Is Your Open Cooling Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for open cooling

In the rapidly evolving landscape of industrial cooling solutions, navigating the complexities of open cooling systems can present significant challenges for international B2B buyers. With the pressing need for energy-efficient, sustainable cooling options across various sectors, including petrochemical, power generation, and HVAC, understanding the intricacies of open-circuit cooling towers is crucial. This guide aims to demystify the open cooling market by exploring different types of systems, their applications, and the benefits they offer.

Buyers will gain insights into the operational efficiencies of open cooling systems compared to closed-loop alternatives, including cost implications and maintenance considerations. Additionally, the guide provides essential strategies for vetting suppliers, ensuring that businesses can source reliable and high-quality cooling solutions tailored to their specific operational needs.

Whether you are based in Africa, South America, the Middle East, or Europe—regions witnessing significant industrial growth—the information contained herein will empower you to make informed purchasing decisions. By addressing critical factors such as lifecycle costs, environmental impact, and technological advancements, this comprehensive resource equips B2B buyers with the knowledge necessary to optimize their cooling systems for enhanced performance and sustainability.

Understanding open cooling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Circuit Cooling Tower | Direct contact between water and air, facilitating evaporative cooling. | Oil refineries, chemical plants, HVAC systems. | Pros: Efficient heat dissipation; Cons: Higher maintenance due to water quality management. |

| Natural Draft Cooling Tower | Utilizes natural convection without mechanical fans; tall structure. | Power generation, large industrial facilities. | Pros: Lower energy consumption; Cons: Limited to specific site conditions due to height. |

| Mechanical Draft Cooling Tower | Uses fans to enhance airflow; can be forced or induced draft design. | Manufacturing plants, data centers, power plants. | Pros: Greater control over cooling capacity; Cons: Higher energy costs and maintenance. |

| Crossflow Cooling Tower | Air flows horizontally across falling water; easier airflow path. | Large-scale industrial operations, HVAC systems. | Pros: Enhanced airflow efficiency; Cons: More susceptible to fouling and maintenance challenges. |

| Counterflow Cooling Tower | Air flows upward against falling water; effective heat exchange. | Petrochemical, power generation, HVAC systems. | Pros: High cooling efficiency; Cons: Complex design may lead to higher initial costs. |

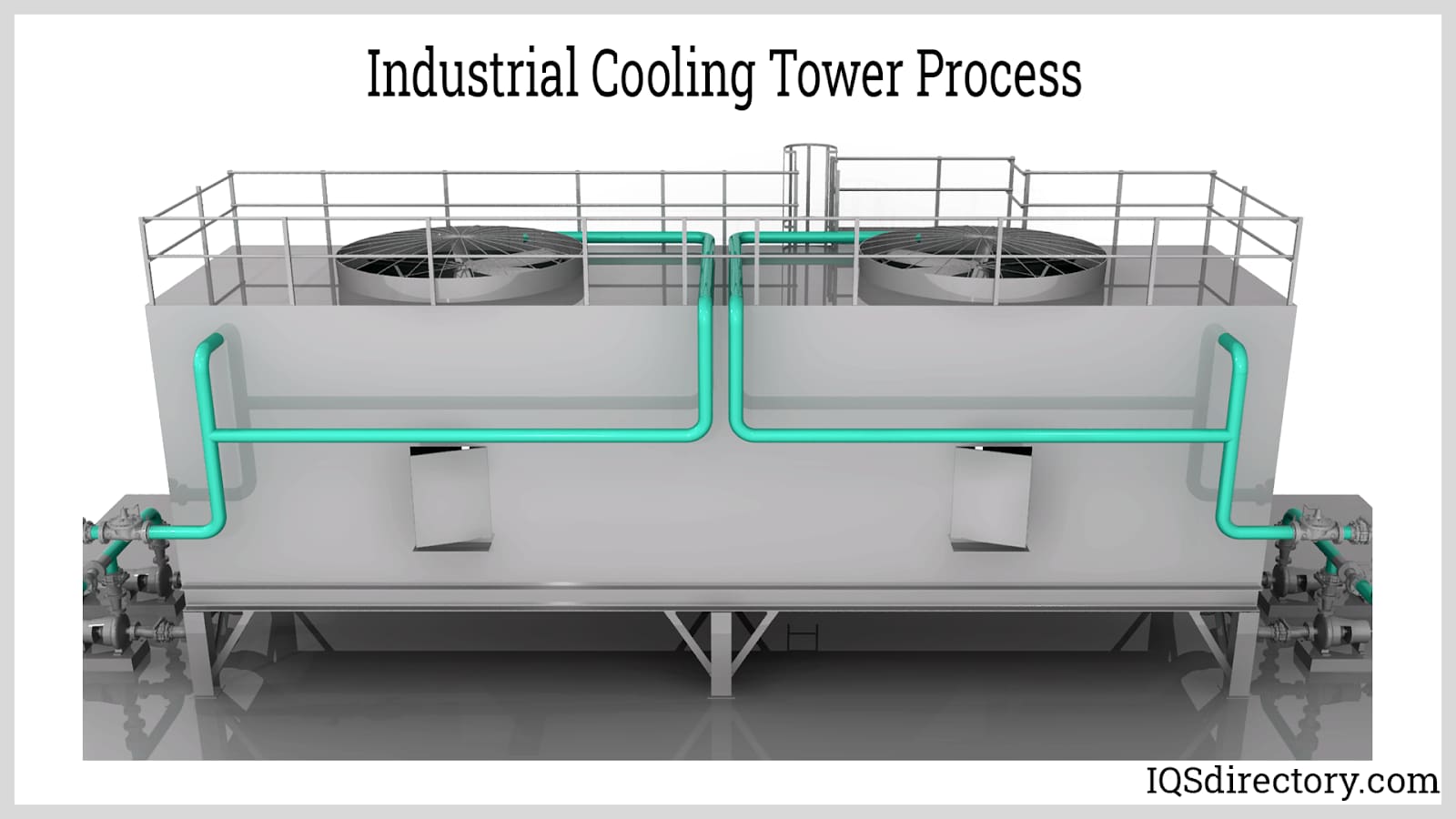

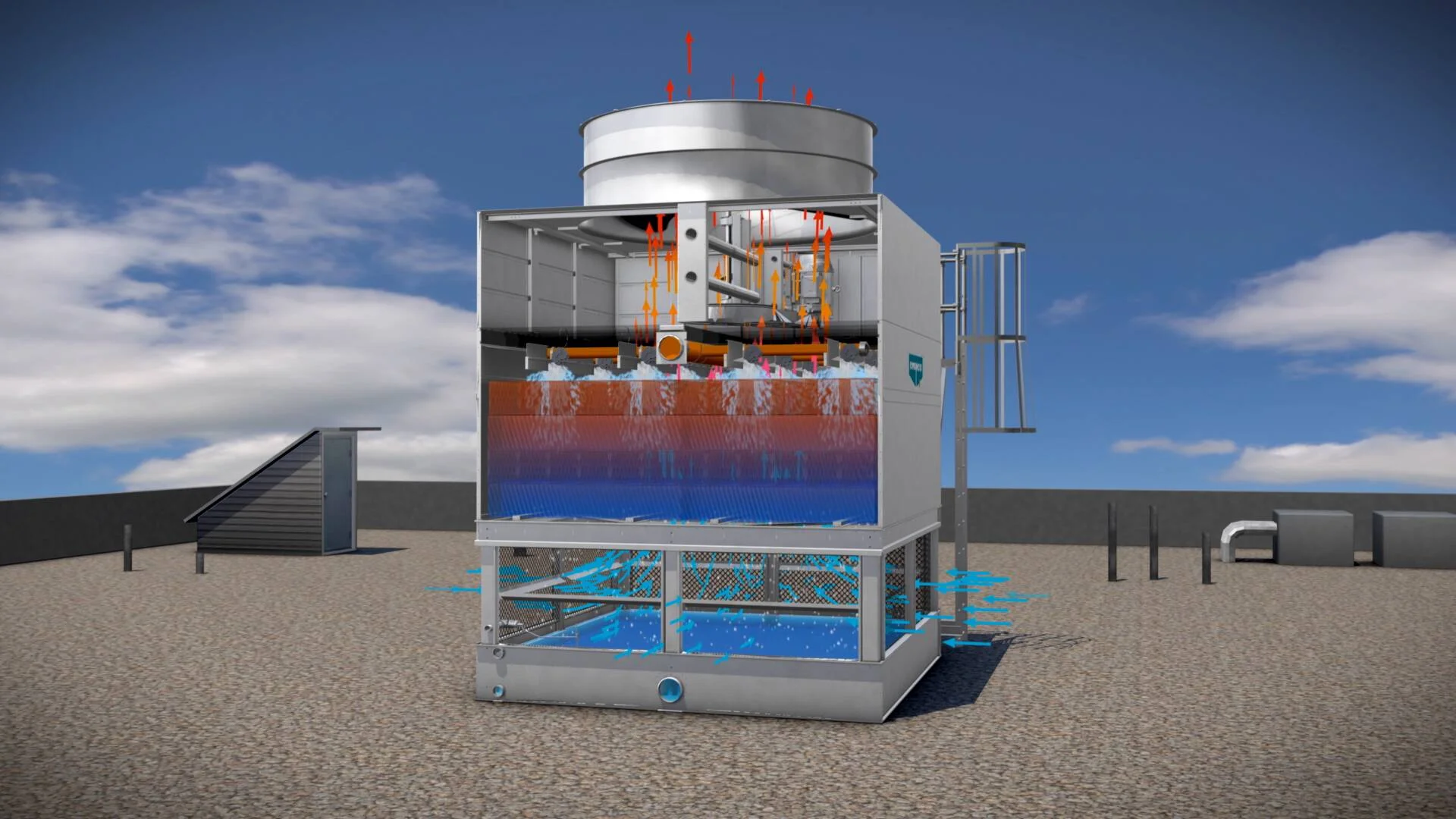

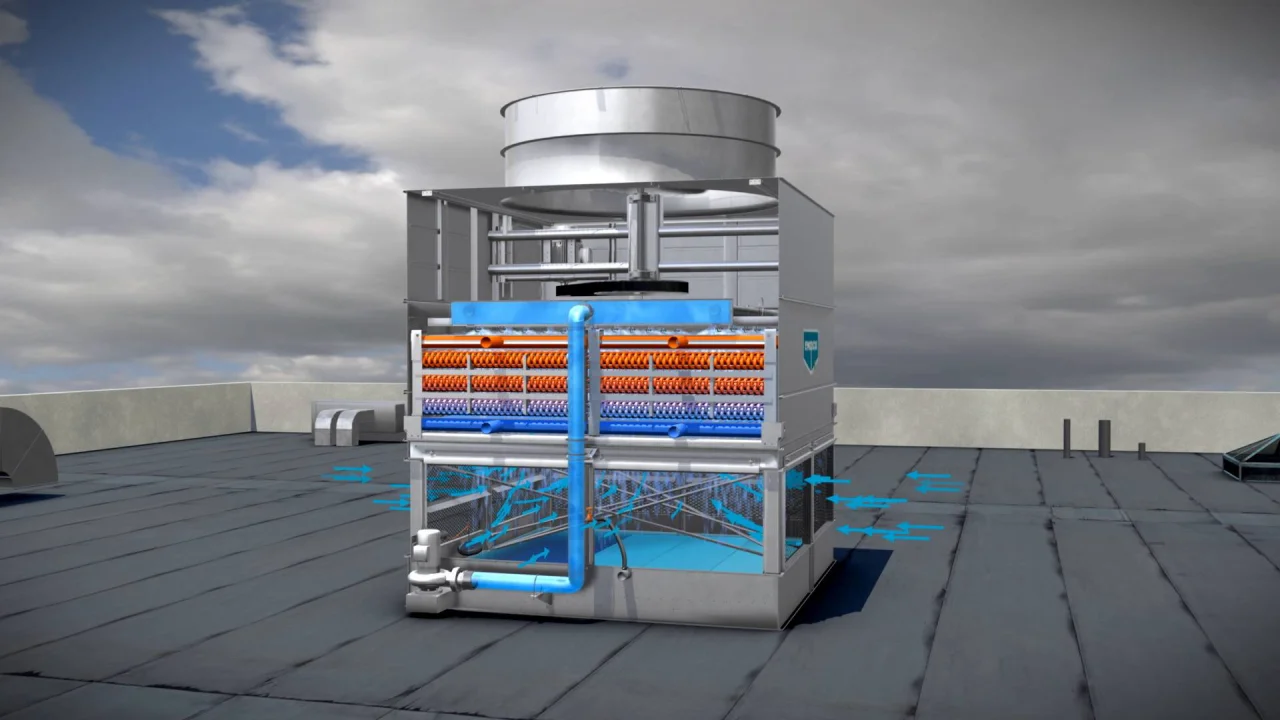

What Are the Characteristics of Open Circuit Cooling Towers?

Open circuit cooling towers are characterized by the direct interaction between water and air. This design allows for efficient heat transfer through evaporation, which cools the water as it descends through the tower’s fill material. Commonly used in industries such as oil refining and HVAC systems, these towers are suitable for applications requiring significant heat dissipation. However, buyers must consider the implications of water quality management, as the system is more prone to scaling and biological growth, necessitating regular maintenance and chemical treatments.

How Do Natural Draft Cooling Towers Operate?

Natural draft cooling towers rely on natural convection to circulate air without the use of mechanical fans. Their tall, hyperbolic shape facilitates airflow as warm air rises and cooler air is drawn in from below. These towers are often found in power generation facilities and large industrial sites where energy efficiency is critical. While they have lower operational costs due to reduced energy consumption, their effectiveness can be limited by site-specific conditions, such as available space and height restrictions.

What Makes Mechanical Draft Cooling Towers Unique?

Mechanical draft cooling towers employ fans to actively move air through the system, enhancing cooling efficiency. They can be designed as forced draft or induced draft towers, each with distinct airflow characteristics. These towers are commonly used in manufacturing plants and data centers where precise cooling control is necessary. Although they provide significant operational flexibility, buyers should weigh the higher energy consumption and maintenance requirements associated with fan operation.

Illustrative image related to open cooling

What Are the Advantages of Crossflow Cooling Towers?

Crossflow cooling towers feature a design where air flows horizontally across the downward flow of water, creating a more efficient path for air movement. This design is particularly advantageous in large-scale industrial operations, allowing for effective heat exchange with lower energy costs. However, the open structure can lead to challenges with fouling and algae growth, requiring diligent maintenance practices to ensure optimal performance.

How Do Counterflow Cooling Towers Maximize Efficiency?

Counterflow cooling towers are designed for air to flow upward against the downward falling water, optimizing heat exchange efficiency. This configuration is prevalent in petrochemical and power generation industries where high cooling capacities are essential. While counterflow towers are known for their effectiveness, buyers should consider the complexity of their design, which may result in higher initial costs and maintenance needs compared to simpler systems.

Key Industrial Applications of open cooling

| Industry/Sector | Specific Application of open cooling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Cooling in refineries and petrochemical plants | Enhances operational efficiency and reduces downtime | Reliability of equipment, local climate adaptability |

| Power Generation | Cooling for thermal power plants | Maximizes energy output while minimizing water usage | Energy efficiency, capacity for high ambient temperatures |

| HVAC Systems | Cooling for commercial and industrial buildings | Improves energy efficiency and air quality | Compliance with local regulations, maintenance support |

| Food & Beverage | Cooling in food processing and storage facilities | Preserves product quality and extends shelf life | Hygiene standards, material compatibility |

| Chemical Manufacturing | Process cooling in chemical production facilities | Reduces risks of overheating and improves safety | Chemical resistance, scalability for production needs |

In the oil and gas industry, open cooling systems are crucial for maintaining optimal temperatures in refineries and petrochemical plants. These systems facilitate the efficient dissipation of waste heat, thereby enhancing operational efficiency and reducing the risk of equipment failure. International buyers should consider the reliability of cooling equipment and its adaptability to local climate conditions, particularly in regions with extreme temperatures.

Power generation facilities utilize open cooling systems to manage the thermal output of power plants. These systems allow for the effective rejection of heat, ensuring that energy output remains maximized while minimizing water consumption. For B2B buyers, key considerations include the energy efficiency of the cooling system and its capacity to operate under high ambient temperatures, which are common in regions like the Middle East and parts of Africa.

Illustrative image related to open cooling

In HVAC systems, open cooling is employed in both commercial and industrial buildings to regulate indoor temperatures. This application is vital for improving energy efficiency and ensuring optimal air quality for occupants. Buyers should focus on compliance with local environmental regulations and the availability of maintenance support, especially in regions where HVAC systems may face unique operational challenges.

The food and beverage sector relies on open cooling systems for various applications, including food processing and storage. These systems help maintain safe temperatures, preserving product quality and extending shelf life. Buyers need to ensure that the cooling solutions meet stringent hygiene standards and are compatible with the materials used in food production, particularly in diverse markets like South America and Africa.

In chemical manufacturing, open cooling systems are essential for controlling temperatures during chemical reactions and processes. This application not only mitigates the risks associated with overheating but also enhances safety in production environments. Buyers should prioritize the chemical resistance of cooling materials and the scalability of the systems to meet fluctuating production demands, especially in rapidly growing markets.

3 Common User Pain Points for ‘open cooling’ & Their Solutions

Scenario 1: The Challenge of Corrosion in Open Cooling Systems

The Problem:

B2B buyers often encounter significant corrosion issues when implementing open cooling systems. This challenge is particularly pressing in environments with high humidity or aggressive contaminants in the air, such as coastal areas or industrial zones. The repeated exposure of cooling water to ambient air can lead to increased dissolved solids and corrosion rates. As corrosion damages the cooling tower infrastructure and equipment, it results in costly repairs and potential downtime, which can severely affect operational efficiency and profitability.

The Solution:

To combat corrosion effectively, buyers should prioritize the selection of corrosion-resistant materials when sourcing open cooling towers. Stainless steel, for instance, is a popular choice due to its durability and resistance to rust. Furthermore, implementing a robust water treatment program is essential. Regular monitoring of water chemistry, including pH levels and concentration of dissolved solids, can help mitigate corrosion risks. Utilizing corrosion inhibitors and ensuring proper water circulation will also minimize stagnant areas where corrosion thrives. Additionally, working with manufacturers who provide long-term warranties and maintenance services can lead to better lifecycle management of cooling systems.

Scenario 2: Algae Growth and Biological Contamination Issues

The Problem:

Another significant pain point for B2B buyers is the growth of algae and other microorganisms in open cooling systems. The combination of warm water, sunlight exposure, and nutrient influx can create an ideal breeding ground for biological growth. This not only affects the efficiency of the cooling process—by reducing heat transfer rates—but can also lead to fouling of equipment, increased maintenance requirements, and potential health hazards.

The Solution:

To address biological contamination, buyers should consider incorporating automated monitoring systems that can track water quality in real-time. These systems can detect changes in parameters such as turbidity and chemical balance, allowing for timely intervention. Regularly scheduled cleaning and disinfection of the cooling tower, including the fill and basin areas, can help control algae growth. Additionally, utilizing ultraviolet (UV) light systems or biocides can effectively inhibit microbial growth without harming the cooling system’s components. Sourcing cooling towers with built-in anti-fouling features can also provide a long-term solution, reducing maintenance costs and prolonging equipment life.

Scenario 3: Water Usage and Environmental Compliance Concerns

The Problem:

In many regions, especially in Africa and South America, water scarcity is a pressing issue. Open cooling systems often require significant water usage, leading to concerns about compliance with environmental regulations and sustainability goals. B2B buyers may face challenges in sourcing water for their cooling systems, especially in areas with stringent water usage restrictions or during drought conditions, which can lead to operational disruptions.

The Solution:

To navigate water usage challenges, buyers should explore advanced water conservation techniques. Implementing a closed-loop system in conjunction with open cooling can reduce water consumption significantly by recirculating water rather than discharging it. Additionally, investing in water-efficient cooling technologies, such as hybrid cooling systems that utilize both evaporative and dry cooling methods, can enhance sustainability. Regularly auditing water usage and implementing a robust water management plan can help organizations stay compliant with local regulations. Engaging with suppliers who offer innovative solutions and support for sustainable practices can position companies as responsible stewards of water resources while ensuring operational efficiency.

Strategic Material Selection Guide for open cooling

What Are the Key Materials for Open Cooling Systems?

When selecting materials for open cooling systems, several factors must be considered, including temperature and pressure ratings, corrosion resistance, and overall compatibility with the cooling media. Here, we analyze four common materials used in open cooling applications: galvanized steel, stainless steel, PVC, and fiberglass-reinforced plastic (FRP).

How Does Galvanized Steel Perform in Open Cooling Applications?

Galvanized steel is a widely used material due to its excellent strength and cost-effectiveness. It is coated with a layer of zinc to enhance corrosion resistance, making it suitable for environments where moisture is prevalent. The typical temperature rating for galvanized steel is around 200°F (93°C), which is adequate for many cooling applications.

Pros: Galvanized steel is durable and relatively inexpensive, making it a popular choice for large-scale installations. Its mechanical properties allow it to withstand significant pressure, which is essential in high-flow systems.

Cons: Despite its corrosion resistance, galvanized steel can suffer from rust over time, especially if the zinc coating is compromised. Additionally, it may require periodic maintenance to ensure longevity.

Impact on Application: Galvanized steel is compatible with various cooling media, but its susceptibility to corrosion means that it may not be ideal for highly corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM A123 for hot-dip galvanizing is crucial. Buyers from regions like Africa and South America should also consider local environmental factors that could affect the material’s longevity.

What Role Does Stainless Steel Play in Open Cooling Systems?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it a preferred choice for applications exposed to harsh conditions. With temperature ratings that can exceed 500°F (260°C), stainless steel is suitable for high-temperature cooling applications.

Pros: Its resistance to corrosion and staining makes stainless steel ideal for environments with high humidity or chemical exposure. Additionally, it requires minimal maintenance, which can lead to lower long-term costs.

Cons: The primary drawback is its higher initial cost compared to other materials. Manufacturing processes for stainless steel can also be more complex, which may impact lead times.

Impact on Application: Stainless steel’s compatibility with various cooling fluids, including those with high chloride content, makes it versatile for different industrial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 is essential. Buyers in Europe and the Middle East may prefer specific grades of stainless steel based on local regulations.

How Does PVC Compare in Open Cooling Systems?

Polyvinyl chloride (PVC) is a lightweight, cost-effective plastic commonly used in open cooling systems for pipes and fittings. It offers good chemical resistance and can handle temperatures up to 140°F (60°C).

Illustrative image related to open cooling

Pros: PVC is resistant to corrosion and is easy to install, which can reduce labor costs. Its lightweight nature also makes it easier to transport and handle during installation.

Cons: The temperature limitations of PVC can be a significant drawback in high-temperature applications. Additionally, it may not be suitable for environments with high mechanical stress.

Impact on Application: PVC is compatible with a wide range of cooling fluids, but its limitations in temperature and pressure ratings may restrict its use in certain industrial settings.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is important. Buyers from regions like South America and Africa should ensure that the PVC used meets local environmental regulations.

What Advantages Does Fiberglass-Reinforced Plastic (FRP) Offer?

Fiberglass-reinforced plastic (FRP) is increasingly popular in open cooling applications due to its lightweight and corrosion-resistant properties. It can handle temperatures up to 200°F (93°C) and is often used in cooling towers and tanks.

Illustrative image related to open cooling

Pros: FRP is highly resistant to corrosion and chemical damage, making it ideal for aggressive environments. Its lightweight nature simplifies installation and reduces structural support requirements.

Cons: The initial cost of FRP can be higher than traditional materials, and it may require specialized installation techniques. Additionally, its mechanical strength is generally lower than that of metals.

Impact on Application: FRP is compatible with various cooling media and is particularly advantageous in environments prone to corrosion.

Considerations for International Buyers: Compliance with standards such as ASTM D3299 is crucial. Buyers from the Middle East and Europe may need to consider local regulations regarding the use of composite materials.

Illustrative image related to open cooling

Summary Table of Material Selection for Open Cooling

| Material | Typical Use Case for Open Cooling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Cooling towers, piping | Cost-effective and durable | Susceptible to rust over time | Medium |

| Stainless Steel | High-temperature cooling applications | Excellent corrosion resistance | Higher initial cost | High |

| PVC | Pipes and fittings in cooling systems | Lightweight and easy to install | Limited temperature tolerance | Low |

| Fiberglass-Reinforced Plastic | Cooling towers, tanks | Highly corrosion-resistant | Higher initial cost and lower strength | Medium |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for open cooling systems, enabling informed decision-making based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for open cooling

What Are the Main Stages of the Manufacturing Process for Open Cooling Towers?

The manufacturing process for open cooling towers involves several key stages, each critical for ensuring the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Open Cooling Towers?

Material preparation is the first step in the manufacturing process. Manufacturers typically use high-quality materials such as galvanized steel, stainless steel, or fiberglass reinforced plastic (FRP) to ensure durability and resistance to corrosion.

Illustrative image related to open cooling

-

Material Selection: The choice of materials is influenced by factors such as environmental conditions, expected lifespan, and specific application requirements. For instance, coastal regions may require more corrosion-resistant materials due to saltwater exposure.

-

Cutting and Shaping: Once selected, materials are cut and shaped according to design specifications. This may involve advanced technologies such as laser cutting or CNC machining to achieve precise dimensions and reduce material waste.

What Techniques Are Used in Forming Open Cooling Tower Components?

Forming is a vital stage where raw materials are transformed into components of the cooling tower.

-

Molding and Fabrication: For plastic components, techniques like injection molding are commonly used, while metal parts may undergo processes like stamping or bending.

-

Welding and Joining: In cases where metal is used, welding techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) are employed to join different parts securely. This ensures that the structural integrity of the cooling tower is maintained.

How Is the Assembly of Open Cooling Towers Conducted?

Assembly is where all the formed components come together to create the final product.

-

Component Assembly: The assembly process typically starts with the base structure, followed by the installation of internal components such as fill media, drift eliminators, and fans.

-

System Integration: Careful integration of all systems (water distribution, airflow, and control systems) is crucial to ensure efficient operation.

-

Initial Testing: Once assembled, the cooling tower undergoes initial testing to verify that all components work together effectively before moving on to finishing touches.

What Finishing Processes Are Essential for Open Cooling Towers?

Finishing processes enhance the durability and appearance of the cooling towers.

-

Surface Treatment: Common finishing techniques include galvanizing, painting, or applying protective coatings. These treatments help prevent corrosion and extend the life of the cooling tower.

-

Final Inspection: Before the cooling towers are shipped, they undergo a thorough inspection to ensure compliance with design specifications and quality standards.

What International Standards and Certifications Are Relevant for Open Cooling Towers?

Quality assurance is crucial in the manufacturing of open cooling systems. Several international standards and industry-specific certifications guide manufacturers in maintaining high-quality products.

Which International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001: This is a globally recognized standard for quality management systems. Compliance indicates that the manufacturer has established a framework for consistent quality and customer satisfaction.

-

CE Marking: For buyers in Europe, CE marking signifies that the product meets EU safety, health, and environmental protection standards.

-

API Standards: In industries such as oil and gas, compliance with American Petroleum Institute (API) standards ensures that cooling systems are suitable for specific operational environments.

What Are the Key Quality Control Checkpoints in Manufacturing Open Cooling Towers?

Quality control (QC) is a systematic process that involves multiple checkpoints to ensure each cooling tower meets the required standards.

What Are the Different QC Checkpoints During Manufacturing?

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components upon arrival at the manufacturing facility. It ensures that all materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC involves continuous monitoring of processes. This includes regular inspections and tests to identify any deviations from quality standards early in the production cycle.

-

Final Quality Control (FQC): The final inspection takes place after assembly and finishing. This comprehensive assessment checks for functionality, safety, and aesthetic quality before the product is shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of suppliers is crucial.

What Methods Can Buyers Use to Verify QC Practices?

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand the testing methods employed and the outcomes of quality checks at various stages.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s operations and product quality, ensuring compliance with required standards.

What Unique QC and Certification Considerations Exist for International Buyers?

International buyers must consider various nuances in quality control and certification processes.

-

Cultural and Regulatory Differences: Different regions may have varying quality standards and regulatory requirements. Buyers should familiarize themselves with local regulations in their target markets to ensure compliance.

-

Language Barriers: Documentation, including certifications and quality reports, may be in different languages. Buyers should ensure they can accurately interpret these documents to avoid misunderstandings.

-

Adaptability to Local Conditions: Manufacturers should demonstrate their ability to adapt their products to meet local environmental conditions, which may impact the performance and longevity of cooling towers.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing open cooling systems, ensuring they select reliable suppliers who adhere to the highest standards.

Illustrative image related to open cooling

Practical Sourcing Guide: A Step-by-Step Checklist for ‘open cooling’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure open cooling systems. Open cooling towers play a vital role in industries such as petrochemical, HVAC, and thermal power generation, where efficient heat dissipation is crucial. The following steps will assist you in making informed purchasing decisions while optimizing operational efficiency and cost-effectiveness.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount for the successful selection of an open cooling system. Consider factors such as the required cooling capacity, water flow rates, and the types of fluids to be cooled. Additionally, assess environmental conditions, including temperature and humidity, as these will influence the system’s performance.

- Cooling Capacity: Determine the maximum heat load your system needs to handle.

- Water Quality Requirements: Identify the quality of water to be used, factoring in potential impurities that could affect system efficiency.

Step 2: Assess Regulatory Compliance and Standards

Ensure that the open cooling systems you are considering meet local and international regulations. Compliance with environmental standards is essential to avoid fines and ensure operational sustainability.

- Local Regulations: Familiarize yourself with specific laws in your region regarding water usage and emissions.

- International Standards: Look for certifications such as ISO 9001, which indicate adherence to quality management principles.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will help you assess the supplier’s reliability and track record.

- Supplier Experience: Look for suppliers with proven expertise in manufacturing and servicing open cooling systems.

- Customer Testimonials: Seek feedback from existing clients to gauge satisfaction levels and service quality.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals outlining their offerings. A comprehensive proposal should include technical specifications, pricing, lead times, and warranty conditions.

- Cost Breakdown: Ensure the proposal provides a clear breakdown of costs, including installation and maintenance.

- After-Sales Support: Evaluate the level of support offered, including training, spare parts availability, and maintenance services.

Step 5: Conduct a Cost-Benefit Analysis

Perform a thorough cost-benefit analysis to determine the long-term value of the open cooling systems being considered. Assess both initial investment and operational costs, such as energy consumption and maintenance expenses.

- Total Cost of Ownership (TCO): Calculate the TCO by factoring in all costs over the system’s expected lifespan.

- Efficiency Ratings: Look for systems with high energy efficiency ratings to minimize operational costs.

Step 6: Plan for Installation and Maintenance

Consider the logistics of installation and ongoing maintenance. A well-planned installation process will minimize downtime and ensure optimal system performance from the outset.

- Installation Timeline: Discuss installation timelines with the supplier to align with your operational schedule.

- Maintenance Schedule: Establish a routine maintenance schedule to keep the system running efficiently and extend its lifespan.

Step 7: Monitor Performance Post-Installation

Once the open cooling system is operational, monitor its performance regularly. Implement performance metrics to evaluate efficiency and identify potential issues early.

- Key Performance Indicators (KPIs): Define KPIs such as cooling efficiency and energy usage to track system performance.

- Feedback Mechanism: Create a feedback loop for operators to report any operational challenges for timely resolution.

By following this checklist, B2B buyers can ensure a thorough and informed procurement process for open cooling systems, ultimately leading to enhanced operational efficiency and cost savings.

Illustrative image related to open cooling

Comprehensive Cost and Pricing Analysis for open cooling Sourcing

What Are the Key Cost Components for Open Cooling Systems?

When analyzing the costs associated with open cooling systems, several core components come into play. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

Materials form a significant portion of the cost structure, encompassing components such as cooling tower fills, fans, pumps, and structural materials. The quality and source of these materials can greatly affect pricing. Labor costs vary based on regional wage rates, with countries in Africa, South America, and the Middle East often experiencing different labor market dynamics compared to Europe.

Manufacturing overhead includes expenses related to factory operations, utilities, and maintenance, while tooling costs pertain to the equipment necessary for production. Quality control (QC) is essential, particularly in industries requiring stringent standards. Implementing robust QC processes can lead to higher upfront costs but ultimately ensures product reliability and longevity.

Logistics costs are another critical factor, influenced by the distance from the supplier to the buyer and the complexity of the supply chain. Finally, margin reflects the profit that suppliers add to cover their risks and operational costs, which can vary based on market competition and supplier reputation.

How Do Price Influencers Impact Open Cooling System Costs?

Several factors influence the pricing of open cooling systems, including volume or minimum order quantities (MOQ), specifications and customization, materials used, quality certifications, supplier relationships, and Incoterms.

Volume and MOQ often lead to discounted rates; larger orders may result in better per-unit pricing. Customization can increase costs significantly, as tailored solutions require additional engineering and production processes. The choice of materials also plays a crucial role, with high-quality or specialized materials driving up the overall price.

Quality certifications are increasingly important, especially for international buyers. Compliance with standards such as ISO or ASME can add to the cost but enhances product credibility. Supplier factors, such as their reputation and reliability, can also affect pricing; established suppliers may charge a premium for their services due to perceived quality and service levels.

Finally, Incoterms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can add hidden costs that impact the final price.

What Are the Best Buyer Tips for Cost-Efficiency in Open Cooling Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, navigating the complexities of open cooling system sourcing requires strategic insight.

Negotiation is vital; understanding market conditions and having multiple suppliers can provide leverage. Buyers should consider Total Cost of Ownership (TCO), which includes initial purchase price, installation costs, maintenance, and operational expenses. Often, opting for a slightly more expensive system can lead to lower TCO due to reduced energy consumption or maintenance requirements.

Illustrative image related to open cooling

Buyers should also be aware of pricing nuances that may arise from currency fluctuations, import tariffs, and local regulations. When dealing with international suppliers, clarity on payment terms and currency can prevent unexpected costs.

Additionally, conducting a thorough supplier evaluation is crucial. Look for suppliers with strong customer references, proven quality track records, and transparent pricing structures. Engaging in long-term partnerships can often yield better pricing and service over time.

Disclaimer on Indicative Prices

Prices for open cooling systems can vary widely based on the factors discussed above. It is essential for buyers to conduct their due diligence, gather multiple quotes, and consider all cost components and influencers before making purchasing decisions. This approach ensures that buyers can secure the best value for their investment while meeting their specific cooling needs.

Alternatives Analysis: Comparing open cooling With Other Solutions

Understanding Alternative Cooling Solutions for B2B Buyers

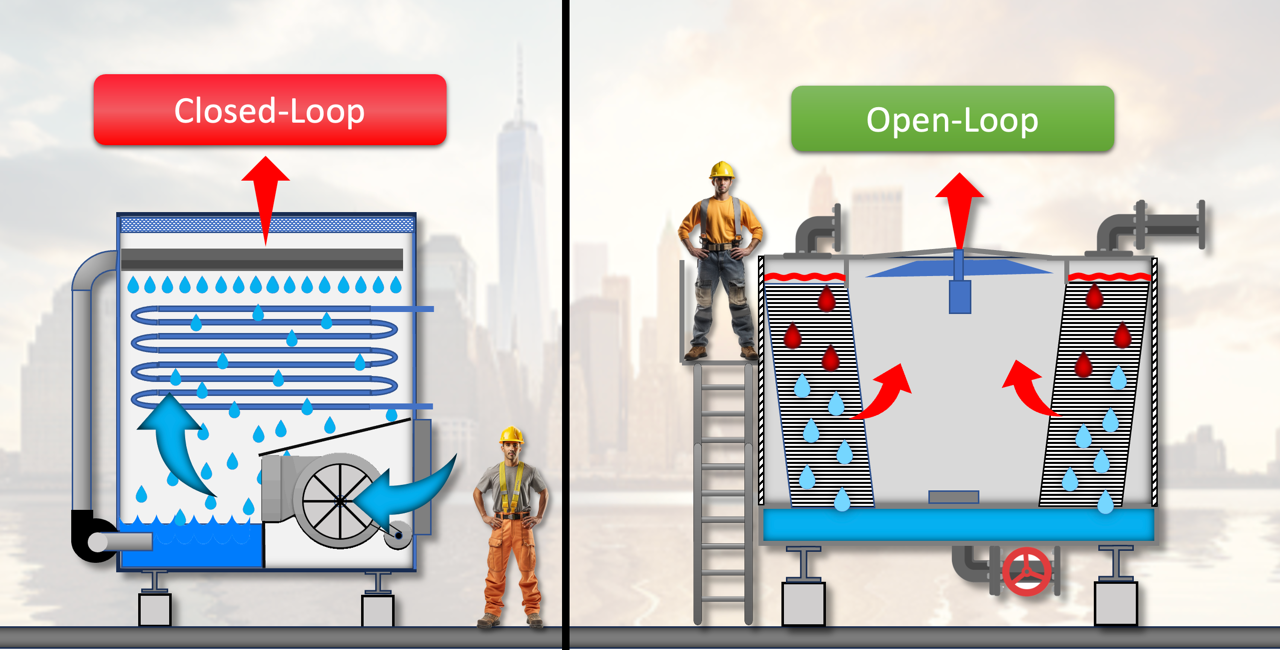

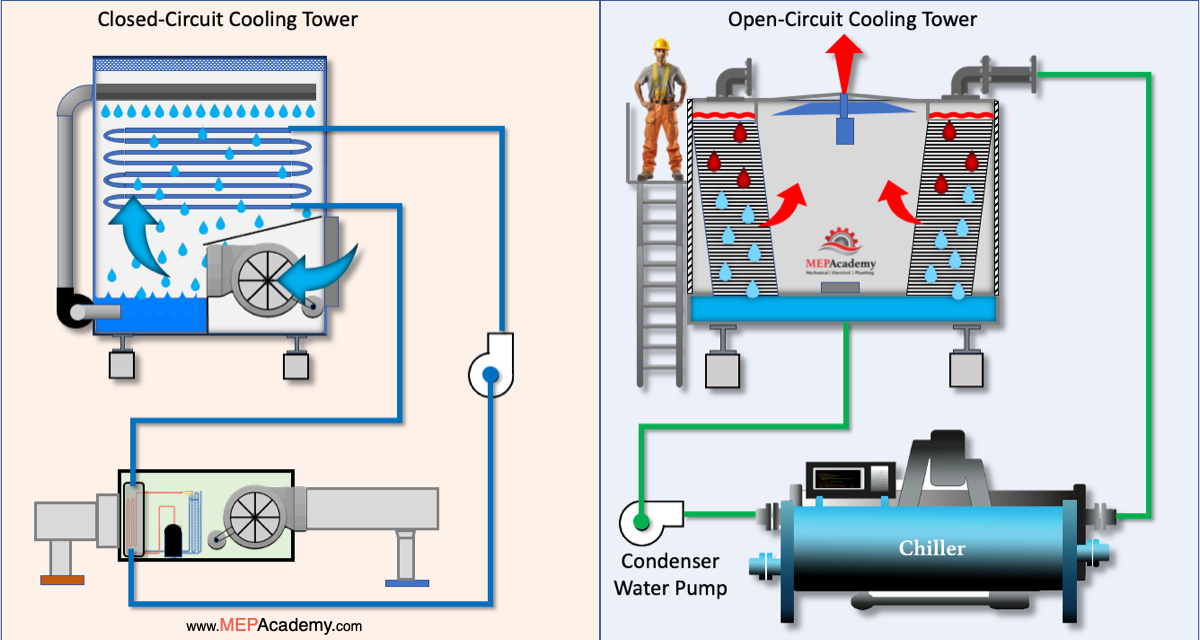

In the quest for efficient cooling solutions, B2B buyers often explore various technologies to meet their operational needs. Among these options, open cooling systems stand out for their effectiveness in dissipating heat through evaporative processes. However, alternatives exist that may offer specific advantages depending on the application, environmental conditions, and operational requirements. This analysis compares open cooling with two viable alternatives: closed-circuit cooling systems and once-through cooling systems.

| Comparison Aspect | Open Cooling | Closed-Circuit Cooling | Once-Through Cooling |

|---|---|---|---|

| Performance | High evaporative efficiency, effective for large heat loads. | Moderate efficiency, less evaporative loss, suitable for sensitive environments. | High initial cooling capacity, but less efficient for continuous use. |

| Cost | Lower initial capital cost, but ongoing water treatment costs. | Higher capital cost, but lower operational costs due to reduced water usage. | Lower initial setup cost, but high water consumption leads to increased long-term costs. |

| Ease of Implementation | Relatively straightforward installation, minimal infrastructure needed. | More complex installation requiring additional components like heat exchangers. | Simple installation but dependent on abundant water supply. |

| Maintenance | Requires regular water treatment and cleaning to prevent fouling. | Lower maintenance due to closed system design; less exposure to contaminants. | Minimal maintenance, but requires consistent monitoring of water quality. |

| Best Use Case | Ideal for industrial applications with high heat loads and access to ample water. | Best suited for environments with stringent water quality requirements. | Effective for processes with intermittent cooling needs and where water is plentiful. |

Exploring the Alternatives in Detail

What Are the Advantages and Disadvantages of Closed-Circuit Cooling Systems?

Closed-circuit cooling systems use a design that separates the cooling fluid from the environment, minimizing contamination risks. The primary advantage of this method is its reduced maintenance requirements and lower water consumption. However, the initial capital investment is significantly higher, and the system may not be as effective in high-heat scenarios compared to open cooling. These systems are particularly beneficial in industries where water quality is critical, such as pharmaceuticals and food processing.

Illustrative image related to open cooling

How Does Once-Through Cooling Compare to Open Cooling?

Once-through cooling systems operate by continuously drawing water from a source, using it to cool processes, and then discharging it back. While this method can provide rapid cooling, it is highly dependent on a reliable water supply and can lead to significant environmental concerns due to thermal pollution. The initial setup cost is typically lower than both open and closed systems, but the long-term costs can escalate due to high water usage and potential regulatory fees. This method is suitable for applications where water is abundant and costs are not a primary concern.

How Can B2B Buyers Choose the Right Cooling Solution?

When selecting the appropriate cooling solution, B2B buyers should evaluate their specific operational needs, including heat load requirements, water availability, and budget constraints. Open cooling systems may be ideal for industries with high cooling demands and sufficient water supply, while closed-circuit systems are better for environments requiring strict water quality control. Once-through cooling can be a cost-effective choice for operations with intermittent cooling needs and ample access to water. By carefully considering these factors, buyers can make informed decisions that align with their operational goals and environmental responsibilities.

Essential Technical Properties and Trade Terminology for open cooling

What Are the Key Technical Properties of Open Cooling Systems?

When considering open cooling systems, understanding the technical properties is essential for making informed purchasing decisions. Here are several critical specifications that influence performance, durability, and efficiency:

-

Material Grade

The material used in the construction of cooling towers, typically fiberglass, stainless steel, or galvanized steel, significantly affects longevity and resistance to corrosion. For instance, stainless steel offers superior durability in harsh environments, making it ideal for industrial applications in regions with high humidity or corrosive elements. Selecting the right material can reduce maintenance costs and extend the lifespan of the equipment. -

Cooling Capacity

This specification refers to the amount of heat that a cooling tower can remove from the water per hour, measured in tons or BTUs. Understanding the cooling capacity is crucial for ensuring that the system meets the demands of your specific application, whether it’s for a manufacturing process or HVAC system. Oversizing or undersizing can lead to inefficiencies, increased operational costs, and potential system failures. -

Water Flow Rate

The water flow rate, typically measured in gallons per minute (GPM), indicates how much water can be circulated through the cooling tower. This metric is vital for determining the efficiency of heat transfer and overall system performance. Accurate flow rate calculations help in optimizing water usage and ensuring that the cooling needs of the process are adequately met. -

Cycles of Concentration

This term refers to the number of times water is reused in the cooling system before being discharged. Higher cycles of concentration indicate more efficient water usage, leading to lower water costs and reduced environmental impact. Understanding this property is essential for organizations looking to enhance sustainability practices and minimize waste. -

Noise Level

Noise generated by cooling towers can impact the surrounding environment and worker comfort. Measured in decibels (dB), this specification is particularly important for installations in urban or residential areas. Selecting a cooling tower with a lower noise level can help in compliance with local regulations and improve workplace conditions.

What Are Common Trade Terms Associated with Open Cooling Systems?

Familiarity with industry jargon is essential for effective communication and negotiations in the B2B landscape. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of open cooling systems, buyers often source components from OEMs to ensure compatibility and quality, which is crucial for long-term performance. -

MOQ (Minimum Order Quantity)

This term refers to the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, as it can affect initial investment and supply chain planning. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For buyers in the open cooling sector, issuing an RFQ can lead to competitive pricing and better understanding of market options. -

Incoterms (International Commercial Terms)

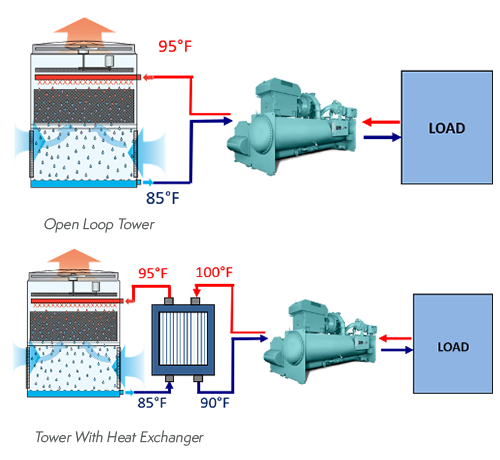

These are a set of international rules that define the responsibilities of sellers and buyers in global trade. Knowledge of Incoterms is essential for managing shipping costs, responsibilities, and risks associated with transporting cooling systems across borders. -

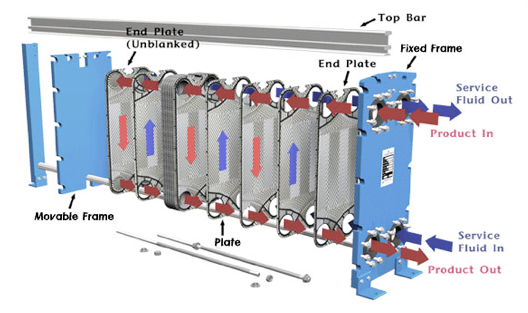

Heat Exchanger

A heat exchanger is a device that transfers heat between two or more fluids. In open cooling systems, heat exchangers play a crucial role in enhancing efficiency and cooling performance, making them an essential component to understand when evaluating options. -

Crossflow and Counterflow Designs

These terms describe the two main airflow patterns in cooling towers. Crossflow towers allow air to flow horizontally while water flows vertically, whereas counterflow towers have air moving upward against the downward flow of water. Understanding these designs helps in selecting the right cooling solution for specific operational needs.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when investing in open cooling systems, ensuring optimal performance and cost-effectiveness.

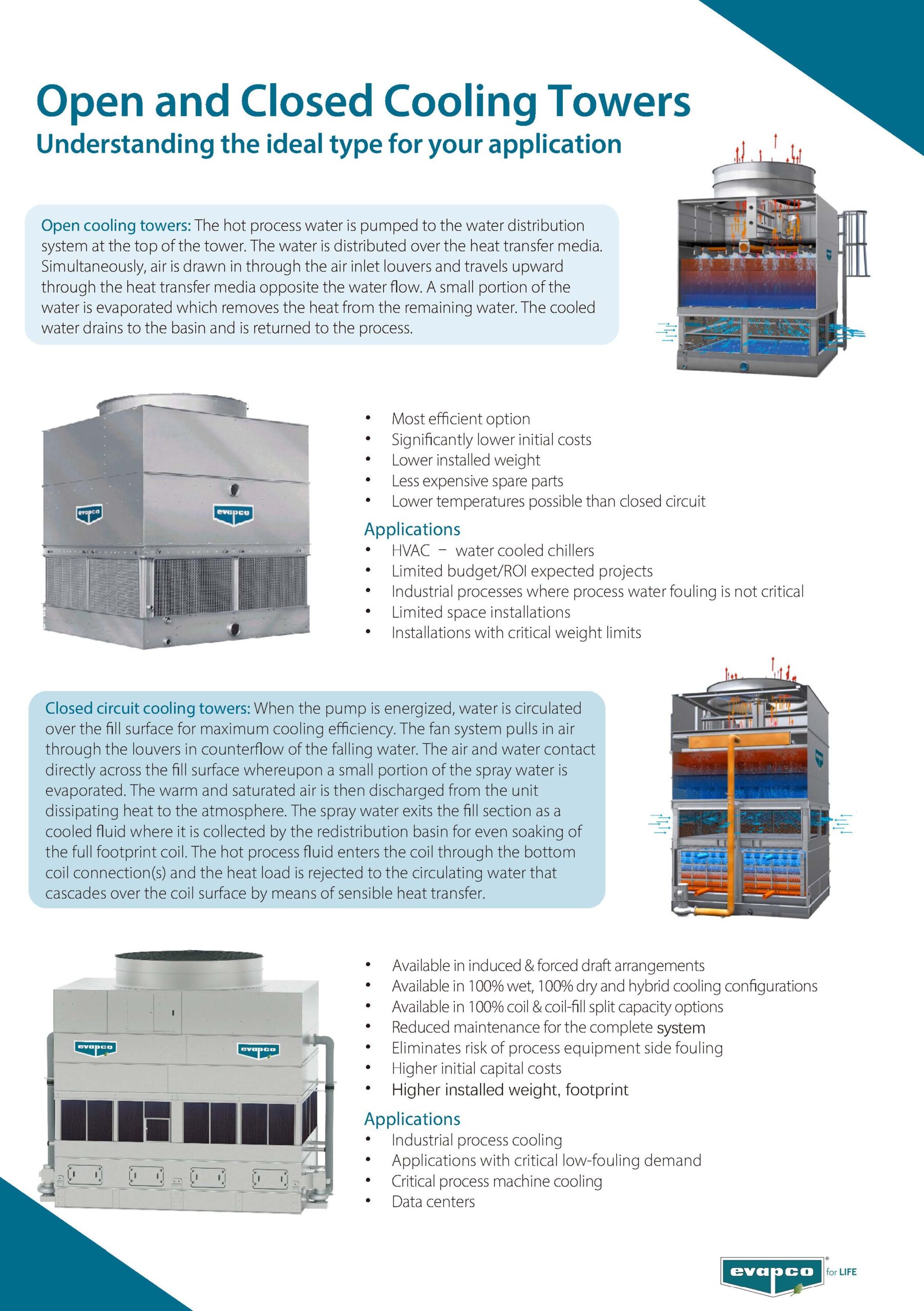

Navigating Market Dynamics and Sourcing Trends in the open cooling Sector

What Are the Current Market Dynamics and Key Trends in the Open Cooling Sector?

The open cooling sector is witnessing substantial growth driven by several global factors. Increasing industrialization, particularly in emerging markets such as Africa, South America, and Southeast Asia, has escalated the demand for efficient cooling solutions. Industries such as petrochemicals, power generation, and HVAC systems are increasingly relying on open cooling systems due to their cost-effectiveness and operational efficiency. Additionally, technological advancements in cooling tower design, such as the integration of IoT for monitoring and control, are enhancing system performance and energy efficiency.

Another key trend is the rising emphasis on sustainability. Businesses are now prioritizing eco-friendly solutions that minimize water usage and reduce emissions. The adoption of open recirculating cooling systems helps in conserving water compared to once-through systems, aligning with global water conservation goals. Moreover, international buyers are seeking suppliers who can offer advanced features like corrosion-resistant materials and low-maintenance designs, which are essential for reducing operational costs over time.

Emerging markets are also seeing increased regulatory pressures to comply with environmental standards, propelling companies to invest in modern cooling technologies. This shift presents a lucrative opportunity for international B2B buyers to source innovative cooling solutions that not only meet regulatory requirements but also enhance operational efficiency.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Open Cooling Sector?

Sustainability is becoming a cornerstone of business strategy in the open cooling sector. The environmental impact of cooling systems is significant, especially concerning water consumption and chemical treatments. Open cooling systems, while efficient, must be managed properly to minimize issues like water contamination and biological growth, which can lead to increased maintenance costs and operational downtime.

Ethical sourcing is equally important, as businesses are increasingly held accountable for their supply chain practices. Buyers are now looking for suppliers who demonstrate a commitment to sustainability through responsible sourcing of materials and adherence to environmental regulations. Certifications such as ISO 14001 for environmental management and LEED for energy efficiency are becoming critical in supplier evaluations.

Incorporating ‘green’ materials, such as those that are recyclable or have lower environmental footprints, can enhance a company’s marketability and compliance with regulations. B2B buyers should prioritize partnerships with manufacturers that are transparent about their sourcing practices and can provide certifications, thereby ensuring that their procurement strategies align with broader sustainability goals.

What is the Brief Evolution and History of Open Cooling Systems?

The evolution of open cooling systems can be traced back to the early 20th century when industrial processes began to scale up significantly. Initially, cooling methods were rudimentary, often relying on natural water bodies, which posed challenges related to water quality and availability. The introduction of cooling towers revolutionized the industry by providing a controlled environment for heat dissipation through evaporation.

Over the decades, advancements in materials and engineering have led to more efficient and durable cooling tower designs. The shift from once-through cooling systems to open recirculating systems marked a significant turning point, allowing for substantial water conservation and reduced environmental impact. Today, innovations such as modular designs and IoT integration are paving the way for smarter, more efficient cooling solutions that cater to the diverse needs of industries across the globe.

As international B2B buyers navigate the complexities of sourcing in this sector, understanding these historical developments can provide valuable context for making informed purchasing decisions that align with current market trends and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of open cooling

-

How do I determine the right open cooling system for my facility?

Selecting the appropriate open cooling system involves assessing your facility’s specific cooling needs, including the heat load, environmental conditions, and available space. Consider factors such as the type of processes being cooled, local climate, and water availability. Additionally, it is essential to evaluate the system’s energy efficiency and maintenance requirements. Engaging with suppliers for detailed specifications and performance data can provide invaluable insights to make a well-informed decision. -

What are the key benefits of using open cooling systems over closed systems?

Open cooling systems offer several advantages, including lower operational costs, reduced energy consumption, and easier maintenance due to fewer mechanical components. They are particularly effective in environments where water availability is not a concern, as they utilize evaporative cooling to dissipate heat. Furthermore, open systems can handle larger volumes of water and are often more suitable for industrial applications requiring high cooling capacities. -

What factors should I consider when vetting suppliers for open cooling systems?

When evaluating suppliers, focus on their industry experience, product quality, and customer reviews. Look for suppliers with a proven track record in providing open cooling solutions tailored to your industry. Certifications, warranties, and post-sale support are also critical factors. Additionally, consider their ability to deliver on time and their responsiveness to inquiries, as these traits often reflect their overall reliability and commitment to customer service. -

What is the minimum order quantity (MOQ) for open cooling systems?

Minimum order quantities for open cooling systems can vary significantly between suppliers. Some may allow for single-unit purchases, especially for specialized or customized systems, while others may require larger orders for standard models. It’s essential to discuss your specific needs with potential suppliers to understand their MOQ policies and explore options for negotiating smaller orders if necessary. -

What payment terms should I expect when sourcing open cooling systems internationally?

Payment terms can differ widely among suppliers and regions. Common options include upfront payments, partial payments upon order confirmation, or payment upon delivery. It is crucial to clarify these terms before finalizing any agreements. Additionally, consider payment methods that offer protection, such as letters of credit or escrow services, especially in international transactions, to mitigate risks associated with cross-border purchases. -

How can I ensure the quality of open cooling systems during international sourcing?

To ensure quality, request detailed product specifications and certifications from suppliers. Conducting factory audits or third-party inspections can provide further assurance of product standards. Additionally, consider sourcing from suppliers who offer warranties and service agreements, as these can indicate a commitment to quality. Engaging in clear communication about your quality requirements and expectations is also vital to achieving satisfactory results. -

What logistics considerations should I keep in mind when importing open cooling systems?

Logistics play a crucial role in the successful importation of open cooling systems. Consider factors such as shipping methods, lead times, and customs regulations in your country. Collaborating with experienced freight forwarders can help navigate these complexities. Additionally, ensure that you understand the total landed cost, including shipping, duties, and taxes, to avoid unexpected expenses. -

What are the common challenges faced when using open cooling systems, and how can they be mitigated?

Common challenges include scaling, corrosion, and biological growth due to the exposure of water to the environment. Regular maintenance and chemical treatments can help manage these issues effectively. Implementing water management strategies, such as monitoring cycles of concentration and adjusting water chemistry, is also beneficial. Partnering with experienced suppliers for ongoing support and maintenance can further enhance system performance and longevity.

Top 5 Open Cooling Manufacturers & Suppliers List

1. Induction Technology Corp – Open Evaporative Cooling Systems

Domain: inductiontech.com

Registered: 1998 (27 years)

Introduction: Open Evaporative Cooling Systems by Induction Technology Corp. are designed for induction melting furnaces, providing a cost-effective and efficient cooling solution. Key features include:

– **Cooling Medium**: Uses water to absorb heat from furnace components, which is then cooled through evaporation in a cooling tower before being recirculated.

– **Advantages**:

– Cost-effective installatio…

2. Sensorex – Water Quality Sensors

Domain: sensorex.com

Registered: 1996 (29 years)

Introduction: Sensorex offers over 2000 sensor packages for various water quality parameters including pH, Oxidation Reduction Potential (ORP), Conductivity (EC), Dissolved Oxygen (DO), Free Chlorine (FCL), Chlorine Dioxide (CLD), and UV Transmittance (UVT). The company also provides a full line of sensor accessories and transmitters, along with expert technical support for custom designs and off-the-shelf prod…

3. ERT Refrigeration Technology – Open Cooling Systems

Domain: ertgmbh.de

Introduction: Open cooling systems offered by ERT Refrigeration Technology GmbH include models VT0-1, VTL-E, S1500E, S3000E, and PTE. These systems are designed for efficient heat dissipation using evaporative cooling, where hot water from the system is cooled by air flow and evaporation. Key features include:

– Highly efficient cooling with low process temperatures

– Small footprints and simple minimum require…

4. Data Center Knowledge – Closed-Loop Cooling Systems

Domain: datacenterknowledge.com

Registered: 2002 (23 years)

Introduction: Closed-loop cooling systems inject chilled air into small, targeted areas, typically individual server racks, rather than cooling the entire server room. This method, also known as close-coupled cooling, focuses on IT equipment, improving cooling and energy efficiency by reducing energy waste in areas that do not require cooling. Closed-loop systems require less energy for cooling and can operate …

5. MEP Academy – Closed Circuit Cooling Towers

Domain: mepacademy.com

Registered: 2020 (5 years)

Introduction: Closed Circuit Cooling Towers:

– Operation: Process fluid circulated within a closed loop; no contact with external water.

– Advantages: Reduced risk of contamination, water conservation, less scaling and fouling, reduced maintenance, lower water treatment costs, energy savings when pumps are off.

– Disadvantages: Higher initial cost, maintenance required to prevent corrosion.

– Applications: …

Strategic Sourcing Conclusion and Outlook for open cooling

What Are the Key Takeaways for B2B Buyers in Open Cooling?

In the evolving landscape of industrial cooling solutions, open cooling systems present a compelling option for businesses aiming to enhance efficiency while reducing operational costs. Key advantages include lower energy consumption compared to closed systems, significant water savings through recirculation, and a simpler maintenance profile. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these benefits can lead to more informed purchasing decisions that align with sustainability goals.

How Can Strategic Sourcing Enhance Your Open Cooling Solutions?

Strategic sourcing plays a vital role in maximizing the value derived from open cooling technologies. By partnering with reputable suppliers who prioritize quality and innovation, businesses can ensure they are investing in systems that not only meet their cooling needs but also offer long-term reliability and performance. This approach reduces the risk of costly downtime and enhances overall operational efficiency.

Illustrative image related to open cooling

What’s Next for International B2B Buyers in Open Cooling?

As we look to the future, the demand for sustainable and efficient cooling solutions is poised to grow. Buyers should consider adopting a proactive approach by exploring partnerships with leading manufacturers and suppliers in the open cooling sector. Investing in advanced cooling technologies today will position your business to thrive in a competitive marketplace. Embrace the opportunity to enhance your operational capabilities and sustainability initiatives by making informed decisions in your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.