Is Your Itw Bgk Finishing Systems Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for itw bgk finishing systems

In an increasingly competitive global market, sourcing reliable and efficient itw bgk finishing systems presents a significant challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With diverse manufacturing needs and varying environmental conditions, finding the right finishing systems that meet quality standards while being cost-effective is paramount. This guide is designed to equip international buyers with comprehensive insights into the different types of itw bgk finishing systems, their applications across various industries, and the essential criteria for supplier vetting.

Throughout this guide, we will delve into the key factors influencing the selection of finishing systems, including technological advancements, production capabilities, and potential cost implications. By addressing these critical aspects, we aim to empower buyers to make informed purchasing decisions that align with their operational goals and market demands.

Whether you are a procurement manager in Nigeria seeking robust solutions for textile finishing or a manufacturer in Vietnam exploring innovative coating technologies, this guide serves as your resource for navigating the complexities of sourcing itw bgk finishing systems. With actionable insights and expert recommendations, you will be well-equipped to enhance your supply chain efficiency and drive your business forward in today’s dynamic marketplace.

Understanding itw bgk finishing systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IR Heat Lamp Systems | Uses infrared technology for rapid drying | Packaging, printing, coatings | Pros: Fast curing time, energy-efficient. Cons: Limited to specific materials. |

| UV Curing Systems | Utilizes ultraviolet light for instant curing | Electronics, automotive, textiles | Pros: Versatile, suitable for various substrates. Cons: Initial equipment cost can be high. |

| Hot Air Drying Systems | Employs hot air circulation for drying | Wood finishing, paper products | Pros: Effective for large volumes, low operational costs. Cons: Longer drying times. |

| Convection Drying Systems | Combines hot air with convection for uniform drying | Food packaging, coatings | Pros: Even heat distribution, adaptable. Cons: Space-intensive setup. |

| LED Curing Systems | Leverages LED technology for curing | Printing, adhesives, coatings | Pros: Low energy consumption, longer lifespan. Cons: May require specific inks or substrates. |

What Are the Key Characteristics of IR Heat Lamp Systems?

IR Heat Lamp Systems are designed to provide rapid drying through infrared radiation, which penetrates the substrate and accelerates moisture evaporation. They are particularly suitable for applications in packaging and printing where quick turnaround times are essential. Buyers should consider the specific materials they are working with, as IR systems are most effective with certain substrates. While these systems are energy-efficient and reduce drying times, they may not be compatible with all materials, limiting their versatility.

How Do UV Curing Systems Stand Out in Various Applications?

UV Curing Systems use ultraviolet light to instantly cure inks and coatings, making them ideal for a wide range of applications, including electronics and textiles. The ability to cure at room temperature allows for the use of heat-sensitive substrates. Buyers should evaluate the initial investment against the long-term benefits of increased production speed and versatility. While UV systems offer numerous advantages, the upfront costs can be significant, and the need for specialized inks may add to the overall expense.

Why Choose Hot Air Drying Systems for High-Volume Needs?

Hot Air Drying Systems employ heated air circulation to dry products effectively, making them suitable for wood finishing and paper products. They are particularly advantageous for high-volume operations due to their lower operational costs and ability to handle large batches. However, buyers should be aware that drying times can be longer compared to other technologies, which may impact production schedules. Space requirements for these systems can also be a consideration, especially in smaller facilities.

What Benefits Do Convection Drying Systems Offer?

Convection Drying Systems utilize a combination of hot air and convection currents to ensure uniform drying across products. This method is particularly effective in food packaging and various coatings. Buyers should appreciate the even heat distribution, which minimizes the risk of uneven drying. However, the space-intensive nature of these systems may require careful planning in facility layout, and they may not be the fastest option available.

How Are LED Curing Systems Transforming the Industry?

LED Curing Systems represent a modern approach to curing that utilizes LED technology, offering significant advantages such as low energy consumption and extended bulb life. These systems are increasingly popular in printing and adhesive applications. Buyers should consider the compatibility of their materials with LED technology, as some inks may not perform optimally. While the energy savings and longevity are compelling benefits, the requirement for specific substrates can limit options for some businesses.

Key Industrial Applications of itw bgk finishing systems

| Industry/Sector | Specific Application of itw bgk finishing systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Surface finishing for automotive components | Enhanced durability and aesthetics, reduced production time | Availability of localized support, compliance with regional standards |

| Electronics | PCB coating and finishing | Improved product reliability and lifespan, reduced defects | Precision requirements, compatibility with various substrates |

| Packaging | Coating for food and beverage packaging | Extended shelf life, improved barrier properties | Regulatory compliance for food safety, eco-friendly options |

| Furniture | Finishing for wooden and metal furniture | Superior finish quality, increased market appeal | Customization options, sustainability practices |

| Textiles | Coating for protective textile finishes | Enhanced durability and stain resistance | Material compatibility, environmental regulations |

How are itw bgk finishing systems applied in automotive manufacturing?

In the automotive sector, itw bgk finishing systems are utilized for surface finishing of components such as body panels and interior parts. These systems provide coatings that enhance both the durability and aesthetics of automotive products. By integrating these finishing solutions, manufacturers can significantly reduce production time and improve the overall quality of their vehicles. International buyers must consider the availability of localized support and ensure that products comply with regional standards, particularly in markets like Nigeria and Vietnam.

What role do itw bgk finishing systems play in the electronics industry?

In electronics manufacturing, itw bgk finishing systems are employed for coating printed circuit boards (PCBs) and other electronic components. These coatings enhance product reliability and lifespan by providing protective barriers against moisture and contaminants, thereby reducing defects during production. Buyers from regions such as South America and the Middle East should focus on precision requirements and ensure compatibility with various substrates to maximize the effectiveness of these systems.

How do itw bgk finishing systems enhance packaging solutions?

For the packaging industry, itw bgk finishing systems are crucial in providing coatings for food and beverage packaging. These coatings improve barrier properties, extending the shelf life of products while maintaining safety standards. Buyers must prioritize regulatory compliance for food safety and consider eco-friendly options, as sustainability becomes increasingly important in global markets. This is particularly relevant for buyers in Europe, where environmental regulations are stringent.

In what ways are itw bgk finishing systems used in furniture production?

In the furniture industry, itw bgk finishing systems are used for finishing wooden and metal products. These systems offer superior finish quality, enhancing the market appeal of furniture items. By utilizing these advanced finishing solutions, manufacturers can meet consumer demands for aesthetics and durability. Buyers should look for customization options and ensure that sourcing practices align with sustainability initiatives, especially in regions like Africa where eco-consciousness is growing.

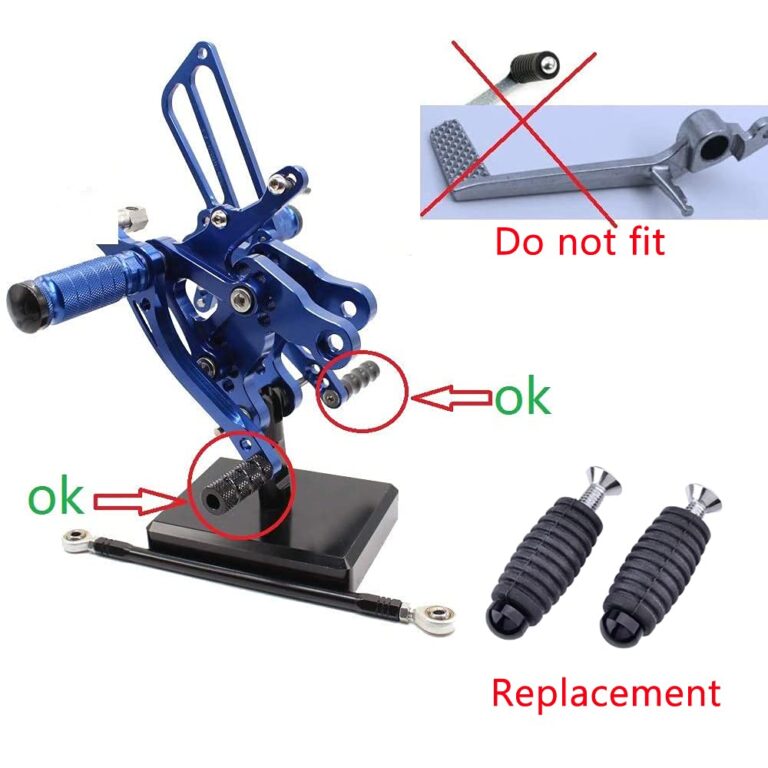

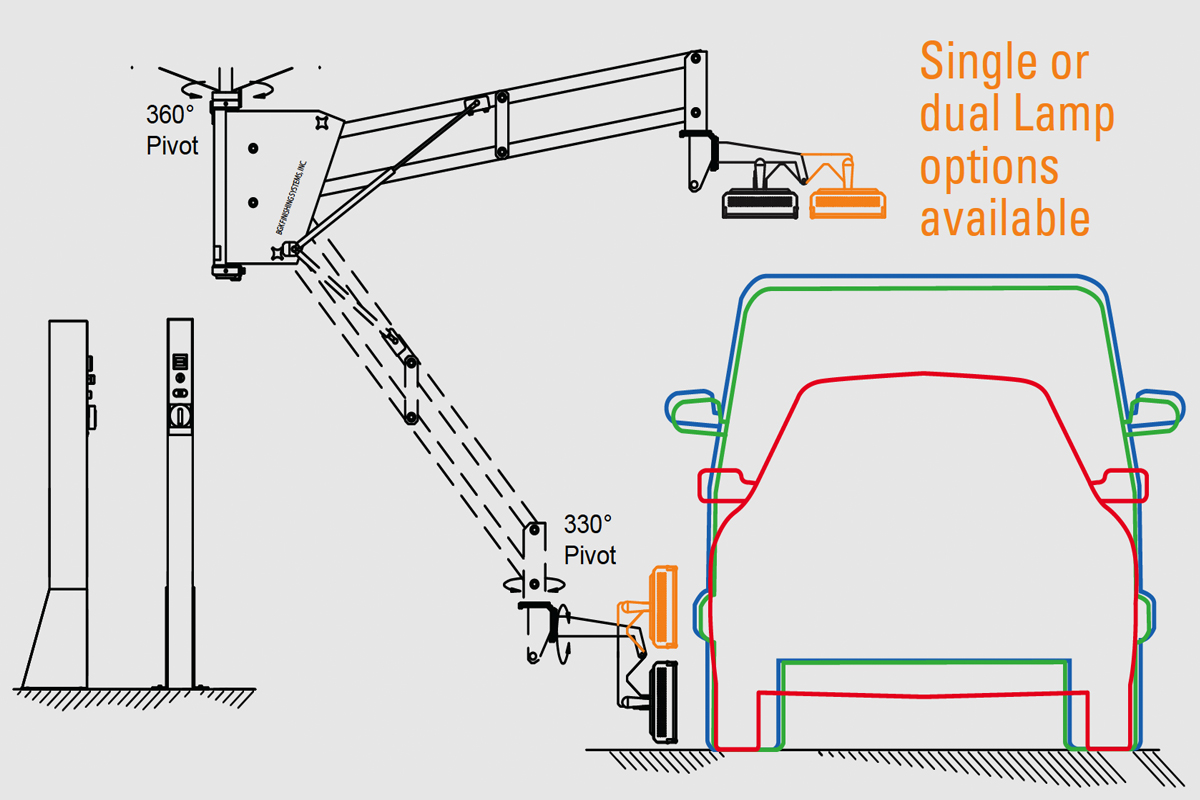

Illustrative image related to itw bgk finishing systems

How do itw bgk finishing systems benefit textile applications?

In textile manufacturing, itw bgk finishing systems are applied for protective coatings that enhance durability and stain resistance. These coatings ensure that textiles maintain their quality over time, making them more appealing to consumers. Buyers must consider material compatibility and adhere to environmental regulations, particularly as global markets increasingly demand sustainable practices. This is especially important for international buyers from regions like South America, where sustainable textile production is gaining traction.

3 Common User Pain Points for ‘itw bgk finishing systems’ & Their Solutions

Scenario 1: Inconsistent Finishing Quality Across Production Runs

The Problem: B2B buyers often face challenges with maintaining consistent finishing quality in their production lines. Variability can stem from multiple factors including equipment calibration, operator skill levels, or variations in substrate materials. When a company produces batches of products, any inconsistency in finishing can lead to defects, increased waste, and customer dissatisfaction. This is particularly critical in sectors such as packaging and automotive where precision is non-negotiable.

The Solution: To address this issue, it is essential to implement a robust training program for operators that focuses on the specific capabilities and settings of ITW BGK finishing systems. Additionally, regular maintenance and calibration of the machinery can help ensure consistent results. Buyers should also consider investing in quality control measures, such as automated inspection systems that can detect flaws in real-time. By establishing standard operating procedures (SOPs) and utilizing predictive maintenance tools, companies can not only enhance product quality but also streamline their production processes.

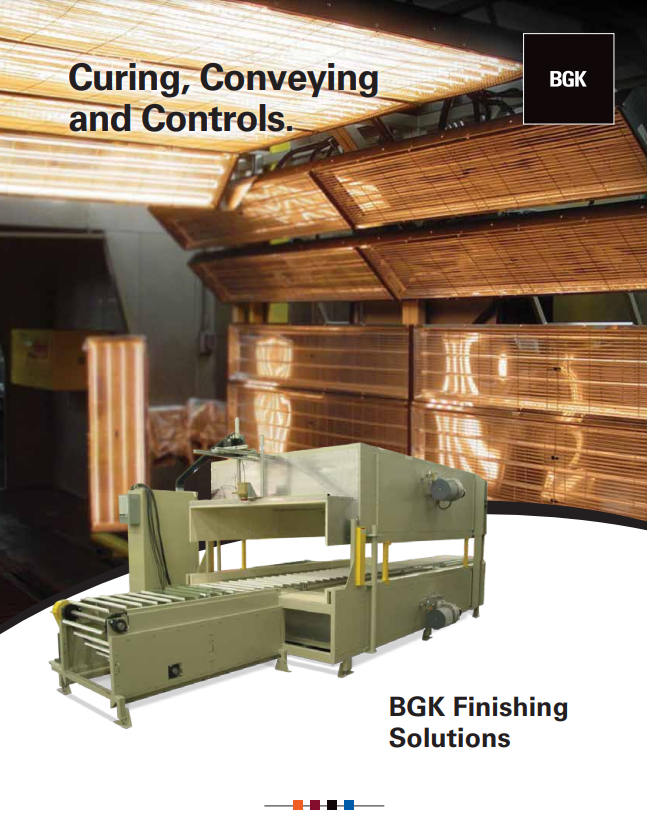

Illustrative image related to itw bgk finishing systems

Scenario 2: High Energy Costs Associated with Finishing Processes

The Problem: Many B2B buyers are increasingly concerned about the rising energy costs associated with finishing processes. Traditional finishing systems can consume significant energy, leading to inflated operational costs, particularly in regions where electricity prices are high. This is a pressing issue for companies looking to improve their bottom line while also committing to sustainable practices.

The Solution: ITW BGK offers advanced finishing systems that are designed for energy efficiency. Buyers should prioritize sourcing equipment that features energy-saving technologies, such as infrared (IR) heating and optimized airflow systems. Conducting an energy audit of existing finishing processes can provide insights into areas where energy consumption can be reduced. Additionally, integrating renewable energy sources, such as solar panels, to power finishing systems can further decrease reliance on conventional energy and reduce operational costs in the long term. Implementing these measures not only helps in cutting costs but also aligns with corporate sustainability goals.

Scenario 3: Difficulty in Integrating Finishing Systems with Existing Production Lines

The Problem: A common pain point for B2B buyers is the integration of new finishing systems into existing production lines. Compatibility issues can arise due to differences in technology, software, or equipment specifications, leading to production delays and increased downtime. For companies that rely on seamless operations, such disruptions can severely impact efficiency and profitability.

The Solution: To overcome integration challenges, buyers should conduct a thorough assessment of their current production setup before purchasing ITW BGK finishing systems. Collaborating with ITW’s technical support team during the planning phase can provide valuable insights into compatibility and required adjustments. Companies should also consider modular systems that allow for gradual integration, minimizing disruption. Additionally, leveraging ITW BGK’s expertise in custom configurations can lead to tailored solutions that fit perfectly within existing workflows. Establishing strong communication between production and engineering teams during the implementation phase can further ensure a smooth transition and operational continuity.

Strategic Material Selection Guide for itw bgk finishing systems

What Are the Key Materials Used in ITW BGK Finishing Systems?

When selecting materials for ITW BGK finishing systems, it’s crucial to consider the properties and suitability of various materials. The following analysis covers four common materials, providing insights into their performance, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Perform in ITW BGK Finishing Systems?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. Its low density allows for easy handling and installation, making it a popular choice in various applications.

Pros: Aluminum’s durability and resistance to corrosion make it suitable for environments where moisture and chemicals are present. It also has a high strength-to-weight ratio, enhancing the performance of finishing systems.

Cons: While aluminum is cost-effective, it can be more susceptible to scratching and denting compared to other metals. Additionally, its thermal expansion properties may require careful consideration in high-temperature applications.

Impact on Application: Aluminum is compatible with various media, including aqueous and solvent-based coatings, making it versatile for different finishing processes.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider local sourcing options to mitigate costs associated with import tariffs and shipping.

What Role Does Stainless Steel Play in ITW BGK Finishing Systems?

Stainless steel is renowned for its strength and resistance to corrosion and staining. It is often used in environments where hygiene and durability are paramount, such as in food processing and pharmaceutical applications.

Pros: Its robustness and resistance to high temperatures and chemicals make stainless steel an excellent choice for demanding applications. It also offers aesthetic appeal, which can be beneficial in customer-facing environments.

Cons: The initial cost of stainless steel can be higher than other materials, and its weight may complicate installation. Additionally, while it is resistant to corrosion, it is not entirely immune, especially in harsh environments.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for various finishing applications.

Considerations for International Buyers: Buyers must ensure compliance with international standards and consider the availability of stainless steel grades that meet specific requirements in their regions.

Illustrative image related to itw bgk finishing systems

How Does Polypropylene Enhance ITW BGK Finishing Systems?

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It is often used in applications requiring flexibility and durability.

Pros: Polypropylene’s resistance to a wide range of chemicals makes it ideal for environments where exposure to solvents and acids is common. Its lightweight nature simplifies handling and installation.

Cons: While polypropylene is durable, it may not withstand high temperatures as effectively as metals. Additionally, it can be less rigid, which may limit its use in certain structural applications.

Impact on Application: Polypropylene is compatible with various media, including water-based and solvent-based coatings, making it versatile for different finishing processes.

Considerations for International Buyers: Buyers should verify compliance with local regulations regarding plastic materials, and consider the environmental impact of polypropylene in their sourcing decisions.

Why Is Glass an Important Material in ITW BGK Finishing Systems?

Glass is often used in finishing systems for its transparency and aesthetic qualities. It is particularly useful in applications where visibility of the process is essential.

Pros: Glass is chemically inert, making it highly resistant to corrosion and staining. Its smooth surface is easy to clean, which is advantageous in maintaining hygiene.

Cons: Glass can be fragile and may require additional protective measures during handling and installation. It also tends to be heavier, which can complicate logistics.

Illustrative image related to itw bgk finishing systems

Impact on Application: Glass is compatible with various media, including coatings that require transparency for visual inspection.

Considerations for International Buyers: Buyers must ensure that glass meets relevant safety standards and consider the logistics of transporting fragile materials.

Summary of Material Properties and Considerations

| Material | Typical Use Case for ITW BGK Finishing Systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Used in lightweight and corrosion-resistant applications | Excellent corrosion resistance | Susceptible to scratching | Medium |

| Stainless Steel | Ideal for high hygiene and durability requirements | High strength and temperature resistance | Higher initial cost | High |

| Polypropylene | Flexible applications requiring chemical resistance | Lightweight and chemically resistant | Limited high-temperature performance | Low |

| Glass | Applications needing visibility and aesthetic appeal | Chemically inert and easy to clean | Fragility and weight | Medium |

This guide provides a comprehensive overview of materials commonly used in ITW BGK finishing systems, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for itw bgk finishing systems

What Are the Key Stages in the Manufacturing Process of ITW BGK Finishing Systems?

The manufacturing process for ITW BGK Finishing Systems consists of several critical stages designed to ensure high-quality output and efficiency. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials that meet industry standards. Materials such as metals, plastics, and specialized coatings are evaluated for their suitability. Suppliers undergo stringent assessments to ensure that materials are compliant with international standards, such as ISO 9001, which emphasizes quality management systems.

-

Forming: In this stage, raw materials are shaped into components using advanced techniques such as CNC machining, injection molding, or laser cutting. Each technique is selected based on the design specifications and the intended application of the finished product. This precision in forming is crucial for ensuring that components fit together correctly during assembly.

-

Assembly: Once the components are formed, they are assembled using automated systems and manual processes. Skilled technicians ensure that each unit meets the precise specifications outlined in the design phase. Assembly lines are often equipped with advanced technologies that facilitate real-time monitoring and adjustments, ensuring a streamlined process.

-

Finishing: The final stage involves surface treatments, coatings, or other finishing processes to enhance durability and aesthetics. Techniques such as powder coating, anodizing, or UV curing are commonly employed. This stage is essential not only for the product’s appearance but also for its resistance to environmental factors, which is especially important for systems used in diverse climates across Africa, South America, the Middle East, and Europe.

How Is Quality Assurance Implemented in ITW BGK Finishing Systems?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for ITW BGK Finishing Systems, ensuring that each product meets stringent quality and safety standards. The QA process typically aligns with both international standards and industry-specific requirements.

-

Adherence to International Standards: ITW BGK Finishing Systems is committed to maintaining compliance with international quality standards, including ISO 9001. This certification focuses on establishing a quality management system that enhances customer satisfaction through consistent product quality.

-

Industry-Specific Certifications: Depending on the specific applications of the finishing systems, additional certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be required. These certifications ensure that products are safe and suitable for use in various industries, including automotive, aerospace, and manufacturing.

-

Quality Control Checkpoints: Quality control (QC) is integrated throughout the manufacturing process through several checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to catch any deviations from quality standards in real-time.

– Final Quality Control (FQC): Once the product is assembled, it undergoes rigorous testing to ensure it meets all specifications before shipping.

What Common Testing Methods Are Used to Ensure Quality in ITW BGK Finishing Systems?

Testing methods are crucial for verifying the quality and performance of ITW BGK Finishing Systems. Various techniques are employed, depending on the product specifications and industry requirements.

-

Visual Inspections: Technicians conduct thorough visual inspections to identify any surface defects, misalignments, or inconsistencies. This initial check is essential for ensuring that products meet aesthetic and functional standards.

-

Functional Testing: Each finishing system is subjected to functional tests that simulate real-world conditions. This includes checking for durability, performance under load, and operational efficiency. For instance, UV curing systems may be tested for their curing capabilities under specific conditions.

-

Stress Testing: Products are often put through stress tests to evaluate their performance under extreme conditions. This is particularly important for systems used in harsh environments, where durability is a key concern.

-

Compliance Testing: To ensure that products meet international safety and performance standards, compliance testing is conducted. This may involve third-party laboratories that specialize in verifying adherence to specific industry regulations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential for mitigating risks and ensuring product reliability.

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to assess their quality control processes. Buyers can evaluate whether suppliers adhere to international standards and their internal quality management practices.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the QC processes, testing methods, and results. This documentation provides insights into how a supplier maintains quality and addresses any issues that arise during production.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent entities can evaluate the manufacturing and QC processes, providing unbiased assessments of supplier capabilities.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their industry and region. Certifications may vary in significance depending on the local market, so understanding these nuances is crucial for ensuring compliance and quality.

Conclusion: Why Quality Assurance Is Essential for ITW BGK Finishing Systems

In summary, the manufacturing processes and quality assurance measures for ITW BGK Finishing Systems are integral to delivering high-quality products that meet the diverse needs of international B2B buyers. By understanding the stages of manufacturing and the importance of robust quality control, buyers can make informed decisions, ensuring that they partner with suppliers who prioritize excellence and reliability in their offerings. This approach not only safeguards their investments but also enhances their reputation in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘itw bgk finishing systems’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring ITW BGK Finishing Systems effectively. Whether you are in Africa, South America, the Middle East, or Europe, following these steps will help ensure that you select the right equipment and suppliers for your finishing needs, optimizing both quality and efficiency.

Step 1: Define Your Technical Specifications

Begin by clearly defining the technical requirements of the finishing systems you need. Consider factors such as the types of materials you’ll be processing, production volume, and desired finish quality.

- Material Compatibility: Ensure the system can handle the specific substrates you use.

- Production Capacity: Assess your output needs to avoid under or over-investment.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify suppliers that specialize in ITW BGK Finishing Systems. Look for companies with a strong market presence and proven expertise.

- Industry Experience: Favor suppliers with extensive experience in your industry sector.

- Customer Reviews: Check testimonials and case studies to gauge customer satisfaction and reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers thoroughly. Request detailed company profiles, case studies, and references from previous clients in similar industries or regions.

- Supplier Certifications: Verify that suppliers hold relevant certifications that demonstrate compliance with industry standards.

- Visit Facilities (if possible): If feasible, arrange for site visits to assess their manufacturing capabilities and quality control processes.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations. Ensure these include pricing, delivery timelines, warranty terms, and maintenance support.

- Comparative Analysis: Analyze quotes not just on price but also on the value offered, including after-sales service and support.

- Hidden Costs: Be aware of potential hidden costs such as shipping, installation, and training.

Step 5: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by your potential suppliers. A robust support system is crucial for minimizing downtime and ensuring operational efficiency.

- Warranty Terms: Understand what is covered under warranty and for how long.

- Support Availability: Check the availability of technical support and whether it is local or requires international assistance.

Step 6: Negotiate Terms and Finalize Contract

Once you have selected a supplier, engage in negotiations to finalize the terms. This may include price adjustments, delivery schedules, and payment terms.

- Flexibility in Terms: Aim for terms that provide flexibility in case of unforeseen circumstances or changes in your production needs.

- Legal Review: Have contracts reviewed by legal experts to ensure that all agreements are clear and enforceable.

Step 7: Plan for Installation and Training

Finally, ensure that there is a comprehensive plan for the installation and training of your staff on the new equipment. Proper training is essential for maximizing the efficiency of the finishing systems.

- Training Programs: Confirm that the supplier offers adequate training for your operational staff.

- Installation Support: Ensure that the supplier has a clear plan for installation and any necessary adjustments post-installation.

By following this checklist, B2B buyers can confidently navigate the procurement process for ITW BGK Finishing Systems, ensuring that they make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for itw bgk finishing systems Sourcing

When sourcing ITW BGK finishing systems, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The following analysis explores the primary cost components, price influencers, and practical tips for negotiations, ensuring buyers can make informed purchasing decisions.

What Are the Key Cost Components in ITW BGK Finishing Systems?

-

Materials: The cost of raw materials is a significant factor in the overall pricing of finishing systems. High-quality components, such as specialized coatings and durable substrates, can increase costs but are essential for performance and longevity. Buyers should consider the material specifications required for their applications.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and installation of the finishing systems. This varies by region and can be influenced by local wage rates and labor regulations. For instance, sourcing from countries with lower labor costs may reduce overall expenses.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize these costs, which in turn affects the final pricing.

-

Tooling: Investment in specialized tooling is often required for the production of customized systems. These costs can be significant, especially for bespoke solutions, and should be factored into the overall pricing strategy.

-

Quality Control (QC): Ensuring that products meet quality standards incurs additional costs. Implementing stringent QC processes enhances product reliability, which may justify a higher price point for buyers seeking quality assurance.

-

Logistics: Shipping and handling costs vary based on the geographical distance from the manufacturer to the buyer, as well as the chosen Incoterms. Buyers should be aware of potential tariffs, taxes, and insurance costs that could affect the total expense.

-

Margin: Suppliers typically add a profit margin to cover operational costs and ensure sustainability. Understanding typical margins in the industry can help buyers assess the fairness of pricing.

How Do Price Influencers Affect ITW BGK Finishing Systems Pricing?

Several factors influence the pricing of ITW BGK finishing systems, which buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should evaluate their needs and consider bulk orders to optimize costs.

-

Specifications/Customization: Customized systems typically incur higher costs due to additional design and manufacturing requirements. Buyers should clearly outline their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: The use of premium materials and obtaining quality certifications can drive up prices. However, these investments can lead to better performance and reliability, essential for long-term applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to manage their total cost effectively.

What Are Effective Buyer Tips for Negotiating Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially for larger orders. Building a relationship can lead to better terms and discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price, but also maintenance, operational efficiency, and potential downtime costs. A lower upfront cost may result in higher TCO if the product requires more frequent repairs or replacements.

-

Be Aware of Pricing Nuances: Understand regional pricing trends and currency fluctuations, as these can impact costs. Additionally, be mindful of local regulations that may affect pricing structures.

-

Request Multiple Quotes: Obtain quotes from various suppliers to compare pricing and terms. This competitive approach often results in better offers.

In conclusion, comprehending the cost components and price influencers associated with ITW BGK finishing systems is essential for making strategic purchasing decisions. By leveraging effective negotiation strategies and focusing on total cost considerations, international buyers can optimize their sourcing strategies and enhance their operational efficiencies.

Disclaimer: Prices and cost structures are indicative and may vary based on specific requirements and market conditions. Always conduct thorough research and consult with suppliers for accurate quotations.

Alternatives Analysis: Comparing itw bgk finishing systems With Other Solutions

In today’s competitive manufacturing landscape, businesses often seek the most effective finishing systems to enhance product quality and operational efficiency. When evaluating options, it’s essential to compare different technologies that deliver similar results. This analysis focuses on ITW BGK Finishing Systems and two viable alternatives: UV Curing Systems and Convection Drying Systems. Each solution has unique advantages and limitations, making it crucial for buyers to consider their specific needs and operational contexts.

| Comparison Aspect | ITW BGK Finishing Systems | UV Curing Systems | Convection Drying Systems |

|---|---|---|---|

| Performance | High-speed and efficient curing with uniform results | Rapid curing, ideal for high-volume production | Slower drying times but effective for various substrates |

| Cost | Moderate initial investment with low operational costs | Higher upfront costs but lower long-term energy expenses | Generally lower initial investment but higher energy consumption |

| Ease of Implementation | Requires specialized training for optimal use | Often needs complex setup and calibration | Easier to integrate with existing systems |

| Maintenance | Low maintenance with minimal downtime | Moderate maintenance needs due to lamp replacement | Higher maintenance due to fan and heater upkeep |

| Best Use Case | Ideal for diverse applications, including coatings and adhesives | Best for high-speed production lines in industries like printing | Suitable for textiles, wood, and certain plastics |

What Are the Advantages and Disadvantages of UV Curing Systems?

UV Curing Systems utilize ultraviolet light to rapidly cure coatings, inks, and adhesives. The primary advantage is speed; products can be processed almost instantly, enhancing throughput significantly. This technology is particularly advantageous in high-volume environments, such as printing and packaging, where time-to-market is critical. However, UV systems come with a higher upfront cost and require careful handling to ensure safety, as UV light can be harmful without proper precautions. Additionally, they may necessitate more complex setups and calibration, which can be a barrier for some businesses.

How Do Convection Drying Systems Compare?

Convection Drying Systems use heated air to evaporate solvents and moisture from products. They are generally easier to integrate into existing production lines, making them an attractive option for businesses looking for straightforward solutions. The lower initial investment can be appealing; however, these systems tend to have longer drying times compared to UV and ITW BGK systems. This can slow down production rates, especially in high-demand environments. Furthermore, the ongoing energy consumption may lead to higher operational costs over time, particularly if the drying process is prolonged.

How Should B2B Buyers Choose the Right Finishing Solution?

Choosing the right finishing system hinges on a thorough understanding of the specific operational needs and production goals of your business. Evaluate factors such as the types of materials being processed, the volume of production, and your budget constraints. If speed and efficiency are paramount, ITW BGK or UV Curing Systems may be more suitable. Conversely, if ease of implementation and lower upfront costs are priorities, Convection Drying Systems could be the better choice. Ultimately, assessing each option’s strengths and weaknesses in the context of your unique requirements will empower you to make an informed decision that aligns with your operational objectives.

Essential Technical Properties and Trade Terminology for itw bgk finishing systems

What Are the Key Technical Properties of ITW BGK Finishing Systems?

When considering ITW BGK Finishing Systems for your industrial applications, it’s essential to understand several critical specifications that define their performance and suitability. Here are some key technical properties:

-

Material Grade

ITW BGK systems often utilize high-grade materials such as stainless steel or specialized alloys. This ensures durability, corrosion resistance, and longevity in demanding environments. For B2B buyers, selecting the right material grade can significantly impact maintenance costs and operational efficiency. -

Temperature Tolerance

Finishing systems must operate effectively within specific temperature ranges. ITW BGK systems are engineered to withstand high temperatures, which is crucial for processes like curing or drying. Understanding temperature tolerance helps buyers ensure that the systems will perform reliably in their specific applications without risk of failure. -

Efficiency Ratings

Efficiency ratings, such as energy consumption per output unit, are vital for assessing the operational costs of finishing systems. ITW BGK systems are designed to optimize energy use while maintaining high production output, making them appealing for cost-conscious businesses aiming for sustainability. -

Production Capacity

The production capacity of finishing systems is often measured in units per hour or batch size. ITW BGK systems provide scalable solutions that can adapt to varying production demands, which is crucial for businesses anticipating growth or fluctuations in order volume. -

Precision Tolerance

Precision in application is critical in finishing processes. ITW BGK systems are designed to maintain strict tolerances, ensuring that the final product meets quality standards. For B2B buyers, this means reduced waste and rework, enhancing overall operational efficiency. -

Control Systems

Advanced control systems allow for real-time monitoring and adjustments during operations. ITW BGK offers intuitive interfaces that facilitate ease of use, making it simpler for operators to manage processes. This feature is particularly important for businesses that require consistent output quality.

What Are the Common Trade Terms Associated with ITW BGK Finishing Systems?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ITW BGK, knowing whether a supplier is an OEM can affect procurement strategies, as it may influence pricing, warranty, and support options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. B2B buyers must be aware of MOQs when planning purchases to avoid overcommitting resources and ensure that they can meet their production needs without excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. It typically includes detailed specifications and quantities required. Understanding how to effectively prepare an RFQ can lead to better pricing and terms from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers mitigate risks related to shipping, insurance, and delivery. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is a critical consideration for B2B buyers who need to align their supply chain schedules and inventory management with production timelines. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it under certain conditions. Understanding warranty terms can protect B2B buyers against potential defects and ensure that they receive value from their investment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational goals and procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the itw bgk finishing systems Sector

What Are the Key Market Dynamics and Trends Influencing the ITW BGK Finishing Systems Sector?

The global market for ITW BGK finishing systems is shaped by several key drivers that influence sourcing and procurement strategies for international B2B buyers. Technological advancements, particularly in automation and digital printing, are transforming traditional finishing processes, making them more efficient and cost-effective. Countries in Africa, South America, the Middle East, and Europe are increasingly adopting these technologies to enhance production capabilities and meet rising consumer demands for quality and speed.

Illustrative image related to itw bgk finishing systems

Emerging trends highlight a significant shift toward integrated finishing solutions that combine multiple processes into one streamlined operation. B2B buyers are looking for systems that offer flexibility and adaptability to accommodate various substrates and printing methods. Moreover, as businesses strive for operational excellence, the demand for data-driven insights and analytics in production workflows is growing, enabling better decision-making and resource allocation.

Additionally, market dynamics are influenced by the rising importance of e-commerce and online retail, prompting companies to invest in finishing systems that can handle smaller batch sizes and customized orders. This trend is particularly relevant for businesses in emerging markets, such as Nigeria and Vietnam, where local industries are rapidly evolving to cater to global standards.

How Is Sustainability Shaping Sourcing Decisions in the ITW BGK Finishing Systems Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the ITW BGK finishing systems sector. The environmental impact of manufacturing processes is under increasing scrutiny, compelling companies to adopt greener practices. This includes using eco-friendly materials, reducing waste, and optimizing energy consumption throughout the supply chain.

Buyers are increasingly prioritizing suppliers that offer sustainable solutions, such as recyclable or biodegradable materials, and those that have obtained relevant green certifications. These certifications not only demonstrate a commitment to environmental stewardship but also enhance the brand’s reputation in a market that increasingly values corporate social responsibility.

Moreover, ethical supply chains are essential for fostering trust and transparency among stakeholders. Buyers are encouraged to engage with suppliers who adhere to fair labor practices and sustainable sourcing methods. This commitment not only mitigates risks associated with supply chain disruptions but also aligns with the values of consumers who are increasingly conscious of the products they purchase.

Illustrative image related to itw bgk finishing systems

What Is the Historical Context of ITW BGK Finishing Systems in the B2B Market?

The evolution of ITW BGK finishing systems can be traced back to the early developments in printing and finishing technology. Originally, finishing processes were manual and time-consuming, but advancements in machinery and automation have revolutionized the industry. The integration of digital technologies has allowed for more precise and efficient finishing solutions, catering to the growing demands of customization and speed in production.

Over the years, ITW BGK has established itself as a leader in the finishing systems market, continually innovating to meet the needs of diverse industries. This historical context is crucial for B2B buyers, as it highlights the company’s commitment to quality and technological advancement, ensuring that they are investing in solutions that are not only reliable but also forward-thinking.

In conclusion, the ITW BGK finishing systems sector is poised for continued growth, driven by technological advancements, sustainability, and evolving market dynamics. For international B2B buyers, understanding these factors is essential for making informed sourcing decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of itw bgk finishing systems

-

How do I ensure quality in itw bgk finishing systems?

To ensure quality when sourcing itw bgk finishing systems, begin by conducting thorough research on the manufacturer’s reputation. Look for certifications and compliance with international quality standards, such as ISO certifications. Request samples to evaluate the performance and durability of the systems. Additionally, inquire about the manufacturer’s quality assurance processes, including testing and inspection protocols. Engaging with previous customers for testimonials can provide insights into their experiences and satisfaction with the product quality. -

What are the key features to consider in itw bgk finishing systems?

When evaluating itw bgk finishing systems, focus on features such as energy efficiency, versatility in application, and ease of use. Systems that offer customizable settings for different materials can enhance operational flexibility. Additionally, look for options with advanced technology for improved curing and drying processes, which can significantly impact production speed and quality. Maintenance requirements and the availability of spare parts are also crucial for long-term usability. -

What is the typical lead time for itw bgk finishing systems?

Lead times for itw bgk finishing systems can vary based on several factors, including the complexity of the order, the manufacturer’s production capacity, and shipping logistics. Generally, expect lead times to range from 4 to 12 weeks. It’s advisable to communicate with your supplier to obtain a precise timeline and consider any potential delays related to customs or international shipping, especially when importing to regions like Africa or South America. -

What are the minimum order quantities (MOQ) for itw bgk finishing systems?

Minimum order quantities (MOQ) for itw bgk finishing systems can differ significantly based on the supplier and the specific product line. Typically, MOQs may range from a single unit for standard models to larger quantities for customized solutions. Discussing your specific needs with the supplier can often lead to flexible arrangements, especially for repeat customers or bulk orders. Be clear about your requirements to negotiate the best terms. -

What payment terms should I expect when sourcing itw bgk finishing systems?

Payment terms for sourcing itw bgk finishing systems typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, particularly for large orders. It’s essential to clarify payment methods accepted by the supplier and any potential fees associated with international transactions. Always ensure that the payment terms are documented clearly in the purchase agreement to avoid misunderstandings. -

How can I customize itw bgk finishing systems to meet my needs?

Customization options for itw bgk finishing systems often include modifications in size, configuration, and features tailored to specific production requirements. Start by discussing your needs with the manufacturer, providing detailed specifications on what you wish to achieve. Many suppliers have dedicated teams for customization, and they may offer design services to help optimize the system for your operations. Be prepared to discuss timelines and costs associated with customization. -

What logistics considerations should I keep in mind when importing itw bgk finishing systems?

When importing itw bgk finishing systems, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Select a reliable freight forwarder familiar with international shipping to ensure smooth transportation. Understand the customs duties and taxes applicable in your country, as these can affect overall costs. Lastly, plan for potential delays at customs and have contingency plans to mitigate disruptions to your production schedule. -

How do I vet suppliers of itw bgk finishing systems for reliability?

To vet suppliers of itw bgk finishing systems, start by checking their business history and industry reputation. Look for reviews, case studies, and testimonials from past clients. Verify their certifications and compliance with international standards. Conducting site visits, if feasible, or requesting virtual tours can provide insights into their manufacturing processes. Additionally, ask for references from previous customers to gauge their experiences regarding product quality and service reliability.

Top 5 Itw Bgk Finishing Systems Manufacturers & Suppliers List

1. ITW BGK Finishing Systems – Electric Infrared Heaters

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: ITW BGK Finishing Systems designs, manufactures and markets high-intensity electric infrared heaters and curing systems for the coating and finishing industries. Their systems can be custom engineered to meet specific needs.

2. BGK Finishing Systems – Electric Infrared Curing Solutions

Domain: airpower-usa.com

Registered: 2000 (25 years)

Introduction: BGK Finishing Systems, an authorized distributor of BGK Finishing, designs and manufactures electric infrared curing systems and industrial coating process conveyors. Founded in 1980, BGK specializes in shortwave Infra-Red Curing technology, offering capabilities for curing a full range of coatings including liquid, powder, wax, UV, and adhesives. Key product offerings include:

– Electric infrared…

3. Total Finishing Supplies – Fast Delivery Solutions

Domain: totalfinishingsupplies.com

Registered: 2020 (5 years)

Introduction: This company, Total Finishing Supplies – Fast Delivery Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. BGK Finishing Systems – Chain-on-Edge Conveyor Technology

Domain: machinetools.com

Registered: 1995 (30 years)

Introduction: This company, BGK Finishing Systems – Chain-on-Edge Conveyor Technology, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. BGK – Precision Engineered Curing Solutions

Domain: otcindustrial.com

Registered: 2016 (9 years)

Introduction: BGK offers precision engineered solutions for curing capabilities across a range of coatings including liquid, powder, wax, UV, and adhesives. Their product line includes infrared curing systems, gas ovens, conveyors, reciprocators, and a full line of controls. Notably, BGK portable infrared curing arms are preferred in automotive OEM touch-up areas. Established in 1980, BGK was acquired by Carlis…

Strategic Sourcing Conclusion and Outlook for itw bgk finishing systems

As international markets evolve, the strategic sourcing of ITW BGK Finishing Systems stands as a cornerstone for businesses aiming to enhance their operational efficiency and product quality. Buyers from regions such as Africa, South America, the Middle East, and Europe must recognize the importance of leveraging advanced technologies and innovative solutions offered by ITW BGK. These systems not only streamline production processes but also ensure compliance with global standards, thereby maximizing return on investment.

Understanding the nuances of strategic sourcing allows businesses to make informed decisions that align with their specific needs and market demands. By establishing strong partnerships with ITW BGK and utilizing their extensive product range, companies can achieve significant cost savings and improved service delivery.

Looking ahead, the landscape of finishing systems will continue to evolve, driven by advancements in technology and sustainability initiatives. International buyers are encouraged to explore these opportunities actively. By integrating ITW BGK’s solutions into their operations, businesses can position themselves for growth and success in an increasingly competitive marketplace. Embrace the future of finishing systems—partner with ITW BGK today to elevate your business performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.