Is Your Or Box Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for or box

In today’s competitive landscape, sourcing high-quality wooden drawer systems, such as the TA’OR BOX, presents a unique challenge for international B2B buyers. With a vast array of options and varying quality standards across regions, making informed purchasing decisions can be overwhelming. This guide aims to demystify the complexities associated with sourcing or box systems by exploring their diverse types and applications, providing insights into supplier vetting, and outlining cost considerations.

Designed specifically for international buyers from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Brazil—this comprehensive resource empowers you to navigate the global market with confidence. We will delve into the innovative features of modern or box systems, highlighting how they can enhance furniture aesthetics while meeting customer demands for customization and sustainability.

By leveraging the information presented in this guide, you will gain the tools necessary to identify reputable suppliers and evaluate products that align with your business’s unique requirements. Whether you are looking to streamline your supply chain, reduce production costs, or enhance your product offerings, understanding the nuances of the or box market will enable you to make strategic decisions that drive success in your business.

Understanding or box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TA’OR Box | Customizable wooden drawer system with 35 billion design options | Furniture manufacturing and retail | Pros: High-quality aesthetics, quick delivery, customizable. Cons: Higher initial investment for customization. |

| ORT Box | Standardized boxes for nose work training | Pet training supplies and events | Pros: Cost-effective, easy to assemble. Cons: Limited design variations. |

| LEGRABOX | Sleek, modern design with superior motion comfort | Kitchen and bathroom cabinetry | Pros: Premium feel, reliable performance. Cons: May require specialized installation. |

| TANDEMBOX antaro | Clean, angular shapes for contemporary furniture | Retail furniture and cabinetry | Pros: Aesthetic appeal, versatile use. Cons: Potentially higher costs compared to basic options. |

| Custom Box Systems | Tailored solutions based on specific client needs | Diverse manufacturing sectors | Pros: Fully personalized, meets unique requirements. Cons: Longer lead times and potentially higher costs. |

What are the Key Characteristics of TA’OR Box?

The TA’OR Box is distinguished by its extensive customization options, allowing for an impressive 35 billion design variations. This wooden drawer system is ideal for furniture manufacturers looking to provide customers with bespoke solutions that align with modern aesthetic trends. The quick assembly and delivery timeline—often within 48 hours—make it a practical choice for businesses aiming to streamline operations. However, the high degree of customization may require a greater upfront investment, which should be considered in the procurement process.

How Does the ORT Box Serve B2B Needs?

The ORT Box is designed primarily for nose work training in dogs, making it a staple for pet training supplies. Available in standardized sizes, these boxes are cost-effective and can be easily assembled, making them suitable for trainers and event organizers. While they offer functional benefits, the lack of design flexibility might limit appeal for businesses seeking unique branding opportunities. B2B buyers should weigh the practicality of these boxes against their specific training needs.

What Makes LEGRABOX a Preferred Choice?

LEGRABOX stands out for its sleek design and exceptional motion comfort, making it a favored option for kitchens and bathrooms. Its premium aesthetic aligns with high-end cabinetry trends, appealing to B2B buyers focused on delivering quality products. The installation process may require specialized skills, which could increase overall costs. Nevertheless, the reliability and performance of LEGRABOX can justify the investment for businesses targeting discerning customers.

Why Choose TANDEMBOX antaro for Contemporary Furniture?

The TANDEMBOX antaro is characterized by its clean lines and angular shapes, which cater to contemporary furniture designs. This type of box is versatile and can be integrated into various retail furniture applications, enhancing the overall aesthetic appeal. While it provides significant design advantages, the associated costs may be higher than simpler alternatives. Businesses should consider their target market’s preferences when choosing this option.

What Advantages Do Custom Box Systems Offer?

Custom box systems provide tailored solutions that address specific client requirements, making them ideal for diverse manufacturing sectors. These systems allow businesses to differentiate their offerings and meet unique customer demands effectively. However, the trade-off often includes longer lead times and potentially increased costs. B2B buyers should evaluate their capacity for customization and the expected return on investment when considering these systems for their operations.

Key Industrial Applications of or box

| Industry/Sector | Specific Application of or box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom wooden drawer solutions | Streamlined production and reduced lead times | Quality of materials, customization options, delivery speed |

| Retail & E-commerce | Packaging for retail display and shipping | Enhanced product presentation and customer satisfaction | Durability, design flexibility, cost-effectiveness |

| Interior Design | Modular storage solutions for homes | Versatile design options that meet diverse client needs | Aesthetic appeal, sustainability, ease of installation |

| Event Management | Storage and organization for event supplies | Efficient logistics and improved event setup | Size and weight, ease of transport, customization capabilities |

| Pet Industry | Training aids for canine sports | Standardized training tools for consistency | Material safety, size variations, compliance with regulations |

How is ‘or box’ Used in Furniture Manufacturing?

In the furniture manufacturing sector, ‘or box’ serves as a customizable wooden drawer solution that can be tailored to meet specific client requirements. By offering a wide range of design options, manufacturers can efficiently produce high-quality furniture without investing heavily in production machinery or storage. This application addresses common challenges such as long lead times and high production costs, allowing businesses to focus on creativity and customer service. International buyers from regions like Africa and Europe should consider the quality of materials and the ability to customize designs to suit local market preferences.

What Role Does ‘or box’ Play in Retail & E-commerce?

In the retail and e-commerce industries, ‘or box’ is utilized for packaging products in a visually appealing manner while ensuring safe transport. This application enhances product presentation, which is crucial for attracting customers in a competitive market. The boxes can be designed to reflect brand identity, thereby increasing customer satisfaction and repeat purchases. For businesses sourcing these solutions, durability and design flexibility are key considerations, especially in diverse markets like South America and the Middle East, where packaging requirements may vary significantly.

Illustrative image related to or box

How Can ‘or box’ Benefit Interior Design Projects?

Interior designers leverage ‘or box’ for creating modular storage solutions that fit seamlessly into various living spaces. The versatility of the drawer systems allows designers to fulfill diverse client needs, from aesthetic preferences to functional requirements. This application not only streamlines the design process but also enhances the overall quality of the finished product. Buyers in Europe and Africa should focus on the aesthetic appeal and sustainability of materials when sourcing these solutions to align with modern design trends and eco-conscious consumer demands.

What Advantages Does ‘or box’ Offer in Event Management?

In the event management industry, ‘or box’ provides effective storage and organization for supplies, facilitating a smoother event setup. The boxes can be customized for specific events, ensuring that all necessary items are easily accessible and well-presented. This application addresses logistical challenges by allowing for efficient transport and setup, which is crucial for success in fast-paced environments. Event planners in regions like the Middle East should consider the size, weight, and customization capabilities of the boxes to optimize their operational efficiency.

How is ‘or box’ Used in the Pet Industry?

The pet industry utilizes ‘or box’ as standardized training aids for canine sports, ensuring consistency in training environments. This application allows trainers to provide uniform experiences for dogs during competitions, which is vital for performance assessments. Buyers in this sector must prioritize material safety and compliance with industry regulations to ensure the well-being of animals. Additionally, offering size variations can cater to different training needs, making ‘or box’ a valuable resource for pet trainers and organizations globally.

Illustrative image related to or box

3 Common User Pain Points for ‘or box’ & Their Solutions

Scenario 1: Managing Diverse Customer Demands with Limited Resources

The Problem:

B2B buyers often face the challenge of catering to a wide range of customer preferences while operating within tight resource constraints. This is particularly relevant in regions where customization is a key selling point, yet the ability to maintain a diverse inventory can strain operational capabilities. For example, a furniture manufacturer in Brazil may want to offer various designs and finishes to meet local tastes, but managing the logistics of multiple stock-keeping units (SKUs) can lead to increased costs and complexity.

The Solution:

To address this issue, consider integrating the TA’OR BOX system into your offerings. The TA’OR BOX allows for an incredible range of design options—up to 35 billion variations—while being pre-assembled and shipped directly to you. This means that instead of investing in extensive inventory, you can use the online configurator to order specific designs tailored to customer requests without the hassle of managing multiple components. By utilizing a drop-ship model, you can significantly reduce storage costs and ensure that your customers receive the exact products they desire without delay. This approach not only enhances customer satisfaction but also optimizes your operational efficiency.

Scenario 2: Overcoming Quality Control Challenges in Production

The Problem:

Quality control is a significant concern for B2B buyers, especially when dealing with custom furniture components. Variability in material quality and workmanship can lead to increased returns, customer dissatisfaction, and ultimately damage to your brand reputation. For instance, a furniture retailer in Europe may struggle to maintain high standards if they rely on multiple suppliers for different parts of their products, resulting in inconsistencies that can frustrate customers.

The Solution:

To mitigate quality control issues, partnering with a manufacturer that offers a complete and reliable solution, such as the TA’OR BOX, is essential. The TA’OR BOX system is manufactured in state-of-the-art facilities with precise processing tolerances, ensuring consistent quality across every order. By sourcing your drawer systems from a single provider known for its rigorous quality standards, you can streamline your supply chain and reduce the risk of defects. Additionally, the use of high-quality materials and innovative design techniques further enhances the durability and aesthetic appeal of your products, thus reinforcing your commitment to quality in the eyes of your customers.

Scenario 3: Streamlining Production to Save Time and Costs

The Problem:

Many B2B buyers find that traditional manufacturing processes are time-consuming and costly, particularly when they must handle the assembly of various components. This can be a significant barrier for smaller companies looking to compete with larger manufacturers that have more resources. For example, a small workshop in South America might struggle to keep up with demand due to the lengthy production times associated with assembling custom drawer systems from scratch.

The Solution:

Implementing a pre-assembled solution like the TA’OR BOX can dramatically streamline your production processes. By opting for pre-assembled drawers, you can eliminate the need for in-house assembly, reducing labor costs and minimizing lead times. The TA’OR BOX is designed for quick installation—simply unpack and mount, allowing your team to focus on other critical areas of your business, such as customer service and design innovation. Additionally, the reduced need for manufacturing equipment and materials means that you can allocate your budget more effectively, enhancing your overall profitability while meeting customer demands more swiftly.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their operational efficiency, maintain high-quality standards, and better satisfy the diverse needs of their clientele.

Strategic Material Selection Guide for or box

What Are the Key Properties of Common Materials for ‘or box’?

When selecting materials for ‘or box’ products, it is crucial to consider their properties, durability, and suitability for specific applications. The most common materials include wood, plastic, metal, and composite materials. Each offers distinct advantages and disadvantages that can impact performance and cost.

Illustrative image related to or box

How Does Wood Perform as a Material for ‘or box’?

Wood is a traditional choice for ‘or box’ applications, known for its aesthetic appeal and structural integrity. Key properties include good strength-to-weight ratio and natural insulation. However, wood can be susceptible to moisture, which may lead to warping or decay if not properly treated.

Pros: Wood provides a timeless look and can be easily customized. It is also biodegradable, making it an environmentally friendly choice.

Cons: The cost of high-quality wood can be significant, and it may require more complex manufacturing processes, including cutting, finishing, and treatment for durability.

International buyers should consider compliance with sustainability standards, particularly in regions like Europe, where regulations on sourcing and treatment of wood are stringent.

What Are the Advantages of Using Plastic for ‘or box’?

Plastic is a versatile material often used for ‘or box’ products due to its lightweight and corrosion-resistant properties. It can withstand a range of temperatures and is generally easy to mold into various shapes.

Pros: The manufacturing process for plastic is typically less complex, allowing for lower production costs and faster turnaround times. It is also resistant to moisture, making it suitable for various environments.

Cons: Plastic may not have the same aesthetic appeal as wood and can be perceived as less durable in high-end applications. Additionally, certain plastics can be less environmentally friendly, raising concerns among eco-conscious consumers.

Illustrative image related to or box

For international buyers, understanding the specific types of plastics that comply with local regulations is essential, especially in markets that prioritize sustainability.

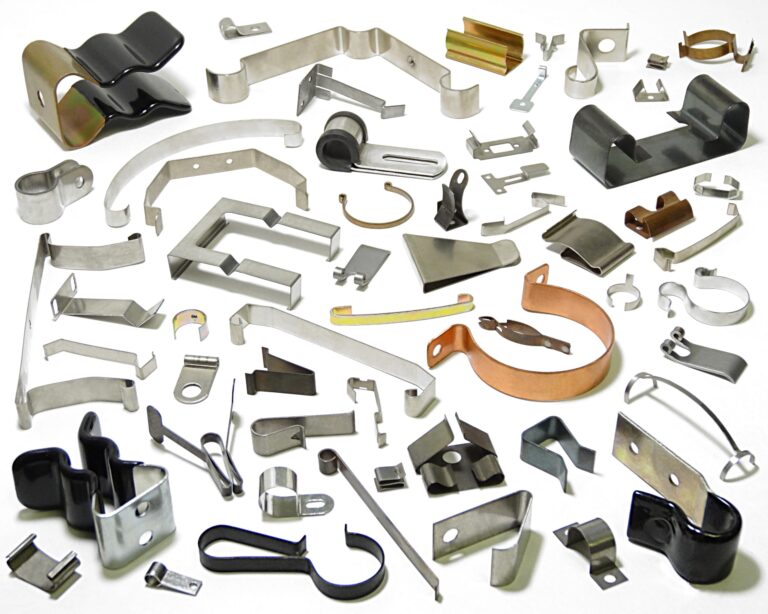

Why Consider Metal as a Material for ‘or box’?

Metal, particularly aluminum or steel, is chosen for its strength and durability. It can withstand high pressures and temperatures, making it suitable for more demanding applications.

Pros: Metal offers excellent longevity and resistance to corrosion, especially when treated or coated. It also provides a modern aesthetic that appeals to certain consumer segments.

Cons: The cost of metal can be higher than other materials, and the manufacturing process may involve more complexity, such as welding or machining.

Illustrative image related to or box

International buyers must be aware of the specific metal standards and certifications required in their regions, such as ASTM for the U.S. or EN standards in Europe.

How Do Composite Materials Impact ‘or box’ Applications?

Composite materials, which combine two or more different materials, are increasingly popular in ‘or box’ applications. They offer a balance of properties from their constituent materials.

Pros: Composites can be engineered for specific performance criteria, such as enhanced strength or reduced weight. They often have good resistance to environmental factors.

Cons: The manufacturing process for composites can be complex and may require specialized equipment, leading to higher costs. Additionally, the long-term durability of some composites can be uncertain compared to traditional materials.

Illustrative image related to or box

For international buyers, understanding the specific composite materials and their compliance with local standards is vital, particularly in regions like Africa and South America where material sourcing may differ.

Summary Table of Material Selection for ‘or box’

| Material | Typical Use Case for or box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | High-end furniture | Aesthetic appeal and customization | Susceptible to moisture and decay | High |

| Plastic | General purpose applications | Lightweight and corrosion-resistant | Less aesthetic appeal | Medium |

| Metal | Heavy-duty applications | High strength and durability | Higher cost and complex manufacturing | High |

| Composite | Specialized applications | Tailored performance properties | Complex manufacturing and potential durability issues | Medium |

This guide provides a comprehensive overview of material options for ‘or box’ products, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for or box

What Are the Main Stages of the Manufacturing Process for ‘or box’?

The manufacturing of ‘or box’ involves several critical stages that ensure both quality and efficiency. Understanding these stages is essential for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, where manufacturing standards may vary.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process begins with the careful selection of raw materials. For ‘or box,’ which often utilizes high-quality wood and sustainable materials, it is crucial to source from reputable suppliers who adhere to environmental standards. The materials are then prepared through processes such as cutting, drying, and treating to ensure durability and aesthetics.

In this phase, suppliers must demonstrate traceability of materials, confirming that they come from sustainable forests or recycled sources. This transparency is particularly vital for international buyers who prioritize sustainability in their supply chains.

What Techniques Are Used in Forming the ‘or box’?

Once the materials are prepared, the next step involves forming the ‘or box.’ This process typically employs advanced manufacturing techniques such as CNC machining and laser cutting, which provide high precision and consistency. These technologies allow for intricate designs and custom dimensions, catering to the diverse needs of B2B clients.

Additionally, techniques like laminating and veneering are used to enhance the aesthetic appeal of the product while maintaining structural integrity. The use of high-tech machinery in this stage ensures that the components fit together seamlessly, which is crucial for the overall quality of the final product.

How Is the Assembly Process Managed for Efficiency?

After forming, the assembly process begins. Pre-assembly is a significant advantage in this stage, as it reduces the time required for final assembly. Components are assembled in a controlled environment, ensuring that quality is maintained throughout the process.

Assembly lines are designed for efficiency, utilizing skilled labor alongside automated systems. This hybrid approach allows for quicker turnaround times while ensuring that quality standards are met. For international buyers, understanding the assembly process can provide insights into lead times and the ability to meet their specific requirements.

What Quality Control Measures Are Implemented During Production?

Quality assurance is integral to the manufacturing of ‘or box.’ This involves adhering to both international standards, such as ISO 9001, and industry-specific certifications, like CE marking for safety in the European market.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the production process. These typically include:

-

Incoming Quality Control (IQC): This initial inspection checks raw materials for defects before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections ensure that production processes adhere to established quality standards.

-

Final Quality Control (FQC): Before products are shipped, a thorough examination is conducted to ensure that they meet all specifications and quality standards.

This multi-tiered approach to quality control ensures that any issues are identified and rectified early in the manufacturing process, reducing the risk of defective products reaching customers.

What Testing Methods Are Commonly Used?

Common testing methods for ‘or box’ include dimensional checks, material integrity tests, and aesthetic evaluations. Dimensional checks ensure that all components fit together as designed, while material integrity tests assess the durability and stability of the materials used. Aesthetic evaluations confirm that the finished product meets visual standards and customer expectations.

Illustrative image related to or box

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are several effective strategies:

-

Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and overall compliance with international standards.

-

Quality Reports: Requesting detailed quality reports provides insights into the supplier’s QC performance over time. These reports should include data on defect rates, testing results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be tailored to specific needs and can cover various aspects of production.

-

Certifications: Reviewing certifications from recognized organizations can assure buyers of the supplier’s commitment to quality. Certifications like ISO 9001 or industry-specific standards demonstrate adherence to international quality benchmarks.

What Are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, particularly from regions such as Africa, South America, and the Middle East, buyers must be aware of certain nuances:

-

Cultural Differences: Understanding local manufacturing practices and quality perceptions can help buyers navigate potential challenges in quality assurance.

-

Regulatory Compliance: Different regions may have varying regulatory requirements, particularly concerning safety and environmental standards. Buyers should ensure that their suppliers comply with both local and international regulations.

-

Communication: Establishing clear communication channels is vital. Buyers should articulate their quality expectations and ensure that suppliers are aligned with these standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for ‘or box’ can significantly impact the purchasing decisions of B2B buyers. By focusing on the critical stages of production and the quality control checkpoints, buyers can make informed choices that align with their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘or box’

Introduction

This sourcing guide is designed to assist B2B buyers in efficiently procuring ‘or boxes’—a versatile and essential component for various applications in the furniture and packaging industries. By following this step-by-step checklist, buyers can ensure that they make informed decisions, optimize their procurement process, and ultimately enhance their business operations.

Step 1: Identify Your Requirements

Understanding your specific needs is the foundation of a successful procurement process. Clearly define the dimensions, materials, and functional specifications of the ‘or box’ you require.

– Consider the intended use (e.g., furniture drawers, packaging) to ensure you select the right type.

– Assess the volume of boxes needed to determine whether bulk ordering is feasible.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ‘or boxes.’ Utilize online resources, industry directories, and trade shows to compile a list of candidates.

– Look for suppliers with a strong reputation and positive customer reviews.

– Prioritize suppliers that demonstrate expertise in your specific industry or application.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, it’s crucial to assess their production capabilities and quality standards. Request detailed information about their manufacturing processes, materials used, and design flexibility.

– Inquire about lead times and minimum order quantities to ensure they align with your operational needs.

– Verify their ability to customize products based on your specifications, as this can significantly impact your final product quality.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that validate their quality and compliance with industry standards. This step is vital for mitigating risks associated with product quality and safety.

– Check for certifications such as ISO 9001 for quality management and other relevant environmental or safety standards.

– Request documentation that proves adherence to these certifications to instill confidence in your supplier’s reliability.

Step 5: Request Samples for Evaluation

Before placing a bulk order, request samples of the ‘or boxes’ to evaluate their quality and functionality. This hands-on assessment will help you determine if the product meets your expectations.

– Pay attention to the craftsmanship, material quality, and overall finish of the samples.

– Test the boxes for durability and usability in real-world scenarios to ensure they fit your operational requirements.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, it’s time to discuss terms and pricing. Effective negotiation can lead to favorable conditions that enhance your profitability.

– Clarify payment terms, delivery schedules, and any potential discounts for bulk purchases.

– Ensure that you understand the warranty and return policies in case the products do not meet your standards.

Step 7: Finalize the Order and Monitor Delivery

After agreeing on the terms, finalize your order and keep an eye on the delivery process. Effective monitoring ensures that you receive the correct quantity and quality on time.

– Establish a communication plan with your supplier to track order progress and address any potential issues promptly.

– Prepare to conduct a quality check upon receipt of the ‘or boxes’ to ensure they meet your established specifications.

By following these steps, B2B buyers can streamline their sourcing process for ‘or boxes,’ ensuring they select the best suppliers and products that align with their business needs.

Comprehensive Cost and Pricing Analysis for or box Sourcing

Understanding the cost structure and pricing for sourcing ‘or box’ products is essential for international B2B buyers aiming to optimize their procurement strategies. This analysis will delve into the various cost components involved, price influencers, and provide actionable tips for negotiation and cost-efficiency.

What Are the Key Cost Components in ‘or box’ Sourcing?

-

Materials: The primary material used in ‘or box’ products is wood, which can vary in quality and type, affecting overall costs. Premium woods or specialty finishes will increase material costs significantly. Additionally, sourcing sustainable or certified wood may incur higher expenses but can enhance marketability.

-

Labor: Labor costs are influenced by the region of production. Skilled labor for high-quality craftsmanship, especially in countries with stringent labor laws, may raise costs. Conversely, regions with lower labor costs can offer more competitive pricing, but this may impact quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes, such as those employed by modern facilities, can help reduce overhead costs, which can then be reflected in the pricing offered to buyers.

-

Tooling: Customization often requires specific tooling, which can be a significant upfront cost. The more complex the design or specifications, the higher the tooling costs. Buyers should consider how these costs will be amortized over their order volumes.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet required standards, but this adds to the overall cost. Buyers should weigh the importance of quality against potential savings from suppliers with less rigorous QC processes.

-

Logistics: Shipping costs depend on the distance from the supplier to the buyer, the mode of transportation, and any tariffs or duties that may apply. Understanding the Incoterms involved will help clarify responsibilities for shipping costs and risks.

-

Margin: Suppliers will typically apply a margin to cover their costs and achieve profit. This margin can vary significantly based on the supplier’s market position, brand reputation, and the complexity of the product.

How Do Price Influencers Affect ‘or box’ Pricing?

-

Volume/MOQ: Bulk purchases often attract discounts due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to benefit from lower unit prices.

-

Specifications and Customization: Customized orders generally lead to higher costs due to added complexity in production and tooling. Clear communication of specifications can help mitigate unnecessary costs.

-

Materials and Quality Certifications: Products with certifications (e.g., FSC for sustainable wood) may command higher prices. Buyers need to assess the value these certifications bring to their offerings.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium due to their proven quality and service levels.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will dictate who bears shipping costs and risks, impacting overall pricing.

What Are Effective Buyer Tips for Cost-Efficiency?

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Understanding their cost drivers can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the product’s lifecycle, including maintenance, logistics, and potential waste costs. This approach can identify more cost-effective sourcing options.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe must consider currency fluctuations, import duties, and local market conditions, which can affect overall costs. Establishing long-term relationships with suppliers can also lead to more favorable terms.

-

Request Indicative Pricing: Given the variability in costs based on customization and order size, request indicative prices for different scenarios to better understand potential expenditures before committing to orders.

By thoroughly analyzing these components and influencers, international B2B buyers can make informed decisions that align with their strategic sourcing goals while maximizing efficiency and cost-effectiveness in their procurement processes.

Alternatives Analysis: Comparing or box With Other Solutions

Understanding Alternatives to ‘Or Box’ Solutions

In the competitive landscape of B2B furniture solutions, businesses often seek alternatives to optimize their offerings. The ‘Or Box’ system, known for its innovative design and manufacturing efficiency, can be compared to other popular solutions in the market. This analysis will provide insights into the performance, cost, ease of implementation, maintenance, and best use cases for ‘Or Box’ against two notable alternatives.

| Comparison Aspect | ‘Or Box’ | Alternative 1: TA’OR Box | Alternative 2: LEGRABOX |

|---|---|---|---|

| Performance | High precision with customizable options; rapid delivery | Excellent design variety; efficient assembly | Smooth operation; elegant aesthetics |

| Cost | Competitive pricing for custom solutions | Higher initial investment; long-term savings | Moderate pricing; premium branding |

| Ease of Implementation | Simple online configurator; quick setup | User-friendly configurator; 48-hour delivery | Requires more assembly time |

| Maintenance | Low maintenance; durable materials | Minimal maintenance; high durability | Regular maintenance required for optimal performance |

| Best Use Case | Custom furniture manufacturing; rapid prototyping | High-end furniture production; bespoke designs | Residential and commercial cabinetry |

What are the Advantages and Disadvantages of TA’OR Box?

TA’OR Box stands out for its extensive design variety, offering up to 35 billion combinations of colors, materials, and sizes. This flexibility allows manufacturers to meet diverse customer needs without overwhelming their production processes. However, the initial investment can be higher, although it pays off through reduced costs in the long run. The system is designed for ease of use, featuring a straightforward configurator and a quick turnaround time, which is particularly beneficial for businesses looking to deliver unique furniture rapidly.

How Does LEGRABOX Compare in Terms of Functionality?

LEGRABOX is celebrated for its sleek design and superior motion comfort, making it a popular choice for high-end cabinetry. Its elegant aesthetics appeal to customers seeking a premium look for their furniture. However, LEGRABOX often requires more time for assembly compared to ‘Or Box,’ which can be a drawback for businesses prioritizing efficiency. While the pricing is moderate, it may not provide the same extensive customization options as ‘Or Box’ or TA’OR Box, which could limit its appeal in certain markets.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution, B2B buyers should consider their specific operational needs and customer expectations. If rapid customization and low maintenance are priorities, ‘Or Box’ offers a compelling choice with its efficient configurator and robust design. Conversely, for businesses targeting high-end markets with bespoke furniture demands, TA’OR Box may be more suitable despite its higher initial costs. LEGRABOX is ideal for those emphasizing aesthetics and elegance but should be evaluated against the potential assembly time required. Ultimately, the best solution hinges on aligning business goals with customer demands to ensure satisfaction and competitiveness in the marketplace.

Essential Technical Properties and Trade Terminology for or box

What Are the Key Technical Properties of an ‘or box’?

-

Material Grade

The quality of materials used in the construction of an ‘or box’ significantly affects its durability and aesthetic appeal. Common materials include high-density fiberboard (HDF) and various grades of wood veneer. Choosing higher-grade materials can enhance product longevity and meet customer expectations for quality, which is crucial for B2B buyers looking to maintain brand reputation. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing. For an ‘or box,’ precision is key; typical tolerance levels might be within 1-2 mm for dimensions. This is important for ensuring that boxes fit perfectly within furniture designs and maintain uniformity across orders, reducing the risk of customer complaints and returns. -

Weight Capacity

Knowing the weight capacity of an ‘or box’ is essential for end-users, particularly in furniture applications. This property indicates how much load the drawer can handle without compromising its structural integrity. A higher weight capacity can be a selling point for B2B buyers, particularly those targeting commercial sectors where durability is paramount. -

Finish and Aesthetic Options

The finish of an ‘or box’ affects both its appearance and functionality. Options may include various coatings and textures that enhance visual appeal while providing resistance to wear and tear. Offering a wide range of finishes allows buyers to cater to diverse customer preferences, making it easier to sell to varied markets. -

Assembly Requirements

Many ‘or boxes’ come partially assembled or require minimal assembly. This property can significantly reduce the time and labor costs associated with installation for B2B buyers. Understanding assembly requirements allows businesses to streamline operations and offer quicker turnaround times to their customers. -

Sustainability Factors

With increasing emphasis on eco-friendly practices, sustainability has become a critical property for buyers. Options like using recycled materials or low-VOC finishes can appeal to environmentally conscious consumers. B2B buyers can leverage these attributes to differentiate their offerings in competitive markets.

Which Trade Terms Should B2B Buyers Understand for ‘or box’?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers seeking to source components for their products without investing heavily in production capabilities. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers, as it helps them gauge how much inventory they need to purchase at once to meet supplier requirements and avoid excessive costs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. B2B buyers should be familiar with RFQs to effectively negotiate pricing and terms with potential suppliers. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which can significantly impact overall purchasing decisions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For buyers, understanding lead time is crucial for planning inventory and managing customer expectations, especially in fast-paced markets. -

Customization Options

This term refers to the ability to modify products to meet specific customer requirements. B2B buyers should assess customization options as they can provide a competitive edge in meeting diverse market demands and enhancing customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational goals and customer expectations, ultimately leading to better business outcomes.

Navigating Market Dynamics and Sourcing Trends in the or box Sector

What Are the Key Market Dynamics and Trends Influencing the ‘or box’ Sector?

The ‘or box’ sector is witnessing significant transformation driven by various global factors. One of the most prominent trends is the increasing demand for customization in furniture design. International B2B buyers are increasingly seeking products that can be tailored to meet specific consumer preferences, which is particularly important in diverse markets like Africa, South America, the Middle East, and Europe. The ability to offer a wide range of colors, materials, and sizes, as exemplified by TA’OR BOX, is becoming a critical competitive advantage.

Technological advancements are also reshaping the sourcing landscape. Automation in manufacturing processes and the use of online configurators streamline the ordering process, enabling businesses to reduce lead times and improve efficiency. For example, TA’OR BOX’s online design tool allows buyers to configure their orders quickly, which is essential for meeting fast-paced consumer demands. This tech-driven approach is particularly beneficial for businesses in emerging markets like Vietnam and Brazil, where operational efficiency can significantly impact profitability.

Moreover, sustainability is becoming a key driver of purchasing decisions. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient production methods, and transparent supply chains. As a result, businesses that can effectively communicate their sustainability credentials are likely to gain a competitive edge in the global marketplace.

How Does Sustainability and Ethical Sourcing Impact the ‘or box’ Sector?

Sustainability and ethical sourcing are no longer optional; they are essential components of a successful B2B strategy in the ‘or box’ sector. The environmental impact of raw material sourcing, particularly wood, has come under scrutiny as consumers become more eco-conscious. Buyers are increasingly looking for products that minimize environmental harm, such as those made from sustainably sourced timber or recycled materials. For instance, the TA’OR BOX system utilizes fine wood veneer and a dimensionally stable HDF core made from recycled material, significantly reducing wood consumption and promoting sustainability.

Ethical supply chains are equally important. B2B buyers are increasingly aware of the social implications of their purchases, including labor practices and community impact. Companies that prioritize ethical sourcing, ensuring fair labor practices and transparency in their supply chains, can appeal to a growing segment of conscious consumers and businesses. Certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) can further enhance credibility and trustworthiness in the eyes of international buyers.

Furthermore, the demand for ‘green’ certifications and materials is shaping sourcing trends. Buyers from regions such as Europe are particularly influenced by stringent environmental regulations and consumer expectations for sustainable products. This shift not only impacts supplier selection but also encourages manufacturers to innovate in their product offerings, aligning with the global push for sustainability.

Illustrative image related to or box

What Is the Brief Evolution of the ‘or box’ Sector?

The ‘or box’ sector has evolved significantly over the years, transitioning from traditional craftsmanship to modern industrial production. Initially, furniture manufacturing relied heavily on artisanal skills, which limited customization and scalability. However, with advancements in technology and manufacturing processes, companies like TA’OR BOX have revolutionized the industry by introducing modular designs and pre-assembled components.

This evolution reflects broader trends in consumer behavior, where personalization and convenience are paramount. The introduction of online configurators and automated production lines has enabled manufacturers to offer an unprecedented variety of options while maintaining high-quality standards. As the market continues to evolve, the focus on sustainability and ethical sourcing will likely remain central to the industry’s future, shaping both product offerings and buyer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of or box

-

How do I solve supply chain delays when sourcing OR boxes internationally?

To mitigate supply chain delays, establish strong relationships with multiple suppliers and understand their production timelines. Ensure you have a clear communication channel for updates on order status and potential disruptions. Utilizing a reliable logistics partner can also enhance shipping efficiency. Consider sourcing from suppliers who offer pre-assembled options, as they often streamline the process and reduce lead times. Additionally, maintaining safety stock can safeguard against unexpected delays. -

What is the best way to customize OR boxes for my specific needs?

When customizing OR boxes, work closely with your supplier to discuss material options, sizes, and design specifications that meet your requirements. Many suppliers offer configurators or design tools to assist in visualizing your customizations. Be clear about your brand’s aesthetic and functional needs, and request samples if possible to assess quality. Engaging in early discussions about your needs can lead to more tailored solutions and faster production times. -

What are the minimum order quantities (MOQs) for OR boxes?

Minimum order quantities vary by supplier and can depend on the specific configurations you require. Typically, manufacturers may set MOQs to ensure production efficiency and cost-effectiveness. For smaller businesses or those just starting, inquire about flexible ordering options or the possibility of combining different configurations to meet the MOQ. Some suppliers may also offer lower MOQs for repeat customers or special arrangements. -

How can I ensure quality assurance (QA) when sourcing OR boxes?

To ensure quality assurance, request detailed product specifications and certifications from your supplier, including compliance with international standards. Conducting factory audits or quality checks during production can provide additional assurance. Additionally, consider ordering samples before committing to larger orders to evaluate the craftsmanship and materials. Establishing a clear QA protocol with your supplier can also help maintain consistent quality across shipments. -

What payment terms should I expect when ordering OR boxes internationally?

Payment terms can vary widely among suppliers, but common practices include upfront deposits followed by balance payments upon shipment. Be sure to clarify the payment structure, including any available credit terms or discounts for bulk orders. Utilizing secure payment methods like letters of credit or escrow services can provide additional security for your transactions. Always ensure that payment terms align with your cash flow and business strategy. -

What logistics considerations should I keep in mind when importing OR boxes?

When importing OR boxes, consider factors such as shipping methods, import duties, and local regulations. Choosing the right shipping partner can significantly impact delivery times and costs. Additionally, familiarize yourself with customs processes and ensure all documentation is in order to avoid delays. It’s also wise to assess the total landed cost, including shipping and tariffs, to better budget for your purchases. -

How do I vet suppliers for OR boxes effectively?

To vet suppliers, start by checking their industry reputation through reviews and references. Look for suppliers with experience in international trade and a proven track record of reliability. Request certifications and compliance documents to ensure they meet quality and safety standards. Engaging in direct communication can also help gauge their responsiveness and willingness to accommodate your specific needs. -

What trends should I be aware of in the OR box market?

Current trends in the OR box market include a growing demand for sustainable materials and customizable solutions. Buyers are increasingly seeking eco-friendly options, such as boxes made from recycled materials. Additionally, the integration of technology in design and ordering processes is becoming more prevalent, allowing for more efficient customization and production. Staying updated on these trends can help you align your offerings with market demands and enhance your competitive edge.

Top 4 Or Box Manufacturers & Suppliers List

1. K9 Nose – ORT Box

Domain: thek9nose.com

Registered: 2015 (10 years)

Introduction: {“name”:”ORT Box”,”pack_size”:”6 pack”,”price”:”from $19.95″,”dimensions”:{“regular_size”:”10\” x 8\” x 3\””,”smaller_size”:”9\” x 6.5\” x 2.75\””},”usage”:”Used for ORTs for NACSW™, AKC®, and CPE trials; smaller size for NACSW Container Element Specialty Trial.”,”shipping”:”Boxes will be shipped partially folded, flat; assembly required.”,”local_pickup”:”Available for Minneapolis & St. Paul custo…

2. Häfele – TA’OR BOX

Domain: hafele.com.de

Introduction: TA’OR BOX is an innovative wooden drawer system designed for modern living and lifestyle demands. It offers 35 billion design variants, allowing customization to meet customer preferences. The drawers are pre-assembled, industrially produced, and delivered within 96 hours, saving time and costs associated with purchasing and stocking components. The system features high-quality materials, includin…

3. Reddit – User-Generated Content

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – User-Generated Content, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Vanhoecke – TA’OR BOX System

Domain: vanhoecke.be

Registered: 1997 (28 years)

Introduction: TA’OR BOX is a wooden mounted box system designed for wooden drawers, featuring fine finishing and innovative technology. It is fully compatible with LEGRABOX by Blum, with precise dimensions accurate to 1/100mm. The system offers maximum flexibility with slender drawer sides and a unique clip mechanism for easy mounting of drawer fronts. Available as a three-sided drawer or inner drawer, it provi…

Strategic Sourcing Conclusion and Outlook for or box

How Can Strategic Sourcing Transform Your Business with OR Box Solutions?

In conclusion, strategic sourcing presents a pivotal opportunity for B2B buyers seeking to optimize their operations and elevate customer satisfaction. The OR Box, with its diverse customization options and rapid delivery, empowers businesses to respond adeptly to market demands without the burdens of extensive inventory management or production overhead. By leveraging the advantages of pre-assembled solutions, companies can not only enhance efficiency but also reduce costs significantly.

Illustrative image related to or box

Moreover, as the demand for high-quality wooden furnishings grows, investing in innovative solutions like the TA’OR BOX can provide a competitive edge. The blend of aesthetic appeal and functionality in these products ensures that international buyers from regions like Africa, South America, the Middle East, and Europe can meet diverse consumer preferences while maintaining operational excellence.

As we look to the future, the emphasis on sustainability and adaptability in sourcing will continue to shape the industry landscape. Embrace these advancements to streamline your supply chain and deliver exceptional value to your customers. Engage with us today to explore how OR Box solutions can transform your business and meet the evolving needs of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to or box

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.