Is Your Scanner X Tool Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for scanner x tool

In the rapidly evolving automotive industry, sourcing the right scanner x tool can present significant challenges for international B2B buyers. As vehicles become increasingly complex, the demand for advanced diagnostic tools is surging, especially in emerging markets across Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource for navigating the global market for scanner x tools, offering insights into various types of diagnostic scanners, their applications in different automotive sectors, and essential tips for supplier vetting and cost analysis.

Understanding the diverse landscape of scanner x tools is crucial for businesses looking to enhance their diagnostic capabilities. With a focus on quality and compatibility, this guide outlines key features to consider, from OBD2 scanners to specialized tools for electric vehicles and heavy-duty trucks. Additionally, we provide actionable strategies for evaluating suppliers, ensuring that you partner with reputable manufacturers who prioritize reliability and after-sales support.

By leveraging the information in this guide, international B2B buyers—particularly those from regions like Nigeria and Brazil—will be empowered to make informed purchasing decisions that align with their specific operational needs. Whether you are looking to expand your service offerings or improve diagnostic efficiency, this resource equips you with the knowledge to succeed in a competitive market.

Understanding scanner x tool Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OBD2 Scanners | Standardized diagnostic protocols, user-friendly interface | Automotive repair shops, fleet management | Pros: Affordable, widespread compatibility. Cons: Limited advanced functions. |

| Heavy-Duty Truck Scanners | Designed for commercial vehicles, robust build | Trucking companies, logistics | Pros: Specialized for heavy-duty diagnostics. Cons: Higher price point. |

| Key Programming Tools | Enables key duplication and programming | Automotive locksmiths, dealerships | Pros: Essential for key management. Cons: May require additional training. |

| Bluetooth/WiFi Scanners | Wireless connectivity, mobile app integration | Mobile mechanics, DIY enthusiasts | Pros: Flexibility and convenience. Cons: Potential connectivity issues. |

| Advanced Diagnostic Tools | Full-system diagnostics, bi-directional control | High-end repair shops, specialized technicians | Pros: Comprehensive features, accurate results. Cons: Higher investment required. |

What Are the Key Characteristics of OBD2 Scanners?

OBD2 scanners are the most common type of diagnostic tool, designed to interface with the standardized onboard diagnostics systems of vehicles. They are widely used in automotive repair shops and fleet management due to their affordability and ease of use. B2B buyers should consider the scanner’s compatibility with various vehicle makes and models, as well as the availability of updates and support. While they offer essential diagnostic capabilities, their limitations in advanced functions may necessitate additional tools for more complex issues.

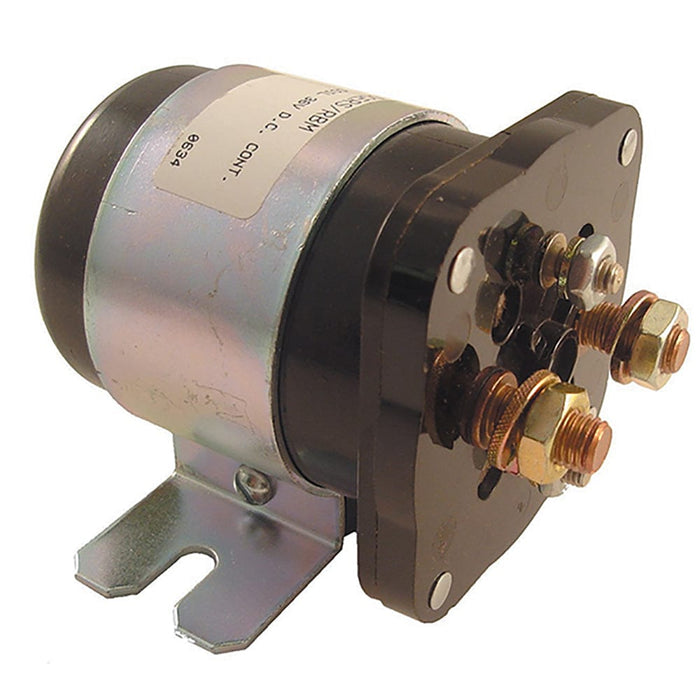

How Do Heavy-Duty Truck Scanners Differ from Standard Scanners?

Heavy-duty truck scanners are specifically engineered for commercial vehicles, featuring robust designs to withstand rigorous use. These tools are essential for trucking companies and logistics providers, allowing for accurate diagnostics of larger engines and systems. Buyers should assess the scanner’s coverage of different truck brands and models, as well as its ability to perform specialized functions. While they provide invaluable support for heavy-duty applications, the higher price point can be a consideration for smaller operators.

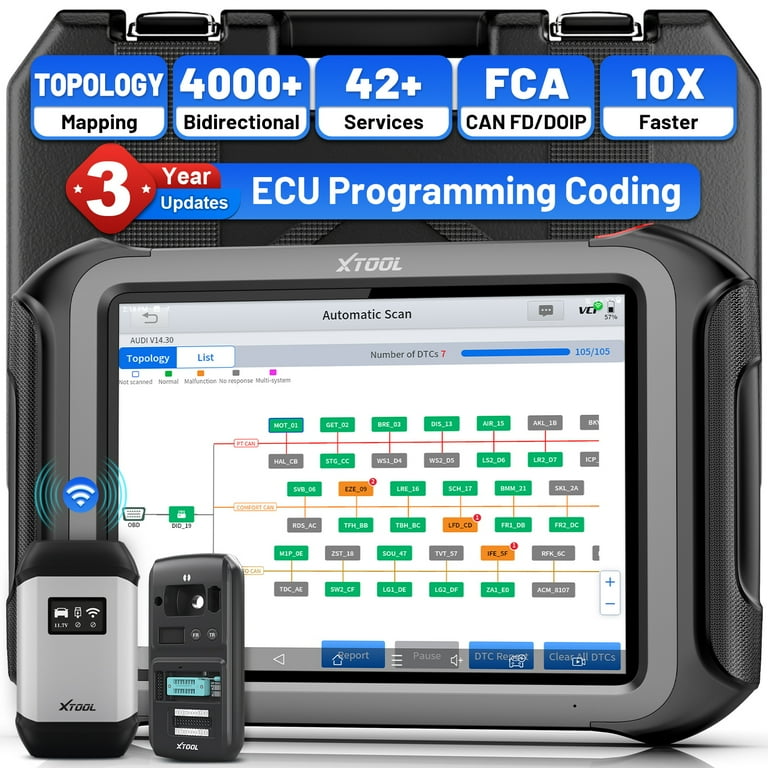

Illustrative image related to scanner x tool

What Benefits Do Key Programming Tools Offer to Automotive Businesses?

Key programming tools are crucial for automotive locksmiths and dealerships, enabling the duplication and programming of vehicle keys. These tools are essential for managing key inventories and ensuring security for vehicles. B2B purchasers should evaluate the tool’s compatibility with various vehicle key systems and the ease of use. Although they are indispensable for key management, these tools may require additional training for effective use, which could impact initial investment considerations.

Why Choose Bluetooth/WiFi Scanners for Mobile Applications?

Bluetooth and WiFi scanners provide the convenience of wireless connectivity, allowing mobile mechanics and DIY enthusiasts to perform diagnostics on-the-go. Their integration with mobile applications enhances usability and flexibility. B2B buyers should look for scanners that offer stable connectivity and comprehensive vehicle coverage. While these tools enhance operational efficiency, potential connectivity issues can pose challenges during critical diagnostics.

What Makes Advanced Diagnostic Tools Suitable for High-End Repairs?

Advanced diagnostic tools offer comprehensive features such as full-system diagnostics and bi-directional control, making them ideal for high-end repair shops and specialized technicians. These tools deliver accurate results and support a wide range of vehicle makes and models, which is essential for complex repairs. B2B buyers should consider the investment required, as these tools typically come with a higher price tag. Their extensive capabilities, however, can lead to significant long-term savings and improved service quality.

Key Industrial Applications of scanner x tool

| Industry/Sector | Specific Application of scanner x tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostic scanning for vehicle faults | Reduces repair time and enhances customer satisfaction | Ensure compatibility with diverse vehicle models |

| Fleet Management | Monitoring fleet vehicle diagnostics | Increases fleet efficiency and reduces downtime | Look for multi-vehicle support and real-time data |

| Manufacturing | Equipment diagnostics and maintenance | Minimizes unexpected breakdowns and maintenance costs | Consider ease of integration with existing systems |

| Logistics and Transport | Cargo vehicle diagnostics | Ensures compliance with safety regulations and reduces risks | Assess durability and reliability in harsh conditions |

| Electric Vehicle (EV) | Battery management and performance analysis | Supports the growing EV market with tailored solutions | Focus on advanced features for EV diagnostics |

How is the scanner x tool used in the automotive repair industry?

In the automotive repair sector, the scanner x tool serves as a critical diagnostic instrument that identifies vehicle faults by interfacing with onboard diagnostic systems. By providing real-time data on engine performance, emissions, and electronic systems, it enables mechanics to quickly pinpoint issues, thereby reducing repair time and enhancing customer satisfaction. For international B2B buyers, particularly in regions like Africa and South America, it is essential to ensure that the tool is compatible with a wide range of vehicle makes and models, considering the diverse automotive landscape in these areas.

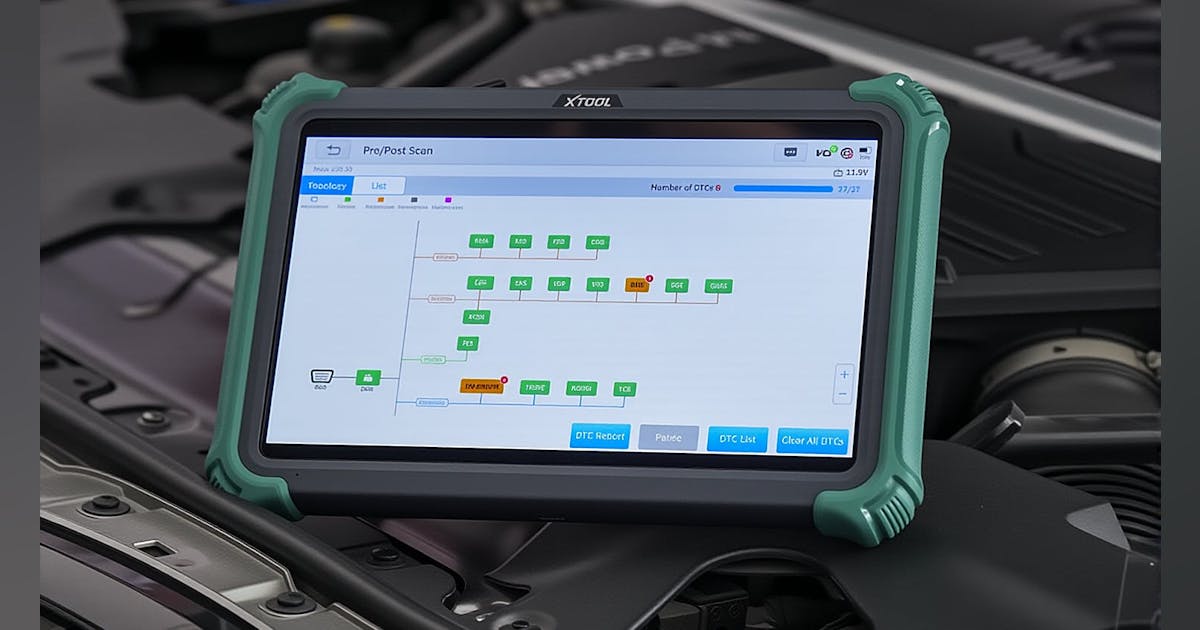

Illustrative image related to scanner x tool

What role does the scanner x tool play in fleet management?

For fleet management, the scanner x tool is invaluable in monitoring vehicle diagnostics across multiple units, allowing fleet operators to maintain optimal vehicle performance. By regularly assessing the health of each vehicle, businesses can proactively address maintenance issues, significantly increasing fleet efficiency and minimizing downtime. Buyers in the Middle East and Europe should prioritize tools that offer multi-vehicle support and real-time data capabilities, enabling them to manage large fleets effectively.

How does the scanner x tool contribute to manufacturing processes?

In manufacturing, the scanner x tool is used for diagnostics and maintenance of equipment, ensuring that machinery operates at peak efficiency. By identifying potential faults before they escalate into serious issues, businesses can minimize unexpected breakdowns and reduce maintenance costs. International buyers should consider tools that integrate seamlessly with existing manufacturing systems and offer robust analytics features, which are crucial for optimizing production lines.

In what ways does the scanner x tool enhance logistics and transport operations?

In the logistics and transport sectors, the scanner x tool assists in diagnosing cargo vehicles to ensure they meet safety regulations and operational standards. This capability helps mitigate risks associated with vehicle failures during transit, thereby protecting cargo and ensuring timely deliveries. Buyers in South America and Africa should assess the tool’s durability and reliability, especially given the challenging road conditions often faced in these regions.

Illustrative image related to scanner x tool

How is the scanner x tool utilized in the electric vehicle market?

The scanner x tool is increasingly essential in the electric vehicle (EV) market, where it is used for battery management and performance analysis. As the demand for EVs grows, businesses need tools that can provide detailed diagnostics on battery health and vehicle performance. Buyers should focus on advanced features that cater specifically to EV diagnostics, ensuring they are equipped to meet the unique challenges of this evolving market.

3 Common User Pain Points for ‘scanner x tool’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with Diverse Vehicle Models

The Problem: B2B buyers often face the challenge of ensuring that their chosen scanner X tool is compatible with a wide range of vehicle models, especially in regions with diverse automotive markets like Africa and South America. This can lead to frustration and wasted investments if the scanner does not support certain brands or models prevalent in their area. Additionally, the lack of clear information regarding vehicle coverage can complicate purchasing decisions, leading to costly mistakes.

The Solution: To address compatibility concerns, buyers should conduct thorough research before purchasing a scanner X tool. This includes consulting the manufacturer’s website for a detailed list of supported vehicles and ensuring that the tool can accommodate the specific models they work with. Additionally, engaging with local distributors or automotive professionals can provide insight into which models are most commonly used in the region. Buyers should also consider investing in a scanner with an expansive database and regular updates, as this will enhance the tool’s longevity and adaptability to new vehicles entering the market.

Scenario 2: Overcoming Software Update Challenges for Optimal Performance

The Problem: Another significant pain point for B2B buyers is managing software updates for their scanner X tool. Many users report that neglecting updates can lead to diminished performance, including the inability to read newer diagnostic codes or support advanced vehicle features. This is particularly problematic in fast-evolving markets where new automotive technologies are frequently introduced, leaving outdated tools unable to meet current diagnostic needs.

The Solution: To mitigate software update issues, businesses should establish a systematic approach for maintaining their scanner X tool. This includes subscribing to the manufacturer’s update service to receive notifications about new software releases and enhancements. Additionally, buyers should schedule regular checks for updates, ideally integrating this into their routine maintenance processes. By ensuring that the tool is regularly updated, companies can maximize its effectiveness and ensure compliance with the latest automotive standards, thus reducing the risk of diagnostic errors.

Scenario 3: Dealing with Technical Support Limitations Post-Purchase

The Problem: After purchasing a scanner X tool, many B2B buyers encounter challenges when it comes to obtaining effective technical support. Users often report difficulties in reaching knowledgeable support staff or receiving timely responses to their inquiries. This can lead to prolonged downtime, which is especially critical in businesses that rely heavily on efficient diagnostic capabilities to serve their customers.

The Solution: To overcome support limitations, businesses should choose a scanner X tool from a manufacturer known for its robust customer service and support infrastructure. Before making a purchase, buyers should research the company’s reputation for technical assistance by reading customer reviews and testimonials. Additionally, it’s beneficial to inquire about the availability of multiple support channels, such as live chat, email, and phone support. Establishing a relationship with the supplier from the outset can also facilitate quicker resolutions to issues. Buyers should consider joining user forums or groups dedicated to the specific scanner model, as these communities can offer valuable peer support and troubleshooting advice.

Strategic Material Selection Guide for scanner x tool

What Are the Key Materials Used in the Production of Scanner X Tools?

When selecting materials for the production of scanner x tools, several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these diagnostic tools, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Plastic Contribute to the Performance of Scanner X Tools?

Key Properties: Plastic is lightweight, corrosion-resistant, and can be molded into complex shapes. It typically has a temperature rating of around -40°C to 85°C, making it suitable for various environments.

Illustrative image related to scanner x tool

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which allows for mass production. However, plastics can be less durable than metals and may degrade over time when exposed to UV light or harsh chemicals.

Impact on Application: Plastic casings are commonly used for handheld scanners, providing a comfortable grip and making the tool portable. However, they may not withstand extreme conditions as effectively as metal alternatives.

Considerations for International Buyers: Buyers should ensure that the plastic used meets regional compliance standards, such as RoHS in Europe or similar regulations in Africa and South America.

What Role Does Aluminum Play in Scanner X Tool Construction?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and a temperature tolerance ranging from -50°C to 150°C.

Pros & Cons: The main advantage of aluminum is its durability and resistance to corrosion, making it ideal for tools that may be exposed to harsh environments. However, it can be more expensive than plastic and may require more complex manufacturing processes.

Illustrative image related to scanner x tool

Impact on Application: Aluminum is often used in the housing of more advanced diagnostic tools, providing a sturdy structure that can protect sensitive electronic components.

Considerations for International Buyers: Buyers should look for aluminum that complies with international standards such as ASTM or DIN. In regions like the Middle East and Africa, where environmental conditions can be extreme, aluminum’s durability is a significant selling point.

How Does Steel Enhance the Functionality of Scanner X Tools?

Key Properties: Steel is known for its high strength and durability, with a temperature rating that can exceed 200°C. It also offers good corrosion resistance when treated properly.

Pros & Cons: Steel provides exceptional durability and strength, making it ideal for tools that require high performance and longevity. However, it is heavier than plastic and aluminum, which could affect portability. Additionally, steel can be more expensive due to higher manufacturing costs.

Illustrative image related to scanner x tool

Impact on Application: Steel components are often used in the internal mechanisms of scanner x tools, ensuring that parts withstand wear and tear during frequent use.

Considerations for International Buyers: Compliance with international standards is crucial, particularly for buyers in Europe, where specific grades of steel may be required. Buyers should also consider the weight implications for shipping and handling.

What Advantages Does Rubber Offer in Scanner X Tool Design?

Key Properties: Rubber is flexible and has excellent temperature resistance, typically ranging from -50°C to 100°C. It also provides good shock absorption.

Pros & Cons: The main advantage of rubber is its ability to provide a non-slip grip, enhancing user comfort. However, rubber can wear out over time and may degrade when exposed to certain chemicals.

Illustrative image related to scanner x tool

Impact on Application: Rubber is commonly used in grips and seals for scanner x tools, ensuring that they are comfortable to hold and protected from dust and moisture.

Considerations for International Buyers: Buyers should ensure that the rubber used is compliant with local regulations regarding chemical safety and environmental impact, especially in regions with strict compliance standards.

Summary of Material Selection for Scanner X Tools

| Material | Typical Use Case for scanner x tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Handheld scanner casings | Lightweight and cost-effective | Less durable than metals | Low |

| Aluminum | Housing for advanced diagnostic tools | Durable and corrosion-resistant | Higher manufacturing costs | Medium |

| Steel | Internal mechanisms | High strength and longevity | Heavier and more expensive | High |

| Rubber | Grips and seals | Non-slip and shock-absorbing | Can wear out over time | Medium |

This analysis provides a comprehensive overview of the materials used in scanner x tools, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

Illustrative image related to scanner x tool

In-depth Look: Manufacturing Processes and Quality Assurance for scanner x tool

What Are the Key Manufacturing Processes for the Scanner X Tool?

The manufacturing process for the Scanner X Tool involves several critical stages that ensure high-quality production. Each stage plays a vital role in the final product’s performance and reliability.

Material Preparation: What Materials Are Used?

The initial phase of manufacturing begins with material preparation. High-grade plastics, metals, and electronic components are sourced from reputable suppliers, ensuring durability and performance. For instance, the scanner’s casing often utilizes ABS or polycarbonate plastics, which are lightweight yet resilient. The electronic components, including microcontrollers and sensors, are selected based on their compatibility and reliability, which are essential for accurate diagnostics.

How Is the Scanner Formed and Assembled?

Following material preparation, the forming process takes place. This involves molding the plastic components and fabricating metal parts. Techniques such as injection molding are commonly used to create the scanner’s outer shell, allowing for precise shaping and minimal waste.

Once formed, the assembly process begins. Skilled technicians assemble the electronic components, integrating circuit boards, displays, and connectors into the scanner’s housing. This process often employs automated machinery for efficiency, but manual inspection ensures quality control at this stage.

What Finishing Touches Are Applied?

The final stage is finishing, where the product undergoes surface treatment and quality checks. This may include painting, applying protective coatings, or adding labels and branding. Finishing not only enhances the scanner’s aesthetic appeal but also contributes to its durability and user experience.

What Quality Assurance Standards Are Relevant for Scanner X Tool?

Quality assurance is critical in the manufacturing of diagnostic tools like the Scanner X Tool. Adhering to international standards helps ensure that products are safe, reliable, and effective.

Which International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are essential for ensuring quality management systems within manufacturing processes. This standard focuses on consistent product quality and customer satisfaction, making it a vital certification for any B2B buyer.

Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) standards are crucial for products used in automotive diagnostics. CE certification indicates compliance with EU safety and health regulations, while API certification ensures quality in automotive lubricants and diagnostic tools.

Illustrative image related to scanner x tool

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control (QC) involves several checkpoints throughout the manufacturing process to catch defects and ensure compliance with standards.

What Are the Main QC Checkpoints?

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival. Suppliers are required to provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to monitor the assembly and functionality of the scanner. This may include testing electronic circuits and ensuring proper alignment of components.

-

Final Quality Control (FQC): After assembly, the scanner undergoes rigorous testing to verify functionality and performance. This includes diagnostic testing to ensure the tool operates correctly across various vehicle models.

What Testing Methods Are Commonly Used for Scanner X Tool?

To validate the quality and reliability of the Scanner X Tool, various testing methods are employed.

How Are Products Tested for Quality Assurance?

-

Functional Testing: Each scanner undergoes functional tests to verify that all features work as intended. This includes simulating real-world diagnostic scenarios.

-

Durability Testing: Products are subjected to stress tests that simulate prolonged use, ensuring they withstand wear and tear.

-

Compliance Testing: Tools are tested for compliance with international standards, ensuring they meet safety and performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

What Steps Can Buyers Take to Verify QC?

-

Supplier Audits: Conducting audits of the manufacturing facilities can provide insights into the supplier’s quality management practices. This helps ensure that their processes align with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess the effectiveness of their quality control measures. These reports should outline testing results, compliance certifications, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These inspections can be particularly valuable when dealing with overseas suppliers.

What Are the QC and Certification Nuances for International Buyers?

When sourcing products internationally, buyers must be aware of specific nuances in quality control and certifications.

How Do Regional Regulations Impact QC?

Different regions may have varying regulations and standards. For example, products sold in Europe must meet CE requirements, while those in the Middle East may need to adhere to local safety standards. Understanding these regional differences is essential for compliance and market acceptance.

Illustrative image related to scanner x tool

Additionally, buyers should be cautious of counterfeit products. Verifying certifications and supplier credentials can mitigate risks associated with subpar products entering the market.

Conclusion: Ensuring Quality in Your Supply Chain

For B2B buyers, understanding the manufacturing processes and quality assurance measures behind the Scanner X Tool is critical for making informed purchasing decisions. By focusing on material preparation, assembly techniques, and rigorous quality control, buyers can ensure they are sourcing reliable products that meet both their operational needs and international standards. Engaging in thorough supplier audits and requesting certification documentation can further enhance confidence in the quality of the tools being procured.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘scanner x tool’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure the ‘scanner x tool’. With the automotive diagnostic tools market rapidly evolving, making informed decisions is crucial. This checklist will help streamline your sourcing process, ensuring you choose a reliable supplier that meets your specific needs.

Step 1: Define Your Technical Specifications

Before starting your procurement process, it’s essential to clearly define the technical specifications you require from the scanner x tool. Consider factors such as compatibility with various vehicle models, functionalities (like OBD2 capabilities), and the types of diagnostics it can perform. This clarity will guide your search and help avoid mismatches with potential suppliers.

Step 2: Research Market Trends and User Reviews

Stay informed about the latest trends in automotive diagnostic technology and customer feedback on various scanner x tools. Look for reviews on industry forums, trade publications, and social media platforms. This information can provide insights into product reliability, performance, and user satisfaction, helping you make a more informed decision.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and references from other buyers in similar markets or industries. Pay attention to their experience in the field and customer service reputation, as these factors can significantly impact your purchasing experience.

- Look for suppliers with a robust support system, including after-sales service.

- Verify their experience in shipping to your region, particularly in Africa, South America, the Middle East, or Europe.

Step 4: Check Compliance and Certifications

Ensure that the scanner x tool and the supplier meet relevant industry standards and certifications. Compliance with international quality standards (such as ISO) and regional regulations is crucial for ensuring product reliability and safety. This step helps mitigate risks associated with non-compliance, which could lead to costly recalls or repairs.

Step 5: Request Product Demonstrations

Whenever possible, request product demonstrations or trials from suppliers. A hands-on experience allows you to assess the scanner’s usability, interface, and functionality in real-world scenarios. This can be particularly beneficial for understanding how well the tool integrates into your existing operations.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms and conditions that align with your business needs. Discuss pricing, payment terms, delivery schedules, and warranty policies. A clear agreement will help prevent misunderstandings and ensure a smoother transaction process.

Illustrative image related to scanner x tool

Step 7: Establish a Feedback Loop

After purchasing the scanner x tool, create a feedback loop with your team to evaluate its performance. Monitor its effectiveness in diagnostics and gather input on user experience. This feedback is invaluable for future procurement decisions and can help you build stronger relationships with your suppliers.

By following this checklist, B2B buyers can enhance their sourcing process for the scanner x tool, ensuring a successful procurement that meets their technical and operational requirements.

Comprehensive Cost and Pricing Analysis for scanner x tool Sourcing

What Are the Key Cost Components in Sourcing the Scanner X Tool?

When sourcing the Scanner X tool, a detailed understanding of its cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to scanner x tool

-

Materials: The quality and source of materials directly impact the final product cost. High-quality components such as circuit boards, sensors, and casing materials may incur higher initial costs but can lead to long-term savings through increased durability.

-

Labor: Labor costs vary significantly based on the region where manufacturing occurs. Countries with lower labor costs may offer attractive pricing, but this can sometimes come at the expense of quality. It’s crucial to balance labor savings with the potential risks associated with inferior craftsmanship.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the overall pricing strategy favorably.

-

Tooling: The initial setup costs for manufacturing tools and molds can be substantial, particularly for customized or specialized scanner models. Buyers should consider these costs when evaluating suppliers, especially if they require unique specifications.

-

Quality Control (QC): Implementing stringent quality control measures adds to the overall cost but is essential for ensuring product reliability and performance. Investing in QC can reduce the likelihood of returns or warranty claims, thus lowering the Total Cost of Ownership (TCO).

-

Logistics: Shipping and handling costs can significantly influence the final price, especially for international buyers. Factors such as distance, shipping method, and customs duties must be considered.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Pricing Influencers Affect the Cost of the Scanner X Tool?

Several factors can influence the pricing of the Scanner X tool, making it imperative for buyers to understand these nuances:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to better pricing. Buyers should assess their needs and consider negotiating with suppliers for favorable terms based on expected volume.

-

Specifications and Customization: Customized tools tailored to specific requirements can lead to increased costs. Buyers must weigh the benefits of customization against potential price hikes.

-

Material Quality and Certifications: Tools made from premium materials or those that meet specific international standards may command higher prices. However, certifications can enhance product credibility and marketability.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon with suppliers is crucial. They dictate the responsibilities of both parties regarding shipping, insurance, and tariffs, which can affect the overall cost.

What Are the Best Tips for Negotiating Costs on Scanner X Tool Purchases?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing practices are essential:

-

Leverage Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the purchase price but the long-term costs associated with maintenance, support, and potential downtime. A slightly higher upfront cost might yield savings over time.

-

Be Transparent About Needs: Clearly communicate your requirements and expectations to suppliers. This transparency can foster trust and potentially lead to better pricing or terms.

-

Benchmark Prices: Research and compare prices from multiple suppliers to identify competitive pricing. This information can be leveraged during negotiations to secure a more favorable deal.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, terms, and priority during supply shortages. Long-term partnerships often yield mutual benefits.

-

Understand Local Market Conditions: Prices can vary significantly based on local market conditions and competition. Being informed about these factors can aid in negotiations and help buyers secure the best deals.

Disclaimer on Indicative Prices

Pricing for the Scanner X tool can fluctuate based on various factors including market demand, supplier pricing strategies, and changes in material costs. Therefore, it’s advisable for buyers to seek up-to-date quotes and consider all influencing factors before making purchasing decisions.

Alternatives Analysis: Comparing scanner x tool With Other Solutions

When considering a purchase in the automotive diagnostic tool sector, it is essential to evaluate various options available in the market. This analysis focuses on comparing ‘Scanner X Tool’ against two viable alternatives: ‘Launch X431’ and ‘Autel MaxiCOM’. Understanding the differences in performance, cost, ease of implementation, maintenance, and best use cases can significantly influence your purchasing decision.

| Comparison Aspect | Scanner X Tool | Launch X431 | Autel MaxiCOM |

|---|---|---|---|

| Performance | High accuracy with full-system diagnostics | Excellent, supports numerous vehicle brands and models | Strong, particularly for Asian and European cars |

| Cost | Mid-range pricing | Higher price point | Competitive pricing |

| Ease of Implementation | User-friendly interface | Slightly complex due to extensive features | Intuitive, with a smooth learning curve |

| Maintenance | Regular software updates included | Subscription required for updates | Updates available, but some models may require fees |

| Best Use Case | Ideal for small garages and DIY enthusiasts | Best for professional mechanics and larger shops | Suitable for workshops focusing on Asian and European vehicles |

How Does Launch X431 Compare to Scanner X Tool?

The Launch X431 diagnostic tool is renowned for its extensive coverage of vehicle brands and models, making it a top choice for professional mechanics. Its performance is exceptional, offering advanced features such as bi-directional control and ECU coding. However, the higher price point may be a barrier for smaller businesses or individual mechanics. Additionally, while it provides a wealth of features, the complexity of the interface might require more training and experience to utilize effectively.

Illustrative image related to scanner x tool

What Advantages Does Autel MaxiCOM Offer Over Scanner X Tool?

The Autel MaxiCOM series is designed with a focus on affordability and functionality. Its competitive pricing makes it accessible for small to medium-sized workshops, while its user-friendly interface ensures that even those with limited technical skills can navigate it effectively. Autel’s strength lies in its compatibility with Asian and European vehicles, making it an excellent choice for workshops specializing in these markets. However, it may lack some advanced features found in higher-end models, which could limit its use for specialized diagnostics.

Conclusion: How to Choose the Right Automotive Diagnostic Tool?

When selecting an automotive diagnostic tool, B2B buyers should consider their specific needs, including the types of vehicles they service, budget constraints, and the level of technical expertise available within their team. For those operating small garages or as DIY enthusiasts, the Scanner X Tool offers a balanced blend of performance and cost-effectiveness. Conversely, larger shops with a diverse clientele may benefit more from the advanced features of the Launch X431, despite the higher investment. Autel MaxiCOM provides a solid middle ground, particularly for those focused on Asian and European vehicles. Ultimately, aligning your choice with your operational requirements and customer base will lead to the best decision.

Essential Technical Properties and Trade Terminology for scanner x tool

What Are the Essential Technical Properties of the Scanner X Tool?

-

Compatibility with Global Vehicles

The Scanner X Tool is designed to be compatible with a wide range of vehicles from various manufacturers worldwide. This feature is crucial for B2B buyers who operate in diverse markets, as it allows them to service multiple brands without needing multiple devices. Compatibility ensures that users can perform diagnostics on both local and imported vehicles, enhancing their service offerings. -

Diagnostic Coverage

This property refers to the range of systems and functions that the Scanner X Tool can diagnose. Typically, this includes engine, transmission, brakes, and other critical systems. For B2B buyers, comprehensive diagnostic coverage is essential, as it translates to fewer limitations when troubleshooting vehicles, thereby increasing efficiency and reducing downtime. -

User Interface and Software Integration

A user-friendly interface and robust software integration make the Scanner X Tool accessible for technicians of varying skill levels. This feature is particularly important in international markets where training resources may be limited. An intuitive design reduces the learning curve, allowing businesses to maximize productivity quickly. -

Data Reporting and Analysis Capabilities

Advanced data reporting features enable users to generate detailed diagnostic reports. These reports can be instrumental for B2B buyers in making informed decisions regarding vehicle repairs and maintenance. The ability to analyze data trends can also help businesses strategize their service offerings and identify areas for improvement. -

Portability and Connectivity Options

The Scanner X Tool often includes Bluetooth or Wi-Fi connectivity, allowing for easy data transfer and real-time diagnostics. Portability is a significant advantage for mobile mechanics or businesses operating in remote locations. This flexibility enables technicians to work efficiently on-site, reducing the need for a physical workshop.

What Are Common Trade Terms Related to the Scanner X Tool?

-

OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle components. In the context of the Scanner X Tool, understanding OEM specifications is vital for ensuring that the tool can interface correctly with the vehicle’s systems. B2B buyers should prioritize tools that adhere to OEM standards for reliable diagnostics and repairs. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. Understanding the MOQ helps businesses negotiate better terms and ensure they have sufficient stock to meet customer demand without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers. This term is crucial for B2B buyers seeking to acquire the Scanner X Tool, as it allows them to compare options and negotiate pricing effectively. A well-structured RFQ can lead to better deals and supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B transactions involving the Scanner X Tool, as they clarify shipping responsibilities, risk management, and payment terms. Proper knowledge of Incoterms can help businesses avoid costly misunderstandings during the import/export process. -

Warranty and After-Sales Support

Warranty refers to the commitment from the manufacturer to repair or replace a product if necessary within a specified period. After-sales support encompasses the services provided post-purchase, such as technical assistance and software updates. B2B buyers should prioritize tools like the Scanner X Tool that offer robust warranties and excellent after-sales support to ensure long-term satisfaction and reliability in their operations. -

Calibration

Calibration refers to the process of configuring the Scanner X Tool to ensure accurate readings and diagnostics. Regular calibration is necessary for maintaining precision in diagnostics, which is essential for B2B operations. Understanding calibration requirements helps businesses maintain tool performance and reliability, ultimately leading to better service outcomes.

Navigating Market Dynamics and Sourcing Trends in the scanner x tool Sector

What Are the Current Market Dynamics and Key Trends in the Scanner X Tool Sector?

The global market for scanner x tools is experiencing robust growth, driven by an increasing demand for advanced diagnostic solutions across various industries, including automotive, industrial, and medical sectors. The rise in the complexity of vehicles and machinery, alongside the growing prevalence of electric and hybrid vehicles, necessitates sophisticated diagnostic tools that can provide accurate and real-time data. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, the ability to access reliable and efficient diagnostic tools has become essential.

Current trends indicate a shift towards wireless and mobile diagnostic solutions, with Bluetooth and WiFi connectivity becoming standard features. This trend not only enhances user experience but also facilitates remote diagnostics, reducing downtime for businesses. Moreover, the integration of artificial intelligence and machine learning into scanner x tools is emerging, enabling predictive maintenance and more accurate diagnostics. This technological evolution is particularly beneficial for B2B buyers seeking to improve operational efficiency and service quality.

Additionally, there is an increasing focus on compatibility with a broader range of vehicles and machinery, reflecting the diverse needs of international markets. Buyers are prioritizing products that offer extensive vehicle coverage and software updates to ensure longevity and relevance in a rapidly evolving landscape.

Illustrative image related to scanner x tool

How Are Sustainability and Ethical Sourcing Affecting the Scanner X Tool Sector?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the scanner x tool sector. The environmental impact of manufacturing and disposing of electronic devices is significant, leading to a growing demand for eco-friendly products. Companies are increasingly expected to adopt sustainable practices, such as utilizing recyclable materials and minimizing waste in production processes.

In response to this demand, many manufacturers are pursuing ‘green’ certifications and materials, which not only enhance their brand reputation but also attract environmentally conscious buyers. For instance, some companies are opting for sustainable packaging solutions and ensuring that their supply chains adhere to ethical labor practices. This shift toward responsible sourcing is not just a trend; it is becoming a crucial factor in purchasing decisions for B2B buyers, particularly in regions where environmental regulations are tightening.

Furthermore, the importance of transparency in the supply chain cannot be overstated. Buyers are seeking partners who provide clear information about the sourcing of materials and the environmental footprint of their products. Companies that can demonstrate a commitment to sustainability and ethical practices will likely have a competitive edge in the global market.

How Has the Scanner X Tool Sector Evolved Over Time?

The scanner x tool sector has undergone significant evolution since its inception, transitioning from basic code readers to sophisticated diagnostic devices capable of performing complex analyses. Initially, these tools were primarily used for simple error code reading; however, advancements in technology have led to the development of multifunctional devices that can perform a variety of tasks, including real-time data monitoring, programming, and system resets.

Illustrative image related to scanner x tool

The introduction of OBD-II technology in the late 1990s marked a turning point, as it standardized vehicle diagnostics, making it easier for manufacturers to create compatible tools. Over the years, the integration of software updates and cloud-based solutions has further enhanced the functionality of scanner x tools, allowing for continuous improvement and expanded vehicle coverage.

Today, the focus on user-friendly interfaces and mobile connectivity is reshaping the landscape, making diagnostic tools more accessible to both professional mechanics and DIY enthusiasts. This evolution reflects the industry’s response to the growing complexity of vehicles and the need for efficient, accurate diagnostic solutions in an increasingly competitive market.

In summary, understanding the market dynamics, sustainability imperatives, and historical evolution of scanner x tools is crucial for B2B buyers looking to make informed purchasing decisions in this rapidly changing sector.

Frequently Asked Questions (FAQs) for B2B Buyers of scanner x tool

-

How do I solve compatibility issues with the scanner X tool?

Compatibility issues can arise when using the scanner X tool with various vehicle models. To address this, ensure that you are using the latest software updates, as these often include expanded vehicle coverage. Additionally, consult the manufacturer’s documentation for a list of compatible vehicles, and consider reaching out to customer support for specific queries regarding vehicle compatibility. This proactive approach will minimize downtime and improve diagnostic accuracy. -

What is the best scanner X tool for small to medium-sized workshops?

For small to medium-sized workshops, the XTOOL D7 series is an excellent choice. It offers a comprehensive range of diagnostic functions, including full system scans and live data reading at a competitive price point. This model balances affordability and functionality, making it ideal for workshops that require versatile diagnostic capabilities without the need for extensive investment. Its user-friendly interface also ensures quick training for staff. -

What are the minimum order quantities (MOQ) for purchasing the scanner X tool?

The minimum order quantity (MOQ) varies by supplier and region. Typically, suppliers may set an MOQ of 10-50 units to ensure cost-effectiveness in shipping and production. It’s advisable to negotiate with suppliers directly, especially if you are looking to establish a long-term relationship. Some manufacturers may offer lower MOQs for first-time buyers or promotional periods, so be sure to inquire about any ongoing deals. -

What payment terms are commonly accepted for international purchases of scanner X tools?

Most suppliers accept a variety of payment methods, including bank transfers, credit cards, and PayPal. Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% prior to shipment. For larger orders, suppliers may offer credit terms after establishing a solid business relationship. Always clarify payment terms upfront to avoid any misunderstandings. -

How can I ensure quality assurance (QA) for the scanner X tool?

To ensure quality assurance, choose suppliers that provide clear QA processes, including certifications such as ISO standards. Request information about the manufacturing process, quality checks, and warranty policies. Conducting a pre-shipment inspection can also help verify product quality before delivery. Partnering with reputable suppliers who have a proven track record in the market is crucial to minimizing risks associated with product quality. -

What logistics considerations should I be aware of when importing the scanner X tool?

When importing scanner X tools, consider shipping methods, customs regulations, and potential tariffs. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that all necessary documentation is in order, including invoices and certificates of origin, to facilitate smooth customs clearance. Collaborating with a reliable freight forwarder can simplify the logistics process and help you navigate international shipping complexities. -

Can I customize the scanner X tool for my business needs?

Many suppliers offer customization options for the scanner X tool, including branding, software modifications, and additional features tailored to specific markets. Discuss your requirements with potential suppliers during initial negotiations to understand the scope of customization available. Customization may involve additional costs and longer lead times, so plan accordingly to align with your business strategy. -

What after-sales support is available for the scanner X tool?

After-sales support typically includes warranty services, technical assistance, and software updates. Reputable suppliers will provide a warranty period (often up to two years) and ensure access to customer support for troubleshooting and repairs. It’s beneficial to inquire about the specific support channels available, such as online resources, phone support, or local service centers, to ensure you have ongoing assistance as needed.

Top 6 Scanner X Tool Manufacturers & Suppliers List

1. XToolTech – 专业汽车诊断仪与车联网解决方案

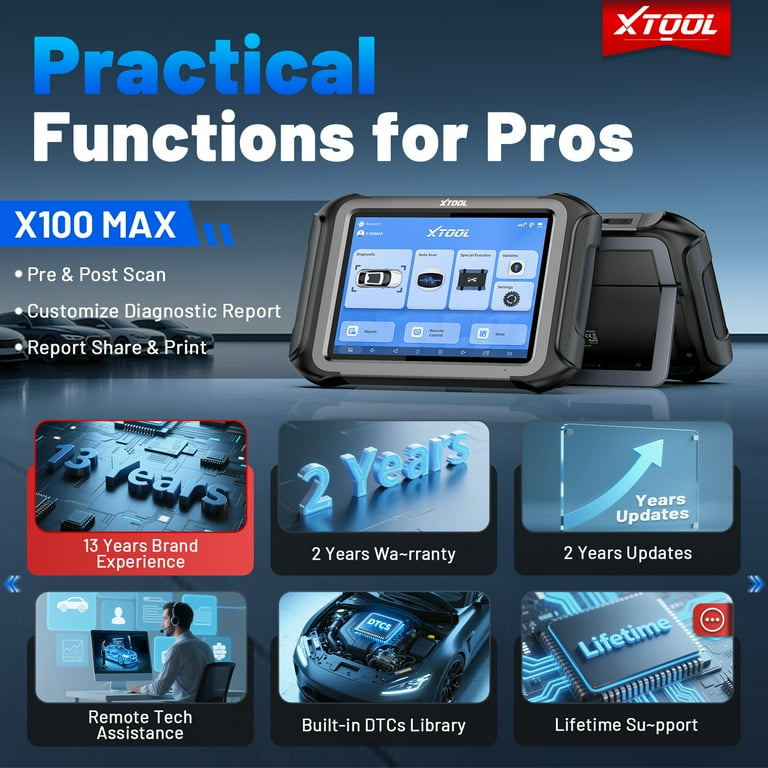

2. XTOOL – Diagnostic Scanners and Tools

Domain: xtoolglobal.com

Registered: 2022 (3 years)

Introduction: XTOOL offers a range of automatic diagnostic scanners and tools including:

– XTOOL IP919 MAX with J2534 – Sale Price: $2,499.00 (Original Price: $3,499.00)

– XTOOL X100 MAX 2 with J2534 – Sale Price: $2,599.00 (Original Price: $3,899.00)

– XTOOL D9 MAX with J2534 – Sale Price: $2,099.00 (Original Price: $2,699.00)

– XTOOL IP900BT – Sale Price: $509.00 (Original Price: $699.00)

– XTOOL D7 – Sa…

3. XTOOL – Automotive Diagnostic Tools

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: XTOOL-Official Store offers a variety of automotive diagnostic tools including:

– XTOOL A30M V2.0 Bidirectional Scan Tool Diagnostic Scanner Auto Code Reader – $129.00

– XTOOL Scanner D7 Auto Full System Diagnostic Bidirectional Tool Key Programmer – $319.00

– XTOOL D7W Wireless Auto Diagnostic Tool Bi-Directional Control Key Programmer – $389.00

– XTOOL D8S V2.0 Auto Diagnostic OBD2 Scanner with …

4. XTOOL – Diagnosis Tools

Domain: xtooleshop.com

Registered: 2016 (9 years)

Introduction: XTOOL Diagnosis Tool

– Models: XTOOL D8, XTOOL D9S PRO, XTOOL D7S, XTOOL D7, XTOOL D7W, XTOOL D8W, XTOOL D8S, XTOOL InPlus IP919PRO

– Features: ECU Coding, Bi-Directional Control, OBDII diagnostics, Auto VIN/VIN scan, extensive vehicle coverage (88+ brands), 38+ service functions, support for CAN FD protocol, DOIP protocol, topology mapping, key programming, active test, and various reset function…

5. XTOOL – Keyless Solutions

Domain: locksmithkeyless.com

Registered: 2015 (10 years)

Introduction: XTOOL Products | Xtool Scanners | Free Shipping for eligible orders over $99 | Zero Interest for 12 Months – Finance with Confidence | Same Day shipping until 5PM EST | Product types include Access Control, Automotive Keys, Automotive Locks, Car Opening Tools, CCTV, Cutting Machines, Deadbolts, Emergency Keys & Blades, Locks and Cylinders, Safes, and more. Categories include Automotive, Door Hardw…

6. XTOOL – OBD2 Scanners & Diagnostic Tools

Domain: xtoolonline.com

Registered: 2023 (2 years)

Introduction: XTOOL OBD2 Scanner, Car Diagnostic Tools, Automotive Scan Tool. Key products include: XTOOL Wireless Series (Bluetooth & WiFi), XTOOL D5/D6 Series (5-inch OBD2 Scanner), XTOOL Locksmith Series (All-in-One Key Programming), XTOOL A30/AD20 Series (Compact and Affordable), XTOOL TPMS TOOLS (Precision Diagnostics). Features include: 8 in 1 Live Data Graphing, Topology Mapping, TPMS Programming, Key Pr…

Strategic Sourcing Conclusion and Outlook for scanner x tool

In conclusion, the strategic sourcing of the Scanner X tool presents significant advantages for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By prioritizing quality, compatibility, and cost-effectiveness, businesses can enhance their operational efficiency and customer satisfaction. The Scanner X tool’s broad vehicle coverage and advanced diagnostic capabilities make it an essential asset for automotive professionals and DIY enthusiasts alike.

Investing in reliable diagnostic tools not only streamlines repair processes but also fosters long-term relationships with customers through superior service. The availability of robust after-sales support and warranties further solidifies the value proposition of the Scanner X tool, ensuring that buyers can make informed decisions with confidence.

Illustrative image related to scanner x tool

Looking ahead, as automotive technology continues to evolve, the demand for sophisticated diagnostic solutions will only grow. International B2B buyers are encouraged to seize this opportunity by exploring partnerships with reputable suppliers of the Scanner X tool. By doing so, they can position themselves at the forefront of the automotive service industry, ready to meet the challenges of tomorrow’s market dynamics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to scanner x tool