Is Your Punch Machine Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for punch machine

Navigating the global market for punch machines presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The quest for high-quality punch machines that meet specific operational needs—whether for manufacturing or entertainment—requires careful consideration and strategic sourcing. This guide aims to illuminate the complexities of acquiring punch machines by providing in-depth insights into various types available, their applications across different industries, and effective supplier vetting techniques.

Understanding the diverse landscape of punch machines, from arcade boxing machines to industrial punching equipment, is crucial for making informed purchasing decisions. This guide will explore the latest innovations, pricing structures, and operational efficiencies that different models offer. By equipping buyers with the necessary knowledge about market trends and supplier capabilities, this resource empowers businesses to choose machines that not only fit their budget but also enhance productivity and profitability.

As the demand for punch machines grows, especially in regions like Saudi Arabia and Nigeria, making informed choices becomes paramount. Whether you’re looking to boost customer engagement in an arcade or streamline manufacturing processes, this guide serves as your comprehensive resource for navigating the intricate global market of punch machines, ensuring that your investment aligns with your strategic business goals.

Understanding punch machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Arcade Punching Machines | Engaging gameplay, score tracking, often equipped with prize dispensers | Entertainment venues, arcades | Pros: High revenue potential; Cons: Requires space and maintenance. |

| Industrial Punching Machines | Versatile processing capabilities, can punch, reform, and tap metal | Manufacturing, metal fabrication | Pros: High efficiency and precision; Cons: High initial investment. |

| Music Punching Machines | Integrated music features, tracks performance, compact design | Fitness centers, home gyms | Pros: Motivating workout experience; Cons: Limited to fitness applications. |

| Combo Punching Machines | Combines punching and kicking functions, customizable settings | Arcades, amusement parks | Pros: Versatility in gameplay; Cons: More complex maintenance. |

| Wall-Mounted Punching Machines | Space-saving design, ideal for smaller venues | Gyms, personal training studios | Pros: Space-efficient; Cons: Limited interaction compared to stand-alone units. |

What Are Arcade Punching Machines and Their Applications?

Arcade punching machines are designed for entertainment, featuring engaging gameplay that encourages users to compete for high scores. They are often equipped with prize dispensers, making them attractive for entertainment venues and arcades. B2B buyers should consider the potential for high foot traffic and revenue generation, but must also account for ongoing maintenance and the need for sufficient space to accommodate these machines.

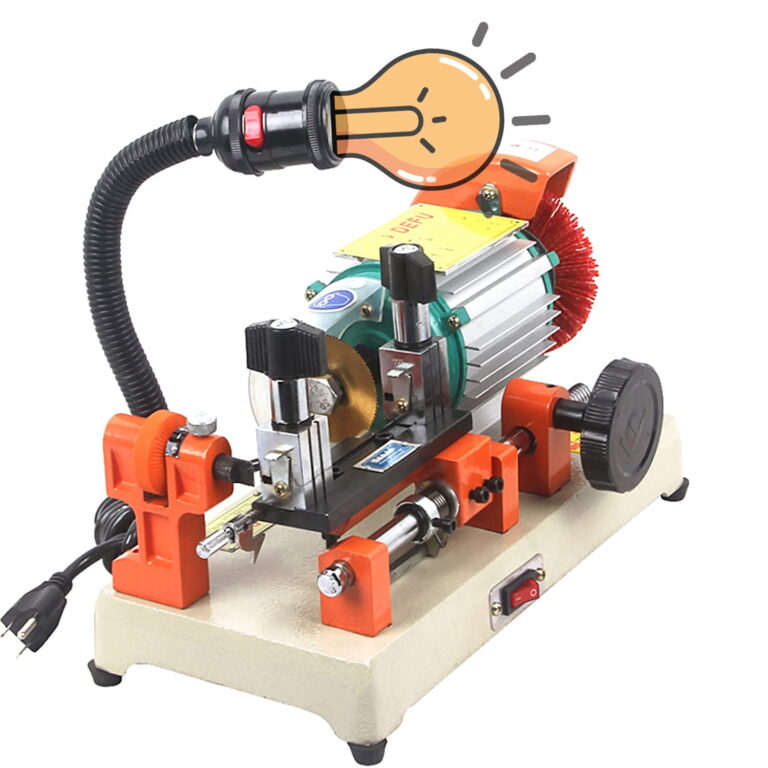

How Do Industrial Punching Machines Enhance Manufacturing Processes?

Industrial punching machines are highly versatile, capable of performing multiple tasks such as punching, reforming, and tapping metal components. These machines are essential in manufacturing and metal fabrication sectors where precision and efficiency are paramount. While they offer significant productivity benefits, B2B buyers should weigh the high initial investment against the long-term gains in throughput and quality.

What Makes Music Punching Machines Ideal for Fitness Centers?

Music punching machines integrate motivational music features to enhance workout experiences, making them suitable for fitness centers and home gyms. They track user performance, providing a dynamic and engaging way to exercise. While they are excellent for promoting fitness, potential buyers should consider their limited application scope compared to more versatile machines.

Why Choose Combo Punching Machines for Amusement Venues?

Combo punching machines offer a unique blend of punching and kicking gameplay, appealing to a broader audience in arcades and amusement parks. Their customizable settings can attract diverse customer demographics, increasing engagement and revenue. However, the complexity of maintenance may be a consideration for B2B buyers looking for ease of operation.

What Are the Benefits of Wall-Mounted Punching Machines?

Wall-mounted punching machines are designed for space efficiency, making them ideal for gyms and personal training studios with limited room. They provide an interactive experience without taking up valuable floor space. However, B2B buyers should note that these machines may offer a less engaging experience compared to stand-alone units, potentially impacting user interaction and satisfaction.

Key Industrial Applications of punch machine

| Industry/Sector | Specific Application of punch machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Sheet metal punching for manufacturing components | Increased production speed and precision | Compatibility with existing machinery and tooling |

| Automotive | Production of body panels and structural parts | Cost-effective mass production and reduced waste | Need for high-volume processing capabilities |

| Electronics | Creating enclosures and brackets for devices | Enhanced design flexibility and reduced lead times | Precision requirements for intricate designs |

| Construction | Fabrication of metal frames and fittings | Improved structural integrity and reduced labor costs | Compliance with local standards and regulations |

| Consumer Goods | Production of custom metal parts for appliances | Customization options and faster time-to-market | Material compatibility and sourcing of specialized tools |

How is Punch Machine Used in Metal Fabrication?

In the metal fabrication industry, punch machines are essential for processing sheet metal into specific shapes and components. They enable manufacturers to punch holes, cut out shapes, and create complex designs efficiently. This technology addresses challenges such as high labor costs and production delays. For international buyers, especially from Africa and South America, sourcing punch machines that can handle various materials and thicknesses is crucial. Additionally, ensuring compatibility with existing machinery can streamline operations and enhance productivity.

What Role Does Punch Machine Play in the Automotive Sector?

Within the automotive sector, punch machines are utilized to produce body panels and structural components, which are vital for vehicle assembly. These machines facilitate high-volume production while maintaining precision, ultimately reducing material waste and costs. Buyers in the Middle East and Europe must consider the scalability of these machines to meet fluctuating demand and ensure they comply with stringent automotive standards. The ability to integrate with automation systems can further enhance efficiency in production lines.

How is Punch Machine Applied in Electronics Manufacturing?

In electronics manufacturing, punch machines are employed to create enclosures, brackets, and other metal parts required for devices. The precision offered by these machines allows manufacturers to produce intricate designs that meet specific functional and aesthetic requirements. For B2B buyers in Europe, sourcing punch machines that can handle small batch sizes while maintaining high quality is vital. Additionally, understanding the machine’s adaptability to various materials, such as aluminum or steel, is essential for meeting diverse product demands.

Why is Punch Machine Important for Construction?

Punch machines play a critical role in the construction industry by fabricating metal frames, fittings, and support structures. They contribute to improved structural integrity and reduced labor costs by streamlining the production process. Buyers from regions like Saudi Arabia and Nigeria should focus on machines that comply with local building codes and standards to ensure safety and reliability. Furthermore, the ability to customize machine settings for different project requirements can provide a competitive edge in the construction market.

How Does Punch Machine Benefit the Consumer Goods Sector?

In the consumer goods sector, punch machines are utilized for producing custom metal parts for appliances, enhancing both functionality and design. These machines allow manufacturers to respond quickly to market trends by enabling rapid prototyping and production. For international buyers, particularly in South America, it is essential to consider the sourcing of specialized tools that can accommodate various product designs. Ensuring that the punch machine can work with diverse materials will also help maintain a competitive advantage in product offerings.

3 Common User Pain Points for ‘punch machine’ & Their Solutions

Scenario 1: Maintaining Operational Efficiency Amid Machine Downtime

The Problem: One of the primary challenges faced by B2B buyers of punch machines is unexpected machine downtime due to maintenance issues or mechanical failures. This can disrupt production schedules, lead to delays in fulfilling orders, and ultimately result in lost revenue. For buyers in fast-paced industries, particularly in regions where manufacturing is ramping up, the pressure to maintain operational efficiency is heightened. Delays can also tarnish relationships with clients who rely on timely deliveries.

The Solution: To mitigate downtime, buyers should prioritize sourcing machines from reputable manufacturers that offer robust support and warranty options. Conduct thorough research on the machine’s reliability and maintenance requirements before purchasing. It’s advisable to invest in a comprehensive maintenance program that includes regular check-ups and prompt repairs. Additionally, consider machines with built-in diagnostic tools that can alert operators to potential issues before they escalate. Training staff on proper usage and care can also minimize the risk of operational interruptions. Establishing a contingency plan, including spare parts procurement or a partnership with local technicians, can further ensure minimal disruption to production.

Scenario 2: Navigating the Complexity of Punch Machine Specifications

The Problem: Another common pain point for B2B buyers is the complexity involved in selecting the right specifications for a punch machine that meets their unique operational needs. With a variety of models available, each offering different capabilities in terms of sheet size, material thickness, and automation features, it can be overwhelming to determine the best fit. Buyers may fear over-investing in unnecessary features or, conversely, under-specifying and hindering production capabilities.

The Solution: To effectively navigate this complexity, buyers should conduct a thorough needs assessment that considers the types of materials they work with, the volume of production, and any specific applications. Engaging with manufacturers or suppliers can provide valuable insights into which features are essential versus optional. Requesting demos or trial periods can also help in making informed decisions. Moreover, consider investing in machines that offer modular components, allowing for future upgrades as business needs evolve. Collaborating with industry experts can further streamline the selection process, ensuring that the chosen machine aligns perfectly with operational goals.

Scenario 3: Ensuring a Return on Investment (ROI) for Punch Machines

The Problem: B2B buyers often grapple with the challenge of justifying the investment in punch machines, particularly when considering the upfront costs versus potential long-term gains. In regions where capital investment is closely scrutinized, buyers need to ensure that the machine will not only meet current demands but also provide a substantial return on investment. The fear of making a poor financial decision looms large, especially in competitive markets.

The Solution: To ensure a solid ROI, buyers should approach the purchase as a strategic investment rather than a mere operational expense. Begin by analyzing the total cost of ownership, which includes purchase price, maintenance, operational costs, and potential revenue generation. It’s beneficial to create a detailed cost-benefit analysis that projects how the punch machine will enhance productivity, reduce labor costs, and improve product quality. Additionally, consider machines that feature energy-efficient technology, which can lead to significant savings over time. Exploring financing options, such as leasing or vendor financing, can also alleviate the burden of upfront costs while still enabling access to high-quality equipment. Finally, establishing clear performance metrics to measure the machine’s output against initial projections will help validate the investment and guide future purchasing decisions.

Strategic Material Selection Guide for punch machine

When selecting materials for punch machines, it is crucial for international B2B buyers to consider the specific properties and performance characteristics of various materials. This guide analyzes four common materials used in the construction of punch machines, highlighting their advantages, disadvantages, and suitability for different applications.

What Are the Key Properties of Steel for Punch Machines?

Steel is one of the most widely used materials in punch machine manufacturing due to its excellent strength and durability. It typically has a high tensile strength, making it suitable for handling significant pressure during the punching process. Steel also offers good corrosion resistance when treated or coated properly, which is essential for machines exposed to various environmental conditions.

Pros: Steel is known for its durability and cost-effectiveness. It can withstand high operational loads and has a long lifespan, making it a popular choice for heavy-duty applications.

Cons: However, steel can be susceptible to rust if not properly treated, and its weight can complicate installation and mobility.

Impact on Application: Steel punch machines are ideal for high-volume production environments where durability is paramount.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM for material quality and durability.

How Does Aluminum Compare for Punch Machine Applications?

Aluminum is another common material, particularly favored for its lightweight properties and resistance to corrosion. Aluminum punch machines are often used in applications where weight is a critical factor, such as portable or mobile units.

Pros: The lightweight nature of aluminum allows for easier handling and installation. It also has a natural resistance to corrosion, which is beneficial in humid or coastal environments.

Cons: On the downside, aluminum is generally less strong than steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is suitable for applications requiring frequent relocation or where reduced weight is advantageous.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with standards like JIS, particularly in regions such as Europe and South America.

What Role Does Stainless Steel Play in Punch Machine Manufacturing?

Stainless Steel is an alloy known for its exceptional corrosion resistance and aesthetic appeal. It is often used in environments where hygiene is crucial, such as food processing or medical applications.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which extends the machine’s lifespan and reduces maintenance costs.

Cons: However, stainless steel can be more expensive than regular steel or aluminum, impacting the overall cost of the punch machine.

Impact on Application: Stainless steel punch machines are ideal for industries where cleanliness and durability are essential.

Considerations for International Buyers: Compliance with international standards for food safety, such as ISO 22000, may be necessary for buyers in the food industry.

How Does Composite Material Enhance Punch Machine Performance?

Composite materials are increasingly being used in punch machine construction, particularly for components that require a combination of strength and lightweight properties. These materials can include a variety of polymers reinforced with fibers.

Pros: Composites can offer excellent strength-to-weight ratios and are often resistant to corrosion and wear, making them suitable for various applications.

Cons: The main limitation is the higher manufacturing complexity and cost associated with composite materials, which may not be justified for all applications.

Impact on Application: Composites are particularly effective in specialized applications where traditional materials may not perform adequately.

Considerations for International Buyers: Buyers should consider the specific manufacturing capabilities and certifications required for composite materials in their respective regions.

Summary Table of Material Selection for Punch Machines

| Material | Typical Use Case for punch machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to rust | Medium |

| Aluminum | Portable or mobile punch machines | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Stainless Steel | Hygiene-sensitive environments | Exceptional corrosion resistance | Higher cost | High |

| Composite | Specialized applications | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for punch machine

What Are the Main Stages in the Manufacturing Process of Punch Machines?

The manufacturing process for punch machines involves several key stages that ensure the final product meets both functional and quality standards. Here’s a breakdown of these stages:

-

Material Preparation: The process begins with selecting high-quality raw materials, typically steel or aluminum, which are essential for durability and performance. These materials are then cut to size using precision cutting tools, ensuring that they meet the specifications required for the machine’s components.

-

Forming: In this stage, the cut materials undergo various forming processes such as punching, bending, and stamping. Advanced techniques like CNC machining are often employed to create precise shapes and sizes. The use of automated systems not only enhances accuracy but also increases production speed.

-

Assembly: After forming, components are meticulously assembled. This stage may involve welding, fastening, or other joining techniques to ensure that all parts fit together seamlessly. Skilled technicians often conduct this process, emphasizing the importance of alignment and integration for the machine’s overall performance.

-

Finishing: The final stage includes surface treatment processes such as painting, powder coating, or galvanizing to protect against corrosion and wear. This not only enhances the aesthetic appeal but also contributes to the longevity of the machine. Quality checks during this phase ensure that the finish meets industry standards.

Which Key Techniques Are Used in Punch Machine Manufacturing?

Manufacturers utilize various techniques to enhance the efficiency and quality of punch machines. Some notable methods include:

-

CNC Technology: Computer Numerical Control (CNC) machining allows for precise control over the manufacturing processes, resulting in higher accuracy and repeatability. This is crucial for producing complex components with tight tolerances.

-

Hydraulic Pressing: This technique is commonly used for forming metal sheets into desired shapes. Hydraulic presses apply significant force, making them suitable for heavy-duty applications.

-

Laser Cutting: For intricate designs and high precision, laser cutting is increasingly adopted. This technique minimizes material waste and reduces the need for secondary processes.

What International Standards Are Relevant to Punch Machine Quality Assurance?

Quality assurance in punch machine manufacturing is critical to ensuring the reliability and safety of the machines. Key international standards include:

-

ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of its size or industry. It emphasizes customer satisfaction and continuous improvement.

-

CE Marking: For machines sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. It’s essential for ensuring that products meet EU regulations.

-

API Standards: For punch machines used in specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary. These standards ensure that equipment meets rigorous safety and performance criteria.

What Are the Quality Control Checkpoints in Punch Machine Manufacturing?

To maintain high-quality standards, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter the production line. This step is crucial to prevent defects from the outset.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor critical parameters and ensure that processes are operating within acceptable limits. This helps identify issues early and minimizes rework.

-

Final Quality Control (FQC): After assembly, a thorough inspection of the finished product is conducted. This includes functional testing and performance evaluations to ensure that the punch machine operates as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are practical steps to ensure supplier reliability:

-

Conduct Audits: Periodic audits of suppliers can help buyers assess their quality management systems. This includes evaluating their adherence to international standards and internal QC procedures.

-

Request Quality Reports: Buyers should ask for documentation such as quality assurance reports, test certificates, and compliance certificates. These documents provide insight into the supplier’s quality processes and outcomes.

-

Utilize Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production, ensuring adherence to specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

When purchasing punch machines from international suppliers, buyers must navigate specific nuances related to quality control and certification. These include:

-

Understanding Local Regulations: Different countries may have unique compliance requirements. Buyers should familiarize themselves with local regulations in their target markets to ensure that imported machines meet necessary standards.

-

Language Barriers: Documentation may be in different languages, making it crucial for buyers to seek translations or clarifications regarding compliance and quality standards.

-

Cultural Considerations: Building relationships with suppliers from different cultural backgrounds can influence negotiations and quality assurance practices. Understanding cultural nuances can facilitate smoother communication and collaboration.

In summary, B2B buyers must be proactive in understanding the manufacturing processes and quality assurance protocols of punch machines. By focusing on these aspects, they can ensure they select reliable suppliers that meet their operational needs and adhere to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘punch machine’

Introduction

This sourcing guide is designed to assist international B2B buyers in procuring punch machines effectively. Whether you are in Africa, South America, the Middle East, or Europe, following this checklist will ensure you make informed decisions, optimize your investment, and choose the right equipment tailored to your business needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for your punch machine. Consider factors such as the type of materials you will process, the thickness of the materials, and the production volume you expect. This clarity will help you narrow down options and avoid purchasing a machine that does not meet your operational needs.

Step 2: Research Available Machine Types

Familiarize yourself with the various types of punch machines available in the market. There are machines designed for different applications, such as manual, semi-automatic, and fully automatic models. Understanding the capabilities of each type will enable you to choose a machine that aligns with your production goals and efficiency requirements.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service standards. Request detailed company profiles, product catalogs, and case studies showcasing their experience in your industry. Look for references from other buyers, especially those located in your region, to gain insights into the supplier’s reliability and service quality.

Step 4: Verify Certifications and Compliance

Ensure that the punch machines you are considering comply with international safety and quality standards. Check for certifications such as ISO, CE, or local regulatory approvals, as these indicate the machine’s reliability and safety. Compliance can also affect your ability to import the machine into your country, so it’s crucial to verify these details upfront.

Step 5: Assess Warranty and After-Sales Support

Evaluate the warranty offered by the manufacturer or supplier, as well as the availability of after-sales support. A robust warranty can protect your investment and provide peace of mind, while reliable after-sales support ensures that you can resolve any issues quickly. Look for suppliers that offer training, maintenance services, and readily available spare parts.

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare pricing and payment terms. Be wary of prices that seem too good to be true, as they may indicate lower quality or hidden costs. Ensure that the payment terms are flexible and align with your financial planning, considering factors like deposits, installment payments, and financing options.

Step 7: Conduct a Final Review and Decision-Making

Before finalizing your purchase, conduct a comprehensive review of all gathered information. Revisit your initial requirements and ensure that the selected machine and supplier align with your operational goals. Engage with your team to gather feedback and make a collective decision that reflects your business’s best interests.

By following this structured approach, you can streamline the sourcing process for punch machines and make informed decisions that enhance your operational capabilities.

Comprehensive Cost and Pricing Analysis for punch machine Sourcing

What Are the Key Cost Components in Punch Machine Sourcing?

Understanding the cost structure of punch machines is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly influences the price. High-quality steel and durable components increase manufacturing costs but enhance the machine’s longevity and performance. Buyers should assess the trade-off between initial costs and long-term durability.

-

Labor: Labor costs can vary significantly based on the region of manufacturing. Countries with lower labor costs can offer competitive pricing, but this may come at the expense of quality. It’s essential to evaluate the skill level of the workforce involved in production.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Efficient production processes can help minimize these overheads, leading to lower pricing.

-

Tooling: Custom tooling can be a significant upfront expense, particularly for specialized punch machines. Buyers should consider whether existing tooling can be utilized or if new investments are necessary.

-

Quality Control (QC): Rigorous QC measures ensure the reliability of the machines. While this adds to the cost, it is essential for preventing defects that could result in costly returns or repairs.

-

Logistics: Shipping and handling costs can vary widely based on the machine’s size and weight, as well as the shipping destination. International buyers should factor in customs duties and taxes that may apply.

-

Margin: Suppliers will add their profit margin to the cost. Understanding industry standards can help buyers negotiate better deals.

What Influences the Pricing of Punch Machines?

Several factors influence the pricing of punch machines, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically qualify for volume discounts. Understanding the supplier’s MOQ can help buyers plan their procurement strategy effectively.

-

Specifications and Customization: Custom features can significantly impact pricing. Buyers should clearly define their requirements to avoid unexpected costs later in the process.

-

Materials and Quality Certifications: Machines that meet international quality standards or possess certifications may come at a premium. Buyers must weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The agreed-upon Incoterms can influence the total landed cost of the machine. Buyers should choose terms that align with their logistical capabilities and budget.

How Can Buyers Negotiate Effectively for Punch Machines?

Negotiating effectively requires a strategic approach:

-

Understand Total Cost of Ownership (TCO): Buyers should look beyond the initial purchase price and consider maintenance, operational costs, and potential downtime. A lower-priced machine may not always be the most cost-effective in the long run.

-

Leverage Competitive Quotes: Obtaining quotes from multiple suppliers allows buyers to understand market rates and negotiate better deals.

-

Build Relationships: Establishing a good rapport with suppliers can lead to more favorable terms and conditions. Long-term relationships often result in better pricing and service.

-

Be Flexible with Specifications: If possible, being flexible with certain specifications can lead to cost savings. Suppliers may be more willing to negotiate if they can utilize standard components.

-

Timing of Purchase: Timing can influence pricing, especially during off-peak seasons when suppliers may offer discounts to boost sales.

What Should International Buyers Consider When Sourcing Punch Machines?

International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the overall cost. Buyers should monitor currency trends and consider locking in prices when favorable.

-

Import Regulations: Understanding local import regulations and tariffs is vital. This knowledge can prevent unexpected costs that arise from compliance issues.

-

Local Market Conditions: The demand for punch machines can vary by region. Buyers should conduct market research to understand local preferences and pricing trends.

-

After-Sales Support: Ensure that the supplier provides adequate support post-purchase, including warranty terms and access to spare parts. This can significantly influence the total cost of ownership.

Disclaimer on Indicative Prices

Prices for punch machines can vary widely based on specifications, supplier, and market conditions. The prices mentioned in reference sources serve as indicative figures and should be confirmed with suppliers for current rates and terms.

Alternatives Analysis: Comparing punch machine With Other Solutions

When evaluating solutions for physical engagement in entertainment or fitness, it’s essential to consider various alternatives to punch machines. This analysis will compare punch machines with two viable alternatives: arcade boxing games and music boxing machines. Each option presents unique advantages and limitations, influencing the decision-making process for B2B buyers.

| Comparison Aspect | Punch Machine | Arcade Boxing Game | Music Boxing Machine |

|---|---|---|---|

| Performance | High energy, great for competitive play | Engaging and fun for groups | Provides workout motivation through music |

| Cost | $6,500 – $10,000 | $6,500 – $11,300 | $99 – $159 |

| Ease of Implementation | Requires space and setup | Similar space requirements, slightly complex | Easy setup, compact size |

| Maintenance | Regular upkeep and part replacement | Minimal maintenance, mostly software | Low maintenance, primarily electronic |

| Best Use Case | Gyms, arcades, entertainment venues | Family entertainment centers, arcades | Home gyms, fitness studios |

What Are the Advantages and Disadvantages of Arcade Boxing Games Compared to Punch Machines?

Arcade boxing games offer a fun and engaging experience that attracts a diverse audience. They typically feature vibrant graphics, various game modes, and competitive scoring systems that can enhance player interaction. The cost of these machines can range from $6,500 to $11,300, making them a significant investment but still competitive with punch machines. Their maintenance is generally low, as they mostly rely on software updates rather than physical components. However, they may not deliver the same physical engagement level as a punch machine, which could be a drawback for fitness-focused environments.

How Do Music Boxing Machines Provide an Alternative to Traditional Punch Machines?

Music boxing machines are an innovative solution for those seeking a more personal and motivational workout experience. Priced between $99 and $159, these machines are significantly more affordable and easier to integrate into smaller spaces, making them ideal for home gyms or personal fitness studios. They combine physical activity with music, encouraging users to stay active while enjoying their favorite tunes. The low maintenance required—mostly electronic—also makes them appealing. However, they may lack the competitive edge and social interaction that punch machines and arcade boxing games provide.

How Can B2B Buyers Determine the Right Solution for Their Needs?

When selecting the right solution, B2B buyers should consider their target audience, space availability, and overall business goals. Punch machines may be best suited for venues aiming to foster a competitive environment, while arcade boxing games can cater to family entertainment settings. Alternatively, music boxing machines are perfect for fitness enthusiasts looking for an engaging way to exercise at home. By assessing these factors, buyers can make informed decisions that align with their operational objectives and customer preferences.

Essential Technical Properties and Trade Terminology for punch machine

What Are the Key Technical Properties of Punch Machines?

When considering the procurement of punch machines, understanding their technical specifications is essential for making informed purchasing decisions. Below are critical specifications that B2B buyers should consider:

1. Material Grade

The material grade of a punch machine typically refers to the quality and type of metals used in its construction, such as stainless steel or high-carbon steel. A higher material grade often translates to enhanced durability and resistance to wear and tear, which is vital for maintaining productivity in high-volume operations. Buyers should assess the material grade to ensure longevity and reliability, particularly in harsh operational environments.

2. Tolerance Levels

Tolerance levels indicate the precision with which a punch machine can produce parts. This specification is crucial for industries that require exact dimensions for components, such as automotive or aerospace manufacturing. A machine with tighter tolerances can reduce the need for secondary processing, thereby streamlining production and minimizing costs. Understanding tolerance requirements helps buyers align machine capabilities with their specific production needs.

3. Punching Force

Punching force, measured in tons, denotes the maximum force that the machine can exert to punch through materials. This specification is critical for determining the thickness and type of materials the machine can handle. Buyers need to evaluate their material processing requirements to select a machine that delivers the necessary force without compromising quality or efficiency.

4. Stroke Length

The stroke length refers to the distance the punch travels during operation. A longer stroke allows the machine to perform multiple operations, such as punching and forming, in one cycle. This versatility can enhance productivity and reduce setup times. Buyers should consider stroke length based on the complexity of the parts they plan to produce.

5. Speed and Cycle Time

The operational speed of a punch machine, often measured in strokes per minute (SPM), directly affects overall production efficiency. Faster machines can significantly boost output, making them suitable for high-demand environments. Evaluating cycle times is essential for aligning machine performance with production schedules and delivery commitments.

6. Automation Capabilities

Many modern punch machines offer automation features that enhance operational efficiency. Automation can include robotic loading/unloading systems, automatic tool changers, and integrated software for monitoring and control. These capabilities can lead to lower labor costs and increased throughput, making automation a key consideration for B2B buyers seeking competitive advantages.

What Are Common Trade Terms Related to Punch Machines?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are some common terms related to punch machines:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of punch machines, buyers should consider OEM relationships for sourcing reliable components and ensuring compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, especially when considering inventory levels and cash flow. It can also influence negotiations regarding pricing and lead times.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For punch machines, issuing an RFQ can help buyers compare offers and make informed purchasing decisions based on cost, specifications, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery responsibilities. Familiarity with Incoterms helps buyers understand their obligations, costs, and risks associated with transporting punch machines across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the punch machine industry, understanding lead times is critical for production planning and inventory management. Buyers should inquire about lead times to avoid disruptions in their operations.

6. After-Sales Support

After-sales support encompasses the services provided by suppliers following the purchase of a punch machine, including maintenance, repairs, and training. This support is crucial for ensuring the longevity and optimal performance of the machine, making it a key consideration for buyers focused on operational efficiency.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing punch machines, ultimately leading to better operational outcomes and enhanced profitability.

Navigating Market Dynamics and Sourcing Trends in the punch machine Sector

What Are the Key Trends Shaping the Global Punch Machine Market?

The punch machine sector is experiencing transformative shifts driven by technological advancements and evolving consumer demands. Key global drivers include the growing emphasis on automation, which enhances operational efficiency and reduces labor costs. In regions such as Africa and South America, where manufacturing is rapidly expanding, buyers are increasingly prioritizing machines that offer both versatility and precision. The integration of smart technologies, such as IoT capabilities, is becoming a significant trend, allowing for real-time monitoring and predictive maintenance, which minimizes downtime and enhances productivity.

Additionally, the rising trend of customizability in punch machines is noteworthy. B2B buyers are looking for equipment that can be tailored to specific production needs, which not only optimizes output but also adapts to varying market demands. Sustainability is another crucial factor shaping purchasing decisions. Companies are increasingly seeking machines that are energy-efficient and manufactured from sustainable materials, aligning with broader corporate social responsibility goals.

In terms of market dynamics, international buyers must navigate fluctuating supply chain conditions, particularly in light of geopolitical tensions and the recent pandemic. This has led to heightened interest in local sourcing options and diversified supplier networks, ensuring resilience against disruptions. As a result, buyers from the Middle East and Europe are exploring partnerships with regional manufacturers who can provide faster turnaround times and reliable service support.

How Is Sustainability and Ethical Sourcing Impacting the Punch Machine Sector?

Sustainability is becoming a non-negotiable criterion for B2B buyers in the punch machine sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. This includes selecting suppliers who prioritize eco-friendly materials and energy-efficient production methods. For instance, machines that incorporate recyclable components or use reduced energy consumption are increasingly favored.

Ethical sourcing is also critical. Buyers are demanding transparency in the supply chain to ensure that materials are sourced responsibly and labor practices are ethical. Certifications like ISO 14001 for environmental management or adherence to Fair Trade practices can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the move towards a circular economy is influencing purchasing decisions. B2B buyers are interested in machines designed for longevity, with options for upgrades and repairs rather than complete replacements. This not only reduces waste but also leads to cost savings over the machine’s lifecycle. As such, suppliers who can provide sustainable solutions will likely gain a competitive advantage in this evolving marketplace.

How Has the Punch Machine Sector Evolved Over Time?

The punch machine sector has undergone significant evolution, transitioning from manual operations to sophisticated automated systems. Initially, punch machines were primarily mechanical devices focused on efficiency in perforating materials. However, advancements in technology have led to the development of CNC (Computer Numerical Control) machines, allowing for precise and intricate designs that meet modern manufacturing requirements.

The introduction of automation and smart technologies has further revolutionized the sector, enabling real-time data analysis and improved production capabilities. As industries demand greater efficiency and customization, punch machines have adapted to accommodate these needs, making them indispensable in various manufacturing processes across the globe. Today, the integration of AI and machine learning is setting the stage for the next generation of punch machines, enhancing their functionality and usability in increasingly complex production environments.

Frequently Asked Questions (FAQs) for B2B Buyers of punch machine

-

How do I choose the right punch machine for my business needs?

When selecting a punch machine, consider the specific applications you require, such as the materials you’ll be working with and the types of parts you’ll produce. Evaluate the machine’s features, such as automation capabilities, tool flexibility, and production speed. It’s also essential to assess the machine’s size and compatibility with your workspace. Engaging with suppliers for demonstrations and detailed specifications can provide clarity on which model aligns best with your operational goals. -

What are the key specifications to look for in a punch machine?

Key specifications include punching force, stroke length, and work area dimensions. Additionally, consider the machine’s tooling options and the variety of materials it can process. Check for automation features that enhance productivity, such as quick-change tooling and programmable settings. Understanding these specifications will help ensure the machine can meet your production demands efficiently. -

What is the minimum order quantity (MOQ) when purchasing punch machines?

MOQs can vary significantly among manufacturers and suppliers. Some may offer single units for small businesses, while others may require larger orders to optimize production and shipping costs. Always inquire directly with suppliers to understand their MOQ policies, as negotiating may be possible based on your needs and long-term purchasing plans. -

How can I ensure the quality of the punch machines I am purchasing?

To ensure quality, request certifications and compliance documents that demonstrate adherence to international manufacturing standards. Conduct supplier audits or request references from other clients. Additionally, consider purchasing machines that come with warranties or service agreements, which can provide peace of mind regarding maintenance and support. -

What payment terms should I expect when sourcing punch machines internationally?

Payment terms can vary, but common arrangements include upfront deposits, payment upon delivery, or financing options. Be cautious of terms that seem unfavorable or uncommonly long. It’s advisable to negotiate terms that align with your cash flow, and consider using secure payment methods that offer buyer protection, such as letters of credit or escrow services. -

What logistics considerations should I be aware of when importing punch machines?

Logistics considerations include shipping methods, customs duties, and delivery timelines. It’s essential to confirm whether the supplier handles shipping or if you need to engage a freight forwarder. Additionally, understand the import regulations in your country, including any necessary permits or documentation to avoid delays at customs. -

Can I customize my punch machine to fit specific production needs?

Many manufacturers offer customization options, allowing you to modify features such as tooling, software, and machine size. When discussing your requirements with suppliers, clearly outline your production goals and constraints. Custom solutions may involve additional costs and lead times, so it’s important to weigh these factors against your operational needs. -

How do I evaluate and vet potential suppliers for punch machines?

Begin by researching suppliers’ reputations through online reviews, industry forums, and trade publications. Verify their experience in manufacturing punch machines and ask for case studies or testimonials from previous clients. Additionally, consider visiting their facilities or requesting virtual tours to assess their production processes and quality control measures. Engaging in open dialogue about your needs will help gauge their responsiveness and customer service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Punch Machine Manufacturers & Suppliers List

1. M&P Amusement – Boxer Spider & Dynamic Arcade Boxing Machines

Domain: mpamusement.com

Registered: 1997 (28 years)

Introduction: New Punching Bag Arcade Games for Sale at M&P Amusement. Featured products include: 1. Boxer Spider Arcade Boxing Machine starting at $6,495. 2. Boxer Dynamic Arcade Boxing Machine priced at $7,195. These machines are designed to add excitement and competitive energy to your business while generating extra income. M&P Amusement offers a large selection of arcade games including boxing machines.

2. TRUMPF – TruPunch Machines

Domain: trumpf.com

Registered: 1996 (29 years)

Introduction: TruPunch machines from TRUMPF offer flexible processing of diverse parts, including punching, reforming metal parts, and tapping on a single machine. Key features include:

– Rotating punching head for minimized setup times and increased productivity.

– Active and retractable die for optimum part quality.

– Intelligent automation options to enhance operator efficiency and throughput.

Product M…

3. MusicPunch – Music Boxing Machines

Domain: musicpunch.store

Registered: 2024 (1 years)

Introduction: {“products”:[{“name”:”MusicPunch™ – Music Boxing Machine (Expert)”,”sale_price”:”€137,95 EUR”,”regular_price”:”€259,95 EUR”,”savings”:”€122,00″},{“name”:”MusicPunch™ – Music Boxing Machine (Amateur)”,”sale_price”:”€120,95 EUR”,”regular_price”:”€233,95 EUR”,”savings”:”€113,00″},{“name”:”MusicPunch™ – Music Boxing Machine (Beginner)”,”sale_price”:”€85,95 EUR”,”regular_price”:”€172,95 EUR”,”savings”:…

4. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

5. Kalkomat – Boxer Fire Punching Game Machine

Domain: punchinggamemachine.com

Registered: 2021 (4 years)

Introduction: Best Punching Game Machines for Sale, Arcade Quality Boxing Machines. Key products include: 1. Kalkomat Boxer Fire Punching Game Machine – $8,199.00 (was $8,999.00, -9% off) 2. Kalkomat Boxer Glove Punching Game Machine – $8,299.00 (was $8,999.00, -8% off) 3. Kalkomat Combo Boxer Punching and Kicking Game Machine – $9,999.00 (was $10,999.00, -9% off) 4. Kalkomat Wheel of Boxing Punching Game Machi…

6. Sidekick Boxing – Ultimate X Gloves

Domain: sidekickboxing.co.uk

Registered: 2010 (15 years)

Introduction: Ultimate X boxing gloves, high-quality kickboxing equipment, endorsed by top fighters, suitable for various uses including home arcade and office, designed for optimal punching technique.

Strategic Sourcing Conclusion and Outlook for punch machine

In today’s competitive landscape, strategic sourcing of punch machines is essential for businesses seeking to enhance their operational efficiency and profitability. By leveraging diverse offerings—from arcade boxing machines that boost entertainment value to advanced industrial punching systems that optimize metal fabrication—companies can cater to a wide range of customer needs.

Understanding the nuances of different models and their applications allows international buyers, particularly in emerging markets like Africa and South America, to make informed decisions that align with their business objectives. The ability to customize machines with features such as LED displays, prize dispensers, and automation options not only enhances user experience but also drives revenue growth.

As you explore sourcing opportunities, consider the importance of supplier reliability and the potential for long-term partnerships. Investing in high-quality punch machines today will not only meet immediate operational demands but also position your business for future growth in a rapidly evolving marketplace.

We encourage buyers from regions like the Middle East and Europe to act decisively in securing the right machines that will propel their businesses forward. Embrace innovation, optimize your sourcing strategies, and unlock new avenues for success in the punch machine sector.