Is Your Open Loop Water Cooling Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for open loop water cooling

In the rapidly evolving landscape of high-performance computing, sourcing efficient open loop water cooling solutions presents a significant challenge for B2B buyers. As the demand for powerful systems grows, so does the need for effective thermal management that ensures optimal performance while minimizing noise and energy consumption. This comprehensive guide is designed to equip international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe (including Germany and Vietnam)—with the critical insights needed to navigate the complexities of the open loop water cooling market.

This guide delves into various types of open loop water cooling systems, their applications across different industries, and the nuances of supplier vetting processes. It also addresses cost considerations, installation best practices, and maintenance tips that ensure long-term reliability and performance. By consolidating essential information and expert recommendations, this resource empowers buyers to make informed purchasing decisions that align with their specific operational needs.

Ultimately, whether you’re a data center manager seeking to enhance cooling efficiency or a manufacturer aiming for peak performance in your products, this guide will serve as a valuable tool in your quest for the ideal open loop water cooling solutions. Equip yourself with the knowledge to invest wisely in technologies that not only enhance performance but also contribute to sustainable operational practices.

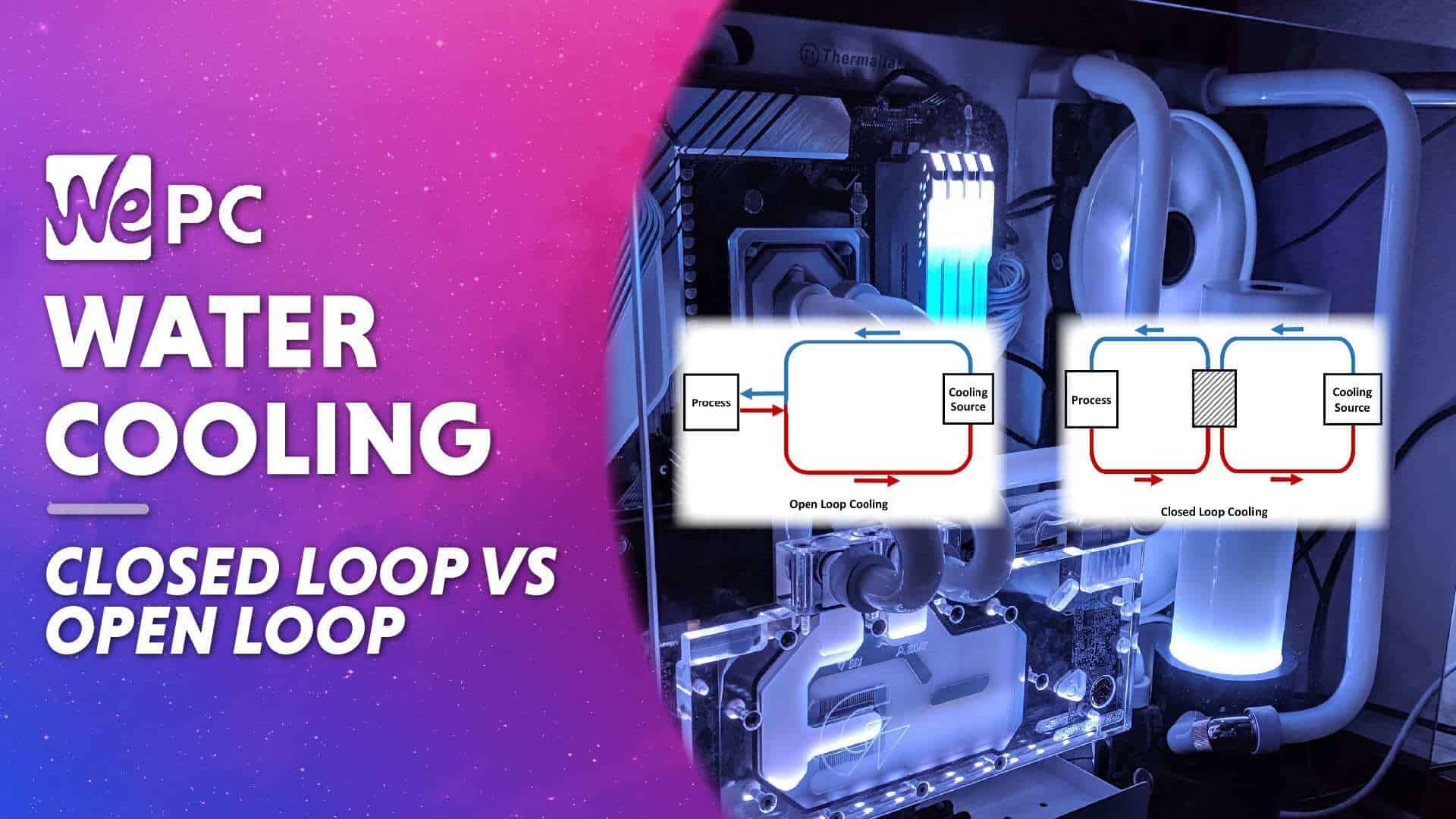

Understanding open loop water cooling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Open Loop | Highly customizable with individual components; allows for expansion and upgrades. | High-performance computing, gaming, and design workstations. | Pros: Optimal cooling, aesthetic appeal. Cons: Complex installation, requires maintenance. |

| Semi-Custom Loop | Pre-configured kits with some customization options; easier installation than fully custom systems. | Small to medium enterprises needing good cooling without extensive setup. | Pros: Easier setup, decent cooling performance. Cons: Limited customization compared to custom loops. |

| Hybrid Systems | Combines open and closed-loop features; often includes a reservoir and pump with some pre-installed components. | Data centers and enterprises looking for a balance of performance and maintenance. | Pros: Versatile, reduced maintenance. Cons: Potentially higher costs, may not achieve maximum cooling efficiency. |

| Direct Liquid Cooling | Directly cools components via liquid; often used in specialized applications like server farms. | High-density computing, telecom, and data centers. | Pros: Exceptional cooling efficiency, energy savings. Cons: Higher initial investment, complex infrastructure requirements. |

| Passive Cooling | Utilizes natural convection without pumps; relies on large radiators and heat sinks. | Environments where noise reduction is critical, such as studios or quiet offices. | Pros: Silent operation, low energy consumption. Cons: Limited cooling capacity, less effective for high-performance systems. |

What Are the Characteristics of Custom Open Loop Water Cooling?

Custom open loop water cooling systems are characterized by their flexibility and performance. Buyers can choose individual components such as pumps, radiators, and water blocks, which allows for tailored cooling solutions based on specific needs. This type is particularly suitable for high-performance applications in sectors like gaming, design, and engineering, where temperature management is crucial for performance. B2B buyers should consider the expertise required for installation and ongoing maintenance, as this system demands more attention compared to pre-packaged solutions.

How Does Semi-Custom Loop Water Cooling Compare?

Semi-custom loop systems provide a middle ground between fully custom solutions and closed-loop systems. They come as kits that offer some degree of customization while simplifying the installation process. This makes them an attractive option for small to medium enterprises that require effective cooling without the complexity of a fully custom setup. When purchasing, businesses should evaluate the cooling capacity and compatibility with existing hardware, as these systems may not offer the same high performance as fully custom options.

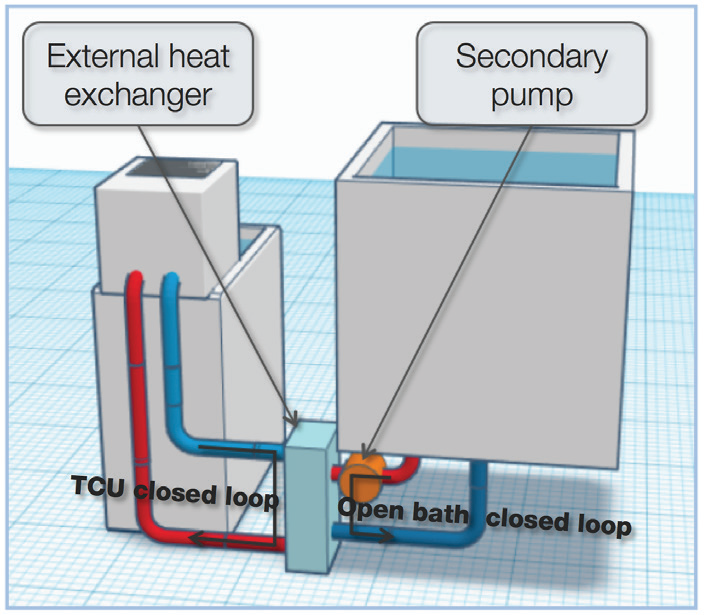

What Are the Benefits of Hybrid Water Cooling Systems?

Hybrid systems incorporate both open and closed-loop features, making them versatile for various applications. They often include a reservoir and pump while allowing for some customization of components. This type is ideal for data centers and enterprises looking for a balance between high performance and manageable maintenance. Buyers should assess the upfront costs versus long-term energy savings and cooling efficiency, as hybrid systems can provide significant operational benefits.

Why Choose Direct Liquid Cooling for High-Density Computing?

Direct liquid cooling is designed for environments that require intense cooling, such as server farms and telecom applications. This system involves directly cooling components with liquid, providing superior efficiency and energy savings. It is particularly beneficial for high-density computing environments where traditional air cooling may fail to keep temperatures in check. B2B buyers must consider the infrastructure required for installation and maintenance, as the initial investment can be substantial but often pays off in reduced energy costs over time.

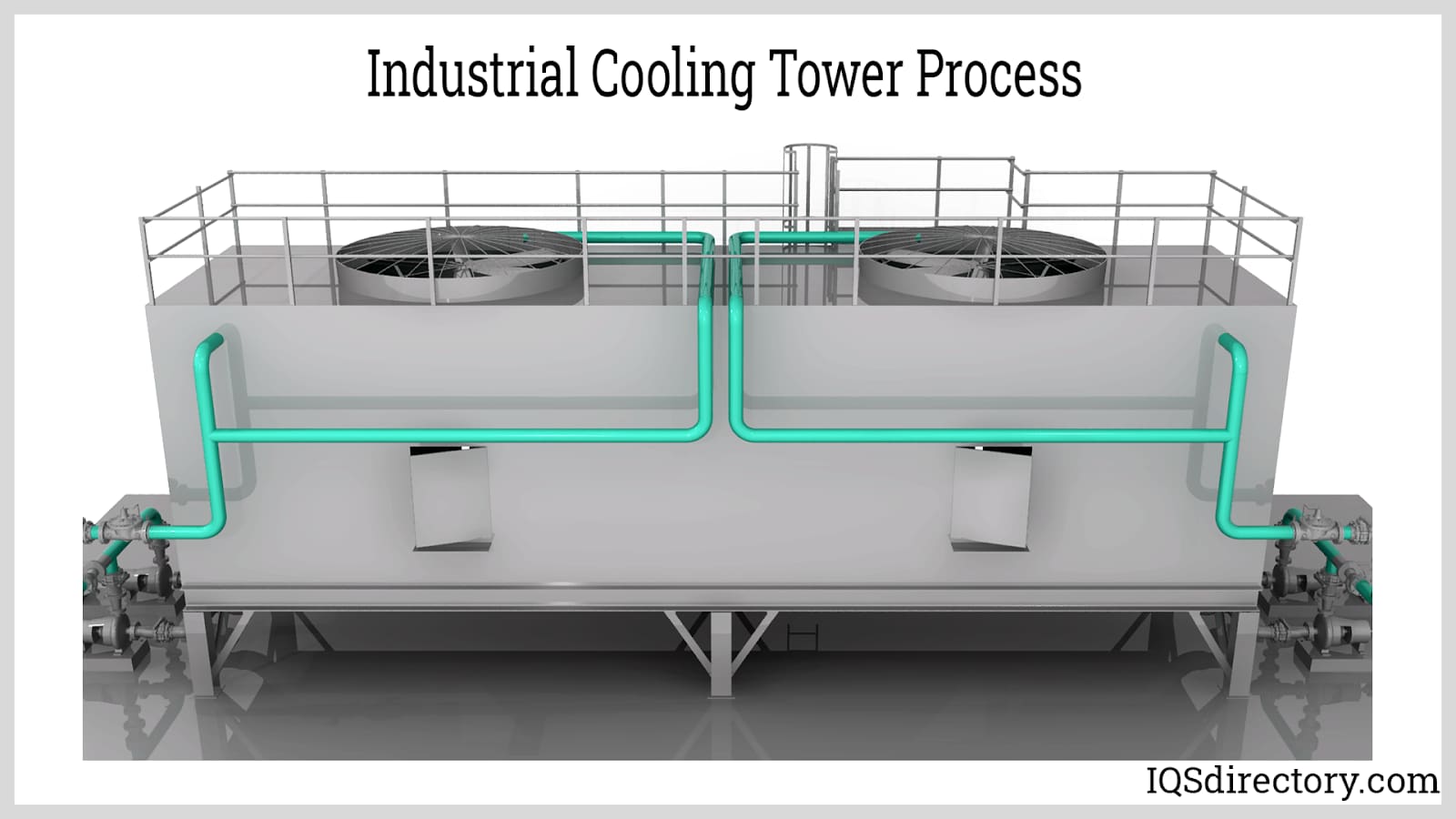

Illustrative image related to open loop water cooling

What Are the Advantages and Disadvantages of Passive Cooling?

Passive cooling systems operate without pumps, relying on natural convection to dissipate heat. They are ideal for environments where noise reduction is a priority, such as studios or quiet office settings. While this type of cooling is energy-efficient and silent, it has limitations in terms of cooling capacity, making it less suitable for high-performance applications. Buyers should weigh the benefits of low noise and energy consumption against the potential need for more robust cooling solutions for demanding tasks.

Key Industrial Applications of open loop water cooling

| Industry/Sector | Specific Application of open loop water cooling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Data Centers | Cooling of high-density server racks | Enhances performance and extends equipment lifespan | Compatibility with existing infrastructure and scalability |

| Industrial Manufacturing | Cooling for CNC machines and laser cutting equipment | Reduces downtime and improves operational efficiency | Durability and maintenance requirements |

| Telecommunications | Cooling for telecom equipment and data transmission systems | Ensures optimal performance and reliability | Energy efficiency and environmental regulations |

| Renewable Energy | Cooling for solar inverters and wind turbine generators | Increases energy output and system reliability | Adaptability to various environmental conditions |

| Automotive | Cooling in electric vehicle (EV) battery systems | Enhances battery performance and longevity | Compliance with industry standards and safety regulations |

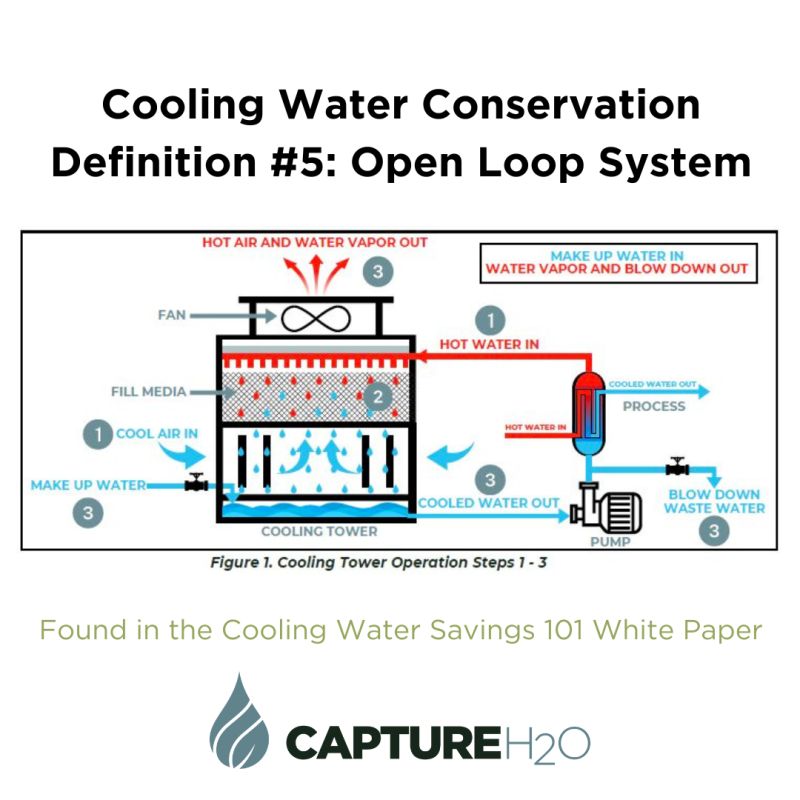

How is Open Loop Water Cooling Used in Data Centers?

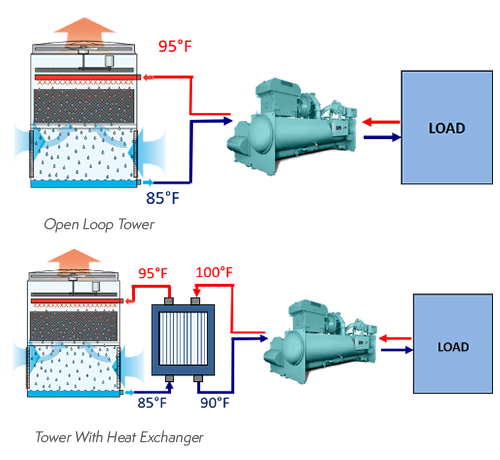

In data centers, open loop water cooling is employed to manage the heat generated by high-density server racks. As servers process vast amounts of data, they produce significant heat, which can lead to performance degradation and hardware failures. By utilizing open loop systems, water absorbs heat efficiently, allowing for lower operational temperatures. Buyers should consider factors such as compatibility with existing cooling infrastructure, scalability to accommodate future expansions, and the ability to integrate with renewable energy sources for sustainability.

What Role Does Open Loop Water Cooling Play in Industrial Manufacturing?

Open loop water cooling systems are critical in industrial manufacturing, particularly for cooling CNC machines and laser cutting equipment. These machines generate substantial heat during operation, which can lead to overheating and increased wear. By implementing an open loop cooling solution, manufacturers can reduce downtime and enhance operational efficiency. B2B buyers must focus on the durability of materials used in the cooling system and the ease of maintenance to ensure long-term reliability and performance.

How Does Open Loop Water Cooling Benefit Telecommunications?

In the telecommunications sector, open loop water cooling is utilized to maintain optimal operating temperatures for telecom equipment and data transmission systems. Efficient cooling is crucial to ensure reliability and minimize signal degradation. The use of water as a cooling medium allows for quieter operations and improved energy efficiency. Buyers should prioritize energy-efficient designs and compliance with local environmental regulations to ensure sustainable operations.

Why is Open Loop Water Cooling Important for Renewable Energy?

Open loop water cooling systems play a vital role in renewable energy applications, particularly in cooling solar inverters and wind turbine generators. Maintaining optimal temperatures is essential for maximizing energy output and ensuring system reliability. As renewable energy sources become more prevalent, the demand for effective cooling solutions increases. Buyers should consider the adaptability of cooling systems to various environmental conditions, as well as the potential for integration with energy management systems.

How is Open Loop Water Cooling Used in the Automotive Industry?

In the automotive sector, particularly with the rise of electric vehicles (EVs), open loop water cooling is critical for managing the temperatures of battery systems. Effective cooling enhances battery performance, longevity, and safety, which are paramount for consumer acceptance and regulatory compliance. B2B buyers need to focus on sourcing components that meet industry standards for safety and efficiency, as well as ensuring compatibility with various battery technologies.

3 Common User Pain Points for ‘open loop water cooling’ & Their Solutions

Scenario 1: Inefficient Cooling Leading to Hardware Throttling

The Problem: As B2B buyers invest in high-performance computing systems, they often encounter challenges with heat management. In environments where multiple high-performance CPUs and GPUs are used, such as data centers or gaming development studios, the inefficiency of air cooling can lead to thermal throttling. This results in reduced performance, potential hardware damage, and increased operational costs due to the need for additional cooling measures. Buyers may feel frustrated when they realize that the cooling solutions they initially selected do not support the demanding workloads typical of their applications.

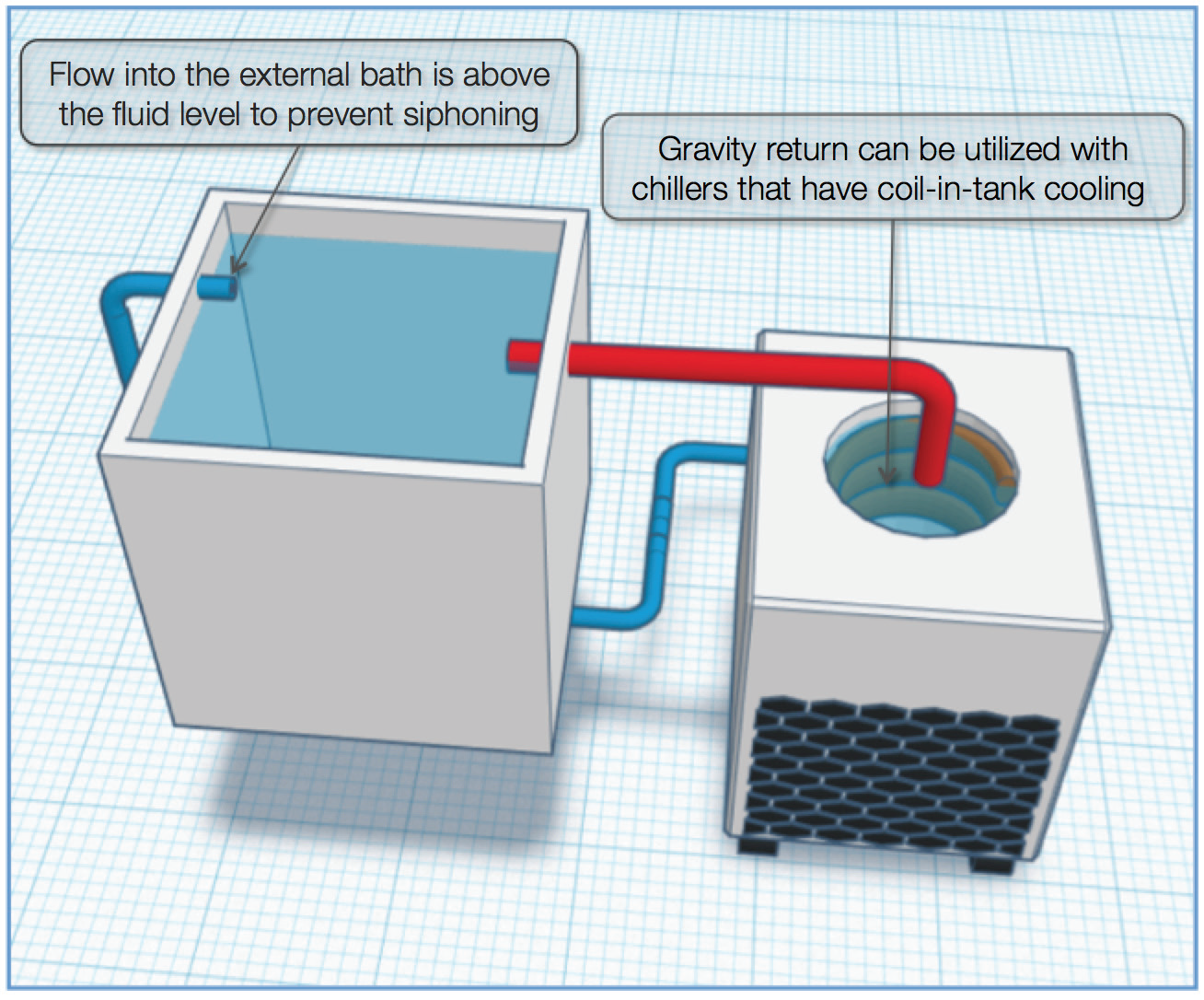

The Solution: To overcome this issue, B2B buyers should consider implementing an open loop water cooling system designed for high heat dissipation. Unlike traditional air coolers, open loop systems use liquid to transfer heat away from components more efficiently. Buyers should prioritize systems that include larger reservoirs and thicker radiators to enhance thermal management. When sourcing components, look for customizable options that allow integration with multiple GPUs and CPUs. This flexibility not only addresses immediate cooling needs but also provides scalability for future upgrades. Engaging with reputable suppliers who can offer tailored advice and support during the installation process will ensure that the system is optimized for specific workloads, ultimately enhancing performance and longevity.

Scenario 2: Complexity in System Maintenance and Upgrades

The Problem: Many businesses face the dilemma of maintaining and upgrading their cooling systems without disrupting ongoing operations. Open loop water cooling systems, while highly effective, can be complex and require regular maintenance to prevent issues like leaks or coolant degradation. B2B buyers might experience anxiety about the potential downtime associated with these maintenance tasks, especially in critical environments where uptime is paramount.

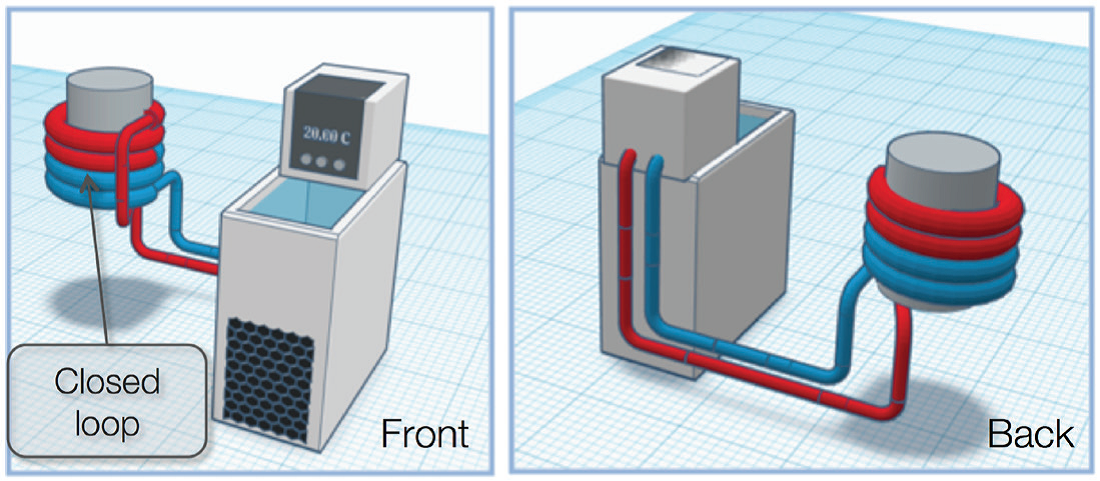

Illustrative image related to open loop water cooling

The Solution: To mitigate maintenance concerns, buyers should invest in modular open loop water cooling solutions that facilitate easier upgrades and repairs. Choosing components with quick-disconnect fittings allows for straightforward maintenance without needing to drain the entire system. It’s also advisable to implement a regular maintenance schedule, including checks on coolant levels and the integrity of tubing connections. Additionally, buyers can benefit from training sessions provided by manufacturers or third-party experts to ensure their IT staff is equipped to handle maintenance tasks efficiently. This proactive approach not only minimizes downtime but also extends the lifespan of the cooling system, providing long-term reliability.

Scenario 3: The Challenge of Customization and Aesthetic Integration

The Problem: In the B2B landscape, particularly within sectors like gaming, visual appeal is as important as performance. Buyers often struggle to find open loop water cooling solutions that not only perform well but also fit into their overall aesthetic vision for their systems. This challenge can be particularly pronounced for businesses looking to showcase their products or brand identity through their hardware.

The Solution: To address customization and aesthetic concerns, buyers should look for open loop cooling systems that offer a wide range of design options. Many manufacturers provide components with various color schemes, materials, and lighting options to match corporate branding or personal preferences. When selecting a system, consider starting with a base kit that allows for expansion—this way, additional components can be added over time as needs change. Collaborating with suppliers who specialize in custom cooling solutions can provide insights into the latest trends and technologies, ensuring that the cooling system not only performs optimally but also enhances the visual appeal of the setup. Engaging in community forums or consulting with experienced users can also yield creative ideas for unique designs that set a business apart from competitors.

Strategic Material Selection Guide for open loop water cooling

What Are the Key Materials for Open Loop Water Cooling Systems?

When selecting materials for open loop water cooling systems, it’s essential to consider their properties and how they affect performance, durability, and maintenance. Below, we analyze four common materials used in these systems: copper, aluminum, stainless steel, and acrylic.

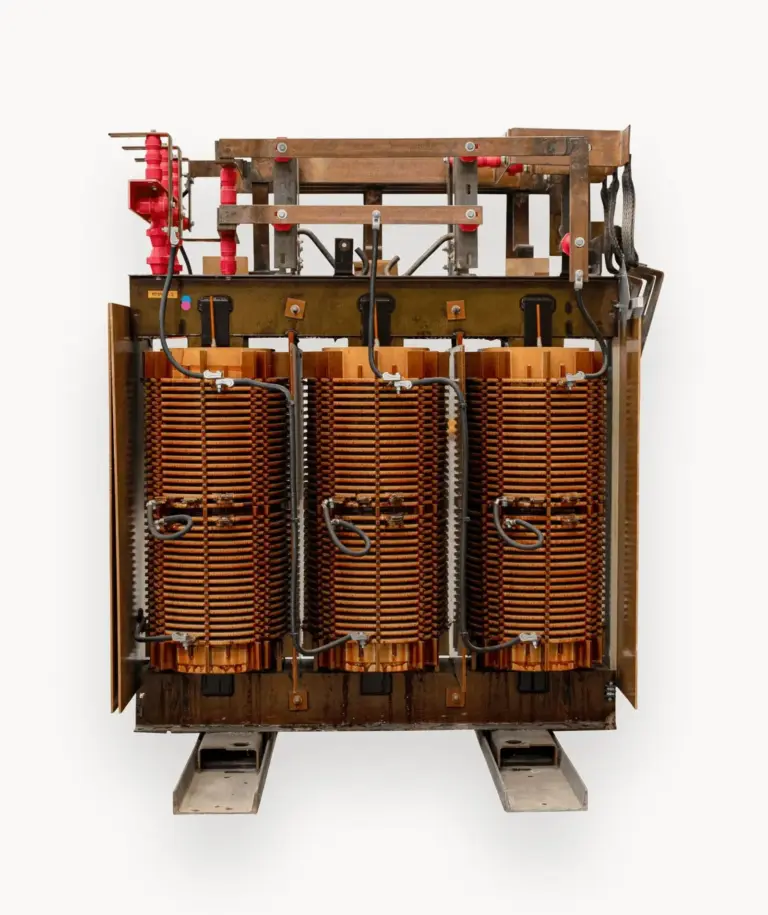

How Does Copper Perform in Open Loop Water Cooling?

Copper is widely regarded as the gold standard for water cooling due to its exceptional thermal conductivity, which allows for efficient heat transfer. With a temperature rating of up to 200°C and a pressure rating of around 300 psi, copper can handle extreme conditions without compromising performance.

Illustrative image related to open loop water cooling

Pros: Copper is highly durable and resistant to corrosion, making it suitable for long-term use. Its high thermal efficiency translates to better cooling performance, particularly in high-load scenarios.

Cons: The primary drawback of copper is its cost; it is more expensive than other materials. Additionally, its manufacturing can be complex, requiring specialized techniques for welding and shaping.

Impact on Application: Copper is compatible with various coolants, including distilled water and specialized additives. However, it may react with certain chemicals, necessitating careful selection of coolant.

Considerations for International Buyers: Buyers should be aware of compliance with international standards such as ASTM and DIN, particularly in regions like Europe and the Middle East where regulations are stringent.

What Role Does Aluminum Play in Open Loop Water Cooling?

Aluminum is another popular material, particularly for radiators and heat exchangers. It has a lower thermal conductivity than copper but is still effective for cooling applications. Its temperature rating is similar to copper, but it can handle pressures up to 150 psi.

Pros: Aluminum is lightweight and less expensive than copper, making it a cost-effective option for large systems. It is also easier to manufacture, allowing for more intricate designs.

Cons: While aluminum is resistant to corrosion, it is more susceptible to galvanic corrosion when in contact with copper. This can lead to reduced lifespan if not properly managed.

Impact on Application: Aluminum works well with most coolants but requires careful monitoring to prevent corrosion issues. It is often used in budget-friendly systems.

Considerations for International Buyers: Aluminum components should comply with JIS standards in Asia and DIN standards in Europe. Buyers should also consider regional preferences for materials based on local climate and water quality.

How Does Stainless Steel Compare for Open Loop Water Cooling?

Stainless steel is known for its strength and corrosion resistance, making it a viable option for water cooling systems. It can withstand temperatures up to 300°C and pressures exceeding 200 psi.

Pros: Its durability and resistance to rust make stainless steel an excellent choice for long-term applications. It is also less reactive with coolants compared to copper and aluminum.

Cons: The main disadvantage is its weight, which can be a concern in mobile or compact systems. Additionally, it is generally more expensive than aluminum.

Impact on Application: Stainless steel is compatible with a wide range of coolants and is less likely to corrode over time. However, its thermal conductivity is lower than that of copper.

Illustrative image related to open loop water cooling

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially in regions like North America and Europe. Buyers should also be aware of the availability of stainless steel components in their local markets.

What Are the Benefits of Using Acrylic in Open Loop Water Cooling?

Acrylic is primarily used for tubing and reservoirs in water cooling systems. Its transparency allows for aesthetic customization, and it can handle temperatures up to 80°C and pressures around 70 psi.

Pros: Acrylic is lightweight and easy to shape, making it ideal for custom designs. It also allows for visual monitoring of coolant flow and levels.

Cons: Acrylic is less durable than metals and can crack or scratch easily. It is also less effective at heat transfer compared to metals, which can impact cooling performance.

Impact on Application: Acrylic is compatible with most coolants but can be sensitive to certain chemicals. Proper care is needed to maintain its appearance and integrity.

Considerations for International Buyers: Buyers should ensure that acrylic components meet local standards for safety and durability, especially in high-temperature environments.

Summary of Material Properties for Open Loop Water Cooling

| Material | Typical Use Case for open loop water cooling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Water blocks, heat exchangers | Excellent thermal conductivity | High cost, complex manufacturing | High |

| Aluminum | Radiators, heat sinks | Lightweight, cost-effective | Susceptible to galvanic corrosion | Medium |

| Stainless Steel | Tubing, fittings | Durable, corrosion-resistant | Heavier, higher cost than aluminum | Medium |

| Acrylic | Tubing, reservoirs | Aesthetic, easy to shape | Less durable, lower thermal efficiency | Low |

This guide provides B2B buyers with a comprehensive overview of the materials used in open loop water cooling systems, focusing on their properties, advantages, and considerations for international compliance. Understanding these factors is crucial for making informed purchasing decisions that align with performance needs and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for open loop water cooling

What Are the Main Stages of Manufacturing Open Loop Water Cooling Systems?

The manufacturing of open loop water cooling systems involves several critical stages, each of which plays a vital role in ensuring the final product’s performance and reliability. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

In the material preparation stage, manufacturers select high-quality materials that can withstand the demands of liquid cooling systems. Common materials include copper for heat exchangers due to its excellent thermal conductivity, and various plastics and rubbers for seals and fittings. Suppliers must ensure that materials meet relevant international and industry-specific standards, such as ASTM or ISO certifications, to guarantee consistency and quality.

What Techniques Are Used in Forming Components for Water Cooling Systems?

Forming techniques are essential in shaping the components of the water cooling systems. For metal parts like radiators and water blocks, processes such as extrusion, CNC machining, and stamping are commonly used. These techniques allow for precise dimensions and surface finishes, which are critical for effective thermal performance and fluid dynamics. The choice of technique often depends on the complexity of the part and the required tolerances.

How Are Components Assembled in Open Loop Water Cooling Systems?

Assembly is a crucial phase where all individual components come together. This process typically involves fitting the water blocks, pumps, radiators, and tubing into a cohesive system. Automated assembly lines may be utilized to enhance efficiency, while skilled technicians perform critical checks to ensure that all connections are leak-free and secure. Advanced techniques such as ultrasonic welding or soldering are often employed to create durable joints.

What Finishing Processes Are Critical for Quality in Water Cooling Systems?

Finishing processes are vital for enhancing the aesthetic and functional aspects of the cooling systems. This may include anodizing aluminum components for corrosion resistance, applying protective coatings, or polishing surfaces for better fluid flow. Quality control is integrated into these processes to ensure that any potential defects are caught before the product reaches the market.

What Are the Quality Assurance Standards Relevant to Open Loop Water Cooling?

Quality assurance (QA) is a fundamental aspect of manufacturing open loop water cooling systems, ensuring that products meet both performance and safety standards. International standards like ISO 9001 guide manufacturers in establishing effective quality management systems. Additionally, industry-specific standards such as CE marking for European markets or API standards for performance might apply.

How Are Quality Control Checkpoints Established?

Quality control checkpoints are established at various stages of the manufacturing process to catch defects early. These typically include:

-

Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process, focusing on dimensions, surface quality, and assembly integrity.

-

Final Quality Control (FQC): A comprehensive assessment of the finished product, including functionality tests, pressure testing for leaks, and visual inspections.

What Common Testing Methods Are Used in Quality Assurance for Water Cooling Systems?

Testing methods play a crucial role in verifying that open loop water cooling systems perform as expected. Common methods include:

- Pressure Testing: To ensure that the system can withstand operational pressures without leaking.

- Thermal Performance Testing: Assessing how efficiently the system can dissipate heat under load conditions.

- Noise Level Testing: Evaluating the operational noise to ensure it meets market demands for quiet performance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Buyers can take several steps:

Illustrative image related to open loop water cooling

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices.

-

Request Quality Reports: Suppliers should provide documentation demonstrating compliance with international standards and internal QA processes.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing open loop water cooling systems. Different regions may have specific standards and regulations that must be adhered to. For instance, European buyers may require CE marking, while those in the U.S. might look for UL certification.

Moreover, buyers should consider logistical factors such as shipping and handling, which can affect product integrity. Establishing clear communication with suppliers about expectations and compliance with local regulations is vital.

Conclusion

Manufacturing open loop water cooling systems is a complex process that requires meticulous attention to detail and adherence to quality assurance standards. By understanding the manufacturing stages and quality control measures, B2B buyers can make informed decisions when selecting suppliers. This diligence not only ensures product reliability and performance but also fosters strong business relationships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘open loop water cooling’

Introduction

This sourcing guide is designed for B2B buyers seeking to procure open loop water cooling systems. With the rising demand for efficient cooling solutions in high-performance computing environments, understanding the nuances of open loop systems is essential. This checklist will guide you through the critical steps necessary to ensure a successful purchase, maximizing performance and reliability while minimizing risks.

1. Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider the cooling capacity needed based on your hardware specifications, including CPU and GPU types, and the expected thermal load during peak operations.

– Key Considerations:

– Calculate the total heat output you need to manage.

– Determine the compatibility of components, including pump, radiator, and reservoir sizes.

2. Research Potential Suppliers

Finding reliable suppliers is crucial to ensure quality and performance. Conduct thorough research to identify vendors that specialize in open loop cooling systems and have a strong track record in your industry.

– What to Look For:

– Supplier experience in similar projects or industries.

– Customer reviews and feedback to gauge reliability and service quality.

3. Evaluate Supplier Certifications

Before making any commitments, verify that your potential suppliers hold relevant industry certifications. This ensures that their products meet international standards for safety and performance.

– Important Certifications:

– ISO certifications for quality management.

– Compliance with environmental regulations, especially if you operate in regions with strict guidelines.

4. Request Samples and Case Studies

Ask for product samples and case studies that demonstrate the effectiveness of the cooling systems in real-world applications. This will provide insight into how the systems perform under load and in various environments.

– Why This Matters:

– Samples allow for hands-on evaluation of quality and performance.

– Case studies provide evidence of successful implementations and customer satisfaction.

5. Assess Customization Options

Open loop systems should offer flexibility to meet your unique cooling needs. Evaluate the extent of customization available from suppliers, including the choice of materials, fittings, and the ability to expand the system in the future.

– Customization Aspects:

– Options for different coolant types and colors.

– Modular designs that allow for easy upgrades and maintenance.

Illustrative image related to open loop water cooling

6. Understand Maintenance and Support Services

Inquire about the maintenance requirements and support services provided by the supplier. A reliable partner should offer comprehensive support, including installation guidance, troubleshooting, and replacement parts.

– Key Questions:

– What are the recommended maintenance schedules?

– Is there a warranty or guarantee period for the products?

7. Compare Pricing and Total Cost of Ownership

Finally, conduct a detailed cost analysis comparing the prices of different suppliers while considering the total cost of ownership. This includes not just the initial purchase price but also potential maintenance costs and energy consumption over time.

– Considerations for Cost Analysis:

– Factor in the longevity and reliability of the components.

– Evaluate energy efficiency ratings to predict operational costs.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for open loop water cooling systems, ensuring optimal performance and value for their investment.

Comprehensive Cost and Pricing Analysis for open loop water cooling Sourcing

When exploring the cost structure and pricing for open loop water cooling systems, it is crucial to understand the various components that contribute to the overall expenses.

What Are the Key Cost Components in Open Loop Water Cooling?

-

Materials: The primary materials used in open loop water cooling systems include high-grade metals for radiators, copper or aluminum for water blocks, and durable tubing. The quality of these materials directly impacts the performance and longevity of the cooling system, with higher-quality materials typically leading to higher costs.

-

Labor: Labor costs can vary significantly based on the complexity of the system and the expertise required for assembly. Skilled technicians are necessary for the assembly and testing of custom systems, which adds to the overall cost.

-

Manufacturing Overhead: This includes costs associated with the production environment, utilities, and equipment maintenance. Efficient manufacturing processes can help lower these overhead costs, but they are an essential consideration in pricing.

-

Tooling: Custom tooling may be required for specific components, especially for unique designs or specifications. This one-time cost can be amortized over production runs, impacting pricing based on volume.

-

Quality Control (QC): Ensuring that each component meets quality standards is vital, particularly in high-performance applications. QC processes can add to costs but are necessary to prevent failures that could lead to warranty claims or reputational damage.

-

Logistics: The costs of shipping and handling, including import/export duties, vary significantly depending on the destination. These logistics costs are particularly relevant for international buyers who may face additional tariffs or shipping delays.

-

Margin: Suppliers will typically include a margin that reflects their operational costs and desired profit level. This can vary widely among suppliers based on market positioning and competition.

How Do Pricing Influencers Affect Open Loop Water Cooling Costs?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Larger orders often lead to reduced per-unit costs due to economies of scale, while smaller orders may incur higher costs.

-

Specifications and Customization: Custom solutions tailored to specific performance requirements or aesthetic preferences can increase costs. The more tailored the solution, the higher the potential price due to increased labor and material costs.

-

Materials and Quality Certifications: Higher-grade materials and certifications (like ISO or RoHS compliance) can enhance system performance and reliability but also raise the cost. Buyers should evaluate whether the added expense aligns with their performance needs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge a premium, while less established companies might offer lower prices at the risk of quality or service issues.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers regarding shipping costs, risks, and insurance. This can significantly impact the total cost of ownership.

What Are the Best Tips for Buyers to Optimize Costs?

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing larger orders. Suppliers may offer discounts or favorable terms for bulk purchases.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors like energy efficiency, maintenance costs, and potential downtime when evaluating systems.

-

Pricing Nuances for International Buyers: Be aware of local market conditions and currency fluctuations that may affect pricing. Additionally, understanding regional supply chain dynamics can provide leverage in negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times, making it a more cost-effective option for many businesses.

-

Evaluate Warranty and Support: A comprehensive warranty and support services can mitigate long-term costs. Investing in a slightly more expensive system with robust support can lead to savings over time.

Conclusion

While the initial costs of open loop water cooling systems can be significant, understanding the underlying cost components and pricing influencers allows international B2B buyers to make informed purchasing decisions. By applying strategic negotiation techniques and considering the total cost of ownership, buyers can optimize their investments in cooling solutions tailored to their specific needs.

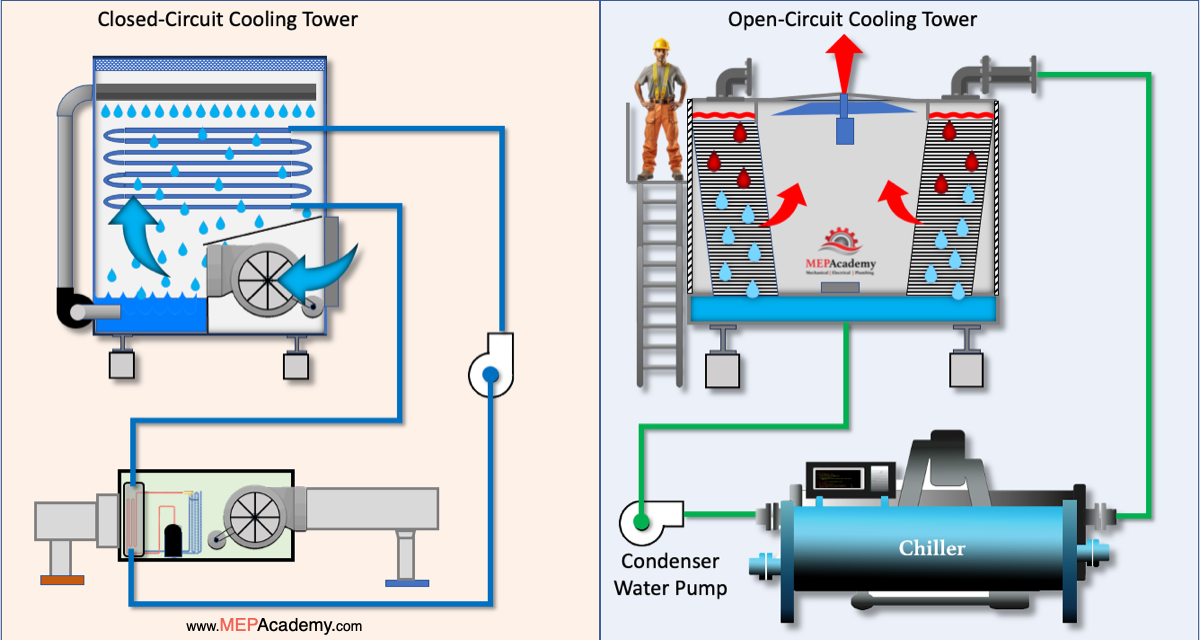

Alternatives Analysis: Comparing open loop water cooling With Other Solutions

Exploring Alternatives to Open Loop Water Cooling Solutions

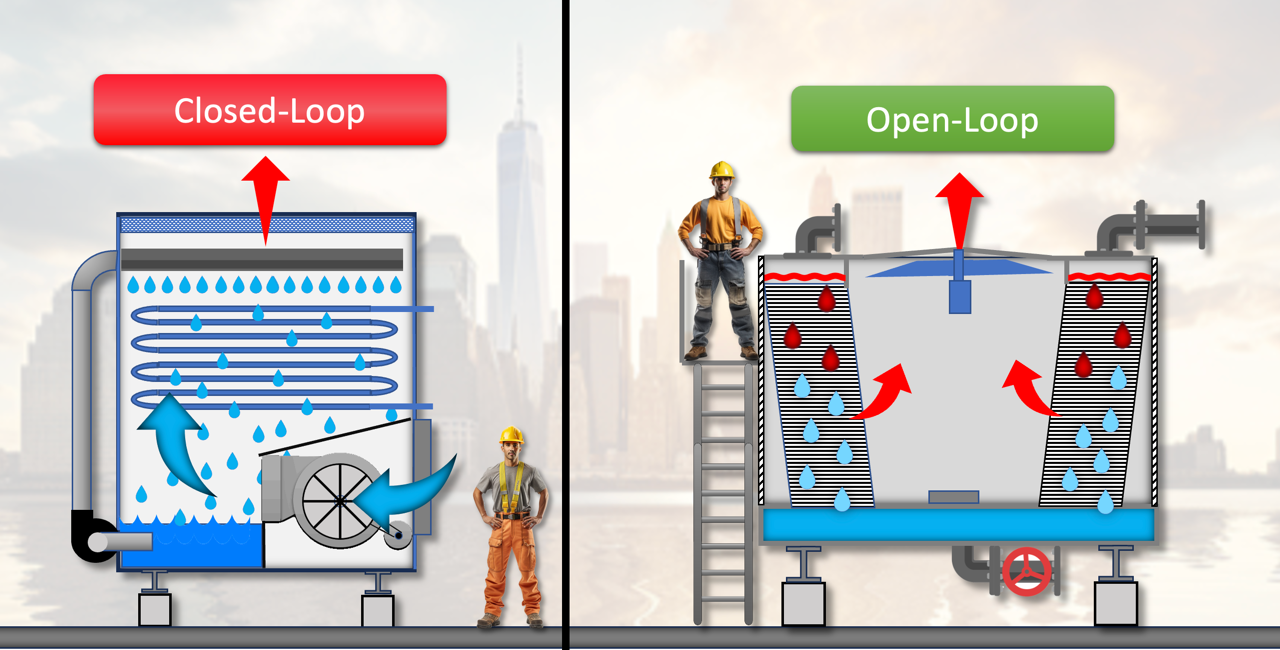

In the realm of cooling technologies, open loop water cooling is just one of several options available to businesses aiming to enhance performance and efficiency in their computing systems. Understanding the alternatives is crucial for B2B buyers who need to balance performance, cost, and maintenance. Below, we compare open loop water cooling with two viable alternatives: closed loop water cooling and air cooling systems.

| Comparison Aspect | Open Loop Water Cooling | Closed Loop Water Cooling | Air Cooling System |

|---|---|---|---|

| Performance | High performance, excellent heat dissipation, especially under heavy loads | Good performance, but limited by radiator size and coolant volume | Moderate performance, often struggles with high thermal loads |

| Cost | Higher initial investment due to custom components and installation | Moderate cost, more affordable than open loop but pricier than basic air coolers | Lower initial cost, generally the most economical option |

| Ease of Implementation | Complex installation requiring technical expertise | Easy to install, typically comes as a pre-assembled unit | Simple installation, no specialized skills needed |

| Maintenance | Requires regular maintenance, including coolant checks and system flushes | Low maintenance, generally maintenance-free unless leaks occur | Very low maintenance, but may require fan cleaning |

| Best Use Case | Ideal for high-performance computing, gaming, and overclocking | Suitable for general use and moderate performance needs | Best for budget systems or environments with minimal heat output |

What Are the Benefits and Drawbacks of Closed Loop Water Cooling?

Closed loop water cooling, also known as all-in-one (AIO) cooling, provides a balance between performance and ease of use. These systems are pre-assembled and designed to be plug-and-play, making them accessible for users without extensive technical knowledge. They offer better cooling than air systems, particularly in compact builds where space is a premium. However, their performance can be limited by the size of the radiator and the amount of coolant, making them less ideal for extreme overclocking compared to open loop systems.

How Do Air Cooling Systems Compare to Open Loop Water Cooling?

Air cooling systems are the most common and cost-effective cooling solution available. They operate by using heat sinks and fans to dissipate heat from the CPU or GPU into the surrounding air. While they are easy to install and require minimal maintenance, their cooling performance can falter under heavy loads, leading to potential overheating. For businesses with less demanding applications or tight budgets, air cooling can be an adequate solution, but it may not meet the needs of high-performance computing environments.

Illustrative image related to open loop water cooling

How Can B2B Buyers Choose the Right Cooling Solution?

Selecting the appropriate cooling solution hinges on understanding your specific requirements, including performance expectations, budget constraints, and maintenance capabilities. For high-performance computing needs, open loop water cooling remains a top choice due to its superior thermal management and customization options. However, if ease of installation and lower costs are paramount, closed loop systems or air cooling may be more appropriate. Assessing the nature of your operations and future scalability will guide you in making an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for open loop water cooling

When considering open loop water cooling systems, understanding key technical properties and industry terminology is essential for making informed decisions. This knowledge not only aids in selecting the right components but also enhances communication with suppliers and stakeholders. Below are critical specifications and common jargon relevant to open loop water cooling.

What Are the Key Technical Properties of Open Loop Water Cooling?

1. Material Grade

The materials used in cooling components, such as water blocks, radiators, and tubing, significantly affect performance and durability. Common materials include copper (high thermal conductivity) and aluminum (lightweight and cost-effective). In a B2B context, specifying material grades helps ensure compatibility, performance longevity, and corrosion resistance, crucial for maintaining system integrity over time.

Illustrative image related to open loop water cooling

2. Tolerance

Tolerance refers to the allowable deviation in dimensions of components such as fittings and tubing. High precision in tolerance is vital for ensuring leak-free connections and optimal flow rates. For B2B buyers, understanding tolerance levels is critical when sourcing components to ensure that they fit together seamlessly, minimizing the risk of system failures.

3. Flow Rate

Flow rate, measured in liters per minute (LPM), indicates how quickly the coolant circulates through the system. A higher flow rate enhances heat transfer efficiency, which is especially important in high-performance setups. Buyers need to assess flow rate specifications to ensure that the cooling system meets the thermal demands of their applications, thereby avoiding overheating and performance throttling.

4. Heat Exchange Capacity

This property measures how effectively a radiator can dissipate heat from the coolant into the surrounding environment. It’s typically expressed in watts (W). Understanding heat exchange capacity helps B2B buyers select radiators that can handle their specific cooling needs, particularly in environments with high thermal loads, such as data centers or gaming rigs.

5. Reservoir Size

The size of the reservoir influences the volume of coolant in the system, which can enhance cooling capacity and stability. Larger reservoirs allow for longer intervals between maintenance and fluid changes. For decision-makers, evaluating reservoir size is crucial in ensuring that the system can maintain optimal temperatures under various operational conditions.

What Common Trade Terms Should You Know in Open Loop Water Cooling?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In open loop water cooling, understanding OEM relationships can help buyers identify reliable sources for components, ensuring quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management, particularly when sourcing components for large projects.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to suppliers requesting pricing and terms for specific products. When procuring open loop water cooling components, submitting an RFQ can streamline the purchasing process and help buyers compare offers effectively.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and delivery obligations when importing cooling components from different regions.

5. Custom Loop

A custom loop refers to a tailored water cooling system where each component is selected based on specific performance requirements. This term is critical for buyers looking for bespoke solutions that meet unique operational needs.

Illustrative image related to open loop water cooling

Understanding these technical properties and trade terms not only equips B2B buyers with essential knowledge but also enhances their ability to navigate the complexities of sourcing and implementing open loop water cooling systems effectively.

Navigating Market Dynamics and Sourcing Trends in the open loop water cooling Sector

What Are the Current Market Dynamics and Key Trends in the Open Loop Water Cooling Sector?

The open loop water cooling sector is witnessing significant growth driven by several global factors. Increasing demand for high-performance computing, particularly in gaming, data centers, and high-performance computing (HPC) applications, has spurred innovation and investment in advanced cooling solutions. As processors and GPUs become more powerful, the need for efficient thermal management is critical to prevent overheating and ensure longevity. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where the tech market is rapidly evolving.

Emerging trends in sourcing indicate a shift towards customizable and modular cooling systems, allowing businesses to tailor solutions according to their specific requirements. This flexibility is crucial for sectors such as gaming and enterprise computing, where performance is paramount. Additionally, the rise of eco-conscious consumers has led to increased interest in sustainable cooling solutions, pushing manufacturers to innovate with environmentally friendly materials and practices.

Moreover, the competitive landscape is marked by collaborations and strategic partnerships among manufacturers, tech firms, and research institutions, aimed at enhancing product offerings. As buyers navigate these dynamics, understanding the interplay of technological advancements and market needs will be essential for making informed sourcing decisions.

Illustrative image related to open loop water cooling

How Can Sustainability and Ethical Sourcing Impact the Open Loop Water Cooling Sector?

Sustainability is becoming a pivotal concern in the open loop water cooling sector. The environmental impact of cooling solutions can be significant, particularly in terms of energy consumption and material waste. As such, B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainable practices. This includes utilizing recyclable materials, minimizing carbon footprints during production, and ensuring that products are energy-efficient.

Ethical sourcing is equally important, as businesses seek to partner with manufacturers who uphold fair labor practices and transparent supply chains. Buyers should look for certifications that indicate adherence to environmental standards, such as ISO 14001 for environmental management systems or Energy Star for energy efficiency. Additionally, materials like biodegradable coolants or components made from recycled plastics are gaining traction, presenting opportunities for buyers to align with green initiatives.

By prioritizing sustainability and ethical sourcing, companies not only fulfill corporate social responsibility (CSR) goals but also enhance brand reputation and attract eco-conscious customers. For international buyers, especially in emerging markets, these factors can influence purchasing decisions and long-term partnerships.

What Is the Evolution of Open Loop Water Cooling Technology?

Open loop water cooling technology has evolved significantly over the past few decades. Initially, these systems were primarily utilized in specialized applications such as supercomputers and high-performance servers. However, as the gaming industry grew and consumer demand for high-performance PCs surged, open loop systems became more accessible and popular among enthusiasts and gamers.

The introduction of customizable components has transformed the landscape, allowing users to design their cooling loops tailored to specific performance needs. This evolution has also been fueled by advancements in materials science, leading to lighter, more efficient, and visually appealing components. Today, open loop water cooling is not only about performance but also aesthetics, with many systems featuring customizable RGB lighting and sleek designs.

Overall, the evolution of open loop water cooling reflects broader trends in technology and consumer preferences, making it a critical area for B2B buyers to consider as they seek innovative and efficient cooling solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of open loop water cooling

-

How do I ensure the quality of open loop water cooling systems?

To ensure the quality of open loop water cooling systems, start by vetting suppliers through certifications, customer reviews, and case studies demonstrating their experience in the industry. Request samples to test their cooling efficiency, noise levels, and overall reliability. It’s also advisable to ask for details about the materials used, as high-quality components will impact performance and longevity. Establishing a quality assurance process that includes testing and documentation can further enhance your confidence in the products you choose. -

What is the best configuration for open loop water cooling systems?

The best configuration for open loop water cooling systems typically includes a robust pump, multiple radiators, and high-quality water blocks for the CPU and GPU. This setup allows for optimal heat dissipation and improved cooling efficiency. For most applications, a dual radiator configuration is recommended, as it provides a larger surface area for heat exchange. Additionally, ensure that the tubing is properly routed to minimize bends and restrictions, which can impede flow and reduce performance. -

How can I customize an open loop water cooling system to fit my needs?

Customization options for open loop water cooling systems are extensive. You can choose from various components, including water blocks, pumps, radiators, and reservoir sizes, to tailor the system to your specific cooling requirements. Many suppliers offer customizable kits that allow you to select the exact parts based on your performance needs and aesthetic preferences. Additionally, consider integrating RGB lighting or unique tubing designs to enhance the visual appeal while maintaining functionality. -

What are the minimum order quantities (MOQ) for open loop water cooling systems?

Minimum order quantities (MOQ) for open loop water cooling systems can vary significantly by supplier and region. Generally, MOQs range from a few units to several dozen, depending on the customization options and the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are a small to medium-sized business looking to enter the market. -

What payment terms should I expect when sourcing open loop water cooling?

Payment terms for sourcing open loop water cooling systems typically vary by supplier and can range from upfront payment to net 30 or 60 days after delivery. Many suppliers may require a deposit, especially for customized orders. It’s crucial to clarify payment terms early in the negotiation process to ensure that they align with your cash flow management. Additionally, consider discussing trade financing options or payment plans if bulk orders are involved. -

How do I handle logistics and shipping for international orders of open loop water cooling systems?

When handling logistics and shipping for international orders, partner with suppliers who have experience in international trade. Ensure they are familiar with customs regulations in your region to avoid delays. Discuss shipping options, including air freight for faster delivery or sea freight for cost savings. It’s also essential to consider insurance for high-value shipments and to track shipments for timely updates on delivery status. -

What should I look for in a supplier’s warranty or return policy for open loop water cooling products?

A robust warranty and return policy are critical when sourcing open loop water cooling products. Look for suppliers that offer a warranty of at least one year, covering defects in materials and workmanship. Additionally, familiarize yourself with the return policy, including the conditions under which returns are accepted and whether restocking fees apply. Clear communication about warranty claims and service support is essential for maintaining a good business relationship. -

How can I assess the compatibility of open loop water cooling systems with my existing hardware?

To assess compatibility, start by reviewing the specifications of your existing hardware, including CPU and GPU models, motherboard socket types, and case dimensions. Most suppliers provide compatibility charts or guides that outline which components work together. Additionally, consulting with suppliers about your specific setup can yield valuable insights. It’s also advisable to check online forums or communities where enthusiasts share their experiences, as this can help identify potential compatibility issues.

Top 8 Open Loop Water Cooling Manufacturers & Suppliers List

1. Reddit – Open Loop vs Closed Loop Water Cooling Systems

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Open Loop: A water cooling system that is not sealed and can be easily opened, allowing for customization and maintenance. Typically built from individual components such as pumps, reservoirs, water blocks, radiators, and tubing. Closed Loop: A sealed unit, often referred to as All-In-One (AIO), which is not designed to be opened once filled. It is a pre-assembled cooling solution that is easy to …

2. Corsair – Hydro X Series Custom Cooling

Domain: corsair.com

Registered: 1995 (30 years)

Introduction: Hydro X Series custom cooling for gaming PCs; features include water blocks, pumps, radiators, fans, fittings & tubing, and coolant; offers 25% lower GPU temperatures, 15% lower CPU temperatures, and 50% lower noise levels; proven performance with lower noise output and better overclocking capabilities; customizable with dynamic RGB lighting; includes a starter’s guide for building custom cooled P…

3. CoolIT Systems – Direct Liquid Cooling Solutions

Domain: coolitsystems.com

Registered: 2001 (24 years)

Introduction: CoolIT Systems offers Direct Liquid Cooling solutions that effectively manage heat generated by high-performance computing components. Key features include:

– Patented Split-Flow Coldplates

– Centralized Pumping

– Adaptable Barb Mounting

– Metal Dripless Quick Disconnects

– Command2 Control System

Types of systems include:

– Closed-loop systems: Self-contained, no maintenance required, ideal for …

4. EKWB – Premium Liquid Cooling Solutions

Domain: ekwb.com

Registered: 2006 (19 years)

Introduction: Custom Loop – EKWB offers premium segment liquid cooling products for DIY PC enthusiasts, including Quantum Line water blocks for RTX 50, 40, and 30 Series, radiators, Torque fittings, Momentum VRM Bridge, and Delta TEC EVO sub ambient cooling. The product range includes custom CPU loops, custom CPU & GPU loops, and extreme custom loops that allow for extensive customization and high performance. …

5. XDA Developers – Custom Liquid Cooling Solutions

Domain: xda-developers.com

Registered: 2002 (23 years)

Introduction: Custom open-loop liquid cooling solutions for PCs, including components like large reservoirs, thicker radiators, and water blocks for GPUs. Benefits include better CPU and GPU performance, easier maintenance and upgrades, and unique aesthetic appeal. Challenges include reduced airflow near hot components and the complexity of planning and assembling the system.

6. Tom’s Hardware – Closed vs. Open Loop Liquid Cooling

Domain: forums.tomshardware.com

Registered: 1997 (28 years)

Introduction: Closed Loop Liquid Cooling:

– Pump is built into the CPU block

– Reservoir is built into the radiator

– Uses Propylene Glycol in the loop

– Fluid does not need to be replaced

– Easier maintenance compared to custom loops

Open Loop Liquid Cooling:

– Requires separate reservoir, pump, block, and radiator

– Coolants must be cleaned out due to gunking up

– Water loops can go 1-2 years withou…

7. Alphacool – Core Storm 360mm XT45 Water Cooling Set

Domain: shop.alphacool.com

Registered: 2003 (22 years)

Introduction: Alphacool Core Storm 360mm XT45 water cooling Set – €279.98 (was €329.98) – in stock; Alphacool Core Wind 240mm ST30 water cooling Set – €199.98 – in stock; Alphacool Core Wind 360mm ST30 water cooling Set – €219.98 – Delivery date exceeded; Alphacool Core Storm 240mm ST30 water cooling Set – €239.98 (was €279.98) – in stock; Alphacool Core Storm 420mm ST30 water cooling Set – €284.98 (was €329.98…

8. AORUS – GeForce RTX 3080 XTREME WATERFORCE WB 10G

Domain: global.aorus.com

Registered: 2012 (13 years)

Introduction: AORUS GeForce RTX 3080 XTREME WATERFORCE WB 10G

Strategic Sourcing Conclusion and Outlook for open loop water cooling

As the demand for high-performance cooling solutions continues to rise, strategic sourcing of open loop water cooling systems presents a unique opportunity for B2B buyers. By leveraging advanced liquid cooling technologies, businesses can enhance the efficiency and longevity of their computing systems while significantly reducing noise levels and energy consumption. The adaptability of open loop systems allows for custom configurations that can meet specific performance requirements, making them an ideal choice for diverse industries across Africa, South America, the Middle East, and Europe.

Investing in open loop water cooling not only improves thermal management but also enables businesses to stay competitive in a rapidly evolving market. With the ability to support higher overclocking capabilities and handle increased thermal loads, these systems empower organizations to maximize their computing potential.

As you consider your sourcing strategy, prioritize partnerships with manufacturers who offer customizable solutions and robust support services. By doing so, you will position your business to harness the full potential of liquid cooling technology. Embrace the future of cooling and explore how open loop water cooling can transform your operations today.

Illustrative image related to open loop water cooling

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.