Is Your Motor And Reducer Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for motor and reducer

In the fast-evolving landscape of industrial machinery, sourcing reliable motors and reducers can pose significant challenges for B2B buyers across diverse markets. With an array of options available, understanding the specific needs of your application—whether in manufacturing, automotive, or renewable energy sectors—becomes crucial. This guide aims to demystify the complexities surrounding motors and reducers by offering a comprehensive overview of various types, applications, and the critical factors to consider when vetting suppliers.

International B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Germany—will find this guide invaluable. It not only addresses the nuances of selecting the right motor and reducer for your operational demands but also delves into cost considerations, supplier reliability, and maintenance best practices. By equipping buyers with actionable insights and a structured approach to sourcing, this guide empowers informed purchasing decisions that align with strategic business goals.

Navigating the global market for motors and reducers requires a keen understanding of both technical specifications and market dynamics. As you explore the contents of this guide, you’ll gain the knowledge necessary to make confident choices that enhance operational efficiency and drive long-term value for your organization.

Understanding motor and reducer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motors | Simple design, robust, low maintenance | Manufacturing, HVAC, pumps | Pros: Cost-effective, durable. Cons: Lower efficiency at variable speeds. |

| DC Motors | High torque at low speeds, adjustable speed | Robotics, conveyors, automotive applications | Pros: Excellent speed control. Cons: Requires maintenance, can be more expensive. |

| Gear Reducers | Reduces speed while increasing torque | Heavy machinery, automotive, conveyor systems | Pros: High torque output. Cons: Increased complexity, potential for wear. |

| Servo Motors | Precise control, high efficiency, closed-loop systems | CNC machines, robotics, automated systems | Pros: Exceptional accuracy and speed. Cons: Higher upfront costs. |

| Planetary Gear Reducers | Compact design, high torque density | Aerospace, automotive, industrial machinery | Pros: Space-efficient, high efficiency. Cons: More complex, can be pricier. |

What Are AC Induction Motors and Their B2B Suitability?

AC induction motors are widely utilized due to their simple construction and reliability. They operate on alternating current and are favored in applications where cost-effectiveness and durability are essential. Commonly found in manufacturing and HVAC systems, these motors require minimal maintenance, making them appealing for businesses looking to reduce operational downtime. However, they may not perform as efficiently at variable speeds, which is a consideration for buyers requiring precise speed control.

How Do DC Motors Stand Out for Specific Applications?

DC motors offer unique advantages such as high torque at low speeds and excellent speed control, making them ideal for applications in robotics and conveyor systems. Their ability to adjust speed seamlessly is beneficial for processes requiring precision. However, they necessitate regular maintenance and can be more expensive than their AC counterparts. Buyers in industries where fine control and torque are critical should weigh these factors when considering DC motors.

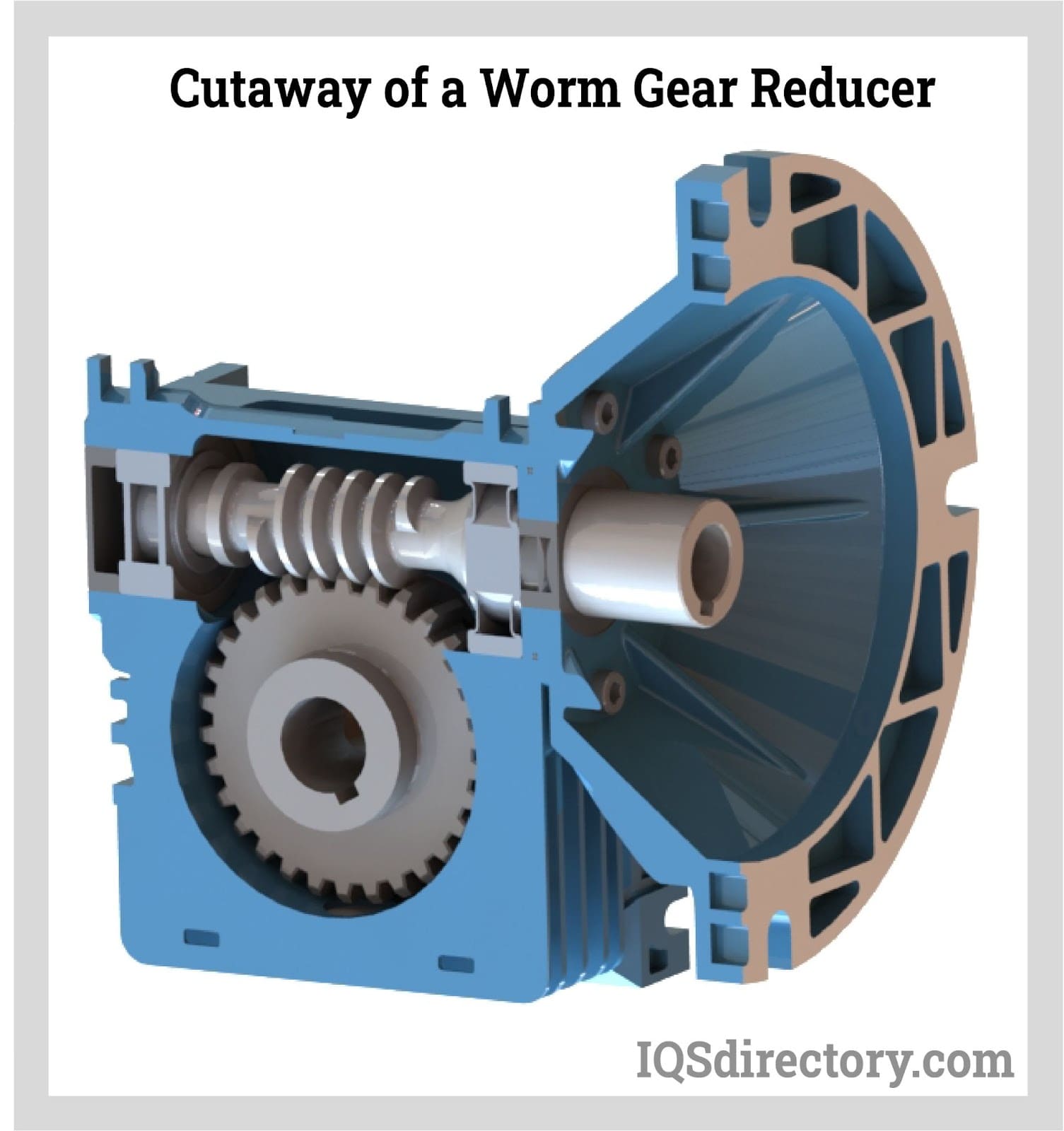

Why Choose Gear Reducers for Heavy Machinery?

Gear reducers are designed to decrease speed while increasing torque, making them essential in heavy machinery and automotive applications. They are characterized by their ability to handle significant loads efficiently. While they provide high torque output, their complexity can lead to wear over time, which is a consideration for maintenance budgets. Businesses focused on durability and performance in demanding environments will find gear reducers to be a vital component of their operations.

What Advantages Do Servo Motors Offer in Automation?

Servo motors are known for their precision and efficiency, operating in closed-loop systems that allow for real-time adjustments. They are particularly valuable in CNC machines and automated systems where accuracy is paramount. Although they come with higher initial costs, their long-term benefits, including reduced energy consumption and enhanced performance, often justify the investment. B2B buyers looking for automation solutions should prioritize servo motors for applications requiring high levels of control.

What Makes Planetary Gear Reducers Ideal for Compact Applications?

Planetary gear reducers are recognized for their compact design and high torque density, making them suitable for aerospace and industrial machinery applications. Their space-efficient nature allows for integration into limited spaces without sacrificing performance. However, their complexity can result in higher costs, which buyers need to consider against the performance benefits. Companies in industries where space and efficiency are critical will find planetary gear reducers to be an advantageous choice.

Key Industrial Applications of motor and reducer

| Industry/Sector | Specific Application of motor and reducer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced efficiency in material handling | Reliability, compatibility with existing systems, and energy efficiency. |

| Agriculture | Irrigation Systems | Improved water distribution and crop yield | Durability in harsh conditions, energy consumption, and maintenance support. |

| Automotive | Assembly Line Automation | Increased production speed and reduced labor costs | Precision engineering, compliance with safety standards, and supplier reliability. |

| Mining | Material Transport Systems | Optimized resource extraction and transport | Resistance to extreme environments, load capacity, and service availability. |

| Food Processing | Packaging Machinery | Streamlined operations and reduced spoilage | Hygiene standards, energy efficiency, and adaptability to various products. |

How Are Motors and Reducers Used in Manufacturing Conveyor Systems?

In the manufacturing sector, motors and reducers are integral to conveyor systems, facilitating the movement of materials along production lines. These systems enhance operational efficiency by automating the transport of goods, reducing manual labor, and minimizing errors. For international buyers, especially in Africa and South America, sourcing reliable motors that can withstand varying power supply conditions is crucial. Additionally, compatibility with existing systems and energy efficiency are key considerations to optimize overall productivity and cost-effectiveness.

What Role Do Motors and Reducers Play in Agriculture Irrigation Systems?

In agriculture, motors and reducers power irrigation systems, ensuring efficient water distribution across fields. This technology directly impacts crop yields by providing consistent water flow, which is essential in regions prone to drought, such as parts of the Middle East and Africa. Buyers should prioritize the durability of these components, as they must withstand harsh environmental conditions. Energy consumption is another critical factor, as efficient systems can significantly reduce operational costs, making them more sustainable for farmers.

How Are Motors and Reducers Essential in Automotive Assembly Line Automation?

The automotive industry relies heavily on motors and reducers for assembly line automation, where they drive machinery that assembles vehicles. These systems enhance production speed and accuracy, reducing labor costs while increasing output. For B2B buyers, especially in Europe like Germany, precision engineering is vital to ensure that components meet strict safety and quality standards. Additionally, sourcing from reliable suppliers who offer comprehensive support and maintenance services can mitigate downtime and ensure smooth operations.

How Do Motors and Reducers Optimize Material Transport in Mining?

In mining operations, motors and reducers are crucial for material transport systems, which move extracted resources efficiently from the mine to processing facilities. These systems help optimize resource extraction and transport, directly affecting productivity and profitability. Buyers in regions with challenging environments, such as South America, must consider the load capacity and resistance to extreme conditions when sourcing these components. Additionally, having a reliable service network for maintenance is essential to minimize operational disruptions.

What Benefits Do Motors and Reducers Provide in Food Processing Packaging Machinery?

In the food processing industry, motors and reducers are used in packaging machinery to streamline operations and reduce spoilage. By automating packaging processes, businesses can achieve higher efficiency and maintain product integrity. International buyers, particularly in regions with strict hygiene standards, should focus on sourcing motors that comply with food safety regulations. Energy efficiency is also a vital consideration, as it can significantly impact operational costs in high-volume production environments.

3 Common User Pain Points for ‘motor and reducer’ & Their Solutions

Scenario 1: Difficulty in Matching Motor and Reducer Specifications

The Problem: B2B buyers often encounter challenges when trying to match the specifications of motors and reducers to their specific applications. For instance, a manufacturer in the automotive sector may require a motor and reducer combination that delivers precise torque and speed but finds it difficult to identify components that meet these criteria. This mismatch can lead to inefficient operations, increased energy consumption, and ultimately, higher costs. Furthermore, the complexity of technical specifications can overwhelm procurement teams, especially when facing tight deadlines.

The Solution: To effectively source the right motor and reducer, buyers should start by conducting a thorough analysis of their application requirements, including load capacity, speed, torque, and environmental conditions. Utilizing tools such as performance calculators and datasheets from manufacturers can aid in understanding the specifications better. Additionally, engaging with suppliers who offer technical consultation services can provide insights into the best combinations for specific applications. Establishing a close partnership with a reputable supplier who understands the industry can also facilitate tailored solutions, ensuring that the selected components enhance operational efficiency.

Scenario 2: High Failure Rates Due to Inadequate Maintenance

The Problem: Many companies experience high failure rates of motors and reducers due to inadequate maintenance practices. This scenario is particularly common in industries like mining and manufacturing, where equipment operates in harsh environments. Without regular maintenance and proper lubrication, motors can overheat, leading to breakdowns and costly downtime. Furthermore, procurement teams may struggle to allocate resources effectively for maintenance, resulting in a reactive rather than proactive approach.

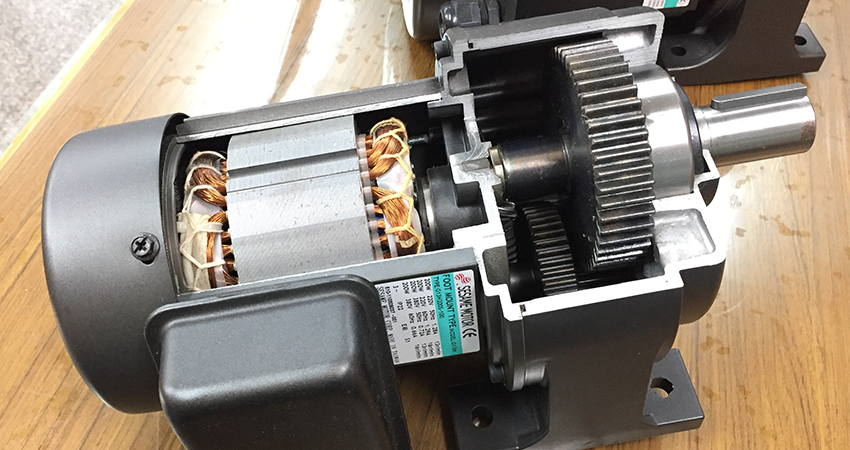

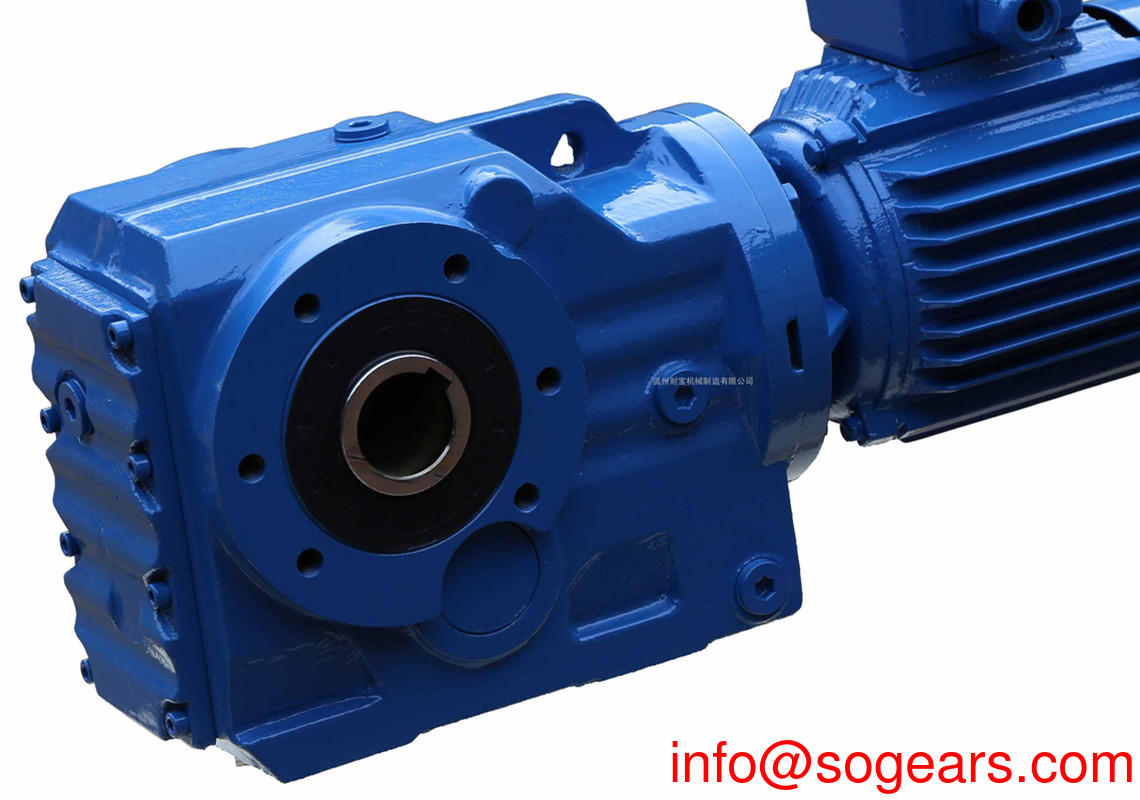

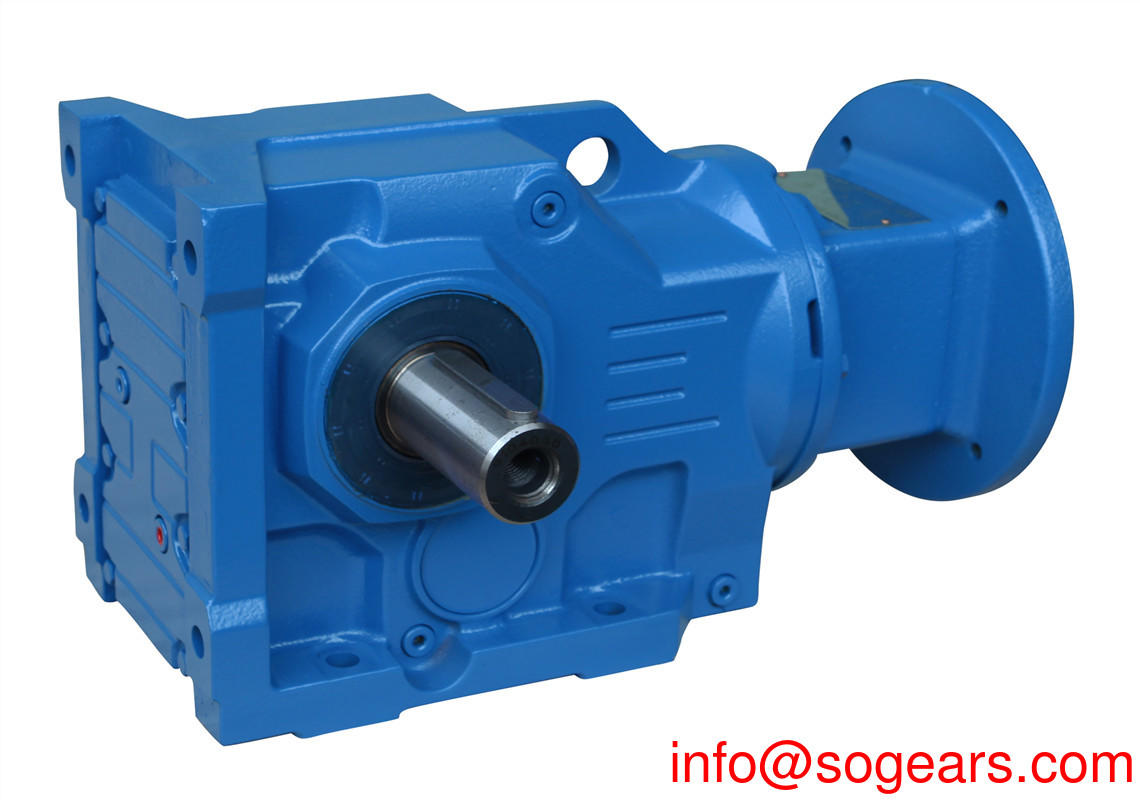

Illustrative image related to motor and reducer

The Solution: Implementing a robust preventive maintenance program is crucial. Buyers should invest in training for their maintenance teams to understand the specific maintenance needs of their motor and reducer systems. Regular checks on lubrication levels, alignment, and overall equipment condition can significantly extend the lifespan of these components. Additionally, integrating IoT sensors can provide real-time monitoring of performance metrics, allowing for early detection of potential issues. This proactive approach not only minimizes downtime but also optimizes the procurement budget by reducing the frequency of emergency repairs.

Scenario 3: Cost Overruns from Inefficient Energy Use

The Problem: In many sectors, especially in developing regions, energy costs can constitute a significant portion of operational expenses. Companies often find that their existing motors and reducers are not energy efficient, leading to unexpected cost overruns. This issue may arise from outdated technology or poorly matched components, which can result in excessive energy consumption and operational inefficiencies. B2B buyers may face pressure to reduce costs while maintaining productivity, creating a challenging balance.

The Solution: To address this pain point, buyers should prioritize energy-efficient motor and reducer options, such as those that meet or exceed energy standards like IE3 or IE4. Conducting an energy audit can help identify underperforming equipment and areas for improvement. Additionally, considering variable frequency drives (VFDs) can optimize motor operation by adjusting the speed and torque according to the load requirements. This not only reduces energy consumption but also enhances process control. Establishing a long-term plan for upgrading to more efficient technologies will yield significant savings and support sustainability initiatives, making a compelling business case for investment.

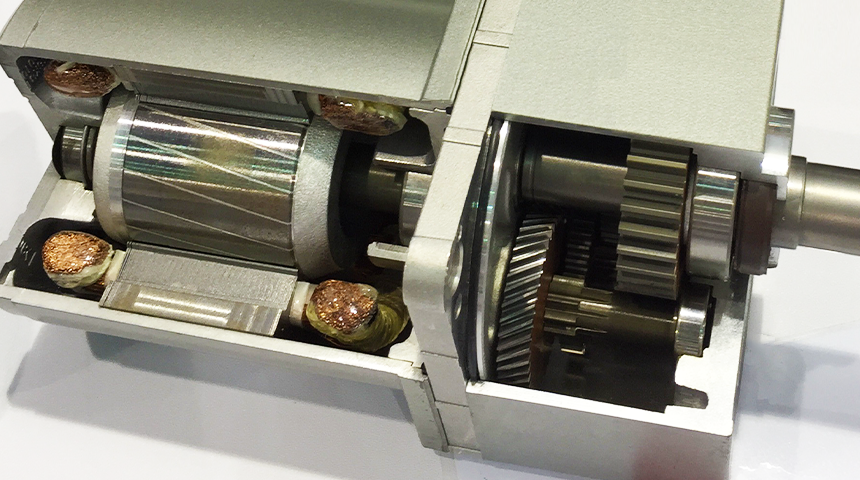

Illustrative image related to motor and reducer

Strategic Material Selection Guide for motor and reducer

What Are the Key Materials for Motors and Reducers?

When selecting materials for motors and reducers, several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in these applications: aluminum, steel, stainless steel, and plastic composites.

How Does Aluminum Perform in Motors and Reducers?

Aluminum is a lightweight material often used in motor housings and components due to its excellent thermal conductivity and resistance to corrosion. Its typical temperature rating can reach up to 150°C, making it suitable for various environments.

Pros: Aluminum’s lightweight nature aids in reducing overall system weight, which can enhance energy efficiency and ease of installation. It also offers good machinability, allowing for complex designs.

Cons: However, aluminum has lower tensile strength compared to steel, which may limit its use in high-load applications. Additionally, it can be more expensive than some alternatives, depending on the alloy used.

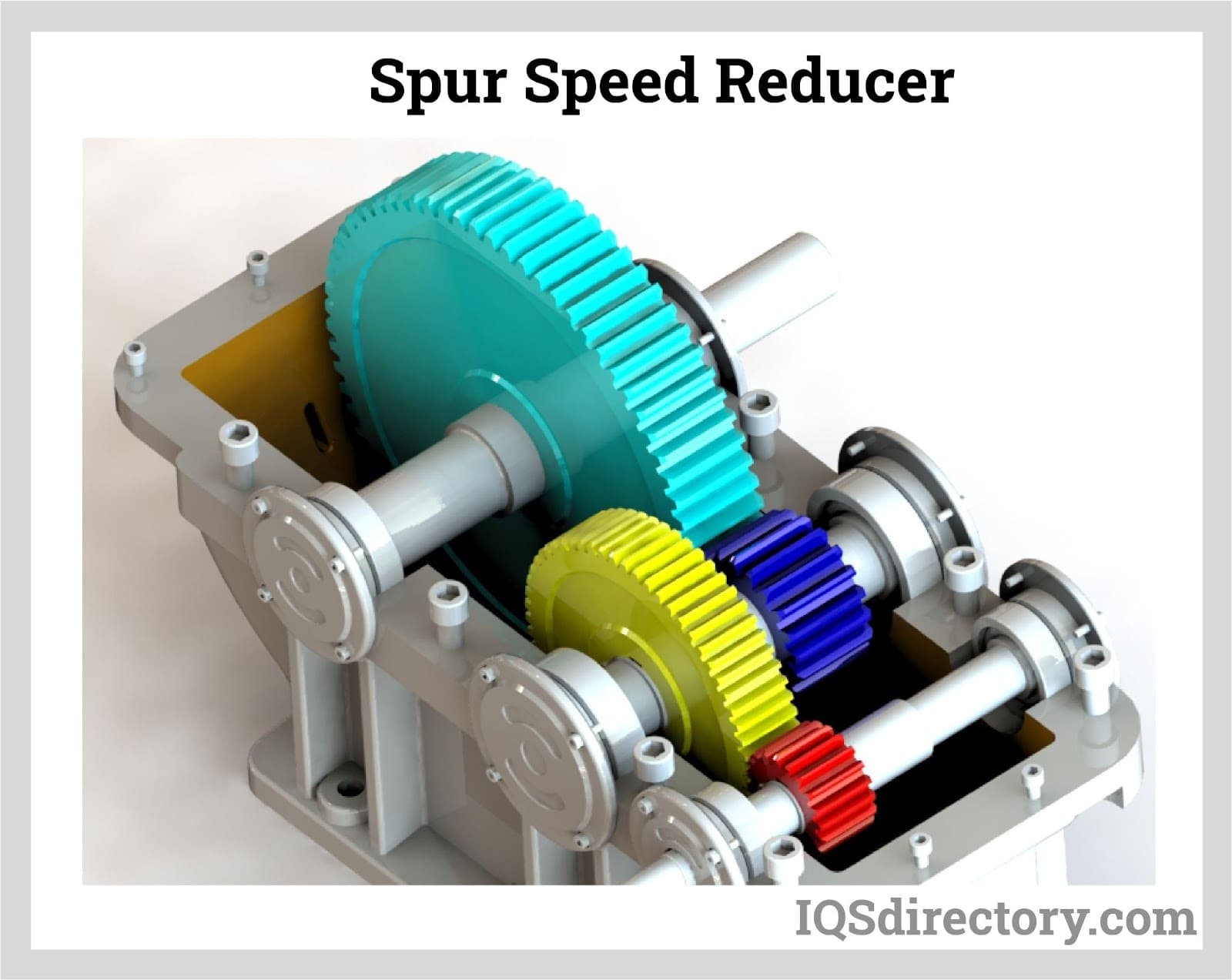

Illustrative image related to motor and reducer

Impact on Application: Aluminum is compatible with various media, including oils and lubricants, but care should be taken in environments with high salt or acidic conditions, as corrosion can occur.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure that aluminum components meet standards such as ASTM B221 or EN 573, which govern the quality and performance of aluminum alloys.

What Role Does Steel Play in Motors and Reducers?

Steel is a traditional choice for motors and reducers due to its high strength and durability. It can withstand high temperatures (up to 300°C) and pressures, making it ideal for heavy-duty applications.

Pros: The primary advantage of steel is its robustness, which allows it to handle significant loads and stresses. It is also relatively cost-effective compared to other materials.

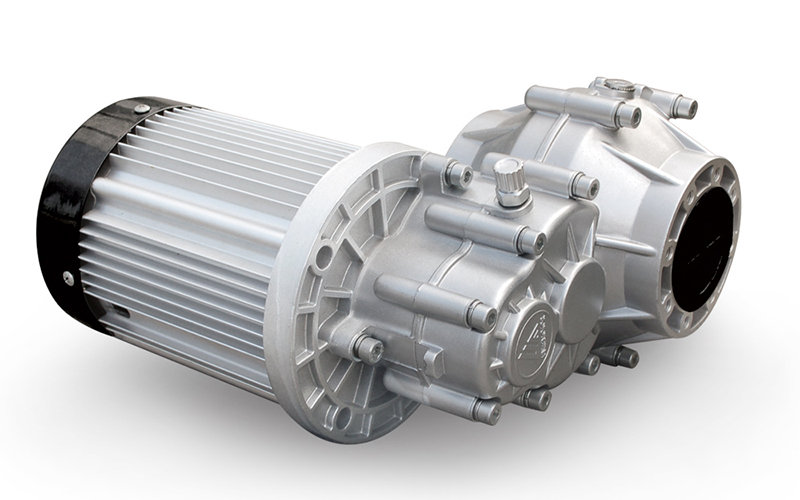

Illustrative image related to motor and reducer

Cons: On the downside, steel is heavier than aluminum and can be prone to rust if not properly coated or treated, especially in humid environments.

Impact on Application: Steel is compatible with a wide range of media, including oils and coolants, but its susceptibility to corrosion necessitates protective coatings in certain environments.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM A36 or DIN 17100, which specify the mechanical properties of structural steel.

Illustrative image related to motor and reducer

Why Choose Stainless Steel for Motors and Reducers?

Stainless steel is known for its exceptional corrosion resistance and is often used in applications exposed to harsh environments, including food processing and marine applications. It can operate effectively at temperatures up to 250°C.

Pros: The primary advantage of stainless steel is its resistance to corrosion and staining, which extends the lifespan of components. It also maintains its strength at high temperatures.

Cons: However, stainless steel is generally more expensive than carbon steel and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with various media, including water and chemicals, making it suitable for diverse applications.

Considerations for International Buyers: Compliance with standards like ASTM A240 or EN 10088 is essential for ensuring quality and performance in international markets.

How Do Plastic Composites Fit into Motor and Reducer Applications?

Plastic composites are increasingly used in motors and reducers, particularly in non-load-bearing applications. They offer excellent insulation properties and can operate effectively at temperatures up to 100°C.

Pros: The lightweight nature of plastic composites contributes to energy savings and ease of handling. They also resist corrosion and are often less expensive than metals.

Cons: The main limitation is their lower strength compared to metals, which can restrict their use in high-stress applications.

Impact on Application: Plastic composites are compatible with various media but may not withstand high temperatures or aggressive chemicals.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM D638, which governs the mechanical properties of plastics.

Summary Table of Material Selection for Motors and Reducers

| Material | Typical Use Case for motor and reducer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Motor housings and lightweight components | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Steel | Heavy-duty applications | High strength and durability | Prone to rust without treatment | Low |

| Stainless Steel | Harsh environments (e.g., food processing) | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic Composites | Non-load-bearing components | Lightweight and cost-effective | Limited strength | Low |

This guide provides a comprehensive overview of material selection for motors and reducers, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for motor and reducer

What Are the Key Stages in the Manufacturing Process of Motors and Reducers?

Manufacturing motors and reducers involves several critical stages that ensure the production of high-quality, reliable products. The process generally includes material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing and preparing raw materials, such as metals and polymers, that meet specific industry standards. Common materials include steel for casings, copper for windings, and various alloys for gears. Suppliers must ensure that materials are free from defects and meet the required specifications.

-

Forming: In this stage, materials undergo processes such as machining, forging, or die-casting. For motors, the stator and rotor are precisely machined to tight tolerances to ensure efficient operation. Reducers often require gear cutting, where precision milling or grinding techniques are employed to achieve the necessary gear profiles.

-

Assembly: This phase involves the integration of various components. For motors, this includes winding the coils, assembling the rotor and stator, and fitting the bearings. Reducers require the assembly of gears, shafts, and housing. Each assembly step must be conducted under controlled conditions to prevent contamination and ensure accuracy.

-

Finishing: The final stage includes processes such as painting, coating, or applying surface treatments to enhance durability and corrosion resistance. Additionally, dynamic balancing may be performed to minimize vibrations during operation. Quality checks are integrated throughout this stage to ensure compliance with design specifications.

What Quality Assurance Practices Are Essential in Motor and Reducer Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of motors and reducers. Adhering to international standards and implementing systematic quality control checkpoints helps ensure that products meet customer expectations and regulatory requirements.

-

International Standards Compliance: Adopting standards such as ISO 9001 helps manufacturers establish a quality management system that focuses on continuous improvement and customer satisfaction. Other relevant certifications may include CE marking for compliance with European safety standards and API (American Petroleum Institute) specifications for products used in the oil and gas sector.

-

Quality Control Checkpoints: Implementing a robust quality control system involves several checkpoints:

– Incoming Quality Control (IQC): This stage checks raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor critical parameters and processes. This includes dimensional checks, visual inspections, and performance tests.

– Final Quality Control (FQC): Before shipping, finished products undergo thorough testing to verify functionality and compliance with specifications. This may include electrical testing for motors and load testing for reducers. -

Common Testing Methods: Various testing methods are employed to validate product quality, including:

– Electrical Testing: Ensuring motors operate efficiently under specified conditions.

– Mechanical Testing: Assessing the strength and durability of components under load.

– Vibration Analysis: Identifying potential issues that could lead to failure in operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure they receive reliable products. Here are several strategies:

-

Supplier Audits: Conducting regular audits allows buyers to assess a supplier’s quality management practices and production capabilities. This includes evaluating their adherence to international standards and internal quality protocols.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, which should include information on testing results, compliance certifications, and non-conformance incidents. These documents provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased assessment of a supplier’s manufacturing and quality control processes. These inspections can be particularly valuable for buyers entering new markets or working with unfamiliar suppliers.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances in quality control that can vary by region and industry:

-

Cultural and Regulatory Differences: Different countries may have varying expectations regarding quality standards. Understanding local regulations and compliance requirements is crucial, especially for markets like Saudi Arabia and Germany, where strict adherence to standards is enforced.

-

Communication Barriers: Language and cultural differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and using standardized documentation can help mitigate these risks.

-

Logistical Considerations: International shipping can introduce risks related to product damage and compliance with import regulations. Buyers should ensure that suppliers have robust packaging and handling procedures to protect products during transit.

By understanding the manufacturing processes and quality assurance practices for motors and reducers, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motor and reducer’

Introduction

Sourcing motors and reducers can be a complex process, especially for international B2B buyers looking to optimize efficiency and performance in their operations. This checklist provides a step-by-step guide to help you navigate the procurement process, ensuring you select the right products and suppliers to meet your technical requirements and business goals.

Illustrative image related to motor and reducer

Step 1: Define Your Technical Specifications

Clearly outlining your technical needs is the first step in sourcing motors and reducers. Consider factors such as torque requirements, speed, and power ratings, as well as the specific application for which the equipment will be used. This clarity will help you communicate effectively with suppliers and ensure that you receive products that meet your operational demands.

- Torque and Speed: Determine the necessary torque and speed ranges for your application.

- Power Rating: Specify the required power output to ensure compatibility with your machinery.

Step 2: Research Market Trends and Innovations

Staying informed about the latest market trends and technological advancements is essential. Understanding industry innovations can help you make informed decisions about the types of motors and reducers that will best suit your needs, including energy-efficient options or those with enhanced control features.

- Energy Efficiency: Look for products that offer lower energy consumption without sacrificing performance.

- Smart Technology: Consider motors and reducers that integrate with IoT for improved monitoring and control.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial. Request company profiles, case studies, and references from other businesses in similar industries or regions. This step ensures that you choose a reliable partner capable of delivering quality products and services.

Illustrative image related to motor and reducer

- Supplier Experience: Look for suppliers with a proven track record in your industry.

- Client Testimonials: Seek feedback from previous customers to gauge satisfaction and reliability.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers hold relevant certifications and comply with industry standards. This verification is essential for quality assurance and can help you avoid potential legal and operational issues.

- ISO Certifications: Check for ISO 9001 or other relevant certifications that indicate quality management systems.

- Compliance with Standards: Confirm compliance with local and international standards, especially if you operate in regulated industries.

Step 5: Request Quotes and Compare Offers

Once you have a shortlist of potential suppliers, request detailed quotes that include pricing, delivery terms, and warranty information. Comparing these offers will help you identify the best value for your investment.

- Breakdown of Costs: Ensure that the quote outlines all costs, including shipping and handling.

- Delivery Times: Assess the delivery timelines to ensure they align with your project schedules.

Step 6: Negotiate Terms and Conditions

Engaging in negotiation is a critical step in securing favorable terms. Discuss payment options, delivery schedules, and after-sales support to ensure that the agreement meets your business needs.

- Payment Terms: Negotiate flexible payment terms that suit your cash flow.

- After-Sales Support: Ensure that the supplier offers comprehensive after-sales support, including installation and maintenance services.

Step 7: Finalize the Purchase and Document Everything

Once you’ve agreed on terms, finalize the purchase and ensure all agreements are documented. This documentation is crucial for future reference and can help prevent misunderstandings down the line.

Illustrative image related to motor and reducer

- Contract Clarity: Ensure that the contract clearly outlines all agreed-upon terms and conditions.

- Follow-Up Procedures: Establish follow-up procedures to monitor the performance of the motors and reducers after installation.

By following this checklist, B2B buyers can streamline the sourcing process for motors and reducers, making informed decisions that align with their operational requirements and strategic goals.

Comprehensive Cost and Pricing Analysis for motor and reducer Sourcing

What Are the Key Cost Components in Motor and Reducer Sourcing?

When sourcing motors and reducers, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the price. Common materials include steel, copper, and various alloys. High-performance motors may require specialized materials that increase costs.

-

Labor: Labor costs vary by region and can affect the overall pricing. Skilled labor is essential for manufacturing precision components, and regions with higher wage standards may see increased prices.

-

Manufacturing Overhead: This encompasses costs associated with production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize these costs, contributing to more competitive pricing.

-

Tooling: The cost of tooling is particularly relevant for custom orders. Specific molds and dies required for unique designs can add to the initial investment but may lead to cost savings in large-volume production.

-

Quality Control (QC): Ensuring that motors and reducers meet stringent quality standards incurs additional costs. However, robust QC processes can prevent costly defects and returns, ultimately saving money in the long run.

-

Logistics: Transportation and handling costs are vital, especially for international shipments. Factors such as distance, mode of transport, and customs duties can influence logistics expenses.

-

Margin: Suppliers will apply a margin to cover their operational costs and profit. Understanding typical margins in your industry can aid in negotiation.

How Do Price Influencers Affect the Cost of Motors and Reducers?

Several factors can influence the final price of motors and reducers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, reducing the per-unit cost. However, smaller orders may incur higher prices due to the fixed costs of production.

-

Specifications and Customization: Custom specifications can drive up costs due to the need for specialized production processes and materials. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (such as ISO or CE) ensure reliability but can increase costs. Buyers should consider the long-term benefits of investing in quality versus opting for lower-cost alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge premium prices but can offer greater assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears the costs and risks during shipping, influencing the final price.

What Are Essential Buyer Tips for Cost Efficiency in Sourcing Motors and Reducers?

To optimize sourcing costs, buyers should consider the following strategies:

-

Negotiate Effectively: Leverage competitive bids and be transparent about your requirements. Establishing long-term relationships with suppliers can also provide negotiating leverage for better pricing.

-

Focus on Total Cost of Ownership (TCO): While initial prices are important, evaluating the TCO can provide a clearer picture of long-term expenses. Consider factors such as energy efficiency, maintenance costs, and lifespan when making decisions.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and trade regulations that may impact costs. Building relationships with local suppliers can help mitigate these risks.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers, considering their pricing structures, product quality, and service levels. This comparison can highlight the best value options.

Conclusion

Understanding the comprehensive cost and pricing landscape for motors and reducers is crucial for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic sourcing tips, buyers can make informed decisions that align with their operational needs and budget constraints. Keep in mind that the prices mentioned can vary significantly based on the factors discussed, so always seek current market insights and quotations.

Alternatives Analysis: Comparing motor and reducer With Other Solutions

Exploring Alternatives to Motors and Reducers

In the landscape of industrial machinery, motors and reducers are prevalent for converting electrical energy into mechanical power. However, various alternative technologies can also fulfill similar roles, offering distinct advantages and disadvantages. Understanding these alternatives enables B2B buyers to make informed decisions that align with their operational requirements, budget constraints, and long-term goals.

Illustrative image related to motor and reducer

| Comparison Aspect | Motor And Reducer | Direct Drive Systems | Pneumatic Actuators |

|---|---|---|---|

| Performance | High torque, variable speed, and precise control. | Excellent torque and speed efficiency with lower mechanical losses. | Good for high-speed applications, but limited precision and control. |

| Cost | Moderate initial investment, with ongoing maintenance costs. | Higher upfront cost but lower operational costs due to energy efficiency. | Generally lower initial costs, but higher long-term costs due to air supply needs. |

| Ease of Implementation | Requires significant installation time and expertise. | Easier integration with fewer components, but may require specialized tools. | Simple installation, but requires an air supply system. |

| Maintenance | Regular maintenance required to ensure longevity. | Low maintenance due to fewer moving parts. | Frequent checks needed for air supply and potential leaks. |

| Best Use Case | Ideal for applications requiring precise control and variable speeds. | Best suited for high-performance applications with minimal energy loss. | Suitable for applications needing rapid actuation without high precision. |

Detailed Breakdown of Alternatives

Direct Drive Systems

Direct drive systems eliminate the need for gears and belts, directly coupling the motor to the load. This technology offers significant advantages in terms of efficiency and reduced mechanical losses, making it ideal for applications requiring high torque and speed. However, the initial investment can be substantial, and the integration process may necessitate specialized tools or skills. These systems excel in environments where energy efficiency and reduced maintenance are paramount.

Pneumatic Actuators

Pneumatic actuators utilize compressed air to create motion, making them an attractive option for many industrial applications. They are often less expensive to install than motors and reducers, making them appealing for budget-conscious operations. However, they typically offer less precision and control, limiting their use in applications requiring exact positioning. Furthermore, the reliance on a consistent air supply can lead to higher long-term operational costs due to energy consumption and potential leakage issues.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between motors and reducers and their alternatives, B2B buyers should assess their specific operational needs and constraints. Factors such as the required precision, energy efficiency, and budget should guide decision-making. For applications demanding high precision and variable speed, motors and reducers remain a robust choice. Conversely, for high-performance requirements with lower maintenance, direct drive systems may be more suitable. Lastly, if cost is a primary concern and high-speed actuation is sufficient, pneumatic actuators might be the best fit. Ultimately, aligning the chosen technology with the application’s demands will lead to improved efficiency and performance in industrial operations.

Essential Technical Properties and Trade Terminology for motor and reducer

What Are the Key Technical Properties of Motors and Reducers?

Understanding the essential technical specifications of motors and reducers is critical for B2B buyers in making informed purchasing decisions. Here are several key properties that should be considered:

Illustrative image related to motor and reducer

-

Material Grade

– Definition: The quality of materials used in the construction of motors and reducers, typically ranging from standard metals to specialized alloys.

– B2B Importance: Higher-grade materials enhance durability and performance, reducing the frequency of replacements. This is crucial for companies looking to minimize operational downtime and maintenance costs. -

Torque Rating

– Definition: The maximum rotational force that a motor or reducer can produce, usually measured in Newton-meters (Nm).

– B2B Importance: A precise torque rating is vital for applications requiring specific performance levels. Understanding torque helps buyers select the right equipment for their operational needs, ensuring efficiency and reliability. -

Efficiency Rating

– Definition: A measure of how effectively a motor converts electrical energy into mechanical energy, often expressed as a percentage.

– B2B Importance: Higher efficiency ratings lead to lower energy costs and less heat generation, which can extend the lifespan of the equipment. For businesses focused on sustainability and cost-reduction, this is a crucial metric. -

Tolerance Levels

– Definition: The allowable deviation from specified dimensions in the manufacturing process, impacting the fit and function of components.

– B2B Importance: Tight tolerances are essential for ensuring that motors and reducers operate smoothly and reliably, particularly in precision applications. Poor tolerances can lead to increased wear and failure rates. -

Operating Temperature Range

– Definition: The range of temperatures in which the motor or reducer can function optimally, often expressed in degrees Celsius.

– B2B Importance: Understanding the operating temperature range is critical for applications in extreme environments. Selecting equipment with the appropriate temperature tolerance can prevent overheating and subsequent failures. -

Input Voltage and Frequency

– Definition: The electrical specifications that indicate the required voltage and frequency for motor operation, commonly expressed in volts (V) and hertz (Hz).

– B2B Importance: Ensuring compatibility with existing electrical systems is crucial for efficient operations. Mismatched voltage or frequency can lead to inefficiencies or equipment damage.

What Are Common Trade Terms in the Motor and Reducer Industry?

Familiarity with industry terminology is essential for effective communication in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify the source of their components and ensure quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory and procurement costs, especially when dealing with international suppliers. -

RFQ (Request for Quotation)

– Definition: A document used to solicit price offers from suppliers for specific products or services.

– Importance: An RFQ is essential for comparing prices and terms from different vendors, ensuring that buyers get the best possible deal. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms helps businesses navigate shipping and delivery responsibilities, reducing the risk of misunderstandings in international transactions. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Knowledge of lead times is crucial for planning production schedules and managing customer expectations. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement.

– Importance: A solid warranty can provide peace of mind and protect against unforeseen failures, making it a key consideration in the purchasing process.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to better operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the motor and reducer Sector

What are the Key Market Dynamics and Trends Influencing the Motor and Reducer Sector?

The global motor and reducer market is currently experiencing significant transformation driven by advancements in technology, increasing demand for energy-efficient solutions, and the rise of automation across various industries. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The shift towards Industry 4.0 is reshaping sourcing strategies, as businesses increasingly integrate IoT and AI into their operations, enhancing productivity and reducing operational costs. This trend is particularly pronounced in industrial sectors such as manufacturing, automotive, and renewable energy.

Additionally, as sustainability becomes a priority, buyers are seeking suppliers that can demonstrate energy-efficient products and eco-friendly manufacturing processes. The demand for high-performance motors and reducers that minimize energy consumption without compromising on output is on the rise. Furthermore, geopolitical factors and supply chain disruptions have prompted companies to diversify their sourcing strategies, focusing on local suppliers to mitigate risks and ensure continuity of supply.

Another emerging trend is the customization of motors and reducers to meet specific industry requirements. As industries evolve, the need for tailored solutions that optimize performance for unique applications is growing. This trend offers opportunities for suppliers to differentiate themselves in a competitive market.

How Important is Sustainability and Ethical Sourcing in the Motor and Reducer Sector?

The environmental impact of manufacturing processes in the motor and reducer sector cannot be overlooked. As global awareness of climate change rises, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of recyclable materials, energy-efficient production methods, and reduced emissions during manufacturing.

Ethical sourcing has also become a key consideration, with buyers demanding transparency in supply chains. Suppliers that can provide documentation of compliance with environmental regulations and ethical labor practices are more likely to win contracts. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications signal a commitment to sustainability and can enhance a supplier’s reputation.

Furthermore, the integration of sustainable materials in product development is gaining traction. Buyers are exploring options like bio-based lubricants and recyclable components in motors and reducers, which not only reduce environmental impact but also align with corporate sustainability goals. As such, B2B buyers should prioritize partnerships with manufacturers who demonstrate a clear commitment to sustainability and ethical sourcing.

Illustrative image related to motor and reducer

What is the Brief Evolution and Historical Context of the Motor and Reducer Sector?

The motor and reducer sector has evolved significantly over the past century, transitioning from mechanical systems powered by steam and manual labor to highly sophisticated electric and hydraulic systems. The introduction of electricity in the late 19th century revolutionized the industry, allowing for more efficient and compact designs.

In the mid-20th century, advancements in materials science and manufacturing techniques enabled the production of more durable and efficient motors and reducers. The advent of computer-aided design (CAD) and automation in manufacturing further accelerated innovation, leading to the development of smart motors that incorporate sensors and IoT technology.

Today, as industries face increasing pressure to enhance efficiency and reduce their carbon footprint, the focus has shifted towards integrating cutting-edge technology with sustainable practices. This historical evolution underscores the importance of adaptability and innovation in meeting the demands of a rapidly changing market landscape. For B2B buyers, understanding this evolution is essential for making informed sourcing decisions that align with future trends and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of motor and reducer

1. How do I choose the right motor and reducer for my application?

Selecting the appropriate motor and reducer involves assessing your specific application requirements, including load capacity, speed, torque, and environmental conditions. Start by defining the power needs and operational parameters of your machinery. Consult manufacturer specifications and performance curves to match these requirements. Additionally, consider factors such as energy efficiency, noise levels, and maintenance needs. Collaborating with suppliers who offer technical support can enhance your decision-making process, ensuring you find a solution tailored to your operational goals.

2. What are the key factors to consider when vetting a supplier for motors and reducers?

When vetting suppliers, focus on their industry reputation, experience, and certifications. Check for customer testimonials and case studies that demonstrate successful partnerships in your sector. Evaluate their product range, quality assurance processes, and compliance with international standards. Assess their capabilities for customization, lead times, and support services, including technical assistance and after-sales service. Additionally, inquire about their logistics capabilities, especially for international shipping, to ensure timely delivery to your location.

3. What is the minimum order quantity (MOQ) for motors and reducers?

Minimum order quantities vary significantly by supplier and the specific type of motor and reducer. Generally, standard products may have lower MOQs, while custom solutions could require larger orders. It’s essential to communicate your needs directly with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility for smaller businesses or first-time buyers, while others may have strict policies. Establishing a good relationship with the supplier can also lead to better terms and conditions.

Illustrative image related to motor and reducer

4. What payment terms should I expect when sourcing motors and reducers internationally?

Payment terms can vary widely among suppliers and regions. Common terms include advance payments, letter of credit, or net 30/60/90 days after delivery. When dealing with international transactions, consider factors like currency exchange rates and transaction fees. It’s advisable to negotiate payment terms that align with your cash flow and financial capabilities. Always ensure that the payment method provides a level of security, such as escrow services, to protect against potential disputes.

5. How can I ensure the quality of motors and reducers before purchase?

To ensure quality, request detailed product specifications and certifications from the supplier. Consider asking for samples or test runs to evaluate performance. Additionally, inquire about the supplier’s quality assurance processes, including testing protocols and compliance with industry standards. Conducting factory visits, if feasible, can provide insights into manufacturing practices and quality control measures. Lastly, consider third-party inspections for large orders to verify that products meet your quality expectations.

6. What logistics considerations should I keep in mind when importing motors and reducers?

When importing, consider shipping methods, costs, and delivery timelines. Different modes of transport (air, sea, or land) will affect pricing and lead times. Assess any import duties, tariffs, and customs clearance requirements specific to your country. Collaborating with a logistics partner experienced in international trade can streamline the process. Ensure that the supplier can provide the necessary documentation for customs, including invoices, packing lists, and certificates of origin.

7. Are motors and reducers customizable to fit specific operational needs?

Yes, many manufacturers offer customization options for motors and reducers to meet specific operational requirements. Customizations can include adjustments in size, speed, torque, mounting configurations, and additional features like integrated controls or sensors. Discuss your unique needs with potential suppliers to explore available options. Custom solutions may come with longer lead times and higher costs, so it’s crucial to weigh these factors against the benefits of tailored performance.

8. What after-sales support should I expect from my motor and reducer supplier?

After-sales support is crucial for maintaining equipment performance and longevity. Expect suppliers to offer technical assistance, troubleshooting, and warranty services. Some may provide training for your team on installation and maintenance. Inquire about the availability of spare parts and the timeline for obtaining them. A supplier with a strong support network can help minimize downtime and ensure your operations run smoothly, particularly in the demanding environments often found in international markets.

Top 9 Motor And Reducer Manufacturers & Suppliers List

1. Apex Industrial Automation – Gear Reducers & Gearmotors

Domain: apexindustrialautomation.com

Registered: 2006 (19 years)

Introduction: Gear reducers and gearmotors are essential components in industrial automation, providing efficient torque conversion and speed reduction. They are designed to enhance the performance of machinery by optimizing power transmission. Key features include various gear ratios, compact designs, and compatibility with different motor types. These products are suitable for a wide range of applications, in…

2. Vortex Reducer – Gear Drives & Gearmotors

Domain: vortexreducer.com

Registered: 2006 (19 years)

Introduction: Gear Drives, Gear Reducers, and Gearmotors are mechanical devices that utilize gears to transmit power and alter speed and torque. A Gearbox is a housing that contains gears to transmit power, while a Gearmotor combines a motor and gearbox, typically as a gear reducer. A Gear Reducer is specifically designed to reduce speed and increase torque. For instance, pairing a 1750 RPM motor with a 20:1 sp…

3. Groschopp – Planetary Right Angle DC Gear Motors

Domain: groschopp.com

Registered: 1995 (30 years)

Introduction: Right Angle reducers are ideal for applications where size and space are at a premium, allowing the output to turn a 90-degree corner. Groschopp offers a line of Planetary Right Angle DC Gear Motors that provide the advantages of standard right angle gearmotors without sacrificing efficiency.

4. Sumitomo Drive Technologies – Gear Reducers

Domain: us.sumitomodrive.com

Registered: 2003 (22 years)

Introduction: Gear reducers, also known as speed reducers, are designed for reliability, durability, and performance in industrial operations. They increase torque by reducing the speed of a power source, making output more useful for industrial tasks. Sumitomo Drive Technologies offers a full lineup of speed reducers with various gear ratios, torque, and horsepower to optimize operations. Key features include:…

5. Grainger – Speed Reducers

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Speed Reducers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Electric Motorsport – Aluminum Gear Reducer 2:1, C-Face

Domain: electricmotorsport.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “Aluminum Gear Reducer 2:1, C-Face”, “price”: “$750.00”, “special_order”: “Allow 2 to 6 Weeks”, “compatible_motors”: [“Motenergy ME0909”, “Motenergy ME0708”, “Motenergy ME0709”, “Motenergy ME1117”, “Motenergy ME1118”, “Motenergy ME1716”, “Motenergy ME1717”, “Motenergy ME1718”, “Motenergy ME1719”, “HPEVS AC-9”], “features”: [“High efficiency”, “Aluminum housing”, “Factory-filled wi…

7. eBay – Gear Reducer Motors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: gear reducer motor products for sale on eBay; popular categories include Motors, Electronics, Collectibles & Art, Home & Garden, Clothing & Accessories, Toys & Hobbies, Sporting Goods, Books, Movies, Music, Health & Beauty, Business & Industrial, Jewelry & Watches, Baby Essentials, Pet Supplies; related searches include Motor Gear Reducers, Gear Reduction Electric Motor, 12 V Gear Reduction Motor;…

8. Sesame Motor – Speed Reducers

Domain: sesamemotor.com

Registered: 2007 (18 years)

Introduction: Speed reducers (or gearboxes) are gearing assemblies used in automation control systems to reduce input power speed from motors, achieving desired output speed and torque. They reduce motor rotational speed while increasing output torque, improving the working capacity of the motor. Speed reducers can change output direction and save installation space. Benefits include cost reduction by allowing …

9. Reddit – Gear Reducer Motors for Recycling Applications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Motor with a 60:1 gear reducer, motor with a 20:1 gear reducer, application for sorting recycling, need for torque output, variable speed device consideration.

Strategic Sourcing Conclusion and Outlook for motor and reducer

In the complex landscape of motors and reducers, strategic sourcing emerges as a pivotal factor for businesses seeking competitive advantage. By understanding the specifications and applications of different motor and reducer types, international B2B buyers can make informed decisions that enhance operational efficiency and reduce costs. The key takeaway is that sourcing high-quality components from reliable suppliers not only improves performance but also fosters long-term partnerships that can lead to innovation and growth.

Moreover, the increasing emphasis on energy efficiency and sustainability in manufacturing processes presents opportunities for buyers to align with suppliers who prioritize eco-friendly practices. As industries evolve, the integration of smart technologies into motor and reducer systems will be crucial for maintaining competitive edge.

Looking ahead, it is essential for buyers from regions such as Africa, South America, the Middle East, and Europe to remain proactive in their sourcing strategies. Engaging with suppliers who demonstrate technical expertise and a commitment to customer service will be vital. As you navigate this dynamic market, consider leveraging digital platforms for sourcing and collaboration to ensure your organization stays ahead in the ever-evolving industrial landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.