Is Your Metal Detector With Color Display Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for metal detector with color display

In today’s competitive landscape, sourcing a reliable metal detector with a color display can be a daunting challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The market is saturated with options, making it essential to discern which features—such as depth detection, target identification accuracy, and user-friendly interfaces—are most beneficial for your specific applications. This comprehensive guide aims to demystify the complexities of selecting the right metal detector with a color display, addressing critical aspects such as types of detectors, their various applications across industries, supplier vetting processes, and cost considerations.

By equipping B2B buyers with actionable insights and detailed comparisons, this guide empowers you to make informed purchasing decisions that align with your operational needs. Whether you are in treasure hunting, archaeological exploration, or security applications, understanding the nuances of different models will enhance your procurement strategy. With a focus on quality, performance, and supplier reliability, you can navigate the global market with confidence, ensuring you invest in a product that not only meets but exceeds your expectations.

Explore the essential features and specifications that matter most, and discover how to evaluate potential suppliers effectively, ensuring that your investment in a metal detector with a color display is both strategic and profitable.

Understanding metal detector with color display Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Multi-Frequency Detectors | Utilizes simultaneous multi-frequency technology for depth and accuracy. | Archaeology, treasure hunting, mining | Pros: High sensitivity, versatile in various soils. Cons: Higher cost, requires training. |

| 2D ID Display Detectors | Features a visual 2D ID map for ferrous and conductive values. | Environmental surveying, metal recovery | Pros: Enhanced target identification, reduces false positives. Cons: Complexity may deter beginners. |

| Waterproof Detectors | IP68-rated for underwater use, often with collapsible designs. | Marine treasure hunting, beachcombing | Pros: Versatile for diverse environments, durable. Cons: Heavier, can be pricier. |

| Entry-Level Color Detectors | Basic color display with essential features, often lightweight. | Hobbyist use, educational purposes | Pros: Affordable, user-friendly. Cons: Limited depth and features compared to advanced models. |

| Professional High-End Detectors | Advanced technology with superior sensitivity and features. | Professional treasure hunting, geological surveys | Pros: Exceptional performance, extensive features. Cons: High investment cost, requires expertise. |

What are Multi-Frequency Detectors and Their B2B Suitability?

Multi-frequency detectors, such as the Minelab MANTICORE, leverage simultaneous multi-frequency technology to enhance detection depth and accuracy. They are particularly suitable for B2B applications in archaeology and mining, where precision is crucial. Buyers should consider the operational environment, as these detectors excel in various soil conditions but may require additional training due to their advanced features.

Illustrative image related to metal detector with color display

How Do 2D ID Display Detectors Enhance Target Identification?

2D ID display detectors provide a visual representation of detected targets, allowing users to assess ferrous and conductive values quickly. This feature is invaluable in environmental surveying and metal recovery operations, where distinguishing between valuable and non-valuable metals is essential. B2B buyers should evaluate the complexity of these devices, as their advanced capabilities may pose a learning curve for inexperienced users.

What Advantages Do Waterproof Detectors Offer for Diverse Environments?

Waterproof detectors are designed with IP68 ratings, making them suitable for underwater exploration and beachcombing. Their collapsible designs enhance portability, appealing to businesses involved in marine treasure hunting. While these detectors offer versatility and durability, buyers should be aware of their potentially higher weight and price compared to standard models.

Why Consider Entry-Level Color Detectors for Educational Purposes?

Entry-level color detectors are ideal for hobbyists and educational institutions due to their affordability and user-friendly interfaces. These detectors provide essential features without overwhelming new users, making them suitable for introductory courses in metal detecting. However, buyers should note that these models may lack the depth and advanced capabilities required for professional applications.

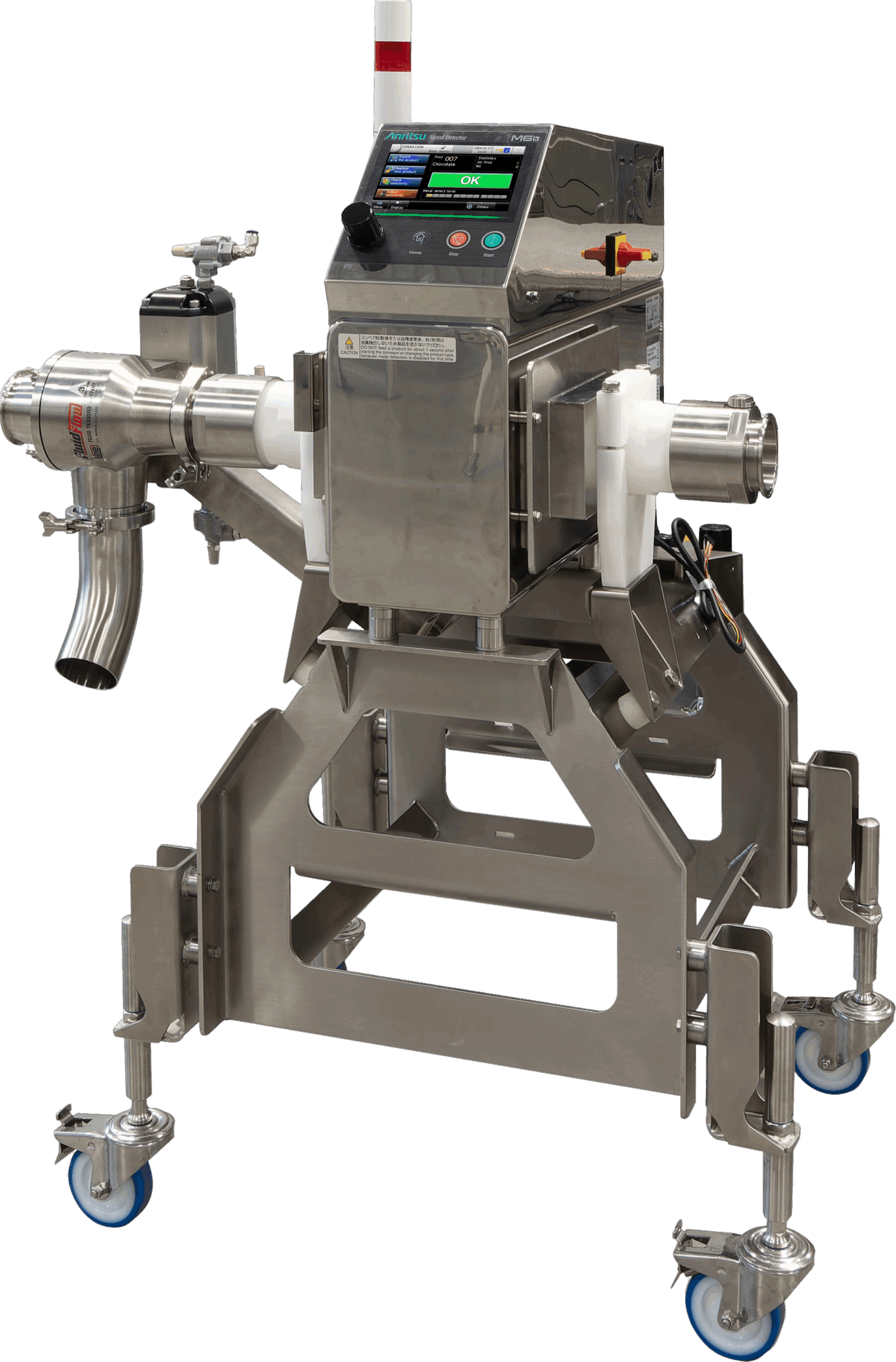

Illustrative image related to metal detector with color display

What Makes Professional High-End Detectors a Wise Investment?

Professional high-end detectors are equipped with cutting-edge technology that significantly enhances sensitivity and feature sets. They are ideal for professional treasure hunting and geological surveys, where performance can directly impact results. While these detectors represent a significant investment, the advanced capabilities they offer justify the cost for serious B2B applications, provided the user possesses the necessary expertise.

Key Industrial Applications of metal detector with color display

| Industry/Sector | Specific Application of Metal Detector with Color Display | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Detecting precious metals and minerals in exploration activities | Increases accuracy in identifying valuable resources | Sensitivity, depth detection capabilities, and ruggedness |

| Construction | Locating buried utilities and reinforcing materials | Prevents costly damage and project delays | Waterproofing, portability, and display clarity in sunlight |

| Archaeology | Finding historical artifacts and buried structures | Enhances research accuracy and cultural preservation | Advanced discrimination features and historical context relevance |

| Security | Screening for concealed weapons and prohibited items | Improves safety and compliance in public spaces | Sensitivity settings, audio feedback options, and battery life |

| Environmental Monitoring | Assessing land for contamination and buried waste | Ensures regulatory compliance and environmental safety | Robust construction, ease of use, and data reporting capabilities |

How is Metal Detector with Color Display Used in Mining?

In the mining industry, metal detectors with color displays are pivotal for locating precious metals and minerals during exploration. These devices enhance the accuracy of identifying valuable resources, minimizing the risk of overlooking deposits. For international buyers, especially from resource-rich regions like Africa and South America, sourcing detectors with high sensitivity and depth detection capabilities is crucial. Additionally, the ruggedness of the equipment is vital to withstand harsh mining environments.

What Role Does Metal Detection Play in Construction Projects?

In construction, metal detectors are essential for locating buried utilities and reinforcing materials. This application prevents costly damage to infrastructure and mitigates project delays caused by unexpected encounters with buried objects. Buyers from regions with developing infrastructure, such as Nigeria and Brazil, should prioritize detectors that offer waterproofing and portability. A clear display that is easy to read in direct sunlight is also a significant consideration for outdoor work.

Illustrative image related to metal detector with color display

How Do Archaeologists Benefit from Metal Detectors with Color Displays?

Archaeologists utilize metal detectors with color displays to discover historical artifacts and buried structures. These devices improve research accuracy and contribute to cultural preservation efforts by enabling precise location tracking of significant findings. For B2B buyers in Europe, where archaeological projects are often subject to strict regulations, it is essential to select detectors with advanced discrimination features that can differentiate between valuable artifacts and less significant metals.

Why Are Metal Detectors Important in Security Applications?

In security settings, metal detectors with color displays are used to screen for concealed weapons and prohibited items. These devices enhance safety in public spaces such as airports, schools, and events. Businesses focused on security in the Middle East and Europe should consider detectors with customizable sensitivity settings and audio feedback options to adapt to various environments. Battery life is also a critical factor, ensuring that devices can operate effectively during extended security checks.

How Can Environmental Monitoring Benefit from Metal Detection Technology?

Environmental monitoring employs metal detectors to assess land for contamination and buried waste. This application ensures regulatory compliance and promotes environmental safety. International buyers looking to source these detectors should focus on robust construction to endure diverse environmental conditions. Additionally, ease of use and data reporting capabilities can significantly enhance operational efficiency, making these detectors invaluable for environmental agencies and compliance organizations.

Illustrative image related to metal detector with color display

3 Common User Pain Points for ‘metal detector with color display’ & Their Solutions

Scenario 1: Difficulty in Interpreting Color Display Signals

The Problem: A common challenge faced by B2B buyers of metal detectors with color displays is the complexity of interpreting the signals shown on the screen. The color codes and graphical representations can be overwhelming, especially for operators who are new to the technology. Misinterpretation can lead to wasted time and resources, as operators may either overlook valuable finds or dig up unwanted targets. This is particularly critical in regions like Africa or South America, where labor and operational costs are significant.

The Solution: To address this issue, manufacturers should invest in creating comprehensive user manuals and training programs that focus on the interpretation of color displays. B2B buyers should look for models that provide clear visual representations of ferrous and non-ferrous targets, along with detailed explanations of what each color signifies. Additionally, using demo units for training sessions before full deployment can help operators gain confidence and proficiency in using the detectors. Implementing a mentorship program where experienced users guide newcomers can further facilitate understanding and effective use of the technology.

Scenario 2: Adapting to Varied Environmental Conditions

The Problem: Another pain point is the inability of metal detectors with color displays to perform optimally across diverse environmental conditions, such as highly mineralized soil or areas with excessive trash. B2B buyers often encounter situations where the detector provides inaccurate readings, leading to frustration and ineffective treasure hunting. This is particularly evident in regions with varying terrain, such as the deserts of the Middle East or the jungles of Brazil, where conditions can change dramatically.

Illustrative image related to metal detector with color display

The Solution: Buyers should prioritize sourcing metal detectors that offer customizable settings for different terrains. Look for models that feature adjustable discrimination settings, recovery speeds, and sensitivity levels. For instance, the MANTICORE’s advanced 2D ID Map allows users to tailor their settings based on the specific environment. Furthermore, conducting on-site testing before finalizing purchases can help businesses understand how well a detector adapts to local conditions. Providing training on how to adjust settings based on environmental factors will empower users to maximize the detector’s capabilities.

Scenario 3: Cost vs. Performance Dilemma

The Problem: In many cases, B2B buyers face a dilemma when it comes to balancing cost with the performance of metal detectors with color displays. Lower-priced models may lack essential features that enhance usability and efficiency, while higher-end models can strain budgets. This is especially critical for businesses in developing markets, where every investment must yield a tangible return. The fear of investing in a subpar product can lead to indecision and missed opportunities.

The Solution: To make informed purchasing decisions, buyers should conduct thorough market research and leverage product comparisons to evaluate the features and performance of different models. It’s advisable to focus on key performance indicators like target identification accuracy, build quality, and user feedback. Additionally, engaging with suppliers who offer trial periods or demo units can allow buyers to assess the detector’s effectiveness in real-world scenarios before committing financially. Consideration of total cost of ownership—including maintenance and potential resale value—can also guide decisions, ensuring that the chosen model meets both performance expectations and budget constraints.

Illustrative image related to metal detector with color display

Strategic Material Selection Guide for metal detector with color display

What Materials Are Commonly Used in Metal Detectors with Color Displays?

When selecting materials for metal detectors equipped with color displays, it is essential to consider their performance characteristics, durability, and suitability for various applications. Here, we analyze four common materials used in the construction of these devices: plastic, aluminum, stainless steel, and carbon fiber.

How Does Plastic Benefit Metal Detectors with Color Displays?

Plastic is often used for the housing of metal detectors due to its lightweight nature and ease of manufacturing. Key properties include good impact resistance and the ability to mold into intricate shapes, which is particularly useful for ergonomic designs. However, plastic can be less durable than metals, particularly in harsh environments.

Pros: Plastic is cost-effective and offers versatility in design. It can be produced in various colors and finishes, enhancing the aesthetic appeal of the product.

Cons: Its susceptibility to UV degradation and lower resistance to extreme temperatures can limit its longevity, especially in regions with harsh climates.

For international buyers, compliance with standards such as ASTM D638 (tensile properties of plastics) is crucial. In markets like Africa and South America, where environmental conditions may vary significantly, selecting high-grade plastics can mitigate some of these risks.

Illustrative image related to metal detector with color display

What Advantages Does Aluminum Offer in Metal Detectors?

Aluminum is favored for its strength-to-weight ratio, making it ideal for components that require both durability and lightweight properties. It exhibits excellent corrosion resistance, particularly when anodized, which is advantageous in humid or saline environments.

Pros: The material is relatively inexpensive and easy to machine, allowing for rapid production. Its lightweight nature enhances user comfort during extended use.

Cons: While aluminum is resistant to corrosion, it can be prone to scratches and dents, which may affect the aesthetic and functional integrity of the detector over time.

Illustrative image related to metal detector with color display

For B2B buyers in the Middle East and Europe, compliance with standards like EN 573 (aluminum and aluminum alloys) is essential to ensure material quality. Additionally, aluminum’s recyclability can be a selling point in environmentally conscious markets.

Why Is Stainless Steel a Preferred Material for Certain Components?

Stainless steel is often used in critical components of metal detectors due to its exceptional strength and corrosion resistance. It is particularly useful in areas exposed to moisture or harsh chemical environments.

Pros: Stainless steel provides high durability and is less likely to deform under stress, making it ideal for the internal mechanisms of metal detectors.

Cons: The primary drawback is its weight, which can make the overall device heavier and less user-friendly for prolonged use. Additionally, stainless steel tends to be more expensive than other materials.

Illustrative image related to metal detector with color display

International buyers should consider compliance with standards such as ASTM A240 (specifications for stainless steel sheets) to ensure that they are sourcing high-quality materials. In regions like Brazil, where mining activities are prevalent, the robustness of stainless steel can be a significant advantage.

How Does Carbon Fiber Enhance the Performance of Metal Detectors?

Carbon fiber is increasingly being used in high-end metal detectors due to its outstanding strength-to-weight ratio and rigidity. It is particularly beneficial for the shafts and frames of detectors, allowing for a lightweight yet durable construction.

Pros: Carbon fiber is resistant to corrosion and does not suffer from fatigue over time, making it ideal for outdoor applications. Its lightweight nature significantly reduces user fatigue.

Illustrative image related to metal detector with color display

Cons: The primary limitation is its cost; carbon fiber is generally more expensive than traditional materials. Additionally, manufacturing processes can be complex, requiring specialized equipment.

For buyers in Europe and the Middle East, understanding compliance with standards like ISO 13019 (carbon fiber composites) is important. In regions with a focus on advanced technology, the adoption of carbon fiber can enhance the perceived value of the product.

Summary Table of Material Selection for Metal Detectors

| Material | Typical Use Case for metal detector with color display | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and ergonomic components | Cost-effective and versatile in design | Susceptible to UV degradation | Low |

| Aluminum | Structural components and frames | Lightweight with good corrosion resistance | Prone to scratches and dents | Medium |

| Stainless Steel | Internal mechanisms and critical components | High durability and corrosion resistance | Heavier and more expensive | High |

| Carbon Fiber | Shafts and frames | Outstanding strength-to-weight ratio | Expensive with complex manufacturing | High |

This strategic material selection guide offers insights for B2B buyers in diverse markets, ensuring informed decisions that align with performance requirements and regional compliance standards.

Illustrative image related to metal detector with color display

In-depth Look: Manufacturing Processes and Quality Assurance for metal detector with color display

What Are the Main Stages in the Manufacturing Process of Metal Detectors with Color Displays?

The manufacturing of metal detectors with color displays involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is vital to ensuring the device meets the required performance and quality standards expected by international B2B buyers.

Material Preparation

The process begins with the selection of high-quality materials, including plastics, metals, and electronic components. For metal detectors, non-corrosive materials such as aluminum or stainless steel are often preferred for the casing to enhance durability, especially in outdoor or underwater conditions. Components such as coils, circuit boards, and display units must be sourced from reputable suppliers to ensure reliability.

Forming

In the forming stage, materials are shaped into the various components of the metal detector. This may involve injection molding for plastic parts, machining for metal components, and the printing of circuit boards. Advanced techniques like 3D printing are also increasingly used for prototyping and small batch production, allowing for rapid design iterations and customizations that cater to specific market needs.

Assembly

The assembly stage involves bringing together all the individual components. Automated assembly lines are commonly used for mass production, where precision is crucial. Workers or machines will fit the electronic components onto the circuit boards, integrate the color display, and attach the casing. Quality control checkpoints are established during assembly to monitor the fitting of parts and ensure that electrical connections are secure.

Finishing

Finishing touches are applied to the product, which may include surface treatments to enhance corrosion resistance or aesthetic appeal. Calibration and software installation are also performed at this stage. For metal detectors with color displays, the software plays a significant role in interpreting signals and providing users with accurate information about detected objects.

Illustrative image related to metal detector with color display

How Is Quality Assurance Implemented in Metal Detector Manufacturing?

Quality assurance (QA) is critical in the manufacturing of metal detectors to ensure that the final product meets international standards and customer expectations. Various international standards, such as ISO 9001, are relevant to this sector, providing a framework for quality management systems.

International Standards and Certifications

ISO 9001 focuses on maintaining quality management principles, including strong customer focus, the involvement of top management, and a process approach. Additionally, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API standards may apply, depending on the market and application of the metal detectors.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials and components before they enter production. Suppliers are evaluated based on their ability to meet specified quality criteria.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing. This includes testing components as they are assembled to catch defects early and reduce waste.

-

Final Quality Control (FQC): After assembly, each metal detector undergoes rigorous testing to ensure it meets performance specifications. This often includes checking the functionality of the color display, sensitivity to metal detection, and battery performance.

What Common Testing Methods Are Employed in Metal Detector Quality Control?

To ensure that metal detectors perform optimally, manufacturers employ various testing methods:

-

Functional Testing: Each unit is tested for its metal detection capabilities, ensuring it can accurately identify different types of metals and discriminate between targets.

-

Environmental Testing: Given that metal detectors may be used in various climates, testing includes exposure to humidity, temperature variations, and even submersion in water to verify durability and functionality under different conditions.

-

Electromagnetic Interference (EMI) Testing: This ensures that the metal detector operates without interference from other electronic devices, which is crucial for accurate readings.

-

Battery Life Testing: Manufacturers measure how long the device operates under typical usage conditions to meet customer expectations for battery performance.

How Can B2B Buyers Verify the Quality Control of Metal Detector Suppliers?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps buyers can take:

Illustrative image related to metal detector with color display

-

Request Documentation: Buyers should ask suppliers for their quality management certification documents, such as ISO 9001, and any relevant product-specific certifications (e.g., CE, API).

-

Conduct Supplier Audits: On-site audits allow buyers to assess the manufacturing processes and quality control measures firsthand. This also provides an opportunity to evaluate the working conditions and overall production environment.

-

Review Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from testing and any corrective actions taken in response to defects.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can provide unbiased assessments of the manufacturing processes and product quality, offering additional assurance to buyers.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various challenges related to quality control and certification:

-

Regulatory Differences: Each region may have different regulatory requirements. Buyers must ensure that the products comply with local laws and standards in their respective markets.

-

Supply Chain Transparency: Understanding the supply chain is vital. Buyers should inquire about where components are sourced and whether they meet the necessary quality standards.

-

Cultural and Language Barriers: Communication may be hindered by cultural differences or language barriers, making it essential for buyers to establish clear channels of communication with suppliers.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with metal detectors featuring color displays, B2B buyers can make informed purchasing decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal detector with color display’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure metal detectors with color displays. As the demand for advanced detection technology grows, understanding the essential features and supplier capabilities is crucial for making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing these sophisticated devices, ensuring you select the best options for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the detection depth, frequency range, and sensitivity levels necessary for your target applications.

– Key Features to Define:

– Display Quality: Ensure the color display offers high resolution and visibility in various lighting conditions.

– Frequency Options: Look for detectors with multi-frequency capabilities for diverse target detection.

Illustrative image related to metal detector with color display

Step 2: Research Market Trends

Understanding current market trends will help you identify the best products available. Research which brands and models are gaining popularity and why.

– Focus Areas:

– User Reviews: Analyze feedback from other businesses regarding performance and reliability.

– Industry Innovations: Keep an eye on emerging technologies that enhance detection accuracy and ease of use.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is critical to ensuring product quality and reliability. Request detailed company profiles, including their manufacturing capabilities and experience in the industry.

– Assessment Criteria:

– Certifications: Check for relevant certifications that demonstrate adherence to international quality standards.

– References: Ask for references from other businesses in your region or industry who have successfully sourced similar products.

Step 4: Compare Product Features and Prices

Conduct a comparative analysis of different models to identify the best value for your investment. Create a side-by-side comparison of features, warranties, and pricing.

– Considerations:

– Warranty and Support: Evaluate the length and terms of warranties, as well as the availability of customer support.

– Customization Options: Determine if suppliers offer customization to meet specific operational needs.

Step 5: Request Samples and Demonstrations

Before finalizing your order, request samples or product demonstrations. This step allows you to assess the detectors’ performance firsthand.

– What to Look For:

– Ease of Use: Evaluate the user interface and controls for intuitiveness.

– Field Performance: Test the detector in various environments to confirm its effectiveness in real-world conditions.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, payment terms, and delivery schedules.

– Negotiation Tips:

– Volume Discounts: Inquire about discounts for bulk purchases.

– Shipping Costs: Clarify shipping responsibilities and costs to avoid unexpected expenses.

Step 7: Finalize Your Order and Monitor Delivery

After agreeing on terms, place your order and establish a timeline for delivery. It’s essential to monitor the delivery process to ensure compliance with agreed schedules.

– Final Checks:

– Order Confirmation: Verify all specifications and quantities on the order confirmation.

– Tracking: Utilize tracking options to stay informed about the shipment status.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for metal detectors with color displays, ensuring they make well-informed decisions that meet their operational needs.

Comprehensive Cost and Pricing Analysis for metal detector with color display Sourcing

Understanding the cost structure and pricing dynamics of metal detectors with color displays is crucial for international B2B buyers. This analysis will shed light on the various cost components, price influencers, and provide actionable tips for effective negotiation and sourcing.

What Are the Key Cost Components in Metal Detector Production?

The cost structure for metal detectors with color displays can be broken down into several critical components:

-

Materials: The primary materials include high-grade plastics, metals for the casing, advanced sensors, and electronic components. The choice of materials significantly impacts both performance and price.

-

Labor: Skilled labor is essential in the assembly and calibration of metal detectors. Labor costs can vary widely depending on the manufacturing location, with regions such as Asia often offering lower labor costs compared to Europe or North America.

-

Manufacturing Overhead: This includes facility costs, utilities, and other indirect costs associated with production. Efficient manufacturing practices can help keep these costs down.

-

Tooling: Customization often requires specialized tooling, which can be a significant upfront investment. Buyers should consider whether the supplier has the necessary tooling capabilities to meet their specific needs.

-

Quality Control (QC): Rigorous QC processes ensure that each unit meets performance standards, contributing to overall reliability. This can add to the cost but is essential for maintaining brand integrity.

-

Logistics: Shipping costs can vary based on the destination, volume, and shipping method. Understanding these factors is crucial for determining the total landed cost.

-

Margin: Manufacturers will typically include a profit margin in their pricing, which can vary based on market positioning and competition.

How Do Price Influencers Affect the Cost of Metal Detectors?

Several factors can influence the pricing of metal detectors with color displays:

-

Volume/MOQ: Ordering in larger quantities often reduces the per-unit cost, making it beneficial for buyers looking to stock inventory. Minimum order quantities (MOQs) can also dictate pricing structures.

-

Specifications and Customization: Custom features or enhancements, such as advanced detection capabilities or specific design elements, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., IP68 for waterproofing) can lead to increased costs but often result in better performance and durability, which are critical in competitive markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The agreed terms of shipping can significantly impact overall costs. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate budgeting.

What Are the Best Tips for Negotiating Prices on Metal Detectors?

-

Conduct Market Research: Understanding current market prices and competitor offerings can empower buyers during negotiations, providing leverage to secure better terms.

-

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider long-term factors like maintenance, warranty, and potential resale value when assessing cost-effectiveness.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, especially for repeat orders or long-term contracts.

-

Be Clear on Requirements: Clearly communicating specifications and expectations can prevent misunderstandings and ensure that quotes reflect the desired product.

-

Consider Local Sourcing: For buyers in regions like Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times, potentially lowering overall expenses.

Conclusion

While indicative prices for metal detectors with color displays can vary widely—from budget-friendly options around $170 to high-end models exceeding $40,000—understanding the cost structure and pricing influencers is essential for making informed purchasing decisions. By strategically navigating these factors, international B2B buyers can optimize their sourcing strategies and achieve cost efficiencies tailored to their specific needs.

Illustrative image related to metal detector with color display

Alternatives Analysis: Comparing metal detector with color display With Other Solutions

Introduction to Alternative Solutions for Metal Detection

When selecting a metal detector, particularly one equipped with a color display, it’s essential to consider various alternatives that may fulfill similar objectives. Metal detectors are widely used in industries such as archaeology, construction, and treasure hunting, and understanding the available options is crucial for B2B buyers. This analysis focuses on comparing the ‘metal detector with color display’ against other viable solutions, including traditional metal detectors without color displays and advanced ground penetrating radar (GPR) systems.

Comparison Table

| Comparison Aspect | Metal Detector With Color Display | Traditional Metal Detector | Ground Penetrating Radar (GPR) |

|---|---|---|---|

| Performance | High accuracy, detailed target ID | Moderate accuracy, basic ID | Very high accuracy, depth profiling |

| Cost | Medium to high ($1,000 – $3,000) | Low to medium ($100 – $1,000) | High ($10,000 – $50,000) |

| Ease of Implementation | User-friendly with intuitive UI | Simple, minimal training needed | Requires specialized training |

| Maintenance | Moderate, periodic updates needed | Low, minimal upkeep | High, requires regular calibration |

| Best Use Case | Treasure hunting, archaeological digs | General use, hobbyists | Professional surveying, construction |

Detailed Breakdown of Alternatives

1. Traditional Metal Detector

Traditional metal detectors typically offer basic functionality without a color display. They are often more affordable and easier to operate, making them suitable for hobbyists and casual users. While they may lack advanced features such as detailed target identification or discrimination, they still provide reliable performance for general metal detection tasks. However, their limitations in identifying specific metal types or distinguishing between valuable and non-valuable targets can hinder efficiency in professional settings.

Pros:

– Cost-effective for budget-conscious buyers.

– Simple operation, requiring little to no training.

– Suitable for casual use and general metal detection.

Cons:

– Limited performance in terms of depth and discrimination.

– Lack of visual representation can lead to missed valuable finds.

– Not ideal for specialized applications.

2. Ground Penetrating Radar (GPR)

GPR systems utilize radar pulses to image the subsurface, offering a highly advanced alternative for detecting buried objects. They excel in providing depth profiling and can distinguish between different materials based on their dielectric properties. This technology is particularly beneficial for construction and archaeological surveys where detailed information about subsurface structures is required. However, GPR systems come with a steep price tag and necessitate specialized training for effective use.

Illustrative image related to metal detector with color display

Pros:

– Extremely high accuracy and depth profiling capabilities.

– Effective for identifying a wide range of buried materials.

– Valuable for professional applications in engineering and archaeology.

Cons:

– High initial investment and ongoing maintenance costs.

– Requires specialized knowledge to operate effectively.

– Less portable compared to traditional metal detectors.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate metal detection solution hinges on various factors, including budget, intended use, and the level of technical expertise available. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these alternatives is vital. Metal detectors with color displays provide high performance and user-friendly interfaces, making them ideal for detailed treasure hunts and archaeological digs. On the other hand, traditional metal detectors serve casual users well, while GPR systems cater to professionals requiring precise subsurface imaging. Ultimately, assessing the specific needs and operational contexts will guide buyers toward the most suitable option.

Essential Technical Properties and Trade Terminology for metal detector with color display

What Are the Key Technical Properties of Metal Detectors with Color Displays?

When evaluating metal detectors with color displays, several critical specifications should be considered to ensure optimal performance and suitability for specific applications.

-

Detection Depth: This property indicates how deeply the detector can identify metal objects. Generally, more advanced models can detect deeper targets, which is crucial for treasure hunting or archaeological work. For B2B buyers, a detector with enhanced depth capability allows for more efficient searches in varied terrains, ultimately leading to greater operational success.

-

Frequency Range: Metal detectors operate on different frequency levels, with higher frequencies being more sensitive to small objects like gold, while lower frequencies are better for larger objects. A detector with a broad frequency range can adapt to various target types, making it more versatile. For international buyers, especially in regions with diverse geological conditions, this feature can significantly impact the effectiveness of the device.

-

2D Target ID Mapping: This advanced feature provides a visual representation of detected targets, displaying ferrous and non-ferrous characteristics. It allows users to make informed decisions about whether to dig, based on accurate discrimination of target types. In a B2B context, this capability can enhance productivity by reducing time spent on unwanted finds.

-

Audio Feedback Options: Metal detectors with customizable audio settings enable users to adjust the sound profiles to suit their preferences. This includes options for tone variations and volume controls. For commercial applications, the ability to tailor audio feedback can improve user experience and facilitate better detection under varying environmental conditions.

-

Water Resistance Rating (IP68): A high IP rating indicates that the device can withstand immersion in water, making it suitable for underwater detection activities. For businesses operating in regions with rivers, lakes, or coastal areas, this feature is essential for expanding operational capabilities and ensuring equipment durability.

-

Weight and Portability: The weight of the metal detector can significantly affect user fatigue during prolonged use. Lightweight models, such as those made with carbon fiber, are easier to handle and transport, making them ideal for extensive fieldwork. For B2B buyers, investing in portable equipment can lead to increased efficiency and reduced labor costs.

What Are Common Trade Terms Related to Metal Detectors?

Understanding industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Buyers should consider OEM relationships to ensure they are sourcing quality components for their metal detectors.

-

MOQ (Minimum Order Quantity): This term defines the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, particularly for businesses planning to distribute metal detectors in different markets.

-

RFQ (Request for Quotation): A document that solicits price bids from suppliers for specific products or services. B2B buyers should utilize RFQs to compare prices and terms among multiple suppliers, ensuring they receive the best value.

-

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international transactions, such as shipping costs and liability. Familiarity with Incoterms can help businesses avoid disputes and clarify expectations during the procurement process.

-

Lead Time: The amount of time from placing an order to delivery. For international buyers, understanding lead times is critical for inventory planning and ensuring timely project execution.

-

Warranty Period: This specifies the duration a product is covered against defects or malfunctions. A robust warranty can be a key indicator of product reliability, providing B2B buyers with assurance regarding their investment.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals in the metal detector market.

Navigating Market Dynamics and Sourcing Trends in the metal detector with color display Sector

What Are the Current Market Dynamics for Metal Detectors with Color Displays?

The global market for metal detectors, particularly those equipped with color displays, is witnessing significant growth driven by increasing consumer interest in treasure hunting, archaeological exploration, and security applications. The integration of advanced technologies such as Multi-IQ+™ systems, which enhance target identification and recovery speed, is revolutionizing the metal detection landscape. This is especially relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where the demand for high-performance equipment is rising.

Emerging trends indicate a shift toward multifunctionality in metal detectors. Buyers are now seeking devices that not only detect metals but also provide visual feedback through high-resolution color displays, allowing for better identification of targets. In addition, the market is seeing an increase in demand for waterproof and robust designs that cater to diverse environments—from beaches to urban areas—making them suitable for a wide range of applications. These features are particularly appealing to B2B buyers looking to invest in versatile, high-quality products that can perform under various conditions.

Furthermore, the rise of e-commerce and digital marketing is transforming sourcing practices. International buyers are increasingly utilizing online platforms to compare features, prices, and reviews, leading to more informed purchasing decisions. As manufacturers continue to innovate and enhance their offerings, B2B buyers are positioned to leverage these advancements to meet their specific needs, ensuring they remain competitive in their respective markets.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Metal Detectors?

Sustainability and ethical sourcing are becoming critical considerations in the metal detector industry. As awareness of environmental impacts grows, buyers are urged to prioritize suppliers who adopt eco-friendly practices. This includes using recyclable materials in manufacturing, minimizing waste, and ensuring energy-efficient production processes. For instance, choosing metal detectors with components sourced from sustainable materials can significantly reduce the ecological footprint associated with these products.

Furthermore, ethical supply chains are essential for maintaining corporate social responsibility. B2B buyers should assess suppliers for compliance with labor standards, transparency in sourcing, and fair trade practices. This not only fosters trust with consumers but also enhances brand reputation in a market where consumers increasingly favor companies that demonstrate social responsibility.

The availability of ‘green’ certifications can serve as a valuable indicator for buyers. Certifications such as ISO 14001, which focuses on effective environmental management systems, can guide buyers in selecting manufacturers committed to sustainable practices. By prioritizing these elements, B2B buyers can not only contribute positively to the environment but also align their purchasing strategies with the growing consumer demand for sustainable products.

What is the Brief Evolution of Metal Detectors with Color Displays?

The evolution of metal detectors with color displays has been marked by significant technological advancements over the past few decades. Initially, metal detectors featured basic analog displays that provided limited information about detected objects. However, with the advent of digital technology, manufacturers began integrating LCD screens, allowing for enhanced visual feedback and better target identification.

The introduction of advanced signal processing technologies, such as the Multi-IQ+™ engine, has further transformed the market. These innovations enable metal detectors to operate across multiple frequencies simultaneously, increasing detection accuracy and depth. As color display technology has improved, detectors now offer detailed visual representations of targets, including ferrous and non-ferrous identification, which is crucial for efficient treasure hunting and archaeological applications.

Today, metal detectors are not only tools for hobbyists but are also widely used in security and industrial applications, reflecting their versatility and the ongoing demand for sophisticated detection equipment. This evolution underscores the importance of staying informed about technological advancements, as they can significantly impact purchasing decisions for B2B buyers seeking the best solutions in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of metal detector with color display

-

How do I choose the right metal detector with a color display for my business needs?

Choosing the right metal detector involves assessing your specific requirements, such as the types of materials you want to detect, the environments in which you will operate, and your budget. Consider detectors with advanced features like adjustable sensitivity, waterproof capabilities, and customizable search modes for diverse applications. Additionally, look for those with robust data interpretation tools, such as 2D ID maps, which can enhance decision-making. Consulting with suppliers about their product specifications can also help ensure that the detector fits your operational needs. -

What are the key features to look for in a metal detector with a color display?

When sourcing a metal detector, prioritize features such as high-resolution color displays for clear visibility, advanced discrimination settings to filter out unwanted metals, and adjustable audio settings for better signal interpretation. Look for detectors with fast recovery speeds for efficient target identification, and waterproof designs for versatility in various terrains. Furthermore, features like customizable search modes and long battery life can significantly enhance usability in the field, making your investment more effective. -

What is the average lead time for purchasing metal detectors internationally?

Lead times for international orders can vary significantly based on the supplier’s location, the shipping method chosen, and customs clearance procedures. Typically, you can expect lead times ranging from 4 to 12 weeks. It’s advisable to discuss timelines with your supplier upfront to align expectations. Ensure to factor in additional time for any potential delays due to customs or local regulations in your country. -

How can I vet suppliers of metal detectors with color displays?

To vet suppliers effectively, start by researching their reputation in the market, including customer reviews and testimonials. Request references from previous clients and check for industry certifications or compliance with international standards. Conduct a thorough background check on the company’s history and their experience in exporting metal detectors. Engaging in direct communication to assess their responsiveness and willingness to provide detailed product information is also vital. -

What are common payment terms when purchasing metal detectors internationally?

Payment terms can vary widely depending on the supplier and the transaction size. Common options include letters of credit, bank transfers, or payment upon delivery. Some suppliers may offer payment plans for bulk purchases. It’s crucial to negotiate terms that protect your interests while ensuring that the supplier remains confident in the transaction. Be sure to document all agreements to avoid misunderstandings. -

What is the Minimum Order Quantity (MOQ) for metal detectors with color displays?

MOQs can differ significantly by supplier and product type. Generally, for metal detectors, MOQs might range from 5 to 50 units. Suppliers may set MOQs based on production costs, inventory levels, or market demand. If you require a smaller quantity, inquire about the possibility of a trial order or sample unit. Discussing your specific needs can help you negotiate more favorable terms. -

How do I ensure quality assurance for my metal detector order?

To ensure quality assurance, request detailed product specifications and quality certifications from your supplier. Discuss the manufacturing processes and any quality control measures they implement during production. Consider requesting samples or conducting third-party inspections prior to shipment. Establishing a clear return policy and warranty terms in your purchase agreement can also safeguard against defective units. -

What logistics considerations should I keep in mind when importing metal detectors?

When importing metal detectors, consider factors such as shipping costs, customs duties, and delivery timelines. Choose a reliable freight forwarder with experience in handling electronics to navigate complex logistics. Understand the import regulations in your country, including any certifications required for electronic devices. Additionally, ensure that the packaging is suitable for international transport to prevent damage during transit.

Top 5 Metal Detector With Color Display Manufacturers & Suppliers List

1. Minelab – MANTICORE Metal Detector

Domain: minelab.com

Registered: 1996 (29 years)

Introduction: MANTICORE Metal Detector features Multi-IQ+ technology, offering 50% more power than the EQUINOX series. It includes a powerful 2D ID Map for identifying targets, adjustable audio settings (1, 2, or 5-tone options), and fast target response with recovery speeds from 0 to 8. The detector has an IP68 rating for underwater use up to 5 meters (16 ft) and a lightweight design at 1.3 kg (2.9 lbs), colla…

2. AJAX DETECTION – Ajax Detection Tropic Metal Detector

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Ajax Detection Tropic Metal Detector with Color Screen”, “brand”: “AJAX DETECTION”, “condition”: “New”, “price”: “$1,960.00”, “shipping”: “Free shipping”, “estimated_delivery”: “Sat, Sep 13 – Sat, Sep 20”, “quantity_available”: “3”, “item_number”: “186312663993”, “feedback_rating”: “78.6% positive feedback”, “payment_options”: “As low as $121.34/mo with Klarna”, “return_policy”: “Return…

3. KENTFAITH – Hand Held Metal Detector with LCD Display

Domain: kentfaith.com

Registered: 2011 (14 years)

Introduction: Product Name: Hand Held Metal Detector with LCD Display

Brand: KENTFAITH

Model: GW50.0060

Price: $21.99 (originally $27.49, 20% OFF)

SKU: GW50.0060

Dimensions: Length 24 cm (9.3 in), Width approx. 1.5 in (3.8 cm) tapered to 0.875 in (2.2 cm)

Weight: 200g

Battery: 9V (not included)

Features:

– LCD display for detection signal strength, battery level, and mode

– High sensitivity with 360° scanning

…

4. Gzzhi – Color Screen Metal Detector

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Gzzhi Color Screen Metal Detector, Higher Accuracy, Adjustable, Waterproof, 11″ Inch Search Coil, Features Pinpoint & Disc Modes, Ideal for Detecting Gold, Coins, and Treasures, Suitable for Treasure Hunting, Encourages Hobby and Family Bonding.

5. MCD – Full Color Touch Display Conveyor Belt Metal Detector

Domain: doorframemetaldetector.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “Full Color Touch Display Conveyor Belt Metal Detector for Food Industry”, “Speed”: “40 m/min”, “Place of Origin”: “China”, “Brand Name”: “MCD”, “Certification”: [“ISO”, “CE”], “Model Number”: “MCD-F500QF”, “Minimum Order Quantity”: “1 set”, “Price”: “Negotiable”, “Packaging Details”: “Strong Wooden Case”, “Delivery Time”: “Normally within 5 working days”, “Payment Terms”: [“T/T”,…

Strategic Sourcing Conclusion and Outlook for metal detector with color display

In the rapidly evolving market of metal detectors with color displays, strategic sourcing is essential for international B2B buyers looking to leverage cutting-edge technology for enhanced detection capabilities. Key takeaways from our guide include the importance of investing in advanced features such as Multi-IQ+ technology for improved target identification and recovery speed. Additionally, the versatility of customizable search modes enables buyers to adapt detectors to various environments, whether for treasure hunting or archaeological exploration.

As businesses from Africa, South America, the Middle East, and Europe consider procurement, aligning with manufacturers that offer robust, high-performance detectors will not only enhance operational efficiency but also ensure a competitive edge in the market. The emphasis on durability, user-friendly interfaces, and waterproof capabilities further underscores the value of these devices in diverse conditions.

Looking forward, the demand for innovative metal detection solutions is poised to grow. We encourage international buyers to engage with suppliers that prioritize quality and technology advancements. By doing so, you can ensure your investment leads to successful outcomes in your detection projects. Start exploring these opportunities today to stay ahead in the dynamic landscape of metal detection.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.