Is Your Rice Washer Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for rice washer

In the competitive landscape of food processing and preparation, sourcing an efficient rice washer can present significant challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. As international demand for high-quality rice rises, the need for effective washing solutions that enhance flavor and reduce processing time becomes paramount. This guide aims to equip buyers with the knowledge necessary to navigate the global market for rice washers, exploring various types, applications, and key considerations for supplier vetting.

Throughout this comprehensive resource, we will delve into the different categories of rice washers available—from commercial-grade machines designed for large-scale operations to more compact models suitable for smaller enterprises. Buyers will gain insights into the latest technologies, including water-efficient systems that conserve resources while maintaining superior cleaning results. Additionally, we will cover essential factors such as cost analysis, maintenance requirements, and compliance with international standards, all critical to making informed purchasing decisions.

By leveraging the information provided in this guide, B2B buyers will be empowered to identify the most suitable rice washing solutions for their specific needs, ensuring they can meet customer expectations while optimizing operational efficiency. Whether you’re a seasoned importer or a new market entrant, understanding the intricacies of the rice washer market will enhance your competitive edge and support your business growth.

Understanding rice washer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MJP Rice Washer | Utilizes mixed air jet pump technology; cleans up to 7.5 kg of rice in under five minutes; minimal water usage; no electricity required. | Commercial kitchens, rice processing plants | Pros: Fast, efficient, eco-friendly; Cons: Requires specific water pressure and drainage setup. |

| Jet Rice Washer | Features a jet washing system that ensures thorough cleaning; designed for high-capacity operations; often incorporates easy drainage systems. | Large-scale rice distributors, restaurants | Pros: High capacity; Cons: May be more complex to operate and maintain. |

| Manual Rice Washer | Simple design, typically involves a perforated container; affordable and easy to use; requires manual effort for washing. | Small restaurants, home kitchens | Pros: Low cost, easy to store; Cons: Time-consuming and labor-intensive. |

| Electric Rice Washer | Powered by electricity, offers automated washing cycles; often includes features like timers and multiple wash settings for customization. | Food processing facilities, catering services | Pros: Convenient and consistent results; Cons: Higher energy costs and requires electrical setup. |

| Multi-Use Strainer | Versatile design for rinsing rice and other small grains; includes features like silicone bases for grip and ease of use; compact size. | Home kitchens, small food businesses | Pros: Multi-functional; Cons: Limited capacity for larger operations. |

What Are the Characteristics of MJP Rice Washers and Their B2B Suitability?

The MJP Rice Washer leverages innovative mixed air jet pump technology to efficiently clean rice without the need for electricity, making it ideal for commercial kitchens and rice processing plants. With a capacity of up to 7.5 kg of rice per cycle and a washing time of under five minutes, this washer is designed for high-volume operations. B2B buyers should consider water pressure requirements and drainage capabilities when purchasing, as these factors can affect operational efficiency.

How Do Jet Rice Washers Stand Out in High-Capacity Operations?

Jet Rice Washers are engineered for high-capacity operations, ensuring thorough cleaning through advanced jet washing systems. They are particularly suitable for large-scale rice distributors and restaurants that require significant quantities of clean rice quickly. While they provide efficiency and speed, buyers should be aware of the complexity involved in their operation and maintenance, which may necessitate specialized training.

Why Choose Manual Rice Washers for Small-Scale Operations?

Manual Rice Washers are straightforward devices that allow users to rinse rice effectively without the need for electricity. Their affordability and ease of use make them ideal for small restaurants and home kitchens. However, buyers should consider that these washers require more time and manual effort, making them less suitable for high-volume environments where efficiency is paramount.

What Benefits Do Electric Rice Washers Offer to Food Processing Facilities?

Electric Rice Washers automate the washing process, providing consistent results with customizable settings for different rice types. These washers are particularly beneficial for food processing facilities and catering services that demand high efficiency and reliability. While they offer convenience, buyers must factor in energy costs and the necessity for electrical infrastructure, which can increase overall investment.

How Do Multi-Use Strainers Enhance Versatility in Kitchen Operations?

Multi-Use Strainers are designed for versatility, allowing users to rinse rice as well as other small grains and produce. Their compact size and silicone grips make them suitable for home kitchens and small food businesses where space is limited. However, their capacity may not meet the demands of larger operations, making it crucial for buyers to evaluate their specific needs before purchase.

Key Industrial Applications of rice washer

| Industry/Sector | Specific Application of rice washer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Pre-cooking rice preparation | Ensures high-quality, clean rice, reducing cooking time and enhancing flavor | Capacity to handle large volumes, water efficiency, and ease of cleaning |

| Restaurant & Catering | Rice preparation for meal service | Provides consistent quality and reduces labor costs during peak times | Durability, ease of use, and compatibility with existing kitchen setups |

| Export & Import | Quality control for rice export | Meets international standards for cleanliness and quality, enhancing marketability | Compliance with export regulations, capacity for bulk washing, and reliability |

| Retail & Wholesale | Consumer-ready rice packaging | Improves product quality, leading to higher customer satisfaction and sales | Scalability, cost-effectiveness, and adaptability to different rice types |

| Agricultural Cooperatives | Processing of harvested rice | Increases efficiency in post-harvest processing, maximizing yield and quality | Adaptability to local rice varieties, ease of maintenance, and training support |

How is a Rice Washer Used in Food Processing and What Problems Does it Solve?

In the food processing sector, rice washers are essential for preparing rice before cooking. They effectively remove contaminants, such as dirt and excess starch, ensuring that the rice is clean and ready for cooking. This process not only enhances the flavor of the rice but also reduces cooking time, which is critical for large-scale operations. Buyers in this sector should consider the washer’s capacity to handle large volumes, its water efficiency, and ease of cleaning to maintain hygiene standards.

What are the Benefits of Using a Rice Washer in Restaurants and Catering Services?

For restaurants and catering businesses, rice washers streamline the rice preparation process, ensuring that chefs can serve high-quality dishes consistently. By automating the washing process, these machines reduce labor costs, especially during busy service periods. Buyers in this industry should prioritize durability, ease of use, and compatibility with existing kitchen equipment to ensure seamless integration into their operations.

How Do Rice Washers Enhance Quality Control in Export and Import Operations?

In the export and import sector, rice washers play a crucial role in meeting international cleanliness standards. By ensuring that rice is thoroughly washed and free from contaminants, exporters can enhance the marketability of their products. This is particularly important for markets in Europe and the Middle East, where strict quality regulations are enforced. Buyers need to consider compliance with export regulations, the capacity for bulk washing, and the reliability of the washer to maintain consistent quality.

Why are Rice Washers Important for Retail and Wholesale Businesses?

Retailers and wholesalers benefit from using rice washers to prepare consumer-ready rice products. By improving the quality of the rice, businesses can increase customer satisfaction and drive sales. The ability to efficiently wash large quantities of rice while maintaining cost-effectiveness is vital for staying competitive in the market. Key sourcing considerations include scalability, adaptability to different rice types, and overall operational costs.

How Do Agricultural Cooperatives Utilize Rice Washers for Post-Harvest Processing?

Agricultural cooperatives leverage rice washers to enhance the efficiency of post-harvest processing. These machines help in maximizing yield and quality by ensuring that harvested rice is cleaned properly. This is particularly important in regions like Africa and South America, where local rice varieties may have specific washing requirements. Buyers should focus on the washer’s adaptability to local rice varieties, ease of maintenance, and availability of training support for operators to ensure effective use.

3 Common User Pain Points for ‘rice washer’ & Their Solutions

Scenario 1: Ensuring Consistency in Rice Quality for Large-Scale Production

The Problem: In the rice processing industry, maintaining consistent quality is paramount. B2B buyers often face challenges in ensuring that every batch of rice is thoroughly cleaned, as inconsistencies can lead to customer dissatisfaction and increased returns. Traditional washing methods may not effectively remove contaminants, leading to variations in taste and quality. This inconsistency can also affect the overall cooking characteristics of the rice, impacting the reputation of the supplier.

The Solution: To address this issue, B2B buyers should invest in commercial rice washers that feature advanced washing technology, such as multi-stage rinsing systems. Look for equipment that uses a combination of air jets and water pressure to remove impurities effectively without damaging the rice. When sourcing these machines, ensure they have adjustable settings to cater to different rice types and volumes, which can help standardize the cleaning process across batches. Additionally, integrating a monitoring system that tracks water quality and washing cycles can further enhance quality control, ensuring that each batch meets the desired standards before reaching customers.

Scenario 2: Reducing Water Usage While Maintaining Cleaning Efficiency

The Problem: Water scarcity is a pressing issue in many regions, particularly in Africa and the Middle East. B2B buyers in rice processing plants often struggle with the dual challenge of needing to use sufficient water to wash rice while also adhering to environmental regulations and sustainability practices. Excessive water usage not only increases operational costs but also raises concerns about environmental impact.

The Solution: To combat this challenge, buyers should opt for rice washers designed for water efficiency. Many modern rice washers utilize innovative technologies that minimize water usage—such as closed-loop systems that recycle wash water or machines that require only a fraction of the water compared to traditional methods. When considering a purchase, look for models that specify water consumption rates and compare them against the cleaning efficacy they provide. Additionally, investing in training for staff on optimal machine settings can maximize water savings without compromising cleaning quality, leading to reduced costs and a smaller environmental footprint.

Scenario 3: Overcoming Equipment Maintenance Challenges in Rice Washing

The Problem: Equipment downtime due to maintenance issues can significantly affect productivity and revenue for rice processing businesses. B2B buyers often face difficulties in finding reliable machines that require minimal maintenance and have readily available spare parts. This situation can lead to prolonged operational halts, impacting supply chain commitments and customer satisfaction.

The Solution: Buyers should prioritize rice washers that are known for their durability and ease of maintenance. Look for models that feature self-cleaning capabilities, as these can reduce the frequency of manual cleaning and maintenance. Additionally, when purchasing, it’s critical to evaluate the manufacturer’s support services, including the availability of spare parts and technical assistance. Establishing a preventive maintenance schedule can further mitigate downtime; this includes regular inspections and timely servicing to identify potential issues before they escalate. Collaborating with suppliers who offer comprehensive warranties and service agreements can also provide peace of mind, ensuring that the equipment remains operational and efficient over the long term.

Strategic Material Selection Guide for rice washer

When selecting materials for rice washers, it’s essential to consider properties that directly impact performance, durability, and compliance with international standards. Below is an analysis of several common materials used in the manufacturing of rice washers, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Stainless Steel for Rice Washers?

Stainless steel is a popular choice for rice washers due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for commercial applications. The material is also easy to clean, which is vital in maintaining hygiene standards in food processing.

Pros:

– High durability and resistance to corrosion.

– Non-reactive, ensuring no contamination of rice.

– Easy to maintain and clean, supporting food safety.

Cons:

– Higher initial cost compared to plastic options.

– Requires more complex manufacturing processes.

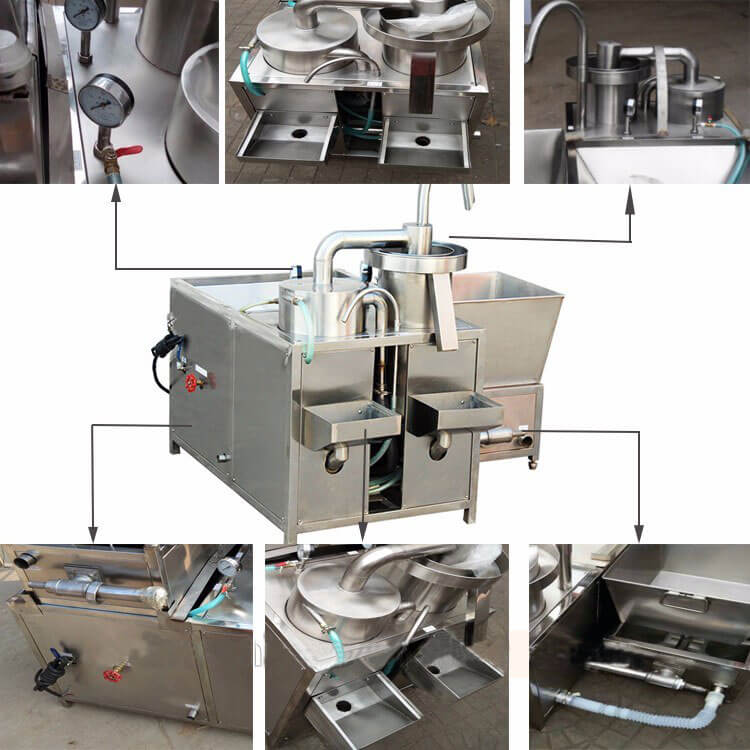

Illustrative image related to rice washer

Impact on Application:

Stainless steel is compatible with various cleaning agents and can handle the abrasiveness of rice without degrading. Its robustness makes it ideal for high-volume operations, especially in regions with stringent food safety regulations.

Considerations for International Buyers:

Compliance with food safety standards such as NSF or FDA is crucial. Buyers from regions like Africa and South America should ensure that the stainless steel used meets local and international quality standards, such as ASTM or JIS.

How Does Plastic Compare as a Material for Rice Washers?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is often used in rice washers due to its lightweight nature and cost-effectiveness. These materials are resistant to chemicals and moisture, making them suitable for food applications.

Pros:

– Lower cost compared to metals.

– Lightweight and easy to handle.

– Good resistance to moisture and chemicals.

Cons:

– Less durable than stainless steel; can crack or warp under extreme conditions.

– Potential leaching of chemicals if not food-grade certified.

Impact on Application:

Plastic rice washers are suitable for smaller operations or household use, where high durability is less critical. However, they may not withstand the rigors of industrial use as effectively as metal options.

Considerations for International Buyers:

Buyers should ensure that the plastic materials used are food-grade and compliant with relevant regulations. For regions like the Middle East, where temperatures can be high, UV resistance may also be a factor.

What Role Does Aluminum Play in Rice Washer Manufacturing?

Aluminum is another material that can be used in rice washers, offering a balance between weight and strength. It is resistant to corrosion and can be manufactured to be lightweight while still providing structural integrity.

Pros:

– Lightweight, making it easy to transport and handle.

– Good corrosion resistance.

– Can be anodized for enhanced durability.

Cons:

– More expensive than plastic but less than stainless steel.

– Not as strong as stainless steel, which may limit its use in heavy-duty applications.

Impact on Application:

Aluminum rice washers can be effective for medium-scale operations but may not be suitable for high-volume processing due to their lower strength compared to stainless steel.

Considerations for International Buyers:

Compliance with international standards is essential, especially in Europe, where regulations on materials in food processing can be stringent. Buyers should verify that the aluminum used is food-safe and meets local standards.

How Does Glass Fiber Reinforced Plastic (GFRP) Enhance Rice Washers?

GFRP is an advanced composite material that combines the lightweight properties of plastic with enhanced strength and durability. It is increasingly being adopted in food processing equipment due to its resistance to corrosion and ease of cleaning.

Pros:

– High strength-to-weight ratio.

– Excellent resistance to chemicals and moisture.

– Lightweight and easy to mold into complex shapes.

Cons:

– Higher manufacturing complexity and cost compared to standard plastics.

– May require specialized handling due to its composite nature.

Impact on Application:

GFRP rice washers are suitable for both commercial and industrial applications, providing durability without the weight of metal. They are particularly beneficial in environments where corrosion is a concern.

Considerations for International Buyers:

As with other materials, buyers should ensure that GFRP complies with food safety standards and is suitable for the specific cleaning processes involved in rice washing.

Summary Table of Material Selection for Rice Washers

| Material | Typical Use Case for Rice Washer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial rice washing | High durability and corrosion resistance | Higher initial cost | High |

| Plastic | Household or small-scale use | Cost-effective and lightweight | Less durable than metals | Low |

| Aluminum | Medium-scale operations | Lightweight with good corrosion resistance | Not as strong as stainless steel | Medium |

| Glass Fiber Reinforced Plastic | Commercial and industrial use | High strength-to-weight ratio | Higher manufacturing complexity | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the advantages and limitations of various materials used in rice washers, ensuring informed purchasing decisions that align with operational needs and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for rice washer

What Are the Key Stages in the Manufacturing Process of Rice Washers?

The manufacturing process for rice washers involves several critical stages that ensure the final product meets the stringent demands of commercial use. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with sourcing high-quality materials such as stainless steel, plastics, and silicone. Stainless steel is often preferred for its durability and resistance to corrosion, which is essential for equipment that will frequently come into contact with water. Suppliers must ensure that the materials meet international standards for food safety and hygiene.

Forming: This stage involves shaping the materials into the desired components of the rice washer. Techniques such as stamping, injection molding, and laser cutting are commonly employed. For example, the forming of stainless steel components may involve precision stamping to create parts that fit together seamlessly, ensuring both functionality and aesthetic appeal.

Assembly: Once the components are formed, they are assembled into the final product. This process can be manual or automated, depending on the complexity of the design. An efficient assembly line is crucial for maintaining production speed while ensuring each unit meets quality specifications. Specialized tools and fixtures may be used to ensure accuracy and consistency during assembly.

Illustrative image related to rice washer

Finishing: The final stage includes polishing, coating, and quality checks. Polishing is essential for stainless steel parts to enhance their appearance and remove any sharp edges. Coatings may be applied to prevent corrosion and enhance durability. This stage often includes final inspections to ensure that the product adheres to design specifications and is ready for market.

How Is Quality Assurance Implemented During the Manufacturing of Rice Washers?

Quality assurance is critical in the manufacturing of rice washers, particularly for B2B buyers who require reliable and efficient equipment. Adherence to international and industry-specific standards is a cornerstone of this process.

International Standards: Many manufacturers adhere to ISO 9001, which sets out criteria for a quality management system. This certification ensures that products consistently meet customer and regulatory requirements. Compliance with CE marking is also essential for products sold in Europe, indicating conformity with health, safety, and environmental protection standards.

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process. Key QC stages include:

Illustrative image related to rice washer

-

Incoming Quality Control (IQC): This initial inspection ensures that raw materials and components meet specified standards before they enter production. Suppliers are often required to provide certificates of compliance to verify the quality of materials.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks are performed to monitor the production process. This may include measuring tolerances and verifying that assembly procedures are followed correctly.

-

Final Quality Control (FQC): After assembly, each rice washer undergoes a final inspection to assess its overall functionality and safety. This includes testing for leaks, ensuring that all components operate correctly, and verifying that the product meets all design specifications.

What Testing Methods Are Commonly Used to Ensure Quality in Rice Washers?

Testing methods play a vital role in the quality assurance of rice washers. Manufacturers often employ various techniques to validate the performance, safety, and durability of their products.

Performance Testing: Rice washers are typically tested for their ability to clean rice effectively. This involves running multiple cycles with different types of rice and measuring the clarity of the water after rinsing. Manufacturers may also assess the washing time and water consumption to ensure efficiency.

Safety Testing: Safety tests are crucial for compliance with regulatory standards. These tests check for electrical safety (if applicable), mechanical safety, and durability under various conditions. For instance, a rice washer that uses high water pressure must be tested for structural integrity to prevent any failure during operation.

Durability Testing: This involves subjecting the rice washer to prolonged use conditions to evaluate its lifespan. Manufacturers may simulate years of use within a shorter timeframe to determine how the product holds up under stress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Buyers can adopt several strategies to ensure their suppliers maintain high standards.

Audits: Conducting regular audits of suppliers’ manufacturing facilities is one of the most effective ways to assess their quality control practices. Audits can reveal the processes in place, adherence to standards, and overall operational efficiency. Buyers can either perform these audits in-house or hire third-party auditors for an unbiased evaluation.

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their manufacturing processes and QC measures. These reports should include information about testing results, compliance certifications, and any non-conformance issues that may have arisen during production.

Third-Party Inspections: Engaging third-party inspection services can provide additional assurance of product quality. These services can conduct inspections at various stages of the manufacturing process, ensuring that products meet specified standards before shipment.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances in quality control when sourcing rice washers from different regions. Understanding these nuances can help buyers make informed decisions and avoid potential issues.

Regulatory Compliance: Different regions may have varying standards and regulations for food-related equipment. Buyers should familiarize themselves with the specific requirements applicable in their target markets. For example, products sold in the European Union must comply with CE standards, while those in the U.S. may need to meet FDA requirements.

Cultural Considerations: Cultural attitudes towards quality and compliance can differ significantly across regions. Buyers should engage with suppliers who understand and prioritize quality assurance, as this can affect the reliability of the products received.

Supply Chain Transparency: Establishing clear communication channels with suppliers is essential for maintaining quality. Buyers should seek suppliers who are willing to share information about their sourcing and manufacturing processes, fostering a transparent supply chain.

By focusing on these aspects, B2B buyers can enhance their procurement strategies, ensuring they invest in high-quality rice washers that meet their operational needs and comply with regional standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rice washer’

In the competitive landscape of rice processing, sourcing the right rice washer is critical for ensuring quality and efficiency in operations. This guide offers a structured approach to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as the volume of rice processed per cycle, the type of rice (e.g., white, brown), and the specific cleaning needs (e.g., removal of starch or impurities). Having a clear understanding of your needs will help you narrow down options and communicate effectively with suppliers.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers. Look for companies that specialize in rice processing equipment and have a proven track record in your target regions, such as Africa, South America, or Europe. Utilize industry directories, trade shows, and online platforms to compile a list of reputable suppliers.

- Tip: Prioritize suppliers with local representation or support teams to facilitate easier communication and service.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards that suppliers adhere to. Certifications such as ISO, NSF, or IAPMO can indicate a commitment to quality and safety. Additionally, check if the equipment meets local regulatory requirements relevant to your region.

- Importance: Ensuring compliance with these standards not only guarantees the safety of your operations but also enhances your product’s marketability.

Step 4: Request Product Demonstrations

Engage with shortlisted suppliers to arrange product demonstrations or trials. This step allows you to assess the rice washer’s performance firsthand. Pay attention to the efficiency of the washing process, the quality of rice post-wash, and ease of use.

- What to Look For: Ensure the demonstration showcases the machine’s ability to remove contaminants without compromising the rice’s integrity.

Step 5: Compare Pricing and Terms

Once you have a shortlist of potential suppliers, compare their pricing structures and terms of sale. Consider not only the upfront cost of the rice washer but also long-term operational costs, including maintenance, spare parts, and energy consumption.

- Cost Consideration: A lower initial price might not always translate to lower total cost of ownership. Evaluate the long-term value proposition.

Step 6: Check References and Reviews

Before finalizing your decision, reach out to references provided by the suppliers. Speak with other businesses that have purchased similar equipment and inquire about their experiences regarding reliability, performance, and customer service.

Illustrative image related to rice washer

- Why This Matters: Genuine feedback from current users can provide invaluable insights into the supplier’s operational practices and product performance.

Step 7: Negotiate Contracts and Warranty Terms

Once you’ve selected a supplier, focus on negotiating contract terms, including delivery schedules, payment terms, and warranty conditions. Ensure that the warranty covers critical components and offers adequate support in case of equipment failure.

- Key Point: A strong warranty can safeguard your investment and ensure uninterrupted operations in the event of unforeseen issues.

By following this checklist, B2B buyers can make informed decisions when sourcing rice washers, ultimately enhancing their operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for rice washer Sourcing

What Are the Key Cost Components in Rice Washer Manufacturing?

When sourcing rice washers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the overall cost. Stainless steel, for example, is more expensive but offers durability and resistance to corrosion. Additionally, specialized components like silicone handles or advanced filtration systems can increase material costs.

-

Labor: Labor costs vary by region and can affect both the manufacturing process and assembly. In countries with lower labor costs, like some regions in Southeast Asia, the overall price of rice washers might be more competitive.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, thus lowering the price for buyers.

-

Tooling: Custom tooling for specific designs or features can add to initial costs but may be necessary for unique requirements. Buyers should consider whether the investment in tooling will pay off through improved efficiency or product differentiation.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards and certifications. While this can add to costs, it is essential for maintaining quality and reducing the risk of returns or defects.

-

Logistics: Shipping and handling costs can vary greatly depending on the origin and destination of the rice washers. Factors such as distance, shipping method, and the current state of global logistics can significantly influence overall pricing.

-

Margin: Manufacturers typically add a margin to cover their expenses and generate profit. Understanding average margins in the industry can help buyers gauge whether a quoted price is reasonable.

How Do Price Influencers Affect Rice Washer Costs?

Several factors influence the pricing of rice washers, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have tiered pricing structures, so understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom features or specifications may increase costs. Buyers should clearly define their requirements to ensure accurate quotes.

-

Material Quality and Certifications: Higher quality materials or compliance with international certifications (such as NSF or ISO) can raise costs. However, these certifications may be necessary for specific markets, making them worthwhile investments.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their experience and quality assurance, while less-known manufacturers might offer lower prices but come with higher risks.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate who bears shipping costs, insurance, and responsibilities at various stages of the shipping process. Understanding these terms is vital for accurate cost assessments.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Rice Washers?

To optimize sourcing strategies and reduce costs, buyers should consider the following tips:

-

Negotiation Strategies: Always negotiate prices and terms with suppliers. Leverage competitive quotes from multiple suppliers to drive down costs.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, energy consumption, and potential downtime. A slightly higher initial investment may lead to lower overall costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that may affect final costs. Engaging with local experts or consultants can provide insights into specific market dynamics.

-

Research Local Regulations: Understanding local regulations regarding food safety and equipment standards can help prevent costly compliance issues in the future.

In conclusion, sourcing rice washers involves navigating a complex landscape of costs and pricing factors. By understanding these components and employing effective negotiation strategies, B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices can vary widely, so thorough research and supplier engagement are essential for successful procurement.

Alternatives Analysis: Comparing rice washer With Other Solutions

Exploring Alternatives to Rice Washers: An In-Depth Comparison

When considering rice washing solutions, it’s essential to evaluate alternatives that can effectively achieve similar results while catering to different operational needs. This analysis compares rice washers with two viable alternatives: traditional manual rinsing and automated rinsing systems. Each option presents unique advantages and drawbacks, making it crucial for B2B buyers to understand which solution aligns best with their requirements.

| Comparison Aspect | Rice Washer | Traditional Manual Rinsing | Automated Rinsing System |

|---|---|---|---|

| Performance | Cleans rice efficiently in under 5 minutes | Varies; can be inconsistent and time-consuming | High efficiency, consistent results |

| Cost | Moderate initial investment | Low upfront cost, but labor-intensive | High initial cost, potential for long-term savings |

| Ease of Implementation | Simple setup; requires water source | Requires minimal equipment | Requires significant installation and setup |

| Maintenance | Low maintenance; minimal parts | Low maintenance; manual cleaning needed | Higher maintenance; requires regular servicing |

| Best Use Case | Ideal for commercial kitchens and restaurants | Suitable for small-scale or home use | Best for large-scale operations and processing facilities |

What Are the Pros and Cons of Traditional Manual Rinsing?

Traditional manual rinsing involves using a colander or strainer to wash rice by hand. This method is low-cost and requires no specialized equipment, making it accessible for small businesses or home kitchens. However, it can be labor-intensive, requiring significant time and effort to achieve the desired cleanliness. The effectiveness of manual rinsing can vary, leading to inconsistent results, especially when large quantities of rice are involved.

How Do Automated Rinsing Systems Compare?

Automated rinsing systems represent a more sophisticated alternative, designed for high-volume processing. These systems can handle large batches of rice with minimal human intervention, ensuring consistent quality and efficiency. While the initial investment is substantial, the potential for long-term savings through reduced labor costs and higher throughput can make them a worthwhile consideration for larger operations. However, they require more complex installation and ongoing maintenance, which can be a disadvantage for smaller businesses.

Conclusion: How Should B2B Buyers Decide on the Right Rice Washing Solution?

Choosing the right rice washing solution ultimately depends on the specific needs and operational context of the buyer. For small businesses or home kitchens, traditional manual rinsing may suffice due to its low cost and simplicity. Conversely, commercial kitchens and large-scale operations may benefit from the efficiency and consistency of rice washers or automated systems, despite the higher initial investment. By carefully assessing performance, cost, ease of implementation, and maintenance needs, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for rice washer

When considering the procurement of rice washers, understanding the essential technical properties and industry terminology is crucial for making informed decisions. This section outlines key specifications and terms that B2B buyers should be familiar with to enhance their purchasing strategy.

What Are the Key Technical Properties of Rice Washers?

-

Material Grade

The material used in rice washers can significantly affect durability and performance. Common materials include stainless steel and high-grade plastics, which resist corrosion and wear. For B2B buyers, selecting a rice washer made from high-quality materials ensures longevity and reduces maintenance costs, making it a wise investment. -

Washing Capacity

This specification indicates the volume of rice that can be washed in a single cycle, typically measured in kilograms or pounds. For example, some commercial rice washers can handle 5-7.5 kg (11-16.5 lbs) of rice at once. Understanding washing capacity is essential for businesses that process large volumes of rice, as it directly impacts operational efficiency and throughput. -

Water Pressure Requirements

Most commercial rice washers require a specific water pressure to operate effectively, often around 40 psi (pounds per square inch). This property is vital for ensuring that the machine functions optimally. Buyers should ensure that their water supply meets these requirements to avoid operational inefficiencies. -

Cycle Time

The time it takes to complete a washing cycle is crucial for high-volume operations. Many modern rice washers can complete a wash in under five minutes. A shorter cycle time enhances productivity, allowing businesses to process more rice in a given timeframe. -

Energy Efficiency

Energy consumption is a critical consideration, especially in regions where energy costs are high. Many rice washers are designed to operate using water pressure alone, minimizing electricity usage. B2B buyers should prioritize energy-efficient models to reduce operational costs and environmental impact. -

Certification Standards

Certifications such as NSF (National Sanitation Foundation) or IAPMO (International Association of Plumbing and Mechanical Officials) ensure that the equipment meets health and safety standards. For businesses, investing in certified rice washers can enhance their credibility and ensure compliance with local regulations.

What Are Common Trade Terms Related to Rice Washers?

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. For rice washers, understanding OEM relationships can help buyers evaluate the quality and reliability of the equipment they are purchasing. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For rice washers, knowing the MOQ is essential for budgeting and inventory planning, particularly for startups or smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for a specific product. B2B buyers should utilize RFQs to compare costs, specifications, and delivery options for rice washers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and logistics associated with purchasing rice washers from abroad. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times for rice washers is vital for inventory management and ensuring that production schedules are met without delays. -

Warranty Terms

Warranty terms outline the manufacturer’s commitment to repair or replace defective products within a specified period. Buyers should carefully review warranty conditions to protect their investment and ensure peace of mind regarding product reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when selecting rice washers, ultimately leading to enhanced operational efficiency and cost-effectiveness in their businesses.

Navigating Market Dynamics and Sourcing Trends in the rice washer Sector

What Are the Key Trends Shaping the Global Rice Washer Market?

The rice washer market is witnessing significant growth driven by rising consumer awareness regarding food quality and the increasing demand for efficient food processing machinery. Key trends include the adoption of advanced technologies such as water-efficient systems and automated processes that enhance productivity while minimizing labor costs. In regions like Africa and South America, where rice is a staple food, there is a growing emphasis on machinery that not only improves washing efficiency but also preserves the quality and flavor of rice.

Emerging B2B technologies, such as IoT-enabled appliances, are beginning to penetrate the market, offering real-time monitoring and maintenance alerts, which can significantly reduce downtime in commercial operations. Furthermore, sustainable sourcing is becoming increasingly important, with buyers prioritizing equipment that utilizes less water and energy. This aligns with global sustainability goals and the demand for eco-friendly practices. In Europe and the Middle East, regulatory frameworks are pushing manufacturers toward compliance with stringent environmental standards, leading to the development of innovative and sustainable rice washing solutions.

How Can Sustainability and Ethical Sourcing Impact B2B Transactions in the Rice Washer Sector?

As the global economy shifts towards sustainability, B2B buyers are increasingly focused on the environmental impact of their purchases. The rice washer sector is no exception, with a growing demand for equipment that minimizes water usage and energy consumption. Efficient rice washers, such as those that utilize innovative water recycling systems, not only help conserve resources but also reduce operational costs for businesses.

Moreover, ethical sourcing is critical in today’s market. Buyers are urged to ensure that their suppliers adhere to fair labor practices and environmentally friendly manufacturing processes. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of recyclable materials in the production of rice washers is becoming a key consideration, as buyers seek to align their procurement strategies with broader corporate social responsibility goals. Implementing these sustainable practices can enhance brand reputation and customer loyalty, which are essential for long-term success in the competitive B2B landscape.

What Is the Historical Context of Rice Washers in B2B Markets?

The evolution of rice washers has its roots in traditional practices where manual washing methods were the norm. Historically, rice was washed using simple techniques that often resulted in poor quality due to the reabsorption of contaminants. The development of mechanical rice washers in the mid-20th century marked a significant shift, as these machines introduced efficiency and consistency to the washing process.

Over the years, advancements in technology have led to the creation of sophisticated rice washing systems that not only improve cleaning efficiency but also enhance the flavor and texture of the rice. Today, the focus is on integrating automation and sustainability into the design of rice washers, reflecting the changing needs of B2B buyers who are looking for reliable, efficient, and environmentally responsible solutions. This historical context highlights the ongoing transformation in the rice washer sector and underscores the importance of innovation in meeting the demands of modern food processing industries.

Frequently Asked Questions (FAQs) for B2B Buyers of rice washer

-

How do I select the right rice washer for my business?

When choosing a rice washer, consider the capacity you need based on your production volume. Look for features that enhance efficiency, such as quick wash cycles and effective dirt removal systems. Additionally, assess the water usage and energy efficiency of the machine. Supplier certifications, such as NSF or IAPMO, can indicate quality and reliability. It’s also crucial to factor in the machine’s adaptability to your existing setup and its maintenance requirements. -

What are the advantages of using a commercial rice washer?

Commercial rice washers provide numerous benefits, including time savings, improved rice quality, and reduced water waste. They are designed to handle larger quantities and can wash rice thoroughly without reintroducing contaminants. Many models are built for durability and efficiency, allowing for continuous operation in a busy environment. Investing in a commercial washer can ultimately lead to better product quality and customer satisfaction, especially in regions with high rice consumption. -

What should I consider regarding supplier reliability for rice washers?

When vetting suppliers, check their reputation in the industry through reviews, testimonials, and case studies. It’s essential to ensure they have a proven track record of delivering quality products and reliable after-sales support. Request samples or demonstrations to assess product quality firsthand. Additionally, inquire about their compliance with international standards and certifications, which can be particularly important for businesses in regions such as Africa and South America. -

What is the typical minimum order quantity (MOQ) for rice washers?

MOQs for rice washers can vary significantly based on the manufacturer and model. Generally, commercial suppliers may set MOQs ranging from one to several units to ensure production efficiency. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are starting small. Some suppliers may also offer flexible options for first-time buyers or bulk orders. -

Are there customization options available for rice washers?

Many manufacturers offer customization options to cater to specific operational needs. Customizations can include size adjustments, enhanced features for water management, or modifications for unique washing processes. When discussing your requirements, provide detailed specifications to ensure the final product meets your expectations. Collaborating closely with the supplier can lead to a tailored solution that enhances your production capabilities. -

What payment terms are standard for international purchases of rice washers?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due prior to shipment. Some suppliers may also offer letters of credit or payment through escrow services to secure transactions. It’s crucial to establish clear payment terms and conditions before finalizing your order to avoid any misunderstandings. Additionally, consider the currency exchange rates and international transaction fees when budgeting. -

What quality assurance measures should I expect from rice washer suppliers?

Reputable suppliers will implement strict quality assurance protocols to ensure their rice washers meet industry standards. Expect to see certifications and test reports that verify product performance and safety. Some manufacturers may offer warranties or guarantees, indicating their confidence in the product’s durability. Additionally, inquire about their quality control processes, including inspections during production and before shipping. -

How can I manage logistics and shipping for international orders of rice washers?

Managing logistics for international orders involves coordinating shipping methods, customs clearance, and delivery timelines. Work with suppliers who have experience in international shipping to streamline the process. It’s advisable to choose reliable shipping partners and consider incoterms that define responsibilities for both parties. Be prepared to handle customs duties and import regulations specific to your country, as these can affect overall costs and delivery times.

Top 2 Rice Washer Manufacturers & Suppliers List

1. Korin – High-Efficiency Rice Cooker

Domain: korin.com

Registered: 1998 (27 years)

Introduction: This company, Korin – High-Efficiency Rice Cooker, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. JC Unitec – MJP Rice Washer

Domain: jcunitec.com

Registered: 2008 (17 years)

Introduction: {‘product_name’: ‘MJP Rice Washer’, ‘type’: ‘Commercial rice washer’, ‘capacity’: ‘5-7.5kg (50 cups; Japanese measurement)’, ‘cleaning_method’: ‘Mixed air Jet Pump (MJP)’, ‘features’: [{‘enhances_flavor’: “Discards contaminated wash water to prevent reabsorption of ‘nuka’ (mucus), resulting in richer flavor.”}, {‘water_saving’: ‘Uses only 3-5 times the volume of water equal to the rice being washe…

Strategic Sourcing Conclusion and Outlook for rice washer

In today’s competitive landscape, the strategic sourcing of rice washers is essential for businesses aiming to enhance operational efficiency and product quality. The variety of rice washers available—from advanced models like the MJP Rice Washer, which optimizes water usage and time, to simpler designs catering to smaller scales—offers options that can meet diverse needs across different markets. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the unique advantages of each model can lead to more informed purchasing decisions that align with their operational goals.

Investing in high-quality rice washers not only improves the washing process but also enhances the flavor and quality of the rice, ultimately leading to greater customer satisfaction. As global demand for rice continues to rise, so does the necessity for efficient and effective washing solutions.

Looking forward, it is crucial for international buyers to engage with suppliers who prioritize innovation and sustainability in their product offerings. By fostering strategic partnerships with reputable manufacturers, businesses can ensure they are well-equipped to meet market demands while optimizing their supply chains. Take the next step in elevating your rice processing capabilities—explore your options and make an informed choice today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.