Is Your Portable Air Conditioner For Car 12V Sourcing Strategy Flawed? Read This 2025…

Introduction: Navigating the Global Market for portable air conditioner for car 12v

In an increasingly mobile world, the demand for effective cooling solutions, such as portable air conditioners for cars operating on 12V, has surged. International B2B buyers face the critical challenge of sourcing reliable and efficient cooling systems that cater to diverse climates and vehicle types. This comprehensive guide delves into the nuances of the global market for portable air conditioners, offering insights into various types, applications, and technological advancements.

From understanding the specifications that ensure optimal performance to identifying key suppliers, this guide equips buyers with the knowledge necessary for informed purchasing decisions. Additionally, we explore the cost implications and potential return on investment for businesses in regions such as Africa, South America, the Middle East, and Europe—where extreme temperatures can significantly impact comfort and productivity.

By addressing the needs of commercial operators and individual consumers alike, this guide aims to empower B2B buyers from countries like Nigeria and Saudi Arabia to navigate their options confidently. With a focus on supplier vetting and best practices for procurement, we provide actionable insights that ensure you select the most suitable portable air conditioning solution for your operational needs. Stay ahead of the competition by leveraging this essential resource for your cooling system requirements.

Understanding portable air conditioner for car 12v Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Miniature Refrigerated Compressors | Compact size, low power consumption, high efficiency | Automotive, logistics, outdoor events | Pros: Energy-efficient, space-saving; Cons: Limited cooling capacity for larger vehicles. |

| Stand-Alone Units | Can operate independently of the vehicle’s power system | Emergency services, remote work vehicles | Pros: Flexibility in usage; Cons: Heavier and bulkier than other options. |

| Auxiliary Battery-Powered Units | Utilizes auxiliary batteries for extended cooling | Long-haul trucking, field operations | Pros: Longer run time without vehicle idling; Cons: Requires additional battery investment. |

| Hybrid Systems | Combines traditional AC with portable features | Commercial fleets, rental services | Pros: Versatile cooling options; Cons: Higher initial investment and complexity. |

| Multi-Environment Units | Designed for use in cars, boats, and RVs | Recreational vehicles, marine applications | Pros: Versatile across different environments; Cons: May require adaptation for specific uses. |

What Are Miniature Refrigerated Compressors and Their B2B Suitability?

Miniature refrigerated compressors are known for their compact design and low power consumption, making them ideal for various automotive applications. These units are particularly suitable for logistics and outdoor events where space and energy efficiency are critical. B2B buyers should consider their cooling capacity and efficiency ratings, as these factors directly impact performance in high-temperature environments.

How Do Stand-Alone Units Benefit B2B Buyers?

Stand-alone air conditioning units are designed to operate independently from a vehicle’s power system, making them invaluable for emergency services and remote work vehicles. They provide flexibility in cooling options, allowing for use in various settings without relying on the vehicle’s battery. However, buyers should be aware of their larger size and weight, which may affect transport and installation.

What Advantages Do Auxiliary Battery-Powered Units Offer?

Auxiliary battery-powered units are engineered to extend cooling time without requiring the vehicle to idle, making them ideal for long-haul trucking and field operations. These units can significantly enhance driver comfort on extended journeys. However, B2B buyers must consider the additional investment in batteries and ensure compatibility with existing vehicle systems.

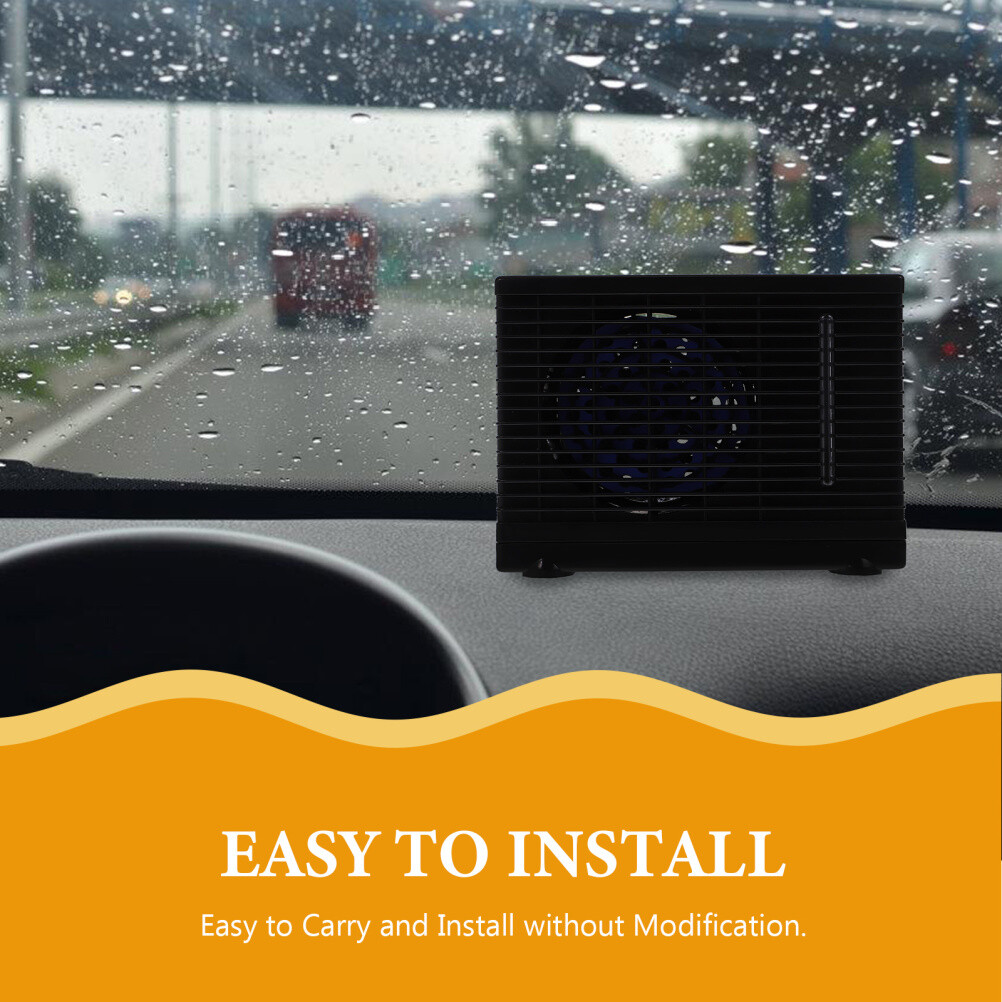

Illustrative image related to portable air conditioner for car 12v

Why Choose Hybrid Systems for Commercial Applications?

Hybrid systems integrate traditional air conditioning with portable features, offering a versatile cooling solution for commercial fleets and rental services. These systems allow for efficient cooling while on the road or parked. While they provide flexibility, B2B buyers should evaluate the higher initial investment and potential complexity in maintenance and operation.

What Makes Multi-Environment Units Versatile for B2B Use?

Multi-environment units are specifically designed for use in diverse settings, such as cars, boats, and RVs, making them an excellent choice for recreational vehicles and marine applications. Their adaptability is a significant selling point for businesses that require reliable cooling across different environments. Buyers should assess the unit’s specifications to ensure it meets the specific cooling demands of each application.

Key Industrial Applications of portable air conditioner for car 12v

| Industry/Sector | Specific Application of Portable Air Conditioner for Car 12V | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Cooling for Delivery Vehicles | Enhances driver comfort and productivity during long hauls. | Power efficiency, portability, and ease of installation. |

| Construction | Cooling for Site Vehicles | Provides a comfortable working environment in extreme heat. | Durability, resistance to dust and moisture, and energy consumption. |

| Emergency Services | Cooling for Emergency Response Vehicles | Ensures operational efficiency and crew comfort in high-stress situations. | Reliability, quick setup, and low maintenance requirements. |

| Tourism and Recreational Vehicles | Cooling for Camper Vans and RVs | Improves customer satisfaction during travel and camping. | Compact design, battery operation, and ease of transport. |

| Agriculture | Cooling for Mobile Equipment | Protects equipment and improves comfort for operators in the field. | Compatibility with various power sources and rugged construction. |

How Can Portable Air Conditioners Improve Logistics and Transportation?

In the logistics and transportation sector, portable air conditioners for cars are essential for cooling delivery vehicles, especially during long hauls in hot climates. They enhance driver comfort, leading to better focus and productivity. For international buyers, especially in regions like Africa and the Middle East, sourcing units that operate efficiently on 12V systems and are easy to install can be crucial. Additionally, ensuring that the units are lightweight and have a robust design can help withstand the rigors of daily use.

What Role Do Portable Air Conditioners Play in Construction?

In construction, portable air conditioners are used in site vehicles to provide relief from extreme heat, ensuring that workers remain comfortable and productive. This is particularly important in areas with high temperatures, such as parts of South America and Africa. Buyers should consider durability and moisture resistance, given the outdoor conditions. Moreover, energy consumption is a key factor since many construction sites operate on limited power resources, making efficient cooling solutions a priority.

How Do Emergency Services Benefit from Portable Air Conditioners?

Emergency response vehicles often operate in high-stress environments where crew comfort is vital. Portable air conditioners help maintain a cool cabin during operations, allowing emergency personnel to focus on their tasks without the distraction of heat. For B2B buyers in this sector, sourcing reliable units that can be quickly set up and require minimal maintenance is essential. Units should also be designed for rugged use, ensuring they can withstand the demands of emergency situations.

Why Are Portable Air Conditioners Important for Tourism and Recreational Vehicles?

In the tourism sector, portable air conditioners are increasingly being used in camper vans and RVs to enhance the travel experience. They provide a much-needed respite from heat during road trips, especially in regions like Europe and South America, where summer temperatures can soar. Buyers should look for compact and lightweight models that can easily be transported and set up. Battery operation capability is also crucial for off-grid camping scenarios, ensuring comfort without reliance on external power sources.

How Can Agriculture Benefit from Portable Air Conditioning?

In agriculture, portable air conditioners can be employed to cool mobile equipment or provide comfort for operators in the field. This is particularly beneficial in hot climates, where excessive heat can hinder productivity and equipment performance. When sourcing for agricultural applications, buyers should focus on compatibility with various power sources, as well as rugged construction to endure outdoor conditions. Ensuring easy maintenance and efficient cooling will also be key considerations for agricultural businesses looking to invest in these solutions.

3 Common User Pain Points for ‘portable air conditioner for car 12v’ & Their Solutions

Scenario 1: Insufficient Cooling for Commercial Fleets

The Problem: B2B buyers managing commercial vehicle fleets often face challenges with traditional air conditioning systems that struggle to keep the interiors cool during extreme weather conditions. This discomfort can lead to decreased driver productivity and increased fatigue, especially during long hauls in regions with high temperatures, such as parts of Africa and the Middle East. Additionally, older vehicles may not have adequate built-in cooling solutions, leaving drivers to endure uncomfortable conditions that can affect their performance and overall satisfaction.

The Solution: To address this issue, buyers should consider sourcing high-capacity 12V portable air conditioners specifically designed for vehicle use. When selecting a unit, prioritize models that feature robust cooling capabilities and low voltage operation to ensure they won’t drain the vehicle’s battery. For instance, products like the RIGID portable air conditioner can provide reliable cooling even in extreme heat, making them ideal for long-distance drivers. Ensure that the units are easy to install and can be integrated seamlessly with the vehicle’s power system. Regular maintenance checks and timely replacements of filters will also help maintain optimal performance, ensuring that drivers remain comfortable and productive on the road.

Illustrative image related to portable air conditioner for car 12v

Scenario 2: Limited Power Supply and Battery Drain Concerns

The Problem: Many B2B buyers in regions with inconsistent power supply or in scenarios where vehicles are parked for extended periods (such as transport hubs or logistics centers) face the challenge of limited power availability. Using a traditional car air conditioning system can lead to significant battery drain, leaving vehicles unable to start. This situation can be particularly concerning for companies relying on just-in-time logistics, where vehicle readiness is crucial.

The Solution: To mitigate these concerns, buyers should consider investing in portable air conditioners that are specifically designed for low power consumption, such as those operating at 12V. Look for models with features like battery-saving modes or energy-efficient compressors. Additionally, consider pairing the air conditioner with an auxiliary battery system that can provide power without relying on the vehicle’s main battery. This setup allows for cooling while parked without risking a dead battery. Regularly monitoring battery health and investing in solar-powered chargers can also provide sustainable solutions for ensuring that vehicles remain operational without compromising comfort.

Scenario 3: Complicated Installation and Usability Issues

The Problem: B2B buyers might encounter portable air conditioning units that are difficult to install or operate, leading to frustration and wasted time. Complicated setups can deter drivers from using these systems, resulting in discomfort during travel. This issue is particularly pronounced in regions where DIY installation is common due to a lack of professional services, and where simple user interfaces are crucial for effective operation.

The Solution: To overcome installation and usability challenges, buyers should prioritize portable air conditioners that are designed for ease of use and straightforward installation. Look for units that come with comprehensive installation kits and clear instructions, ensuring that even those with limited technical skills can set them up efficiently. Additionally, consider models that feature intuitive controls, such as wireless remote operation, allowing drivers to adjust settings without having to leave their seats. Training sessions on unit operation can further enhance usability, ensuring drivers are comfortable and confident in using the system. Investing in units with good customer support and warranty options can also provide peace of mind, knowing that assistance is available if any issues arise.

Strategic Material Selection Guide for portable air conditioner for car 12v

What are the Key Materials Used in Portable Air Conditioners for Cars?

When selecting materials for portable air conditioners designed for cars, particularly 12V systems, it is essential to consider their properties, manufacturing complexities, and suitability for various applications. The following analysis focuses on four common materials: aluminum, plastic, copper, and stainless steel, providing insights relevant to B2B buyers across diverse international markets.

Illustrative image related to portable air conditioner for car 12v

How Does Aluminum Perform in Portable Air Conditioners?

Aluminum is widely used in the construction of portable air conditioners due to its excellent thermal conductivity and lightweight nature. It typically has a temperature rating of up to 150°C, making it suitable for heat exchange applications.

Pros: Aluminum is highly resistant to corrosion, which is crucial for units exposed to varying climates. Its lightweight property facilitates easier installation and transportation, reducing shipping costs.

Cons: While aluminum is durable, it can be prone to dents and scratches. Additionally, it may require surface treatments to enhance its corrosion resistance, which can increase manufacturing complexity.

Impact on Application: Aluminum is compatible with refrigerants commonly used in air conditioning systems, ensuring efficient heat exchange.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. In regions like Africa and the Middle East, where humidity can be high, selecting anodized aluminum may be beneficial to enhance durability.

What Role Does Plastic Play in Portable Air Conditioners?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are frequently used for housings and internal components of portable air conditioners.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs. They also exhibit good resistance to moisture and chemicals.

Illustrative image related to portable air conditioner for car 12v

Cons: Plastic materials may not withstand high temperatures as effectively as metals, with a typical temperature limit of about 80°C. They can also be less durable than metals, particularly under mechanical stress.

Impact on Application: Plastic components can be designed to be compatible with various refrigerants, but their thermal insulation properties can limit cooling efficiency.

Considerations for International Buyers: Buyers should consider the specific grades of plastic that comply with local regulations, such as RoHS in Europe, which restricts hazardous substances.

Illustrative image related to portable air conditioner for car 12v

How Does Copper Contribute to Air Conditioning Efficiency?

Copper is a traditional choice for heat exchangers and tubing in air conditioning systems due to its exceptional thermal conductivity and resistance to corrosion.

Pros: Copper’s high thermal conductivity allows for efficient heat transfer, which is critical for cooling performance. It is also durable and has a long lifespan.

Cons: The primary drawback of copper is its cost, which is higher than aluminum and plastic. Additionally, copper can be susceptible to corrosion if not properly treated or maintained.

Impact on Application: Copper tubing is highly compatible with various refrigerants and is often used in high-pressure applications, making it ideal for portable air conditioners.

Considerations for International Buyers: Buyers should ensure that copper components meet relevant standards such as ASTM B280 for copper tubing. In regions with high temperatures, ensuring proper insulation around copper lines is crucial to maintain efficiency.

Illustrative image related to portable air conditioner for car 12v

What Advantages Does Stainless Steel Offer?

Stainless steel is often used for structural components and casings in portable air conditioners due to its strength and corrosion resistance.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, making it suitable for various environmental conditions. It also has a high-temperature rating, typically up to 870°C.

Cons: The main disadvantages include its weight and cost, which are higher than aluminum and plastic. Manufacturing processes for stainless steel can also be more complex.

Impact on Application: Stainless steel is compatible with a wide range of refrigerants and can withstand high pressures, making it suitable for robust applications.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM A240 for stainless steel. In regions with extreme weather, the durability of stainless steel can be a significant advantage.

Summary Table of Material Properties

| Material | Typical Use Case for portable air conditioner for car 12v | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat exchangers, housing | Lightweight and corrosion-resistant | Prone to dents and scratches | Medium |

| Plastic | Housings, internal components | Cost-effective and moldable | Limited temperature resistance | Low |

| Copper | Tubing and heat exchangers | Excellent thermal conductivity | Higher cost and corrosion potential | High |

| Stainless Steel | Structural components and casings | Highly durable and corrosion-resistant | Heavy and costly | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to invest in portable air conditioning solutions for cars, ensuring they make informed decisions based on material properties and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for portable air conditioner for car 12v

What are the Key Stages in the Manufacturing Process of Portable Air Conditioners for Cars?

The manufacturing process of portable air conditioners designed for 12V applications involves several critical stages, each essential for producing high-quality, reliable units. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The first step involves sourcing high-quality materials such as metals, plastics, and insulation components. Manufacturers often prioritize lightweight yet durable materials to enhance portability and efficiency. For instance, aluminum is frequently used for the casing due to its lightweight properties and resistance to corrosion. -

Forming:

During the forming stage, raw materials are shaped into specific components. This may involve techniques such as extrusion for aluminum parts and injection molding for plastic components. Precision in this stage is crucial, as any discrepancies can lead to inefficiencies in the final product’s performance. -

Assembly:

The assembly stage combines the various components into a complete unit. This process often employs automated machinery for tasks such as soldering electrical connections and securing parts together. Manual assembly may also be necessary for intricate components or quality checks. Ensuring that each unit is assembled correctly is vital for operational efficiency and longevity. -

Finishing:

The finishing stage involves applying protective coatings and conducting any necessary surface treatments. This can include powder coating for aesthetics and added durability or applying thermal insulation to improve energy efficiency. Quality checks during this phase are essential to ensure that the finish meets both aesthetic and functional standards.

How is Quality Control Integrated into the Manufacturing Process?

Quality control (QC) is an integral part of the manufacturing process, ensuring that each portable air conditioner meets international standards and customer expectations. Several checkpoints and testing methods are implemented throughout the production cycle.

-

International Standards:

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on consistent quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can be critical for ensuring compliance with safety and performance regulations, particularly in international markets. -

Quality Checkpoints:

Quality control checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for quality and compliance with specifications before they enter the production line.

– In-Process Quality Control (IPQC): During assembly, periodic checks are conducted to ensure that components are being assembled correctly and functionally tested to meet performance criteria.

– Final Quality Control (FQC): Once the units are fully assembled, a comprehensive inspection is performed. This includes functionality tests, safety checks, and aesthetic evaluations to ensure that the product meets all required standards before shipping. -

Common Testing Methods:

Testing methods often used for portable air conditioners include:

– Performance Testing: Evaluating cooling efficiency and power consumption under various conditions.

– Durability Testing: Subjecting units to extreme temperatures and humidity to assess their performance and reliability.

– Safety Testing: Ensuring that units comply with electrical safety standards to prevent risks of overheating or electrical failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is critical to ensuring product reliability and safety. Here are several methods to effectively assess supplier QC:

-

Conducting Audits:

B2B buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, QC practices, and overall facility standards. Audits can reveal the supplier’s commitment to quality and adherence to international standards. -

Requesting Quality Reports:

Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These documents can give buyers insight into the frequency of defects, corrective actions taken, and overall product quality. -

Engaging Third-Party Inspectors:

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities. These services often include pre-shipment inspections and compliance checks against international standards, ensuring that the products meet the required specifications before they are shipped.

What Nuances Should International B2B Buyers Consider for Quality Assurance?

International B2B buyers must navigate several nuances when it comes to quality assurance, particularly in diverse markets such as Nigeria and Saudi Arabia.

-

Understanding Regional Standards:

Different regions may have specific regulations regarding product safety and performance. Buyers should familiarize themselves with local standards and ensure that their suppliers comply with these regulations to avoid legal issues and ensure market acceptance. -

Cultural and Communication Barriers:

Effective communication is essential for quality assurance. Language differences and cultural nuances can lead to misunderstandings. Establishing clear communication channels and expectations can mitigate risks associated with these barriers. -

Logistics and Supply Chain Considerations:

The logistics involved in international shipping can impact product quality. Buyers should work with suppliers who understand the complexities of transporting sensitive equipment, ensuring that products are packaged correctly to avoid damage during transit.

Conclusion: Ensuring Quality in Portable Air Conditioner Manufacturing

The manufacturing processes and quality assurance protocols for portable air conditioners for cars are complex yet vital for delivering reliable products to B2B buyers. Understanding the key stages in manufacturing, the importance of robust quality control systems, and effective methods to verify supplier practices are essential for ensuring product reliability. By prioritizing these factors, international buyers can make informed decisions and secure quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘portable air conditioner for car 12v’

To successfully procure a portable air conditioner for cars operating on 12V, B2B buyers must navigate a series of critical steps. This guide offers a structured checklist to ensure that your purchasing process is efficient and meets the specific needs of your business and clientele.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring compatibility with your vehicles and meeting user expectations. Consider factors such as power consumption, cooling capacity, and dimensions. These specifications will guide your supplier selection and ensure that the units can operate effectively in the intended environments.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and innovations in portable air conditioning technology. This knowledge can help you identify cutting-edge products that offer enhanced efficiency and features, such as low voltage operation and compact design. Understanding market demands will also enable you to provide solutions that cater to your customers’ evolving needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, including their history, production capabilities, and client references. Pay particular attention to suppliers that have experience in your target markets, such as Africa, South America, the Middle East, and Europe, as they will be more attuned to regional requirements.

- Check Certifications: Ensure that suppliers adhere to international quality standards (e.g., ISO, CE) and possess necessary certifications for safety and efficiency.

- Review Customer Feedback: Look for reviews and testimonials from businesses similar to yours to gauge reliability and product performance.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their products. Testing these samples in real-world conditions will allow you to evaluate their performance and suitability for your specific applications. Pay attention to cooling efficiency, noise levels, and ease of installation, as these factors significantly impact user satisfaction.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure favorable pricing and payment terms. Consider bulk purchasing discounts, warranty provisions, and after-sales support. Establishing clear terms upfront can prevent misunderstandings and ensure a smoother transaction process.

Step 6: Plan for Logistics and Distribution

Consider the logistics involved in importing the units, especially if sourcing internationally. Evaluate shipping options, costs, and delivery timelines. Additionally, ensure that you have a robust distribution plan to get the products to your customers efficiently, minimizing delays.

Step 7: Implement Post-Purchase Evaluation

After procuring the portable air conditioners, establish a system for post-purchase evaluation. Gather feedback from end-users regarding product performance and comfort levels. This information is invaluable for refining your sourcing strategy and enhancing customer satisfaction in future purchases.

By following this structured checklist, B2B buyers can navigate the procurement process more effectively, ensuring they acquire portable air conditioners that meet both their operational needs and their customers’ expectations.

Comprehensive Cost and Pricing Analysis for portable air conditioner for car 12v Sourcing

What Are the Key Cost Components for Portable Air Conditioners for Cars?

When sourcing portable air conditioners for cars operating on 12V systems, understanding the cost structure is critical for B2B buyers. The main cost components include:

-

Materials: The choice of materials directly impacts the quality and durability of the air conditioner. Common materials include high-grade plastics for housing, copper for the refrigerant lines, and various metals for internal components. Cost variations occur based on the quality and source of these materials.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing and assembly. In regions with higher labor costs, such as Europe, the overall manufacturing cost may increase. Conversely, sourcing from regions with lower labor costs can lead to savings.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses tied to the production facility. Efficient production processes can mitigate overhead costs, enhancing overall price competitiveness.

-

Tooling: Initial setup costs for tooling and molds can be significant, especially for customized or high-spec units. These costs are typically amortized over the production volume.

-

Quality Control (QC): Ensuring product reliability and safety necessitates investment in quality control measures. Rigorous testing and certification processes can add to the overall cost but are essential for maintaining market standards.

-

Logistics: Shipping costs depend on the mode of transport, distance, and volume. For international buyers, understanding Incoterms and potential duties is vital for accurate cost estimation.

-

Margin: Suppliers often include a profit margin that can range from 10% to 30% based on market conditions and competition. This margin is influenced by the perceived value of the product and brand reputation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing for portable air conditioners, which can vary significantly across regions:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Higher volume orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Units with specialized features, such as advanced cooling technology or energy efficiency certifications, often command higher prices. Customization options can also increase costs but may be necessary to meet specific market demands.

-

Materials and Quality Certifications: The choice of components, such as refrigerants or energy-efficient compressors, impacts pricing. Additionally, certifications like CE or ISO can enhance product credibility but may also increase costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their reputation, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms is crucial for cost calculations. Different Incoterms (like FOB or CIF) can shift responsibility for shipping costs, affecting the overall price structure.

What Are the Best Practices for Buyers to Negotiate Cost-Effective Solutions?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, negotiating the best deal requires strategic planning:

-

Leverage Volume for Discounts: Engage suppliers in discussions about discounts for larger orders. This can significantly reduce per-unit costs and improve overall profitability.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and energy consumption over the product’s lifespan. A slightly higher upfront cost may lead to lower operational costs.

-

Conduct Market Research: Understanding market prices and competitor offerings can provide leverage during negotiations. This insight can help buyers make informed decisions and spot potential red flags.

-

Build Long-Term Relationships: Establishing a reliable partnership with suppliers can lead to better terms, priority during stock shortages, and insights into upcoming product innovations.

-

Stay Informed on Pricing Nuances: Currency fluctuations, local regulations, and import tariffs can all affect the final price. Staying informed about these variables can help in budgeting and negotiations.

Conclusion

In summary, a comprehensive understanding of cost components, price influencers, and negotiation strategies is crucial for B2B buyers sourcing portable air conditioners for cars. By focusing on these factors, businesses can make informed decisions that not only meet their cooling needs but also align with their financial goals. As a reminder, prices can vary based on market conditions, and buyers should seek quotes tailored to their specific requirements for the most accurate pricing information.

Alternatives Analysis: Comparing portable air conditioner for car 12v With Other Solutions

The demand for effective cooling solutions in vehicles has led to the development of various technologies, including portable air conditioners specifically designed for cars. However, buyers should consider alternative options that may also address their cooling needs. Below, we compare the ‘Portable Air Conditioner for Car 12V’ with two viable alternatives: traditional vehicle air conditioning systems and evaporative coolers.

| Comparison Aspect | Portable Air Conditioner For Car 12V | Traditional Vehicle AC System | Evaporative Cooler |

|---|---|---|---|

| Performance | Provides targeted cooling; effective in small spaces | Cools entire vehicle, but may struggle in extreme heat | Effective in dry climates; relies on low humidity |

| Cost | Moderate upfront cost (approx. $700) | Higher installation/repair costs; ongoing maintenance | Lower initial cost; minimal maintenance required |

| Ease of Implementation | Easy to install; portable and flexible | Requires professional installation; fixed system | Simple setup; requires water source |

| Maintenance | Minimal maintenance; periodic cleaning | Regular maintenance needed (recharge, filter changes) | Low maintenance; occasional water refill |

| Best Use Case | Ideal for road trips, camping, and small vehicles | Suitable for everyday use in modern cars | Best for dry climates and outdoor use |

What Are the Pros and Cons of Traditional Vehicle Air Conditioning Systems?

Traditional vehicle air conditioning systems are integrated into the vehicle’s design, providing efficient cooling for the entire cabin. The primary advantage is their ability to maintain a comfortable environment regardless of external conditions. However, these systems can be costly to install and maintain, especially in older vehicles where repairs may be needed. They also rely heavily on the vehicle’s engine, which can lead to increased fuel consumption and potential overheating during prolonged use.

How Do Evaporative Coolers Work as an Alternative?

Evaporative coolers, also known as swamp coolers, function by using water evaporation to lower air temperature. This method is particularly effective in dry climates, making it a suitable option for regions with low humidity. The benefits include lower initial costs and minimal maintenance requirements. However, their effectiveness diminishes in high-humidity environments, and they require a continuous water supply, which may not be practical for all users.

Conclusion: How to Choose the Right Cooling Solution for Your Needs

When selecting a cooling solution for vehicles, B2B buyers should assess their specific needs, including climate conditions, vehicle type, and budget. The portable air conditioner for car 12V offers flexibility and targeted cooling, making it ideal for outdoor adventures and smaller vehicles. Traditional air conditioning systems provide comprehensive cooling but at a higher cost and maintenance commitment. Evaporative coolers present a cost-effective solution for dry climates but may fall short in humid environments. By weighing the pros and cons of each option, buyers can make an informed decision that aligns with their operational requirements and financial considerations.

Essential Technical Properties and Trade Terminology for portable air conditioner for car 12v

What Are the Key Technical Specifications of Portable Air Conditioners for Cars?

When evaluating portable air conditioners for cars, especially those operating on 12V systems, several technical specifications are crucial for B2B buyers. Understanding these properties can aid in making informed procurement decisions.

1. Power Consumption (Amps)

This specification indicates how much electrical current the unit requires to operate. For example, a portable air conditioner may consume around 4.5 Amps at maximum power. Understanding power consumption is essential for buyers to ensure compatibility with vehicle electrical systems and to gauge energy efficiency. Lower power consumption not only reduces operational costs but also minimizes the risk of draining the vehicle’s battery.

2. Cooling Capacity (BTU)

The cooling capacity, measured in British Thermal Units (BTU), reflects the unit’s ability to cool a specific volume of air. A higher BTU rating means the air conditioner can cool larger spaces or operate effectively in hotter climates. B2B buyers should assess the BTU ratings to ensure the product meets their cooling needs, particularly in regions with extreme temperatures, such as Africa or the Middle East.

3. Operating Voltage

Most portable air conditioners for cars operate on a 12V or 24V system. This specification is critical, as it determines the unit’s compatibility with different vehicle electrical systems. B2B buyers should verify the voltage requirements to avoid purchasing incompatible products, which can lead to inefficiencies or damage.

4. Weight and Dimensions

The weight and size of the air conditioning unit are vital for ease of transport and installation. Compact models, like those measuring around 10″x13″x18″, are ideal for vehicles with limited space. Buyers should consider these dimensions to ensure that the product fits comfortably within the intended vehicle without obstructing passenger space.

5. Warranty and Support

A robust warranty and customer support are essential for B2B transactions. Most reputable manufacturers offer at least a one-year warranty on parts and labor, along with a satisfaction guarantee. This assurance is crucial for businesses to minimize risks associated with product failures and to ensure long-term operational reliability.

Which Trade Terminology Should B2B Buyers Understand?

Navigating the procurement landscape for portable air conditioners involves familiarizing oneself with specific trade terminology. Below are common terms that B2B buyers should know.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source parts or collaborate with manufacturers for branding purposes.

2. MOQ (Minimum Order Quantity)

This term denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to assess whether they can meet purchasing requirements without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. This process allows buyers to compare pricing and terms from multiple vendors, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are critical when sourcing products from different regions.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to plan inventory and ensure timely delivery for their customers.

By grasping these technical specifications and trade terms, B2B buyers can navigate the procurement of portable air conditioners for cars more effectively, ensuring they select products that meet their specific needs while optimizing their supply chain operations.

Navigating Market Dynamics and Sourcing Trends in the portable air conditioner for car 12v Sector

What Are the Key Market Trends Affecting the Portable Air Conditioner for Car 12V Sector?

The portable air conditioner market for vehicles, particularly those operating on 12V systems, is experiencing a significant transformation influenced by various global trends. One of the primary drivers is the growing need for comfort in vehicles, especially in regions with extreme temperatures. In Africa, South America, the Middle East, and parts of Europe, rising temperatures are driving demand for efficient cooling solutions. The increasing prevalence of road trips and outdoor activities also fuels this market, as consumers seek to enhance their travel experiences.

Emerging technologies in cooling systems are reshaping the landscape. Innovations such as miniaturized compressors and advanced thermal management systems allow for more efficient, compact, and powerful units. B2B buyers are increasingly looking for portable air conditioning solutions that not only offer high performance but are also lightweight and easy to install. Furthermore, the trend towards integration with smart technology is gaining traction, with features like remote control and mobile app connectivity becoming increasingly popular.

Illustrative image related to portable air conditioner for car 12v

Market dynamics are shifting as international B2B buyers prioritize suppliers who can offer customization options and flexible sourcing solutions. For example, businesses in Nigeria and Saudi Arabia may seek tailored products that cater to local climate conditions and consumer preferences. As such, suppliers who can provide localized support and rapid response to market changes will have a competitive advantage.

How Is Sustainability and Ethical Sourcing Impacting the Portable Air Conditioner for Car 12V Sector?

Sustainability is becoming a critical consideration for B2B buyers in the portable air conditioner market. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, leading to a growing demand for energy-efficient solutions. Portable air conditioners that operate on 12V systems are often marketed as more energy-efficient, which aligns with the increasing consumer and regulatory demand for greener technologies.

Ethical sourcing is equally vital. B2B buyers are now more inclined to partner with manufacturers who adhere to sustainable practices, including the use of recyclable materials and adherence to ethical labor standards. Certifications such as Energy Star or ISO 14001 can serve as benchmarks for suppliers aiming to showcase their commitment to sustainability. Buyers in regions like Europe and the Middle East are particularly sensitive to these factors, as they often prioritize products that align with their sustainability goals.

Additionally, the use of eco-friendly refrigerants and materials in portable air conditioners is becoming more prevalent. This trend not only addresses environmental concerns but also enhances brand reputation and marketability among environmentally conscious consumers. B2B buyers are encouraged to evaluate potential suppliers based on their environmental policies and product certifications to ensure alignment with their own sustainability objectives.

What Is the Evolution of the Portable Air Conditioner for Car 12V Market?

The portable air conditioner for car 12V market has evolved significantly over the past few decades. Initially, these systems were bulky and inefficient, primarily serving niche markets such as commercial vehicles and emergency services. However, technological advancements have led to the development of compact, efficient units that are now accessible to everyday consumers.

The introduction of lightweight materials and efficient cooling technologies has made portable air conditioners more user-friendly, enabling widespread adoption across various markets. Today, these units are not only essential for comfort during road trips but also serve as vital tools for businesses in hot climates, enhancing productivity and safety for drivers and passengers alike.

The evolution continues as manufacturers innovate to meet changing consumer needs and environmental regulations, ensuring that portable air conditioners remain a relevant and necessary solution for vehicle cooling in diverse markets worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of portable air conditioner for car 12v

-

How do I solve the issue of inadequate cooling during long road trips?

To tackle inadequate cooling during long journeys, consider investing in a portable air conditioner designed for vehicles, such as a 12V model. These units operate efficiently on the vehicle’s electrical system, providing immediate relief from high temperatures. Look for models with features like variable speed settings and remote control for optimal comfort. Additionally, ensure the unit is compact for easy installation and does not consume excessive power, allowing you to maintain your vehicle’s battery health. -

What is the best portable air conditioner for cars in hot climates?

For hot climates, a portable air conditioner that operates on 12V power is ideal. Look for units that feature high cooling capacity, energy efficiency, and low power consumption. Brands like RIGID offer compact designs with variable speed controls, ensuring that you can achieve the desired temperature quickly. Additionally, consider models that include an exhaust air hose for better airflow and cooling efficiency, making them suitable for extended use in extreme heat conditions. -

What should I consider when vetting suppliers for portable air conditioners?

When vetting suppliers, focus on their experience in manufacturing portable air conditioning units and their reputation in the industry. Check for certifications and compliance with international standards, which indicate quality assurance. Request samples to assess product quality firsthand and inquire about customer reviews. Additionally, confirm their ability to provide after-sales support, warranty terms, and return policies to ensure a reliable partnership. -

What are the common payment terms for purchasing portable air conditioners in bulk?

Payment terms can vary by supplier but typically include options like a deposit upfront (often 30% to 50%) with the balance due before shipment or upon delivery. Some suppliers may offer net payment terms, allowing buyers to pay within a specified period after receiving the goods. Ensure clarity on payment methods accepted, such as bank transfers, letters of credit, or PayPal, and discuss potential discounts for bulk orders to optimize your purchasing costs. -

What is the minimum order quantity (MOQ) for portable air conditioners?

Minimum order quantities for portable air conditioners can range significantly based on the manufacturer. Many suppliers set MOQs between 50 to 100 units, especially for customized orders. It’s essential to discuss MOQs upfront when negotiating with suppliers to ensure they align with your purchasing needs. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, so don’t hesitate to inquire about options that suit your requirements. -

How can I ensure quality assurance (QA) for my order of portable air conditioners?

To ensure quality assurance, request detailed information on the supplier’s QA processes, including testing and inspection protocols. Ask for quality certifications such as ISO or CE, which indicate adherence to international manufacturing standards. Consider arranging for third-party inspections before shipment, especially for larger orders, to verify that products meet your specifications. Establishing a clear communication channel with the supplier can also facilitate timely updates and quality checks throughout the production process. -

What logistics considerations should I keep in mind when importing portable air conditioners?

When importing portable air conditioners, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling electronic goods to ensure timely delivery. Be aware of the packaging requirements to prevent damage during transit, and confirm that the supplier provides necessary documentation for customs clearance. Understanding local regulations regarding the import of electrical appliances is crucial to avoid delays and additional costs. -

Are there customization options available for portable air conditioners?

Many manufacturers offer customization options for portable air conditioners, allowing you to tailor features such as color, branding, and technical specifications to meet your market needs. Discuss your specific requirements with potential suppliers, including any desired modifications to cooling capacity or energy efficiency. Customization may also extend to packaging and labeling, which can enhance your brand’s visibility. Be sure to clarify any associated costs and lead times for customized orders during negotiations.

A Look at Portable Air Conditioner For Car 12V Manufacturers & Suppliers

Could not verify enough suppliers for portable air conditioner for car 12v to create a list at this time.

Strategic Sourcing Conclusion and Outlook for portable air conditioner for car 12v

In conclusion, the demand for portable air conditioners for cars powered by 12V systems is rapidly increasing, driven by the need for effective cooling solutions in regions with extreme temperatures. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing of these innovative products is crucial. Key takeaways include understanding the competitive advantages offered by different manufacturers, such as energy efficiency, portability, and ease of installation.

Illustrative image related to portable air conditioner for car 12v

Investing in high-quality portable air conditioners can enhance customer satisfaction, especially for commercial vehicles and long-distance travelers. Buyers should prioritize partnerships with reliable suppliers who demonstrate a commitment to product innovation and customer support.

Looking ahead, the market for portable air conditioning solutions is poised for growth, with advancements in technology promising even more efficient and effective products. Now is the time to engage with manufacturers and distributors to secure favorable sourcing agreements. By doing so, businesses can position themselves to meet the evolving demands of consumers while capitalizing on emerging market opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to portable air conditioner for car 12v

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.