Is Your National Bolt Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for national bolt

In the ever-evolving landscape of global manufacturing, sourcing reliable national bolts can pose significant challenges for international B2B buyers. The complexity of selecting the right fasteners—considering factors such as material specifications, application requirements, and compliance with industry standards—demands a comprehensive understanding of the market. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany, with actionable insights into the diverse world of national bolts.

Within this resource, you will find an extensive exploration of various types of national bolts, nuts, and washers, along with their specific applications across multiple industries, including construction, automotive, and energy. We will also delve into the crucial aspects of supplier vetting, ensuring that you can confidently identify manufacturers who uphold rigorous quality standards and offer timely delivery. Furthermore, the guide addresses cost considerations and procurement strategies that can help you optimize your purchasing decisions.

By leveraging the knowledge shared in this guide, B2B buyers will be empowered to make informed choices that enhance operational efficiency and product reliability. Navigate the complexities of the national bolt market with confidence, and unlock the potential for successful partnerships that drive your business forward.

Understanding national bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Bolt | Six-sided head for easy tool engagement | Construction, Automotive, Heavy Equipment | Pros: Versatile and widely used; Cons: Limited in tight spaces. |

| Carriage Bolt | Rounded head and square neck to prevent rotation | Wood-to-wood connections, Furniture | Pros: Secure fastening; Cons: Limited to soft materials. |

| Socket Head Bolt | Cylindrical head for Allen wrench use | Machinery, Electronics, Automotive | Pros: High torque application; Cons: Requires specific tools. |

| Flange Bolt | Integrated flange for load distribution | Structural applications, Steel construction | Pros: Reduces need for washers; Cons: Can be bulkier. |

| Lag Bolt | Large, coarse threads for wood applications | Decking, Timber construction | Pros: Strong grip in wood; Cons: Not suitable for metal. |

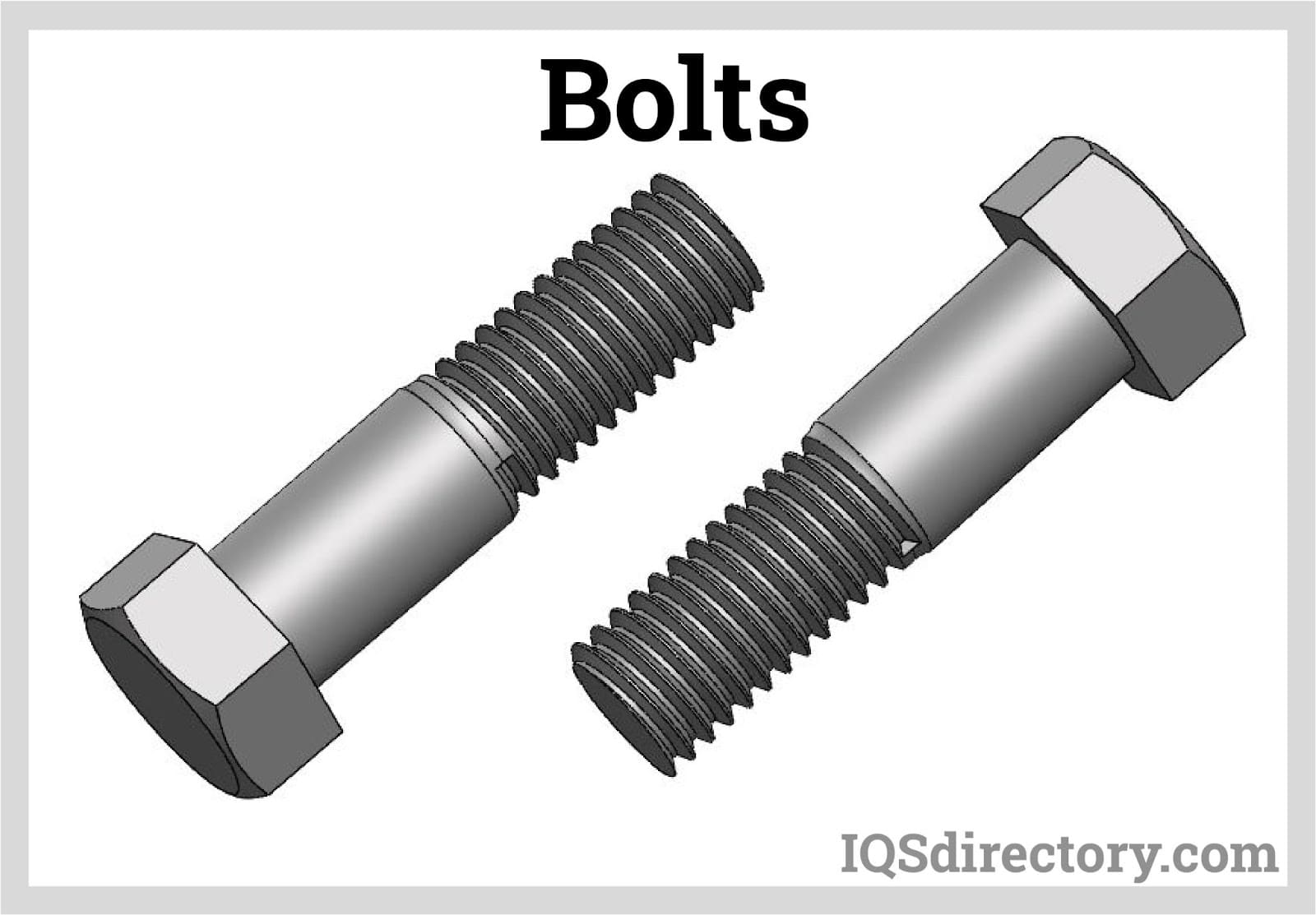

What Are the Characteristics of Hex Head Bolts and Their Suitability for B2B Buyers?

Hex head bolts are characterized by their six-sided heads, which allow for easy engagement with standard tools such as wrenches. They are widely used across various industries, including construction and automotive, due to their versatility and strength. B2B buyers should consider the material and finish to ensure corrosion resistance, especially in outdoor applications. Hex head bolts can be less suitable for tight spaces where a wrench cannot fit, so evaluating the installation environment is crucial.

How Do Carriage Bolts Stand Out in Wood-to-Wood Connections?

Carriage bolts feature a rounded head and a square neck that prevents them from turning when tightened. This design makes them ideal for applications requiring wood-to-wood connections, such as furniture assembly and deck building. While they provide a secure fastening solution, buyers should note that carriage bolts are primarily suited for softer materials and may not be appropriate for heavy-duty metal applications. Understanding the specific requirements of the project will help in making the right choice.

Illustrative image related to national bolt

Why Choose Socket Head Bolts for Machinery and Electronics?

Socket head bolts are distinguished by their cylindrical heads designed for use with an Allen wrench. This type of bolt is preferred in machinery and electronic applications due to its ability to handle high torque. B2B buyers should consider the specific tooling required for installation and ensure compatibility with existing components. While socket head bolts offer excellent fastening strength, the need for specialized tools can be a drawback for some users.

What Makes Flange Bolts Suitable for Structural Applications?

Flange bolts come with an integrated flange that helps distribute the load over a larger area, making them ideal for structural applications in steel construction. This design reduces the need for separate washers, streamlining the installation process. However, buyers should be aware that flange bolts can be bulkier than standard bolts, which may affect aesthetic considerations in visible applications. Assessing load requirements and installation constraints is essential for optimal use.

In What Scenarios Are Lag Bolts Most Effective?

Lag bolts are designed with large, coarse threads that provide a strong grip in wood, making them particularly effective for decking and timber construction. They are essential for applications where a secure hold is necessary to withstand heavy loads. However, lag bolts are not suitable for use with metal, so buyers must evaluate the materials involved in their projects. Understanding the load and environmental conditions will help in selecting the right type of fastener for optimal performance.

Key Industrial Applications of national bolt

| Industry/Sector | Specific Application of National Bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural connections in buildings and bridges | Ensures safety and stability of structures | Need for high-strength materials; compliance with local codes |

| Mining | Fasteners for heavy machinery and equipment | Increases equipment reliability and operational efficiency | Resistance to harsh environments; custom sizes and materials |

| Transportation | Fasteners for vehicles and rail systems | Enhances safety and performance of transport vehicles | Compliance with industry standards; corrosion resistance |

| Agriculture | Custom fasteners for farming equipment | Improves durability and longevity of agricultural machinery | Ability to withstand extreme conditions; specific material needs |

| Petrochemical | Fasteners for pipelines and storage tanks | Guarantees safety and efficiency in chemical handling | High corrosion resistance; certifications for hazardous materials |

How is National Bolt Used in the Construction Industry?

In the construction sector, National Bolt’s fasteners are critical for structural connections in buildings and bridges. These fasteners ensure the safety and stability of constructions by providing robust support. Buyers from regions like Europe and Africa must consider local building codes and standards to ensure compliance. The ability to customize fasteners for specific applications, such as high-strength materials that resist corrosion, is a significant advantage for construction projects.

What Role Does National Bolt Play in the Mining Sector?

In mining, National Bolt supplies durable fasteners for heavy machinery and equipment, essential for both surface and underground operations. These fasteners are designed to withstand extreme conditions, including high loads and abrasive environments, which enhances the reliability and efficiency of mining operations. International buyers should focus on sourcing fasteners that meet their specific operational requirements, including custom sizes and materials tailored to the mining environment.

How Does National Bolt Benefit the Transportation Industry?

For the transportation sector, National Bolt provides specialized fasteners for vehicles, including trucks and rail systems. These fasteners are vital for ensuring the safety and performance of transport vehicles, meeting stringent industry standards. Buyers should prioritize sourcing fasteners that offer corrosion resistance and compliance with transportation regulations, especially in regions with varying climate conditions.

Why are National Bolt’s Fasteners Important in Agriculture?

In agriculture, National Bolt’s custom fasteners are integral to the durability and longevity of farming equipment. Fasteners used in plows, planters, and other machinery must withstand extreme conditions, such as moisture and heavy loads. Buyers in South America and Africa should look for fasteners that can endure these challenges and offer customization options to meet specific agricultural needs, ensuring optimal performance in the field.

How Does National Bolt Address Needs in the Petrochemical Industry?

National Bolt supplies fasteners specifically designed for the petrochemical sector, where safety and efficiency in chemical handling are paramount. These fasteners are engineered to resist corrosion and high temperatures, making them suitable for pipelines and storage tanks. Buyers need to ensure that the fasteners meet rigorous industry certifications for hazardous materials, emphasizing the importance of sourcing from a reputable manufacturer like National Bolt.

3 Common User Pain Points for ‘national bolt’ & Their Solutions

Scenario 1: Difficulty Sourcing Custom Fasteners for Unique Applications

The Problem: B2B buyers often face challenges when sourcing custom fasteners that meet specific project requirements. This can arise in industries like construction or automotive, where standard fasteners may not suffice due to unique sizes, materials, or finishes needed for specialized applications. Buyers may struggle with long lead times, inconsistent quality, or a lack of knowledge on how to communicate their needs effectively, leading to project delays and increased costs.

The Solution: National Bolt provides a streamlined approach for sourcing custom fasteners. To begin, buyers should prepare a detailed specification sheet that includes measurements, material requirements, and any specific environmental conditions the fasteners must withstand, such as high temperatures or corrosive environments. Utilizing National Bolt’s quick custom quote feature allows buyers to receive fast and accurate pricing, enabling them to make informed decisions quickly. Additionally, engaging with their team of experts can provide insights into the best materials and finishes suitable for the application, ensuring the right fasteners are delivered on time. By leveraging these resources, buyers can reduce lead times and ensure the quality and durability of their fasteners.

Scenario 2: Urgent Need for Fasteners in Critical Operations

The Problem: In industries such as mining or transportation, equipment downtime can lead to significant financial losses. Buyers may encounter emergencies where fasteners are needed urgently to keep machinery operational, but standard suppliers may not be able to meet the tight deadlines required. This situation can create stress and pressure on procurement teams who must find a reliable source for emergency supplies.

The Solution: National Bolt offers a 24-hour emergency turnaround service that can be a lifesaver in critical situations. Buyers should establish a proactive relationship with National Bolt by discussing their emergency fastener needs ahead of time and understanding the specific fasteners that can be produced quickly. By keeping a list of frequently used fasteners and their specifications on hand, buyers can expedite the ordering process in emergencies. Furthermore, maintaining an ongoing communication channel with National Bolt’s team can ensure that they are always ready to assist in urgent situations, minimizing downtime and maintaining operational efficiency.

Illustrative image related to national bolt

Scenario 3: Ensuring Compliance with Industry Standards

The Problem: Different industries have strict regulations and compliance requirements for fasteners, especially in sectors such as automotive, petrochemical, and alternative energy. Buyers often find it challenging to source fasteners that not only meet their application needs but also adhere to necessary certifications and standards. Failing to comply can result in costly penalties or project failures.

The Solution: National Bolt is committed to quality and compliance, providing buyers with the necessary certifications and documentation for their fasteners. To navigate compliance effectively, buyers should first familiarize themselves with the specific standards applicable to their industry. They can then work closely with National Bolt’s knowledgeable team to identify fasteners that meet these standards, ensuring they receive the appropriate documentation such as material certifications and compliance letters. By leveraging National Bolt’s in-house quality control department, which is A2LA accredited, buyers can ensure traceability and quality assurance, ultimately safeguarding their projects from compliance-related issues.

Strategic Material Selection Guide for national bolt

What Are the Key Properties of Common Materials Used for National Bolt Fasteners?

When selecting materials for fasteners, it’s crucial to consider their properties and how they align with specific application requirements. Here are four common materials used in the production of national bolt fasteners, analyzed from a B2B perspective.

1. Carbon Steel

Key Properties: Carbon steel fasteners exhibit high tensile strength and excellent hardness, making them suitable for high-stress applications. They typically have a temperature rating of up to 300°C and can withstand moderate pressure.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it an attractive option for bulk orders. However, it is prone to corrosion unless coated, which can add to manufacturing complexity. This material is ideal for applications in construction and automotive industries but may not be suitable for environments with high humidity or corrosive substances.

Impact on Application: Carbon steel fasteners are widely used in structural applications and heavy machinery. However, international buyers must consider the need for protective coatings to enhance corrosion resistance, especially in humid climates like those in parts of Africa and South America.

2. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and can withstand temperatures up to 800°C. It also offers good mechanical properties, making it suitable for a variety of applications.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, which makes it ideal for outdoor and marine applications. However, it is generally more expensive than carbon steel, and its manufacturing process can be more complex due to the need for specialized tooling.

Impact on Application: Stainless steel fasteners are commonly used in the petrochemical and food processing industries, where corrosion resistance is critical. Buyers from Europe and the Middle East may prefer stainless steel due to stringent compliance standards regarding material safety and hygiene.

3. Brass

Key Properties: Brass fasteners are characterized by good corrosion resistance and excellent machinability. They can handle temperatures up to 250°C and are non-magnetic, making them suitable for electrical applications.

Pros & Cons: The primary advantage of brass is its aesthetic appeal and resistance to tarnishing, which is beneficial for decorative applications. However, brass is softer than steel, which may limit its use in high-stress environments. Additionally, it can be more expensive than carbon steel.

Impact on Application: Brass fasteners are often used in plumbing and electrical applications. For international buyers, particularly in South America, it’s essential to consider local regulations regarding the use of brass in plumbing systems to ensure compliance.

Illustrative image related to national bolt

4. Alloy Steel

Key Properties: Alloy steel fasteners are designed to provide enhanced performance characteristics, including higher strength and better wear resistance. They can withstand temperatures of up to 600°C and are often used in high-pressure applications.

Pros & Cons: The key advantage of alloy steel is its superior strength-to-weight ratio, making it ideal for aerospace and automotive applications. However, the manufacturing process can be more complex and costly, which may not be suitable for all buyers.

Impact on Application: Alloy steel fasteners are often required in industries that demand high-performance materials, such as automotive and aerospace. International buyers should be aware of specific standards (like ASTM or DIN) that may apply to alloy steel products in their regions.

Summary Table of Material Selection for National Bolt Fasteners

| Material | Typical Use Case for national bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications in construction | Cost-effective for bulk orders | Prone to corrosion without coating | Low |

| Stainless Steel | Petrochemical and food processing | Excellent corrosion resistance | Higher cost and complex tooling | High |

| Brass | Plumbing and electrical applications | Aesthetic appeal and tarnish resistance | Softer than steel, limiting use | Medium |

| Alloy Steel | Aerospace and automotive applications | Superior strength-to-weight ratio | Higher manufacturing complexity | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for national bolt

What Are the Key Stages in the Manufacturing Process of National Bolts?

The manufacturing process for national bolts involves several crucial stages designed to ensure quality, durability, and performance. Understanding these stages is essential for B2B buyers looking to source reliable fasteners.

Material Preparation: How Is Raw Material Selected and Processed?

The manufacturing journey begins with the selection of high-quality raw materials, typically steel, stainless steel, brass, or specialty alloys. Suppliers often utilize advanced metallurgy techniques to evaluate material properties and ensure they meet specific industry standards. Once selected, the materials undergo preparation, which may include cutting, shaping, and heat treatment to enhance strength and durability.

This stage is critical as it sets the foundation for the overall quality of the fasteners. Buyers should ensure that suppliers can provide documentation regarding material certifications, including chemical composition and mechanical properties, which are essential for compliance with international standards.

What Forming Techniques Are Commonly Used in Bolt Production?

Once the raw materials are prepared, the next stage is forming. Manufacturers employ various techniques such as cold heading, hot forging, and machining to shape the materials into the desired bolt configurations.

- Cold Heading: This method is frequently used for producing bolts and fasteners, where metal is deformed at room temperature. It results in stronger and more precise products due to the refinement of the grain structure.

- Hot Forging: This technique involves heating the metal to a high temperature, making it malleable, and then shaping it under pressure. It is ideal for larger bolts and those requiring specific mechanical properties.

- Machining: For custom or complex designs, machining processes like turning and milling are applied to achieve precise dimensions and tolerances.

Buyers should inquire about the specific forming techniques used and their implications for product quality and performance.

How Is the Assembly Process Managed for Complex Fasteners?

For bolts that require additional components, such as nuts and washers, assembly is a critical stage. This may involve threading, welding, or attaching various parts to create a complete fastener assembly. Manufacturers typically employ automated systems to ensure high efficiency and accuracy during this process.

Quality control measures during assembly ensure that all components fit together correctly and function as intended. B2B buyers should ask suppliers about their assembly processes and the extent to which they can accommodate custom designs.

What Finishing Processes Enhance the Durability of Fasteners?

Finishing processes are vital for enhancing the durability and corrosion resistance of bolts. Common techniques include:

- Coating: This involves applying protective layers, such as zinc plating, black oxide, or galvanization, to prevent rust and wear. The choice of coating depends on the application environment and specific customer requirements.

- Heat Treatment: This process alters the physical and sometimes chemical properties of the fasteners, improving their strength and hardness.

- Passivation: Particularly for stainless steel products, passivation removes free iron and enhances corrosion resistance.

Buyers should seek detailed information about the finishing processes used and any certifications related to corrosion resistance that align with their industry standards.

What Quality Assurance Practices Are Implemented in Bolt Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that every bolt meets stringent standards before reaching the customer.

Which International Standards Govern Bolt Manufacturing and Quality Control?

National Bolt and Nut Corporation adheres to international quality standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates a commitment to continuous improvement, customer satisfaction, and consistent product quality.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API standards for the oil and gas sector may apply. These certifications assure buyers that the fasteners are safe and suitable for their intended applications.

How Are Quality Control Checkpoints Structured Throughout the Manufacturing Process?

Quality control is embedded at multiple checkpoints during the manufacturing process, including:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to catch any deviations from quality standards early on.

- Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing and inspection, including dimensional checks, strength tests, and surface quality assessments.

B2B buyers should confirm that their suppliers maintain detailed records of these QC processes and that they are willing to provide access to audit trails.

What Testing Methods Ensure Compliance and Performance of Fasteners?

Common testing methods for fasteners include tensile testing, hardness testing, and fatigue testing, which assess the mechanical properties of the bolts. Non-destructive testing (NDT) methods, such as ultrasonic testing or magnetic particle inspection, may also be employed to detect internal flaws without damaging the product.

Buyers should request specific test reports and certifications to verify that the fasteners meet their performance requirements and industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is crucial. Here are several strategies to ensure confidence in your supplier’s QA processes:

- Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing environment, processes, and adherence to quality standards.

- Documentation Requests: Suppliers should provide comprehensive documentation, including quality management system certificates, material test reports, and product specifications.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes and product compliance.

Understanding these verification methods can help buyers mitigate risks associated with sourcing fasteners internationally, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Conclusion: How Do Quality Assurance and Manufacturing Processes Impact Your Sourcing Decisions?

The manufacturing processes and quality assurance practices of national bolts are integral to ensuring that the fasteners perform reliably in their intended applications. By understanding these processes, B2B buyers can make informed sourcing decisions, ensuring that they choose suppliers who prioritize quality and compliance with international standards. This knowledge not only enhances operational efficiency but also strengthens supply chain reliability in competitive global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘national bolt’

To streamline the procurement process for national bolts and related fasteners, this practical sourcing guide provides a step-by-step checklist tailored for international B2B buyers. The goal is to ensure that you secure high-quality products that meet your project specifications while establishing reliable supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. This includes dimensions, materials, and any specific finishes needed for your bolts and fasteners.

– Material Considerations: Choose from options like stainless steel, brass, or specialized alloys based on your application needs.

– Dimensional Accuracy: Specify whether you need standard or custom sizes, as this can significantly impact performance and compatibility in your projects.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the industry. Focus on companies known for manufacturing high-quality fasteners.

– ISO Certification: Ensure that suppliers hold relevant certifications, such as ISO, which indicates adherence to international quality standards.

– Industry Experience: Look for suppliers that have a proven track record in your specific industry, whether it’s construction, automotive, or energy.

Step 3: Request Samples for Evaluation

Once you have a shortlist of potential suppliers, request samples of the fasteners to assess their quality. This step is crucial to ensure that the products meet your specifications.

– Quality Assessment: Inspect the samples for dimensional accuracy, material integrity, and finish quality.

– Testing: If applicable, conduct stress tests or other evaluations to determine how well the fasteners perform under expected operational conditions.

Step 4: Evaluate Supplier Capabilities

It’s important to understand the manufacturing capabilities of your chosen suppliers. This will help you gauge whether they can meet your quantity and delivery requirements.

– Production Capacity: Confirm that the supplier can handle your order volume, especially for large projects.

– Lead Times: Discuss typical lead times for both standard and custom orders, as timely delivery is crucial for project schedules.

Step 5: Verify Compliance and Certifications

Ensure that the fasteners you intend to procure comply with industry standards and regulations. This is particularly important for sectors like automotive and aerospace, where safety is paramount.

– Documentation: Request any necessary compliance documentation or certifications that validate the quality and safety of the fasteners.

– Traceability: Ensure that the supplier can provide material traceability, which is essential for quality assurance and accountability.

Step 6: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, negotiate terms that are favorable for both parties. This includes pricing, payment terms, and delivery schedules.

– Volume Discounts: Discuss pricing structures, particularly if you’re making large orders, to secure the best deal.

– Contract Clarity: Ensure that the contract clearly outlines all specifications, delivery timelines, and penalties for non-compliance.

Step 7: Establish Ongoing Communication

After finalizing the contract, maintain open lines of communication with your supplier. This fosters a good relationship and helps address any issues that may arise during the procurement process.

– Regular Updates: Schedule periodic check-ins to discuss order progress and any potential adjustments.

– Feedback Loop: Provide feedback on product performance and service to help your supplier improve and better meet your future needs.

By following this checklist, B2B buyers can ensure a comprehensive and effective sourcing process for national bolts, ultimately leading to successful project outcomes and reliable supplier partnerships.

Comprehensive Cost and Pricing Analysis for national bolt Sourcing

What Are the Key Cost Components in National Bolt Sourcing?

When sourcing national bolts, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of raw materials significantly influences the overall cost. Common materials include various grades of steel, stainless steel, brass, and specialty alloys. Prices fluctuate based on global market conditions and material availability.

-

Labor: Labor costs encompass both direct and indirect expenses related to the workforce involved in manufacturing. Skilled labor may be required for custom fabrication, impacting overall production costs.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, maintenance, and administrative expenses. High-quality production often requires sophisticated machinery and technology, which can add to overhead.

-

Tooling: The creation of custom fasteners often necessitates specialized tooling. Tooling costs can be significant, especially for non-standard sizes and unique designs, and are typically amortized over the production volume.

-

Quality Control (QC): Implementing robust QC measures ensures that products meet required specifications and certifications, which is especially important for industries like automotive and aerospace. The costs associated with QC processes can vary based on the complexity of the product.

-

Logistics: Shipping and handling costs are critical, particularly for international transactions. These costs can vary based on the distance, shipping method, and local tariffs or customs duties.

-

Margin: Suppliers will typically add a margin to cover their operating costs and profit. This margin can vary based on the supplier’s position in the market and the level of competition.

How Do Price Influencers Affect National Bolt Sourcing?

Several factors can influence the pricing of national bolts, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Purchasing in bulk often leads to lower unit prices. Understanding the minimum order quantity (MOQ) is essential for negotiating better terms.

-

Specifications/Customization: Custom bolts that require specific dimensions or materials will generally cost more. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials: As mentioned, the choice of materials directly impacts pricing. Suppliers offering a range of material options may help buyers balance quality and cost.

-

Quality/Certifications: Products that require specific industry certifications (e.g., ISO, ASTM) may incur additional costs due to the rigorous testing and documentation processes involved.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can influence pricing. Established suppliers with a proven track record may charge a premium for reliability.

-

Incoterms: Understanding the agreed-upon Incoterms is vital for assessing total costs, as they dictate who bears the risk and costs at various stages of transportation.

What Are the Best Negotiation and Cost-Efficiency Strategies for International Buyers?

For international B2B buyers, particularly those from diverse regions, employing effective negotiation and cost-efficiency strategies can lead to significant savings.

-

Negotiate Terms: Engage in negotiations to secure favorable payment terms, delivery schedules, and pricing. Building a strong relationship with suppliers can lead to better deals over time.

-

Consider Total Cost of Ownership: Evaluate the total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs. Sometimes, a higher upfront cost may lead to lower long-term expenses due to durability and reliability.

-

Understand Pricing Nuances: Be aware of regional pricing differences and market conditions. For instance, sourcing from a local supplier may reduce shipping costs and lead times.

-

Evaluate Currency Fluctuations: Exchange rates can impact the total cost, especially for international transactions. Locking in rates can help manage financial exposure.

Disclaimer on Indicative Prices

It’s important to note that pricing for national bolts can vary widely based on the factors mentioned above. Buyers should seek custom quotes from suppliers to obtain the most accurate and relevant pricing information tailored to their specific needs.

Alternatives Analysis: Comparing national bolt With Other Solutions

Exploring Alternatives to National Bolt: A Comparative Analysis

In the fasteners industry, businesses often seek out various solutions to meet their specific operational needs. National Bolt is a prominent provider of custom fasteners, but it’s essential to consider alternative solutions that may offer distinct advantages depending on the application, budget, and operational requirements. Below, we compare National Bolt with two viable alternatives: Standardized Fasteners and 3D Printed Fasteners.

| Comparison Aspect | National Bolt | Standardized Fasteners | 3D Printed Fasteners |

|---|---|---|---|

| Performance | High durability; custom solutions | Reliable but limited to standards | Varies widely; can be tailored |

| Cost | Higher due to customization | Generally lower; mass-produced | Can be high due to material costs |

| Ease of Implementation | Requires detailed specifications | Simple ordering process | Requires design and printing time |

| Maintenance | Low; designed for longevity | Moderate; standard replacements | Varies; may require post-processing |

| Best Use Case | Heavy machinery, specialized industries | General use in various sectors | Prototyping, complex geometries |

Understanding Standardized Fasteners: Pros and Cons

Standardized fasteners are pre-manufactured components available in common sizes and materials. They are typically less expensive due to mass production and can be easily sourced from multiple suppliers. This makes them suitable for general applications where specific customization is not critical. However, they may not meet the unique requirements of specialized industries, such as heavy machinery or aerospace, where performance and reliability are paramount. In these cases, businesses may face challenges in ensuring compatibility and durability.

Evaluating 3D Printed Fasteners: Advantages and Disadvantages

3D printed fasteners represent an innovative approach to manufacturing. They allow for significant customization and rapid prototyping, making them ideal for projects that require unique designs or complex geometries. The ability to produce small batches on-demand can reduce inventory costs. However, the technology can be costly, and the performance of 3D printed materials can vary significantly depending on the printing process and materials used. Additionally, these fasteners may require further processing to achieve the desired strength and surface finish, adding to the overall time and cost.

Conclusion: How to Choose the Right Fastening Solution

When selecting the best fastening solution, B2B buyers should assess their specific project requirements, including the operational environment, performance standards, and budget constraints. National Bolt excels in providing high-quality custom fasteners tailored to unique specifications, making it an excellent choice for industries with stringent demands. On the other hand, standardized fasteners may suffice for general applications, while 3D printed fasteners can be a game-changer for innovative designs and prototypes. By carefully evaluating these alternatives, businesses can ensure they select the most suitable fastener solution for their needs, enhancing both efficiency and productivity.

Essential Technical Properties and Trade Terminology for national bolt

What are the Essential Technical Properties of National Bolts?

When considering national bolts for your projects, understanding key technical properties is crucial to ensure they meet your operational needs. Here are some critical specifications:

-

Material Grade: The material grade defines the strength and durability of the bolt. Common grades include ASTM A307 (low carbon steel) and ASTM A325 (high-strength steel). Selecting the appropriate grade is essential for applications subject to high stress or environmental conditions, ensuring longevity and safety.

-

Tensile Strength: This property measures the maximum amount of tensile (pulling) stress a bolt can withstand before failing. Typically expressed in psi (pounds per square inch), tensile strength is vital for load-bearing applications. For example, bolts used in construction must have high tensile strength to support structural integrity.

-

Diameter and Length: The diameter and length of a bolt are critical for compatibility with nuts and other fastening components. These dimensions affect load distribution and the overall strength of the assembly. Accurate sizing ensures proper fit, reducing the risk of mechanical failure.

-

Thread Type and Pitch: Bolts can have various thread types (e.g., coarse or fine) and pitches, which influence the ease of installation and the strength of the connection. Coarse threads are generally easier to install and provide better grip in softer materials, while fine threads offer better tensioning and are ideal for precision applications.

-

Corrosion Resistance: This property is crucial for bolts used in harsh environments. Different finishes (such as zinc plating or hot-dip galvanizing) enhance corrosion resistance, prolonging the life of the fasteners in applications exposed to moisture, chemicals, or extreme temperatures.

-

Tolerance: Tolerance refers to the allowable variation in dimensions. High tolerance levels ensure that bolts fit precisely within their intended applications. This is particularly important in industries like automotive or aerospace, where precision is paramount for safety and performance.

What are Common Trade Terms in the National Bolt Industry?

Familiarity with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications helps in sourcing the right bolts that meet your equipment requirements.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQ is essential for budgeting and inventory management, as it affects procurement strategies.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing for specific products or services. It is a critical step in the procurement process, allowing buyers to compare offers and negotiate better terms.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowing Incoterms is vital for understanding shipping costs, risks, and obligations, especially when dealing with international suppliers.

-

Lead Time: This term refers to the time taken from placing an order to delivery. In fast-paced industries, understanding lead times helps in planning projects and managing timelines effectively.

-

Heat Treatment: A process applied to metals to alter their physical and sometimes chemical properties. Heat treatment can enhance the strength and durability of bolts, making it a critical consideration for applications in demanding environments.

Understanding these technical properties and trade terms can significantly enhance your ability to make informed decisions regarding national bolts, ensuring that your projects meet quality and safety standards.

Navigating Market Dynamics and Sourcing Trends in the national bolt Sector

What Are the Key Market Dynamics and Trends Influencing the National Bolt Sector?

The national bolt sector is experiencing robust growth driven by several global factors. A primary driver is the increasing demand for durable, high-quality fasteners across various industries, including construction, automotive, and aerospace. The rise of infrastructure projects in developing regions, especially in Africa and South America, is pushing the need for reliable fastening solutions. Additionally, the ongoing transition towards renewable energy sources has amplified the demand for specialized fasteners used in solar and wind energy installations.

Current sourcing trends indicate a shift towards digital procurement solutions, allowing international B2B buyers to streamline their purchasing processes. E-commerce platforms and online marketplaces are becoming essential for sourcing fasteners, enabling buyers to compare products and suppliers efficiently. Moreover, there is a growing emphasis on customization, as companies seek tailored solutions to meet specific project requirements. This trend is particularly relevant for buyers in the Middle East and Europe, where industry standards often necessitate non-standard sizes and unique materials.

Emerging technologies such as automation and AI are also reshaping the manufacturing landscape, leading to improved production efficiency and reduced lead times. For international buyers, this translates into more reliable supply chains and faster turnaround times, crucial for maintaining competitive advantage in their respective markets.

How Is Sustainability and Ethical Sourcing Shaping the National Bolt Industry?

Sustainability has become a pivotal concern in the national bolt sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of fastener production, including resource extraction and manufacturing processes, necessitates a focus on sustainable sourcing. International B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to reducing their carbon footprint and implementing waste reduction strategies.

Ethical sourcing is equally critical, as companies recognize the importance of maintaining transparent supply chains. Buyers from Africa, South America, and Europe are seeking manufacturers who comply with international labor standards and ethical practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria in supplier selection.

In addition, the use of ‘green’ materials is gaining traction. Manufacturers are exploring alternative materials, such as recycled metals and eco-friendly coatings, to appeal to environmentally conscious buyers. By investing in sustainable practices and materials, suppliers can not only meet regulatory requirements but also enhance their brand reputation and attract a broader customer base.

What Is the Historical Context of the National Bolt Sector?

The national bolt sector has evolved significantly over the past few decades. Initially dominated by traditional manufacturing processes, the industry has embraced technological advancements that have transformed production methods. The introduction of CNC (Computer Numerical Control) machining and automated assembly lines has increased efficiency and precision, allowing manufacturers to meet the growing demand for custom fasteners.

Historically, the sector faced challenges related to quality control and supply chain disruptions, particularly during economic downturns. However, the establishment of stringent quality standards and certifications, such as ISO 9001, has enhanced product reliability. This evolution has positioned the national bolt industry as a critical component in global supply chains, particularly for B2B buyers seeking high-quality, durable fastening solutions.

As the industry continues to adapt to market demands and technological innovations, the focus on quality, sustainability, and ethical practices will likely shape its future trajectory, making it essential for international buyers to stay informed and engaged with their suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of national bolt

-

How can I ensure the quality of the national bolt products I purchase?

To ensure the quality of national bolt products, it’s crucial to work with ISO-certified manufacturers, as they follow stringent quality management systems. Request certifications related to materials and manufacturing processes, such as A2LA accreditation, which verifies compliance with industry standards. Conducting a factory audit or reviewing customer testimonials can also provide insights into the manufacturer’s reputation and product reliability. Additionally, specify your quality requirements in the purchase order to ensure that the supplier meets your standards. -

What are the customization options available for national bolts?

National bolt manufacturers often provide extensive customization options to meet specific project needs. This includes variations in size, material, finish, and bolt type. For instance, you can request custom bolts made from stainless steel for corrosion resistance or special finishes like black oxide for aesthetic purposes. Discuss your requirements with the supplier early in the sourcing process to ensure they can accommodate your needs and provide a detailed quote. -

What is the minimum order quantity (MOQ) for national bolt products?

Minimum order quantities (MOQs) for national bolt products can vary significantly based on the manufacturer and the specific product type. Typically, custom bolts may have higher MOQs due to the specialized production process, while standard items might have lower MOQs. It’s advisable to communicate your purchasing needs upfront and inquire about bulk pricing options, especially if you’re looking to establish a long-term partnership for recurring orders. -

What payment terms can I expect when sourcing national bolts?

Payment terms for national bolts can vary by supplier, but common practices include upfront deposits ranging from 30% to 50%, with the balance due upon delivery or after inspection. Some suppliers may offer flexible payment options, including letters of credit for international transactions, which can enhance security for both parties. Always clarify payment terms before finalizing your order to avoid misunderstandings and ensure smooth transaction processes. -

How do I vet potential suppliers for national bolt products?

To effectively vet suppliers, start by checking their certifications and industry experience. Look for ISO certifications and customer references to gauge their reliability and product quality. Conduct background research on their financial stability and market reputation through online reviews or industry reports. Engaging in a conversation with the supplier can also reveal their commitment to customer service and responsiveness, which are critical in B2B relationships. -

What logistics considerations should I keep in mind when importing national bolts?

When importing national bolts, consider factors such as shipping methods, customs regulations, and delivery timelines. Work with suppliers who have experience in international shipping to ensure compliance with import/export laws. Additionally, discuss logistics arrangements upfront, including who will handle shipping costs and responsibilities. It’s beneficial to have a clear understanding of delivery schedules to align with your project timelines. -

What are the common industries that require national bolt products?

National bolt products are widely utilized across various industries, including construction, automotive, agriculture, mining, and petrochemicals. Each sector has specific requirements; for example, construction may demand high-strength bolts for structural integrity, while the automotive industry often requires precise specifications for safety. Understanding your industry’s unique needs can help you communicate effectively with suppliers and select the right fasteners for your applications. -

How can I handle quality assurance (QA) for national bolt purchases?

Implementing a robust quality assurance process is crucial when sourcing national bolts. This can include establishing clear specifications in your purchase agreements, conducting pre-shipment inspections, and requesting quality control documentation from the supplier. Consider collaborating with third-party QA agencies for independent assessments of products before they reach your facility. This proactive approach will help mitigate risks and ensure that the fasteners meet your quality standards upon arrival.

Top 5 National Bolt Manufacturers & Suppliers List

1. National Bolt – Industrial Supply

Domain: national-bolt.com

Registered: 2002 (23 years)

Introduction: National Bolt and Industrial Supply Co., Inc. offers a wide range of products including abrasives, cutting tools, fasteners, brushes, mechanical anchors, safety supplies, tools, MRO supplies, and welding supplies. They carry brands such as ACT, AERVOE®, Armour Guard, BEST WELDS®, B’LASTER®, Blue Star, Bondhus, CGW Abrasives, Chem Star, Coilhose®, Diablo, Drillco Cutting Tools, ESAB, and many other…

2. NBIS – Promotions & Lunch

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, NBIS – Promotions & Lunch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. National Bolt & Nut Corp – Custom Large Diameter Fasteners

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, National Bolt & Nut Corp – Custom Large Diameter Fasteners, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. National Bolt & Nut Corporation – High-Quality Bolts & Nuts

Domain: industrial-bolts.net

Registered: 2002 (23 years)

Introduction: National Bolt & Nut Corporation is a leading manufacturer and distributor of high-quality bolts and nuts, founded in 1977. They offer a wide variety of bolt products including standard bolts, hex bolts, carriage bolts, anchor bolts, flange bolts, and more, available in various sizes, materials, and finishes. The company emphasizes the quality of its products, using only high-quality materials and …

5. Yelp – Best Nuts and Bolts

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: TOP 10 BEST Nuts and Bolts near Lincoln Acres, CA 91950 – Updated 2025 – Yelp. Sponsored Results: Downtown Ace Hardware – 4.4 stars, 234 reviews, 675 6th Ave, San Diego, CA 92101, offers great customer service. Grand Entrances – 3.6 stars, 60 reviews, 7816 Miramar Rd, San Diego, CA 92126, specializes in custom entry doors and hardware. Clairemont Equipment Rentals – 2.9 stars, 20 reviews, 4726 Con…

Strategic Sourcing Conclusion and Outlook for national bolt

As the demand for high-quality fasteners continues to rise across various industries, strategic sourcing of custom bolts and fasteners from National Bolt & Nut Corporation presents an invaluable opportunity for international B2B buyers. By prioritizing quality, reliability, and customization, businesses can ensure they receive products tailored to their specific needs, enhancing operational efficiency and reducing downtime.

National Bolt’s extensive range of products—from standard to bespoke solutions—combined with their ISO certification and commitment to excellence, positions them as a trusted partner in the fastener industry. With rapid turnaround times, including a 24-hour emergency service, buyers can rely on timely deliveries, essential for maintaining project timelines.

Looking ahead, the evolving landscape of global manufacturing and the increasing emphasis on sustainable practices will further shape the fastener market. International buyers from regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to engage with National Bolt, leveraging their expertise to meet the challenges of tomorrow. Explore the potential of strategic sourcing today, and ensure your business remains competitive in an increasingly interconnected world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.