Is Your Liquid Filtration Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for liquid filtration

In today’s competitive landscape, sourcing reliable liquid filtration solutions poses significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Germany. The need for effective filtration systems spans various industries, from food and beverage to pharmaceuticals, where maintaining product integrity and compliance with stringent quality standards is paramount. This guide serves as a comprehensive resource to help buyers navigate the complexities of liquid filtration, covering essential topics such as types of filters, applications, supplier vetting processes, and cost considerations.

By delving into the intricacies of liquid filtration, this guide empowers decision-makers to make informed purchasing choices. Whether you’re seeking high-performance filter elements, durable housings, or specialized filtration systems, understanding the nuances of each option is critical to optimizing operational efficiency and reducing long-term costs. Furthermore, we provide actionable insights to help buyers evaluate supplier credibility, ensuring that your sourcing process aligns with your quality expectations and business goals. With a focus on global market dynamics and regional considerations, this guide is designed to facilitate strategic decision-making for B2B buyers aiming to enhance their liquid filtration processes.

Understanding liquid filtration Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bag Filters | Simple design, cost-effective, various material options | Water treatment, food & beverage, chemicals | Pros: Low initial cost, easy to replace. Cons: Limited filtration precision, may require frequent changes. |

| Cartridge Filters | Compact, high filtration efficiency, customizable | Pharmaceuticals, electronics, food processing | Pros: High dirt-holding capacity, versatile. Cons: Higher upfront cost, may require specific housings. |

| Membrane Filters | Fine filtration capabilities, removes bacteria and viruses | Biotechnology, pharmaceuticals, water purification | Pros: High purity levels, long lifespan. Cons: Expensive, requires regular maintenance and monitoring. |

| Granular Media Filters | Uses layers of media to filter, effective for large particles | Wastewater treatment, aquaculture, swimming pools | Pros: Effective for large volumes, low operational costs. Cons: Space-intensive, requires backwashing. |

| Depth Filters | Multi-layered structure, captures particles throughout the medium | Oil and gas, food and beverage, chemicals | Pros: High dirt-holding capacity, continuous flow. Cons: Can be less efficient for very fine particles. |

What Are Bag Filters and When Are They Suitable for B2B Buyers?

Bag filters are a popular choice for various industries due to their simplicity and cost-effectiveness. They consist of a fabric bag that captures solid particles as liquid passes through. Bag filters are particularly suitable for water treatment, food and beverage production, and chemical processing. Buyers should consider the filtration rating and material of the bags, as these factors can significantly impact performance and longevity. While they are easy to replace, their limited precision may necessitate more frequent changes, impacting operational efficiency.

How Do Cartridge Filters Differ from Other Types of Liquid Filtration?

Cartridge filters are known for their compact design and high filtration efficiency. They are widely used in industries like pharmaceuticals, electronics, and food processing, where cleanliness and precision are paramount. The customizable nature of cartridge filters allows B2B buyers to select specific dimensions and filtration levels to meet their unique requirements. Although they come with a higher initial cost, their durability and effectiveness in removing contaminants often justify the investment, particularly in applications demanding stringent quality standards.

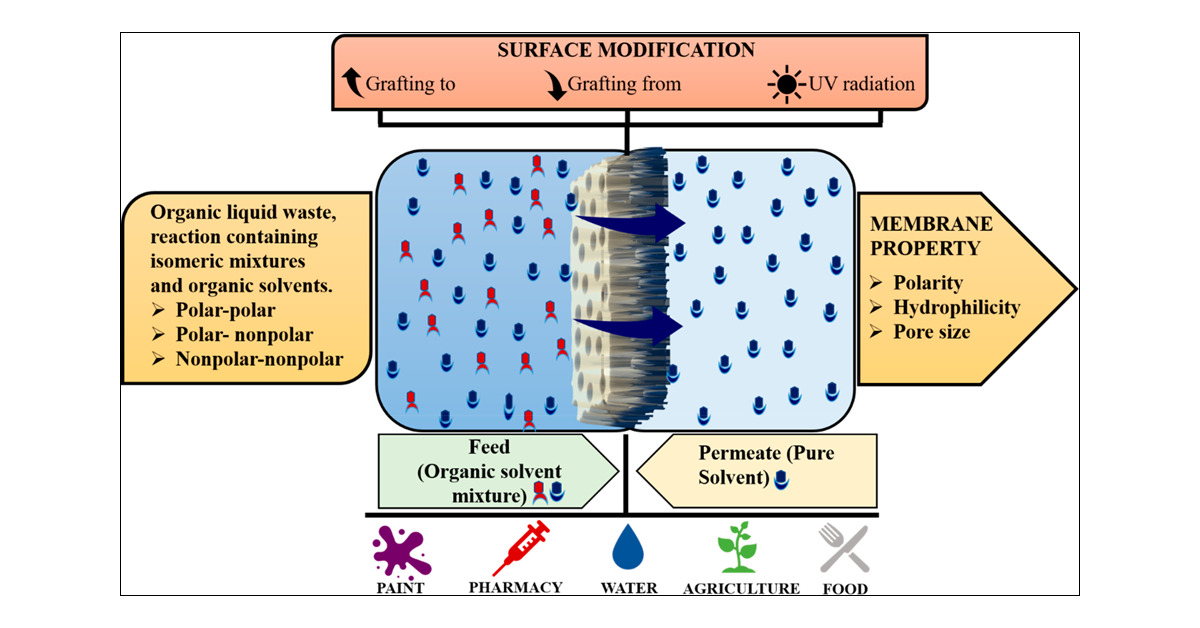

Why Choose Membrane Filters for High-Purity Applications?

Membrane filters are essential for applications requiring high levels of purity, such as biotechnology and pharmaceuticals. Their fine filtration capabilities can effectively remove bacteria and viruses, making them ideal for water purification and sterile processing. While membrane filters offer a long lifespan and exceptional performance, they come with a higher price tag and require regular maintenance to ensure optimal functioning. B2B buyers must weigh the cost against the critical need for purity in their specific applications.

What Are the Advantages of Granular Media Filters in B2B Settings?

Granular media filters utilize layers of filter media to capture larger particles, making them effective for high-volume applications like wastewater treatment and aquaculture. These filters are known for their low operational costs and ability to handle significant amounts of water without frequent replacements. However, they require more space and periodic backwashing to maintain efficiency. B2B buyers should consider their facility layout and maintenance capabilities when evaluating granular media filters for their operations.

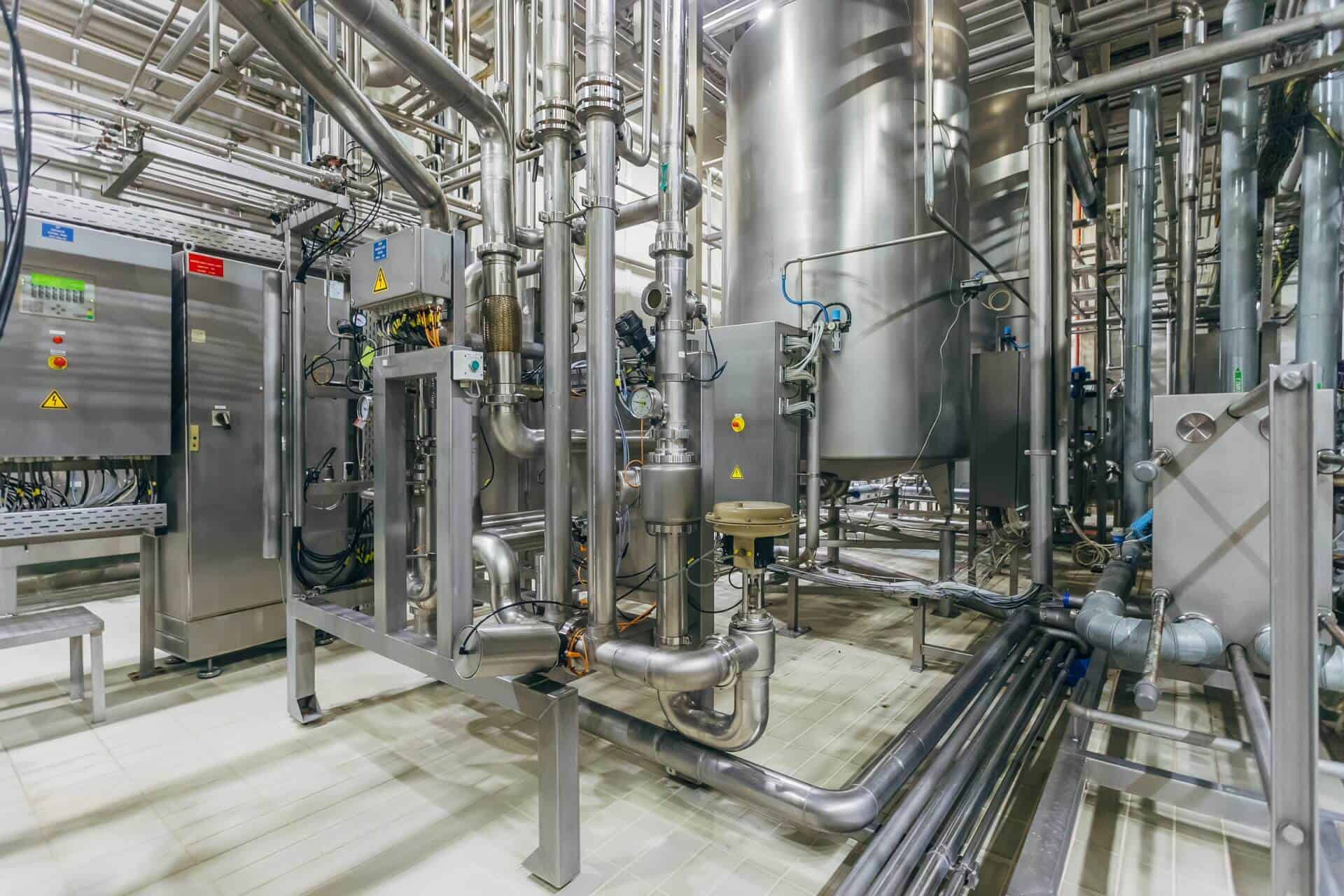

Illustrative image related to liquid filtration

How Do Depth Filters Provide Versatility in Liquid Filtration?

Depth filters feature a multi-layered structure that captures particles throughout the medium, making them versatile for various applications, including oil and gas, food and beverage, and chemical processing. Their high dirt-holding capacity allows for continuous flow, reducing downtime for filter changes. While depth filters are effective, they may not be as efficient for very fine particles compared to other types. Buyers should assess their specific filtration needs and the types of contaminants present in their liquids to determine the best fit.

Key Industrial Applications of liquid filtration

| Industry/Sector | Specific Application of Liquid Filtration | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration of non-alcoholic beverages | Ensures product purity and extends shelf life | Compliance with food safety regulations, filter material safety |

| Pharmaceuticals | Sterile filtration of drug formulations | Guarantees safety and efficacy of medications | Need for high-performance filters with strict quality standards |

| Water Treatment | Removal of contaminants from drinking water | Protects public health and complies with regulations | Consideration of filter types for specific contaminants |

| Oil and Gas | Filtration of drilling fluids and produced water | Enhances operational efficiency and equipment longevity | Selection of durable materials resistant to harsh conditions |

| Chemical Processing | Filtration of process liquids in chemical manufacturing | Improves product quality and operational reliability | Customization for specific chemicals and flow rates |

How is Liquid Filtration Used in the Food and Beverage Industry?

In the food and beverage sector, liquid filtration is crucial for maintaining product integrity and safety. It is employed to remove particulates, microorganisms, and contaminants from non-alcoholic beverages, ensuring compliance with health standards. This process extends the shelf life of products and enhances flavor by preserving the purity of ingredients. Buyers in this sector must prioritize filters that meet food safety regulations, focusing on materials that do not leach harmful substances into the liquids.

What Role Does Liquid Filtration Play in Pharmaceuticals?

Liquid filtration in pharmaceuticals is vital for producing sterile drug formulations. It removes bacteria, viruses, and particulate matter, ensuring that medications are safe for consumption. This level of filtration is critical in protecting patients and maintaining the efficacy of the drugs. International buyers should seek high-performance filtration systems that comply with stringent regulatory standards, emphasizing reliability and quality to avoid costly production disruptions.

How is Liquid Filtration Implemented in Water Treatment?

In water treatment, liquid filtration systems are essential for removing contaminants from drinking water, ensuring it meets health and safety standards. Filtration processes can eliminate harmful particles, chemicals, and microorganisms, protecting public health. Buyers in this industry must consider the specific contaminants present in local water sources and select appropriate filter types, such as membrane filters or activated carbon filters, to ensure effective treatment.

Why is Liquid Filtration Important in the Oil and Gas Industry?

Liquid filtration is a critical component in the oil and gas sector, particularly for filtering drilling fluids and produced water. This process enhances operational efficiency by preventing equipment wear and tear caused by contaminants. Effective filtration systems can significantly reduce maintenance costs and downtime. Buyers should focus on sourcing durable filtration solutions that can withstand harsh operational environments and consider the specific requirements of their drilling and production processes.

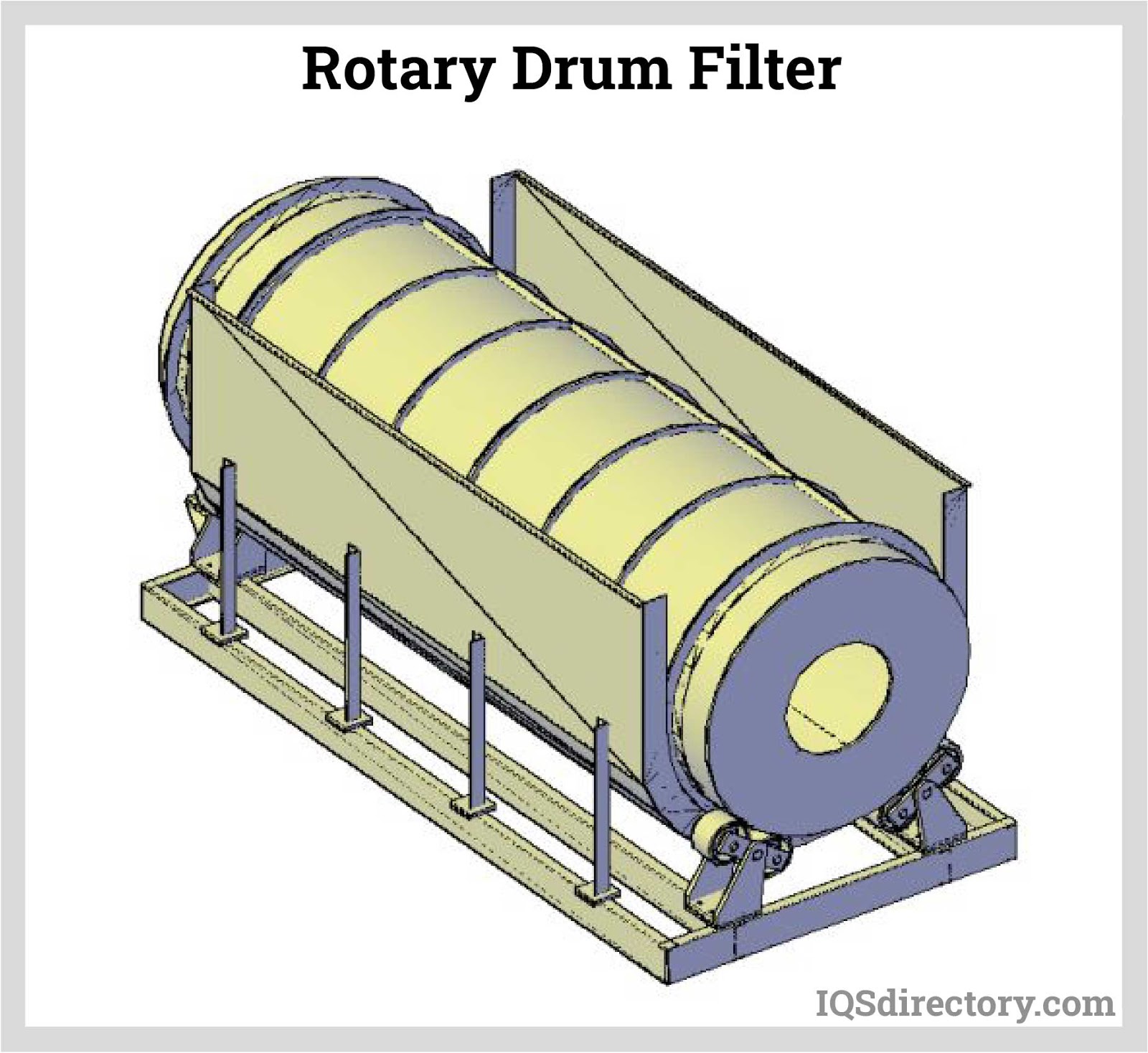

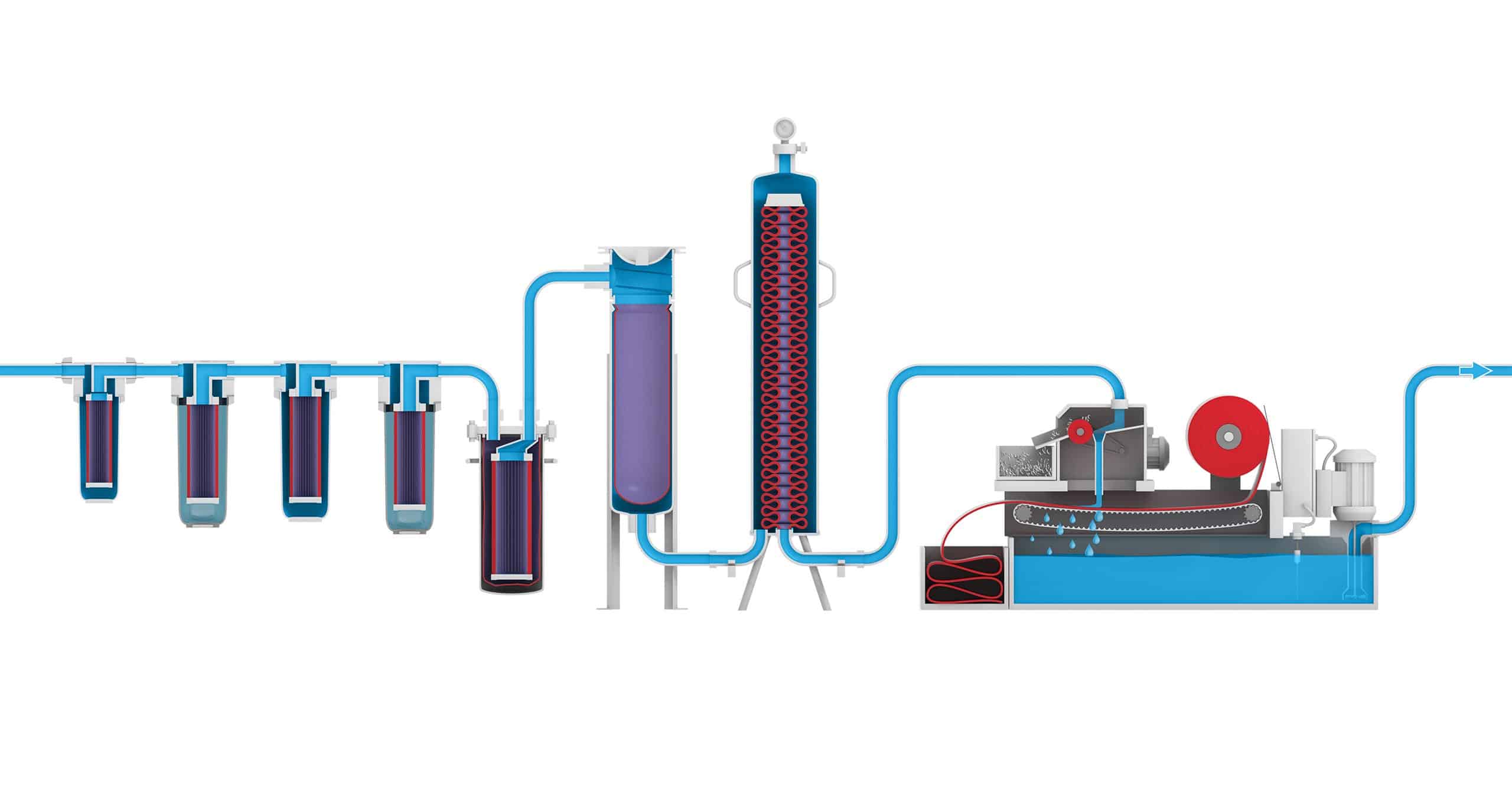

Illustrative image related to liquid filtration

What Benefits Does Liquid Filtration Provide in Chemical Processing?

In chemical processing, liquid filtration is essential for ensuring the quality and consistency of process liquids. It removes impurities that could affect chemical reactions and product quality, thereby enhancing operational reliability. Buyers in this sector need to consider customized filtration solutions that address specific chemical properties, flow rates, and potential chemical interactions to optimize their production processes.

3 Common User Pain Points for ‘liquid filtration’ & Their Solutions

Scenario 1: Inconsistent Liquid Quality During Production

The Problem: B2B buyers in industries such as food and beverage or pharmaceuticals often face the challenge of maintaining consistent liquid quality. Variability in filtration efficiency can lead to product contamination, impacting the integrity and safety of the final product. This inconsistency not only risks compliance with health and safety regulations but can also damage a company’s reputation and lead to financial losses from product recalls or customer dissatisfaction.

The Solution: To address this issue, buyers should invest in high-performance filtration systems tailored to their specific application requirements. Implementing premium filter elements, like those made from LifeTec™ materials, can enhance filtration efficiency and reduce the risk of contamination. Additionally, establishing a routine maintenance schedule for filter systems is crucial. Regularly checking and replacing filters based on operational metrics ensures optimal performance and helps maintain liquid quality. Investing in monitoring technologies that track filtration efficiency in real-time can also provide valuable insights, allowing for proactive adjustments before quality issues arise.

Scenario 2: High Operational Costs Due to Inefficient Filtration

The Problem: Many businesses struggle with the high operational costs associated with liquid filtration processes. Inefficient systems may require frequent filter replacements, excessive energy consumption, and higher labor costs for maintenance and monitoring. This inefficiency can erode profit margins and hinder a company’s competitiveness in the global market, especially for international buyers who are sensitive to cost fluctuations.

The Solution: Buyers should focus on sourcing filtration systems that offer long-term cost benefits, such as low-maintenance and high-durability options. For instance, investing in advanced filter housings designed for high-flow applications can significantly reduce the frequency of filter changes. Selecting filter materials that offer greater chemical resistance can prolong filter life, reducing waste and operational downtime. Additionally, conducting a comprehensive cost analysis to evaluate the total cost of ownership (TCO) rather than just the initial purchase price can help identify solutions that provide the best value over time. Training staff to optimize filtration processes can further enhance efficiency and reduce costs.

Scenario 3: Difficulty in Sourcing Reliable Filtration Systems

The Problem: B2B buyers, particularly in emerging markets like Africa and South America, often encounter challenges in sourcing reliable liquid filtration systems. Issues may include limited availability of high-quality products, lack of local suppliers, and difficulties in navigating international shipping and import regulations. These challenges can lead to delays in production and increased operational risks, making it critical for businesses to find dependable filtration solutions.

The Solution: To effectively navigate these sourcing challenges, buyers should establish relationships with reputable filtration manufacturers that have a proven track record in global markets. Engaging with suppliers that offer comprehensive support, including technical assistance and after-sales service, can provide reassurance and facilitate smoother operations. Buyers should also consider leveraging online marketplaces or platforms that connect them with vetted suppliers and manufacturers. Conducting thorough research to understand local regulations and compliance requirements can further streamline the sourcing process. Finally, exploring options for local partnerships or collaborations can enhance supply chain resilience and ensure timely access to quality filtration products.

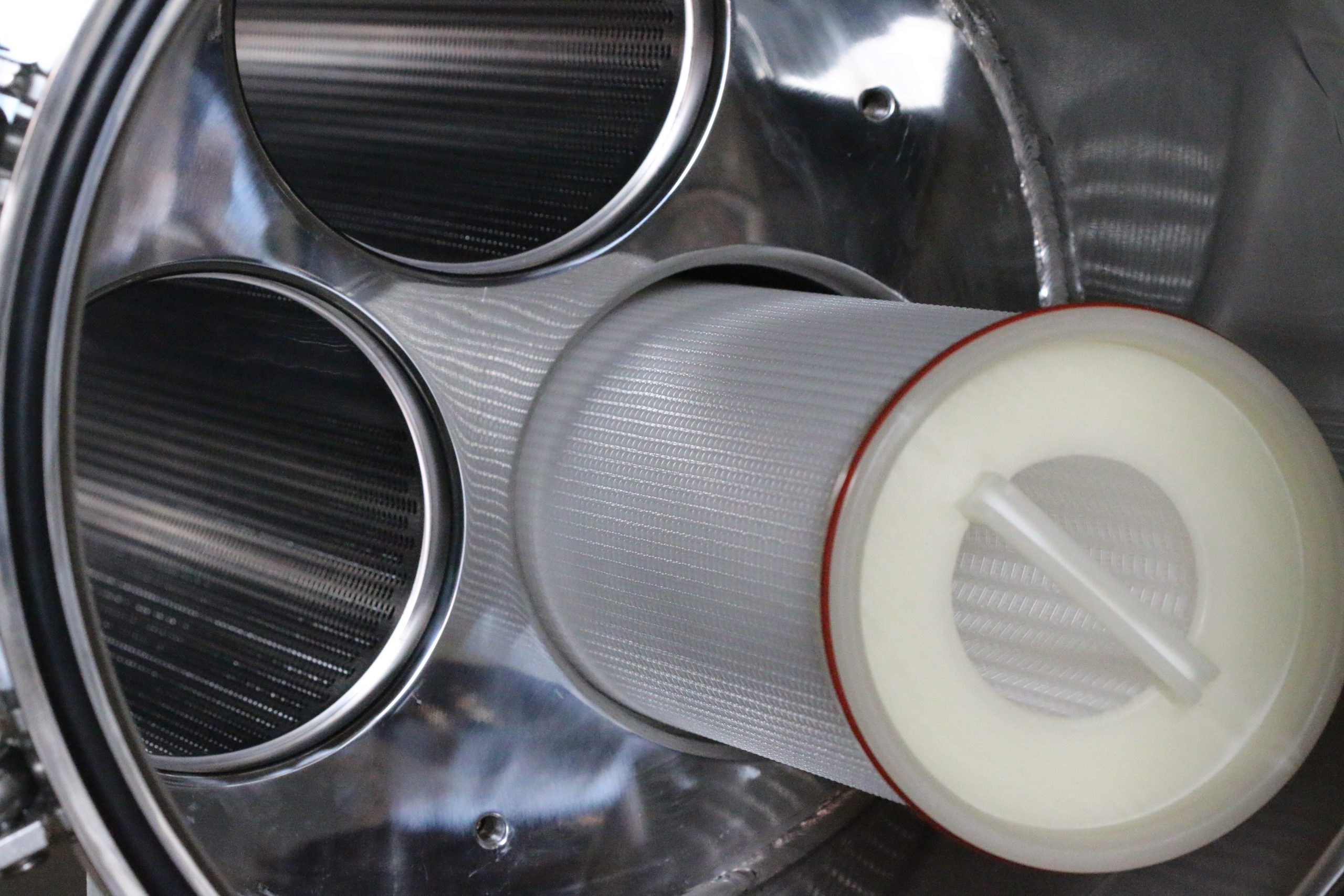

Illustrative image related to liquid filtration

Strategic Material Selection Guide for liquid filtration

What Are the Key Materials Used in Liquid Filtration Systems?

When selecting materials for liquid filtration systems, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of filtration solutions. Below, we analyze four common materials used in liquid filtration, focusing on their applications, benefits, and considerations for international B2B buyers.

How Does Polypropylene (PP) Perform in Liquid Filtration?

Polypropylene (PP) is widely used in liquid filtration due to its excellent chemical resistance and lightweight characteristics. It can withstand temperatures up to 60°C and pressures of around 6-10 bar, making it suitable for various applications, including water treatment and food processing.

Pros: PP is durable, cost-effective, and easy to manufacture. It is compatible with a wide range of chemicals, which makes it a versatile choice for many industries.

Cons: While PP is resistant to many chemicals, it may not perform well with strong oxidizing agents. Its lower temperature tolerance compared to other materials can limit its use in high-temperature applications.

Impact on Application: PP is ideal for filtering water and non-aggressive liquids, but it may not be suitable for applications involving high temperatures or aggressive chemicals.

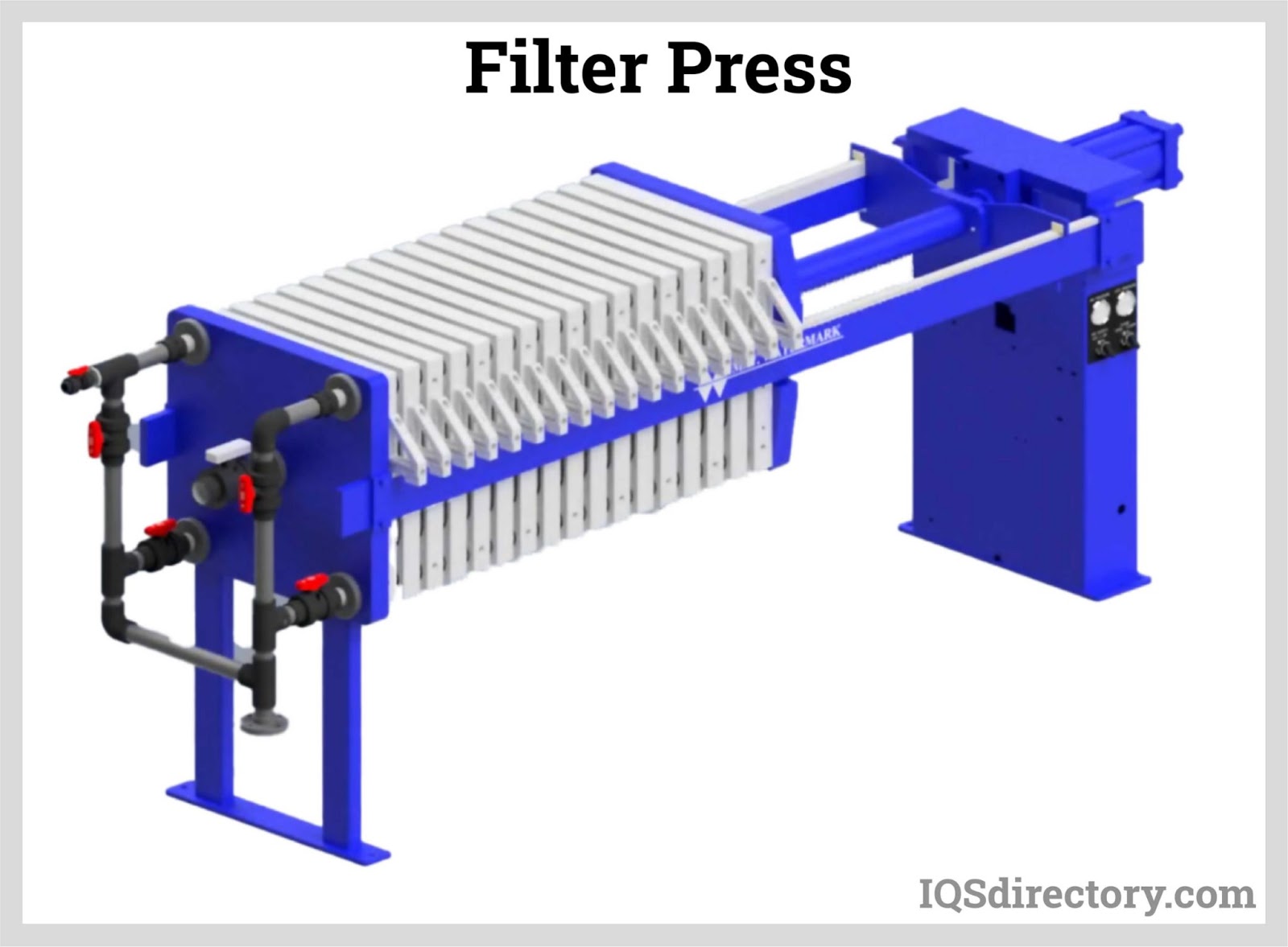

Illustrative image related to liquid filtration

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM and DIN, especially in food and beverage applications where safety regulations are stringent.

What Advantages Does Polyvinylidene Fluoride (PVDF) Offer?

Polyvinylidene fluoride (PVDF) is another popular material in liquid filtration, known for its high chemical resistance and ability to handle extreme temperatures (up to 90°C). Its strength and durability make it suitable for demanding applications, including pharmaceuticals and chemical processing.

Pros: PVDF is highly resistant to UV light, chemicals, and high temperatures, which enhances its longevity and performance in harsh environments.

Cons: The primary drawback is its higher cost compared to PP and other materials. Additionally, manufacturing PVDF components can be more complex, which may lead to longer lead times.

Impact on Application: PVDF is particularly effective in applications where chemical compatibility and temperature stability are crucial, such as in the filtration of aggressive solvents.

Considerations for International Buyers: Companies in the Middle East and Africa should verify that PVDF products meet local compliance standards, as regulations may vary significantly between regions.

Why Is Stainless Steel a Preferred Material for Liquid Filtration?

Stainless steel is often chosen for liquid filtration systems due to its exceptional durability and corrosion resistance. It can withstand high temperatures and pressures, making it ideal for industrial applications.

Pros: Stainless steel is robust, easy to clean, and resistant to corrosion, which extends the lifespan of filtration systems. It is also compatible with a wide range of liquids, including aggressive chemicals.

Cons: The primary disadvantage is its higher initial cost compared to plastic materials. Additionally, stainless steel components can be heavier, which may affect installation and handling.

Illustrative image related to liquid filtration

Impact on Application: Stainless steel is commonly used in food and beverage processing, pharmaceuticals, and chemical industries where hygiene and durability are paramount.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure that stainless steel filtration systems comply with EU regulations regarding food safety and material standards.

What Role Does Polyester Play in Liquid Filtration?

Polyester is frequently used in filter bags and cartridges due to its excellent filtration efficiency and cost-effectiveness. It can handle moderate temperatures and pressures, making it suitable for various applications.

Pros: Polyester is relatively inexpensive and provides good filtration performance. It is lightweight and easy to handle, which reduces shipping costs.

Cons: Polyester has limited chemical resistance and may degrade when exposed to strong solvents or high temperatures, which restricts its use in certain applications.

Illustrative image related to liquid filtration

Impact on Application: Polyester is best suited for general-purpose filtration, such as in water treatment and non-aggressive liquid applications.

Considerations for International Buyers: Buyers should be aware of local regulations regarding material safety, especially in food and beverage applications, where compliance with standards like JIS may be necessary.

Summary of Material Selection for Liquid Filtration

| Material | Typical Use Case for Liquid Filtration | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Water treatment, food processing | Excellent chemical resistance and cost-effective | Limited high-temperature performance | Low |

| Polyvinylidene Fluoride (PVDF) | Pharmaceuticals, chemical processing | High chemical resistance and durability | Higher cost and complex manufacturing | High |

| Stainless Steel | Food and beverage processing, chemicals | Exceptional durability and corrosion resistance | Higher initial cost and heavier weight | High |

| Polyester | General-purpose filtration | Cost-effective and good filtration efficiency | Limited chemical resistance | Low |

This guide provides valuable insights for B2B buyers considering liquid filtration solutions, helping them make informed decisions based on material properties and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for liquid filtration

What are the Main Stages in the Manufacturing Process of Liquid Filtration Products?

The manufacturing process for liquid filtration products is meticulous and involves several key stages to ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing and preparing raw materials such as polypropylene (PP), polyethylene (PE), or polyvinylidene fluoride (PVDF). The choice of material depends on the application and the specific properties required, such as chemical resistance and temperature tolerance. Materials are often subjected to rigorous quality checks to ensure they meet industry standards before they proceed to the next stage.

-

Forming: This stage encompasses the transformation of raw materials into usable filter components. Techniques like extrusion, molding, or weaving are employed. For instance, filter cartridges can be created through the extrusion of thermoplastic materials, while filter bags may be woven from specialized fabrics. The forming process is crucial as it defines the structural integrity and filtration efficiency of the final product.

-

Assembly: After forming, individual components are assembled into finished products. This may involve the combination of filter elements with housings, seals, and other accessories. Attention to detail during assembly is vital, as improper alignment or insecure fittings can compromise the filtration system’s performance. Automated assembly lines may be utilized to enhance efficiency and maintain consistency across large production runs.

-

Finishing: The final manufacturing stage includes surface treatments, labeling, and packaging. Finishing processes may involve sterilization, especially for sanitary applications, to eliminate any contaminants. The products are then inspected visually and through automated systems to ensure compliance with specifications before being packaged for shipment.

How is Quality Assurance Implemented in Liquid Filtration Manufacturing?

Quality assurance (QA) is integral to the manufacturing of liquid filtration products, ensuring that each item meets both international and industry-specific standards.

-

Relevant International Standards: Manufacturers often adhere to ISO 9001:2015, which outlines a framework for quality management systems. Compliance with this standard indicates that a company consistently provides products that meet customer and regulatory requirements. Additionally, certifications like CE mark for products sold in Europe and API standards for the oil and gas industry may also apply, depending on the specific filtration application.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are critical throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During production, random samples may be tested to monitor manufacturing processes and detect any deviations from quality standards.

– Final Quality Control (FQC): Before products leave the facility, they undergo rigorous testing to confirm that they meet all specifications, including filtration efficiency and physical integrity. -

Common Testing Methods: Various testing methods are employed to ensure product quality, including:

– Flow Rate Testing: Assesses the filtration efficiency and capacity of the filter.

– Pressure Drop Testing: Measures the resistance to flow through the filter, indicating potential clogging.

– Chemical Compatibility Testing: Ensures that the materials used in the filters will not degrade when exposed to the specific liquids they will filter.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure reliability and compliance.

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insights into the supplier’s quality management practices. Buyers can assess the cleanliness of the production environment, the qualifications of staff, and the presence of quality assurance processes.

-

Quality Assurance Reports: Suppliers should provide detailed reports outlining their quality control measures, testing results, and compliance with relevant standards. These documents serve as evidence of the supplier’s commitment to maintaining high-quality production standards.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of products before shipment. These independent inspections can provide an unbiased assessment of the manufacturer’s adherence to quality standards and specifications.

What are the Nuances of Quality Control for International B2B Buyers?

When dealing with suppliers from different regions, international B2B buyers should be aware of several nuances that may impact quality control.

-

Cultural Differences: Different countries may have varying standards of quality and production practices. Understanding these cultural differences can help buyers set realistic expectations and establish effective communication with suppliers.

-

Regulatory Requirements: Buyers must familiarize themselves with local regulations regarding liquid filtration systems in their target markets. For instance, products sold in Europe must comply with EU regulations, while those in the Middle East may need to meet different standards. Ensuring that suppliers are compliant with these regulations is crucial.

-

Language Barriers: Effective communication is vital in ensuring quality. Buyers should ensure that they can communicate clearly with suppliers, which may involve using professional translators or engaging local representatives who understand the language and culture.

By understanding the manufacturing processes and quality assurance measures in the liquid filtration industry, B2B buyers can make informed decisions, ensuring they partner with suppliers who maintain high standards of quality and reliability. This diligence will ultimately contribute to the success and integrity of their operations in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘liquid filtration’

The following practical sourcing guide provides a structured approach for B2B buyers looking to procure liquid filtration systems. By following these steps, you can ensure that you select the most suitable filtration solutions for your specific needs, enhancing product quality and operational efficiency.

Illustrative image related to liquid filtration

Step 1: Define Your Technical Specifications

Before beginning your search for liquid filtration systems, it’s essential to clearly define your technical requirements. Consider factors such as the type of liquid being filtered, desired particle size removal, flow rates, and operating conditions (e.g., temperature and pressure). Documenting these specifications helps narrow down your options and ensures that the solutions you evaluate are tailored to your application.

Step 2: Research Different Types of Filtration Systems

Understanding the various types of liquid filtration systems available is crucial. Familiarize yourself with options such as bag filters, cartridge filters, and membrane filters, each of which serves different applications and offers unique advantages. Knowing the differences will help you make an informed decision based on your filtration needs and budget constraints.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct thorough evaluations. Look for suppliers with a solid reputation in the industry and check for relevant certifications (e.g., ISO 9001:2015). Request case studies or references from clients in similar industries to assess their reliability and product performance.

Illustrative image related to liquid filtration

- Key considerations:

- Supplier experience and market presence.

- Customer support and service offerings.

- Delivery timelines and logistics capabilities.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their filtration products. Testing these samples in your specific operational environment allows you to evaluate their effectiveness and compatibility with your existing systems. Ensure that the samples meet your predefined technical specifications before making a larger commitment.

Step 5: Compare Pricing and Total Cost of Ownership

While price is an important factor, it shouldn’t be the sole criterion for your decision. Analyze the total cost of ownership, which includes initial purchase price, maintenance costs, and lifespan of the filtration system. A higher upfront investment may lead to lower operating costs and better performance over time, ultimately providing greater value.

Step 6: Review Warranty and Support Terms

Before finalizing your purchase, carefully review the warranty and support terms offered by the supplier. A robust warranty indicates confidence in the product quality and can save you from unexpected costs due to failures. Additionally, ensure that the supplier provides adequate technical support and maintenance services to assist you throughout the lifecycle of the filtration system.

Step 7: Negotiate Contract Terms

Once you have selected a supplier, engage in negotiations to finalize the contract terms. Pay attention to delivery schedules, payment terms, and any additional services included in the agreement. Clear communication and mutual understanding of expectations will help foster a successful long-term relationship with your supplier.

By following this structured checklist, you can confidently navigate the procurement process for liquid filtration systems, ensuring that your final selection aligns with your operational needs and quality standards.

Illustrative image related to liquid filtration

Comprehensive Cost and Pricing Analysis for liquid filtration Sourcing

What are the Key Cost Components in Liquid Filtration Sourcing?

When sourcing liquid filtration solutions, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type and quality of materials used for filters and housings significantly influence costs. Options range from basic polypropylene to high-grade PVDF or stainless steel, impacting both price and performance.

-

Labor: Labor costs can vary based on geographic location, with regions like Europe generally incurring higher labor costs than those in Africa or South America. Skilled labor may be necessary for manufacturing specialized filtration systems, which could further drive costs.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Efficient manufacturing processes can reduce these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs for specialized filter designs can be substantial. These costs are often amortized over larger production runs, making it beneficial for buyers to consider minimum order quantities (MOQs) that maximize cost-effectiveness.

-

Quality Control (QC): Investing in robust QC processes ensures that products meet industry standards and certifications, which can add to costs but ultimately reduce the risk of failures and associated liabilities.

-

Logistics: The cost of shipping and handling, particularly for international buyers, can be significant. Factors such as distance, shipping method, and the need for specialized handling (e.g., temperature control) can all impact logistics costs.

-

Margin: Suppliers will typically include a profit margin that reflects their operational costs and market conditions. Understanding industry standards for margins can aid in negotiation.

How Do Price Influencers Affect Liquid Filtration Costs?

Several factors can influence the pricing of liquid filtration products:

-

Volume/MOQ: Bulk purchasing often leads to cost savings. Buyers should negotiate MOQs that align with their needs while maximizing savings.

-

Specifications/Customization: Custom solutions tailored to specific applications can incur higher costs. Buyers should weigh the benefits of customization against potential savings from standardized products.

-

Materials: Higher quality materials generally lead to higher prices, but they also offer better performance and longevity. Assessing the total cost of ownership (TCO) can help justify the initial investment.

-

Quality/Certifications: Products with recognized certifications (e.g., ISO, FDA) may command higher prices due to the assurance of quality and compliance. Buyers should consider these certifications as part of their purchasing criteria.

-

Supplier Factors: Supplier reliability, reputation, and service capabilities can impact pricing. Established suppliers may charge a premium, but they often provide better support and product reliability.

-

Incoterms: Understanding the terms of sale can greatly influence overall costs. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting final pricing.

What Are the Best Buyer Tips for Negotiating Liquid Filtration Prices?

To secure the best pricing and terms, B2B buyers should adopt several strategies:

-

Negotiate Effectively: Leverage knowledge of market prices and competitor offerings during negotiations. Don’t hesitate to ask for discounts based on volume or long-term commitments.

-

Focus on Cost-Efficiency: Evaluate suppliers not just on price but on the overall value they provide, including reliability, delivery times, and after-sales support.

-

Consider Total Cost of Ownership: Beyond initial purchase price, consider maintenance, operational efficiency, and lifespan of the filtration systems when assessing value.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that may affect the final cost of products.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and terms. Suppliers are more likely to provide favorable conditions to loyal customers.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, geographic location, and specific buyer requirements. Always consult multiple suppliers to obtain accurate and competitive pricing tailored to your needs.

Alternatives Analysis: Comparing liquid filtration With Other Solutions

In the realm of liquid processing, choosing the right filtration solution is crucial for ensuring product integrity and operational efficiency. While liquid filtration systems are widely recognized for their effectiveness, several alternative methods exist that can also achieve similar goals. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their unique operational requirements.

| Comparison Aspect | Liquid Filtration | Membrane Filtration | Centrifugation |

|---|---|---|---|

| Performance | High efficiency in removing solids and particulates | Very effective for microorganisms and dissolved solids | Efficient for separating liquids and solids based on density |

| Cost | Moderate initial investment, with variable ongoing costs based on maintenance | Higher initial costs; requires specialized equipment | Generally lower operating costs, but high capital investment |

| Ease of Implementation | Relatively straightforward installation | Requires technical expertise for setup and operation | Complex setup; may need specialized training |

| Maintenance | Regular filter replacements; manageable | Membrane fouling; requires routine cleaning | Requires maintenance of centrifuge and regular cleaning |

| Best Use Case | Ideal for food and beverage, pharmaceuticals | Suitable for water treatment, dairy processing | Best for chemical separation, wastewater treatment |

What Are the Advantages and Disadvantages of Membrane Filtration?

Membrane filtration utilizes a semi-permeable membrane to separate particles from liquids. This method excels in removing microorganisms and small dissolved solids, making it particularly beneficial for applications in water treatment and dairy processing. However, the initial investment can be significant due to the specialized equipment required. Moreover, membranes can foul over time, necessitating routine cleaning and maintenance to maintain efficiency, which can increase operational costs.

How Does Centrifugation Compare to Liquid Filtration?

Centrifugation employs centrifugal force to separate liquids based on density, making it highly effective for separating solids from liquids in various industrial processes. This method is particularly advantageous for applications in chemical separation and wastewater treatment, where quick and effective separation is required. Although centrifugation has lower ongoing operational costs, the initial capital investment can be quite high. Additionally, the complexity of the setup may require specialized training for personnel, which can be a barrier for some organizations.

Illustrative image related to liquid filtration

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating liquid filtration and its alternatives, B2B buyers should consider several factors, including performance requirements, budget constraints, and operational capabilities. Each solution has its strengths and weaknesses, making it vital to align the choice with the specific application and industry standards. For instance, industries requiring stringent microbial control might prioritize membrane filtration, while those focusing on cost-effective solid-liquid separation may lean towards centrifugation. Ultimately, the decision should reflect a balance between initial investment, operational efficiency, and maintenance requirements to ensure long-term success.

Essential Technical Properties and Trade Terminology for liquid filtration

What Are the Key Technical Properties of Liquid Filtration Systems?

When selecting liquid filtration systems, understanding the essential technical properties is crucial for ensuring optimal performance and compliance with industry standards. Here are several critical specifications that B2B buyers should consider:

-

Material Grade

– The material of the filter elements and housings significantly affects durability and compatibility with various liquids. Common materials include polypropylene (PP), polyethylene (PE), and polyvinylidene fluoride (PVDF). Each material has unique chemical resistance properties, impacting its suitability for different applications. Choosing the right material can reduce maintenance costs and extend the lifespan of the filtration system. -

Filtration Rating

– This specification indicates the particle size that the filter can effectively capture, typically measured in microns (µm). For instance, a filter rated at 1 micron can remove particles of that size or larger. Understanding the filtration rating is vital for industries such as food and beverage, pharmaceuticals, and chemicals, where product purity is paramount. -

Operating Pressure

– The maximum pressure at which the filtration system can operate is another critical property. Standard operating pressures often range from 6 to 10 bar. Selecting a filter with the appropriate operating pressure ensures safety and optimal flow rates, preventing system failures that can lead to costly downtimes. -

Flow Rate

– This refers to the volume of liquid that can pass through the filter per unit of time, usually measured in liters per minute (L/min). A higher flow rate can enhance operational efficiency, especially in high-demand environments. However, it is essential to balance flow rate with the filtration efficiency to maintain product integrity. -

Temperature Tolerance

– Different materials and filter designs have varying temperature tolerances, affecting their performance in specific environments. For instance, PVDF can withstand higher temperatures (up to 90ºC) compared to polypropylene (60ºC). This property is crucial for industries that deal with heated liquids, ensuring the filter’s integrity and functionality under operational conditions.

What Are Common Trade Terms in Liquid Filtration?

Navigating the liquid filtration market requires familiarity with specific jargon and trade terminology. Here are some essential terms that B2B buyers should know:

Illustrative image related to liquid filtration

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that may be marketed under another company’s brand. In the context of liquid filtration, understanding OEM relationships can help buyers identify reliable suppliers and ensure product compatibility. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, particularly for businesses that require large volumes of filtration products. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products or services. Issuing an RFQ is a standard practice in B2B transactions, allowing buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms can help buyers understand shipping costs, risks, and responsibilities, leading to smoother transactions. -

Lead Time

– This term refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is crucial for project planning and inventory management, ensuring that operations run smoothly without interruptions. -

Filter Media

– This term describes the material used to capture contaminants in the liquid being filtered. Filter media can vary widely, including synthetic materials, natural fibers, and metals. Selecting the right filter media is vital for achieving desired filtration results in specific applications.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when selecting liquid filtration systems, ensuring they meet their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the liquid filtration Sector

What Are the Current Market Dynamics and Key Trends in Liquid Filtration?

The liquid filtration market is experiencing significant growth driven by various global factors. Increasing demand for clean water and stringent regulations regarding water quality are major drivers. Industries such as food and beverage, pharmaceuticals, and chemicals are particularly focused on enhancing product quality and safety, leading to a surge in demand for advanced filtration solutions. Emerging technologies, such as smart filtration systems equipped with IoT capabilities, are revolutionizing the way businesses monitor and maintain filtration processes, allowing for real-time data analytics and predictive maintenance. This trend is especially beneficial for international buyers in Africa, South America, the Middle East, and Europe, as it enhances operational efficiency and reduces downtime.

Moreover, there is a noticeable shift towards customized filtration solutions that cater to specific industry requirements. For instance, the rise of high-performance filter elements, such as Donaldson’s LifeTec™ filters, underscores the importance of efficiency and reliability in liquid filtration systems. As companies increasingly seek to optimize their supply chains, sourcing high-quality filter housings and elements that can withstand diverse operational conditions is becoming paramount. Buyers are encouraged to explore partnerships with manufacturers that prioritize innovation and quality, ensuring they remain competitive in their respective markets.

How Is Sustainability Influencing Sourcing Trends in Liquid Filtration?

Sustainability is rapidly becoming a critical factor in sourcing decisions within the liquid filtration sector. The environmental impact of filtration processes and materials is under scrutiny, prompting businesses to seek ‘green’ certifications and eco-friendly materials. For instance, manufacturers that utilize recyclable or biodegradable filter media are gaining favor among buyers who prioritize sustainable practices. This shift is particularly relevant in regions like Europe, where regulatory frameworks are increasingly stringent regarding environmental compliance.

Ethical sourcing is also gaining traction, with businesses recognizing the importance of transparent supply chains. Companies are now more inclined to partner with suppliers that demonstrate a commitment to ethical labor practices and environmental stewardship. This approach not only mitigates risks associated with supply chain disruptions but also enhances brand reputation and customer loyalty. Buyers should consider evaluating their suppliers based on their sustainability practices, ensuring alignment with their own corporate social responsibility goals.

What Is the Historical Evolution of Liquid Filtration Technology?

The evolution of liquid filtration technology can be traced back to the early industrial revolution, where simple mechanical filters were utilized to separate solids from liquids. Over the decades, advancements in materials science and engineering have led to the development of sophisticated filtration systems capable of removing particulates at a micron level. The introduction of synthetic filter media, such as polypropylene and polyethylene, has significantly improved the efficiency and longevity of filtration systems.

In recent years, the industry has witnessed a shift towards automation and smart technologies, enhancing the capabilities of traditional filtration systems. This evolution is particularly relevant for B2B buyers who are looking to leverage technology for improved operational efficiencies. As the market continues to advance, staying abreast of technological innovations will be essential for businesses aiming to optimize their liquid filtration processes.

In summary, understanding the market dynamics, sourcing trends, and historical context of liquid filtration is crucial for B2B buyers. By prioritizing sustainability, technological advancements, and innovative partnerships, companies can enhance their competitive edge in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of liquid filtration

-

How do I select the right liquid filtration system for my industry?

Selecting the appropriate liquid filtration system requires a thorough understanding of your specific application. Begin by identifying the type of liquid being filtered, its contaminants, and the desired purity level. Evaluate the filtration methods available—such as bag filters, cartridge filters, or membrane systems—based on efficiency, flow rate, and maintenance needs. Consider factors like chemical compatibility and temperature tolerance of materials used in the filtration system. Consulting with suppliers who can provide tailored recommendations based on your unique requirements can further streamline the selection process. -

What are the key factors to consider when sourcing liquid filtration suppliers?

When sourcing suppliers for liquid filtration, prioritize their industry experience, product range, and certifications. Look for companies with a proven track record in your specific sector, whether it’s food and beverage, pharmaceuticals, or industrial applications. Evaluate their production capabilities, quality assurance processes, and customer service. Additionally, consider their ability to provide customization options to meet your specific needs. Request references or case studies to gauge their reliability and responsiveness in past projects. -

What are the benefits of custom liquid filtration solutions?

Custom liquid filtration solutions offer significant advantages over standard options. They are designed to meet the specific requirements of your application, ensuring optimal filtration efficiency and product quality. Custom solutions can address unique challenges such as extreme temperatures, specific contaminant types, or unique flow rates. Additionally, they often lead to cost savings in the long run by minimizing waste and reducing maintenance needs. Collaborating with a supplier that understands your industry’s nuances can facilitate the development of a tailored solution that enhances operational performance. -

What is the minimum order quantity (MOQ) for liquid filtration products?

Minimum order quantities (MOQs) for liquid filtration products vary by supplier and product type. Typically, MOQs can range from a few units for specialized items to larger quantities for standard products. Discussing your requirements with potential suppliers is crucial to understanding their MOQ policies. Some suppliers may offer flexibility on MOQs for first-time orders or ongoing partnerships, especially if you commit to long-term agreements. Understanding your usage patterns can help negotiate favorable terms that align with your operational needs. -

What payment terms should I expect when purchasing liquid filtration products?

Payment terms for liquid filtration products can differ widely among suppliers. Common arrangements include net 30 or net 60 terms, where payment is due within 30 or 60 days post-delivery. Some suppliers may require a deposit upfront, especially for custom orders or high-value items. It’s essential to clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider discussing options for bulk discounts or extended payment plans if you’re making a significant investment, as this can improve cash flow management for your business. -

How can I ensure quality assurance in liquid filtration products?

To ensure quality assurance in liquid filtration products, request documentation that verifies compliance with industry standards and certifications, such as ISO or FDA approvals. Inquire about the supplier’s quality control processes, including testing procedures for materials and finished products. Conducting audits or site visits can provide deeper insights into their manufacturing practices. Additionally, consider establishing a quality agreement that outlines expectations, testing protocols, and responsibilities to safeguard your interests and ensure the reliability of the filtration solutions provided. -

What logistics considerations should I keep in mind when importing liquid filtration products?

When importing liquid filtration products, logistics considerations are critical for timely and cost-effective delivery. Assess shipping methods and costs, including freight, customs duties, and insurance. Be aware of regulations and documentation requirements specific to your country, as these can impact delivery times. Work with suppliers who have experience in international shipping to navigate potential challenges. Additionally, consider inventory management strategies, such as just-in-time ordering, to align with your operational demands and minimize storage costs. -

How do I troubleshoot common issues with liquid filtration systems?

Troubleshooting common issues with liquid filtration systems begins with identifying symptoms such as reduced flow rates, increased pressure drops, or product contamination. Start by checking for clogged filters or bags, which may need replacement or cleaning. Inspect the system for leaks or improper connections that could affect performance. Regular maintenance schedules and monitoring pressure gauges can help preemptively identify issues. If problems persist, consult the supplier’s technical support for guidance or consider professional service to ensure optimal system functionality.

Top 6 Liquid Filtration Manufacturers & Suppliers List

1. FiltraSupply – Liquid Filtration Solutions

Domain: filtrasupply.com

Registered: 2018 (7 years)

Introduction: Liquid Filtration Products include: Industrial Bag Filter Housings, Vessels, Pods, Liquid Bag Filters (filter socks), FSI/Pall Replacement Filters, Accessories for Industrial Liquid Process Applications, Filtra-Systems Bag Filter Housing Replacement Parts, PFAS/PFOA/PFOS Removal Filters, Universal Refrigerator/Freezer Inline PFAS/PFOA/PFOS Removal Water Filters. Key product types include: 1 micron…

2. Entegris – Liquid Filtration Solutions

Domain: entegris.com

Registered: 1999 (26 years)

Introduction: Liquid Filtration and Purification products include Liquid Filters, Liquid Purifiers, Liquid Filter Housings, and various solutions for contamination control and fluid management. The product catalog features chemistries, chemical delivery systems, specialty chemicals, cleaning solutions, and advanced deposition materials. Key offerings include TitanKlean® and PlanarClean® cleaning solutions, Fluo…

3. General Filtration – Liquid Filtration Solutions

Domain: generalfiltration.com

Registered: 1998 (27 years)

Introduction: General Filtration offers a variety of liquid filtration products including:

1. Filter Cartridges – Available in various formats, materials, and micron ratings for diverse applications.

2. Filter Housings – Vessels for bags, cartridges, and custom options for unique applications.

3. Filter Bags – Felt, mesh, and specialty bags in various sizes.

4. Adsorbents & Stabilizers – Carbon and silica-base…

4. Liquid Filters – Essential Filtration Solutions

Domain: liquid-filters.net

Registered: 2002 (23 years)

Introduction: Liquid filters are porous mechanisms that enable filtration systems to remove solid particles from a fluid stream. They are essential in industrial processes that rely on various fluids which can easily get contaminated by unwanted solids. Key types of liquid filters include: 1. Bag Filters 2. Biodiesel Filters 3. Cartridge Filters 4. Chemical Filters 5. Filter Media 6. Gas Filters 7. Hydraulic Fi…

5. 3M – Filtration & Separation Solutions

Domain: 3m.com

Registered: 1988 (37 years)

Introduction: 3M Filtration & Separation offers a variety of products including:

– 3M™ High Flow Series System DWS160-L: For Cold Beverage Applications, 0.2 um NOM, 2.5 gpm, 6000 gal, 1/Case

– 3M™ Under Sink Drinking Water Filter Cartridge 3MDW311-1: 0.2 um, 1/Case

– 3M™ High Flow Series DUAL PORT TRIPLE MANIFOLD (DP3XX): 3/4 in, MNPT, 1/Case

– 3M™ OCS Series Water Filtration System VH3/OWS120-L: For Espres…

6. The Cary Company – Industrial Liquid Filtration

Domain: thecarycompany.com

Registered: 1999 (26 years)

Introduction: Wholesale Bulk Distributor of Industrial Liquid Filtration. Categories include Liquid Filtration, Liquid Filter Bags, Liquid Filter Cartridges, and Replacement Filter Cartridges for Liquid Filter Bags. Additional filtration products include Filtration Basket Strainers.

Strategic Sourcing Conclusion and Outlook for liquid filtration

How Can Strategic Sourcing Enhance Your Liquid Filtration Solutions?

In today’s competitive landscape, strategic sourcing is critical for optimizing liquid filtration processes across various industries. By prioritizing high-quality filtration systems, businesses can ensure product integrity, enhance operational efficiency, and reduce overall costs. Selecting reliable suppliers who offer advanced filtration technologies, such as LifeTec™ filter elements and various filter housing solutions, can significantly impact your production quality and sustainability efforts.

Furthermore, as global demand for clean and safe liquids continues to rise, particularly in emerging markets across Africa, South America, and the Middle East, it is imperative for international buyers to stay ahead of industry trends. Investing in innovative filtration solutions not only addresses regulatory compliance but also positions your company as a leader in sustainability and product excellence.

Looking forward, we encourage B2B buyers to leverage strategic partnerships with reputable filtration manufacturers. This approach will not only enhance your filtration capabilities but also foster long-term growth and resilience in your supply chain. Take the next step towards optimizing your liquid filtration processes today—partner with the right suppliers to secure your operational success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to liquid filtration

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.