Is Your Shear Mixers Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for shear mixers

In today’s fast-paced manufacturing landscape, sourcing the right shear mixers can be a daunting challenge for businesses looking to enhance their production processes. High shear mixers are essential tools for achieving precise emulsions and dispersions, crucial for industries ranging from pharmaceuticals to food processing. However, navigating the global market for shear mixers requires a comprehensive understanding of various types, applications, and supplier capabilities to ensure optimal performance and cost-effectiveness.

This guide is designed to empower international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—with actionable insights into the diverse world of shear mixers. We will explore the different types of mixers available, including benchtop and in-line models, and their specific applications across various sectors. Additionally, we will provide strategies for vetting suppliers to ensure reliability and quality, as well as a detailed breakdown of costs to help you make informed purchasing decisions.

By leveraging the information presented in this guide, you will be equipped to select the most suitable shear mixers that align with your operational needs and budget constraints, ultimately driving efficiency and innovation in your production processes.

Understanding shear mixers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Shear Mixers | Operate at high speeds to create emulsions and dispersions | Food processing, pharmaceuticals, cosmetics | Pros: Efficient mixing, versatile applications. Cons: Higher initial cost. |

| Benchtop Lab Dispersers | Compact, suitable for small batch processing | R&D labs, pilot studies | Pros: Space-saving, cost-effective. Cons: Limited capacity. |

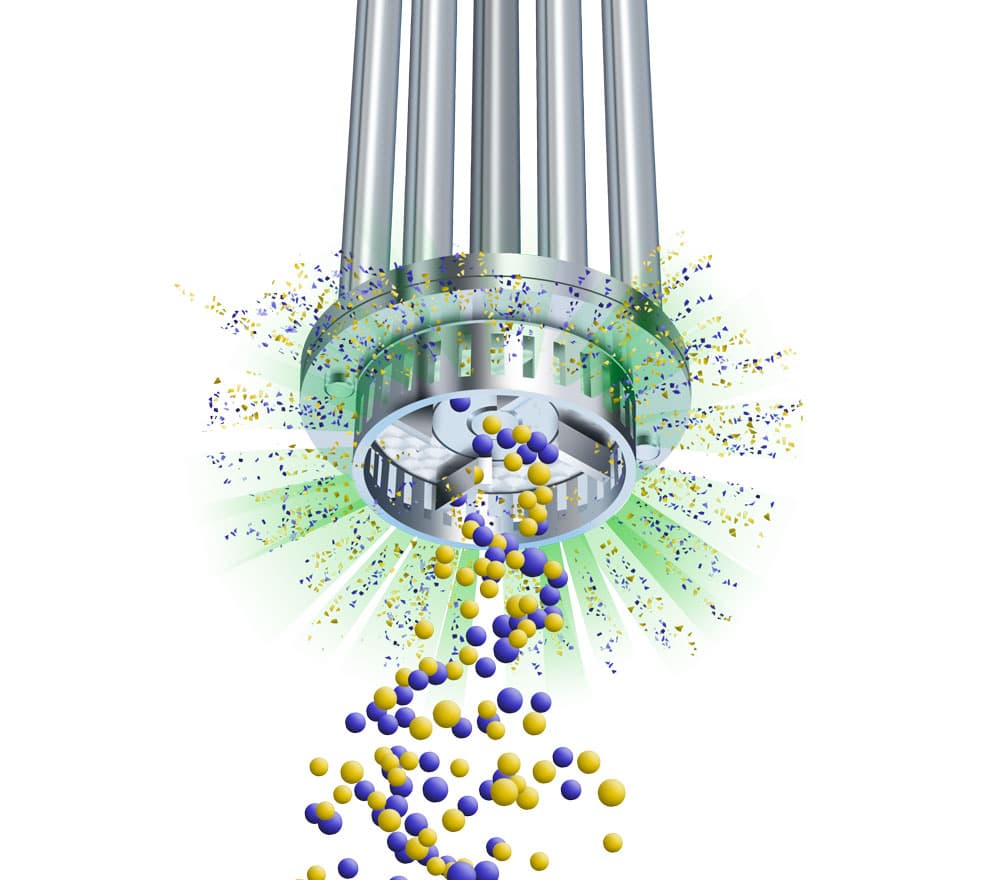

| In-Line Rotor Stator Mixers | Continuous mixing with integrated pumping | Large-scale production, chemical manufacturing | Pros: Consistent quality, reduced processing time. Cons: Installation complexity. |

| Dual Shaft Mixers | Feature two shafts for enhanced mixing of viscous materials | Paints, adhesives, and coatings | Pros: Handles high viscosity, effective for thick mixtures. Cons: More maintenance required. |

| Three Roll Mills | Use three horizontally positioned rolls to grind and mix | Ink, cosmetics, and specialty chemicals | Pros: Excellent particle size reduction. Cons: Slower processing speed. |

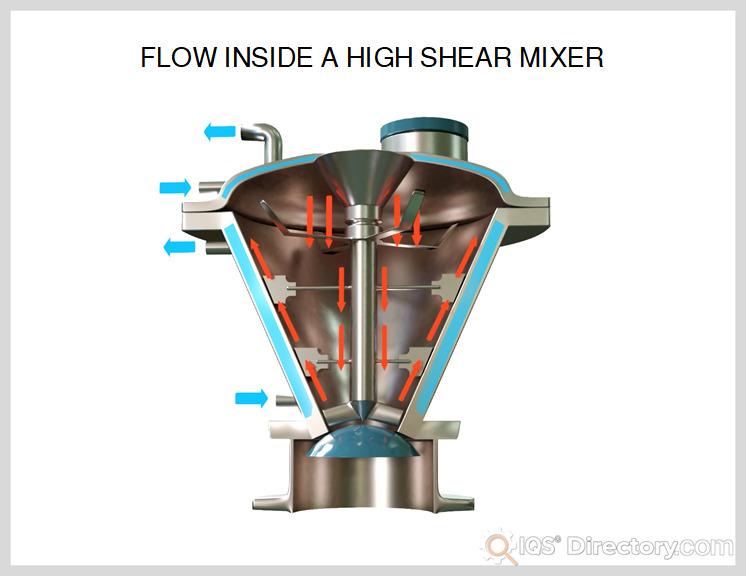

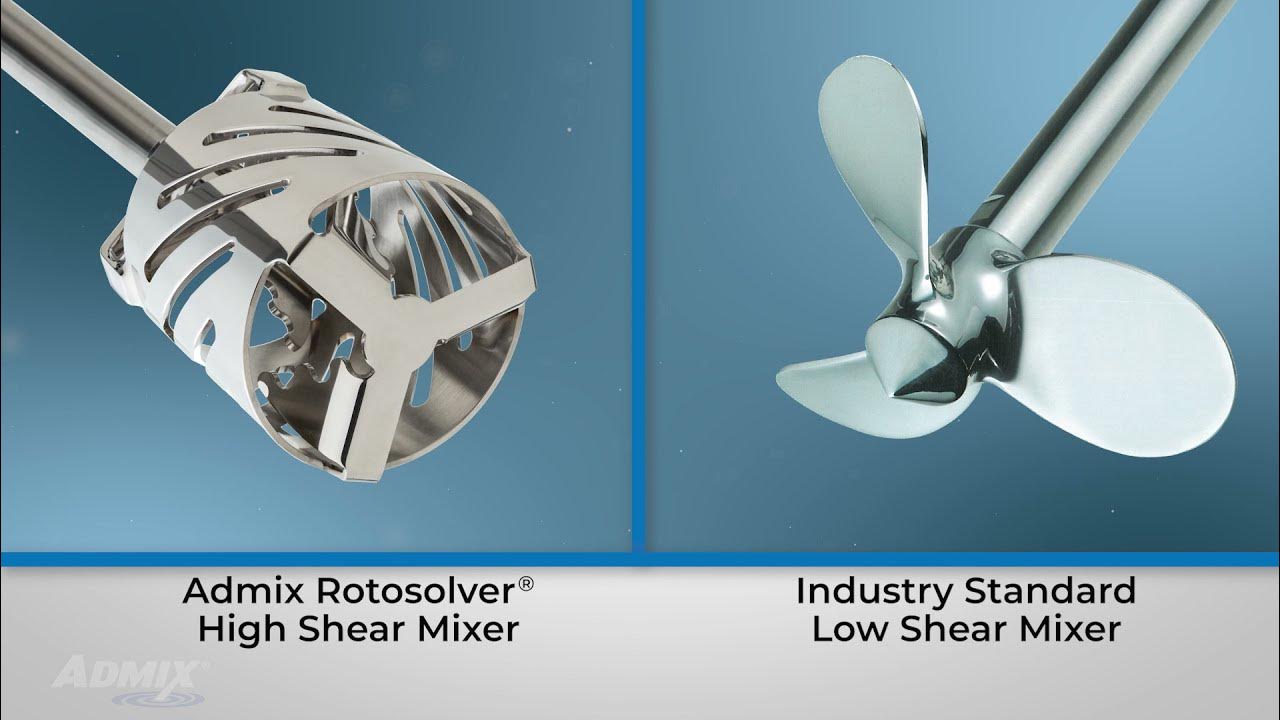

What Are High Shear Mixers and Their Applications in B2B?

High shear mixers are designed to operate at elevated speeds, effectively creating fine emulsions and dispersions. These mixers are particularly suitable for industries such as food processing, pharmaceuticals, and cosmetics, where consistency and quality are paramount. When considering a high shear mixer, B2B buyers should evaluate the specific viscosity and volume requirements of their applications, as well as the energy efficiency of the mixer to ensure optimal performance.

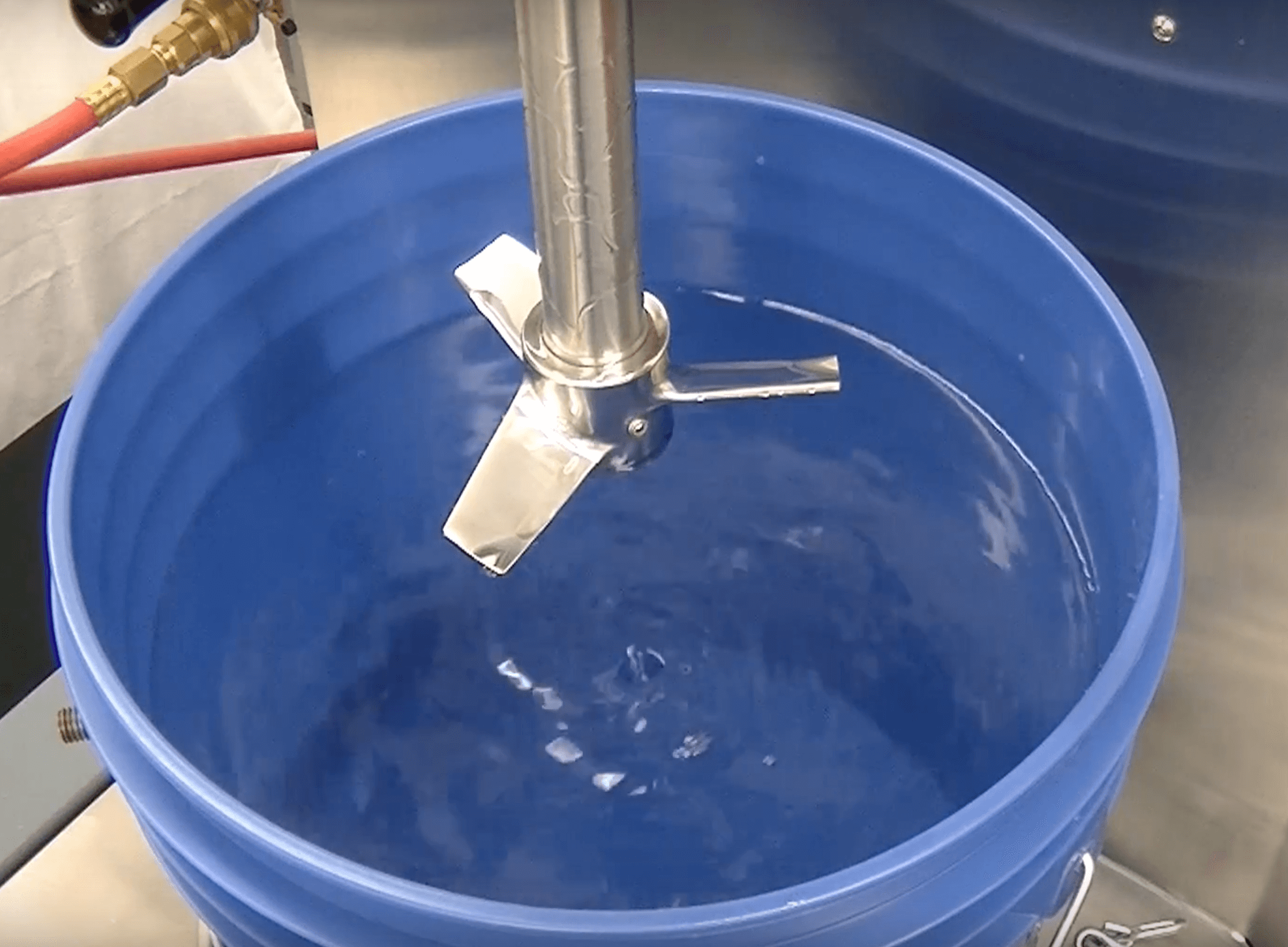

Why Choose Benchtop Lab Dispersers for Small-Scale Mixing?

Benchtop lab dispersers are ideal for small batch processing and are commonly used in research and development laboratories. Their compact design allows for easy integration into limited workspace environments, making them a cost-effective solution for pilot studies. Buyers should consider the capacity of the disperser and the types of materials they will be mixing to ensure the equipment meets their specific needs without compromising on quality.

Illustrative image related to shear mixers

How Do In-Line Rotor Stator Mixers Enhance Production Efficiency?

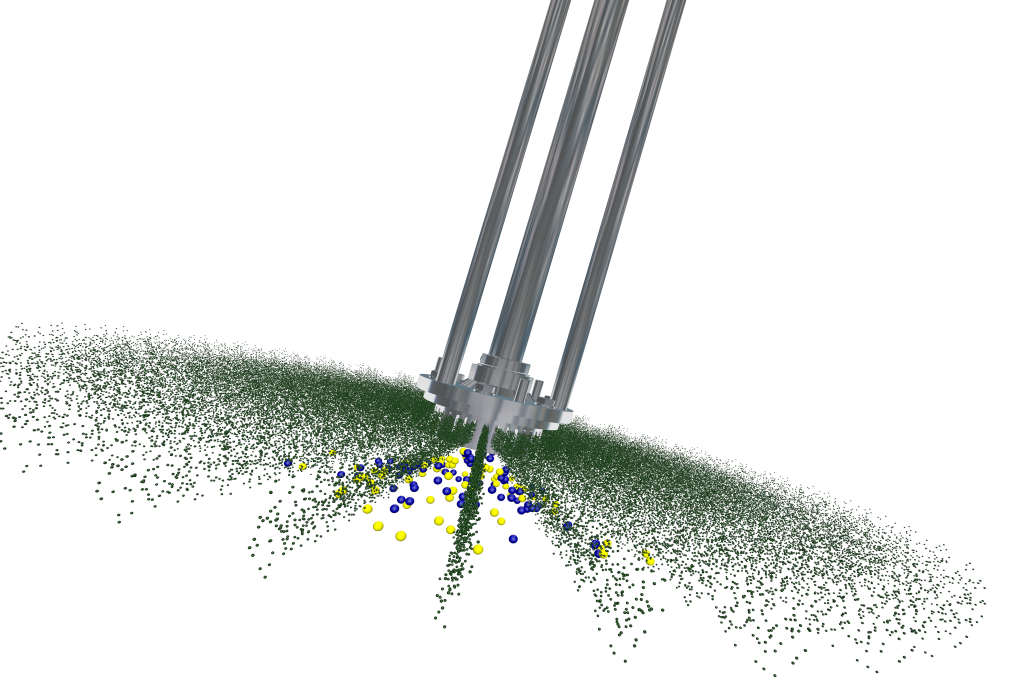

In-line rotor stator mixers facilitate continuous mixing processes, making them invaluable in large-scale production environments such as chemical manufacturing. These mixers not only ensure uniformity in product quality but also significantly reduce processing times. B2B buyers should assess the installation requirements and compatibility with existing production lines, as well as the potential for scalability when investing in this equipment.

What Advantages Do Dual Shaft Mixers Offer for Viscous Materials?

Dual shaft mixers are specifically designed to handle high-viscosity materials, making them perfect for industries such as paints, adhesives, and coatings. The dual-shaft design allows for efficient mixing of thick materials, ensuring homogeneous results. Buyers should weigh the benefits of enhanced mixing capabilities against the increased maintenance needs and operational costs associated with these more complex systems.

Why Are Three Roll Mills Essential for Particle Size Reduction?

Three roll mills are instrumental in achieving a fine particle size through the grinding and mixing of materials. They are widely used in industries such as ink, cosmetics, and specialty chemicals, where particle size plays a critical role in product performance. When considering a three roll mill, B2B buyers should focus on the throughput and the desired fineness level, as well as the potential for customization to meet specific production demands.

Key Industrial Applications of shear mixers

| Industry/Sector | Specific Application of shear mixers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Emulsifying sauces, dressings, and spreads | Ensures consistent texture and flavor profiles | Compliance with food safety standards and certifications |

| Pharmaceuticals | Homogenizing creams and ointments | Enhances bioavailability and effectiveness | Need for precise control over particle size and dispersion |

| Cosmetics and Personal Care | Creating stable emulsions for lotions and creams | Improves product stability and shelf life | Sourcing equipment that meets hygienic design standards |

| Chemicals and Coatings | Dispersing pigments and fillers in paints | Achieves uniform color and consistency | Equipment compatibility with various viscosities and formulations |

| Plastics and Polymers | Mixing additives into polymers | Enhances material properties and performance | Consideration of processing temperatures and shear rates |

How Are Shear Mixers Used in the Food and Beverage Industry?

In the food and beverage sector, shear mixers are pivotal for emulsifying sauces, dressings, and spreads. These mixers create stable emulsions by breaking down oil and water phases, ensuring a consistent texture and flavor profile. For B2B buyers, sourcing shear mixers that comply with food safety standards is crucial, particularly in regions like Africa and South America where regulations may vary. Additionally, equipment that offers easy cleaning and maintenance can enhance operational efficiency in production lines.

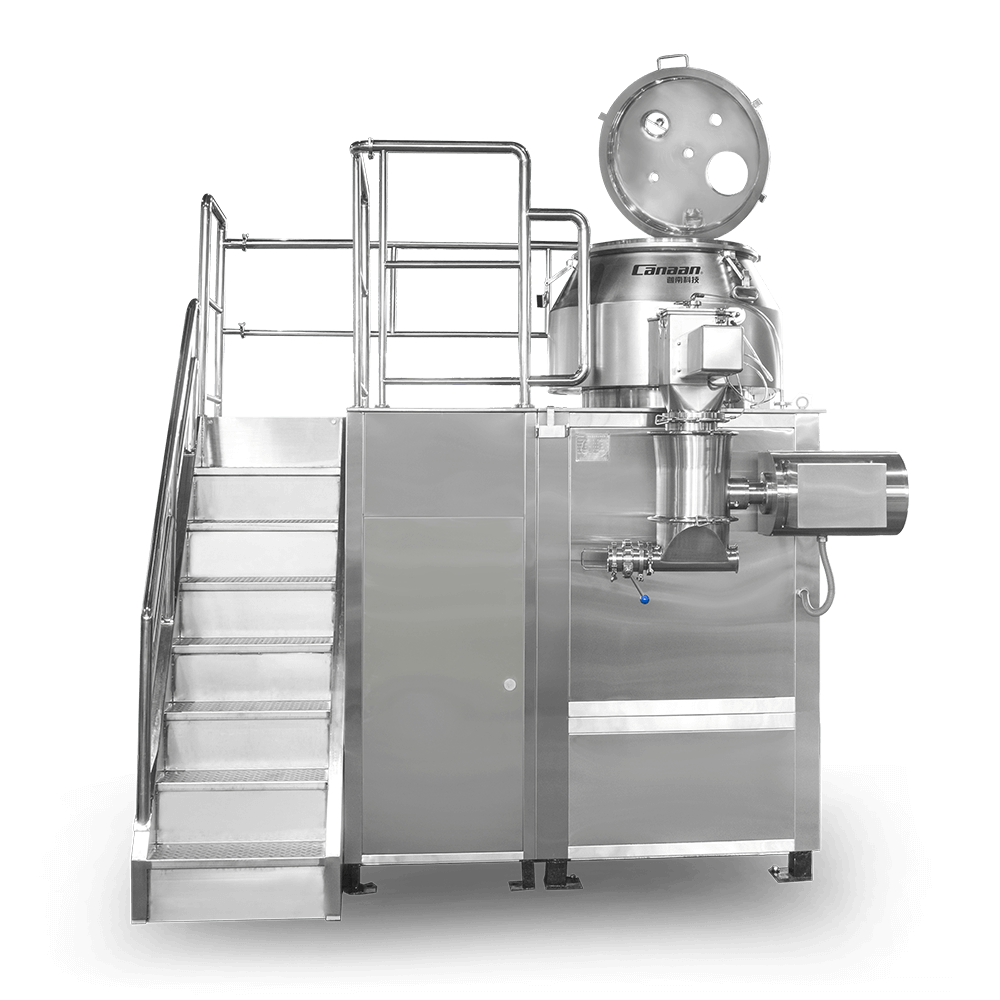

Illustrative image related to shear mixers

What Role Do Shear Mixers Play in Pharmaceuticals?

In the pharmaceutical industry, shear mixers are essential for homogenizing creams and ointments. This process enhances the bioavailability of active ingredients, ensuring that medications are effective and safe for consumers. Buyers in this sector must prioritize mixers that provide precise control over particle size and dispersion rates, as these factors significantly impact product efficacy. Compliance with regulatory standards and the ability to handle sterile processes are also critical considerations for sourcing equipment.

How Are Shear Mixers Beneficial in Cosmetics and Personal Care?

Shear mixers are widely used in cosmetics and personal care to create stable emulsions for lotions and creams. By effectively dispersing oil and water phases, these mixers improve product stability and extend shelf life, which is vital for maintaining consumer satisfaction. For international buyers, especially in regions like the Middle East and Europe, sourcing mixers that adhere to hygienic design standards ensures product safety and quality, while also meeting local regulations.

Why Are Shear Mixers Important in Chemicals and Coatings?

In the chemicals and coatings industry, shear mixers are utilized for dispersing pigments and fillers in paints. This ensures uniform color and consistency across batches, which is essential for product quality. When sourcing shear mixers, businesses should consider equipment compatibility with various viscosities and formulations, as well as the ability to handle high shear rates for effective mixing. Understanding the specific needs of different formulations can lead to better product outcomes.

How Do Shear Mixers Enhance Plastics and Polymers Processing?

In the plastics and polymers sector, shear mixers play a critical role in mixing additives into polymers. This process enhances the material properties, such as strength and flexibility, which are crucial for end-product performance. Buyers should focus on equipment that can accommodate varying processing temperatures and shear rates, as these factors influence the final product’s quality. Additionally, sourcing from reputable manufacturers can ensure reliability and durability in high-demand production environments.

3 Common User Pain Points for ‘shear mixers’ & Their Solutions

Scenario 1: Inconsistent Mixing Results Leading to Product Quality Issues

The Problem:

B2B buyers in industries such as food processing or pharmaceuticals often encounter challenges with achieving consistent mixing results. Inconsistent shear forces can lead to variations in product quality, impacting emulsions, dispersions, or suspensions. For example, a manufacturer producing a cream-based product may find that some batches have a grainy texture while others are smooth. This inconsistency not only affects customer satisfaction but can also result in costly product recalls and diminished brand reputation.

The Solution:

To mitigate quality issues, buyers should consider investing in high-shear mixers equipped with advanced rotor-stator designs that ensure uniform mixing. It’s crucial to specify the mixer based on the viscosity and batch size of the material being processed. For instance, a dual-shaft mixer may be beneficial for high-viscosity materials, as it combines both high shear and axial flow, promoting thorough blending. Additionally, implementing process controls and regular maintenance checks can help ensure that the shear mixer operates within optimal parameters, thus enhancing product consistency. Regularly reviewing and adjusting mixing speeds and times based on batch characteristics will further improve outcomes.

Scenario 2: High Operational Costs Due to Inefficient Mixing Processes

The Problem:

Many B2B buyers face high operational costs stemming from inefficient mixing processes. When shear mixers are not optimized for specific applications, they can consume excessive energy, leading to increased operational expenses. For example, a chemical manufacturer may find that its current shear mixer requires longer processing times and higher energy inputs to achieve desired results, ultimately affecting the bottom line.

The Solution:

To optimize operational efficiency, buyers should evaluate their shear mixers for energy consumption and processing speed. Selecting a mixer with variable speed control allows for adjustments based on material characteristics, reducing energy usage during lower shear requirements. Additionally, consider in-line shear mixers, which often provide continuous processing capabilities and can significantly lower cycle times. Conducting a cost-benefit analysis of different mixer models and configurations can help identify the most energy-efficient solution tailored to specific production needs. Collaborating with suppliers to ensure that the selected shear mixer aligns with the facility’s energy efficiency goals can lead to significant long-term savings.

Scenario 3: Limited Flexibility in Processing Diverse Materials

The Problem:

B2B buyers often deal with a range of materials requiring different mixing techniques, which can be a significant pain point when their current shear mixer lacks versatility. For instance, a cosmetic manufacturer might need to switch between formulations that include oils, powders, and emulsions. If the shear mixer cannot accommodate varying viscosities or batch sizes, it can lead to bottlenecks in production and delayed time-to-market.

The Solution:

To address this flexibility issue, buyers should look for shear mixers that offer modular designs or interchangeable mixing heads. This allows for quick adaptations to different formulations without the need for significant downtime or investment in multiple machines. Additionally, consider investing in portable shear mixers that can be moved between different production areas, allowing for greater versatility. Training staff on best practices for adjusting the mixer settings based on material properties will also enhance operational flexibility. By investing in equipment that can handle a wide range of mixing tasks, businesses can streamline operations and respond more quickly to market demands.

Strategic Material Selection Guide for shear mixers

What Are the Key Materials Used in Shear Mixers and Their Properties?

In the realm of shear mixers, the choice of materials is crucial for ensuring optimal performance, durability, and compatibility with various media. Below, we analyze four common materials used in shear mixer construction: stainless steel, carbon steel, plastic (polypropylene), and ceramic. Each material has distinct properties, advantages, and disadvantages that can significantly influence operational efficiency and product quality.

How Does Stainless Steel Contribute to Shear Mixer Performance?

Stainless steel is a popular choice for shear mixers due to its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. Typically, grades like 304 and 316 are used, with 316 offering superior resistance to chlorides and other corrosive agents.

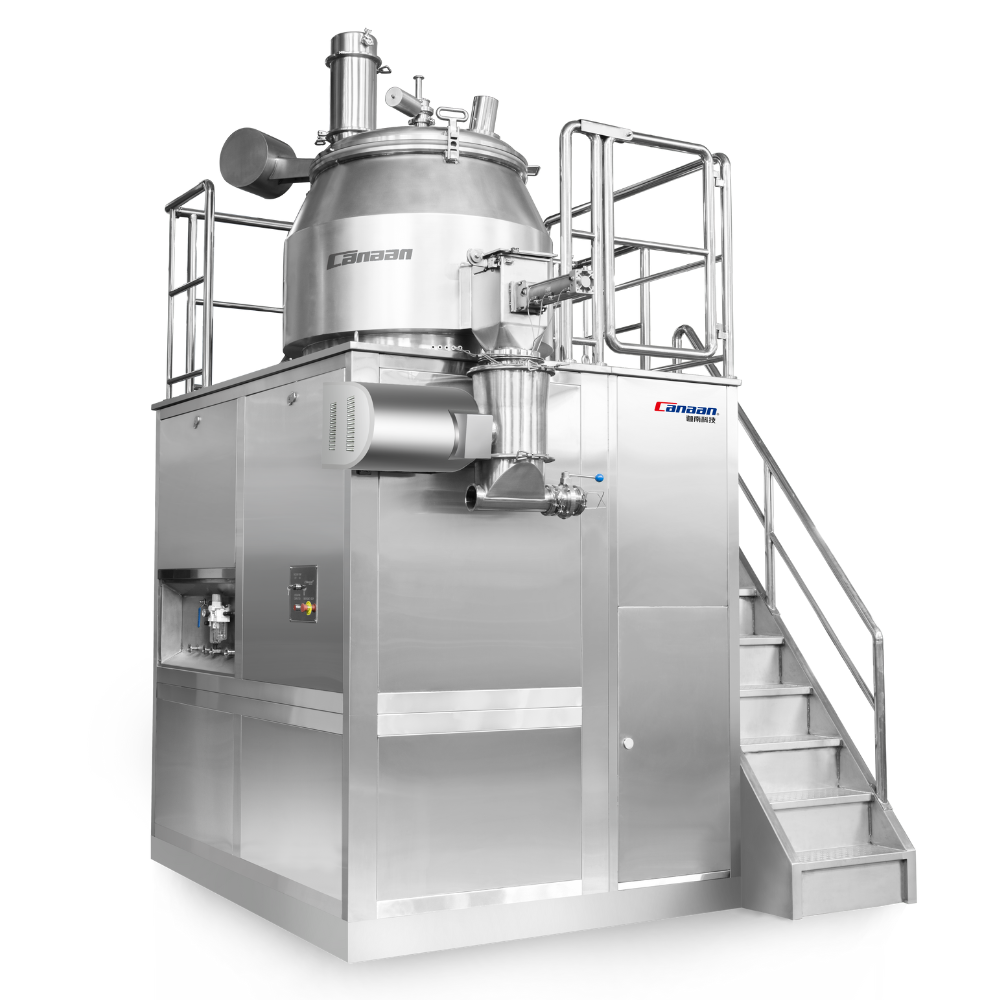

Illustrative image related to shear mixers

Pros:

– Exceptional durability and longevity.

– High resistance to rust and corrosion, making it suitable for food and pharmaceutical applications.

– Easy to clean and maintain, which is essential for hygiene-sensitive industries.

Cons:

– Higher initial cost compared to other materials.

– More complex manufacturing processes may lead to longer lead times.

Impact on Application: Stainless steel is ideal for mixing aggressive chemicals or food products, ensuring compliance with health regulations.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN, which often dictate the use of stainless steel in food and pharmaceutical applications.

What Role Does Carbon Steel Play in Shear Mixers?

Carbon steel is another common material, primarily due to its strength and cost-effectiveness. It is often treated with coatings or linings to enhance its corrosion resistance.

Illustrative image related to shear mixers

Pros:

– Lower cost compared to stainless steel, making it a budget-friendly option.

– High tensile strength, suitable for heavy-duty applications.

Cons:

– Prone to rust and corrosion if not properly coated or maintained.

– Limited temperature resistance compared to stainless steel.

Impact on Application: Carbon steel is suitable for mixing non-corrosive materials, but its susceptibility to rust makes it less ideal for food or chemical applications without protective coatings.

Considerations for International Buyers: Buyers in Africa or South America should be aware of local environmental conditions that may accelerate corrosion, necessitating additional protective measures.

How Do Plastics Like Polypropylene Enhance Shear Mixer Functionality?

Plastic materials, particularly polypropylene, offer unique advantages in specific applications. They are lightweight, resistant to many chemicals, and cost-effective.

Illustrative image related to shear mixers

Pros:

– Excellent chemical resistance, particularly to acids and bases.

– Lightweight and easy to handle, reducing transportation costs.

Cons:

– Lower temperature and pressure ratings compared to metals.

– Less durable in high-stress applications.

Impact on Application: Polypropylene is ideal for mixing aggressive chemicals in non-heat-intensive processes, making it suitable for laboratories and certain industrial applications.

Illustrative image related to shear mixers

Considerations for International Buyers: Compliance with local regulations regarding plastics in food contact applications is vital, especially in regions like Europe, where standards are stringent.

Why Are Ceramics Used in Shear Mixers?

Ceramic materials are increasingly being used in shear mixers due to their hardness and resistance to wear and corrosion. They are particularly effective in applications involving abrasive materials.

Pros:

– Exceptional hardness and wear resistance, extending the lifespan of the mixer.

– High chemical resistance, suitable for harsh environments.

Cons:

– Brittle nature can lead to breakage under impact.

– Higher manufacturing costs and complexity.

Impact on Application: Ceramics are ideal for industries dealing with abrasive slurries or corrosive chemicals, ensuring long-term reliability.

Considerations for International Buyers: Buyers should consider the availability of ceramic components and any specific import regulations that may affect procurement.

Summary Table of Material Selection for Shear Mixers

| Material | Typical Use Case for shear mixers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical applications | Excellent corrosion resistance | Higher initial cost | High |

| Carbon Steel | Heavy-duty industrial applications | Cost-effective | Prone to rust | Low |

| Plastic (Polypropylene) | Laboratory and chemical mixing | Lightweight and chemically resistant | Lower temperature ratings | Med |

| Ceramic | Abrasive and corrosive material mixing | High wear resistance | Brittle and costly | High |

This analysis provides a comprehensive overview of material selection for shear mixers, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for shear mixers

What Are the Key Manufacturing Processes for Shear Mixers?

The manufacturing of shear mixers involves several critical stages that ensure the final product meets the high standards required by various industries. Understanding these processes helps B2B buyers assess the quality and reliability of potential suppliers.

Illustrative image related to shear mixers

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing shear mixers is the careful selection and preparation of raw materials. Common materials include stainless steel, carbon steel, and various alloys, chosen for their durability and resistance to corrosion. Suppliers often utilize high-grade materials that comply with international standards, ensuring the mixers can withstand rigorous industrial applications.

Once selected, materials undergo processes such as cutting, machining, and surface treatment. Machining involves precise shaping to achieve the required dimensions, while surface treatments, such as polishing or coating, enhance corrosion resistance and improve hygiene—critical factors in industries like food processing and pharmaceuticals.

What Forming Techniques Are Used in Shear Mixer Production?

After material preparation, the next stage is forming. This can involve processes like forging, casting, or welding, depending on the design and specifications of the shear mixer.

- Forging is commonly used for components that require high strength and durability, such as rotors and stators.

- Casting may be employed for complex shapes that would be difficult to achieve through forging.

- Welding is crucial for assembling various parts of the mixer, ensuring a robust structure that can handle high shear forces.

These techniques are vital for achieving the precise tolerances needed for optimal mixing performance.

How Is the Assembly Process Conducted for Shear Mixers?

The assembly stage is where individual components come together to form the complete shear mixer. This process often involves skilled technicians who ensure that every part is fitted correctly and securely.

Illustrative image related to shear mixers

During assembly, key components such as motors, blades, and housing are integrated. Attention to detail is critical, as misalignment can lead to inefficiencies or equipment failure. Many manufacturers implement automated systems to assist in the assembly process, enhancing precision and reducing the risk of human error.

What Finishing Techniques Enhance the Quality of Shear Mixers?

Finishing processes are essential for ensuring that shear mixers not only perform well but also meet aesthetic and safety standards. Common finishing techniques include:

- Surface Finishing: Techniques like sandblasting or electro-polishing are used to create smooth surfaces that reduce friction and facilitate cleaning.

- Coating: Protective coatings may be applied to prevent corrosion and wear, particularly in harsh environments.

- Testing and Inspection: Each unit undergoes rigorous testing to ensure it meets performance specifications before leaving the factory.

These finishing touches are what often differentiate high-quality mixers from standard offerings.

What Quality Assurance Measures Are Critical for Shear Mixers?

Quality assurance (QA) is a vital aspect of manufacturing shear mixers, ensuring that products not only meet customer expectations but also comply with international standards.

Which International Standards Should B2B Buyers Be Aware Of?

For buyers operating across different regions, understanding relevant international standards is crucial. ISO 9001 is the most recognized quality management standard, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for those used in the oil and gas sector should be considered.

Illustrative image related to shear mixers

These certifications indicate that a manufacturer adheres to established quality processes, which can significantly reduce the risk of defects or failures.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. The main checkpoints include:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specifications before they are used in production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to catch any deviations from quality standards early in the process.

- Final Quality Control (FQC): Once assembly is complete, each mixer undergoes thorough testing to validate performance and safety before shipment.

These checkpoints help maintain a consistent quality level and build trust with buyers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. Here are several methods to achieve this:

-

Audits: Regular audits of the manufacturing facility can provide insights into the production processes and adherence to quality standards. Buyers can conduct these audits themselves or hire third-party services.

-

Quality Reports: Requesting documentation regarding quality control processes, including test results and compliance certifications, can help verify claims made by suppliers.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and product quality before shipment.

-

References and Reviews: Seeking feedback from other clients or industry contacts can provide valuable insights into a supplier’s reliability and quality assurance practices.

What Unique QC Considerations Exist for International Buyers?

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, additional QC considerations come into play. Factors such as local regulations, import standards, and cultural expectations can influence quality requirements.

Buyers should ensure that suppliers are not only compliant with international standards but also familiar with local regulations in the buyer’s country. This dual compliance can prevent potential legal issues and ensure a smoother import process.

Illustrative image related to shear mixers

In conclusion, understanding the manufacturing processes and quality assurance measures for shear mixers is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing processes, as well as robust QC practices, buyers can make informed decisions that lead to successful procurement and long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shear mixers’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of shear mixers, essential equipment for applications requiring high precision in emulsification and dispersion. By following this step-by-step checklist, buyers can ensure they select the right shear mixer tailored to their operational needs while minimizing risks associated with supplier selection.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for your shear mixer. Consider factors such as mixing capacity, viscosity range, and the specific materials you will be processing.

– Mixing Capacity: Determine the volume of materials you typically handle to choose a mixer that can efficiently accommodate your batch sizes.

– Viscosity Range: Identify the viscosity of your materials to ensure the mixer can handle the required shear rates for effective mixing.

Step 2: Research Different Shear Mixer Types

There are various types of shear mixers available, each suited for specific applications. Familiarize yourself with options such as batch mixers, inline mixers, and benchtop dispersers.

– Batch vs. Inline: Batch mixers are ideal for smaller operations, while inline mixers are more efficient for continuous processes.

– Special Features: Look for mixers with features like variable speed settings or interchangeable rotor-stator configurations for enhanced versatility.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your business standards and requirements. Request detailed company profiles, product catalogs, and customer testimonials.

– Industry Experience: Focus on suppliers with a proven track record in your specific industry to ensure they understand your unique needs.

– Customer Support: Assess the level of after-sales support and service they offer, as this can significantly affect your operational efficiency.

Step 4: Request and Compare Quotes

Once you’ve shortlisted suppliers, request detailed quotes that include pricing, lead times, and warranty terms. Comparing these quotes allows for informed decision-making.

– Inclusions in Quotes: Ensure that quotes cover not just the initial purchase price but also installation, training, and ongoing maintenance costs.

– Total Cost of Ownership: Consider the long-term costs associated with energy consumption and potential downtime when evaluating quotes.

Step 5: Verify Compliance and Certifications

Ensure that the shear mixers you are considering comply with relevant industry standards and regulations. This is particularly important for international transactions.

– Quality Certifications: Look for certifications such as ISO or CE that demonstrate compliance with quality and safety standards.

– Local Regulations: Familiarize yourself with any local regulations that might affect equipment installation and operation in your region.

Step 6: Conduct Site Visits or Virtual Demos

If possible, arrange site visits to the supplier’s facility or request virtual demonstrations of the mixers in action. Observing equipment firsthand can provide valuable insights.

– Operational Insights: A demonstration can showcase the mixer’s performance and allow you to ask specific questions about its operation.

– Customization Options: Use this opportunity to discuss customization options that may better suit your specific mixing requirements.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that the purchase agreement reflects all terms discussed, including payment schedules, delivery timelines, and support services.

– Clear Terms: Specify warranty periods and service agreements to avoid any misunderstandings in the future.

– Legal Review: Have your legal team review the contract to ensure all clauses are favorable and protect your interests.

By following this checklist, B2B buyers can navigate the complexities of sourcing shear mixers, ensuring a successful procurement process that aligns with their operational goals.

Comprehensive Cost and Pricing Analysis for shear mixers Sourcing

What Are the Key Cost Components in Shear Mixers Manufacturing?

When sourcing shear mixers, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The quality and type of materials used significantly influence the pricing. High-grade stainless steel or specialized alloys for corrosion resistance can elevate costs. Additionally, components such as rotors and stators may require specific materials tailored for certain applications.

-

Labor: Skilled labor is essential for manufacturing shear mixers, especially for assembly and quality control. Labor costs can vary based on geographic location, with regions offering lower wages potentially providing more cost-effective solutions.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory operation. Efficient manufacturing processes can minimize these overheads, leading to competitive pricing.

-

Tooling: Custom tooling for specialized shear mixer designs can incur significant upfront costs. However, once established, these tools can improve production efficiency and reduce costs in the long run.

-

Quality Control (QC): Rigorous QC processes ensure that the mixers meet industry standards and specifications. Investments in quality testing may increase initial costs but can prevent costly returns and repairs.

-

Logistics: Transportation and shipping expenses, including duties and tariffs, play a vital role in the overall cost. For international buyers, understanding Incoterms is essential to determine who bears these costs.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. This margin can vary significantly based on the supplier’s market position, brand reputation, and service level.

How Do Price Influencers Affect Shear Mixers Sourcing?

Several factors can influence the pricing of shear mixers, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their current and future needs to negotiate favorable terms.

-

Specifications and Customization: Customized mixers designed for specific applications may command higher prices. Clear communication of requirements can help suppliers provide accurate quotes.

-

Materials and Quality Certifications: The choice of materials and any required quality certifications (e.g., ISO, CE) can affect pricing. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Supplier Factors: The reputation, reliability, and service level of suppliers can impact pricing. Established suppliers may charge premium prices but offer better warranties and customer support.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Different Incoterms (like FOB, CIF) can shift cost responsibilities between buyers and suppliers, affecting the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Shear Mixers?

To achieve cost-efficient sourcing of shear mixers, buyers should consider the following strategies:

-

Negotiate: Engage in discussions with suppliers to explore flexible pricing options, particularly for larger orders or repeat business. Leverage competitive quotes to strengthen your negotiating position.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. A higher initial investment may lead to long-term savings.

-

Be Aware of Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe may face unique challenges, such as fluctuating exchange rates or shipping delays. Factor these into your budgeting.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various suppliers can provide insight into market pricing and help identify the best value.

-

Stay Informed on Market Trends: Keeping abreast of market trends and changes in material costs can help buyers make informed decisions and anticipate pricing fluctuations.

Disclaimer

The prices mentioned throughout this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always request formal quotes from suppliers to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing shear mixers With Other Solutions

Exploring Alternative Mixing Solutions to Shear Mixers

In the pursuit of efficient mixing solutions, businesses often encounter a variety of technologies that can fulfill similar functions to shear mixers. Understanding these alternatives is crucial for B2B buyers looking to optimize their mixing processes, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis will compare shear mixers to two viable alternatives: high-speed dispersers and three-roll mills.

| Comparison Aspect | Shear Mixers | High-Speed Dispersers | Three-Roll Mills |

|---|---|---|---|

| Performance | Excellent for emulsifying and dispersing high-viscosity materials | Effective for dispersions but less efficient for emulsions | Ideal for fine particle reduction and uniformity |

| Cost | Moderate to high initial investment | Generally lower than shear mixers | High initial cost, especially for industrial models |

| Ease of Implementation | Requires skilled operators for optimal results | Easier to operate with less training | Complex setup and requires specialized knowledge |

| Maintenance | Moderate; regular inspection needed | Low; minimal parts wear out | High; requires frequent maintenance to ensure optimal performance |

| Best Use Case | Ideal for pharmaceutical and food industries | Suitable for coatings and inks | Best for cosmetics and specialty chemicals |

What Are the Advantages and Disadvantages of High-Speed Dispersers?

High-speed dispersers are designed to mix and disperse materials rapidly. They are known for their ability to handle a range of viscosities and are particularly effective in applications like coatings and inks. The primary advantage of high-speed dispersers is their cost-effectiveness; they typically come at a lower price point than shear mixers. Additionally, they require less operator training, making them easier to implement in various production environments. However, they may not achieve the same level of emulsification as shear mixers, which could be a critical factor for certain applications, such as those in the food and pharmaceutical industries.

How Do Three-Roll Mills Compare to Shear Mixers?

Three-roll mills are specialized equipment that excels in grinding and refining materials, ensuring uniform particle sizes and textures. Their performance in achieving fine dispersions is unparalleled, making them a preferred choice for cosmetic and specialty chemical formulations. However, the initial investment for three-roll mills can be quite high, which may be a barrier for smaller manufacturers. The complexity of their operation also requires skilled personnel, leading to additional training costs. Maintenance can be intensive, necessitating regular checks to maintain optimal performance. While they offer unique advantages, the costs and operational demands can limit their applicability for some businesses.

How Should B2B Buyers Choose the Right Mixing Solution?

When selecting a mixing solution, B2B buyers should assess their specific operational needs and production goals. Key considerations include the type of materials being processed, the required mixing outcomes, budget constraints, and the skill level of available operators. For those focused on high-viscosity emulsions, shear mixers may be the most suitable option. Conversely, if the focus is on cost and ease of use, high-speed dispersers could be a better fit. Meanwhile, industries requiring fine particle size and uniformity may find three-roll mills to be the best solution despite their higher costs. Ultimately, a thorough evaluation of these factors will guide buyers in making informed decisions that align with their operational objectives.

Essential Technical Properties and Trade Terminology for shear mixers

What Are the Key Technical Properties of Shear Mixers That B2B Buyers Should Know?

When evaluating shear mixers for industrial applications, understanding their technical properties is crucial for ensuring optimal performance and compatibility with production needs. Here are some essential specifications to consider:

Illustrative image related to shear mixers

-

Material Grade

Shear mixers are often constructed from stainless steel or other corrosion-resistant materials. The grade of stainless steel (e.g., 304, 316) affects durability, resistance to chemical reactions, and the ability to maintain hygiene standards, especially in food and pharmaceutical industries. Selecting the appropriate material grade ensures longevity and compliance with industry regulations. -

Motor Power (HP)

The motor power, typically measured in horsepower (HP), determines the mixer’s capacity to handle different viscosities and volumes. A higher HP rating allows for the mixing of thicker materials and larger batches, thus improving productivity. For B2B buyers, understanding the required power helps align equipment with production demands. -

Speed Range (RPM)

The speed at which the mixer operates, measured in revolutions per minute (RPM), impacts the efficiency of emulsification and dispersion processes. Different applications may require varying speed settings; therefore, a mixer with adjustable speed features provides flexibility. This adaptability is vital for businesses needing to process diverse materials. -

Volume Capacity

Shear mixers come in various sizes, from benchtop models for small batches to large-scale mixers designed for industrial production. Understanding the volume capacity helps businesses select equipment that fits their production scale, ensuring efficiency without bottlenecks. It is essential for B2B buyers to assess their operational needs against the mixer’s specifications. -

Tolerance Levels

Tolerance refers to the acceptable deviation from specified dimensions or performance standards. High tolerance levels are necessary for precision applications where consistency in product quality is critical. For manufacturers, ensuring that their shear mixers meet required tolerance levels can lead to better product quality and reduced waste.

What Are Common Trade Terms Associated with Shear Mixers?

Familiarity with industry terminology can facilitate smoother transactions and enhance communication between buyers and suppliers. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. When sourcing shear mixers, buyers might encounter OEM products that meet specific standards and requirements, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to manage inventory levels and ensure they are purchasing sufficient quantities to meet production needs without excess. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. By preparing a detailed RFQ for shear mixers, buyers can receive competitive pricing and evaluate suppliers based on cost and capability. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international trade. Understanding Incoterms helps B2B buyers clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, thus preventing misunderstandings in transactions. -

Lead Time

Lead time is the amount of time that passes from the initiation of a process until its completion. For shear mixers, this includes manufacturing, shipping, and delivery times. Knowing the lead time is crucial for planning production schedules and inventory management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right shear mixers that align with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the shear mixers Sector

What Are the Current Market Dynamics and Key Trends in the Shear Mixers Sector?

The global shear mixers market is experiencing significant growth, driven by the increasing demand for high-quality emulsions and dispersions across various industries, including food and beverage, pharmaceuticals, and cosmetics. Key trends include the rise of automation and smart technology, which are enhancing the efficiency and precision of mixing processes. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced shear mixing solutions that offer scalability and versatility.

Moreover, emerging technologies such as in-line mixing systems and dual-shaft mixers are gaining traction. These innovations allow for continuous processing, which is essential for industries looking to streamline operations and reduce production costs. Additionally, the trend toward customization is evident, as businesses are looking for tailored solutions that meet specific operational requirements. Buyers are advised to consider suppliers that offer a range of mixing solutions, including benchtop and large-scale options, to accommodate varying production needs.

How Are Sustainability and Ethical Sourcing Influencing the Shear Mixers Market?

Sustainability has become a pivotal factor for B2B buyers in the shear mixers sector. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek suppliers who prioritize eco-friendly practices. This includes utilizing sustainable materials and adopting energy-efficient manufacturing processes. Certifications such as ISO 14001 (Environmental Management) are increasingly important, as they signify a commitment to sustainability.

Furthermore, ethical sourcing is critical as companies strive to maintain transparency in their supply chains. Buyers are encouraged to partner with manufacturers that adhere to ethical labor practices and demonstrate a commitment to fair trade. By prioritizing suppliers who embrace sustainability, businesses not only enhance their corporate social responsibility (CSR) profile but also appeal to an increasingly eco-conscious consumer base.

What Is the Historical Context of Shear Mixers in B2B Applications?

The evolution of shear mixers dates back to the early 20th century when the demand for efficient mixing solutions began to rise in industries such as food processing and pharmaceuticals. Initially, manual mixing methods were prevalent, but the introduction of mechanical mixers revolutionized the industry, allowing for greater precision and consistency. Over the decades, shear mixers have evolved significantly, integrating advanced technologies that enhance their capabilities. Today, high shear mixers are indispensable in producing fine emulsions and dispersions, meeting the sophisticated demands of modern manufacturing processes. This historical context underscores the importance of adapting to technological advancements, a critical consideration for B2B buyers looking to invest in reliable mixing solutions.

Illustrative image related to shear mixers

Frequently Asked Questions (FAQs) for B2B Buyers of shear mixers

-

1. How do I choose the right shear mixer for my application?

Selecting the appropriate shear mixer hinges on several factors, including the viscosity of the materials you plan to mix, batch size, and desired end product characteristics. Begin by evaluating your specific application needs—whether you require high-speed emulsification or gentle mixing. Consider the mixer type (e.g., batch vs. inline), power requirements, and any necessary attachments for customization. Engaging with suppliers who can provide technical specifications and application guidance is crucial for making an informed decision. -

2. What are the advantages of high shear mixers in industrial applications?

High shear mixers are designed to produce uniform emulsions and dispersions, enhancing product quality and consistency. They are particularly effective in breaking down particles and mixing viscous substances, which is essential in industries such as food processing, pharmaceuticals, and cosmetics. The ability to handle various batch sizes—from small laboratory units to large-scale production—makes them versatile. Additionally, their efficiency can lead to reduced processing time and lower energy costs. -

3. What customization options are available for shear mixers?

Many manufacturers offer customization options to tailor shear mixers to specific operational needs. These may include varying rotor-stator configurations, adjustable speed settings, and different materials of construction to accommodate corrosive or abrasive substances. Additionally, you can request specific features like explosion-proof designs for hazardous environments. Discussing your unique requirements with suppliers will help identify the best customization options available. -

4. What are the typical minimum order quantities (MOQs) for shear mixers?

Minimum order quantities for shear mixers can vary significantly by supplier and product type. While some manufacturers may allow orders for single units, others may have MOQs ranging from 5 to 10 units, especially for customized models. It’s advisable to communicate your needs with potential suppliers to explore flexibility in MOQs and negotiate terms that suit your purchasing strategy. -

5. How do I ensure the quality of shear mixers when sourcing internationally?

To guarantee product quality, consider suppliers with established reputations and certifications, such as ISO standards. Request samples or product demonstrations to assess performance firsthand. Additionally, inquire about the quality assurance processes they employ, including testing and validation methods. Collaborating with third-party inspection agencies can also provide an added layer of assurance before committing to a large purchase. -

6. What payment terms should I expect when purchasing shear mixers?

Payment terms can vary widely among suppliers, but it’s common to encounter options such as upfront payments, deposits, or net terms (e.g., net 30 or net 60 days). International transactions may require additional considerations like letters of credit or escrow services for larger orders. Always clarify payment terms before finalizing the deal and consider negotiating terms that can enhance your cash flow management. -

7. What logistics considerations should I keep in mind when importing shear mixers?

Logistics play a critical role in the importation of shear mixers. Key factors include shipping methods (air vs. sea), lead times, and customs clearance processes. Ensure that you understand the total landed cost, including shipping, duties, and taxes. It’s beneficial to work with logistics partners experienced in international trade to streamline the import process and avoid potential delays. -

8. How can I verify the reliability of a shear mixer supplier?

To assess a supplier’s reliability, research their track record through customer reviews, case studies, and testimonials. Verify their industry experience and the range of products offered. Request references from previous clients and inquire about after-sales support, warranty conditions, and service capabilities. Engaging in direct communication can also provide insights into their responsiveness and commitment to customer service.

Top 4 Shear Mixers Manufacturers & Suppliers List

1. Mixer Direct – High Shear Mixers

Domain: mixerdirect.com

Registered: 2008 (17 years)

Introduction: High Shear Mixers are engineered for precise emulsions and dispersions in various mixing processes. They include options such as Benchtop Lab Dispersers, Post Mount Dispersers, and In-Line Rotor Stator Mixers. The mixers come with various horsepower options ranging from 3/4 HP to 40 HP, and impeller diameters from 2 in. to 16 in. They have shaft lengths of 28 in. to 50 in. and total heights rangin…

2. Silverson – High Shear Mixers

Domain: silverson.com

Registered: 1996 (29 years)

Introduction: High Shear Mixers from Silverson include a range of products designed for various applications: 1. **Lab Series**: Ideal for laboratory work and R&D, including Laboratory Mixers, Laboratory In-Line Mixers, and Laboratory Powder/Liquid Mixers. 2. **Batch Series**: Mix, emulsify, homogenize, disintegrate, and dissolve with Batch Mixers and Pilot Scale Batch Mixers. 3. **In-Line Series**: Reduce mixi…

3. ROSS – High Shear Mixers

Domain: mixers.com

Registered: 1999 (26 years)

Introduction: High Shear Mixers from ROSS offer power, precision, and versatility, revolutionizing mixing technology and processing efficiency across various industries including pharmaceutical, food, cosmetic, ink, adhesives, chemicals, and coatings. Types of High Shear Mixers include: Laboratory High Shear Mixers, Batch High Shear Mixers, Inline High Shear Mixers, Ultra High Shear Inline Mixers, and Solids/Li…

4. GEA – High Shear Mixers

Domain: gea.com

Registered: 1995 (30 years)

Introduction: GEA offers a comprehensive range of high shear mixers designed for efficient mixing and high-quality end products. Key products include:

1. GEA BATCH FORMULA® MIN High Shear Mixer – A semi-automatic, compact system for dairy, beverage, plant-based beverage, and liquid food applications.

2. GEA BATCH FORMULA® PRO High Shear Mixer – Available with or without vacuum, optimizing mixing and process ti…

Strategic Sourcing Conclusion and Outlook for shear mixers

What Are the Key Takeaways for Strategic Sourcing of Shear Mixers?

In the competitive landscape of industrial mixing, strategic sourcing of shear mixers is crucial for optimizing production efficiency and product quality. High shear mixers offer precise emulsions and dispersions, allowing businesses to enhance their operational capabilities. By investing in tailored solutions such as benchtop lab dispersers or high-capacity in-line rotor stator mixers, companies can significantly improve their mixing processes to meet diverse industry demands.

Why Is Strategic Sourcing Essential for International Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of shear mixer technology and supplier reliability can lead to substantial cost savings and improved product outcomes. Engaging with reputable suppliers that offer customizable options can also facilitate compliance with local regulations and standards, thereby reducing operational risks.

How Can Buyers Prepare for Future Trends in Shear Mixing Technology?

As the market evolves, the demand for advanced mixing solutions will grow, driven by innovations in materials and processes. Buyers should remain proactive in researching emerging technologies and supplier capabilities to harness these advancements. By prioritizing strategic sourcing today, businesses can position themselves for success in the dynamic landscape of tomorrow’s manufacturing environment.

Take the next step towards enhancing your operations by exploring the latest shear mixer technologies and connecting with trusted suppliers who can meet your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.