Is Your Right Handed Thread Bolt Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for right handed thread bolt

In the dynamic landscape of global commerce, sourcing right-handed thread bolts presents unique challenges for international B2B buyers, especially those in emerging markets like Africa and South America, as well as established regions such as the Middle East and Europe. The complexity of selecting the right fasteners—critical for ensuring the integrity of mechanical assemblies—can often lead to costly mistakes if not approached with expertise. This comprehensive guide is designed to demystify the intricacies of right-handed thread bolts, covering essential topics such as thread types, applications, supplier vetting, and cost considerations.

International buyers will benefit from an in-depth analysis of various right-handed thread bolt configurations, their specific uses in different industries, and insights on how to evaluate potential suppliers. Understanding the technical specifications, including thread pitch and compatibility, is crucial for making informed decisions that enhance operational efficiency and product reliability. Additionally, this guide will provide actionable strategies for navigating regional supply chains and mitigating risks associated with procurement.

By equipping B2B buyers with the knowledge to confidently source and select the right-handed thread bolts that meet their specific needs, this resource empowers organizations to optimize their procurement processes and achieve greater success in their respective markets.

Understanding right handed thread bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Unified Thread Standard (UTS) | Widely used in North America; available in coarse and fine threads. | Automotive, machinery, and construction. | Pros: Standardized sizes make sourcing easy. Cons: Limited to U.S. specifications. |

| Metric Thread | International standard; sizes are denoted in millimeters. | Global applications across various industries. | Pros: Universally recognized, suitable for international trade. Cons: Requires precise measurement for compatibility. |

| Acme Thread | Features a trapezoidal profile for improved load capacity. | Power transmission and machinery tools. | Pros: High strength and resistance to wear. Cons: More expensive than standard threads. |

| Buttress Thread | Asymmetrical thread profile designed for heavy loads. | Heavy lifting equipment and hydraulic applications. | Pros: Excellent load-bearing capabilities. Cons: Not suitable for general fastening tasks. |

| Square Thread | Square-shaped profile for maximum engagement and load capacity. | Machine tools and presses requiring high precision. | Pros: High efficiency in power transmission. Cons: Limited availability and higher manufacturing costs. |

What Are the Characteristics of Unified Thread Standard (UTS) Bolts?

Unified Thread Standard (UTS) bolts are characterized by their prevalence in North America and their availability in both coarse and fine thread variations. These bolts are essential in automotive, machinery, and construction applications due to their standardized sizes, making them easy to source and replace. When purchasing UTS bolts, buyers should consider compatibility with existing fasteners and the specific requirements of their projects, as these threads are primarily used in the U.S., which may limit options for international buyers.

Why Choose Metric Thread Bolts for Global Applications?

Metric thread bolts are distinguished by their sizing in millimeters, making them the go-to standard for international applications. Their global recognition facilitates trade across various industries, including automotive, electronics, and construction. B2B buyers should focus on ensuring precise measurements and compatibility with metric systems to avoid costly errors. The international standardization of metric threads is a significant advantage for companies involved in global supply chains.

What Makes Acme Thread Bolts Suitable for Machinery?

Acme thread bolts feature a trapezoidal thread profile that enhances their load capacity, making them particularly suitable for power transmission applications and machinery tools. These bolts provide high strength and resistance to wear, which is essential in environments where durability is critical. Buyers should weigh the higher costs of Acme threads against their long-term performance benefits, especially in heavy-duty applications.

How Do Buttress Thread Bolts Perform Under Heavy Loads?

Buttress thread bolts are uniquely designed with an asymmetrical profile that excels in heavy load-bearing applications. Commonly used in heavy lifting equipment and hydraulic systems, these bolts are engineered to withstand significant forces without loosening. B2B buyers should consider the specific load requirements of their applications when selecting buttress threads, as their specialized design may not be suitable for general fastening needs.

What Are the Advantages of Using Square Thread Bolts?

Square thread bolts are known for their square-shaped profile, which maximizes engagement and load capacity. They are ideal for machine tools and presses that require high precision and efficiency in power transmission. However, their limited availability and higher manufacturing costs may deter some buyers. When selecting square threads, companies should evaluate the specific requirements of their machinery to ensure optimal performance and longevity.

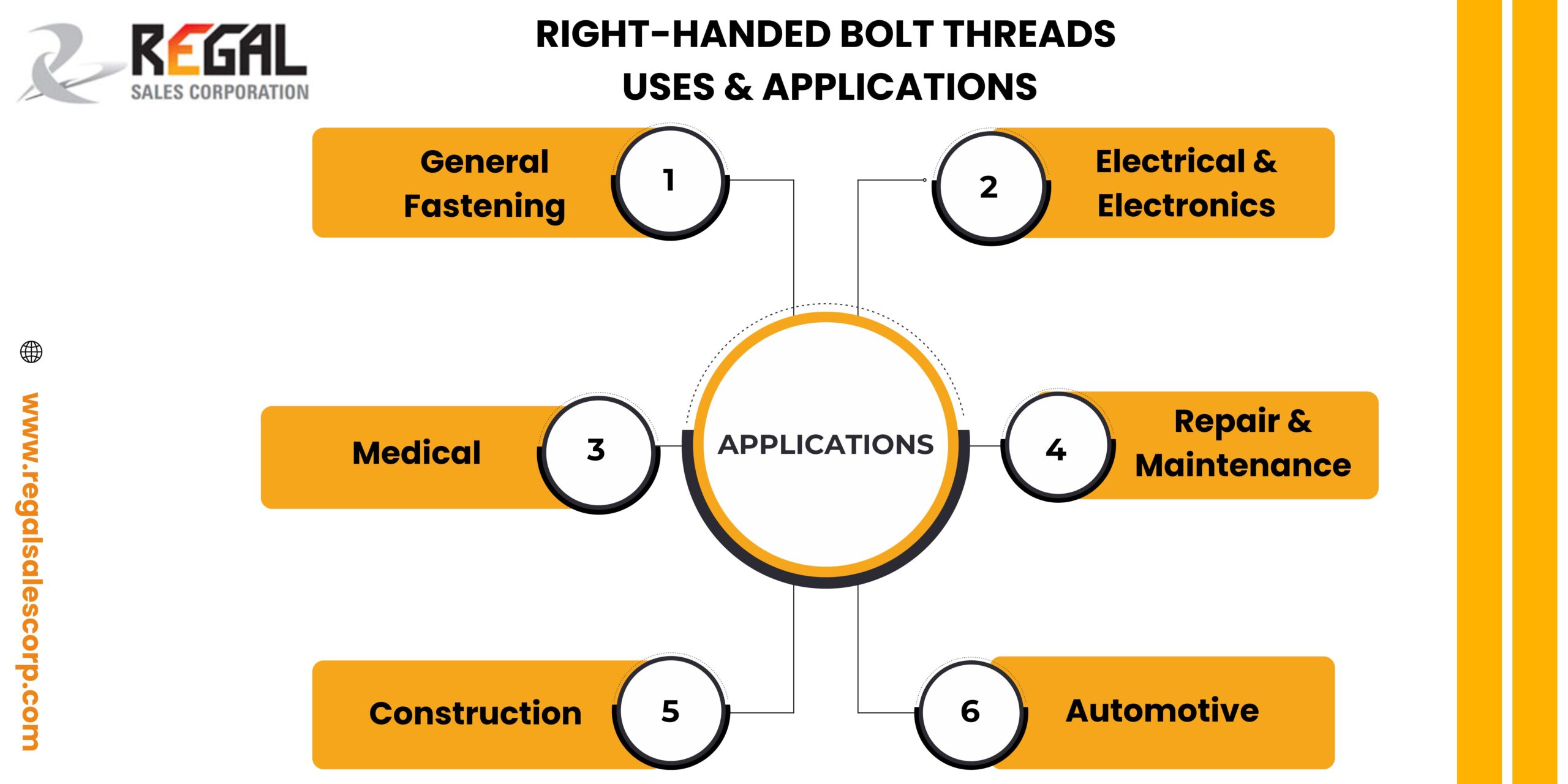

Key Industrial Applications of right handed thread bolt

| Industry/Sector | Specific Application of right handed thread bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing engine components | Ensures reliability and safety under high-stress conditions | Material quality (e.g., corrosion resistance), certifications (ISO, ASTM) |

| Construction | Fastening structural elements like beams and frames | Provides structural integrity and safety for buildings | Compliance with local building codes, load-bearing specifications |

| Electrical & Electronics | Mounting circuit boards and securing components | Guarantees stable connections and prevents failures | Sourcing from certified manufacturers, ensuring compatibility with electronic standards |

| Oil & Gas | Securing piping systems and valves | Prevents leaks and ensures operational efficiency | Resistance to corrosion, ability to withstand high pressures, compliance with industry standards |

| Machinery Manufacturing | Connecting parts in machinery and tools | Enhances the longevity and functionality of equipment | Precision in thread sizing, availability in various materials for different environments |

How is Right-Handed Thread Bolt Used in Automotive Applications?

In the automotive industry, right-handed thread bolts are essential for securing engine components, transmission systems, and other critical parts. These bolts ensure that fastened components remain secure, even under extreme conditions such as high vibrations and thermal expansions. For international buyers, particularly in regions like Brazil and Saudi Arabia, sourcing bolts that meet specific material and certification standards is crucial to ensure reliability and compliance with safety regulations.

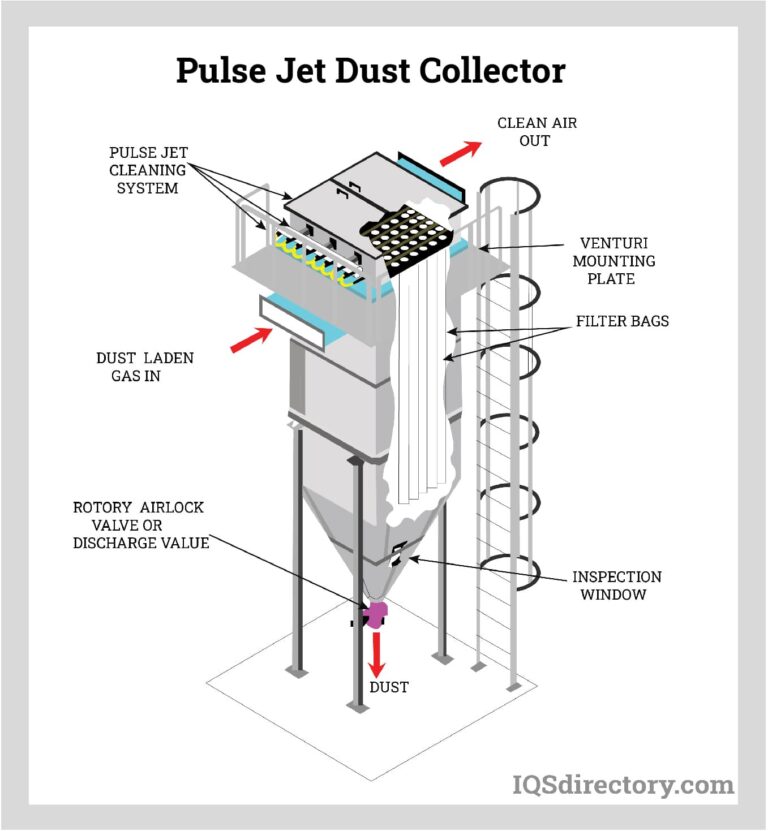

Illustrative image related to right handed thread bolt

What Role Does Right-Handed Thread Bolt Play in Construction?

In construction, right-handed thread bolts are used extensively to fasten structural elements like beams and frames. They provide the necessary strength to withstand heavy loads and environmental stresses, ensuring the safety and integrity of buildings. Buyers from Africa and South America should consider local building codes and standards when sourcing these bolts, as compliance is vital for project approval and safety.

How Do Right-Handed Thread Bolts Benefit Electrical & Electronics Industries?

Right-handed thread bolts are vital in the electrical and electronics sectors for mounting circuit boards and securing components. They ensure stable connections that prevent electrical failures, which can be costly. For B2B buyers in Europe, sourcing from certified manufacturers who adhere to international electrical standards is critical to guarantee product performance and safety.

Why are Right-Handed Thread Bolts Critical in Oil & Gas Applications?

In the oil and gas industry, right-handed thread bolts are used to secure piping systems and valves, preventing leaks that could lead to environmental disasters and operational inefficiencies. These bolts must withstand high pressures and corrosive environments. International buyers should prioritize sourcing materials that are resistant to corrosion and compliant with industry-specific standards to ensure safe operations.

What is the Importance of Right-Handed Thread Bolts in Machinery Manufacturing?

Right-handed thread bolts play a significant role in machinery manufacturing by connecting various parts in tools and machines. They enhance the longevity and functionality of equipment, which is essential for maintaining productivity. For buyers across different regions, ensuring precision in thread sizing and availability in various materials is important to meet diverse operational requirements.

3 Common User Pain Points for ‘right handed thread bolt’ & Their Solutions

Scenario 1: Sourcing Right-Handed Thread Bolts for Specialized Applications

The Problem: B2B buyers often struggle with sourcing right-handed thread bolts that meet specific industry standards and applications. In sectors such as automotive and construction, the precision of the bolt’s specifications—including thread size, pitch, and material—is crucial. A buyer might find it challenging to procure the right bolts, leading to project delays or compromised safety standards due to incorrect fitment. Moreover, the global supply chain can introduce variability in product quality, making it difficult for buyers to trust that they will receive the correct specification consistently.

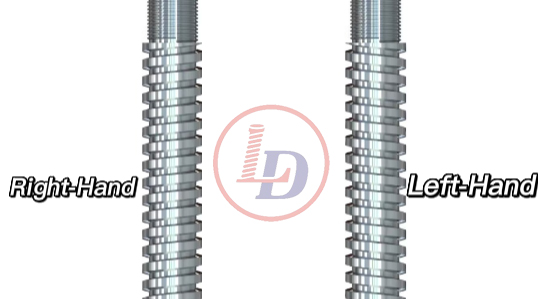

Illustrative image related to right handed thread bolt

The Solution: To mitigate sourcing challenges, B2B buyers should establish relationships with reputable suppliers who specialize in fasteners for their specific industry. Conducting thorough supplier audits and seeking certifications (such as ISO 9001) can ensure quality and compliance with international standards. Furthermore, buyers should create a detailed specification sheet for right-handed thread bolts, outlining material requirements, dimensions, and tolerances. Utilizing advanced procurement technologies like e-procurement platforms can streamline the sourcing process, allowing for real-time inventory checks and quicker turnaround times.

Scenario 2: Preventing Thread Stripping During Installation

The Problem: Another common issue encountered by B2B buyers is thread stripping during the installation of right-handed thread bolts. This can occur when excessive torque is applied or when the bolt is mismatched with the nut or tapped hole. Stripped threads not only compromise the integrity of the joint but also lead to costly downtime and the need for replacement parts. The pressure to complete projects on time can exacerbate this issue, as workers may rush the installation process without adequately checking specifications.

The Solution: To prevent thread stripping, it is essential to adhere to the recommended torque specifications provided by the bolt manufacturer. Utilizing a calibrated torque wrench can help ensure that the right amount of force is applied during installation. Additionally, training installation teams on the importance of matching bolt specifications with corresponding nuts or holes can significantly reduce the risk of thread damage. Incorporating thread-locking adhesives or coatings can also provide additional security, preventing loosening due to vibration without the risk of stripping threads.

Scenario 3: Managing Inventory of Right-Handed Thread Bolts

The Problem: B2B buyers often face challenges in managing inventory levels of right-handed thread bolts, particularly when dealing with multiple projects and varying specifications. Over-purchasing can tie up capital and increase storage costs, while under-purchasing can lead to project delays. Additionally, fluctuating demand and supply chain disruptions can complicate the balance of maintaining adequate stock levels.

The Solution: Implementing an inventory management system that leverages data analytics can help B2B buyers optimize their stock levels of right-handed thread bolts. By analyzing historical usage patterns and projecting future needs based on upcoming projects, buyers can make informed purchasing decisions. Additionally, maintaining a safety stock level for critical fasteners can act as a buffer against supply chain disruptions. Establishing just-in-time (JIT) inventory practices can further enhance efficiency, allowing businesses to minimize storage costs while ensuring they have the necessary components available for timely project execution.

Strategic Material Selection Guide for right handed thread bolt

What Are the Key Properties of Common Materials for Right-Handed Thread Bolts?

When selecting materials for right-handed thread bolts, it is essential to consider properties such as strength, corrosion resistance, and temperature ratings. Here, we analyze four common materials used in manufacturing right-handed thread bolts: carbon steel, stainless steel, brass, and titanium.

How Does Carbon Steel Perform as a Material for Right-Handed Thread Bolts?

Key Properties: Carbon steel is known for its high tensile strength and durability, making it suitable for a variety of applications. It typically withstands moderate temperatures and pressures, though it is susceptible to corrosion if not properly treated.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and ease of manufacturing. However, its susceptibility to rust and corrosion can limit its applications, particularly in environments exposed to moisture or harsh chemicals.

Impact on Application: Carbon steel bolts are commonly used in construction, automotive, and machinery applications. However, in humid or corrosive environments, additional protective coatings or treatments (like galvanization) may be necessary.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards, such as ASTM for the U.S. or equivalent standards in their countries. Carbon steel bolts are widely available and often the most economical choice.

What Advantages Does Stainless Steel Offer for Right-Handed Thread Bolts?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance. It is often used in applications where hygiene is crucial, such as in the food and medical industries.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it suitable for outdoor and marine applications. However, it is more expensive than carbon steel and may require more complex manufacturing processes.

Impact on Application: Stainless steel bolts are ideal for use in environments where exposure to moisture or corrosive substances is a concern. They are commonly used in plumbing, marine applications, and high-stress environments.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of the various grades of stainless steel (e.g., 304, 316) that may be specified in local standards. Compliance with DIN or JIS standards is often necessary.

Why Choose Brass for Right-Handed Thread Bolts in Specific Applications?

Key Properties: Brass is a copper-zinc alloy known for its good machinability and corrosion resistance. It performs well in low to moderate temperature and pressure applications.

Pros & Cons: The primary advantage of brass is its aesthetic appeal and resistance to corrosion, making it suitable for decorative applications. However, it is not as strong as steel and may not be suitable for high-stress applications.

Impact on Application: Brass bolts are often used in electrical applications due to their excellent conductivity and resistance to corrosion. They are also commonly found in plumbing fixtures.

Considerations for International Buyers: Buyers should ensure that brass fasteners meet local standards for electrical and plumbing applications. Compliance with ASTM or ISO standards may also be required.

Illustrative image related to right handed thread bolt

What Makes Titanium a Premium Choice for Right-Handed Thread Bolts?

Key Properties: Titanium is known for its exceptional strength-to-weight ratio and outstanding corrosion resistance, especially in harsh environments. It can withstand high temperatures and is non-magnetic.

Pros & Cons: The key advantage of titanium is its lightweight and high strength, making it ideal for aerospace and medical applications. However, it is significantly more expensive than other materials and requires specialized manufacturing processes.

Impact on Application: Titanium bolts are often used in aerospace, military, and high-performance automotive applications where weight savings and strength are critical.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades of titanium and their compliance with international standards. The higher cost may be a consideration for budget-sensitive projects.

Summary Table of Material Selection for Right-Handed Thread Bolts

| Material | Typical Use Case for right handed thread bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive, machinery | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Plumbing, marine applications, high-stress | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Electrical applications, plumbing fixtures | Good machinability and aesthetic appeal | Not suitable for high-stress use | Medium |

| Titanium | Aerospace, military, high-performance automotive | Exceptional strength-to-weight ratio | Very high cost | High |

This strategic material selection guide equips international B2B buyers with the insights needed to choose the right materials for their right-handed thread bolt applications, ensuring compliance and suitability for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for right handed thread bolt

What Are the Key Stages in the Manufacturing Process of Right-Handed Thread Bolts?

The production of right-handed thread bolts involves a series of well-defined stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Right-Handed Thread Bolts?

The manufacturing process begins with the selection of raw materials, commonly high-quality steel or alloy, which are known for their strength and durability. The chosen material is then subjected to various treatments, such as heat treatment, to enhance its mechanical properties. This is crucial as the material must withstand significant stress and strain during its operational life.

After selection, the material is cut into appropriate lengths, typically using precision cutting tools. This initial preparation ensures that the bolts will have the correct dimensions before they undergo further processing.

What Techniques Are Used to Form Right-Handed Thread Bolts?

The forming stage primarily involves machining operations such as forging, cold heading, or turning.

-

Forging: This method involves shaping the heated metal using dies, which provides superior strength characteristics. The forging process aligns the grain structure of the metal, enhancing its load-bearing capabilities.

-

Cold Heading: In this technique, metal is deformed at room temperature, which allows for the creation of complex shapes while maintaining the integrity of the material. Cold heading is efficient for mass production and can significantly reduce waste.

-

Turning: For bolts that require precise dimensions, turning on a lathe is employed. This process allows for fine adjustments and the creation of threads with high accuracy.

After forming, the threads are typically created using a rolling or cutting process. Thread rolling is preferred for high-volume production due to its ability to create stronger threads without removing material.

What Are the Final Stages of Manufacturing Right-Handed Thread Bolts?

Once the bolts are formed and threaded, they move into the assembly phase, where additional components, such as washers or nuts, may be attached if necessary. This step is critical for ensuring that the bolts are ready for end-use applications.

The finishing stage involves several steps, including surface treatment and coating. Common methods include:

-

Plating: To prevent corrosion, bolts are often plated with materials like zinc or nickel. This not only extends their lifespan but also enhances their aesthetic appeal.

-

Passivation: This process removes free iron and enhances the corrosion resistance of stainless steel bolts.

-

Quality Inspection: After finishing, a thorough quality inspection is conducted to ensure that the bolts meet all specifications.

What International Standards Guide Quality Assurance for Right-Handed Thread Bolts?

Quality assurance in the manufacturing of right-handed thread bolts is governed by several international standards, with ISO 9001 being the most recognized. This standard outlines the criteria for a quality management system and emphasizes customer satisfaction and continual improvement.

Illustrative image related to right handed thread bolt

In addition to ISO 9001, industry-specific standards may apply depending on the application of the bolts. For instance:

-

CE Marking: This indicates compliance with European health, safety, and environmental protection standards, particularly important for products sold in Europe.

-

API Standards: For bolts used in the oil and gas industry, adherence to American Petroleum Institute standards is crucial to ensure reliability under extreme conditions.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing process of right-handed thread bolts, with multiple checkpoints designed to catch defects early.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): During production, various measurements and tests are conducted to ensure that the bolts are being manufactured to the specified dimensions and tolerances. This may include monitoring temperature, pressure, and other critical parameters.

-

Final Quality Control (FQC): After production, a final inspection is performed, which may include visual inspections, dimensional checks, and functional tests to ensure that the bolts meet all required standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the supplier’s manufacturing practices and quality management systems. This allows buyers to assess compliance with international standards and identify areas for improvement.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the supplier’s QC processes, including results from various inspections and tests.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of verification. These independent organizations can provide unbiased assessments of a supplier’s products and processes, ensuring they meet specified standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers should be aware of certain nuances in quality control and certification when sourcing right-handed thread bolts. Different regions may have specific regulations and standards that impact the manufacturing and certification processes.

-

Local Regulations: Understanding local regulations in the target market is vital. For example, products sold in the European Union must comply with CE marking requirements, while those in the Middle East may require adherence to specific Gulf Standards Organization (GSO) certifications.

-

Documentation: Ensure that suppliers provide all necessary documentation, including certificates of compliance, material safety data sheets, and test reports. This documentation is essential for customs clearance and regulatory compliance.

-

Cultural Considerations: Building strong relationships with suppliers is crucial in many cultures. Establishing trust can lead to better communication and more reliable quality assurance practices.

In summary, the manufacturing processes and quality assurance practices for right-handed thread bolts are critical factors for B2B buyers. Understanding these elements enables buyers to make informed decisions and ensures that the products meet the required specifications and standards for their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘right handed thread bolt’

To successfully procure right-handed thread bolts, it’s essential to follow a systematic approach that ensures quality, compatibility, and reliability. This checklist will guide B2B buyers through the necessary steps to secure the right fasteners for their applications.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the right-handed thread bolts you need. Consider factors such as size, length, thread pitch, and material type (e.g., stainless steel, carbon steel). Defining these specifications helps in sourcing the correct product that meets your operational demands.

- Size and Length: Ensure that the dimensions align with your equipment or assembly requirements.

- Material Properties: Different materials provide varying strengths and corrosion resistance, which can be critical depending on your application.

Step 2: Research Supplier Capabilities

Conduct thorough research on potential suppliers to assess their ability to meet your specifications. Look for suppliers who specialize in fasteners and have a proven track record in your industry.

- Experience: Prefer suppliers with experience in producing right-handed thread bolts for similar applications.

- Production Capacity: Ensure they can handle your order volume and timelines without compromising quality.

Step 3: Verify Supplier Certifications

Before finalizing a supplier, check their certifications and quality control processes. Certifications such as ISO 9001 indicate a commitment to quality management and consistency in production.

- Quality Assurance: Inquire about their quality control methods and whether they perform regular testing on their products.

- Compliance: Ensure they comply with relevant industry standards and regulations, particularly if your application is in a sensitive sector like automotive or aerospace.

Step 4: Request Samples for Evaluation

Before placing a bulk order, request samples of the right-handed thread bolts to evaluate their quality and compatibility with your needs. Testing samples can help identify any potential issues before committing to a larger order.

- Physical Testing: Check for thread engagement, strength, and material integrity.

- Compatibility Testing: Ensure the samples fit with existing components or assemblies.

Step 5: Review Pricing and Payment Terms

Analyze the pricing structures provided by different suppliers and ensure they align with your budget. Consider not only the unit price but also payment terms, shipping costs, and potential discounts for bulk orders.

- Total Cost of Ownership: Factor in shipping and handling as well as potential tariffs, especially for international transactions.

- Payment Flexibility: Look for suppliers offering favorable payment terms that can help manage cash flow.

Step 6: Establish Communication Channels

Effective communication is crucial throughout the sourcing process. Establish clear lines of communication with your selected supplier to ensure timely updates and address any concerns that may arise.

- Point of Contact: Designate a representative for managing interactions, ensuring consistent communication.

- Feedback Mechanism: Set up a system for providing feedback on product quality and service to foster a collaborative relationship.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in the procurement process. Confirm shipping timelines and methods to ensure that the right-handed thread bolts arrive when needed.

- Delivery Schedule: Align delivery dates with your production schedules to avoid any delays.

- Shipping Methods: Evaluate shipping options that balance cost and speed, particularly for urgent requirements.

By adhering to this checklist, B2B buyers can ensure a streamlined sourcing process for right-handed thread bolts, leading to successful procurement outcomes and minimized operational disruptions.

Comprehensive Cost and Pricing Analysis for right handed thread bolt Sourcing

What Are the Key Cost Components in Sourcing Right-Handed Thread Bolts?

When sourcing right-handed thread bolts, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials for right-handed thread bolts include carbon steel, stainless steel, and alloys. Prices can vary widely based on market demand, material grade, and local availability.

-

Labor: Labor costs encompass the wages of personnel involved in the manufacturing process, including machine operators, quality control inspectors, and assembly workers. Labor costs can fluctuate based on geographical location and the skill level required.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Manufacturing overhead can account for a substantial portion of the total cost, especially in regions with high operational costs.

-

Tooling: The cost of tooling is a significant factor in bolt production. Tooling costs include the expense of molds, dies, and specialized equipment necessary for manufacturing specific bolt designs and sizes. Custom tooling can add to the initial setup costs but may result in lower per-unit costs at higher volumes.

-

Quality Control (QC): Ensuring that bolts meet industry standards and specifications is essential. QC costs involve testing and inspection processes, which can increase the overall cost but are necessary to minimize defects and returns.

-

Logistics: The costs associated with transporting the bolts from the manufacturing facility to the buyer can vary based on distance, mode of transport, and shipping terms. Import duties, customs clearance, and warehousing may also contribute to logistics expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing structure. This margin varies based on the supplier’s business model, market position, and competitive landscape.

How Do Price Influencers Affect Right-Handed Thread Bolt Sourcing?

Several factors influence the pricing of right-handed thread bolts, which international B2B buyers should consider:

Illustrative image related to right handed thread bolt

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to cost savings. Suppliers may offer tiered pricing structures where larger orders reduce the per-unit cost. Understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom specifications can significantly impact pricing. Unique designs or materials may require additional tooling and production time, leading to higher costs. It is essential to balance the need for customization with budget constraints.

-

Materials: The choice of materials not only affects the initial cost but also impacts durability and performance. Higher-grade materials may have a higher upfront cost but can lead to lower total ownership costs due to increased longevity.

-

Quality and Certifications: High-quality bolts often come with certifications (like ISO or ASTM standards) that validate their reliability. While certified products may cost more, they can provide peace of mind and reduce the risk of failures in critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium, but their experience and quality assurance processes can lead to fewer issues and lower overall costs.

-

Incoterms: Understanding the agreed Incoterms is essential for cost calculation. Different terms (like FOB, CIF, etc.) dictate who bears the shipping costs, insurance, and responsibilities, affecting the total landed cost.

What Buyer Tips Can Enhance Cost Efficiency in Bolt Sourcing?

To navigate the complexities of sourcing right-handed thread bolts, buyers can adopt several strategies:

-

Negotiation: Engage in negotiations with suppliers to explore price adjustments based on order volume or long-term commitments. Building relationships with suppliers can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not just the purchase price but also shipping, handling, and potential costs associated with quality issues or failures. This holistic view can reveal more cost-effective options.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market conditions, import tariffs, and currency fluctuations is vital for accurate cost assessment.

-

Quality Over Price: While it may be tempting to choose the lowest-cost option, prioritizing quality can save money in the long run by reducing the frequency of replacements and maintenance.

-

Consider Local Sourcing: Where feasible, consider sourcing from local suppliers to reduce logistics costs and lead times. Local sourcing can also enhance supply chain resilience.

Disclaimer

Prices for right-handed thread bolts can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. The information provided here is indicative and should be verified with suppliers for accurate pricing.

Alternatives Analysis: Comparing right handed thread bolt With Other Solutions

Exploring Alternatives to Right Handed Thread Bolts

When considering fastening solutions, right handed thread bolts are a well-established choice in various industries. However, alternative methods and technologies can offer distinct advantages depending on specific application requirements, material compatibility, and operational environments. This analysis will compare right handed thread bolts with two viable alternatives: left handed thread bolts and locking fasteners, providing insights for B2B buyers navigating their options.

| Comparison Aspect | Right Handed Thread Bolt | Left Handed Thread Bolt | Locking Fasteners |

|---|---|---|---|

| Performance | Excellent for most applications; reliable under normal conditions. | Ideal for applications prone to loosening; provides a secure fit in rotating mechanisms. | Offers enhanced resistance to loosening due to vibration; effective in high-stress environments. |

| Cost | Generally lower cost; widely available in various materials and sizes. | Often more expensive due to lower production volume; less common. | Higher initial cost; however, can save costs on maintenance and replacement in the long run. |

| Ease of Implementation | Simple installation; compatible with most tools and machinery. | Requires careful selection to ensure compatibility; installation may be less intuitive. | Installation can be straightforward, but specific tools or techniques may be necessary for optimal performance. |

| Maintenance | Minimal maintenance required; straightforward replacement if damaged. | Similar maintenance needs; replacement can be challenging if not readily available. | Requires periodic checks to ensure locking mechanisms function correctly; may need replacing more frequently than standard bolts. |

| Best Use Case | General fastening across various applications including automotive and construction. | Suitable for specialized applications like rotating machinery or gas systems. | Best used in environments with high vibration or dynamic loads, such as automotive or aerospace sectors. |

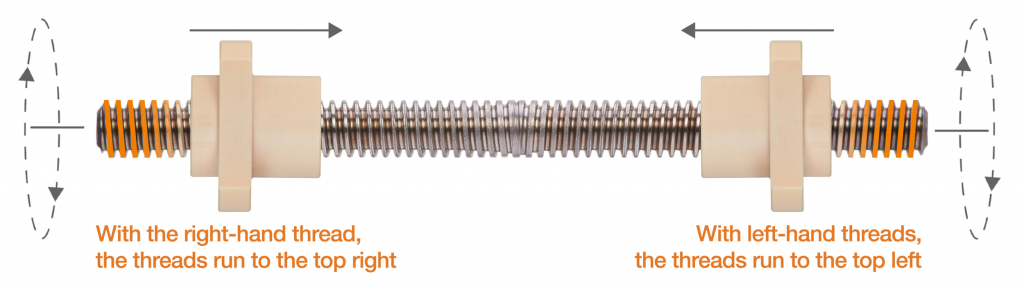

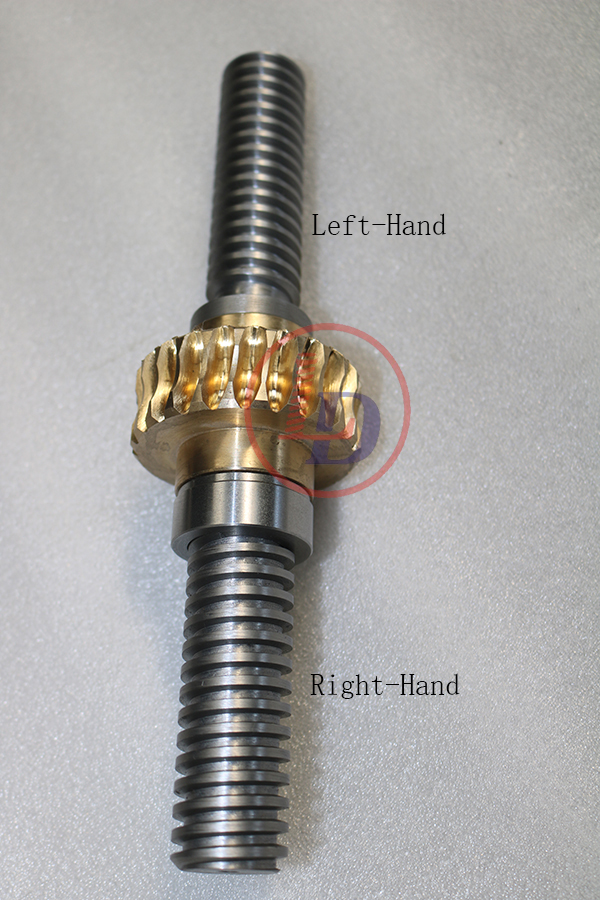

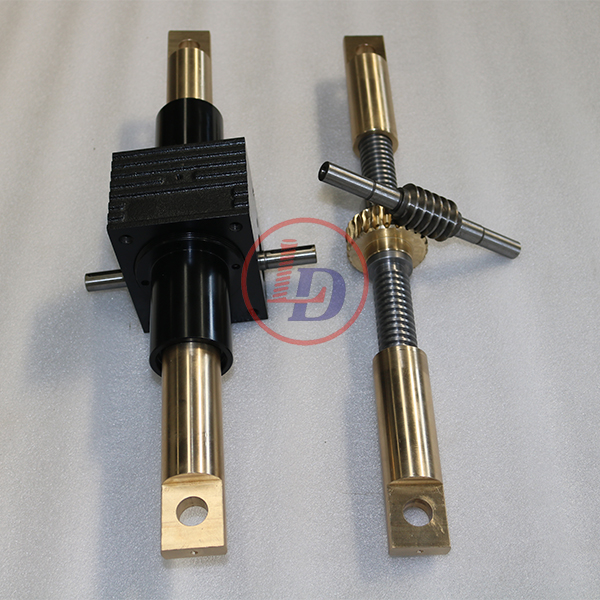

What Are the Pros and Cons of Left Handed Thread Bolts?

Left handed thread bolts are specifically designed to counteract the loosening effects often seen in right handed threads, particularly in applications with rotational movement. Their unique design makes them ideal for securing components like propane tanks and automotive tie rods. However, their specialized nature means they are not as readily available as right handed threads, which can complicate sourcing and increase costs. While they perform exceptionally in niche applications, their overall market presence is limited.

How Do Locking Fasteners Enhance Performance?

Locking fasteners, which can include various designs such as nylon insert lock nuts and serrated flange bolts, provide additional security against loosening due to vibration and dynamic loads. They are particularly beneficial in high-stress environments, such as aerospace or heavy machinery. However, these fasteners can be more expensive than traditional bolts, and their installation may require specific tools or techniques to ensure optimal performance. While the initial investment is higher, the long-term savings in maintenance and replacement can make them a cost-effective choice.

Conclusion: Which Fastening Solution is Right for Your Needs?

Choosing the right fastening solution involves evaluating the specific requirements of your application, including performance needs, budget constraints, and operational conditions. Right handed thread bolts remain a versatile and cost-effective choice for general use, while left handed thread bolts and locking fasteners offer specialized advantages in particular scenarios. B2B buyers should carefully assess their application needs and consider factors such as availability, ease of implementation, and long-term maintenance costs to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for right handed thread bolt

When considering the procurement of right-handed thread bolts, understanding their essential technical properties and trade terminology is crucial for making informed decisions. Here, we outline critical specifications and common jargon that will aid international B2B buyers in navigating this sector effectively.

What Are the Key Technical Properties of Right-Handed Thread Bolts?

1. Material Grade

Material grade indicates the composition and strength of the bolt. Common grades include ASTM A307 for general-purpose bolts, ASTM A325 for heavy structural applications, and stainless steel grades like A2 and A4 for corrosion resistance. Selecting the right material grade is essential for ensuring that the bolt can withstand the intended loads and environmental conditions, thus avoiding premature failure.

2. Thread Pitch

Thread pitch refers to the distance between adjacent threads, measured in millimeters (for metric threads) or threads per inch (for imperial threads). Standard pitches for right-handed threads include 1.0 mm for M8 bolts or 1/4-20 for UNC threads. Understanding thread pitch is critical for ensuring compatibility with nuts and tapped holes, as mismatches can lead to ineffective fastening.

3. Tolerance

Tolerance specifies the allowable deviation from specified dimensions, impacting the fit and function of the bolt. For instance, a tolerance of ±0.05 mm ensures that the bolt fits snugly within its intended application. In B2B transactions, tight tolerances are often required in precision applications like aerospace or automotive sectors, where safety and performance are paramount.

4. Coating and Finish

Coatings, such as zinc plating, black oxide, or hot-dip galvanizing, enhance corrosion resistance and aesthetic appeal. The choice of coating impacts the bolt’s lifespan in various environments. B2B buyers must consider the operational conditions—like exposure to moisture or chemicals—when selecting the appropriate finish to ensure durability.

5. Length and Diameter

The length and diameter of a bolt determine its strength and suitability for specific applications. Common diameters range from M3 to M30 or 1/4″ to 1″ for standard sizes. Buyers must evaluate the load-bearing requirements and the thickness of the materials being fastened to select the correct dimensions.

Illustrative image related to right handed thread bolt

What Are Common Trade Terms Related to Right-Handed Thread Bolts?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. Understanding OEM relationships is vital for B2B buyers as it often influences pricing, quality standards, and supply chain dynamics.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget effectively, ensuring they meet supplier requirements while optimizing their purchase volume.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a detailed price quote for specific products or services. This process is critical for comparing costs and ensuring that buyers receive competitive pricing for right-handed thread bolts.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and risks in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time is crucial for project planning and ensuring that components are available when needed, especially in industries with tight deadlines.

Understanding these essential properties and trade terms will empower B2B buyers to make strategic decisions when sourcing right-handed thread bolts, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the right handed thread bolt Sector

What are the Global Drivers and Key Trends in the Right-Handed Thread Bolt Market?

The right-handed thread bolt market is experiencing significant growth driven by several global factors. The increasing demand for durable and reliable fastening solutions across various industries, including construction, automotive, and manufacturing, is propelling market expansion. In regions such as Africa, South America, the Middle East, and Europe, infrastructure development and industrialization are key contributors. For example, Brazil’s booming construction sector and Saudi Arabia’s Vision 2030 initiative both highlight the need for reliable fastening solutions.

Illustrative image related to right handed thread bolt

Emerging technologies are also shaping the sourcing landscape. The adoption of Industry 4.0 practices, including automation and real-time data analytics, enhances supply chain efficiency and responsiveness. B2B buyers are increasingly leveraging digital platforms to streamline procurement processes, allowing for better price comparisons and supplier evaluations. Additionally, the rise of e-commerce in B2B transactions is fostering a more competitive market, enabling buyers to access a wider range of suppliers and products.

Moreover, sustainability is becoming a critical consideration in the sourcing of right-handed thread bolts. Buyers are increasingly looking for suppliers that prioritize eco-friendly practices, such as using recycled materials or minimizing waste during production. This shift not only meets regulatory requirements but also aligns with the growing consumer demand for sustainable products.

How is Sustainability and Ethical Sourcing Impacting the Right-Handed Thread Bolt Sector?

The environmental impact of manufacturing processes for right-handed thread bolts is under scrutiny, leading to a shift toward sustainable practices within the industry. As international buyers become more environmentally conscious, the demand for ethically sourced materials and manufacturing methods has risen. For B2B buyers, understanding the supply chain’s environmental footprint is essential, as it directly influences brand reputation and compliance with local and global regulations.

Illustrative image related to right handed thread bolt

Ethical sourcing involves ensuring that materials are obtained responsibly, with consideration for human rights and fair labor practices. Buyers are increasingly seeking suppliers who hold certifications such as ISO 14001, which demonstrates a commitment to environmental management, or those who utilize materials with certifications like the Global Recycled Standard (GRS). These certifications not only provide assurance of sustainability but can also enhance the credibility of the buyer’s own brand.

Furthermore, the shift toward green manufacturing practices is leading to the development of innovative materials for right-handed thread bolts. Using eco-friendly alternatives and reducing carbon footprints in production processes can significantly appeal to environmentally conscious businesses. For B2B buyers, engaging with suppliers committed to sustainability can provide a competitive edge in their respective markets.

What is the Historical Context of Right-Handed Thread Bolts in B2B Markets?

The history of right-handed thread bolts is rooted in the evolution of fastener technology, which dates back to ancient civilizations. The introduction of standardized thread sizes in the 19th century revolutionized the manufacturing process, enabling greater consistency and reliability in fastening solutions. The right-handed thread became the dominant choice due to its intuitive tightening direction, aligning with the natural motion of most users.

As industrialization progressed, the demand for right-handed thread bolts surged, particularly in burgeoning sectors such as automotive and construction. This trend continued into the 20th century, where advancements in metallurgy and manufacturing processes further enhanced the strength and versatility of right-handed thread bolts. Today, they are ubiquitous in various applications, from household items to complex machinery, underlining their importance in the global supply chain.

Understanding the historical context of right-handed thread bolts not only helps B2B buyers appreciate their significance but also aids in recognizing the evolution of standards and innovations that continue to shape the market today.

Frequently Asked Questions (FAQs) for B2B Buyers of right handed thread bolt

-

How do I ensure the right handed thread bolt is compatible with my application?

To ensure compatibility, first, identify the specifications of the right handed thread bolt required for your application, including thread diameter, pitch, and length. Consult technical documents or industry standards relevant to your sector. It’s crucial to match the bolt with the corresponding nut or hole to avoid issues like stripping or loosening. If you’re unsure, consider reaching out to the manufacturer or supplier for detailed product specifications and recommendations based on your application needs. -

What is the best material for right handed thread bolts in harsh environments?

For harsh environments, stainless steel is often the best choice for right handed thread bolts due to its corrosion resistance and strength. If exposure to extreme temperatures is a concern, consider high-temperature alloys or coated bolts that can withstand thermal stress. Additionally, ensure that the material meets relevant industry standards, such as ASTM or ISO certifications, to guarantee performance and durability in specific applications. -

What should I look for when vetting suppliers for right handed thread bolts?

When vetting suppliers, focus on their industry experience, reputation, and certifications. Request product samples to assess quality and consistency. Verify their manufacturing processes and quality control measures to ensure compliance with international standards. It’s also beneficial to check customer reviews and testimonials. Finally, consider their ability to meet your specific needs, such as customization options and response times to inquiries. -

What is the minimum order quantity (MOQ) for right handed thread bolts?

MOQs can vary significantly among suppliers, ranging from a few dozen to several thousand units depending on the manufacturer and the complexity of the bolt. When sourcing, inquire about the MOQ and whether it can be adjusted for first-time orders or trial runs. Some suppliers may offer flexibility, especially if you are establishing a long-term partnership, so be sure to communicate your needs and expectations clearly. -

How can I customize right handed thread bolts for my specific application?

Customization options for right handed thread bolts often include variations in size, thread pitch, coating, and material. Discuss your specific requirements with potential suppliers, as many manufacturers can accommodate custom requests. Be prepared to provide detailed specifications and potentially prototypes to ensure that the final product meets your application’s demands. Always confirm the lead times and costs associated with custom orders. -

What payment terms are typically offered for international purchases of right handed thread bolts?

Payment terms can vary by supplier and region but typically include options such as advance payment, letter of credit, or payment upon delivery. For larger orders, suppliers may offer favorable terms, such as partial payment upfront and the remainder upon delivery. Always clarify payment terms before finalizing the order to avoid misunderstandings. Additionally, consider using escrow services for added security in international transactions. -

How do I ensure quality assurance for right handed thread bolts during sourcing?

To ensure quality assurance, request detailed quality control processes from your supplier, including certifications such as ISO 9001. Ask for test reports or certificates of compliance for the bolts to verify material properties and strength. Implementing a pre-shipment inspection can also be beneficial, where a third-party service evaluates the batch before shipping. Establish clear communication channels for addressing any quality issues that may arise post-delivery. -

What logistics considerations should I be aware of when importing right handed thread bolts?

When importing right handed thread bolts, consider shipping methods, costs, and delivery times. Ensure that your supplier provides appropriate documentation, including invoices, packing lists, and certificates of origin. Familiarize yourself with import regulations and duties in your country to avoid unexpected fees. Partnering with a reliable freight forwarder can help streamline the logistics process and provide guidance on customs clearance.

Top 5 Right Handed Thread Bolt Manufacturers & Suppliers List

1. Accu Components – Left-Hand vs Right-Hand Threads

Domain: accu-components.com

Registered: 2020 (5 years)

Introduction: Left-Hand vs Right-Hand Threads: Understanding the differences between left-hand and right-hand threads is crucial for precision engineering components. Right-hand threads tighten clockwise and are more commonly used due to their universality and compatibility. Left-hand threads, which tighten anti-clockwise, are used in specific applications to prevent loosening under anti-clockwise forces, such …

2. McMaster – Right and Left Hand Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Right and Left Hand Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Dependable Acme – Right-Handed & Left-Handed Fasteners

Domain: dependableacme.com

Registered: 2000 (25 years)

Introduction: Right-handed threads are the standard for fasteners, used by 70-95% of the population. Left-handed threads operate in reverse, requiring a counter-clockwise turn to tighten. They are beneficial in situations where the rotation of an object could cause it to loosen, commonly found on left bicycle pedals, certain circular saws, and turnbuckles. Dependable ACME offers fasteners with both right and le…

4. Allied Bolt – Specialty Threads

Domain: alliedbolt.com

Registered: 1996 (29 years)

Introduction: This company, Allied Bolt – Specialty Threads, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Reddit – Reverse Thread Bolt

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Reverse thread bolt with a bolt symbol indicating left-hand thread; turning it left tightens the bolt.

Strategic Sourcing Conclusion and Outlook for right handed thread bolt

What are the Key Takeaways for B2B Buyers of Right-Handed Thread Bolts?

In the fast-paced global market, the importance of strategic sourcing for right-handed thread bolts cannot be overstated. By understanding the specific applications and advantages of right-handed threads, businesses can secure reliable and efficient fastening solutions for a variety of industries. Right-handed threads are predominant in applications ranging from automotive to construction, offering versatility and compatibility that streamline operations.

How Can Strategic Sourcing Enhance Your Supply Chain?

Engaging in strategic sourcing allows international buyers to leverage local and global suppliers, ensuring access to quality materials at competitive prices. This proactive approach not only mitigates risks associated with supply chain disruptions but also fosters strong relationships with suppliers, enhancing negotiation leverage. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying informed about sourcing trends and innovations will position your business for success.

What’s Next for International Buyers?

As the demand for reliable fastening solutions grows, now is the time to evaluate your sourcing strategies for right-handed thread bolts. Take action by identifying potential suppliers, assessing their capabilities, and exploring partnerships that align with your business goals. Embrace the future of sourcing by prioritizing quality, efficiency, and sustainability, ensuring your operations remain competitive in an ever-changing landscape.

Illustrative image related to right handed thread bolt

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.