Is Your Planetary Differential Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for planetary differential

In the fast-evolving landscape of mechanical engineering, sourcing the right planetary differential can pose a significant challenge for international B2B buyers. These essential components are pivotal in applications ranging from automotive to industrial machinery, offering the advantage of compact design without compromising on torque and speed. As businesses in regions such as Africa, South America, the Middle East, and Europe (including Germany and Vietnam) expand their operations, understanding the intricacies of planetary differentials becomes crucial for informed purchasing decisions.

This comprehensive guide delves into the various types of planetary differentials, their applications across diverse industries, and key considerations for supplier vetting. It explores cost factors, performance metrics, and the latest technological advancements, providing a holistic view of the market. By highlighting critical elements such as load capacity, efficiency, and durability, this guide equips B2B buyers with the insights needed to navigate the complexities of sourcing and selecting the ideal planetary differential for their specific needs.

Ultimately, this resource aims to empower international buyers by demystifying the procurement process and facilitating strategic partnerships with reliable suppliers. With the right knowledge and tools, businesses can optimize their operations and drive competitive advantage in their respective markets.

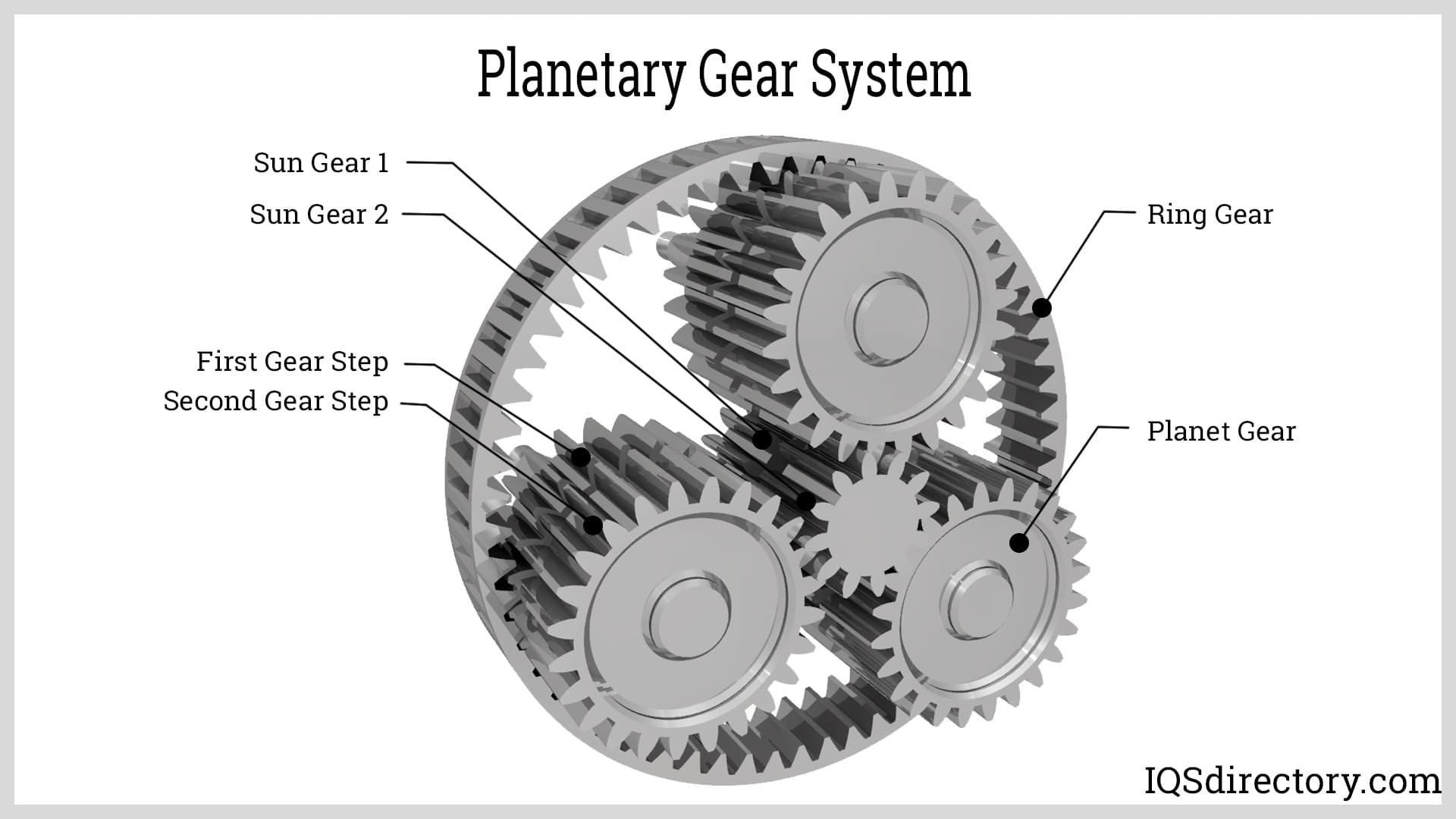

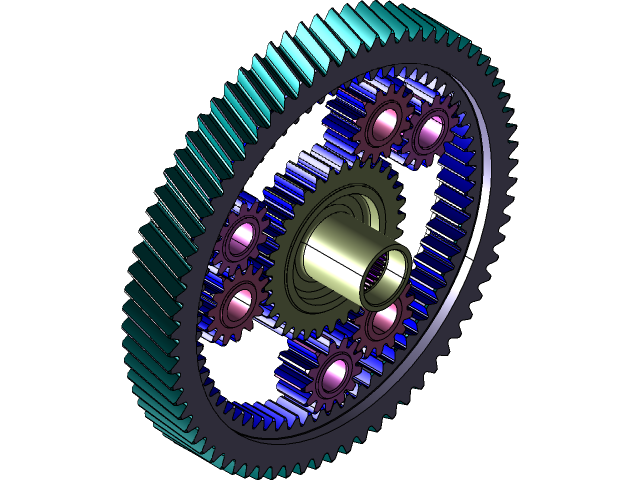

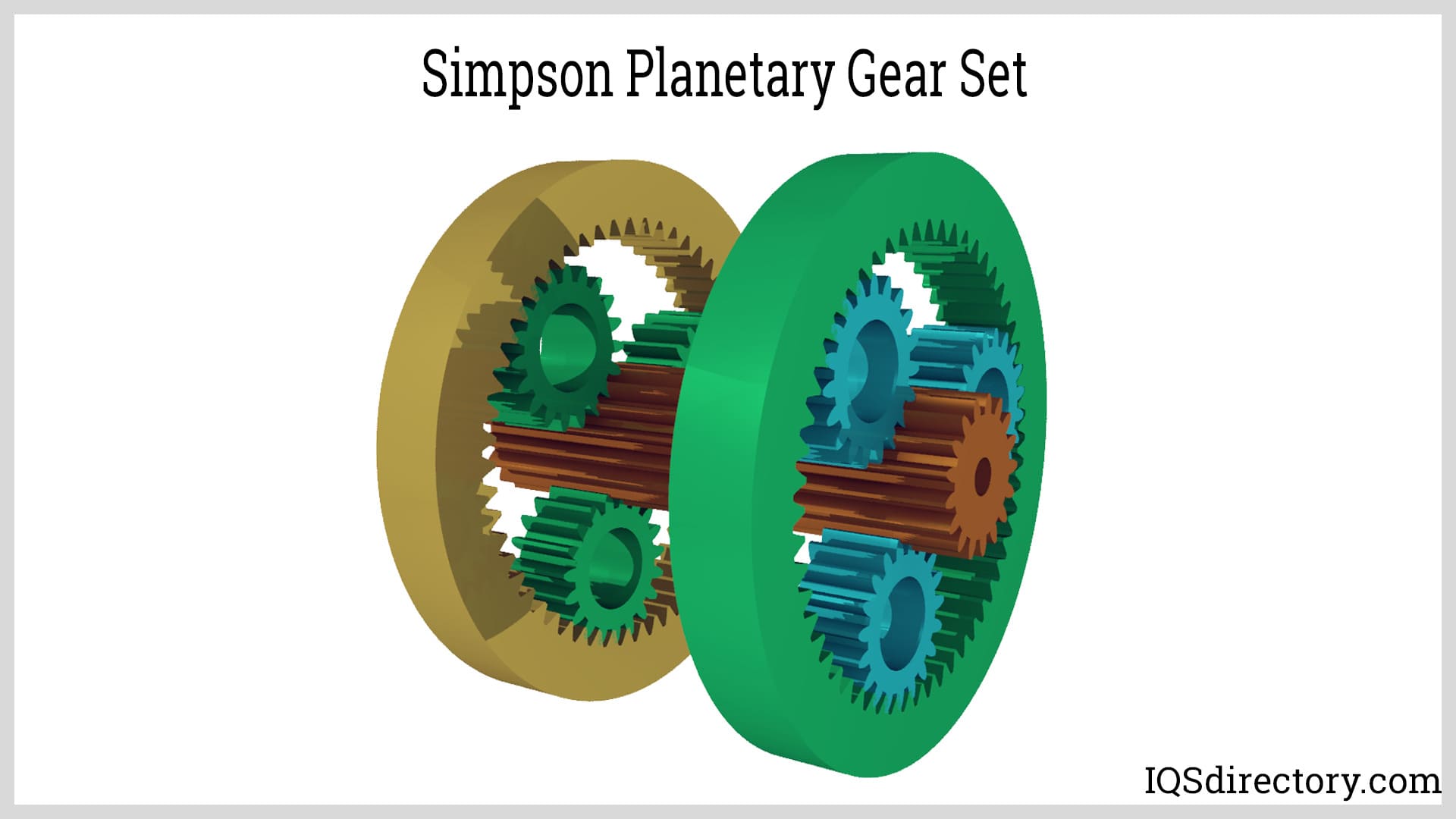

Understanding planetary differential Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Simple Planetary Differential | Utilizes a sun gear, planet gears, and a fixed ring gear for torque distribution. | Automotive differentials, robotics | Pros: Compact design, high torque output. Cons: Limited speed reduction capabilities. |

| Compound Planetary Differential | Incorporates multiple planet gears on the same shaft, allowing for greater speed reduction. | Industrial machinery, conveyors | Pros: High efficiency, versatile gear ratios. Cons: More complex design may increase maintenance needs. |

| Differential Bevel Gears | Combines bevel gears with planetary arrangements for angular motion. | Automotive, aerospace | Pros: Allows for changes in direction, efficient torque transfer. Cons: Requires precise alignment. |

| Hybrid Planetary Differential | Integrates standard gear reducers with planetary systems for enhanced performance. | Heavy machinery, construction | Pros: Greater flexibility in speed and torque, can handle high input speeds. Cons: Potentially higher initial costs. |

| Epicyclic Gear Trains | Features multiple rotating gears with one or more fixed elements, allowing complex motion. | Aerospace, marine applications | Pros: High load capacity, compact design. Cons: Complex assembly can lead to higher failure rates if not properly managed. |

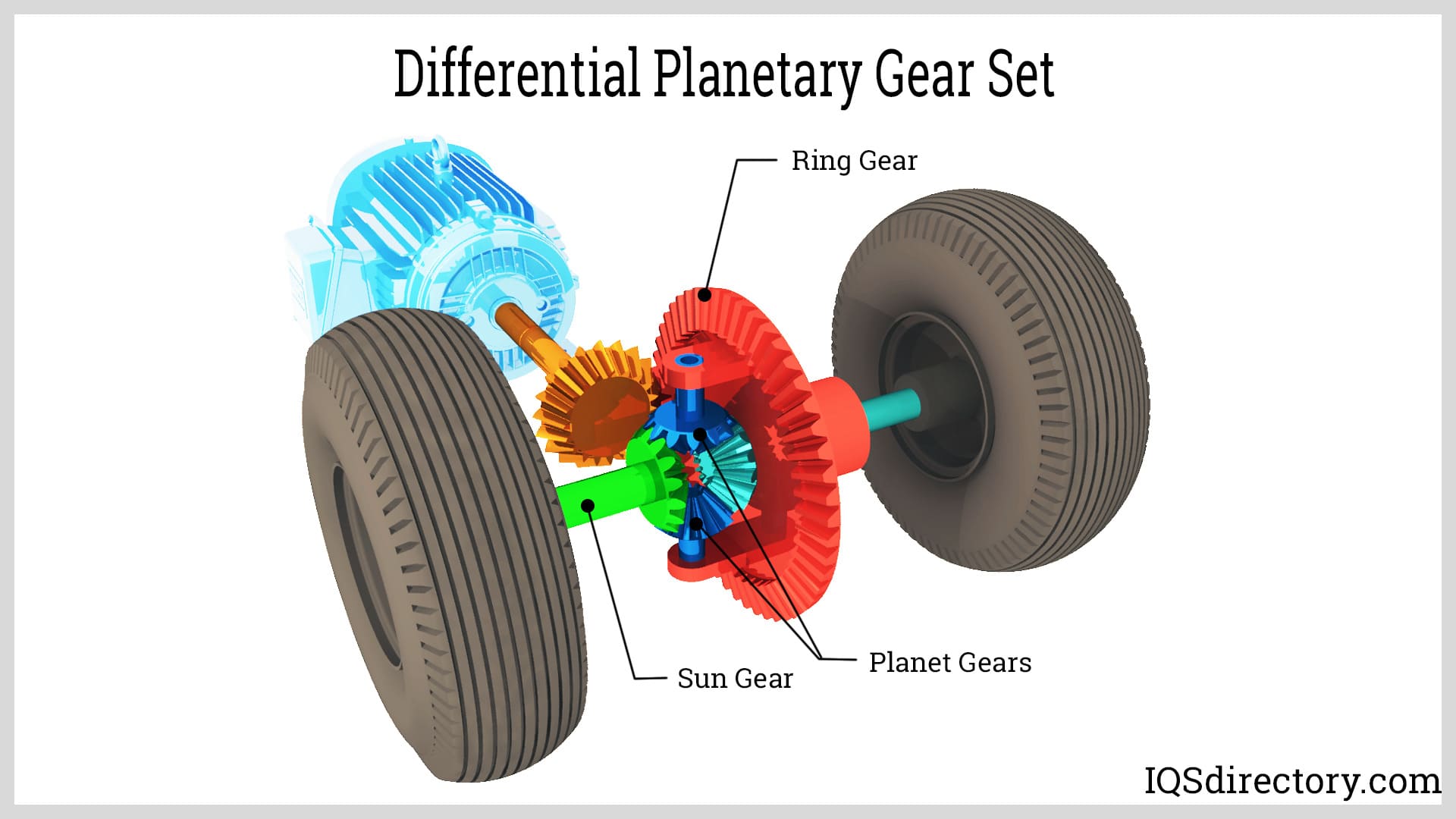

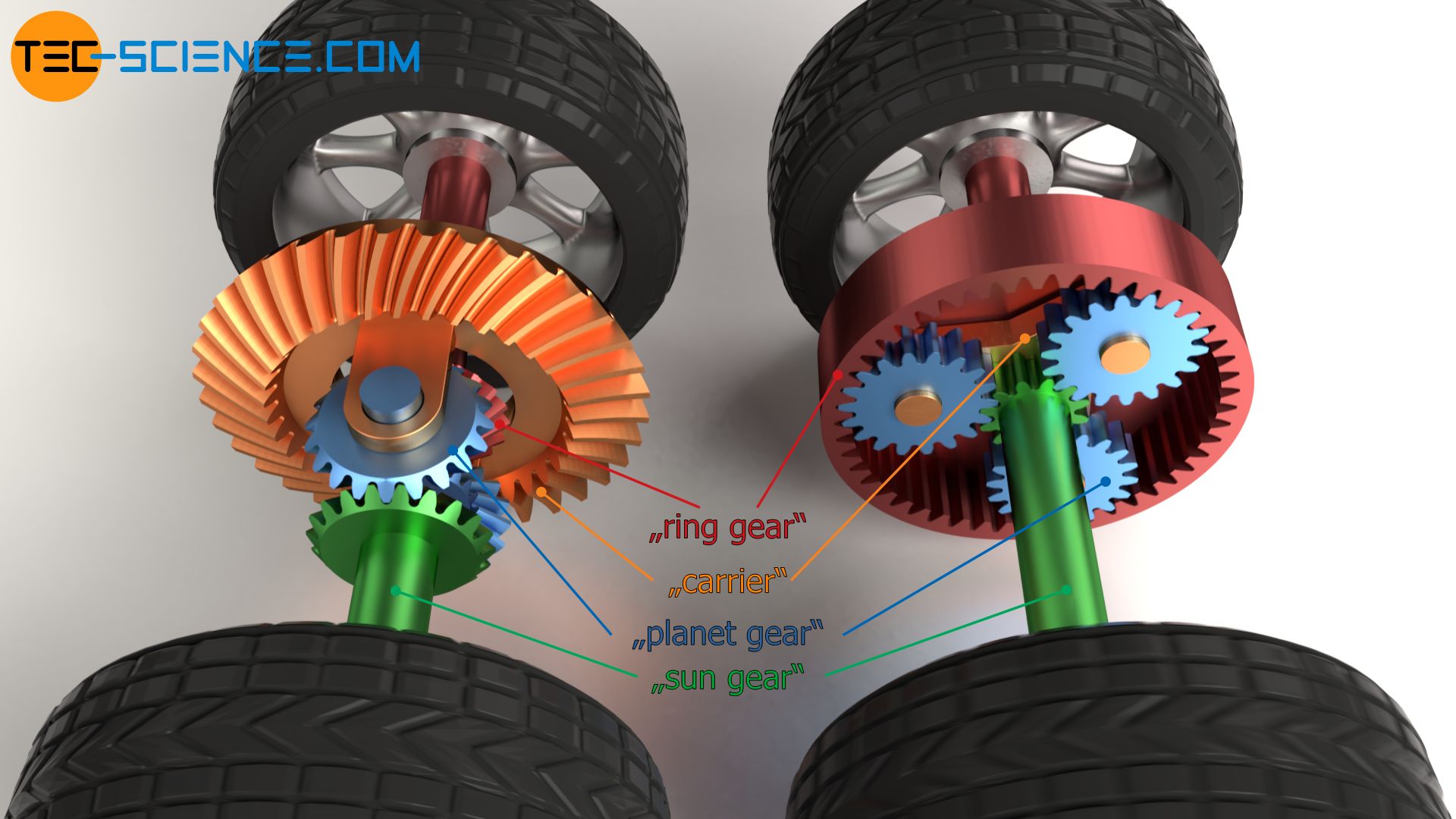

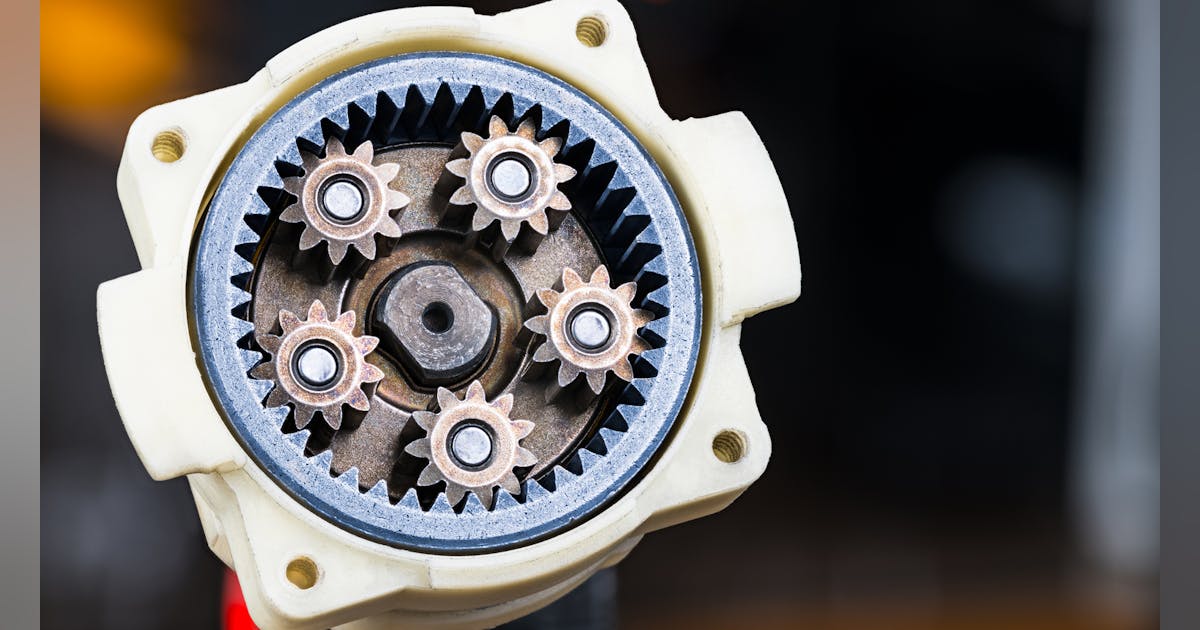

What Are the Characteristics of Simple Planetary Differentials?

Simple planetary differentials consist of a sun gear, planet gears, and a fixed ring gear, which work together to distribute torque effectively. This design is particularly suitable for automotive applications, where space is limited, and high torque output is necessary. B2B buyers should consider the compactness and efficiency of these units, although they may have limitations in speed reduction capabilities compared to more complex systems.

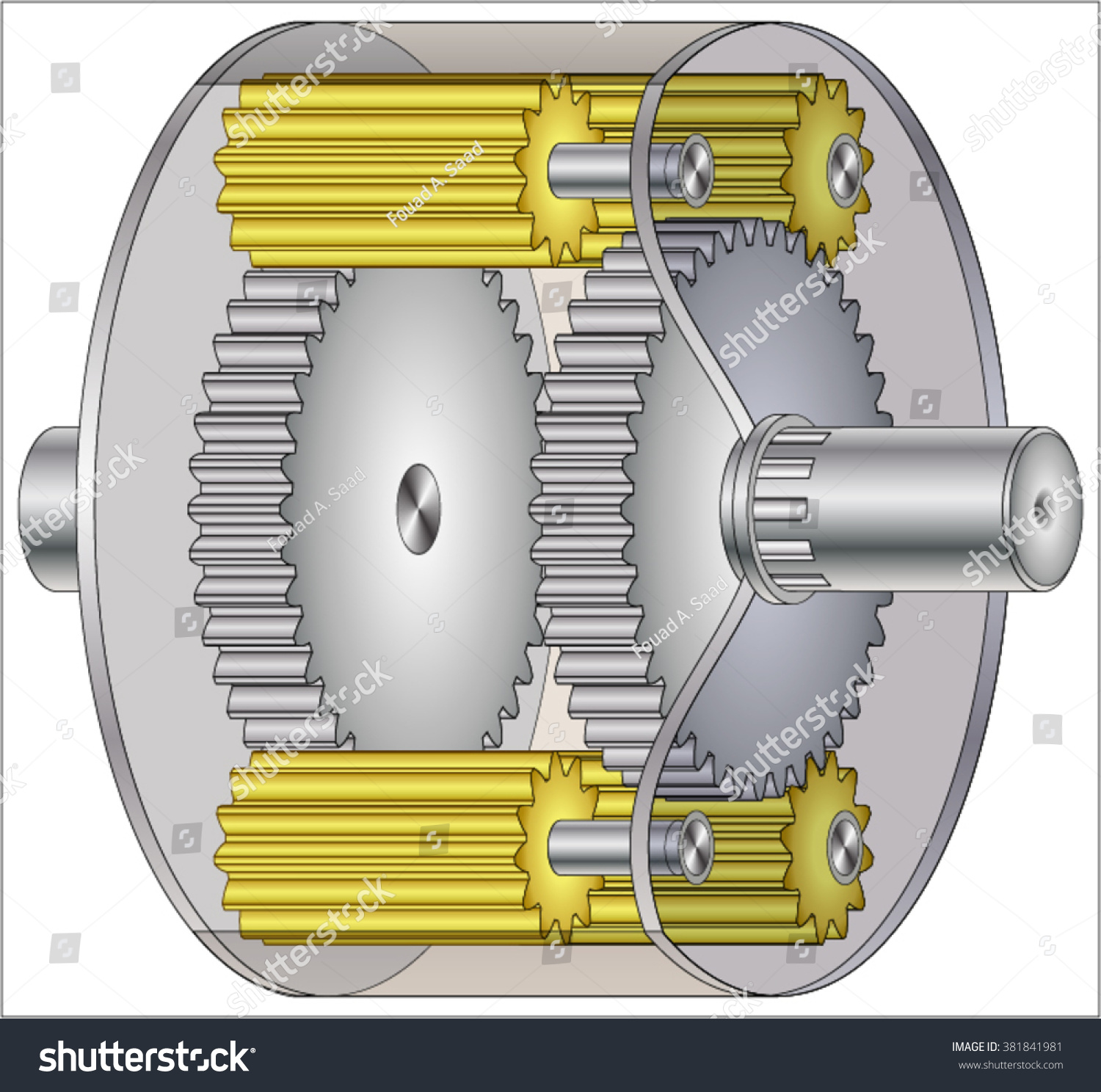

How Do Compound Planetary Differentials Enhance Performance?

Compound planetary differentials enhance performance by using multiple planet gears attached to the same shaft, allowing for a greater range of speed reduction. This makes them ideal for use in industrial machinery and conveyor systems, where efficiency and adaptability are crucial. Buyers should evaluate their operational requirements, as the complexity of these systems may increase maintenance needs but provides significant advantages in performance.

What Are the Benefits of Differential Bevel Gears?

Differential bevel gears are designed to change the direction of power transmission while maintaining efficiency in torque transfer. Commonly used in automotive and aerospace applications, these gears provide a robust solution for systems that require angular motion. Buyers should ensure precise alignment during installation to avoid performance issues, but the benefits of directional flexibility often outweigh these considerations.

Why Choose Hybrid Planetary Differentials for Heavy Machinery?

Hybrid planetary differentials combine standard gear reducers with planetary systems, offering enhanced performance in heavy machinery and construction applications. They allow for greater flexibility in managing speed and torque, which can be particularly beneficial in environments with high input speeds. Buyers should be aware of the potentially higher initial costs but consider the long-term efficiency gains.

What Makes Epicyclic Gear Trains Suitable for Aerospace and Marine Applications?

Epicyclic gear trains consist of multiple rotating gears with one or more fixed components, facilitating complex motions while maintaining high load capacity. These systems are ideal for aerospace and marine applications, where compact design and efficiency are paramount. B2B buyers should consider the higher complexity and potential failure rates associated with these systems, ensuring robust management practices to maintain operational reliability.

Key Industrial Applications of planetary differential

| Industry/Sector | Specific Application of planetary differential | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Differential gears in vehicles | Enhanced vehicle performance, allowing for smooth turns and better traction | Reliability, weight, and torque capacity; compatibility with existing systems |

| Construction Equipment | Drive systems in excavators and cranes | Improved load handling and operational efficiency | Durability under heavy loads, maintenance requirements, and service life |

| Robotics | Actuators in robotic arms and automated systems | Precision control and high torque output in compact designs | Customization options, integration with control systems, and precision engineering |

| Aerospace | Gear systems in aircraft engines | Increased efficiency and reduced weight, leading to fuel savings | Compliance with aerospace standards, weight considerations, and reliability |

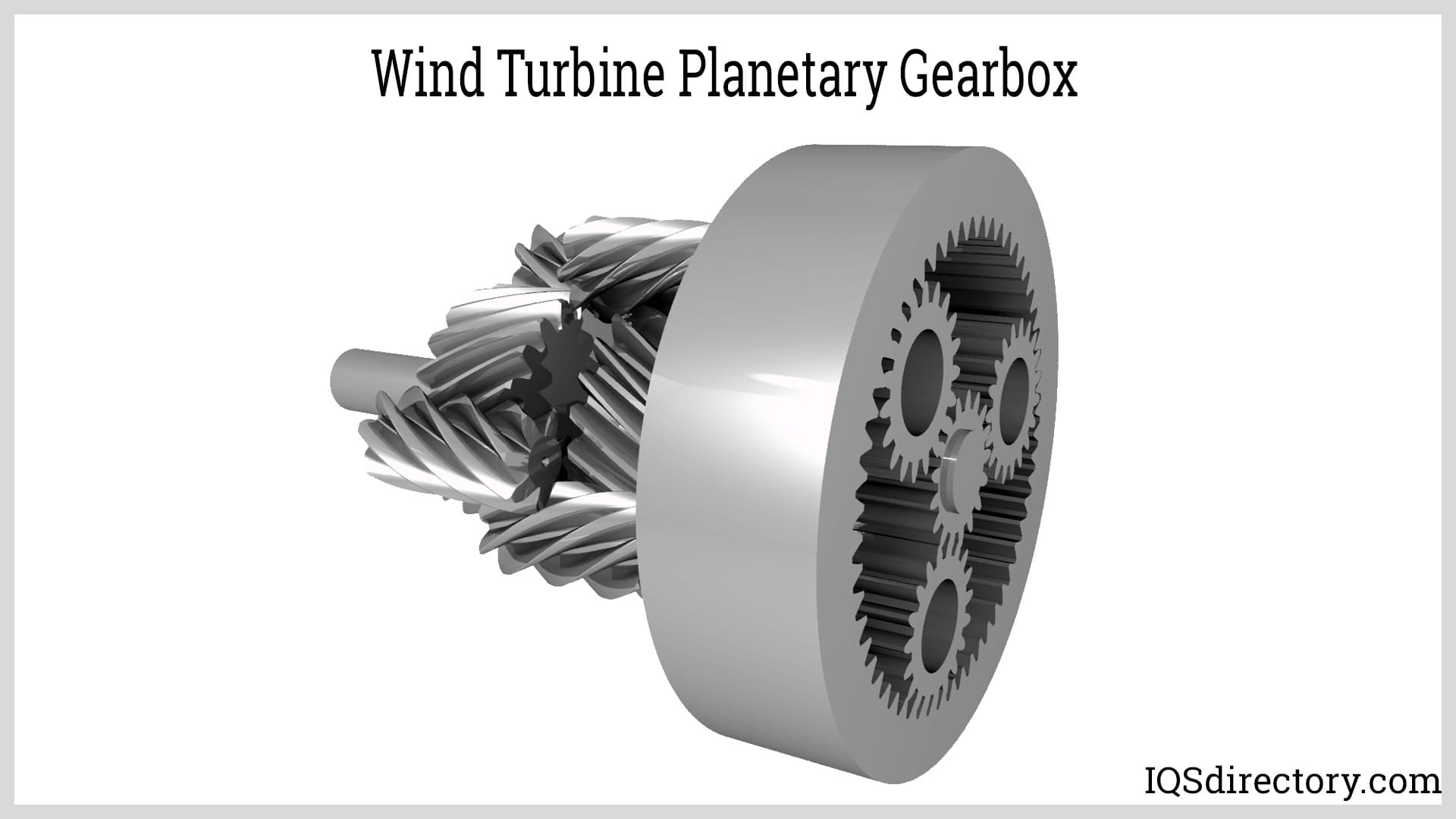

| Renewable Energy | Gearboxes in wind turbines | Improved energy conversion efficiency, leading to higher output | Environmental resistance, maintenance cycles, and operational reliability |

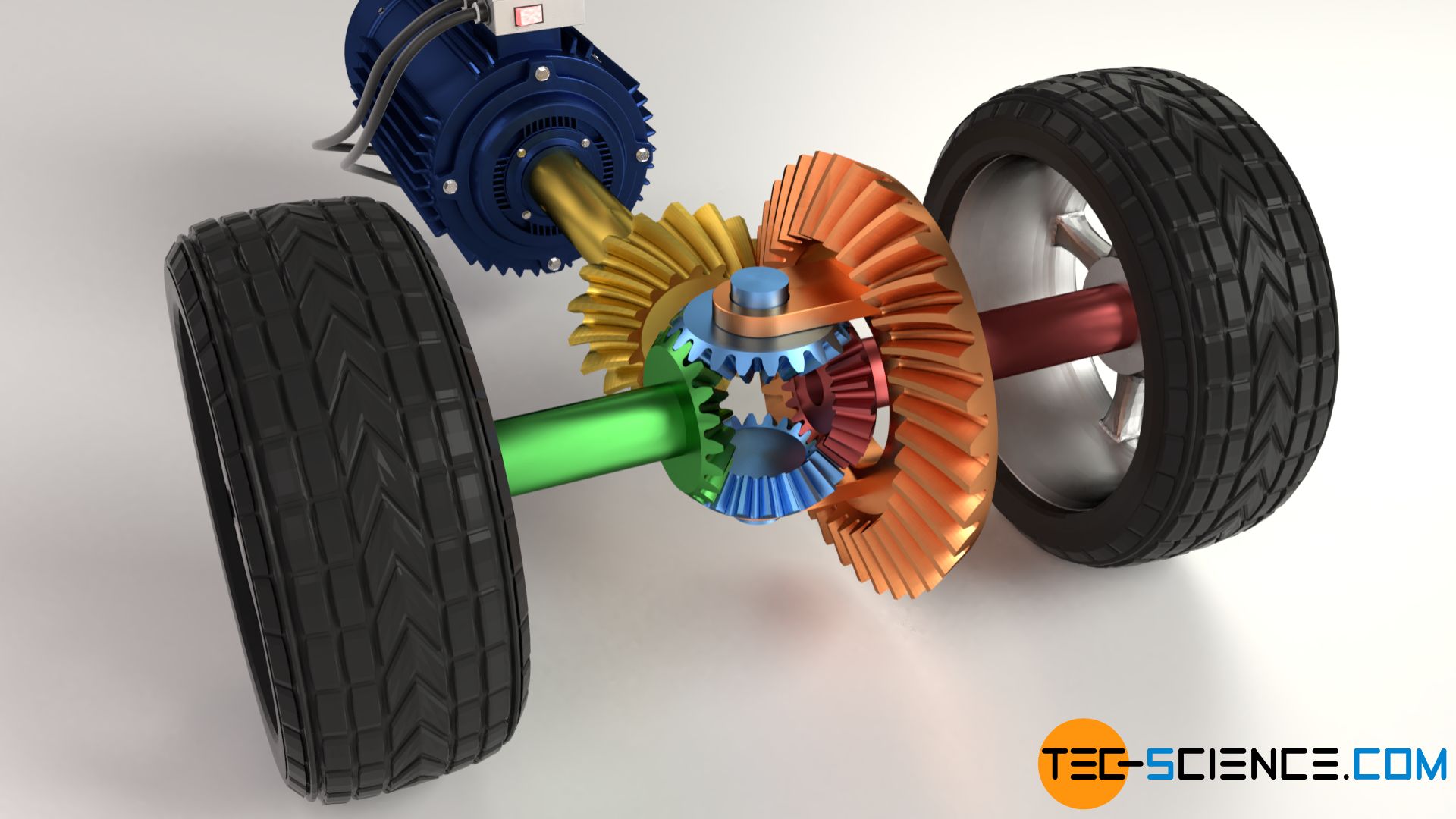

How is Planetary Differential Used in the Automotive Industry?

In the automotive sector, planetary differentials are crucial for vehicle drive systems, particularly in providing torque to the wheels during turns. By allowing the wheels to rotate at different speeds, these differentials enhance vehicle performance, improving traction and stability. Buyers in this sector should prioritize sourcing reliable components that can withstand rigorous conditions, ensuring compatibility with various vehicle types and focusing on weight reduction to improve fuel efficiency.

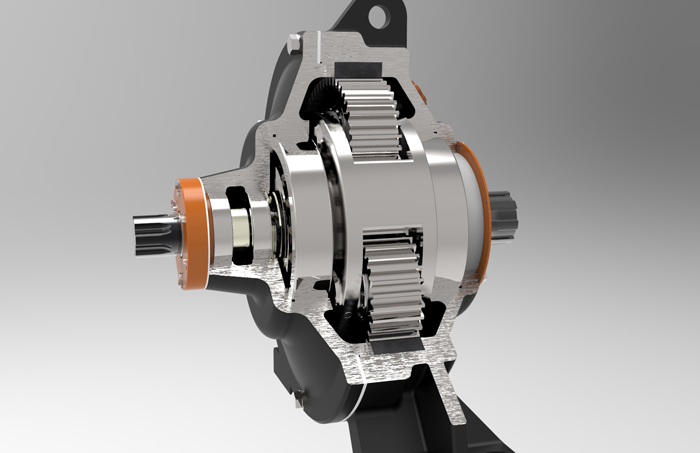

Illustrative image related to planetary differential

What Role Does Planetary Differential Play in Construction Equipment?

Planetary differentials are integral to drive systems in construction equipment like excavators and cranes. They facilitate the efficient transfer of power to the wheels, allowing for superior load handling and operational efficiency. B2B buyers in this industry must consider the durability of the components under heavy loads, as well as the maintenance requirements to minimize downtime. Sourcing from reputable manufacturers with a track record in heavy machinery is essential.

How Does Planetary Differential Enhance Robotics Applications?

In the robotics industry, planetary differentials are employed in actuators for robotic arms and automated systems. Their design allows for precise control and high torque output in a compact form factor, which is critical for intricate operations. Buyers should look for customization options that fit specific robotic applications and ensure seamless integration with existing control systems. Precision engineering is vital to meet the demanding standards of this sector.

Why is Planetary Differential Important in Aerospace Applications?

In aerospace, planetary differentials are used in gear systems for aircraft engines, where they contribute to increased efficiency and reduced weight. This leads to significant fuel savings and improved overall aircraft performance. Buyers in this sector must ensure compliance with stringent aerospace standards and focus on sourcing components that offer high reliability, as the stakes are considerably higher in aviation applications.

How Does Planetary Differential Contribute to Renewable Energy Solutions?

Planetary differentials are key components in gearboxes used in wind turbines, where they enhance energy conversion efficiency. By optimizing the output, these systems can significantly increase the power generated, making renewable energy solutions more viable. B2B buyers should consider environmental resistance and the operational reliability of these components, as they often operate in harsh conditions. Understanding maintenance cycles is also crucial for ensuring long-term performance.

3 Common User Pain Points for ‘planetary differential’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Speed and Torque Ratios

The Problem: B2B buyers often face challenges in obtaining the optimal balance between speed and torque in their machinery. For instance, a manufacturer in the automotive industry may require a planetary differential to enable precise control over wheel speeds during turns. However, if the selected planetary differential does not provide the expected reduction ratios or torque, it can lead to inefficiencies, increased wear and tear on components, and ultimately, production delays.

The Solution: To effectively address this issue, buyers should prioritize understanding the specific requirements of their applications before sourcing planetary differentials. This includes calculating the desired output speed and torque ratios based on the machinery’s operational parameters. Working closely with suppliers, buyers should seek expert guidance on selecting compound planetary gear systems that offer higher reduction capabilities and are tailored to their specifications. Additionally, conducting thorough testing with prototypes can help ensure that the selected differential meets performance expectations before large-scale implementation.

Illustrative image related to planetary differential

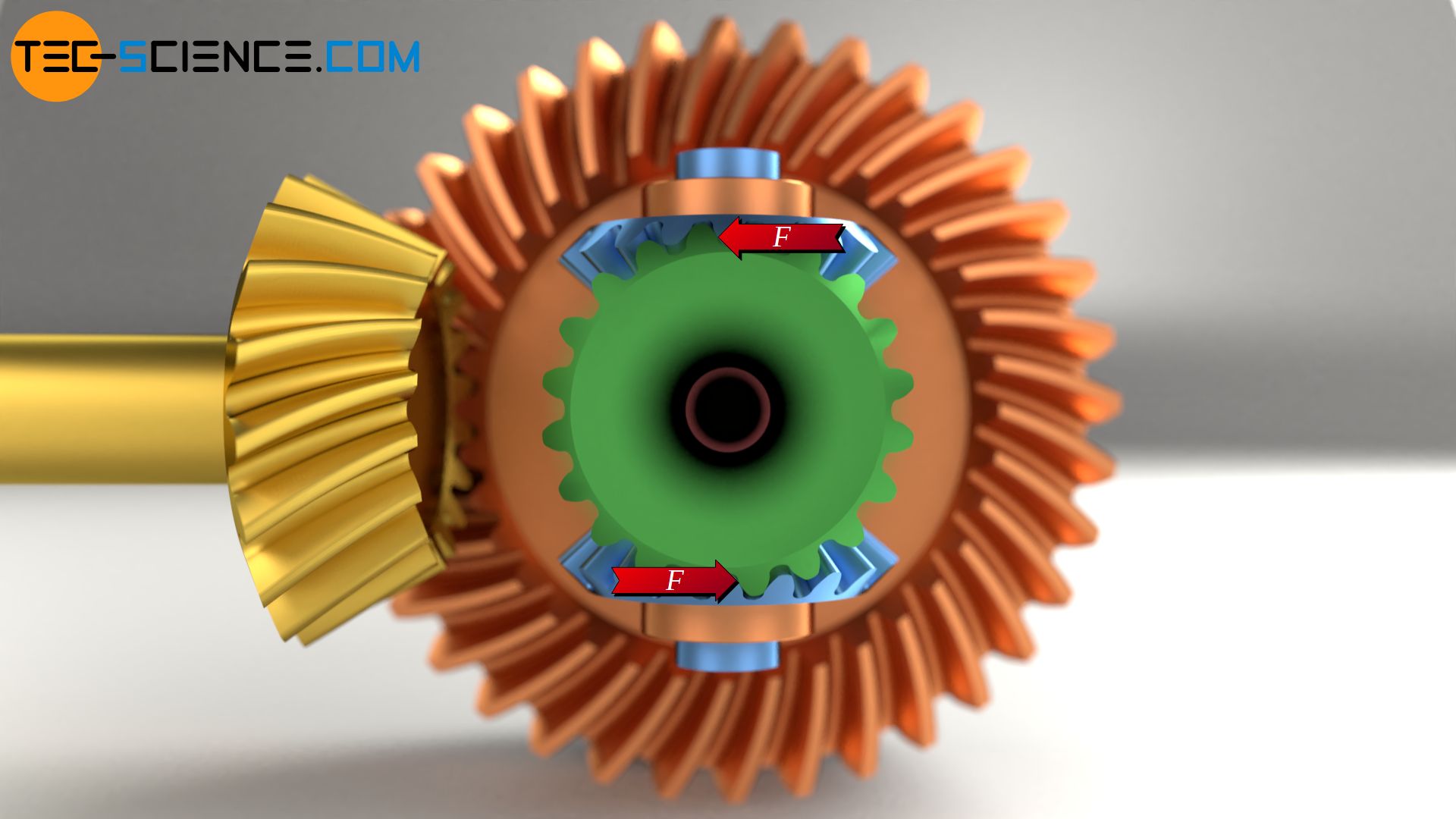

Scenario 2: High Wear Rates on Bearings in Planetary Differentials

The Problem: Another common pain point for B2B buyers is the premature wear of bearings within planetary differentials. This issue is particularly prevalent in high-load applications where the forces exerted on the bearings can lead to increased maintenance costs and unscheduled downtime. A mining equipment manufacturer, for instance, may find that their planetary differentials are failing more frequently than anticipated, resulting in costly repairs and production halts.

The Solution: To mitigate this challenge, buyers should focus on sourcing planetary differentials that incorporate high-quality bearing materials and designs. Engaging with suppliers who offer options with enhanced load distribution, such as multiple smaller planet gears, can significantly improve the bearing life. Furthermore, implementing regular maintenance schedules that include lubrication checks and inspections can help identify potential issues before they escalate. Buyers should also consider investing in advanced monitoring technologies that can provide real-time data on bearing conditions, allowing for proactive maintenance and reducing the risk of failures.

Scenario 3: Imbalances Leading to Operational Inefficiencies

The Problem: Many buyers encounter problems related to imbalances within their planetary differentials, which can lead to excessive vibrations and noise during operation. For example, a company producing heavy machinery may experience operational inefficiencies due to the uneven distribution of loads among the planet gears, resulting in reduced performance and potential damage to the system.

The Solution: To address imbalances effectively, it is crucial for buyers to ensure precise assembly and alignment during the installation of planetary differentials. This may involve utilizing advanced manufacturing techniques that allow for higher tolerances and better balancing of the gear systems. Buyers should also collaborate with engineers to explore the use of floating subassemblies or soft mounts that permit slight adjustments in positioning, thereby promoting load equalization. Regularly scheduled balance testing and vibration analysis can further help in identifying and rectifying imbalances, ultimately enhancing the operational reliability and lifespan of the planetary differential systems.

Illustrative image related to planetary differential

Strategic Material Selection Guide for planetary differential

What Are the Key Materials for Planetary Differentials?

When selecting materials for planetary differentials, it is crucial to consider their mechanical properties, manufacturing complexities, and suitability for specific applications. Here, we analyze four common materials used in planetary differentials: steel, aluminum, brass, and composite materials.

How Does Steel Perform in Planetary Differentials?

Steel is a traditional choice for planetary differential components due to its high strength and durability. Its excellent temperature and pressure ratings make it suitable for high-torque applications. Steel components can withstand significant wear and tear, making them ideal for heavy-duty machinery and automotive applications.

Pros: Steel offers high tensile strength, excellent durability, and good machinability, which makes it easier to manufacture complex geometries. It also has good fatigue resistance, which is essential for components subjected to cyclic loads.

Cons: The primary drawback of steel is its susceptibility to corrosion, especially in harsh environments. This can necessitate additional surface treatments or coatings, increasing manufacturing complexity and costs.

Impact on Application: Steel’s compatibility with various lubricants and operating conditions makes it versatile. However, in regions with high humidity or corrosive environments, additional protective measures may be required.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial when sourcing steel components. Buyers from regions like Africa and South America should also consider local sourcing options to mitigate import costs.

What Role Does Aluminum Play in Planetary Differentials?

Aluminum is increasingly popular in planetary differentials due to its lightweight properties and good strength-to-weight ratio. It is particularly advantageous in applications where weight savings are critical, such as in aerospace and automotive industries.

Pros: Aluminum is resistant to corrosion, which can enhance the longevity of components in various environments. It is also easier to machine than steel, allowing for complex shapes and designs.

Illustrative image related to planetary differential

Cons: While aluminum has good strength, it is not as strong as steel, which may limit its use in high-torque applications. Additionally, its lower melting point can be a concern in high-temperature environments.

Impact on Application: Aluminum’s compatibility with various media makes it suitable for diverse applications, but its lower strength may require careful consideration in high-load scenarios.

Considerations for International Buyers: Buyers should ensure compliance with JIS standards when sourcing aluminum components. Preference for aluminum in regions with stringent weight regulations, such as Europe, is also notable.

Why Consider Brass for Planetary Differentials?

Brass is often used for smaller components in planetary differentials, such as bushings and bearings, due to its excellent machinability and resistance to corrosion.

Pros: Brass is highly resistant to corrosion and has good wear properties, making it suitable for applications where lubrication is limited. Its machinability allows for precise manufacturing of intricate parts.

Cons: The primary limitation of brass is its lower tensile strength compared to steel and aluminum, which may restrict its use in high-load applications. Additionally, brass can be more expensive than other materials.

Impact on Application: Brass components can be particularly effective in environments where corrosion is a concern, such as marine applications. However, its strength limitations may require careful application consideration.

Considerations for International Buyers: Brass components should comply with relevant ASTM standards. Buyers in the Middle East may find brass a preferred choice due to its corrosion resistance in humid environments.

How Do Composite Materials Enhance Planetary Differentials?

Composite materials, including carbon fiber and reinforced plastics, are gaining traction in planetary differentials, especially in applications requiring lightweight and high-strength components.

Pros: Composites can offer excellent strength-to-weight ratios and are highly resistant to corrosion and wear. They can also be tailored for specific performance characteristics, such as thermal stability.

Illustrative image related to planetary differential

Cons: The primary disadvantage of composites is their higher manufacturing complexity and cost. Additionally, they may not be suitable for all load conditions, particularly in high-torque applications.

Impact on Application: Composites can be particularly advantageous in aerospace and automotive applications, where weight savings are critical. However, their performance must be validated for specific operational conditions.

Considerations for International Buyers: International buyers should be aware of the varying standards for composite materials across regions. Compliance with local regulations is essential, particularly in Europe, where material specifications can be stringent.

Illustrative image related to planetary differential

Summary Table of Material Selection for Planetary Differentials

| Material | Typical Use Case for planetary differential | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery and automotive | High strength and durability | Susceptible to corrosion | High |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Brass | Bushings and bearings | Excellent corrosion resistance | Lower tensile strength | Medium |

| Composite | Aerospace and automotive lightweight parts | Tailored strength-to-weight ratio | Higher manufacturing complexity and cost | High |

This analysis provides B2B buyers with insights into the strategic selection of materials for planetary differentials, enabling informed decision-making based on performance, cost, and regional considerations.

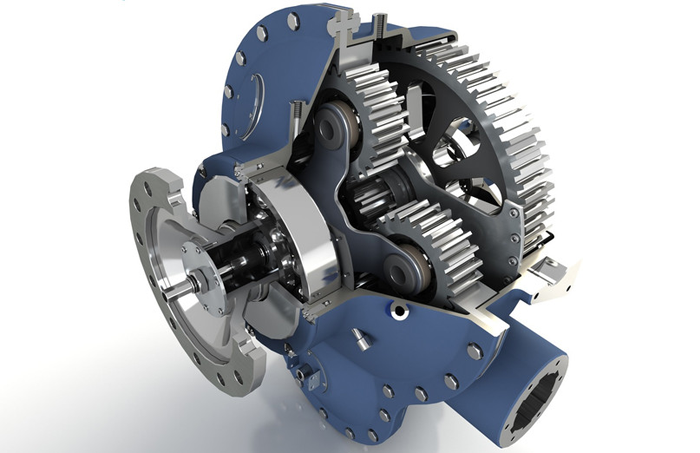

In-depth Look: Manufacturing Processes and Quality Assurance for planetary differential

What Are the Key Stages in the Manufacturing Process of Planetary Differentials?

The manufacturing process of planetary differentials involves several critical stages, each integral to ensuring the performance and reliability of the final product. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The primary materials used in the production of planetary differentials are high-strength steel alloys, aluminum, and various composites. The choice of material is essential, as it impacts the strength, weight, and durability of the differential.

In the material preparation phase, raw materials undergo rigorous inspections to confirm they meet specified mechanical properties. Techniques such as heat treatment may be employed to enhance material characteristics like hardness and fatigue resistance. This is particularly crucial in regions with diverse climates, as temperature fluctuations can affect performance.

Illustrative image related to planetary differential

Forming: What Techniques Are Used to Shape Components?

The forming stage typically employs techniques such as machining, forging, and casting. Machining processes, including CNC (Computer Numerical Control) turning and milling, create precise shapes and dimensions for gears, shafts, and housings. Forging can be used to produce strong, lightweight components, while casting allows for complex geometries that may be difficult to achieve through machining alone.

Precision is vital in this stage, as even minor deviations can lead to significant performance issues. For example, the alignment of gear teeth must be exact to ensure smooth operation and reduce wear. The use of advanced CAD (Computer-Aided Design) software aids in achieving these precise dimensions before production begins.

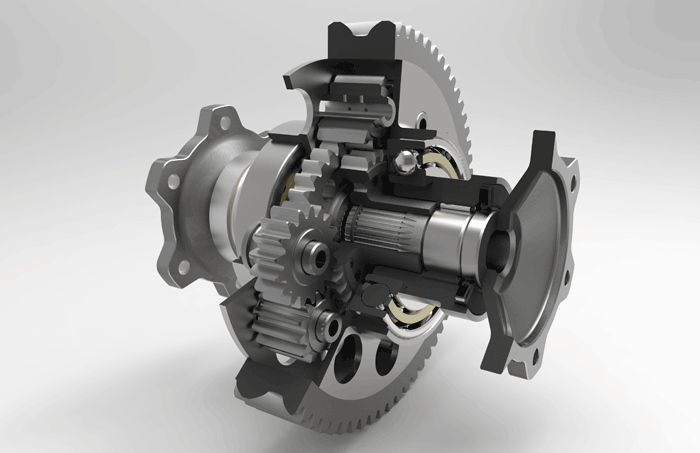

Assembly: How Are Components Brought Together?

Once individual components are formed, the assembly stage begins. This involves meticulously fitting together the various parts, including the sun gears, planet gears, and carrier. Specialized fixtures and jigs are often used to maintain alignment during assembly.

Attention to detail is paramount during this stage. For instance, the proper lubrication of gears is crucial to reduce friction and wear during operation. Additionally, the assembly process may involve the use of automated machinery to enhance efficiency and ensure consistency.

Finishing: What Final Touches Ensure Quality and Performance?

The finishing stage includes surface treatments such as grinding, polishing, and coating to enhance durability and performance. These processes not only improve the aesthetic appeal of the components but also minimize friction and wear.

Illustrative image related to planetary differential

Heat treatment may also be applied to finalize the hardness of gears and other load-bearing components. This step is critical for ensuring that the differential can withstand the stresses it will encounter in real-world applications.

What Quality Control Measures Are Implemented During the Manufacturing of Planetary Differentials?

Quality control (QC) is a crucial aspect of the manufacturing process for planetary differentials, ensuring that products meet both international standards and specific customer requirements.

Which International Standards Should B2B Buyers Be Aware Of?

For manufacturers targeting international markets, adherence to standards such as ISO 9001 is essential. This standard provides a framework for quality management systems, emphasizing customer satisfaction and continuous improvement. Other industry-specific certifications, such as CE marking for compliance with European safety standards or API (American Petroleum Institute) standards for oil and gas applications, may also be relevant depending on the application of the planetary differential.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for defects before they enter production. B2B buyers should inquire about the IQC processes in place, as they directly impact the quality of the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are performed to ensure that components meet design specifications. This includes monitoring machining tolerances, assembly alignment, and surface finishes.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is conducted. This may involve functional testing of the differential under simulated operational conditions to verify performance metrics such as torque capacity and noise levels.

What Testing Methods Are Commonly Used to Ensure Reliability?

Several testing methods are employed to ensure the reliability of planetary differentials. These include:

-

Dimensional Inspection: Utilizes tools like calipers and coordinate measuring machines (CMM) to verify that components meet specified tolerances.

-

Load Testing: Simulates operational conditions to assess the differential’s performance under various loads.

-

Vibration Analysis: Monitors vibration patterns during operation to identify potential issues such as misalignment or wear.

-

Thermal Imaging: Used to detect hotspots that may indicate friction or lubrication problems.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure the reliability of suppliers, B2B buyers should implement a robust verification process.

What Steps Can Be Taken to Conduct Supplier Audits?

Conducting regular audits is an effective way for buyers to verify a supplier’s quality control measures. Audits can assess compliance with international standards, review documentation, and evaluate the effectiveness of QC processes. It’s advisable to utilize third-party inspection services to obtain an unbiased assessment of a supplier’s operations.

How Should Buyers Request QC Reports and Documentation?

B2B buyers should insist on receiving detailed QC reports, including results from IQC, IPQC, and FQC stages. Documentation should also include certification of compliance with relevant international standards. Buyers can also request historical data on defect rates and corrective actions taken to address any issues.

What Are the Quality Control Nuances for International Buyers?

When sourcing planetary differentials from international suppliers, understanding the local manufacturing practices and standards is essential. For example, suppliers in Europe may have stricter regulatory requirements than those in other regions. Buyers should familiarize themselves with these nuances to ensure that products meet their specific needs.

Illustrative image related to planetary differential

In summary, the manufacturing processes and quality assurance protocols for planetary differentials are multifaceted and critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘planetary differential’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure planetary differentials. Planetary differentials are essential components in various applications, including automotive, industrial machinery, and robotics, where they facilitate efficient torque distribution and speed management. Ensuring the right selection can significantly impact operational efficiency and performance, making this checklist a critical resource.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is paramount. Consider factors such as the required torque, speed reduction ratio, load capacity, and dimensions. Precise specifications help in narrowing down suitable products and ensure compatibility with existing systems.

Illustrative image related to planetary differential

- Torque and Speed Requirements: Assess the maximum torque and speed needed for your application.

- Space Constraints: Measure the available space for installation to avoid compatibility issues.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is crucial for securing high-quality planetary differentials. Conduct thorough research to create a shortlist of manufacturers known for their expertise and reliability.

- Industry Experience: Look for suppliers with a strong track record in your specific industry.

- Geographical Considerations: Consider suppliers located in regions with favorable trade agreements, especially if sourcing from Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that suppliers hold relevant certifications. Certifications such as ISO 9001 can indicate adherence to quality management standards.

- Quality Assurance: Certifications ensure that the products meet international quality standards, reducing the risk of defects.

- Regulatory Compliance: Check for compliance with local and international regulations, especially if you operate in heavily regulated industries.

Step 4: Request Samples or Prototypes

To assess quality and performance, request samples or prototypes of the planetary differentials. This step allows for hands-on evaluation before making bulk purchases.

Illustrative image related to planetary differential

- Performance Testing: Test the samples under real-world conditions to ensure they meet your specifications.

- Material Quality: Evaluate the materials used in the construction for durability and reliability.

Step 5: Analyze Pricing and Terms

Comparative pricing analysis is essential to ensure you receive competitive rates. However, the lowest price may not always equate to the best value.

- Total Cost of Ownership: Consider not just the purchase price, but also maintenance costs, expected lifespan, and warranty terms.

- Payment Terms: Negotiate favorable payment terms that align with your cash flow needs.

Step 6: Check Customer Support and Service

Evaluate the level of customer support and after-sales service offered by potential suppliers. Reliable support can be critical in minimizing downtime and ensuring smooth operation.

- Technical Assistance: Ensure that the supplier provides technical support for installation and maintenance.

- Response Times: Consider the supplier’s responsiveness to inquiries and issues that may arise post-purchase.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure that all terms are clearly defined in a contract. A well-drafted agreement protects both parties and sets clear expectations.

- Delivery Schedules: Specify timelines for delivery to avoid operational disruptions.

- Liability Clauses: Include clauses that address potential liabilities in case of product failure or defects.

By following this checklist, B2B buyers can navigate the procurement process for planetary differentials with confidence, ensuring that their operational needs are met effectively.

Comprehensive Cost and Pricing Analysis for planetary differential Sourcing

What Are the Key Cost Components in Sourcing Planetary Differentials?

When sourcing planetary differentials, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost components include:

Illustrative image related to planetary differential

-

Materials: The choice of materials significantly impacts costs. High-strength steels, alloys, and sometimes composites are commonly used. The price can fluctuate based on global market conditions, availability, and material specifications.

-

Labor: Labor costs encompass skilled workforce wages for assembly and quality assurance. Regions with lower labor costs can offer competitive pricing, but this might affect quality if not managed properly.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can reduce overhead, allowing for more competitive pricing.

-

Tooling: Initial tooling costs can be significant, particularly for custom or high-precision components. These costs are often amortized over the production run, making larger orders more cost-effective.

-

Quality Control (QC): Ensuring that planetary differentials meet specific performance and safety standards incurs additional costs. Rigorous QC processes are crucial, especially for markets with stringent regulations.

-

Logistics: Transportation costs, including shipping and handling, can vary widely based on location and shipping methods. Incoterms play a critical role in defining who bears these costs and risks.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. Understanding the supplier’s cost structure can aid in negotiating better terms.

How Do Price Influencers Affect the Cost of Planetary Differentials?

Several factors influence the pricing of planetary differentials:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be beneficial for buyers looking to optimize costs.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or ASME) often come at a premium. However, investing in quality can lead to lower maintenance and operational costs in the long run.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can affect pricing. Engaging with reputable suppliers can result in better quality and support, justifying higher costs.

-

Incoterms: These terms define the responsibilities of buyers and sellers in shipping arrangements. Understanding Incoterms can help buyers avoid hidden costs related to logistics.

What Are the Best Practices for Negotiating Planetary Differential Pricing?

B2B buyers can adopt several strategies to negotiate more effectively:

-

Research and Benchmarking: Gather data on market prices and competitor offerings. Having a clear understanding of the price landscape can empower negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of just looking at the purchase price, consider the TCO, including maintenance, operational efficiency, and lifecycle costs. This broader perspective can help justify investments in higher-quality products.

-

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Loyal customers may receive preferential treatment during negotiations.

-

Be Clear on Specifications: Clearly define your requirements upfront to avoid miscommunication and potential cost overruns. This clarity can foster trust and streamline the procurement process.

-

Leverage Volume for Discounts: If possible, consolidate purchases to maximize volume discounts. Suppliers are often willing to negotiate better terms for larger orders.

Are There Pricing Nuances for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique pricing nuances:

-

Currency Fluctuations: Be aware of currency exchange rates, as they can significantly affect costs. Locking in exchange rates can mitigate risks.

-

Tariffs and Duties: Import tariffs can add to the total cost. Understanding local regulations and working with experienced logistics partners can help navigate these challenges.

-

Cultural Factors: Negotiation styles vary by culture. Familiarize yourself with local business practices to enhance communication and foster successful negotiations.

Disclaimer on Indicative Prices

Prices for planetary differentials can vary widely based on the aforementioned factors. Buyers should conduct thorough market research and consult with multiple suppliers to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing planetary differential With Other Solutions

Introduction to Alternative Solutions for Planetary Differentials

In the realm of mechanical systems, planetary differentials are renowned for their compact design and high efficiency in torque and speed management. However, various alternative technologies exist that can fulfill similar roles, each with distinct advantages and limitations. This analysis will compare planetary differentials against two viable alternatives: standard gear-and-pinion systems and worm gear drives. Understanding these alternatives will help B2B buyers make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Planetary Differential | Standard Gear-and-Pinion | Worm Gear Drive |

|---|---|---|---|

| Performance | High torque and speed reduction in a compact form | Moderate torque and speed reduction, larger footprint | High torque but lower speed reduction; efficient at right angles |

| Cost | Higher initial investment but lower long-term maintenance costs | Generally lower initial cost; maintenance can add up | Moderate cost, but efficiency can lead to savings |

| Ease of Implementation | Requires precise assembly; compact design may complicate integration | Easier to implement; widely understood technology | Requires specific mounting and alignment considerations |

| Maintenance | Lower maintenance due to load distribution; potential bearing wear | Higher maintenance needs; wear on gears over time | Requires regular lubrication; potential for wear in gear teeth |

| Best Use Case | High-performance applications requiring compactness | General applications with moderate performance needs | Applications needing high torque at low speeds, especially at right angles |

Detailed Breakdown of Alternatives

Standard Gear-and-Pinion Systems

Standard gear-and-pinion systems are widely used due to their straightforward design and implementation. They are generally easier to assemble and understand, making them ideal for applications where speed and cost are critical. However, these systems typically occupy more space and may not provide the same level of torque or speed reduction as planetary differentials. Maintenance can also be a concern, as wear on the gears can lead to performance degradation over time.

Worm Gear Drives

Worm gear drives are effective in applications that require a high torque output at low speeds and are particularly useful for transmitting motion at right angles. They offer a compact design, but the efficiency can be lower than planetary differentials, especially in high-load situations. While the initial costs are moderate, the need for regular lubrication and the potential for gear wear can lead to higher long-term maintenance costs. Additionally, the implementation may require precise alignment to ensure optimal performance.

Illustrative image related to planetary differential

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate drive solution, B2B buyers should carefully consider their specific operational requirements, including performance needs, cost constraints, and maintenance capabilities. Planetary differentials excel in high-performance scenarios where space is at a premium, while standard gear-and-pinion systems may be better suited for general applications. Worm gear drives are ideal for applications requiring substantial torque and right-angle motion but may involve more maintenance. Ultimately, understanding these alternatives will empower buyers to choose the solution that best aligns with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for planetary differential

What Are the Key Technical Properties of Planetary Differentials?

Understanding the technical properties of planetary differentials is essential for B2B buyers, particularly when evaluating products for heavy machinery, automotive applications, or industrial equipment. Here are several critical specifications that inform decision-making:

-

Material Grade

– Definition: Material grade refers to the type and quality of materials used in the construction of the planetary differential, often including metals like steel or aluminum alloys.

– B2B Importance: The material grade impacts strength, durability, and resistance to wear. Buyers must consider the operating environment and load conditions to ensure the differential can withstand stresses without premature failure. -

Gear Ratio

– Definition: Gear ratio is the ratio of the number of teeth on the driven gear to the number of teeth on the driving gear, affecting speed and torque output.

– B2B Importance: A well-chosen gear ratio allows for optimal performance in specific applications. For instance, higher ratios can provide more torque at lower speeds, which is crucial for heavy machinery. -

Tolerances

– Definition: Tolerances are the permissible limits of variation in a physical dimension, ensuring that components fit and function correctly.

– B2B Importance: Tight tolerances are critical for high-precision applications, as they ensure proper alignment and minimize wear. Understanding tolerances helps buyers evaluate manufacturing capabilities and quality control processes. -

Load Capacity

– Definition: Load capacity indicates the maximum load that the planetary differential can handle while maintaining functionality and safety.

– B2B Importance: Knowing the load capacity is vital for application suitability. Buyers must match this specification to the expected operational loads to prevent breakdowns or inefficiencies. -

Efficiency Rating

– Definition: Efficiency rating measures how much input energy is converted into useful output energy, often expressed as a percentage.

– B2B Importance: Higher efficiency ratings lead to lower energy consumption and operational costs. Businesses seeking to optimize performance and reduce expenses should prioritize products with superior efficiency. -

Operating Temperature Range

– Definition: This specification defines the temperature limits within which the planetary differential can operate effectively.

– B2B Importance: Knowing the operating temperature range helps buyers assess whether the differential is suitable for their application, particularly in environments with extreme temperatures that could affect performance and longevity.

What Are Common Trade Terms Related to Planetary Differentials?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to planetary differentials:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for buyers looking for compatible parts or seeking to establish long-term supply agreements. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchasing strategy and inventory management, especially when dealing with large components like planetary differentials. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Understanding Incoterms is essential for managing shipping costs, risks, and responsibilities, particularly for international transactions. -

Lead Time

– Definition: Lead time is the time it takes from placing an order to receiving the product.

– Importance: Buyers should consider lead time when planning their projects to avoid delays in production or service delivery. -

Warranty Period

– Definition: The warranty period is the duration during which a manufacturer guarantees the product against defects.

– Importance: A robust warranty can provide buyers with confidence in the product’s reliability and reduce the risk associated with their investment.

By understanding these properties and terms, B2B buyers can make more informed decisions when selecting planetary differentials, ensuring they meet their operational needs effectively.

Illustrative image related to planetary differential

Navigating Market Dynamics and Sourcing Trends in the planetary differential Sector

What Are the Key Market Trends Impacting the Planetary Differential Sector?

The planetary differential sector is witnessing significant growth driven by the increasing demand for compact, efficient, and high-performance mechanical systems across various industries. Key markets such as automotive, aerospace, and industrial machinery are rapidly adopting planetary differentials due to their ability to provide high torque and speed reduction in a compact design. In particular, international B2B buyers from Africa, South America, the Middle East, and Europe are focusing on sourcing advanced gear solutions that enhance operational efficiency and reduce energy consumption.

Emerging technologies, such as automation and IoT integration, are reshaping the sourcing landscape. Buyers are increasingly looking for suppliers that offer smart planetary gear systems capable of real-time monitoring and predictive maintenance. This trend is particularly relevant for industries in regions like Germany and Vietnam, where manufacturing efficiency is crucial. Additionally, the rise of electric vehicles (EVs) is creating new opportunities for suppliers who can provide specialized planetary differentials that meet the unique performance requirements of EV drivetrains.

The global supply chain dynamics are also evolving, with an emphasis on local sourcing to mitigate risks associated with geopolitical tensions and trade policies. Buyers are prioritizing suppliers that can offer reliable delivery times and flexible terms, which is essential for maintaining competitive advantage in fast-paced markets.

How Does Sustainability and Ethical Sourcing Impact the Planetary Differential Sector?

Sustainability is becoming a cornerstone in the sourcing strategy for planetary differentials, reflecting the growing awareness of environmental impact among B2B buyers. As industries face increasing pressure to reduce their carbon footprints, the demand for eco-friendly manufacturing processes and materials is on the rise. Buyers are keen on sourcing from suppliers that utilize sustainable practices, such as energy-efficient production methods and recyclable materials.

The importance of ethical supply chains cannot be overstated, especially as consumers and regulatory bodies demand greater transparency. Buyers are now more inclined to partner with manufacturers that adhere to ethical sourcing standards, ensuring that raw materials are obtained responsibly and without exploitation. Certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria in the procurement process.

Moreover, the adoption of ‘green’ certifications and sustainable materials in the production of planetary differentials is increasingly influencing purchasing decisions. Buyers are looking for suppliers who can provide evidence of sustainable practices and materials, such as those derived from renewable resources or with minimal environmental impact, to align with their corporate social responsibility goals.

What Is the Evolution of the Planetary Differential Technology in the B2B Landscape?

The evolution of planetary differential technology has been marked by a continuous drive for innovation and efficiency. Initially developed for mechanical applications in the automotive sector, planetary differentials have transformed into versatile solutions applicable across various industries. The integration of advanced materials and manufacturing techniques, such as additive manufacturing and computer-aided design, has enhanced the performance and reliability of these systems.

Over the decades, the focus has shifted from merely providing mechanical advantages to incorporating smart technologies that enable real-time data analysis and predictive maintenance. This evolution has positioned planetary differentials as critical components in modern machinery, particularly in automated and electric applications. As industries seek to optimize performance and reduce downtime, the evolution of planetary differential technology continues to play a pivotal role in meeting the demands of a rapidly changing market.

In summary, the planetary differential sector is navigating significant market dynamics influenced by technological advancements, sustainability demands, and evolving buyer preferences. International B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and ethical commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of planetary differential

-

How do I choose the right planetary differential for my application?

Selecting the appropriate planetary differential involves assessing your specific application requirements. Key factors include the desired torque output, speed reduction ratio, and space constraints. It’s essential to evaluate the operating conditions, such as load types and environmental factors, to ensure compatibility. Consulting with manufacturers or suppliers who offer customization options can also help tailor the differential to your needs. Additionally, reviewing case studies or technical specifications can provide insights into performance in similar applications. -

What are the common applications of planetary differentials in industry?

Planetary differentials are widely used in various industries, including automotive, aerospace, and industrial machinery. They excel in applications requiring high torque and compact design, such as electric vehicles, robotics, and conveyor systems. In automotive applications, they enable smooth turning and speed differentiation between wheels. Understanding the specific demands of your industry will help you identify the best planetary differential to enhance efficiency and performance. -

What should I consider when vetting suppliers of planetary differentials?

When evaluating suppliers, consider their experience, reputation, and quality certifications. Look for manufacturers with a proven track record in producing planetary differentials, as well as those who adhere to international standards like ISO 9001. Request references or case studies from previous clients to gauge reliability. Additionally, inquire about their production capabilities, lead times, and after-sales support to ensure they can meet your specific needs and timelines. -

What are the typical minimum order quantities (MOQ) for planetary differentials?

Minimum order quantities for planetary differentials can vary significantly by supplier and product type. Some manufacturers may have an MOQ of just a few units for standard models, while others might require larger quantities for customized or specialized units. It’s advisable to discuss your requirements directly with potential suppliers to understand their MOQ policies, as some may offer flexibility based on your specific needs or project scale. -

How can I ensure quality assurance for planetary differentials during sourcing?

To ensure quality assurance, request detailed documentation from suppliers, including test reports and certifications. It’s beneficial to inquire about their quality control processes, such as inspections and testing protocols. Consider visiting manufacturing facilities if feasible or requesting third-party inspections for large orders. Additionally, establishing a clear agreement on quality standards and performance metrics in your purchase contract can help safeguard your investment. -

What payment terms are typically offered by suppliers for planetary differentials?

Payment terms can vary by supplier, but common practices include upfront deposits followed by balance payments upon delivery or installation. Some suppliers may offer net terms (e.g., net 30 or net 60 days), especially for established relationships. It’s important to discuss payment options early in negotiations and ensure that terms are clearly defined in the contract to avoid misunderstandings later. -

What logistics considerations should I be aware of when importing planetary differentials?

When importing planetary differentials, consider shipping methods, customs regulations, and potential duties or tariffs that may apply. Work with logistics providers who are experienced in handling industrial equipment to ensure timely delivery. It’s also essential to confirm that the supplier can provide the necessary documentation for customs clearance. Additionally, factor in lead times for manufacturing and shipping when planning your project timelines. -

How do I handle potential issues with planetary differentials after purchase?

Addressing issues with planetary differentials post-purchase begins with clear communication with your supplier. Ensure you have access to warranty information and service agreements. If a problem arises, document the issue thoroughly and reach out to the supplier’s technical support for guidance. Many suppliers offer troubleshooting resources or can provide on-site assistance. Establishing a good relationship with your supplier will facilitate faster resolution of any concerns.

Top 8 Planetary Differential Manufacturers & Suppliers List

1. MeVirtuoso – Differential Planetary Gears

Domain: mevirtuoso.com

Registered: 2023 (2 years)

Introduction: Differential planetary gears are essential in various devices, particularly in automobiles, allowing car wheels to spin at different speeds for efficient operation. Key components include input and output shafts, a carrier, a ring gear, a sun gear, and planet gears. The mechanism manages torque, accommodates different rotation speeds, and is compact and lightweight, making it suitable for aerospac…

2. Chief Delphi – Planetary Gearbox Intake System

Domain: chiefdelphi.com

Registered: 1998 (27 years)

Introduction: Planetary gearbox used as an unbalanced differential; designed for over-the-bumper top-roller intake; capable of intaking from the floor and ejecting game pieces at the top; incorporates a single stage planetary gearbox; drives 4″ compliant wheels at 2400 to 3600 rpm (20-30fps); arm lift is slightly over-sprung; arm and intake controlled by the same motor; requires multistage gear reduction; ring …

3. Tec Science – Differential Gear

Domain: tec-science.com

Registered: 2017 (8 years)

Introduction: Differential gear allows wheels to rotate at different speeds, essential for cornering in automobiles. It consists of a drive shaft divided for each wheel, enabling independent rotation. The design includes pins and freely rotatable bars, which are later replaced by bevel gears for effective power transmission. The arrangement typically features two spider gears to avoid bending stresses in the dr…

4. SDP/SI – Planetary Gear Solutions

Domain: shop.sdp-si.com

Registered: 1995 (30 years)

Introduction: Planetary Gear Design – Gears, Differentials, Racks & Pinions. Product categories include: Spur Gears (Metal, Plastic, Anti-backlash, Composite), Bevel Gears (Spiral, Precision, Commercial, Hypoid), Miter Gears, Racks (Gear Racks, Flexiracks), Helical Gears, Internal Gears, Worm Gear Pairs, Differentials (Anti-Backlash, Hollow-Shaft, Solid Shaft), Gear Clamps (various types), Pinion Shafts, Cluste…

5. Arrma – Kraton 8S Maintenance Guide

Domain: arrmaforum.com

Registered: 2015 (10 years)

Introduction: Arrma RC’s Kraton 8S; Differential planetary gears; Issues with gear wear; Maintenance frequency: every 7-8 packs; Oil types: 500k rear, 20mi center, 1mi front; Potential causes of wear: lack of oil, loose contact, casing screws backing out, bent CVD and shafts; User experiences and troubleshooting tips.

6. Eng-Tips – Differential Planetary Gearbox

Domain: eng-tips.com

Registered: 1997 (28 years)

Introduction: Differential planetary gearbox for light duty winch with high reduction ratio (around 250:1). Key components include: fixed ring gear (63 teeth), output ring gear (66 teeth), sun gear (6 teeth), and planet gear (29 teeth). Calculation formula for gear ratios: (1+R/S) * (R(fixed)/(R(fixed)-R(output))). AGMA 6123-B06 standard provides design guidance.

7. TRAXXAS – Planetary Gear Differential

Domain: azturnandburn.com

Registered: 2021 (4 years)

Introduction: This company, TRAXXAS – Planetary Gear Differential, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Engineering Clicks – Planetary Gears Overview

Domain: engineeringclicks.com

Registered: 2016 (9 years)

Introduction: This company, Engineering Clicks – Planetary Gears Overview, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for planetary differential

How Can Strategic Sourcing Enhance Your Planetary Differential Procurement?

In today’s competitive landscape, strategic sourcing for planetary differentials is not just a necessity but a critical driver of operational efficiency and cost-effectiveness. By leveraging advanced planetary gear technology, businesses can achieve significant torque and speed reductions within compact designs, which are vital for various applications across industries. International buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who offer high-quality, innovative solutions that meet their specific operational needs.

The key to successful procurement lies in understanding the complex dynamics of planetary gearing systems. Buyers should assess the performance metrics, longevity, and adaptability of differentials to ensure they are investing in products that will enhance their machinery’s efficiency and reliability. Furthermore, focusing on suppliers that emphasize sustainability and technological advancement can lead to long-term benefits, including reduced maintenance costs and improved operational resilience.

As you navigate the sourcing landscape, consider the evolving market trends and technological advancements in planetary differentials. Engage with knowledgeable suppliers and explore partnerships that can provide customized solutions to meet your unique challenges. The future of efficient machinery is here—embrace it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.