Is Your Quartz Window Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for quartz window

In the rapidly evolving landscape of architectural solutions, sourcing high-quality quartz windows poses significant challenges for international B2B buyers. Whether you’re in Brazil, Nigeria, or any corner of Europe, navigating the complexities of material specifications, supplier reliability, and application requirements can be daunting. This comprehensive guide is designed to demystify the global market for quartz windows, providing insights into various types, applications, and essential factors to consider when making purchasing decisions.

From luxury residential designs to robust commercial applications, quartz windows are increasingly favored for their superior thermal efficiency and aesthetic appeal. This guide covers a wide range of topics, including the different types of quartz windows available, their specific applications across industries, and crucial aspects of supplier vetting to ensure quality and reliability. Additionally, we will address cost considerations and market trends that can influence your purchasing strategies.

By equipping B2B buyers with the necessary knowledge and tools, this guide empowers you to make informed decisions that align with your project needs and budget constraints. Whether you’re looking to enhance the visual impact of a luxury home or seeking durable solutions for industrial use, understanding the nuances of quartz windows will be key to your success in the competitive global market.

Understanding quartz window Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Quartz Windows | High thermal stability, excellent UV transmission | Optical instruments, semiconductor equipment | Pros: High durability; Cons: Higher cost than glass |

| Optical Quartz Windows | Customizable shapes and sizes, high clarity | Laboratory equipment, photonics | Pros: Tailored solutions; Cons: Longer lead times |

| Commercial Quartz Windows | Standardized sizes, robust construction | Industrial applications, sight glasses | Pros: Cost-effective; Cons: Limited customization |

| Specialty Quartz Windows | Specific coatings for enhanced performance | Medical devices, scientific research | Pros: Enhanced functionality; Cons: Potentially higher prices |

| Quartz Insulating Windows | Superior thermal insulation properties | Energy-efficient buildings, HVAC systems | Pros: Energy savings; Cons: Installation complexity |

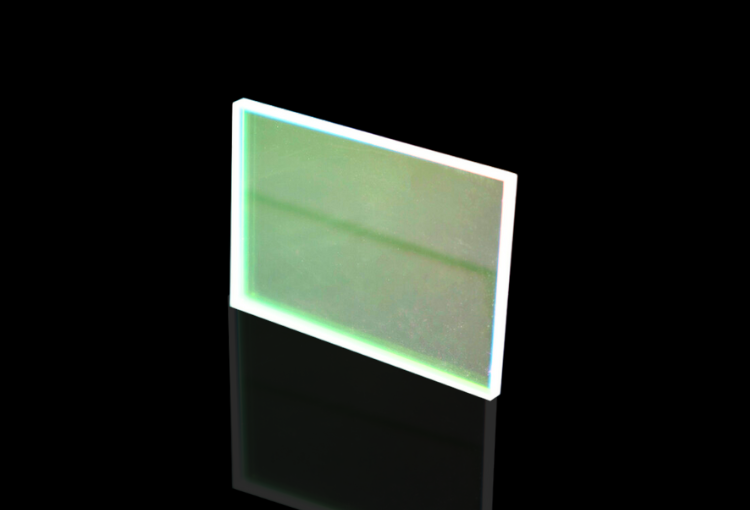

What Are Fused Quartz Windows and Their Key Benefits for B2B Buyers?

Fused quartz windows are known for their exceptional thermal stability and ability to transmit UV light effectively. These windows are suitable for applications in optical instruments and semiconductor manufacturing, where precision and durability are paramount. B2B buyers should consider the long-term durability and performance benefits, although they may come at a higher price point compared to traditional glass options.

How Do Optical Quartz Windows Stand Out for Custom Solutions?

Optical quartz windows offer customization in terms of shape and size, making them ideal for laboratory equipment and photonics applications. Their high clarity ensures minimal distortion, which is crucial for scientific measurements. Buyers should weigh the advantages of tailored solutions against potential longer lead times, which could affect project timelines.

Illustrative image related to quartz window

What Are the Advantages of Commercial Quartz Windows for Industrial Use?

Commercial quartz windows are designed for robustness and standardized sizes, making them a practical choice for industrial applications like sight glasses. Their cost-effectiveness makes them appealing for bulk purchasing, though buyers should be aware that the options for customization may be limited. This can be a deciding factor depending on specific project requirements.

Why Choose Specialty Quartz Windows for Advanced Applications?

Specialty quartz windows come with specific coatings that enhance their performance in demanding environments, such as medical devices and scientific research. While these windows provide significant functional advantages, including enhanced transmission and protection against environmental factors, buyers should also consider the potential for higher costs associated with these specialized products.

How Do Quartz Insulating Windows Contribute to Energy Efficiency?

Quartz insulating windows are designed to provide superior thermal insulation, making them an excellent choice for energy-efficient buildings and HVAC systems. These windows help reduce energy consumption, leading to cost savings in the long run. However, the complexity of installation can be a drawback, and buyers should ensure they have access to skilled professionals for proper fitting.

Key Industrial Applications of quartz window

| Industry/Sector | Specific Application of quartz window | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Semiconductor Manufacturing | Optical Windows for Photolithography | High precision and clarity for intricate circuit designs | Ensure high transmission rates and custom sizes are available |

| Aerospace | Sight Glasses for Aircraft Instruments | Enhanced durability and resistance to extreme conditions | Look for quartz with high thermal stability and low weight |

| Renewable Energy | Solar Panel Glass Enclosures | Improved energy efficiency and UV resistance | Sourcing should focus on anti-reflective coatings |

| Medical Equipment | Windows for Diagnostic Imaging Devices | Superior optical clarity and resistance to sterilization | Verify quality standards and certifications for safety |

| Research Laboratories | Windows for Laser Systems | Minimal distortion and high transmission for accurate results | Consider custom shapes and sizes, along with coating options |

How Is Quartz Window Used in Semiconductor Manufacturing?

In semiconductor manufacturing, quartz windows are critical for photolithography processes, where they facilitate the precise transfer of circuit patterns onto silicon wafers. The high optical clarity and transmission rates of quartz ensure that intricate designs are accurately replicated, reducing defects and enhancing yield. B2B buyers in this sector must prioritize sourcing quartz windows that meet stringent standards for size and optical performance, as even minor deviations can lead to significant production losses.

What Role Do Quartz Windows Play in Aerospace Applications?

Quartz windows serve as sight glasses in various aircraft instruments, providing pilots with essential visibility of critical readings. Their exceptional durability and resistance to extreme temperatures make them ideal for aerospace applications, where reliability is paramount. Buyers in this industry should focus on sourcing lightweight quartz windows that can withstand high pressures and harsh environments, ensuring safety and performance in flight operations.

How Are Quartz Windows Beneficial for Renewable Energy Solutions?

In the renewable energy sector, quartz windows are often used in solar panel enclosures, where they enhance energy efficiency by allowing maximum light transmission while resisting UV degradation. This application is crucial for maintaining the longevity and effectiveness of solar technology. International buyers should look for quartz windows with anti-reflective coatings to optimize performance and increase energy yield, especially in regions with high solar exposure.

What Applications Exist for Quartz Windows in Medical Equipment?

Quartz windows are integral to diagnostic imaging devices, such as X-ray and ultrasound machines, where they provide superior optical clarity and are resistant to sterilization processes. This is essential for maintaining hygiene and accuracy in medical environments. B2B buyers must ensure that the quartz sourced complies with medical safety standards and offers the necessary optical properties to support precise imaging.

Why Are Quartz Windows Important in Research Laboratories?

In research laboratories, quartz windows are used in laser systems, where minimal optical distortion is crucial for accurate experimental results. The high transmission rates of quartz facilitate effective light propagation, which is essential in various scientific applications. Buyers in this field should consider sourcing custom-shaped quartz windows to fit specific experimental setups, along with options for specialized coatings that enhance performance.

3 Common User Pain Points for ‘quartz window’ & Their Solutions

Scenario 1: Challenges in Sourcing High-Quality Quartz Windows

The Problem: B2B buyers often struggle with sourcing high-quality quartz windows that meet specific performance criteria, especially in markets where standards may vary. For instance, buyers in regions like Africa or South America may encounter difficulties in finding suppliers who can provide quartz windows that not only comply with local regulations but also offer superior thermal efficiency and durability. This lack of access can lead to project delays and increased costs, impacting overall project timelines and budgets.

Illustrative image related to quartz window

The Solution: To effectively source high-quality quartz windows, B2B buyers should begin by conducting comprehensive market research to identify reputable suppliers with a proven track record in providing luxury fenestration solutions. It’s crucial to request detailed specifications, including thermal performance ratings, UV resistance, and mechanical durability. Establishing a relationship with suppliers who offer customization options can further ensure that the windows meet unique architectural demands. Additionally, attending industry trade shows or exhibitions can facilitate direct interactions with manufacturers and provide valuable insights into the latest innovations and materials in quartz window technology.

Scenario 2: Navigating Installation Complexities of Quartz Windows

The Problem: Even when high-quality quartz windows are sourced, B2B buyers often face installation challenges that can compromise the integrity and performance of the product. For example, improper installation techniques can lead to air leaks, reduced energy efficiency, and potential damage during extreme weather conditions. This issue is especially pronounced in regions with diverse climates, such as the Middle East and Europe, where temperature fluctuations can be extreme.

The Solution: To navigate installation complexities, buyers should engage with experienced contractors who specialize in quartz window installation. It’s advisable to ensure that the installation team is familiar with the specific requirements of quartz materials, including the appropriate handling techniques to avoid damage. Providing thorough training or access to installation guidelines from the manufacturer can also be beneficial. Furthermore, implementing a quality assurance process during installation can help identify and rectify potential issues early on, ensuring that the windows function optimally and provide the desired energy efficiency benefits.

Illustrative image related to quartz window

Scenario 3: Addressing Aesthetic and Design Compatibility Issues

The Problem: A significant pain point for B2B buyers is ensuring that quartz windows align aesthetically with their overall architectural vision. In many cases, buyers may find that the available designs do not complement the existing structures or the intended style, which can lead to dissatisfaction and the need for costly modifications. This is particularly relevant in regions with rich architectural heritages, like Europe, where design consistency is paramount.

The Solution: To address aesthetic compatibility issues, buyers should work closely with architects and designers during the selection process of quartz windows. Engaging in collaborative design workshops can help align the window styles with the architectural narrative. Buyers should also explore manufacturers that offer a variety of customizable options in terms of color, shape, and finish. This flexibility allows for better integration of quartz windows into the overall design, ensuring that they enhance rather than detract from the architectural vision. Additionally, leveraging advanced visualization tools, such as CAD software, can assist in visualizing how different window styles will look in the intended setting, making the selection process more informed and effective.

Strategic Material Selection Guide for quartz window

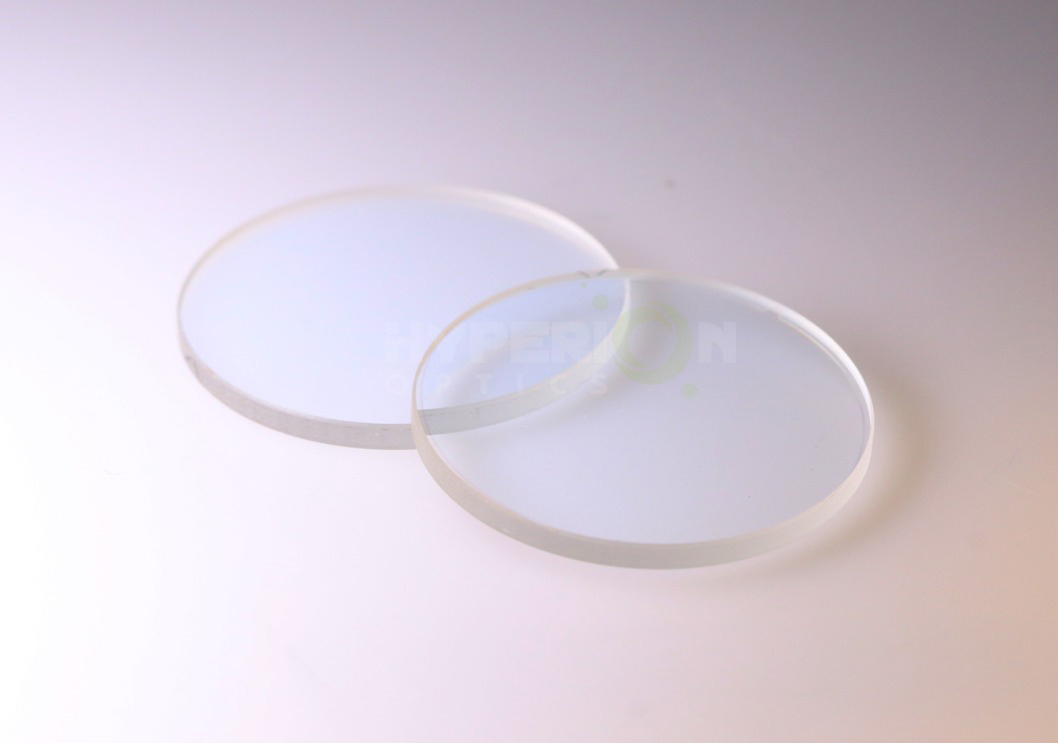

What Are the Key Properties of Common Materials Used for Quartz Windows?

In the realm of quartz windows, material selection is critical to ensure optimal performance across various applications. Here, we analyze four common materials: Fused Quartz, UV Fused Silica, Crystal Quartz, and IR Fused Quartz. Each material presents unique properties that influence their suitability for specific applications.

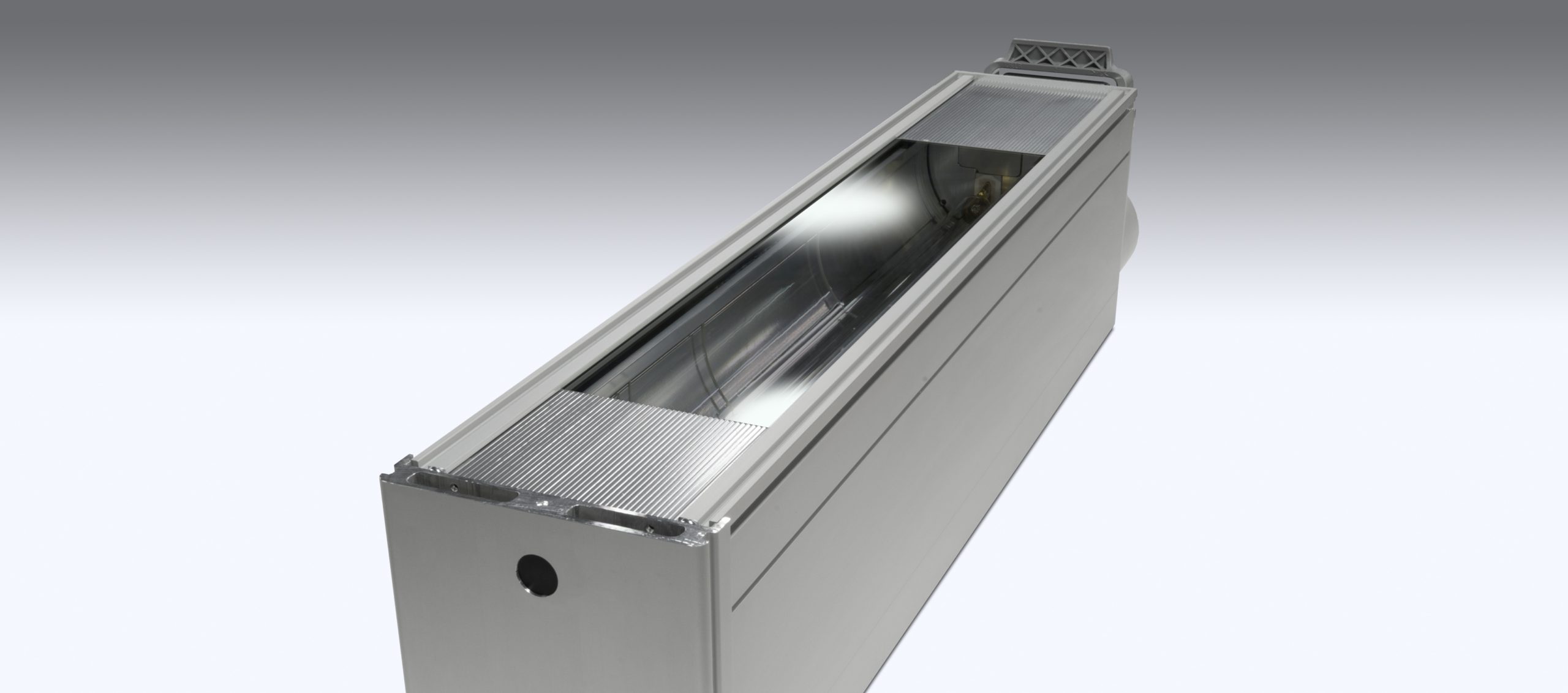

Fused Quartz: Versatile and Resilient

Fused quartz is known for its high thermal stability, withstanding temperatures up to 1050°C. It boasts excellent optical clarity, with over 80% transmission from 260 nm to 2500 nm, making it ideal for a range of UV applications. However, it is less effective at wavelengths below 250 nm, where transmission drops significantly.

Pros:

– Exceptional thermal and chemical resistance.

– High optical clarity and transmission.

– Customizable shapes and sizes.

Illustrative image related to quartz window

Cons:

– Higher manufacturing complexity due to the need for precision shaping.

– Cost can be prohibitive for large-scale applications.

Impact on Application:

Fused quartz is suitable for high-temperature environments and UV applications, such as lasers and optical devices. Buyers should consider the specific wavelength requirements of their application.

Considerations for International Buyers:

Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America may face additional logistical challenges in sourcing high-quality fused quartz.

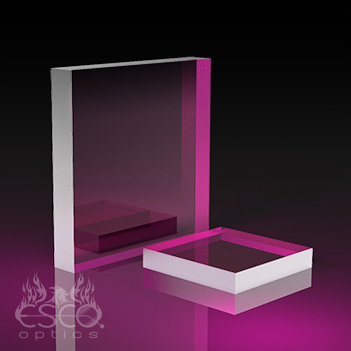

UV Fused Silica: Optimal for Deep UV Applications

UV fused silica is specifically engineered for deep UV applications, maintaining high transmission rates down to 175 nm. It is an excellent choice for photolithography and other precision optical applications.

Pros:

– Outstanding UV transmission properties.

– High resistance to thermal shock.

– Excellent surface quality.

Illustrative image related to quartz window

Cons:

– More expensive than standard fused quartz.

– Limited availability in certain regions.

Impact on Application:

Ideal for semiconductor manufacturing and other high-precision industries, UV fused silica is essential where deep UV light is utilized.

Considerations for International Buyers:

Buyers must ensure that suppliers adhere to strict quality standards, particularly in regions with less stringent regulations. Understanding local preferences for UV applications is also beneficial.

Crystal Quartz: Natural Elegance and Stability

Crystal quartz is prized for its natural beauty and stability. It offers good thermal stability and is often used for decorative applications as well as functional windows.

Pros:

– Aesthetic appeal due to natural patterns.

– Good thermal and chemical resistance.

– Relatively easy to source.

Cons:

– Lower thermal resistance compared to fused quartz.

– More expensive due to its natural sourcing.

Impact on Application:

Crystal quartz is suitable for applications where aesthetics are paramount, such as luxury architectural designs.

Considerations for International Buyers:

Buyers should be aware of the sourcing implications and ensure compliance with environmental regulations in their region, especially in Europe where sustainability is a priority.

IR Fused Quartz: Specialized for Infrared Applications

IR fused quartz is designed for applications involving infrared light, maintaining clarity and strength at elevated temperatures.

Pros:

– Excellent infrared transmission.

– High thermal stability.

– Durable against thermal shock.

Cons:

– Limited to infrared applications, which may restrict versatility.

– Higher production costs.

Impact on Application:

Ideal for infrared spectroscopy and thermal imaging, IR fused quartz is crucial in scientific and industrial applications requiring infrared transparency.

Considerations for International Buyers:

Understanding the specific needs of the local market for infrared applications can guide procurement decisions. Compliance with local and international standards is also essential.

Summary Table of Material Selection for Quartz Windows

| Material | Typical Use Case for quartz window | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fused Quartz | UV applications, lasers | High thermal and chemical resistance | Complex manufacturing process | High |

| UV Fused Silica | Semiconductor manufacturing | Outstanding UV transmission | Limited regional availability | High |

| Crystal Quartz | Decorative and functional windows | Aesthetic appeal | Lower thermal resistance | Med |

| IR Fused Quartz | Infrared spectroscopy | Excellent infrared transmission | Limited application versatility | High |

This guide provides a comprehensive overview of the materials used in quartz windows, helping international B2B buyers make informed decisions based on their specific requirements and regional considerations.

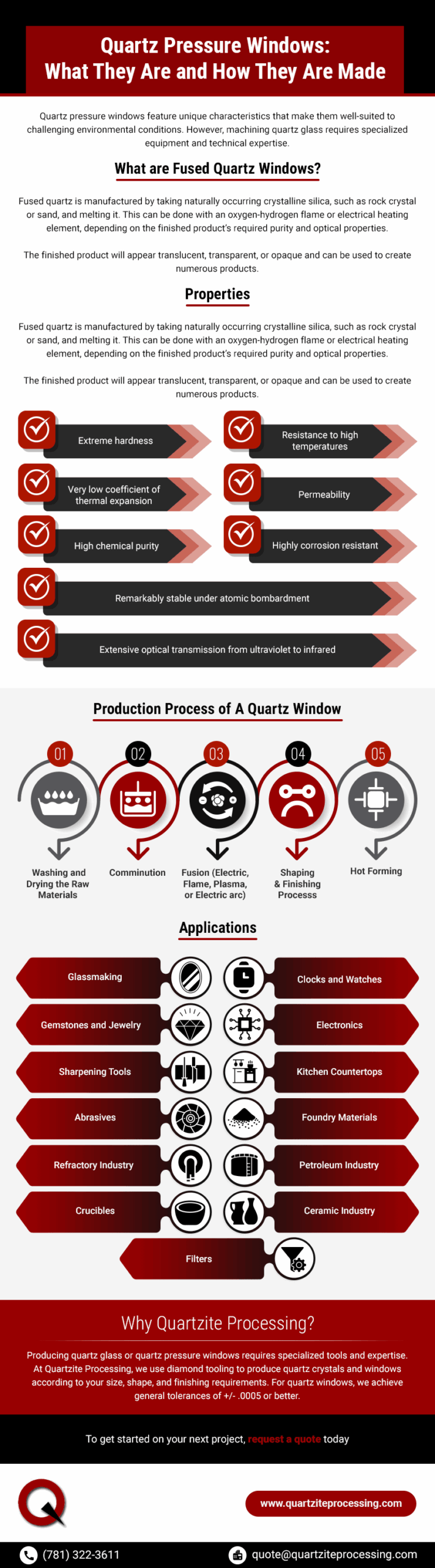

In-depth Look: Manufacturing Processes and Quality Assurance for quartz window

What Are the Key Stages in the Manufacturing Process of Quartz Windows?

The manufacturing process of quartz windows is intricate and involves several key stages, each critical to ensuring the final product meets high-performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Quartz Sourced and Processed?

The first step in manufacturing quartz windows is sourcing high-quality quartz material. Quartz is preferred due to its superior strength, thermal resistance, and optical clarity compared to traditional glass. After sourcing, the quartz undergoes several processes:

-

Purification: Impurities are removed to enhance optical clarity. This may involve chemical treatments or high-temperature treatments to ensure that the quartz is free from contaminants.

-

Cutting and Shaping: The purified quartz is then cut into sheets of desired thickness and size using techniques such as CNC machining or water jet cutting. This precision ensures that the final dimensions adhere to the specifications required by customers.

-

Surface Treatment: The surface of the quartz may undergo treatments such as polishing or coating to improve optical properties and reduce reflections. Anti-reflective coatings can be applied to enhance transmission performance, which is crucial for applications requiring high light clarity.

What Techniques Are Employed in the Forming Stage?

The forming stage focuses on shaping the quartz into the desired window configuration. This is where advanced techniques come into play:

Illustrative image related to quartz window

-

CNC Machining: This technology allows for precise shaping and engraving of quartz to achieve complex designs. It is essential for creating custom windows that meet specific architectural requirements.

-

Heat Treatment: Some quartz windows undergo heat treatment to enhance their durability and thermal properties. This process involves heating the quartz to high temperatures and then cooling it rapidly to improve its resistance to thermal shock.

-

Molding: For certain designs, quartz can be molded into specific shapes. This technique is less common but can be used for unique applications or architectural features.

How Is the Assembly Process Managed for Quartz Windows?

Once the quartz has been shaped, the next step is assembly. This process involves integrating various components to form a complete window unit.

-

Frame Integration: Quartz windows typically require an aluminum or other durable frame to ensure structural integrity. The quartz is carefully fitted into the frame, ensuring that seals and barriers are in place to prevent air and water infiltration.

-

Sealing: High-quality seals are applied around the edges of the quartz to enhance energy efficiency and prevent moisture ingress. This step is crucial for maintaining the thermal performance of the window.

-

Final Assembly: All components, including any mechanical parts (like hinges for operable windows), are assembled to create the final product. This stage requires meticulous attention to detail to ensure that all parts function seamlessly.

What Finishing Processes Ensure High-Quality Quartz Windows?

The finishing stage is where the final touches are applied to ensure the product meets aesthetic and functional standards.

-

Quality Inspection: Each quartz window undergoes a thorough inspection for optical clarity, surface defects, and dimensional accuracy. This includes checking for scratches, bubbles, or any other imperfections that could affect performance.

-

Coatings and Treatments: Additional coatings may be applied at this stage for enhanced durability or aesthetic appeal. Options like UV coatings can protect the window from environmental damage.

-

Packaging: Finally, the windows are packaged carefully to prevent damage during transportation. This stage is crucial for ensuring that the products arrive safely at their destination.

What International Standards and Quality Control Measures Are Relevant?

Quality assurance in quartz window manufacturing is paramount, especially when catering to international markets. Adhering to recognized standards ensures that products meet both safety and performance benchmarks.

Illustrative image related to quartz window

Which International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate their commitment to quality. Compliance with ISO 9001 indicates that a manufacturer has robust processes in place for quality assurance.

-

CE Marking: Particularly relevant for the European market, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

-

API Standards: For applications in industries such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary, particularly for windows used in hazardous environments.

What Are the Key Quality Control Checkpoints in Quartz Window Manufacturing?

Quality control (QC) is a critical aspect of quartz window manufacturing, with specific checkpoints established throughout the process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Any subpar materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the production process. This helps catch defects early and prevents faulty products from progressing to the next stage.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is conducted to evaluate the product against predetermined specifications. This includes testing for thermal performance, optical clarity, and overall structural integrity.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, ensuring that suppliers maintain high-quality standards is essential. Here are effective strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control practices. This can include reviewing their compliance with international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the QC processes used, including any certifications obtained. This documentation can help verify that the supplier adheres to necessary standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. This can be particularly beneficial for large orders or when sourcing from new suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control across different regions is crucial for B2B buyers. Factors such as regional regulations, cultural attitudes towards quality, and logistical challenges can all influence supplier performance. Buyers should consider:

- Local Regulations: Familiarize yourself with local regulations that may impact product quality and compliance.

- Cultural Differences: Be aware of how cultural attitudes towards quality can affect manufacturing practices. Building strong relationships with suppliers can facilitate better communication and adherence to quality standards.

- Logistical Considerations: Understand the logistics of transporting quartz windows, which can be sensitive to damage during transit. Ensure that suppliers have robust packaging and shipping protocols in place.

By paying close attention to the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing quartz windows, ensuring they receive products that meet their performance and aesthetic needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘quartz window’

To assist B2B buyers in procuring quartz windows, this guide provides a step-by-step checklist to streamline the sourcing process. Whether you are in Africa, South America, the Middle East, or Europe, following these steps will ensure you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as size, thickness, and optical clarity, as these will directly impact the performance of the quartz windows in your application. Additionally, assess the environmental conditions they will be exposed to, such as temperature fluctuations and UV exposure.

- Key Specifications to Consider:

- Diameter and thickness requirements.

- Desired optical properties (e.g., UV transmission, surface quality).

Step 2: Research Suppliers and Manufacturers

A thorough supplier research phase is vital to ensure quality and reliability. Investigate potential suppliers’ backgrounds, focusing on their experience with quartz windows and their reputation in the industry. Look for suppliers who specialize in your required specifications to ensure they can meet your needs effectively.

- Where to Find Suppliers:

- Online industry directories and trade shows.

- Recommendations from industry peers and professionals.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers comprehensively. Request company profiles, product catalogs, and case studies showcasing their work in similar industries or applications. Don’t hesitate to ask for references from previous clients to gauge their reliability and service quality.

- Considerations During Evaluation:

- Production capabilities and lead times.

- Customer service responsiveness and support.

Step 4: Request Samples and Test Performance

Obtaining samples is crucial for assessing the quality and performance of quartz windows. This step allows you to evaluate their optical properties, durability, and overall suitability for your project. Testing under real-world conditions can provide insights into how well the product meets your specifications.

- Sample Testing Focus Areas:

- Clarity and optical performance.

- Resistance to thermal and mechanical stress.

Step 5: Verify Compliance and Certifications

Ensure that the suppliers’ products comply with relevant industry standards and certifications. This is particularly important for quartz windows used in specialized applications, such as optical or industrial uses. Compliance guarantees that the products meet safety and performance requirements.

- Key Certifications to Look For:

- ISO certifications for quality management.

- Specific industry certifications relevant to your application.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to finalize pricing and terms. Consider not only the cost of the quartz windows but also factors like delivery schedules, payment terms, and warranty conditions. A well-negotiated agreement can significantly impact your overall project budget.

- Negotiation Tips:

- Be clear about your budget constraints.

- Explore options for bulk purchasing discounts.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of quartz windows upon delivery. This step is essential to ensure that the products meet your specifications and function as intended. Establish clear protocols for inspection and testing before installation.

- Quality Assurance Measures:

- Define acceptance criteria for delivered products.

- Schedule regular inspections during installation.

By following this checklist, B2B buyers can enhance their sourcing strategy for quartz windows, ensuring they find the right products that meet their technical and business requirements.

Comprehensive Cost and Pricing Analysis for quartz window Sourcing

What Are the Key Cost Components in Quartz Window Manufacturing?

When sourcing quartz windows, it’s essential to understand the various cost components that contribute to the final price. These include:

-

Materials: The primary material, quartz, is typically more expensive than conventional glass due to its superior properties, such as high thermal resistance and optical clarity. The cost can vary significantly based on the quality and sourcing location of the quartz.

-

Labor: Skilled labor is required for the precision manufacturing of quartz windows. This includes cutting, shaping, and finishing processes that demand a high level of craftsmanship.

-

Manufacturing Overhead: This encompasses the costs associated with factory operations, equipment maintenance, utilities, and administrative expenses. Advanced manufacturing processes, such as CNC machining or custom shaping, can increase overhead costs.

-

Tooling: Custom tooling for unique designs or specifications adds to the initial investment. Buyers should be aware that one-time tooling costs can be amortized over larger orders.

-

Quality Control (QC): Rigorous quality control processes are crucial for ensuring that the windows meet industry standards. This involves testing for optical clarity, thermal performance, and structural integrity, all of which add to the overall costs.

-

Logistics: Transportation and shipping costs vary based on the distance from the manufacturing facility to the buyer’s location. International shipping can be particularly costly and should be factored into the total cost.

-

Margin: Suppliers typically include a margin that reflects their operational costs and profit expectations. Understanding the margin can help buyers gauge the competitiveness of the pricing.

How Do Price Influencers Affect Quartz Window Sourcing?

Several factors can influence the pricing of quartz windows, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield significant discounts. Buyers should negotiate for lower prices based on anticipated volume.

-

Specifications and Customization: Customized windows, such as those with specific dimensions or additional coatings, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Material Quality and Certifications: Higher-quality quartz and certified products can command higher prices. Certifications can also assure buyers of compliance with relevant standards, which can be crucial for international markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can significantly impact the total cost. Understanding whether costs include shipping, insurance, and duties is vital for accurate budgeting.

What Buyer Tips Can Enhance Cost Efficiency in Quartz Window Procurement?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are strategic tips for cost-effective sourcing:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms and prices. Establishing long-term relationships with suppliers can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes installation, maintenance, and energy efficiency over the product’s lifecycle. High-quality quartz windows can offer better thermal performance, reducing energy costs.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and other trade regulations that can impact pricing. Building relationships with local agents can provide insights into market conditions.

-

Be Informed About Market Trends: Staying updated on market trends and new technologies can provide leverage in negotiations and help buyers make informed decisions about the types of quartz windows that will best suit their needs.

Disclaimer on Indicative Prices

Prices for quartz windows can vary widely based on the aforementioned factors, including supplier, materials, and customization. It is advisable for buyers to request quotes from multiple suppliers to ensure competitive pricing and to confirm that all costs are included in the final offer.

Alternatives Analysis: Comparing quartz window With Other Solutions

When considering the best window solutions for various applications, it is essential to evaluate alternatives to quartz windows. Each option may offer distinct advantages and limitations, depending on specific project requirements, environmental conditions, and budget constraints. Below, we compare quartz windows to two viable alternatives: traditional glass windows and polycarbonate panels.

| Comparison Aspect | Quartz Window | Traditional Glass Window | Polycarbonate Panel |

|---|---|---|---|

| Performance | High thermal efficiency, UV transmission up to 80% | Moderate thermal performance, UV resistance varies | Good insulation, high impact resistance |

| Cost | Higher initial investment | Generally lower cost | Mid-range cost, but varies by thickness |

| Ease of Implementation | Requires specialized installation | Standard installation processes | Easy to handle and install |

| Maintenance | Low maintenance, resistant to scratching | Requires regular cleaning, can scratch easily | Low maintenance, resistant to yellowing |

| Best Use Case | Laboratory settings, high-end architecture | Residential and commercial buildings | Greenhouses, sports facilities, safety applications |

How Does Traditional Glass Compare to Quartz Windows?

Traditional glass windows are widely used in both residential and commercial applications due to their affordability and versatility. They provide adequate thermal performance but may not match the energy efficiency of quartz windows. One significant downside is their susceptibility to scratching and breakage, which can increase maintenance costs over time. Furthermore, glass windows offer limited UV protection, making them less suitable for environments where UV exposure is a concern.

Illustrative image related to quartz window

What Are the Benefits of Polycarbonate Panels Over Quartz Windows?

Polycarbonate panels are an increasingly popular choice for many applications due to their high impact resistance and lightweight nature. They are particularly beneficial in settings where safety is paramount, such as in sports facilities or greenhouses. While polycarbonate panels are generally easier to install and handle than quartz windows, they may not provide the same level of thermal efficiency or aesthetic appeal. Additionally, while they offer decent UV resistance, they can yellow over time, which may impact their clarity and overall appearance.

How to Choose the Right Window Solution for Your Needs?

Selecting the appropriate window solution for your project ultimately hinges on your specific requirements. If your focus is on high performance, durability, and UV protection, quartz windows might be the best option despite their higher cost. Conversely, if budget constraints are a priority and the application does not require exceptional UV resistance, traditional glass windows can suffice. For projects prioritizing safety and ease of installation, polycarbonate panels may be the ideal choice. By carefully evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and budgetary limits.

Essential Technical Properties and Trade Terminology for quartz window

What Are the Key Technical Properties of Quartz Windows?

Quartz windows are renowned for their durability and optical clarity, making them a preferred choice in various applications, from architectural designs to scientific instruments. Understanding the critical specifications of quartz windows can help B2B buyers make informed purchasing decisions.

1. Material Grade

Quartz windows are typically made from high-purity fused quartz or UV fused silica. The grade of quartz affects its thermal and optical properties. Higher-grade materials can withstand extreme temperatures (up to 1050°C) and offer superior optical transmission (over 80% from 260nm to 2500nm). For B2B buyers, selecting the right material grade is crucial for ensuring product longevity and performance in specific applications.

2. Tolerance

Tolerance refers to the permissible limit of variation in a material’s dimensions. For quartz windows, common tolerances might include diameter and thickness tolerances of ±0.125 mm. Understanding these tolerances is essential for B2B buyers as they impact the compatibility of the quartz window with existing systems or equipment, ensuring a proper fit and optimal performance.

Illustrative image related to quartz window

3. Surface Quality

Surface quality is a measure of the window’s finish and is typically rated using scratch-dig standards (e.g., 60-40 or better). A better surface quality ensures higher optical performance by minimizing light scattering and distortion. For international buyers, ensuring high surface quality is vital for applications requiring precision optics, such as scientific instruments.

4. Parallelism

Parallelism indicates how parallel the surfaces of the quartz window are, which can affect optical performance. Specifications often require less than 1 arc minute of deviation. This property is important for B2B buyers in fields such as telecommunications or laser applications, where precise alignment is critical for system efficiency.

5. Flatness

Flatness is another crucial specification, often measured in waves (e.g., <1/2 waves). This property influences how light passes through the window and is particularly relevant for applications like spectrometry. Buyers must consider flatness to ensure accurate results in optical measurements.

Illustrative image related to quartz window

What Common Trade Terminology Should B2B Buyers Understand?

Navigating the procurement process for quartz windows involves familiarity with specific industry jargon. Here are some common terms that can aid B2B buyers in their decision-making.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who can provide customized quartz windows that meet specific application needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to plan their purchases effectively and manage inventory costs. Suppliers often set MOQs based on production efficiencies and material costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting a price quote for specific products. For B2B buyers, submitting an RFQ is a critical step in the procurement process, allowing them to compare pricing and specifications from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping responsibilities, insurance coverage, and risks associated with transporting quartz windows.

5. Custom Coating

Custom coatings are specialized treatments applied to quartz windows to enhance their properties, such as anti-reflective coatings. B2B buyers should consider custom coatings to improve performance in specific applications, thereby maximizing the value of their investment.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can better navigate the complexities of purchasing quartz windows, ensuring they select the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the quartz window Sector

What Are the Global Drivers and Key Trends Influencing the Quartz Window Market?

The quartz window sector is experiencing transformative changes driven by several global factors. As international B2B buyers seek innovative and durable solutions, the demand for quartz windows has surged due to their superior strength compared to traditional glass options. This trend is particularly pronounced in emerging markets such as Africa and South America, where urbanization and infrastructural development are accelerating. Additionally, the architectural industry is gravitating towards large, aesthetically pleasing windows that offer both functionality and style, making quartz an attractive choice due to its design versatility.

Technological advancements in manufacturing processes are also reshaping the market dynamics. Companies are leveraging automation and smart technologies to improve production efficiency and customization capabilities. For example, patented techniques that enhance thermal performance and energy efficiency are increasingly important as sustainability becomes a priority for builders and consumers alike. As a result, buyers from regions like the Middle East and Europe are increasingly inclined towards suppliers who can offer high-quality, energy-efficient quartz windows that comply with stringent building regulations.

Illustrative image related to quartz window

Furthermore, the rise of e-commerce platforms has revolutionized sourcing practices, enabling international buyers to access a wider range of suppliers and products. This shift is particularly beneficial for buyers in remote or developing areas, as they can now compare prices and specifications online, ultimately leading to better purchasing decisions.

How Is Sustainability Shaping the Sourcing of Quartz Windows?

Sustainability is a pivotal concern in the sourcing of quartz windows, as environmental impacts and ethical supply chains gain prominence. The production of quartz windows entails significant energy consumption and resource extraction, making it essential for suppliers to adopt sustainable practices. B2B buyers are increasingly scrutinizing the environmental credentials of their suppliers, seeking those who prioritize sustainable sourcing methods and materials.

In this context, certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management Systems) have become crucial. These certifications ensure that manufacturers adhere to environmentally responsible practices throughout their supply chains. Additionally, the increasing popularity of recycled and eco-friendly materials in the production of quartz windows is reshaping buyer preferences. This trend is particularly relevant for international buyers in regions like Europe, where regulatory frameworks and consumer demand for sustainable products are more stringent.

Moreover, the use of advanced materials that enhance energy efficiency can significantly reduce the carbon footprint of buildings. By opting for quartz windows that boast superior insulation properties, buyers not only contribute to environmental sustainability but also benefit from long-term cost savings through reduced energy consumption.

What Is the Historical Context of Quartz Windows in the B2B Market?

The evolution of quartz windows in the B2B sector reflects significant advancements in material science and architectural design. Historically, quartz was primarily used in specialized applications due to its high thermal resistance and optical clarity. However, as the construction industry evolved, so did the applications of quartz, leading to its widespread adoption in luxury residential and commercial buildings.

In the last few decades, the development of advanced manufacturing techniques has made quartz windows more accessible and cost-effective for a broader range of applications. As architects and builders began to recognize the aesthetic and functional benefits of quartz, its popularity soared. Today, quartz windows are not only a symbol of luxury but also a preferred choice for energy-efficient and sustainable building practices.

This historical context underscores the growing recognition of quartz windows as a vital component in modern architecture, providing B2B buyers with a compelling case for investment in this innovative product category.

Frequently Asked Questions (FAQs) for B2B Buyers of quartz window

-

How do I choose the right quartz window for my project?

Selecting the appropriate quartz window involves assessing your project’s specific requirements, such as thermal efficiency, aesthetic preferences, and structural needs. Consider the types available, including single hung, casement, and picture windows, each offering unique benefits. Evaluate the energy performance ratings, design options, and how they align with your architectural vision. Collaborating with a knowledgeable supplier can provide insights into the best options for your regional climate and building codes. -

What are the key benefits of using quartz windows compared to traditional glass?

Quartz windows offer superior strength, temperature resistance, and durability compared to traditional glass. They can withstand extreme temperatures (up to 1050°C) and provide excellent UV transmission (over 80%) for various applications. Their high thermal efficiency can lead to energy savings, making them an ideal choice for both residential and commercial projects. Furthermore, quartz is less prone to breakage, enhancing safety and longevity. -

What customization options are available for quartz windows?

Many suppliers offer extensive customization options for quartz windows, including sizes, shapes, and coatings. You can request specific dimensions, edge finishes, and even custom patterns or colors to match your design needs. Additionally, antireflective and special coatings can enhance performance in various applications. Engaging directly with manufacturers can help you explore all available options to achieve your desired specifications. -

What is the minimum order quantity (MOQ) for quartz windows when sourcing internationally?

The MOQ for quartz windows can vary significantly among manufacturers and depends on factors such as the complexity of the order and customization requirements. Typically, MOQs range from a few units for standard sizes to larger quantities for custom designs. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that align with your project scale and budget. -

How can I ensure the quality of quartz windows before purchasing?

Quality assurance is critical when sourcing quartz windows. Request certifications and test results that confirm compliance with industry standards for thermal performance, strength, and durability. Inquire about the supplier’s manufacturing processes and quality control measures. If possible, visit the production facility or request samples to evaluate the product firsthand. Establishing a relationship with reputable suppliers known for their quality can also help mitigate risks. -

What payment terms are commonly offered for international purchases of quartz windows?

Payment terms for international purchases can vary widely among suppliers. Common terms include full payment upfront, partial payment with the balance due upon delivery, or payment via letter of credit. It’s important to clarify payment options, including accepted currencies and methods, to avoid any misunderstandings. Negotiating favorable terms that provide security for both parties is essential for a successful transaction. -

How do logistics and shipping work when importing quartz windows?

Logistics for importing quartz windows typically involve coordinating with freight forwarders or shipping companies to handle transport. Key considerations include packaging to prevent damage, choosing the right shipping method (air or sea), and understanding customs regulations in your destination country. Ensure that your supplier provides necessary documentation, such as invoices and shipping labels, to facilitate smooth customs clearance. -

What are the common applications for quartz windows in various industries?

Quartz windows are versatile and used in various applications across industries. In the construction sector, they serve as high-performance windows for luxury homes and commercial buildings, enhancing aesthetics and energy efficiency. In scientific and industrial settings, quartz windows are employed in optical devices, UV applications, and laboratory equipment due to their superior transmission properties. Understanding your specific industry needs can help you select the right quartz window solution.

Top 6 Quartz Window Manufacturers & Suppliers List

1. McMaster – Quartz Windows

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Quartz Windows, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

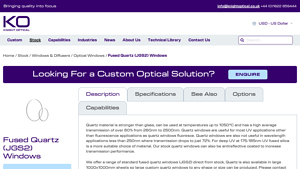

2. Knight Optical – Quartz Windows (JGS2)

Domain: knightoptical.com

Registered: 2007 (18 years)

Introduction: Product: Quartz Windows (JGS2)\nMaterial: Fused Quartz\nTemperature Resistance: Up to 1050°C\nTransmission: Over 80% from 260nm to 2500nm\nFluorescence: Not suitable for fluorescence applications\nTransmission below 250nm: Drops to 72%\nSuitable for deep UV: 175-185nm (UV fused silica recommended)\nCoating Options: Antireflective coating available\nStandard Sizes: Available in stock, custom sizes …

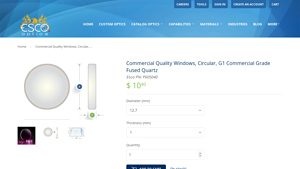

3. Esco Optics – G1 Fused Quartz Windows

Domain: escooptics.com

Registered: 2012 (13 years)

Introduction: This company, Esco Optics – G1 Fused Quartz Windows, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

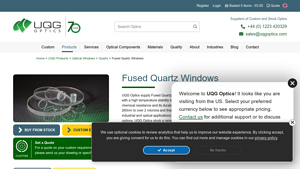

4. UQG Optics – Fused Quartz Windows

Domain: uqgoptics.com

Registered: 2001 (24 years)

Introduction: Fused Quartz Windows from UQG Optics. Key features include:

– Material: Fused Quartz

– Temperature Stability: Up to 1050°C

– Thermal Shock Resistance

– Chemical Resistance

– Transmission Range: 260nm to over 2 microns

– Available Grades: Commercial to Precision

– Dimensions: Diameters from 5mm to 400mm; Commercial grade up to 1200mm x 1200mm

– Thickness Range: 0.1mm to 50mm

– Tolerance: U…

5. Thorlabs – Infrasil® Optical Quartz Windows

Domain: thorlabs.com

Registered: 1995 (30 years)

Introduction: Infrasil® (Optical Quartz) Windows: Uncoated Windows for 300 nm – 3 µm, available in thicknesses of 1.0, 3.0, or 5.0 mm. Sizes include Ø1/2″, Ø1″, and Ø2″. Enhanced transmission above 1 µm. Specific product codes: UDP10 (Ø1″, 1.0 mm Thick), UDP053 (Ø1/2″, 3.0 mm Thick), UDP05 (Ø1/2″, 1.0 mm Thick), UDP105 (Ø1″, 5.0 mm Thick), UDP20 (Ø2″, 1.0 mm Thick). Features include flat transmission from 300 n…

6. Bucksci – Quartz Windows

Domain: bucksci.com

Registered: 1996 (29 years)

Introduction: Quartz Windows

Price: $120.00

Description: This item is a recurring or deferred purchase. By continuing, I agree to the cancellation policy and authorize you to charge my payment method at the prices, frequency and dates listed on this page until my order is fulfilled or I cancel, if permitted.

Strategic Sourcing Conclusion and Outlook for quartz window

In conclusion, the strategic sourcing of quartz windows presents a robust opportunity for international B2B buyers seeking high-performance architectural solutions. The versatility of quartz, with its superior strength, thermal efficiency, and aesthetic appeal, positions it as a preferred choice across diverse markets, including Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who offer innovative designs, customizable options, and advanced manufacturing processes to ensure they meet specific project requirements and client expectations.

Illustrative image related to quartz window

Strategic sourcing not only enhances product quality but also fosters long-term partnerships that can yield significant cost savings and operational efficiencies. Engaging with reputable manufacturers and distributors who understand local market dynamics can further streamline procurement processes, ensuring timely delivery and compliance with regional standards.

As the demand for high-quality architectural fenestration continues to grow, now is the time for buyers to invest in quartz windows that promise durability, energy efficiency, and striking design. Take the next step towards enhancing your projects by connecting with trusted quartz window suppliers today. Embrace the future of architectural excellence and elevate your offerings in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.