Is Your Nema Connectors Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for nema connectors

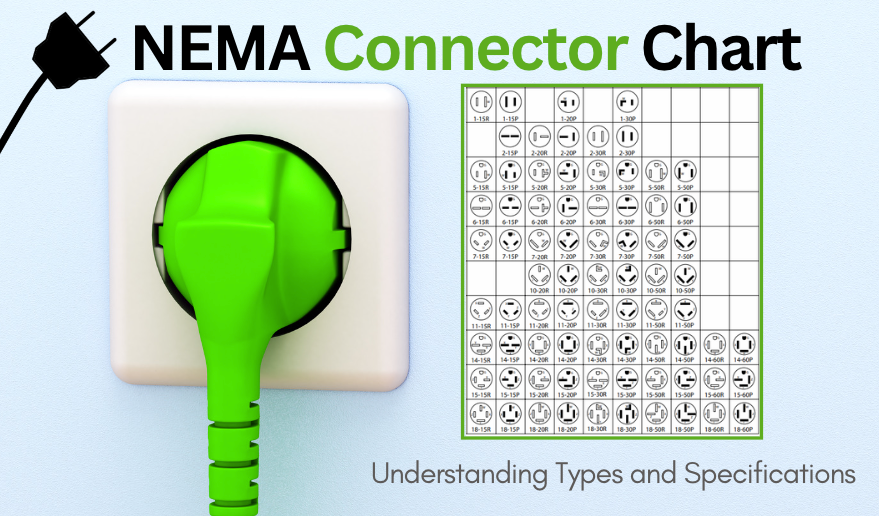

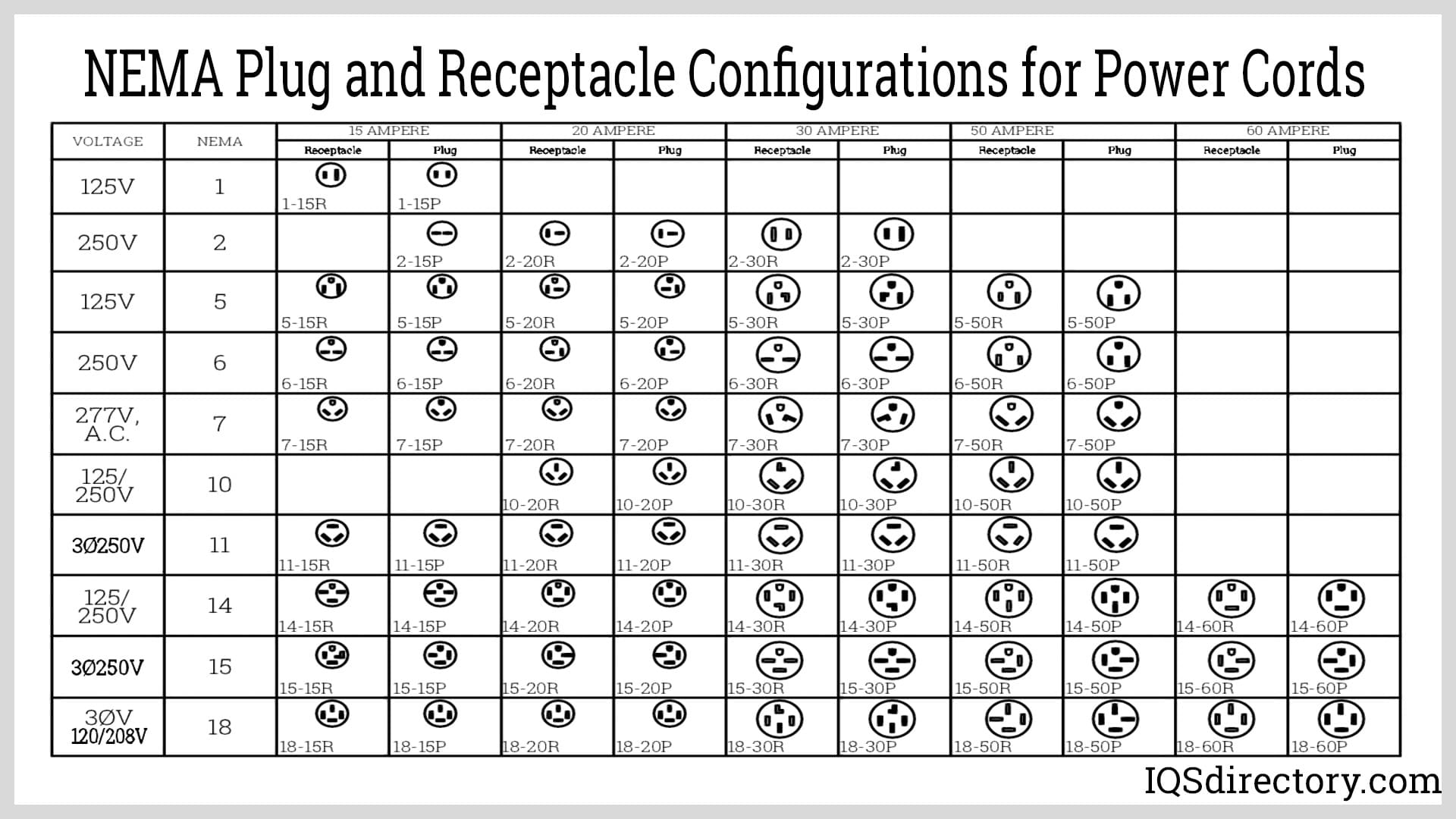

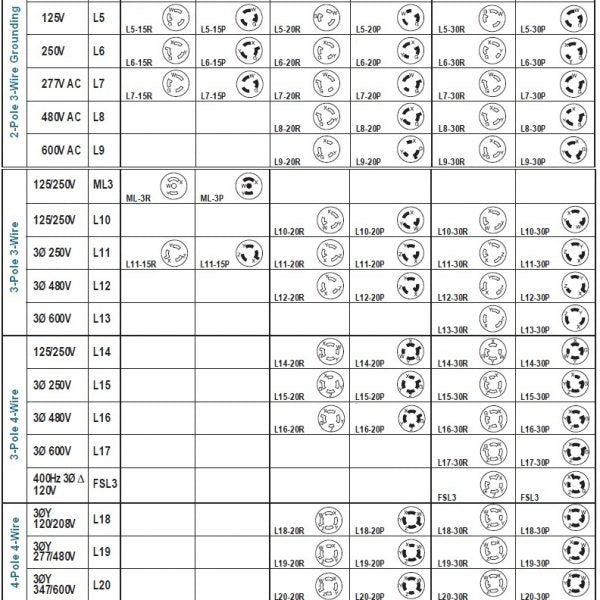

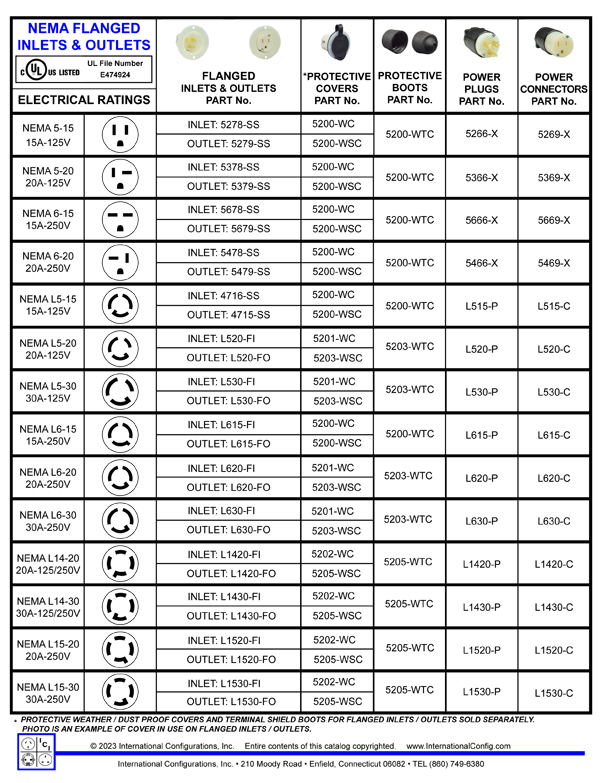

In an increasingly interconnected world, sourcing the right NEMA connectors can pose significant challenges for international B2B buyers. With a variety of types and configurations tailored to specific applications, understanding the nuances of NEMA connectors is crucial for ensuring compatibility and safety in electrical installations. This guide delves into the diverse landscape of NEMA connectors, covering essential information on their types, applications, and the critical factors to consider when vetting suppliers.

From the common NEMA 5-15 connectors used in household appliances to the robust NEMA L14 connectors designed for industrial settings, each type serves a unique purpose. Buyers will gain insights into the specifications that matter most—current ratings, voltage configurations, and the advantages of locking versus non-locking mechanisms. Additionally, the guide offers practical advice on cost considerations and how to navigate potential pitfalls in the procurement process.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—this comprehensive resource empowers decision-makers to make informed purchasing choices. By equipping buyers with the knowledge needed to select the right connectors for their applications, the guide aims to facilitate smoother transactions and foster long-term supplier relationships.

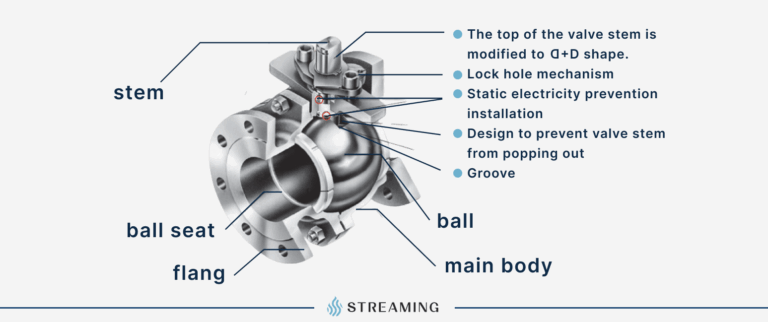

Understanding nema connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5 | Three-prong, 125V, 15A; grounded design for safety | IT equipment, appliances | Pros: Widely used, easy to source; Cons: Limited to lower amperage applications. |

| NEMA L14 | Four-wire, 125/250V, 30A; locking mechanism for secure connections | Generators, large audio systems | Pros: Secure connection, ideal for high power; Cons: More expensive due to locking feature. |

| NEMA 14-50 | Four-wire, 250V, 50A; commonly used for EV charging | Electric vehicle charging stations | Pros: High amperage for fast charging; Cons: Requires compatible infrastructure. |

| NEMA L6-30 | Two-pole, 240V, 30A; designed for industrial settings | Heavy machinery, commercial use | Pros: Durable, suitable for high-demand applications; Cons: May require specialized installation. |

| NEMA TT-30 | Three-prong, 120V, 30A; designed for RVs and trailers | RV parks, recreational vehicles | Pros: Compatibility with standard outlets; Cons: Limited to specific applications. |

What Are the Key Characteristics of NEMA 5 Connectors?

NEMA 5 connectors are widely recognized for their three-prong design, operating at 125 volts and 15 amps. Their grounded configuration enhances safety, making them ideal for use in IT equipment and household appliances. B2B buyers should consider their availability and the compatibility with a broad range of devices, though they may find limitations in amperage for high-demand applications.

How Do NEMA L14 Connectors Enhance Safety and Reliability?

NEMA L14 connectors feature a four-wire system with a locking mechanism that ensures secure connections, making them suitable for generators and large audio systems. The ability to handle 125/250 volts and up to 30 amps provides versatility in demanding environments. Buyers should weigh the benefits of secure connections against the higher costs associated with locking features, which can be essential for preventing accidental disconnections in critical applications.

Why Choose NEMA 14-50 Connectors for Electric Vehicle Charging?

The NEMA 14-50 connector is a four-wire system rated for 250 volts and 50 amps, commonly used in electric vehicle charging stations. Its high amperage allows for faster charging, making it an attractive option for businesses looking to support EV infrastructure. However, buyers must ensure their facilities can accommodate the necessary electrical requirements, which may involve additional investment in infrastructure.

What Are the Advantages of NEMA L6-30 Connectors in Industrial Settings?

NEMA L6-30 connectors are specifically designed for industrial applications, featuring a two-pole configuration that operates at 240 volts and 30 amps. Their robust design makes them suitable for heavy machinery and commercial equipment. Buyers should consider the durability and reliability of these connectors in high-demand scenarios, although the installation may require specialized skills and equipment.

In What Scenarios Are NEMA TT-30 Connectors Most Useful?

NEMA TT-30 connectors are three-prong, 120-volt systems designed primarily for recreational vehicles. They offer compatibility with standard outlets, making them highly accessible in RV parks and for personal use. While they provide convenience, buyers should note that their application is limited to specific contexts, which may not meet the needs of all commercial operations.

Key Industrial Applications of nema connectors

| Industry/Sector | Specific Application of NEMA Connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering industrial machinery | Ensures reliable power supply to heavy equipment | Voltage and amperage ratings, environmental conditions |

| Construction | Temporary power supply for construction sites | Provides safe and flexible power distribution | Durability, weather resistance, and compliance with local codes |

| Renewable Energy | Connecting solar inverters and wind turbines | Facilitates efficient energy conversion and distribution | Compatibility with existing systems, certifications, and ratings |

| Electric Vehicle Charging | Charging stations for electric vehicles | Supports the growing EV market with standardized connections | Connector type, installation requirements, and local regulations |

| Data Centers | Powering IT equipment and servers | Enhances operational efficiency and equipment safety | Ampacity, grounding requirements, and international standards |

How Are NEMA Connectors Used in Manufacturing?

In the manufacturing sector, NEMA connectors are crucial for powering industrial machinery. These connectors are designed to handle high currents and voltages, ensuring a reliable power supply to heavy equipment. For international buyers, especially in regions with variable power quality, selecting connectors with appropriate voltage and amperage ratings is essential. Additionally, understanding local environmental conditions—such as humidity and temperature—can influence the choice of connectors, ensuring they withstand harsh manufacturing environments.

What Role Do NEMA Connectors Play in Construction?

NEMA connectors are commonly used to provide temporary power supply solutions at construction sites. They facilitate safe and flexible power distribution for tools and machinery, which is vital for maintaining productivity. For businesses operating in regions like Africa and South America, sourcing connectors that are durable and weather-resistant is critical, given the outdoor conditions. Compliance with local electrical codes is also a key consideration to prevent safety hazards and ensure project continuity.

Illustrative image related to nema connectors

How Are NEMA Connectors Beneficial in Renewable Energy?

In the renewable energy sector, NEMA connectors are integral to connecting solar inverters and wind turbines. They enable efficient energy conversion and distribution, which is essential for maximizing the performance of renewable energy systems. B2B buyers should consider compatibility with existing systems and ensure that the connectors meet necessary certifications and ratings for reliability. This is particularly important in markets across Europe and the Middle East, where renewable energy initiatives are rapidly expanding.

Why Are NEMA Connectors Important for Electric Vehicle Charging?

Electric vehicle (EV) charging stations utilize NEMA connectors to standardize connections across different vehicle models. This standardization supports the growing EV market by providing reliable and safe charging solutions. Businesses looking to invest in EV infrastructure must consider the specific type of connector required, installation requirements, and adherence to local regulations. This is especially relevant in regions like Germany, where EV adoption is accelerating, and regulatory compliance is stringent.

How Do NEMA Connectors Enhance Data Center Operations?

In data centers, NEMA connectors are essential for powering IT equipment and servers. They enhance operational efficiency and ensure the safety of critical infrastructure. For international buyers, it is vital to assess the ampacity and grounding requirements of the connectors, as well as their compliance with international standards. This ensures that the data center operates smoothly, minimizing downtime and protecting sensitive equipment from power-related issues.

3 Common User Pain Points for ‘nema connectors’ & Their Solutions

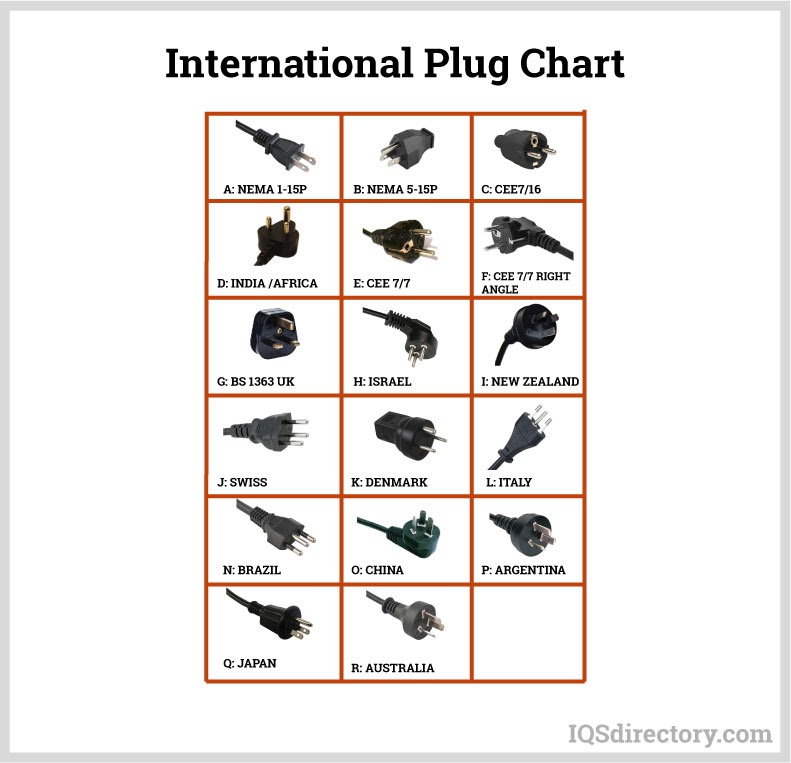

Scenario 1: Ensuring Compatibility Across Different Regions

The Problem:

One of the primary challenges faced by B2B buyers dealing with NEMA connectors is ensuring compatibility across various international standards. Buyers from regions like Africa or South America may find themselves sourcing equipment that requires specific NEMA connectors, only to discover that their local electrical infrastructure employs different standards. This can lead to delays in project timelines, increased costs from needing adapters or additional equipment, and potential safety hazards from improper connections.

Illustrative image related to nema connectors

The Solution:

To mitigate this issue, B2B buyers should conduct thorough research on the NEMA connector specifications required for their equipment before purchasing. This involves understanding not only the type of NEMA connector needed (such as NEMA 5-15 or NEMA L14-30) but also the voltage and amperage ratings that correspond with local electrical standards. Engaging with suppliers who specialize in international electrical standards can provide insights into which connectors are universally compatible and help ensure that the equipment sourced can operate seamlessly in the intended environment. Additionally, maintaining an inventory of commonly used adapters can provide a quick fix for compatibility issues, ensuring that project timelines remain intact.

Scenario 2: Addressing Durability Concerns in Harsh Environments

The Problem:

Another significant pain point for B2B buyers is the concern over the durability and reliability of NEMA connectors in harsh environments. Industries operating in extreme temperatures, humidity, or exposure to corrosive substances often require connectors that can withstand these conditions. Buyers may purchase standard NEMA connectors only to find that they fail under pressure, leading to equipment downtime and increased maintenance costs.

The Solution:

To tackle this issue, buyers should prioritize sourcing connectors specifically designed for harsh environments. This means looking for NEMA connectors that are rated for outdoor use, have weatherproof enclosures, or are constructed with corrosion-resistant materials. Engaging with manufacturers who offer customized solutions can provide options tailored to specific environmental challenges. Additionally, conducting thorough testing of connectors before full-scale implementation can help identify potential weaknesses. Establishing a relationship with a reliable supplier who understands the unique demands of your industry can also ensure that you have access to the right products that meet durability requirements.

Scenario 3: Navigating the Complexity of Wiring and Installation

The Problem:

B2B buyers often face difficulties during the installation and wiring of NEMA connectors due to the complexity of the electrical configurations. Misunderstanding wiring requirements can lead to improper installations, resulting in equipment failures or even safety hazards. This is particularly critical in industrial settings where multiple connectors are used in tandem, and the stakes for safety and functionality are high.

The Solution:

To address these challenges, it’s essential for buyers to invest in comprehensive training for their installation teams. This can include workshops or certifications focused on NEMA wiring standards and best practices. Additionally, utilizing detailed installation guides and diagrams provided by manufacturers can serve as valuable resources. Buyers should also consider partnering with experienced electricians or consultants who specialize in NEMA connectors for more complex installations. This approach not only reduces the risk of errors but also enhances the overall efficiency of the installation process, ensuring that the equipment is safe and operational from the outset. Regular audits of installed systems can further help identify any potential issues early, allowing for timely interventions.

Strategic Material Selection Guide for nema connectors

What Are the Common Materials Used in NEMA Connectors?

NEMA connectors are essential components in various electrical applications, and the choice of materials significantly impacts their performance and suitability for specific environments. Here, we analyze four common materials used in NEMA connectors: thermoplastics, thermosetting plastics, aluminum, and brass.

How Do Thermoplastics Perform in NEMA Connectors?

Thermoplastics, such as polycarbonate and nylon, are frequently used in NEMA connectors due to their excellent electrical insulation properties and resistance to impact. These materials can withstand temperatures ranging from -40°C to 100°C, making them suitable for diverse environments.

Illustrative image related to nema connectors

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, which simplifies manufacturing processes. They also offer good chemical resistance, making them suitable for applications where exposure to oils or solvents may occur.

Cons: While thermoplastics provide decent durability, they may not perform well under extreme temperatures or prolonged exposure to UV light, leading to degradation over time.

Impact on Application: Thermoplastics are compatible with a wide range of media, but their limitations in high-temperature environments may restrict their use in industrial applications requiring robust performance.

Illustrative image related to nema connectors

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial, especially in regions like Europe and South America, where regulations may dictate material specifications for safety and performance.

What Role Do Thermosetting Plastics Play in NEMA Connectors?

Thermosetting plastics, such as epoxy and phenolic resins, are known for their exceptional heat resistance and structural integrity. They can withstand temperatures up to 150°C and are less prone to deformation under stress.

Pros: These materials exhibit high durability and excellent electrical insulation properties, making them ideal for heavy-duty applications. They also resist moisture and chemicals, ensuring longevity in challenging environments.

Cons: The manufacturing process for thermosetting plastics is more complex and time-consuming, which can increase production costs. Additionally, once set, they cannot be re-molded, limiting design flexibility.

Impact on Application: Thermosetting plastics are particularly suitable for applications involving high-temperature or high-stress conditions, such as in industrial machinery or outdoor installations.

Considerations for International Buyers: Buyers in regions with stringent electrical safety standards, such as Germany, should ensure that thermosetting plastics meet local compliance requirements to avoid penalties.

Why Choose Aluminum for NEMA Connectors?

Aluminum is often used for the housing and structural components of NEMA connectors due to its lightweight nature and excellent conductivity. It can handle temperatures ranging from -40°C to 120°C.

Pros: Aluminum is highly durable and resistant to corrosion, especially when anodized. Its lightweight nature reduces shipping costs, making it an economical choice for large-scale applications.

Cons: While aluminum provides good conductivity, it is susceptible to galvanic corrosion when in contact with dissimilar metals. This necessitates careful material selection and coating processes.

Impact on Application: Aluminum connectors are ideal for outdoor applications or environments with high humidity, as they can withstand corrosion and maintain performance.

Considerations for International Buyers: Buyers should be aware of the need for proper surface treatment to prevent corrosion, particularly in humid regions like parts of Africa and South America.

How Does Brass Compare in NEMA Connectors?

Brass, an alloy of copper and zinc, is commonly used for the pins and contacts in NEMA connectors due to its excellent electrical conductivity and resistance to wear.

Pros: Brass connectors offer superior conductivity, ensuring efficient power transfer. They are also resistant to corrosion and wear, making them suitable for frequent connections.

Cons: Brass can be more expensive than other materials, and its susceptibility to tarnishing may require regular maintenance.

Impact on Application: Brass is particularly effective in applications requiring frequent connections and disconnections, such as in portable equipment or temporary installations.

Illustrative image related to nema connectors

Considerations for International Buyers: In regions with varying climate conditions, such as the Middle East, buyers should consider the need for protective coatings to enhance the longevity of brass connectors.

Summary Table

| Material | Typical Use Case for NEMA Connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and light industrial applications | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Thermosetting Plastics | Heavy-duty industrial applications | High durability and heat resistance | Complex manufacturing process | Medium |

| Aluminum | Outdoor and humid environments | Corrosion-resistant and lightweight | Susceptible to galvanic corrosion | Medium |

| Brass | Portable equipment and frequent connections | Superior conductivity | Higher cost and tarnishing issues | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on performance, cost, and compliance considerations across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for nema connectors

What Are the Main Stages in the Manufacturing Process of NEMA Connectors?

The manufacturing process of NEMA connectors involves several key stages, each critical for ensuring the reliability and safety of the final product. Understanding these stages can provide B2B buyers with insights into the quality of connectors they are sourcing.

Material Preparation: What Materials Are Used in NEMA Connectors?

The first stage of manufacturing NEMA connectors is material preparation, which primarily involves selecting the right materials to ensure durability and electrical conductivity. Common materials include:

Illustrative image related to nema connectors

- Copper: Used for the blades and pins due to its excellent electrical conductivity.

- Thermoplastics: Employed for the connector housing, providing insulation and protection against environmental factors.

- Stainless Steel: Often used in locking mechanisms for its resistance to corrosion.

Material quality is crucial; therefore, suppliers often conduct thorough inspections to ensure that all incoming materials meet specified standards before moving on to the next phase.

How Are NEMA Connectors Formed?

Forming is the next step, where raw materials are shaped into the desired forms. This process can involve several techniques:

- Stamping: Used for creating the metal components of the connectors. High-precision dies are employed to ensure consistent dimensions and shapes.

- Injection Molding: This technique is used for the thermoplastic components. It allows for complex shapes and ensures that the housings are produced quickly and efficiently.

- Machining: Some components may require additional machining for precise fitting, especially in locking connectors.

Each of these techniques is performed with strict tolerances to ensure that the connectors will function correctly and safely in their intended applications.

What Does the Assembly Process Involve for NEMA Connectors?

Once the components are formed, they move to the assembly stage. This stage involves several steps:

- Component Integration: The various parts, including blades, housings, and locking mechanisms, are assembled. Automation is often employed to improve efficiency and reduce human error.

- Soldering and Welding: In some cases, connections between components are soldered or welded to ensure a solid and reliable bond.

After assembly, connectors are subject to initial inspections to confirm that all components fit properly and operate as intended.

What Finishing Techniques Are Used for NEMA Connectors?

Finishing is a vital stage that enhances both the aesthetics and functionality of NEMA connectors. Common finishing processes include:

- Plating: Connectors may be plated with nickel or gold to improve conductivity and resistance to corrosion.

- Coating: A protective coating may be applied to prevent wear and tear from environmental factors, especially for connectors intended for outdoor use.

- Labeling: Proper labeling is crucial for identification and compliance with international standards.

These finishing touches not only enhance the durability of the connectors but also ensure compliance with various regulatory requirements.

What Quality Control Measures Are Implemented in NEMA Connector Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, ensuring that NEMA connectors meet both international and industry-specific standards.

Which International Standards Govern NEMA Connectors?

Manufacturers of NEMA connectors typically adhere to various international standards, with ISO 9001 being one of the most recognized. This standard ensures that organizations have a quality management system in place, focusing on meeting customer and regulatory requirements.

In addition to ISO standards, connectors may also need to comply with specific industry standards such as:

- CE Marking: Required for products sold in the European Economic Area, ensuring they meet safety and environmental protection standards.

- API Standards: Particularly relevant for connectors used in industrial applications, ensuring quality and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch any defects early. Key checkpoints include:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps detect any deviations from quality standards in real-time.

- Final Quality Control (FQC): After assembly and finishing, each connector undergoes rigorous testing to ensure it meets all specifications before it is shipped.

What Testing Methods Are Commonly Used for NEMA Connectors?

Various testing methods are employed to verify the performance and safety of NEMA connectors, including:

- Electrical Testing: Ensures that connectors can handle their rated voltage and current without failure.

- Mechanical Testing: Assesses the durability of connectors under physical stress, such as pulling and twisting.

- Environmental Testing: Evaluates the performance of connectors under different environmental conditions, including humidity, temperature extremes, and exposure to chemicals.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical to ensuring product reliability.

What Steps Can Buyers Take to Ensure Supplier Compliance?

- Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures.

- Requesting Quality Reports: Buyers should ask for documentation of quality testing results, certifications, and compliance with relevant standards.

- Third-Party Inspections: Engaging independent inspectors to assess manufacturing facilities can provide an unbiased evaluation of the supplier’s quality practices.

What Are the Nuances of Quality Certification for International Buyers?

B2B buyers must be aware that quality certifications can vary significantly by region. For instance, while CE marking may be crucial for European buyers, other markets may emphasize different certifications. Understanding these nuances can help buyers navigate the complexities of international sourcing and ensure they receive products that meet their specific requirements.

In conclusion, the manufacturing processes and quality assurance measures for NEMA connectors are critical factors that international B2B buyers must consider when sourcing these essential components. By understanding the intricacies of manufacturing and quality control, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nema connectors’

Introduction

Sourcing NEMA connectors requires careful consideration of technical specifications, supplier reliability, and compliance with industry standards. This checklist is designed to guide B2B buyers through the essential steps to ensure a successful procurement process, maximizing value and minimizing risk.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for NEMA connectors. This includes determining the voltage ratings (125V, 250V, etc.), current ratings (15A, 30A, etc.), and the specific type of connector needed (locking vs. non-locking).

– Why it matters: Accurate specifications prevent compatibility issues and ensure that the connectors meet your operational needs.

Illustrative image related to nema connectors

Step 2: Research Compliance Standards

Understand the compliance requirements relevant to your industry and region. NEMA connectors must adhere to the standards set by the National Electrical Manufacturers Association and may also need to comply with local electrical codes.

– What to check: Review documentation that verifies compliance, such as UL certification or CE marking, especially if you are sourcing from international suppliers.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure they can meet your specifications reliably. Request detailed company profiles, including their manufacturing capabilities, experience in your industry, and customer testimonials.

– Key aspects to assess:

– Production capacity and lead times.

– Previous projects or case studies that demonstrate their ability to deliver.

Step 4: Request Samples

Before placing a bulk order, request samples of the NEMA connectors you plan to purchase. Testing samples in your application helps validate quality and compatibility.

– Why it’s crucial: This step allows you to identify any potential issues early, saving time and costs related to returns or reorders.

Step 5: Confirm Warranty and Support Policies

Inquire about the warranty terms and post-sale support offered by the supplier. A strong warranty and responsive customer service are indicators of a reliable supplier.

– What to look for: Ensure that the warranty covers defects and that the supplier provides technical support for installation and troubleshooting.

Step 6: Review Pricing and Payment Terms

Compare pricing among various suppliers but don’t base your decision solely on cost. Consider the total cost of ownership, including shipping and potential duties, and evaluate the payment terms offered.

– Considerations:

– Discounts for bulk purchases.

– Payment flexibility and credit terms.

Step 7: Finalize Your Order and Establish Communication

Once you’ve selected a supplier, finalize your order and establish clear lines of communication. Confirm delivery timelines and any specific requirements regarding packaging or labeling.

– Importance of communication: Maintaining open communication ensures that both parties are aligned on expectations, reducing the likelihood of misunderstandings.

Following this checklist will help ensure that your procurement of NEMA connectors is efficient, cost-effective, and meets the high standards required for your business operations.

Illustrative image related to nema connectors

Comprehensive Cost and Pricing Analysis for nema connectors Sourcing

What Are the Key Cost Components in NEMA Connectors Sourcing?

When sourcing NEMA connectors, understanding the cost structure is crucial for effective budget planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The raw materials for NEMA connectors, such as copper for conductors and thermoplastics for housings, are significant cost drivers. Fluctuations in global commodity prices can affect overall costs.

-

Labor: Labor costs encompass the wages of workers involved in assembly and quality assurance. Regions with higher wage standards will naturally see increased labor costs.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can mitigate these overheads.

-

Tooling: Initial tooling costs for molds and dies can be substantial, especially for custom or specialized connectors. These costs are amortized over production runs, impacting unit pricing.

-

Quality Control (QC): Ensuring compliance with industry standards necessitates investment in QC processes, which can vary depending on the complexity and specifications of the connectors.

-

Logistics: Transportation costs, including shipping and handling, can fluctuate based on distance, mode of transport, and geopolitical factors. This is particularly pertinent for international buyers.

-

Margin: Supplier profit margins can vary widely based on market competition, product uniqueness, and brand reputation.

How Do Price Influencers Affect NEMA Connectors Costs?

Several factors influence the pricing of NEMA connectors, which can significantly affect the total cost for buyers:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs) that can impact pricing tiers.

-

Specifications and Customization: Custom connectors or those with specific technical requirements typically command higher prices due to the additional engineering and production costs involved.

-

Materials: The choice of materials directly impacts costs. Higher-quality materials may lead to increased durability and performance but will also raise the initial price.

-

Quality and Certifications: Connectors that meet specific safety and performance certifications may cost more but offer assurance of reliability, which is crucial for compliance in various applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge a premium, reflecting their assurance of product performance.

-

Incoterms: The agreed-upon Incoterms can affect logistics costs and risk allocation. Understanding whether costs include shipping, insurance, and duties is essential for accurate pricing assessments.

What Are Effective Buyer Tips for NEMA Connectors Sourcing?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective sourcing:

-

Negotiation: Establishing a good rapport with suppliers can open doors for negotiation on price, especially for larger orders. Don’t hesitate to discuss terms that can lead to cost savings.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as expected lifespan, warranty provisions, and maintenance costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs that can impact the final cost. Understanding the local market dynamics is crucial for making informed purchasing decisions.

-

Quality Assurance: Prioritize suppliers who can provide certifications and quality guarantees. This can prevent costly failures or recalls in the future.

Conclusion

Sourcing NEMA connectors requires a comprehensive understanding of cost components and pricing influencers. By leveraging effective negotiation strategies, considering total cost of ownership, and being aware of international pricing nuances, buyers can make informed decisions that align with their operational needs. Remember to consult with multiple suppliers and gather quotes to ensure competitive pricing.

Alternatives Analysis: Comparing nema connectors With Other Solutions

Introduction: Exploring Alternatives to NEMA Connectors

In the realm of electrical connectors, NEMA connectors are widely recognized for their reliability and standardization in North America. However, various alternatives exist that may better suit specific applications or regional standards, especially for international B2B buyers. This analysis will compare NEMA connectors with two viable alternatives: IEC connectors and Anderson Powerpole connectors, focusing on critical aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | NEMA Connectors | IEC Connectors | Anderson Powerpole Connectors |

|---|---|---|---|

| Performance | Reliable, standardized for North America; rated up to 600V | High performance, versatile in various applications; rated for high voltages | Excellent for DC applications, high current handling, modular design |

| Cost | Generally affordable; price varies by type and rating | Moderate to high; depends on specifications and certifications | Cost-effective for bulk applications; modular design can save costs |

| Ease of Implementation | Simple installation, but requires specific receptacles | Requires adherence to international standards; may need adapters for NEMA | Easy to implement, especially in custom applications; requires crimping tools |

| Maintenance | Low maintenance; durable but can suffer from wear | Low maintenance; robust design | Moderate; connectors may require periodic checks for secure connections |

| Best Use Case | Residential, commercial, and light industrial settings | Industrial settings, global applications requiring compliance with international standards | High-current applications, battery connections, and modular systems |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of IEC Connectors?

IEC connectors, governed by the International Electrotechnical Commission standards, are widely used in Europe and other regions. Their design allows for high performance and versatility across various applications, especially in industrial environments. They support a range of voltages and currents, making them suitable for devices that require compliance with international safety standards. However, the initial cost can be higher, and implementation may require adapters for compatibility with NEMA systems, which can complicate installations in regions where NEMA is standard.

How Do Anderson Powerpole Connectors Compare?

Anderson Powerpole connectors are a modular connector system ideal for DC applications, particularly in high-current scenarios such as battery connections and power distribution. They offer a unique advantage with their color-coded, stackable design, allowing for easy customization and scalability in systems. Their cost-effectiveness becomes apparent in bulk applications, but they do require specific crimping tools for installation. While they are straightforward to implement, periodic maintenance checks are recommended to ensure secure connections, particularly in high-vibration environments.

Conclusion: How Should B2B Buyers Choose the Right Connector Solution?

When selecting the appropriate connector solution, B2B buyers should consider their specific application requirements, regional compliance standards, and budget constraints. NEMA connectors are ideal for those primarily operating within North America, offering ease of use and low maintenance. Conversely, IEC connectors are preferable for international projects requiring compliance with global standards. Anderson Powerpole connectors are an excellent choice for high-current applications, providing flexibility and modularity. Ultimately, the decision should align with the operational context and future scalability needs of the business.

Illustrative image related to nema connectors

Essential Technical Properties and Trade Terminology for nema connectors

What Are the Key Technical Properties of NEMA Connectors?

Understanding the essential technical properties of NEMA connectors is critical for B2B buyers, as these specifications directly influence performance, safety, and compatibility in various applications. Here are some of the most important properties:

-

Current Rating (Amperage)

The current rating, typically ranging from 15 to 60 amps, indicates the maximum electrical load a connector can handle without overheating. In B2B contexts, selecting a connector with an appropriate current rating is essential to ensure operational safety and efficiency. Overloading a connector can lead to equipment failure or electrical hazards. -

Voltage Rating

Voltage ratings for NEMA connectors can vary from 125 volts to 600 volts. Choosing a connector with the correct voltage rating is vital for compatibility with electrical systems and to prevent malfunctions. For businesses in sectors like construction or manufacturing, adhering to voltage specifications can also meet regulatory standards. -

Material Grade

NEMA connectors are often made from high-grade materials such as thermoplastics and copper alloys. The choice of material affects the durability and resistance to environmental factors like moisture and temperature fluctuations. For B2B buyers, selecting connectors with appropriate material grades can minimize maintenance costs and enhance longevity. -

Configuration Type

Connectors can be classified as either straight-blade (non-locking) or curved-blade (locking). Locking connectors provide a secure connection, preventing accidental disconnections, which is particularly important in industrial applications. Understanding configuration types helps businesses choose the right connector for specific environments, thereby ensuring operational reliability. -

Ingress Protection (IP) Rating

The IP rating indicates the level of protection against dust and moisture. An appropriate IP rating is crucial for connectors used in harsh environments, such as outdoor installations or industrial facilities. Buyers should assess the IP rating to ensure that the connectors can withstand their operational conditions, reducing the risk of equipment failure.

What Are Common Trade Terms Related to NEMA Connectors?

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some common trade terms associated with NEMA connectors:

-

OEM (Original Equipment Manufacturer)

OEMs are companies that produce parts or equipment that may be marketed by another manufacturer. In the context of NEMA connectors, partnering with reputable OEMs ensures that buyers receive high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for inventory management and cost efficiency, as purchasing below this threshold may lead to higher per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. When seeking NEMA connectors, submitting an RFQ allows buyers to compare prices and terms, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery responsibilities when importing NEMA connectors from different regions. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for B2B buyers to ensure that projects proceed on schedule, especially when dealing with critical components like NEMA connectors.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and align with their specific requirements.

Navigating Market Dynamics and Sourcing Trends in the nema connectors Sector

What Are the Current Market Dynamics and Key Trends in the NEMA Connectors Sector?

The global market for NEMA connectors is experiencing significant growth driven by the rising demand for electrical equipment across diverse industries, including manufacturing, construction, and electric vehicle (EV) charging infrastructure. The shift towards renewable energy sources and the electrification of transportation are key factors propelling this demand. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of the growing trend towards standardized and interoperable solutions, which are crucial for ensuring compatibility in multi-national operations.

Emerging technologies like smart grids and Internet of Things (IoT) applications are reshaping the NEMA connectors landscape. These technologies necessitate advanced power management solutions, prompting manufacturers to innovate connector designs that enhance performance and reliability. Furthermore, the growing emphasis on automation in industrial applications is leading to an increase in the usage of locking NEMA connectors, which provide enhanced safety and security against accidental disconnections.

International buyers should also consider the competitive landscape, where regional manufacturers are increasingly collaborating with global players to enhance their product offerings. This trend not only broadens the variety of available connectors but also leads to more competitive pricing and improved supply chain efficiencies. Understanding these dynamics can help B2B buyers make informed sourcing decisions that align with their operational needs and market demands.

How Can Sustainability and Ethical Sourcing Influence My Procurement of NEMA Connectors?

Sustainability is becoming an integral aspect of the procurement process for NEMA connectors. Buyers are increasingly focused on the environmental impact of their sourcing decisions, as the push for greener practices in the electrical and electronics industries gains momentum. This shift is catalyzed by both consumer demand and regulatory pressures aimed at reducing carbon footprints. As such, B2B buyers are encouraged to seek suppliers who employ sustainable manufacturing practices, utilize recycled materials, and minimize waste throughout the production process.

Ethical sourcing is equally important, as it directly affects brand reputation and compliance with international standards. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, ensuring fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the adoption of ‘green’ materials in NEMA connectors—such as lead-free solder and environmentally friendly plastics—can enhance the overall sustainability of electrical installations. By prioritizing suppliers with these credentials, B2B buyers can not only meet regulatory requirements but also appeal to a growing segment of environmentally conscious consumers and businesses.

How Have NEMA Connectors Evolved Over Time to Meet Industry Needs?

The evolution of NEMA connectors is a testament to the industry’s response to changing technological demands and safety standards. Established in 1926, the National Electrical Manufacturers Association (NEMA) developed these standards to ensure safety and compatibility across various electrical applications. Initially, NEMA connectors focused primarily on residential and light commercial use; however, as industries expanded and technology advanced, so did the complexity and variety of connectors.

Over the decades, the introduction of twist-lock connectors addressed the need for secure connections in industrial settings, where accidental disconnections could lead to significant safety hazards. With the rise of electric vehicles and renewable energy systems, newer NEMA connector types have been developed to accommodate higher voltage and current requirements, ensuring that they remain relevant in today’s rapidly evolving electrical landscape.

As B2B buyers navigate this market, understanding the historical context of NEMA connectors can provide insights into their reliability and suitability for various applications, enabling better procurement decisions that align with both current and future technological needs.

Frequently Asked Questions (FAQs) for B2B Buyers of nema connectors

-

How do I ensure the NEMA connectors I source meet international standards?

To ensure compliance with international standards, verify that the NEMA connectors adhere to the specifications set by the National Electrical Manufacturers Association (NEMA) and relevant local regulations. Request certification documents from suppliers, such as UL or CE certifications, which validate safety and performance. Additionally, consider conducting third-party testing for quality assurance. Engaging with suppliers who have a proven track record in the industry can also provide confidence in their adherence to international standards. -

What is the best type of NEMA connector for industrial applications?

For industrial applications, the NEMA L-series (locking connectors) are typically the best choice due to their secure connection, which prevents accidental disconnections caused by vibrations or movements. Connectors such as NEMA L14-30 and L6-50 are commonly used for heavy machinery and equipment. When selecting a connector, consider factors like amperage requirements, voltage ratings, and the specific environment in which the connector will be used to ensure optimal performance. -

How can I vet suppliers when sourcing NEMA connectors internationally?

Begin by conducting thorough research on potential suppliers, including their reputation, years in business, and customer reviews. Request samples to assess product quality and compliance with your specifications. It’s also advisable to ask for references from other businesses that have worked with the supplier. Additionally, consider visiting manufacturing facilities or utilizing third-party inspection services to evaluate their production capabilities and quality control processes. -

What are the typical minimum order quantities (MOQs) for NEMA connectors?

Minimum order quantities (MOQs) for NEMA connectors can vary significantly based on the supplier and the type of connectors required. Generally, MOQs can range from as low as 100 units for standard connectors to 1,000 units or more for specialized or custom options. When negotiating with suppliers, discuss your specific needs and see if they can accommodate smaller orders, especially if you are testing a new product line or entering a new market. -

What payment terms should I expect when sourcing NEMA connectors?

Payment terms can vary widely among suppliers, but common arrangements include a 30% deposit upfront with the balance due upon shipment or a net 30-day payment term post-delivery. For larger orders, some suppliers may offer more flexible terms based on your purchasing history. Always ensure that payment methods are secure, and consider using letters of credit or escrow services for added protection, especially in international transactions. -

How do I handle logistics and shipping for NEMA connectors sourced internationally?

When sourcing NEMA connectors internationally, coordinate with your supplier to determine the best shipping method based on your timeline and budget. Common options include air freight for faster delivery or sea freight for cost-effectiveness. Ensure that you understand customs regulations and import duties in your country to avoid unexpected costs. Partnering with a logistics provider experienced in international shipping can help streamline the process and ensure timely delivery. -

What customization options are available for NEMA connectors?

Many suppliers offer customization options for NEMA connectors, including specific amperage ratings, colors, and branding. Customization may also involve modifications to pin configurations or additional features like weatherproofing for harsh environments. When discussing customization, provide detailed specifications and be prepared for potential minimum order quantities that may apply. It’s essential to communicate your requirements clearly to ensure the final product meets your operational needs. -

What quality assurance processes should I expect from NEMA connector suppliers?

Reputable NEMA connector suppliers typically implement comprehensive quality assurance (QA) processes, including incoming material inspections, in-process quality checks, and final product testing. Request documentation detailing their QA procedures and any relevant certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, inquire about warranty policies and return procedures in case the connectors do not meet your expectations, ensuring that you are protected in your investment.

Top 4 Nema Connectors Manufacturers & Suppliers List

1. BSA Electronics – NEMA Plug and Outlet Chart

Domain: bsaelectronics.com

Registered: 2017 (8 years)

Introduction: NEMA Plug and Outlet chart includes descriptions of common NEMA outlets: 5-15 (15A 120V), 5-20 (20A 120V), 6-15 (15A 240V), 6-20 (20A 240V), 6-50 (50A 240V), 10-30 (30A 240V Dryer), 14-30 (30A 240V 4-prong Dryer), 14-50 (50A 240V 4-prong Range), TT-30 (30A 120V Travel Trailer), L6-30 (30A 240V Twist-Lock). The chart emphasizes the importance of identifying outlets correctly, noting that 220/240V o…

2. McMaster – NEMA Connectors

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – NEMA Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. IQS Directory – NEMA Connectors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: NEMA connectors are essential for linking electronic devices to power sources, accommodating either AC or DC. They are designed for current ratings from 15 to 60 amps and voltage ratings spanning 125 to 600 volts. Common types include NEMA 1-15P and NEMA 5-15P, with molded rubber housing and prongs made of steel or brass. NEMA connectors are categorized into locking and non-locking types, with loc…

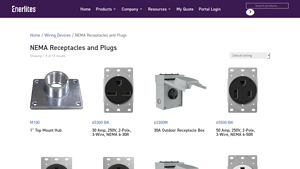

4. Enerlites – NEMA Receptacles and Plugs

Domain: enerlites.com

Registered: 2007 (18 years)

Introduction: NEMA Receptacles and Plugs include various types such as: 1) M100 1″ Top Mount Hub 2) 30 Amp, 250V, 2-Pole, 3-Wire, NEMA 6-30R 3) 30A Outdoor Receptacle Box 4) 50 Amp, 250V, 2-Pole, 3-Wire, NEMA 6-50R 5) 50A EV Charger Receptacle, Heavy Duty, 14-50R 6) 50A EV Charger Receptacle, Heavy Duty, Weather Resistant, 14-50R 7) 50A Outdoor Receptacle Box 8) Flush Mount Receptacle NEMA 14-30R 9) Industrial …

Strategic Sourcing Conclusion and Outlook for nema connectors

What Are the Key Benefits of Strategic Sourcing for NEMA Connectors?

In conclusion, the strategic sourcing of NEMA connectors offers significant advantages for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the diverse types of NEMA connectors—ranging from non-locking to locking variants—enables businesses to select the most suitable products for their specific applications, ensuring safety and reliability.

Moreover, leveraging established relationships with suppliers can lead to improved pricing, enhanced product availability, and access to the latest innovations in connector technology. As industries increasingly adopt electric vehicles and advanced manufacturing processes, the demand for reliable power connections will continue to grow, making NEMA connectors a vital component in these developments.

How Can Buyers Prepare for Future Trends in NEMA Connectors?

Looking ahead, international buyers should stay informed about evolving standards and technologies related to NEMA connectors. Engaging with suppliers who prioritize quality and compliance will be crucial in navigating this dynamic landscape. By investing in strategic sourcing now, businesses can secure a competitive edge and ensure they are well-positioned to meet the demands of tomorrow’s marketplace. Consider reaching out to trusted manufacturers and distributors to explore tailored sourcing strategies that align with your business objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to nema connectors

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.