Is Your Intex Pool Spares Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for intex pool spares

In the ever-evolving landscape of pool maintenance, sourcing quality Intex pool spares presents a significant challenge for international B2B buyers. As the demand for above-ground pools continues to rise across regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—businesses must navigate a complex array of spare parts to ensure optimal performance and longevity of their pool systems. This comprehensive guide aims to demystify the process of sourcing Intex pool spares by detailing the types of parts available, their applications, and essential considerations for supplier vetting.

Understanding the intricacies of Intex spare parts is crucial for maintaining high-quality pool operations. From filtration systems and pool ladders to skimmers and cleaning tools, each component plays a pivotal role in ensuring safety and enjoyment for end-users. This guide not only highlights the various categories of parts but also offers insights into cost factors, shipping logistics, and the importance of original quality assurance.

By equipping B2B buyers with actionable insights and a clear framework for evaluating suppliers, this resource empowers businesses to make informed purchasing decisions. As you delve into the specifics of Intex pool spares, you will gain the confidence needed to enhance your product offerings and meet the growing expectations of your clientele.

Understanding intex pool spares Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Filtration Systems | Includes sand, cartridge, and saltwater systems | Pool maintenance and sanitation | Pros: Effective cleaning, reduces chemical use. Cons: Initial investment can be high. |

| Structural Components | Frame parts, connectors, and pool liners | Pool assembly and repair | Pros: Durable and reliable, ensures pool integrity. Cons: Specific compatibility needed. |

| Cleaning Equipment | Robotic cleaners, manual vacuums, and brushes | Regular pool cleaning and maintenance | Pros: Saves labor, enhances cleanliness. Cons: Some models may require frequent repairs. |

| Heating Systems | Electric heaters and solar covers | Pool heating and temperature control | Pros: Extends swimming season, energy-efficient options available. Cons: Higher operational costs. |

| Safety Accessories | Ladders, skimmers, and safety covers | Pool safety and access | Pros: Essential for safety compliance, easy installation. Cons: May need regular replacement. |

What Are the Key Characteristics of Filtration Systems for Intex Pools?

Filtration systems are critical for maintaining water quality in Intex pools. They come in various types, including sand, cartridge, and saltwater systems, each offering unique benefits. Sand filters are known for their longevity and low maintenance, while cartridge filters are easy to clean and replace. Saltwater systems reduce the need for traditional chemicals, appealing to eco-conscious buyers. When purchasing, consider the pool size, desired maintenance level, and water chemistry preferences.

How Do Structural Components Impact Pool Longevity and Performance?

Structural components, such as frame parts, connectors, and liners, are vital for the integrity of Intex pools. These parts are designed for specific models, ensuring a precise fit and optimal performance. High-quality materials provide durability against environmental factors. B2B buyers should evaluate the compatibility of parts with existing pool models and consider bulk purchasing options to reduce costs. Investing in robust structural components can significantly extend the lifespan of the pool.

What Advantages Do Cleaning Equipment Offer for Pool Maintenance?

Cleaning equipment, including robotic cleaners and manual vacuums, plays a crucial role in pool maintenance. Robotic cleaners automate the cleaning process, saving time and labor, while manual vacuums offer a more hands-on approach. Both types enhance water clarity and hygiene, which are essential for customer satisfaction in commercial settings. When selecting cleaning equipment, consider factors such as pool size, cleaning frequency, and ease of use. Regular maintenance of these tools is essential to ensure their effectiveness.

How Do Heating Systems Enhance the Usability of Intex Pools?

Heating systems, such as electric heaters and solar covers, are designed to extend the swimming season by maintaining comfortable water temperatures. Electric heaters provide quick heating, while solar covers utilize sunlight for energy efficiency. B2B buyers should assess the local climate and pool usage patterns when selecting a heating solution. Although initial costs may be higher, the long-term benefits of increased usage and customer satisfaction often outweigh these expenses.

Why Are Safety Accessories Essential for Intex Pools?

Safety accessories, including ladders, skimmers, and safety covers, are crucial for ensuring safe pool access and compliance with regulations. These items not only prevent accidents but also enhance the overall pool experience for users. B2B buyers should prioritize high-quality safety accessories to reduce liability risks and improve customer trust. Regular inspections and replacements of these items are necessary to maintain safety standards and operational efficiency.

Key Industrial Applications of intex pool spares

| Industry/Sector | Specific Application of intex pool spares | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Replacement parts for hotel pools and spas | Ensures guest satisfaction and safety, enhancing the hotel’s reputation. | Original parts for compatibility, reliable suppliers, quick delivery. |

| Recreation & Leisure | Maintenance of community and public pools | Reduces downtime, ensuring public access and safety. | Bulk purchasing options, warranty terms, and local availability. |

| Retail & Distribution | Stocking spare parts for retail sale | Increases revenue through diverse product offerings. | Supplier reliability, competitive pricing, and product variety. |

| Construction & Landscaping | Installation and upkeep of residential pools | Adds value to properties and attracts potential buyers. | Quality assurance, compliance with local regulations, and custom orders. |

| Sports Facilities | Repair and maintenance of swimming facilities | Guarantees operational efficiency and safety for athletes. | Timely access to parts, volume discounts, and compatibility checks. |

How are Intex Pool Spares Applied in the Hospitality Industry?

In the hospitality sector, Intex pool spares are vital for maintaining pools and spas in hotels and resorts. Regular replacement of components like filters, pumps, and ladders ensures that facilities remain operational and safe for guests. This not only enhances guest satisfaction but also protects the establishment’s reputation. B2B buyers in this sector must prioritize sourcing original parts to guarantee compatibility and quality, as well as consider suppliers that can provide quick delivery to minimize downtime.

What Role Do Intex Pool Spares Play in Recreation & Leisure?

Community and public pools rely heavily on Intex pool spares for maintenance and repairs. The availability of spare parts like skimmers and cleaning systems ensures that these facilities remain safe and accessible to the public. Reducing downtime is crucial, as it directly impacts community enjoyment and safety. Buyers in this sector should seek bulk purchasing options and focus on suppliers who can offer warranties and reliable service to ensure ongoing support.

How Can Retailers and Distributors Benefit from Intex Pool Spares?

Retailers and distributors can significantly increase their revenue by stocking a wide range of Intex pool spares. Offering products such as replacement filters, cleaning tools, and repair kits attracts customers looking for quality maintenance solutions. B2B buyers in this space should focus on establishing relationships with reliable suppliers who provide competitive pricing and a diverse product range to meet various customer needs.

Why are Intex Pool Spares Important for Construction & Landscaping?

In the construction and landscaping sectors, Intex pool spares are essential for the installation and upkeep of residential pools. Proper maintenance extends the lifespan of the pool and adds value to residential properties, making them more attractive to potential buyers. Buyers in this field should ensure they source high-quality parts that comply with local regulations, and consider suppliers who can accommodate custom orders for specific project requirements.

How Do Sports Facilities Utilize Intex Pool Spares?

Sports facilities depend on Intex pool spares for the repair and maintenance of swimming pools used for training and competitions. Regular maintenance ensures operational efficiency and athlete safety, which is critical for any sporting event. B2B buyers in this sector must ensure timely access to parts, explore volume discount options, and verify compatibility with existing systems to maintain uninterrupted service and safety for all users.

3 Common User Pain Points for ‘intex pool spares’ & Their Solutions

Scenario 1: Difficulty in Sourcing Authentic Intex Pool Parts

The Problem: B2B buyers often struggle to find genuine Intex pool spare parts due to a saturated market filled with counterfeit products. This issue is particularly prevalent in regions such as Africa and South America, where the demand for affordable pool maintenance supplies can lead to compromised quality. Purchasing counterfeit parts not only risks the integrity and functionality of the pool equipment but also results in increased costs for replacements and repairs down the line. Buyers may face delays in their operations, damaging customer relationships and profitability.

The Solution: To ensure sourcing authentic Intex pool spares, buyers should establish direct relationships with authorized distributors or manufacturers. Conducting thorough research online can help identify reputable suppliers. Look for certifications or endorsements from Intex, and request product samples before making bulk purchases. Additionally, consider leveraging online platforms that specialize in pool supplies and offer customer reviews and ratings. This practice not only mitigates the risk of counterfeit parts but also fosters trust and reliability in the procurement process.

Scenario 2: Compatibility Issues with Existing Equipment

The Problem: Another significant pain point for B2B buyers is the compatibility of new spare parts with existing Intex pool systems. As models evolve and parts are updated, finding components that fit older models can be challenging. This issue can lead to prolonged downtimes as buyers search for the right parts, which can be detrimental for businesses reliant on pool services for revenue.

The Solution: To address compatibility issues, buyers should maintain a comprehensive inventory of part numbers and specifications for all Intex models in use. When ordering spare parts, always cross-reference these specifications with the parts being purchased. Many suppliers provide detailed descriptions and compatibility charts on their websites, which can aid in the selection process. Additionally, engaging with customer service representatives from suppliers can provide insights on the best parts for specific models. Implementing a regular maintenance schedule can also help in identifying parts that may need replacing before they fail, thereby reducing the pressure of last-minute sourcing.

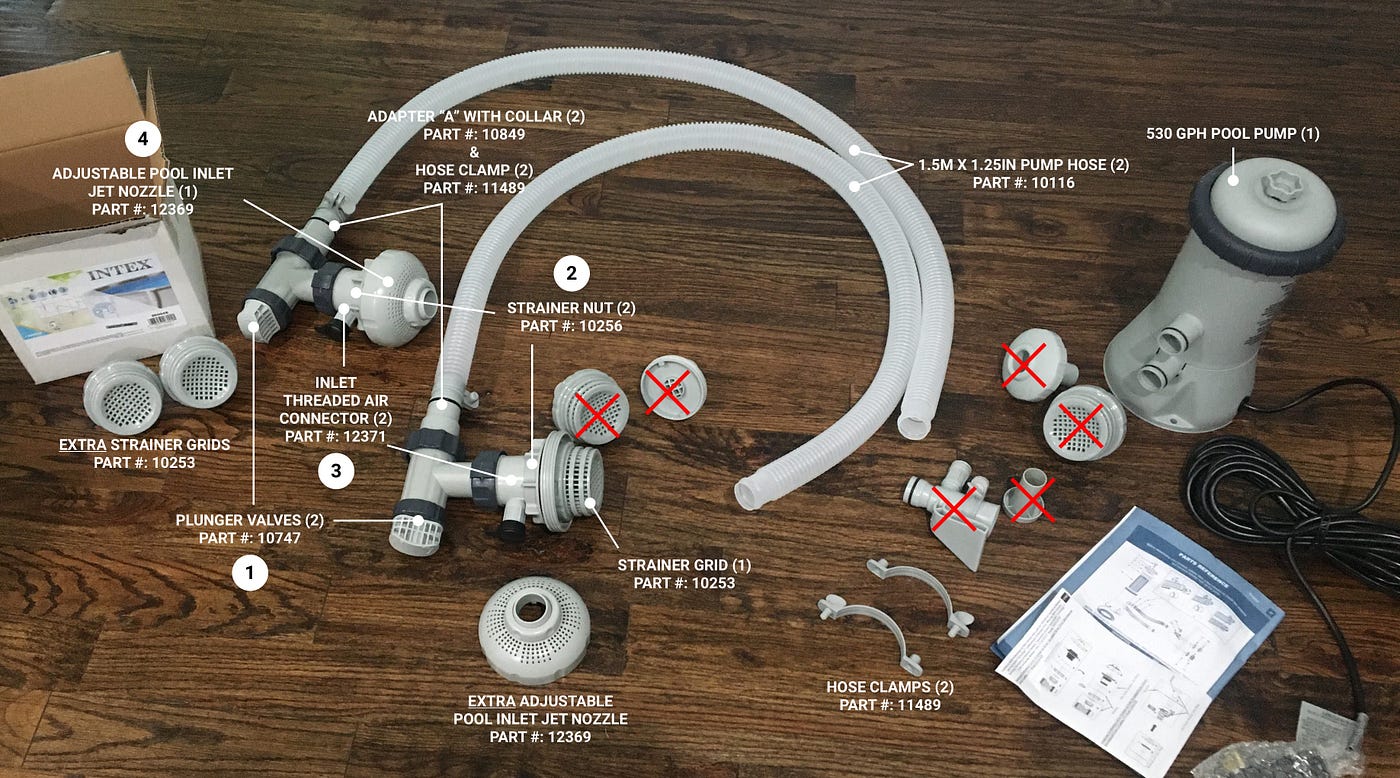

Illustrative image related to intex pool spares

Scenario 3: Lack of Technical Knowledge for Installation and Maintenance

The Problem: Many B2B buyers lack the technical expertise required for the installation and maintenance of Intex pool spares. This gap in knowledge can result in improper installation, leading to equipment malfunctions and increased operational costs. For businesses that offer pool services, the inability to efficiently manage repairs can hinder customer satisfaction and affect service reputation.

The Solution: To overcome this challenge, businesses should invest in training programs for their staff, focusing on the installation and maintenance of Intex pool components. Many suppliers offer tutorials, installation guides, and even videos that can be used as training materials. Additionally, consider partnering with local technicians who specialize in pool maintenance to provide hands-on training. Another approach is to create a centralized knowledge base that includes common issues, troubleshooting tips, and best practices for maintaining Intex pool systems. By empowering staff with the right knowledge and resources, businesses can enhance operational efficiency and service quality, ultimately boosting customer satisfaction and retention.

Strategic Material Selection Guide for intex pool spares

What Are the Key Materials Used in Intex Pool Spares?

When selecting materials for Intex pool spares, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. This knowledge helps ensure that the selected components will meet performance requirements and compliance standards specific to different regions, including Africa, South America, the Middle East, and Europe.

How Does PVC Contribute to Intex Pool Spare Parts?

Polyvinyl Chloride (PVC) is commonly used in various pool components such as liners, hoses, and fittings. Its key properties include excellent resistance to corrosion and chemicals, making it suitable for water applications. PVC also has a moderate temperature rating, typically between -15°C to 60°C, which is adequate for most pool environments.

Pros: PVC is lightweight, cost-effective, and easy to fabricate, which simplifies manufacturing processes. It also offers good durability and flexibility, allowing it to withstand pressure variations.

Cons: However, PVC can become brittle over time when exposed to UV light, which may lead to cracking. Additionally, its temperature limitations may not be suitable for extreme climates.

Impact on Application: PVC is compatible with various pool chemicals, making it a versatile choice for pool maintenance products. However, buyers should consider the local climate and potential UV exposure when selecting PVC components.

What Role Does Polypropylene Play in Pool Spare Parts?

Polypropylene is another popular material used in pool components, particularly for skimmers and filter systems. This thermoplastic is known for its high melting point (around 160°C) and excellent chemical resistance.

Pros: Polypropylene is highly durable and resistant to fatigue, making it ideal for moving parts. It is also lightweight and cost-effective, which is beneficial for bulk purchases.

Illustrative image related to intex pool spares

Cons: On the downside, polypropylene can be less flexible than PVC, which may limit its use in certain applications. It may also be susceptible to UV degradation unless treated.

Impact on Application: Polypropylene’s high chemical resistance makes it suitable for use in various water treatment processes. Buyers should ensure that the specific polypropylene grades used comply with local regulations for pool safety.

How Does Stainless Steel Enhance Pool Spare Parts Durability?

Stainless steel is often used for structural components like ladders and frames due to its strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for various environments.

Pros: The primary advantage of stainless steel is its exceptional durability and aesthetic appeal. It is resistant to rust and can last significantly longer than other materials.

Cons: However, stainless steel is generally more expensive than plastic alternatives. It also requires more complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel components are ideal for high-traffic areas and can withstand harsh weather conditions. Buyers should consider the additional costs and ensure that the stainless steel grades used meet international standards such as ASTM or DIN.

What Advantages Does Rubber Offer for Pool Spare Parts?

Rubber is commonly used in seals, gaskets, and O-rings in pool systems. Its key properties include excellent elasticity and resistance to water and chemicals.

Pros: Rubber provides a superior seal, preventing leaks and ensuring efficient operation. It is also relatively inexpensive and easy to manufacture.

Cons: However, rubber can degrade over time due to UV exposure and extreme temperatures, which may lead to premature failure.

Impact on Application: Rubber components are essential for maintaining water integrity in pool systems. Buyers should ensure that the rubber used is suitable for the specific pool chemicals prevalent in their region.

Summary Table of Material Selection for Intex Pool Spares

| Material | Typical Use Case for Intex Pool Spares | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Liners, hoses, fittings | Lightweight and cost-effective | Brittle over time with UV exposure | Low |

| Polypropylene | Skimmers, filter systems | High durability and chemical resistance | Less flexible than PVC | Med |

| Stainless Steel | Ladders, frames | Exceptional durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Rubber | Seals, gaskets, O-rings | Superior sealing capability | Degrades under UV exposure | Low |

This guide provides B2B buyers with essential insights into material selection for Intex pool spares, ensuring they make informed decisions that align with performance, cost, and compliance standards in their respective markets.

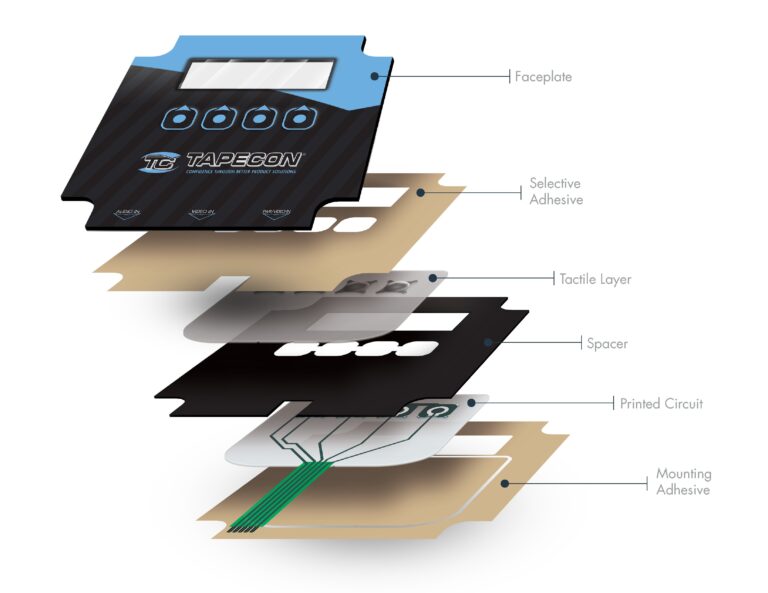

In-depth Look: Manufacturing Processes and Quality Assurance for intex pool spares

What Are the Key Stages in the Manufacturing Process of Intex Pool Spares?

The manufacturing process for Intex pool spares involves several critical stages that ensure each component meets high-quality standards. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to intex pool spares

How Is Material Prepared for Intex Pool Spare Parts?

Material preparation begins with sourcing high-quality raw materials such as durable plastics, metals, and rubber. Suppliers often conduct rigorous testing to ensure materials meet specifications. This stage is crucial as the longevity and performance of pool spares heavily depend on the quality of the raw materials used.

Once materials are sourced, they undergo treatment processes such as cleaning, cutting, and shaping to prepare them for forming. This step may also involve the application of protective coatings to enhance resistance to environmental factors like UV rays and chlorine.

What Techniques Are Used in the Forming Stage of Pool Spare Manufacturing?

Forming is a pivotal stage where prepared materials are transformed into specific shapes and sizes. Techniques such as injection molding, extrusion, and blow molding are commonly employed for plastics, while stamping and machining may be used for metal components.

Injection molding, for instance, allows for the production of complex shapes with high precision, which is essential for parts like pool filters and pumps. Additionally, this method supports high-volume production, making it cost-effective for large-scale manufacturing.

How Is Assembly Conducted for Intex Pool Spare Parts?

The assembly stage involves putting together the various components to create a finished product. This process may include integrating mechanical parts, seals, and electrical components, particularly in more complex items like filtration systems and pool heaters.

Quality control measures are embedded within the assembly process, where workers are trained to follow standardized procedures to ensure proper fitting and functionality. Automated systems may also assist in this stage, especially for repetitive tasks, enhancing speed and consistency.

What Finishing Techniques Are Applied to Ensure Quality in Pool Spares?

Finishing techniques play a crucial role in enhancing the aesthetics and durability of the final product. Common finishing processes include painting, coating, and polishing. For instance, protective coatings are applied to prevent corrosion and extend the lifespan of metal parts.

Final inspections are conducted post-finishing to check for defects such as surface imperfections or color mismatches. These checks help ensure that only high-quality products reach the market, reducing the likelihood of returns or warranty claims.

Illustrative image related to intex pool spares

What Quality Assurance Standards Are Relevant for Intex Pool Spare Parts?

Quality assurance is integral to maintaining the reliability and safety of Intex pool spares. The industry often adheres to international standards such as ISO 9001, which outlines a framework for consistent quality management systems.

How Do International Standards Impact Quality Assurance in Pool Spare Manufacturing?

ISO 9001 certification demonstrates a manufacturer’s commitment to quality management and continuous improvement. B2B buyers should look for suppliers with this certification as it indicates that the manufacturer has implemented rigorous quality control processes.

Additionally, industry-specific certifications such as CE marking for safety compliance in Europe or API standards for pumps and valves can further assure buyers of product reliability. These certifications signify that the products have been tested against stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in Pool Spare Manufacturing?

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers often provide certificates of analysis to verify material quality.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted at various stages to ensure that processes remain within specified tolerances. This may involve monitoring temperature, pressure, and material dimensions.

-

Final Quality Control (FQC): After assembly and finishing, the final products undergo comprehensive testing to ensure they meet design specifications and performance standards. This may include functional testing, pressure tests, and visual inspections.

How Can B2B Buyers Verify the Quality Control Practices of Suppliers?

B2B buyers can employ several strategies to assess the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate manufacturing processes, QC checkpoints, and overall compliance with international standards. This firsthand assessment can provide valuable insights into the supplier’s operational quality.

-

Requesting Quality Assurance Reports: Buyers should request documentation that outlines the supplier’s quality management systems, including results from past inspections, testing methods, and corrective actions taken for any identified issues.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance. These independent inspectors can evaluate the manufacturing process and product quality, providing unbiased reports to the buyer.

What Nuances Should International B2B Buyers Consider Regarding QC?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying regulatory requirements, which can impact product compliance and safety standards.

Buyers should familiarize themselves with local regulations and standards applicable to pool products in their respective markets. This knowledge will aid in selecting suppliers who not only meet international standards but also comply with local regulations, ensuring smoother import processes and market entry.

Additionally, establishing clear communication with suppliers about quality expectations and compliance requirements can foster stronger partnerships and lead to more successful procurement outcomes.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing Intex pool spares, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘intex pool spares’

In this practical sourcing guide, we will outline a structured checklist for B2B buyers looking to procure Intex pool spares. This guide aims to streamline your sourcing process, ensuring that you make informed decisions and procure quality parts for your pool systems.

Step 1: Identify Your Specific Needs

Begin by assessing the specific parts required for your Intex pool. This includes evaluating the model and type of pool, as different models may require unique components. Documenting the exact specifications will help you communicate effectively with suppliers and ensure compatibility with your existing systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in Intex pool spares. Look for companies that have a strong reputation in the market and offer a wide range of products. Pay attention to their product availability, delivery options, and customer service quality, as these factors can significantly impact your purchasing experience.

Step 3: Verify Product Quality and Authenticity

Ensure that the spare parts you are considering are original or certified by Intex. Original parts are designed to fit perfectly and maintain the integrity of your pool system. Request product certifications or warranty information from suppliers to confirm the authenticity and quality of the parts.

Step 4: Evaluate Supplier Certifications

Before making a purchase, verify that your chosen suppliers possess relevant certifications and licenses. This is crucial in ensuring that they comply with international quality standards and regulations. Look for certifications such as ISO or those specific to pool equipment, which can provide additional assurance of their reliability.

Step 5: Request Samples or Detailed Specifications

If possible, request samples or detailed specifications of the spare parts you are considering. This step is essential for evaluating the fit and function of the parts within your existing setup. Detailed specifications will also help you compare different suppliers and make informed decisions based on quality and compatibility.

Step 6: Assess Pricing and Payment Terms

Compare pricing across different suppliers to ensure you are getting a fair deal. However, do not compromise quality for lower prices. Additionally, review the payment terms offered by suppliers, including bulk discounts or credit options, which can be beneficial for larger purchases.

Step 7: Check Reviews and References

Finally, examine customer reviews and request references from previous clients. This feedback can provide insights into the supplier’s reliability and customer service. Engaging with other businesses that have sourced Intex pool spares can offer valuable information on potential pitfalls and best practices.

By following these steps, you can ensure a more efficient and effective sourcing process for Intex pool spares, ultimately leading to a smoother operation of your pool systems.

Comprehensive Cost and Pricing Analysis for intex pool spares Sourcing

What Are the Key Cost Components in Sourcing Intex Pool Spares?

When sourcing Intex pool spares, it is essential to understand the various components that contribute to the overall cost structure. These components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts cost. Original Intex parts are made from high-quality, durable materials that ensure longevity and performance. Buyers should evaluate the cost differences between original and aftermarket parts, as cheaper alternatives may lead to higher replacement rates.

-

Labor: Labor costs vary depending on the region of production. Countries with lower labor costs might offer cheaper products, but this could compromise quality. Understanding the labor market in the supplier’s location can provide insights into potential cost savings.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and equipment used in production. Suppliers with advanced manufacturing processes may have higher overheads but can offer better quality assurance and efficiency.

-

Tooling: Initial tooling costs can be significant, especially for custom parts. Buyers should consider the implications of tooling costs on pricing, particularly for large volume orders.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet industry standards and specifications. Investing in quality can reduce long-term costs associated with failures and replacements.

-

Logistics: Shipping costs can vary dramatically based on the distance, mode of transport, and weight of the products. International buyers must factor in these costs, especially when sourcing from regions like Europe or the Middle East.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Impact Intex Pool Spare Parts?

Several factors can influence the pricing of Intex pool spares, including volume or minimum order quantity (MOQ), specifications and customization, material quality and certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Buying in bulk usually results in cost savings. Suppliers often offer discounts for larger orders, which can significantly reduce the per-unit price.

-

Specifications and Customization: Custom parts or specific features often come at a premium. Buyers should clarify their needs upfront to avoid unexpected costs.

-

Materials and Quality Certifications: Higher quality materials and certifications can lead to higher prices. Buyers should assess whether the additional cost correlates with enhanced performance and longevity.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency in sourcing Intex pool spares.

-

Negotiation: Always negotiate prices, particularly for larger orders. Suppliers may have flexibility in pricing, especially if they want to secure a long-term relationship.

-

Total Cost of Ownership (TCO): Evaluate not just the upfront price but the total cost associated with the spare parts. This includes maintenance, replacement frequency, and operational efficiency.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs. These can impact the final price significantly. It’s advisable to establish clear payment terms to mitigate risks.

-

Research and Compare: Conduct thorough research on various suppliers and their offerings. Compare prices, terms, and delivery times to make informed decisions.

-

Consider Local Suppliers: Depending on the region, local suppliers might offer competitive pricing and faster delivery times, reducing logistics costs.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on supplier, region, and specific requirements. Always consult with multiple suppliers and conduct thorough due diligence before finalizing purchases.

Alternatives Analysis: Comparing intex pool spares With Other Solutions

Understanding Alternatives in Pool Spare Parts

In the realm of pool maintenance, particularly for above-ground pools, ensuring the longevity and efficiency of equipment is paramount. While Intex pool spares are a popular choice due to their compatibility and quality, various alternative solutions exist that may cater to different needs and preferences. This analysis will explore these alternatives, comparing their performance, cost, ease of implementation, maintenance, and ideal use cases.

Illustrative image related to intex pool spares

| Comparison Aspect | Intex Pool Spares | Generic Pool Spare Parts | Custom Fabrication Services |

|---|---|---|---|

| Performance | High-quality, designed for Intex models | Varies by brand; may not fit perfectly | Tailored to specific requirements |

| Cost | Moderate price range, often competitive | Typically lower, but quality may vary | Higher due to labor and material costs |

| Ease of Implementation | Easy DIY installation with clear instructions | Depends on compatibility and instructions | Requires professional installation |

| Maintenance | Low; designed for durability | Varies; some may require more frequent replacement | Maintenance depends on custom design |

| Best Use Case | Ideal for Intex pools needing reliable parts | Suitable for budget-conscious consumers | Best for unique setups or non-standard designs |

What Are the Benefits and Drawbacks of Generic Pool Spare Parts?

Generic pool spare parts offer a cost-effective solution for pool maintenance. They can be significantly cheaper than branded options, making them attractive for budget-conscious buyers. However, the downside is that generic parts may not fit as precisely as original parts, potentially leading to compatibility issues. Additionally, the quality can vary widely, and users might find themselves replacing these parts more frequently than expected. This option is best suited for those looking for quick fixes or temporary solutions.

How Do Custom Fabrication Services Compare to Intex Pool Spares?

Custom fabrication services provide a unique solution tailored specifically to a buyer’s needs, especially for non-standard pool sizes or configurations. These services can create parts that fit perfectly and perform optimally, ensuring longevity. However, the primary drawbacks include a higher cost due to labor and materials, as well as a longer lead time for production and installation. This option is ideal for businesses with specialized pool designs or those that require bespoke solutions.

Conclusion: How Should B2B Buyers Choose Between Intex Pool Spares and Alternatives?

Selecting the right spare parts for pool maintenance is crucial for maximizing operational efficiency and minimizing downtime. B2B buyers should evaluate their specific needs, such as budget constraints, installation capabilities, and the uniqueness of their pool systems. Intex pool spares remain a reliable choice for standard Intex models, offering high performance and ease of use. However, for those on a tight budget or with unique requirements, exploring generic parts or custom solutions may yield satisfactory results. Ultimately, the decision should align with the buyer’s long-term maintenance strategy and operational goals.

Essential Technical Properties and Trade Terminology for intex pool spares

What Are the Key Technical Properties of Intex Pool Spares?

Understanding the technical specifications of Intex pool spares is crucial for ensuring compatibility, performance, and longevity of pool systems. Below are some critical specifications that buyers should consider:

-

Material Grade

The material used in pool parts significantly affects durability and performance. Common materials include high-density polyethylene (HDPE), stainless steel, and PVC. Each material has different resistance to corrosion, UV exposure, and temperature fluctuations. Selecting the right material grade can enhance the lifespan of the pool spare, reducing the need for frequent replacements. -

Dimensional Tolerances

Dimensional tolerance refers to the permissible limit or limits of variation in a physical dimension. For Intex pool spares, precise dimensions are critical for parts like fittings and connectors to ensure they fit perfectly with existing systems. Tighter tolerances often indicate higher quality manufacturing, which can lead to fewer leaks and better overall performance. -

Compatibility Standards

Compatibility is essential when sourcing Intex pool spares. Parts must meet specific design and functionality standards to ensure they work seamlessly with existing pool systems. Buyers should look for spares that are explicitly labeled as compatible with their pool models to avoid costly mistakes and downtime. -

Pressure Ratings

Many pool components, such as pumps and filters, operate under specific pressure conditions. Understanding the pressure rating of these components ensures they can handle the operational demands without risk of failure. Choosing parts with appropriate pressure ratings helps maintain safety and efficiency, minimizing the risk of leaks or equipment damage. -

Flow Rates

Flow rate is a measure of how quickly water can pass through a system, typically expressed in liters per minute (L/min) or gallons per minute (GPM). For filtration systems, selecting parts that match the required flow rates is crucial for effective water circulation and cleanliness. Mismatched flow rates can lead to inadequate filtration, impacting water quality. -

Thermal Resistance

Thermal resistance indicates how well a material can withstand temperature changes, which is particularly relevant for pool components exposed to sunlight or heated water. Parts with high thermal resistance are less likely to warp or degrade, ensuring they maintain functionality over time.

What Are Common Trade Terms in the Intex Pool Spare Industry?

Familiarizing yourself with key industry terminology can enhance communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are then sold under another company’s brand name. In the context of Intex pool spares, buying OEM parts ensures that you receive components specifically designed for optimal compatibility and performance with Intex products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers, as it can affect inventory management and cash flow. Negotiating favorable MOQs can lead to better pricing and inventory flexibility. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. Crafting a detailed RFQ for Intex pool spares helps ensure accurate pricing and terms, facilitating smoother procurement processes. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms for shipping Intex pool spares can help avoid misunderstandings regarding delivery and payment obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is received. Understanding lead times is essential for planning inventory and ensuring that pool maintenance can proceed without delays. -

Warranty Period

The warranty period defines the timeframe during which a buyer can claim repairs or replacements for defective products. A clear understanding of warranty terms helps buyers assess the risk associated with purchasing specific Intex pool spares and can influence purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right Intex pool spares for their operational needs.

Illustrative image related to intex pool spares

Navigating Market Dynamics and Sourcing Trends in the intex pool spares Sector

What Are the Key Market Drivers and Trends Impacting the Intex Pool Spares Sector?

The global market for Intex pool spares is witnessing significant growth driven by increased consumer interest in outdoor leisure activities, particularly in regions with warm climates like Africa, South America, the Middle East, and parts of Europe. As economies stabilize and disposable incomes rise, more households are investing in pool installations and maintenance. This trend is further propelled by the rising popularity of DIY pool care, leading to a growing demand for readily available spare parts and accessories.

Emerging technologies are reshaping sourcing strategies within the sector. B2B buyers are increasingly leveraging e-commerce platforms to procure spare parts directly from manufacturers, reducing lead times and ensuring access to genuine products. Additionally, the use of digital supply chain management tools is enabling companies to enhance inventory tracking and optimize procurement processes. Moreover, a focus on customer experience is pushing suppliers to offer comprehensive product catalogs and user-friendly purchasing experiences.

International buyers, particularly from Brazil and Germany, are also becoming more discerning regarding product quality and compatibility with existing pool systems. They are seeking suppliers who can provide detailed product specifications and support services, ensuring that their purchases meet specific operational requirements. As such, the market is becoming increasingly competitive, necessitating that suppliers differentiate themselves through superior product offerings and customer service.

Illustrative image related to intex pool spares

How Does Sustainability Influence Sourcing Decisions in the Intex Pool Spares Sector?

Sustainability is becoming an essential consideration for B2B buyers in the Intex pool spares market. The environmental impact of pool maintenance and the production of spare parts is prompting companies to seek solutions that minimize their carbon footprint. Ethical sourcing practices are gaining traction, with buyers increasingly favoring suppliers who demonstrate a commitment to sustainable materials and manufacturing processes.

The demand for ‘green’ certifications is on the rise. Suppliers who can provide documentation on eco-friendly materials used in their products, such as recycled plastics or sustainably sourced components, stand to gain a competitive edge. Additionally, transparent supply chains that prioritize ethical labor practices are becoming critical for international buyers, particularly in regions sensitive to social responsibility.

Investing in sustainable practices not only enhances a company’s brand image but can also lead to cost savings in the long run. For instance, energy-efficient filtration systems and eco-friendly cleaning products can reduce overall operational costs. As a result, suppliers who integrate sustainability into their business models will likely attract a growing segment of environmentally conscious buyers.

What Is the Historical Context Behind the Intex Pool Spares Market?

The Intex pool spares market has evolved significantly since the introduction of above-ground pools in the late 20th century. Initially, the focus was primarily on the manufacturing of pool structures, with limited attention given to spare parts. However, as the popularity of above-ground pools surged, the need for reliable and easily accessible spare parts became evident.

Over the years, Intex has established itself as a leading brand in the pool industry, offering a diverse range of products and accessories. The expansion of e-commerce platforms in the 21st century further transformed the market, enabling B2B buyers to source spare parts globally with unprecedented ease. This evolution reflects the changing dynamics of consumer behavior and the increasing importance of quality, convenience, and sustainability in the purchasing process. As the market continues to grow, understanding this historical context will be crucial for international buyers looking to navigate the complexities of sourcing Intex pool spares.

Illustrative image related to intex pool spares

Frequently Asked Questions (FAQs) for B2B Buyers of intex pool spares

-

How do I solve common issues with Intex pool spares?

To address common issues such as leaks, poor filtration, or equipment malfunction, first identify the specific part causing the problem. Check for visible damage or wear on components like pumps, filters, or hoses. For minor issues, replacement parts can often be installed without professional assistance, thanks to their design for easy DIY repairs. If the problem persists, consult with suppliers for troubleshooting tips or consider hiring a local technician familiar with Intex products to ensure proper repair and maintenance. -

What is the best spare part for maintaining Intex pools?

The best spare parts for maintaining Intex pools include high-quality filters, pump motors, and seals. Regularly replacing filters ensures optimal water clarity and sanitation. Pump motors are crucial for effective circulation, while seals prevent leaks and maintain system pressure. When sourcing these parts, choose original Intex components for compatibility and durability, as they are specifically designed to work seamlessly with your pool system, enhancing its longevity and performance. -

How can I verify the credibility of suppliers for Intex pool spares?

To verify the credibility of suppliers, start by checking their online reviews and testimonials from previous customers. Request references and inquire about their experience in handling Intex products. Additionally, assess their certification and compliance with international quality standards. A reputable supplier should be transparent about their sourcing practices and offer warranties on parts. Engaging in direct communication can also provide insights into their customer service and responsiveness. -

What are the minimum order quantities (MOQs) for Intex pool spares?

Minimum order quantities for Intex pool spares can vary significantly between suppliers. Some may offer flexible MOQs, allowing you to order single units for specific parts, while others might require bulk orders to reduce costs. Before placing an order, inquire about the supplier’s MOQ policies and whether they provide discounts for larger purchases. This information is crucial for managing your inventory and optimizing procurement costs, especially for B2B buyers in diverse markets. -

What payment terms are typically offered for international purchases of Intex pool spares?

Payment terms for international purchases of Intex pool spares often include options such as advance payment, letters of credit, or payment upon delivery. Terms can vary based on supplier policies and your business relationship. It’s essential to discuss and agree on payment terms before finalizing any orders. Be sure to clarify currency conversion rates, transaction fees, and any potential taxes that may apply, particularly for cross-border transactions. -

How can I ensure quality assurance for Intex pool spares?

Ensuring quality assurance for Intex pool spares involves sourcing from reputable suppliers who provide original parts and adhere to strict quality control standards. Request detailed product specifications, certifications, and warranty information for the parts you intend to purchase. Additionally, consider conducting a small trial order to evaluate the product quality and supplier reliability before committing to larger purchases. Regular communication with your supplier can also help maintain quality assurance throughout your buying process. -

What logistics considerations should I keep in mind when importing Intex pool spares?

When importing Intex pool spares, consider logistics factors such as shipping methods, delivery times, and customs regulations specific to your country. Choose a reliable freight forwarder who understands the complexities of international shipping and can handle documentation efficiently. Additionally, factor in potential delays caused by customs clearance and be aware of any tariffs or import duties that may apply to your shipment. Planning ahead can help ensure timely delivery and minimize unexpected costs. -

Can Intex pool spares be customized for specific needs?

Some suppliers may offer customization options for Intex pool spares, depending on the part and your specific requirements. Customization can include modifications to dimensions, materials, or colors to better suit your pool setup. Discuss your needs with potential suppliers to see if they can accommodate such requests. Keep in mind that customized parts may have longer lead times and could require higher MOQs, so it’s essential to factor these aspects into your procurement strategy.

Top 4 Intex Pool Spares Manufacturers & Suppliers List

1. INTEX – Above Ground Pools & Filtration Systems

Domain: intexcorp.com

Registered: 1995 (30 years)

Introduction: INTEX offers a variety of replacement parts for Above Ground Swimming Pools, Krystal Clear Filtration & Sanitation systems, and Spas. The product categories include:

– Above Ground Pools: Easy Set, Metal Frame, Prism Frame, Ultra XTR Frame.

– Filtration & Sanitation: Cartridge Filter Pumps, Sand Filter Pumps, Saltwater Systems, Combination Systems.

– Spas: PureSpa Bubble Massage, PureSpa Plus Bub…

2. Intex – Above Ground Pool Accessories

Domain: intexwetset.co.uk

Registered: 2004 (21 years)

Introduction: Above Ground Pool Accessories, Deluxe Pool Ladders, Pool Covers, Pool Fittings, Rectangular Prism, Chevron Pool, Prism Frame, Graphite Frames, Metal Frame, Ultra Frame, Easy Set, Oval Frame Pools.

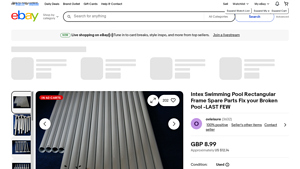

3. Intex – Swimming Pool Rectangular Frame Spare Parts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Intex Swimming Pool Rectangular Frame Spare Parts

– Condition: Used

– Price: Approx. $12.14 GBP / 8.99

– Available Sizes: 2.2m Pool Spare, 2.6m Pool Spare, 3.0m Pool Spare, 4.5m Pool Spare

– Available Parts: Horizontal Beam (A, B, C, D), Vertical Corner Leg, Inverted T Side Support Leg, Inverted T Side Support

– Quantity Available: More than 10 available

– Sold: 375 have already sold

– Seller: ovl…

4. Intex SA – Pools & Airbeds

Domain: intexsa.co.za

Registered: 2016 (9 years)

Introduction: This company, Intex SA – Pools & Airbeds, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for intex pool spares

In conclusion, strategic sourcing of Intex pool spares is essential for ensuring the longevity and optimal performance of pool systems across diverse markets, including Africa, South America, the Middle East, and Europe. By focusing on original spare parts, buyers can enhance the reliability and efficiency of their pool operations, ultimately leading to higher customer satisfaction. The availability of a wide range of components—from filtration systems to cleaning accessories—allows for tailored solutions that meet specific regional demands and preferences.

As international buyers navigate the complexities of sourcing, prioritizing partnerships with reputable suppliers who offer quality assurance, competitive pricing, and efficient logistics will be crucial. Emphasizing compatibility and ease of installation will also empower businesses to minimize downtime and reduce maintenance costs.

Looking ahead, the demand for high-quality Intex pool spares is projected to grow, driven by an increasing consumer focus on outdoor leisure and wellness. Buyers are encouraged to explore strategic partnerships that facilitate access to a comprehensive inventory of spare parts, ensuring they stay ahead in this competitive market. Engage with trusted suppliers today to secure your pool systems for tomorrow’s demands.

Illustrative image related to intex pool spares

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.