing Analysis for silicon tubing Sourcing

Understanding the cost structure and pricing analysis for silicone tubing is crucial for international B2B buyers aiming to make informed procurement decisions. This analysis delves into the various components that contribute to the overall cost, as well as the factors that influence pricing, especially for buyers from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Silicone Tubing Manufacturing?

The cost structure of silicone tubing encompasses several critical components:

-

Materials: The primary material used in silicone tubing is silicone rubber, which can vary significantly in quality and formulation. High-grade silicone, such as platinum-cured silicone, tends to be more expensive due to its superior properties and certifications, especially for medical and food applications.

-

Labor: Labor costs can fluctuate based on the geographic location of the manufacturing facility. Countries with lower wage rates may offer more competitive pricing, but this can come at the expense of quality control.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Advanced manufacturing technologies and cleanroom environments, particularly for medical-grade silicone tubing, can increase overhead costs.

-

Tooling: The initial setup for custom molds and tooling can be a significant investment, especially for specialized tubing. This cost is often amortized over large production runs, influencing pricing for smaller orders.

-

Quality Control (QC): Rigorous QC processes are essential, particularly for applications in healthcare and food safety. The costs associated with testing and certification (e.g., FDA approval, ISO certifications) are factored into the final price.

-

Logistics: Shipping costs can vary based on the distance from the supplier to the buyer. For international transactions, logistics also includes customs duties and tariffs, which can substantially impact the total cost.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. This can vary widely based on market conditions and competition.

How Do Price Influencers Affect Silicone Tubing Costs?

Several factors can influence the pricing of silicone tubing:

-

Volume/MOQ: Bulk orders often attract significant discounts. Suppliers may set minimum order quantities (MOQs), which can affect pricing strategies for smaller buyers.

-

Specifications and Customization: Custom sizes, colors, or formulations can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or additional certifications will command higher prices. Buyers should assess their needs to avoid over-specifying and incurring unnecessary costs.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance practices.

-

Incoterms: The choice of Incoterms affects the distribution of costs and risks between buyer and seller. Understanding these terms is vital for managing total costs effectively.

What Are the Best Practices for Negotiating Silicone Tubing Prices?

For international B2B buyers, particularly in regions like Nigeria and Germany, implementing strategic negotiation tactics can enhance cost-efficiency:

-

Research and Benchmarking: Understand market pricing by comparing quotes from multiple suppliers. This knowledge can empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term implications of maintenance, logistics, and potential quality issues. A lower upfront cost might lead to higher TCO if it results in frequent replacements or poor performance.

-

Leverage Volume Discounts: If possible, consolidate orders or collaborate with other buyers to increase order volume, thereby negotiating better rates.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to favorable terms, priority service, and potential discounts on future orders.

Conclusion

While the pricing of silicone tubing can vary based on numerous factors, understanding the cost structure and key influencers allows B2B buyers to make informed decisions. By applying strategic negotiation techniques and focusing on the total cost of ownership, buyers can optimize their sourcing strategy to achieve both quality and value in their silicone tubing procurement. Always remember that the prices mentioned are indicative and may fluctuate based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing silicon tubing With Other Solutions

Understanding Alternatives to Silicone Tubing in B2B Applications

In the pursuit of effective solutions for fluid transfer and containment, silicone tubing stands out due to its versatility and performance in various industries. However, it is essential for B2B buyers to evaluate alternative materials and methods that may better suit specific applications or budgets. This comparison will provide insights into silicone tubing against two viable alternatives: PVC tubing and rubber tubing.

Comparison Table

| Comparison Aspect | Silicone Tubing | PVC Tubing | Rubber Tubing |

|---|---|---|---|

| Performance | High temperature resistance, biocompatible, flexible | Good chemical resistance, less flexible | Excellent elasticity, durable |

| Cost | Moderate to high cost | Low cost | Moderate cost |

| Ease of Implementation | Easy to cut and customize | Simple to install, lightweight | Requires more effort to install |

| Maintenance | Low maintenance, resistant to degradation | Moderate, prone to wear over time | Moderate maintenance required |

| Best Use Case | Medical, food and beverage, high-temperature applications | General-purpose industrial applications | Automotive, industrial machinery |

Detailed Breakdown of Alternatives

PVC Tubing: Is It a Cost-Effective Alternative?

PVC (Polyvinyl Chloride) tubing is often favored for its low cost and good chemical resistance. It is lightweight, making it easy to handle and install, which is particularly advantageous in large-scale industrial settings. However, PVC tubing lacks the high-temperature resistance and flexibility of silicone, making it unsuitable for applications that require biocompatibility or exposure to extreme conditions. Additionally, PVC may degrade over time when exposed to UV light, which can lead to increased maintenance costs.

Rubber Tubing: Durable but Less Versatile

Rubber tubing is known for its excellent elasticity and durability, making it suitable for applications that demand resilience under pressure. It performs well in automotive and industrial machinery contexts. However, rubber tubing can be less flexible than silicone, which may complicate installations requiring tight bends. Furthermore, while rubber can withstand various temperatures, it may not perform as well in extreme conditions compared to silicone. This material typically requires more maintenance, especially in environments prone to wear and tear.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the most suitable tubing for your application, B2B buyers should consider several factors, including performance requirements, budget constraints, and ease of installation. Silicone tubing excels in high-temperature and biocompatible applications, making it ideal for medical and food industries. Conversely, PVC and rubber tubing can be more cost-effective for general-purpose applications. Ultimately, understanding the unique demands of your project will guide you in making an informed decision that balances performance, cost, and longevity.

Essential Technical Properties and Trade Terminology for silicon tubing

What Are the Key Technical Properties of Silicone Tubing That B2B Buyers Should Consider?

When selecting silicone tubing for industrial applications, understanding its technical properties is crucial. Here are several key specifications that influence performance and suitability:

-

Material Grade

Silicone tubing is available in various grades, including medical, food-grade, and industrial. Medical-grade silicone is designed for biocompatibility and purity, making it essential for applications in healthcare and pharmaceuticals. Food-grade silicone meets safety standards for food contact, vital for food processing and packaging. Choosing the appropriate material grade ensures compliance with regulatory requirements and enhances product safety. -

Temperature Resistance

Silicone tubing typically boasts a wide temperature range, often between -60°F to 600°F (-51°C to 315°C). This property is crucial for applications that involve extreme heat or cold, such as in automotive or HVAC systems. A high-temperature tolerance allows for greater flexibility in application and can lead to longer service life, reducing replacement costs for businesses. -

Wall Thickness

The wall thickness of silicone tubing affects its durability and pressure resistance. Standard options range from 0.062″ to 0.125″, with thicker walls providing higher strength and better performance under pressure. For B2B buyers, understanding the wall thickness is essential for ensuring the tubing can withstand the operational demands of their specific applications, including chemical transfer or hydraulic lines. -

Flexibility and Pliability

Silicone tubing is known for its excellent flexibility, making it easy to maneuver in complex setups. This characteristic is particularly important in applications like infusion pumps or laboratory settings where precise movements are required. The pliability of silicone also allows it to return to its original shape after deformation, which enhances its longevity and reliability in dynamic environments. -

Chemical Resistance

Depending on the formulation, silicone tubing can exhibit varying degrees of chemical resistance. Understanding the chemical compatibility of the tubing with the substances it will encounter is vital for preventing degradation and ensuring system integrity. This property is especially important in industries like pharmaceuticals and food production, where contamination can have serious implications. -

Compression Set

A low compression set indicates that the silicone tubing will maintain its shape and performance even after prolonged compression. This property is particularly important in applications requiring consistent pressure and volume, such as in peristaltic pumps. B2B buyers should consider compression set metrics when selecting tubing for applications where dimensional stability is crucial.

What Are Common Trade Terms Used in Silicone Tubing Procurement?

Understanding industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another company. For silicone tubing, knowing the OEM can help buyers ensure compatibility with existing systems and specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to plan their inventory and manage costs effectively. It can also affect budgeting and procurement strategies, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For silicone tubing, submitting an RFQ can help buyers compare prices, quality, and delivery terms from multiple suppliers, ensuring they receive the best deal. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk management, and cost allocation, which are critical when sourcing silicone tubing from global suppliers. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is crucial for effective supply chain management and ensuring timely project completion, especially in industries with tight deadlines. -

Certification Compliance

This refers to whether the silicone tubing meets specific industry standards or regulatory requirements, such as FDA approval for food-grade materials or USP Class VI for medical applications. Buyers should prioritize certified products to ensure safety and compliance with industry regulations.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the silicon tubing Sector

What Are the Current Market Dynamics and Key Trends in the Silicone Tubing Sector?

The silicone tubing market is experiencing robust growth driven by several global factors. The increasing demand from industries such as medical, food and beverage, and pharmaceuticals is a primary driver. Silicone’s biocompatibility and temperature resistance make it a preferred choice for medical applications, particularly in regions like Europe and the Middle East, where stringent regulations govern medical equipment. Additionally, the rise in manufacturing capabilities in Africa and South America is fostering local production, which can reduce costs and improve supply chain efficiency for B2B buyers.

Emerging technologies in manufacturing, such as 3D printing and automation, are reshaping sourcing trends. B2B buyers are increasingly looking for suppliers who can offer custom solutions that leverage these technologies, enabling them to meet specific application requirements more efficiently. Furthermore, the trend towards e-commerce platforms is facilitating easier access to diverse suppliers globally, allowing businesses in regions like Nigeria and Brazil to source silicone tubing from established manufacturers in Europe and North America.

The market dynamics are also influenced by fluctuating raw material costs and supply chain disruptions, emphasizing the need for agile sourcing strategies. Buyers must stay informed about market changes and consider developing relationships with multiple suppliers to mitigate risks associated with single-source dependency.

How Is Sustainability and Ethical Sourcing Impacting the Silicone Tubing Industry?

Sustainability has become a focal point for B2B buyers in the silicone tubing sector. The environmental impact of production processes is under scrutiny, driving the demand for materials that are not only effective but also environmentally friendly. Buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices, such as using low-emission production methods and sourcing raw materials responsibly.

Ethical sourcing is equally important, particularly in regions where labor practices may vary significantly. Buyers are encouraged to seek suppliers with certifications that validate their commitment to ethical practices, including fair labor standards and environmental stewardship. This focus on sustainability and ethics is not just a trend; it is becoming a critical component of corporate responsibility and brand image.

Furthermore, the adoption of ‘green’ certifications for silicone tubing materials is rising. Products that are certified as food-safe, biocompatible, or made from recycled materials can provide B2B buyers with a competitive edge in markets that value environmental and health standards.

What Is the Historical Evolution of Silicone Tubing and Its Relevance Today?

Silicone tubing has evolved significantly since its introduction in the mid-20th century. Initially used in medical applications due to its flexibility and resistance to temperature extremes, it has expanded into various industries, including food processing, automotive, and pharmaceuticals. The introduction of platinum-cured silicone in the 1980s marked a turning point, enhancing the material’s purity and making it suitable for critical applications like biopharmaceutical manufacturing.

Today, the evolution of silicone tubing reflects broader trends in technology and sustainability. Innovations in manufacturing processes have led to more versatile and cost-effective products, while the increasing demand for environmentally friendly materials has driven the development of sustainable silicone options. This historical context is vital for B2B buyers as it highlights the importance of selecting suppliers who not only understand the material’s legacy but also prioritize innovation and sustainability in their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of silicon tubing

-

How do I choose the right silicone tubing for my application?

Choosing the right silicone tubing requires considering several factors, including the specific application, temperature and pressure requirements, and material compatibility. For medical or food applications, opt for platinum-cured silicone tubing, which meets stringent purity standards. Additionally, evaluate the tubing’s diameter, wall thickness, and flexibility based on your operational needs. Consulting with suppliers for samples and technical specifications can also help ensure that the selected tubing meets your performance criteria. -

What are the key benefits of using silicone tubing in industrial applications?

Silicone tubing offers numerous advantages in industrial applications, such as high-temperature resistance, biocompatibility, and flexibility. Its ability to maintain integrity in extreme temperatures (up to 600°F/315°C) makes it suitable for various processes, including chemical transfer and food processing. Moreover, silicone is resistant to UV degradation and oxidation, ensuring longevity and durability. These properties make silicone tubing an excellent choice for diverse sectors, including pharmaceuticals, food and beverage, and manufacturing. -

What customization options are available for silicone tubing?

Many suppliers offer customization options for silicone tubing, including variations in diameter, wall thickness, length, and color. You can also request specific formulations to enhance resistance to chemicals or improve flexibility. It’s essential to communicate your requirements clearly to the supplier, ensuring they can meet your needs. Some manufacturers may also provide specialized options like reinforced tubing or custom fittings, which can enhance the functionality of the tubing in your specific application. -

What is the minimum order quantity (MOQ) for silicone tubing?

The minimum order quantity for silicone tubing can vary significantly between suppliers and depends on the type of tubing and customization requested. Generally, standard products may have lower MOQs, while customized options could require larger quantities. It’s advisable to inquire directly with potential suppliers about their MOQs and consider how it aligns with your production needs. If you anticipate ongoing demand, negotiating favorable terms for larger orders may also be possible. -

How can I verify the quality of silicone tubing from suppliers?

To ensure the quality of silicone tubing, request certifications from suppliers that demonstrate compliance with industry standards, such as FDA approval for food-grade tubing or ISO certifications for manufacturing processes. Conducting third-party testing or quality assurance audits can also provide additional assurance. Furthermore, consider requesting samples to evaluate the tubing’s performance, flexibility, and durability before making a larger commitment. -

What payment terms are typically offered by silicone tubing suppliers?

Payment terms can vary among suppliers, but common options include upfront payments, net 30 or net 60 terms, and letters of credit for international transactions. It’s crucial to clarify payment expectations before finalizing any agreements. Understanding the supplier’s policies on deposits, discounts for early payment, and consequences for late payments can help you manage cash flow effectively. Always ensure that payment terms are documented in the contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when sourcing silicone tubing internationally?

When sourcing silicone tubing internationally, consider factors such as shipping costs, lead times, and customs regulations. It’s vital to work with suppliers who have experience exporting to your region and can provide necessary documentation for customs clearance. Additionally, evaluate shipping options (air vs. sea) based on your urgency and budget. Collaborating with a logistics partner can also streamline the process and mitigate potential delays in transit. -

How do I handle issues with silicone tubing after purchase?

If you encounter issues with silicone tubing after purchase, first consult the supplier’s warranty or return policy. Document any defects or performance issues, providing evidence such as photos or detailed descriptions. Communicate with the supplier to understand their process for addressing such concerns, which may include replacements or refunds. Maintaining a good relationship with your supplier can facilitate problem resolution and support future collaborations.

Top 1 Silicon Tubing Manufacturers & Suppliers List

1. Fisher Scientific – Bioprene Tubing

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: {“Product Type”: [“Bioprene Tubing”, “Laboratory Tubing”, “Pressure and Vacuum Tubing”, “Pump Tubing”, “Rubber Hose”, “Soft Laboratory Tubing”, “Tubing”, “Tubing Assembly”, “Tubing Set”], “Materials”: [“FKM”, “Flexelene™ Polyolefin Elastomer”, “Flexelene™ 121C”, “Gum Rubber”, “Kflex”, “Latex”, “Natural Rubber”, “Polyolefin Elastomer”, “Rubber”, “Rubber (Cloth-covered)”, “Silicone”, “TPE”, “Tygon A…

Strategic Sourcing Conclusion and Outlook for silicon tubing

What Are the Key Takeaways for B2B Buyers of Silicone Tubing?

In today’s competitive landscape, strategic sourcing of silicone tubing is essential for businesses seeking reliable and high-quality materials. The versatility of silicone tubing, with its impressive temperature resistance and biocompatibility, makes it an ideal choice for a wide range of applications, from medical to industrial uses. Buyers should focus on suppliers that offer custom solutions, such as different diameters, lengths, and grades, to meet specific operational needs.

How Can International Buyers Leverage Market Trends?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should capitalize on the growing demand for silicone tubing driven by industries like pharmaceuticals, food processing, and automotive. By establishing strong relationships with reputable suppliers, businesses can ensure a steady supply of high-performance tubing that meets global standards and regulations.

What Is the Future Outlook for Silicone Tubing Sourcing?

Looking ahead, the silicone tubing market is poised for growth, driven by innovations in manufacturing and the increasing emphasis on sustainability. As companies prioritize quality and compliance, strategic sourcing will not only enhance operational efficiency but also support long-term business objectives. B2B buyers are encouraged to explore partnerships with suppliers who are committed to technological advancements and sustainability practices, ensuring they remain competitive in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.