Is Your Hydrau Lift Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for hydrau lift

In today’s fast-paced global economy, sourcing hydraulic lifts that meet diverse operational needs can be a daunting challenge for B2B buyers. The complexity of selecting the right hydraulic lift—be it for construction, automotive, or healthcare applications—demands a thorough understanding of various types, functionalities, and safety standards. This guide serves as a comprehensive resource designed to navigate the multifaceted world of hydraulic lifts, addressing key aspects such as types of lifts, their specific applications across industries, supplier vetting processes, and cost considerations.

By empowering international buyers, especially those from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Brazil—this guide aims to simplify the purchasing decision-making process. It equips you with actionable insights to identify reliable suppliers and negotiate favorable terms, ensuring that your investment in hydraulic lifting solutions aligns with your operational requirements and budget constraints.

As the demand for efficient material handling systems continues to grow, understanding the intricacies of hydraulic lifts will not only enhance productivity but also foster safety and compliance in your workplace. Dive into this guide to uncover the essential knowledge that will lead to informed purchasing decisions and successful project outcomes.

Understanding hydrau lift Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Lift Tables | Flat platform design for stable load handling | Warehousing, manufacturing, assembly lines | Pros: Versatile; easy to use. Cons: Limited height range. |

| Patient Hydraulic Lifts | Designed for safe patient transport; often portable | Healthcare facilities, nursing homes | Pros: Enhances patient safety; easy maneuverability. Cons: Higher maintenance due to frequent use. |

| Aircraft Hydraulic Lifts | Capable of lifting heavy aircraft components; specialized design | Aerospace industry | Pros: Optimized for heavy loads; enhances safety. Cons: Requires specialized training for operation. |

| Pallet Lifts | Designed specifically for lifting pallets and palletized loads | Warehousing, logistics | Pros: Efficient for material handling; space-saving. Cons: Limited to pallet use. |

| Custom Hydraulic Lifts | Tailored to specific operational needs; can include unique features | Diverse industries requiring specialized solutions | Pros: Meets specific requirements; enhances efficiency. Cons: Potentially higher costs and longer lead times. |

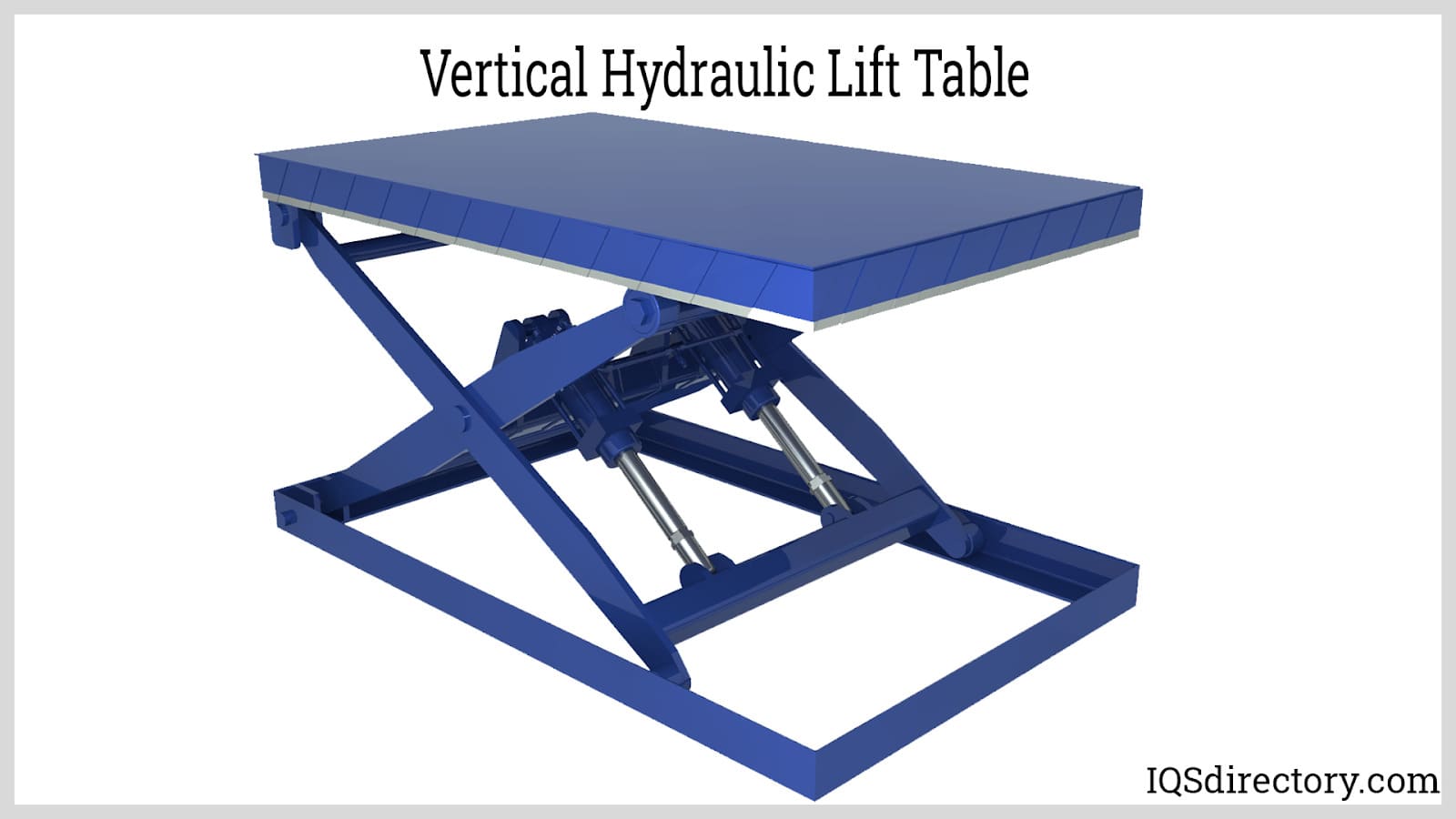

What Are the Key Characteristics of Hydraulic Lift Tables?

Hydraulic lift tables feature a flat platform that provides a stable base for transporting heavy loads. They are commonly used in warehouses and manufacturing settings where the efficient movement of goods is critical. Buyers should consider factors such as load capacity, height range, and mobility options when selecting a lift table, as these can impact operational efficiency and safety.

How Do Patient Hydraulic Lifts Enhance Safety in Healthcare?

Patient hydraulic lifts are specifically designed to transport individuals safely within healthcare facilities. Their portability and ease of use make them invaluable in nursing homes and hospitals, where patient safety is paramount. When purchasing, B2B buyers should evaluate the lift’s weight capacity, maneuverability, and maintenance requirements to ensure they meet healthcare standards.

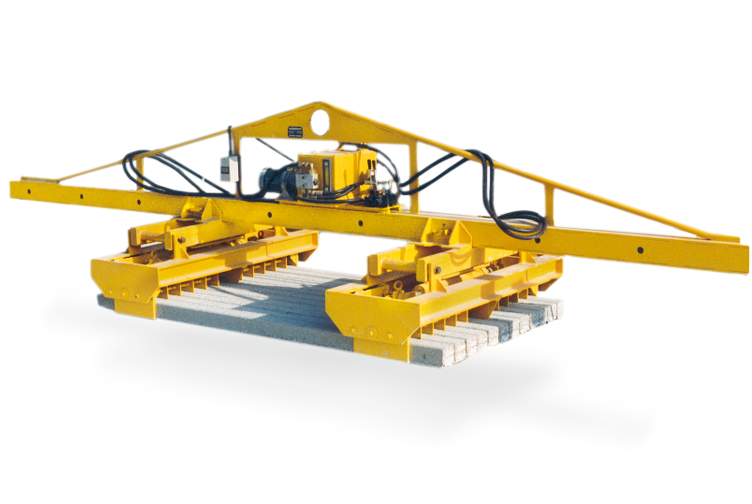

Why Are Aircraft Hydraulic Lifts Essential for the Aerospace Industry?

Aircraft hydraulic lifts are engineered to handle the heavy and oversized components of aircraft, facilitating maintenance and assembly operations. Their robust design ensures safety and efficiency in the aerospace sector. B2B buyers must consider the lift’s load capacity, operational training needs, and compliance with aviation safety regulations when making purchasing decisions.

Illustrative image related to hydrau lift

What Makes Pallet Lifts a Smart Choice for Warehousing?

Pallet lifts are specialized hydraulic lifts designed to elevate pallets and palletized goods, making them ideal for logistics and warehousing applications. Their design allows for efficient material handling and space-saving operations. When selecting a pallet lift, buyers should assess the lift’s height capabilities, load capacity, and compatibility with existing warehouse equipment.

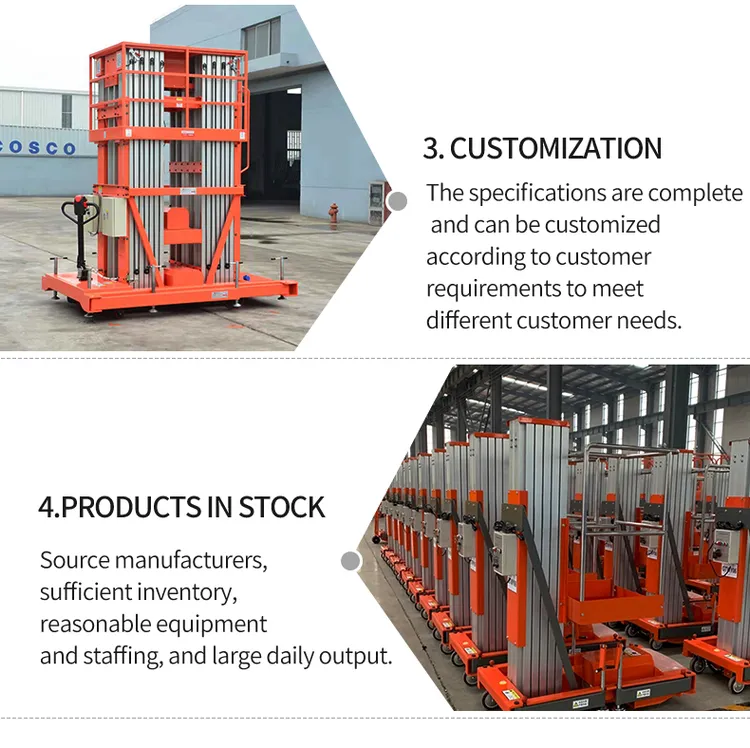

How Can Custom Hydraulic Lifts Meet Unique Business Needs?

Custom hydraulic lifts can be tailored to meet specific operational requirements across various industries. These lifts can incorporate unique features, such as specialized materials or multi-axis rotation, to enhance efficiency. B2B buyers should weigh the benefits of customization against potential costs and lead times, ensuring the chosen solution aligns with their operational goals.

Key Industrial Applications of hydrau lift

| Industry/Sector | Specific Application of hydrau lift | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient lifting in hospitals and clinics | Enhances patient safety and comfort during transfers | Compliance with medical regulations and safety standards; ease of use for healthcare staff. |

| Construction | Lifting heavy materials and equipment | Increases efficiency and reduces manual handling injuries | Durability to withstand harsh environments; customization options for specific lifting needs. |

| Automotive | Vehicle inspection and repair | Improves accessibility for technicians, enhancing productivity | Weight capacity requirements; compatibility with various vehicle types. |

| Industrial Manufacturing | Material handling and assembly line operations | Streamlines operations, reducing downtime and labor costs | Load capacity; integration with existing systems; safety features. |

| Mining | Transporting heavy loads in mining operations | Ensures safety and efficiency in challenging environments | Robust construction for harsh conditions; compliance with mining regulations. |

How is ‘hydrau lift’ Used in Healthcare Settings?

In healthcare, hydraulic lifts are essential for safely transferring patients between beds, wheelchairs, and examination tables. This application addresses the challenge of manual lifting, which can lead to injuries for both patients and healthcare staff. Buyers in this sector must ensure that the lifts comply with medical safety standards and are user-friendly for staff. Additionally, features like adjustable height and portability are critical for maximizing utility in various clinical environments.

What Role Does ‘hydrau lift’ Play in Construction?

In the construction industry, hydraulic lifts are crucial for moving heavy materials and equipment vertically across job sites. They significantly reduce the risk of injury associated with manual lifting, thereby enhancing worker safety and productivity. For international buyers, durability and load capacity are paramount, as construction environments can be harsh. Custom solutions that cater to specific lifting heights and weights are also valuable to ensure compliance with local regulations and operational needs.

How is ‘hydrau lift’ Utilized in Automotive Industries?

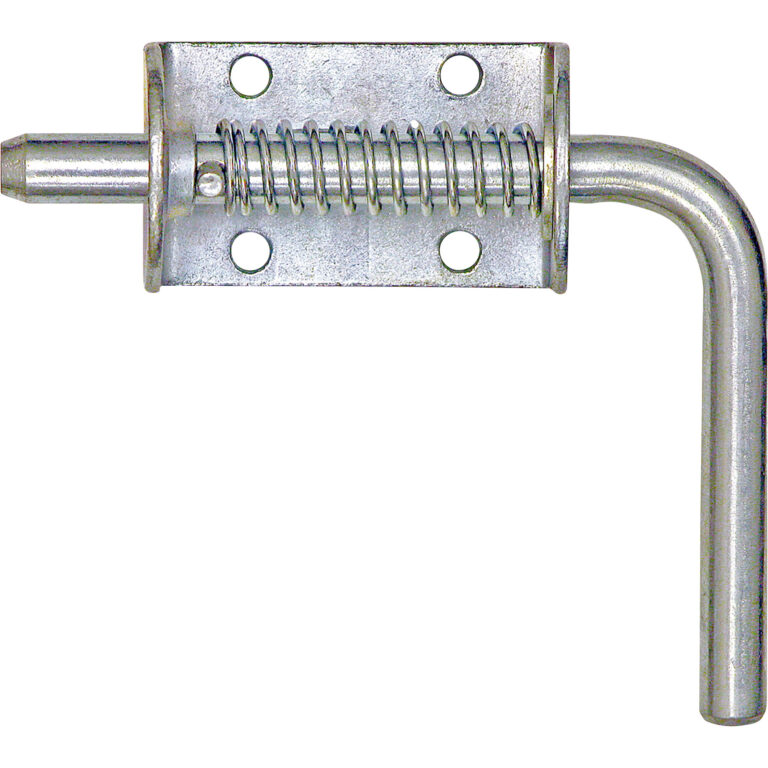

Hydraulic lifts in the automotive sector facilitate the inspection and repair of vehicles by elevating them to accessible heights. This application enhances technician productivity by allowing full access to the vehicle’s undercarriage and components. When sourcing hydraulic lifts for automotive use, businesses should consider the weight capacities required for different vehicle types and ensure compatibility with their service bays. Safety features, such as locking mechanisms and stability, are also essential to prevent accidents.

What is the Application of ‘hydrau lift’ in Industrial Manufacturing?

In industrial manufacturing, hydraulic lifts streamline material handling processes on assembly lines. They enable the efficient movement of heavy components and products, reducing labor costs and downtime. Buyers should focus on the lift’s load capacity and compatibility with existing material handling systems. Additionally, safety features and ease of integration into current workflows are critical considerations to enhance operational efficiency.

How Does ‘hydrau lift’ Support Mining Operations?

In mining, hydraulic lifts are vital for transporting heavy loads, such as rocks and equipment, in challenging conditions. These lifts enhance safety by minimizing the need for manual handling of heavy materials, which can lead to accidents. Buyers in the mining sector should prioritize robust construction that can withstand harsh environments and ensure compliance with industry regulations. Customization options may also be beneficial to meet specific operational requirements.

3 Common User Pain Points for ‘hydrau lift’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Hydraulic Lift for Specific Applications

The Problem: B2B buyers often struggle to identify the right hydraulic lift for their specific operational needs, which can lead to inefficiencies and increased costs. For instance, a construction company might require a lift that can handle heavy materials and operate in rugged environments, while a medical facility may need a lift that prioritizes safety and ease of use for patients. Without a clear understanding of the available options and their specifications, buyers can end up investing in equipment that does not meet their requirements.

The Solution: To effectively source the right hydraulic lift, buyers should begin by conducting a thorough needs assessment. This includes evaluating the weight capacities, operational environments, and any specific safety or regulatory requirements pertinent to their industry. Engaging with reputable suppliers who specialize in hydraulic lifts is crucial; they can provide insights into different types of lifts, such as portable hydraulic tables for warehouses or specialized medical lifts for healthcare settings. Buyers should also inquire about customization options to ensure the lift can be tailored to their unique needs, including frame dimensions and material specifications. Finally, leveraging customer reviews and case studies can provide valuable context on the performance of various models in similar applications.

Illustrative image related to hydrau lift

Scenario 2: Maintenance and Downtime Concerns with Hydraulic Lifts

The Problem: Another common pain point for B2B buyers is the concern over maintenance and potential downtime of hydraulic lifts. Companies often worry that if their lift fails, it can disrupt operations, lead to safety hazards, and incur significant repair costs. For instance, an automotive workshop relying on hydraulic lifts for vehicle inspections may face delays in service if the equipment is not maintained properly.

The Solution: To mitigate maintenance issues, buyers should prioritize purchasing hydraulic lifts from manufacturers that offer comprehensive warranties and robust customer support. Establishing a scheduled maintenance program is also essential; regular inspections and servicing can help identify potential issues before they escalate into costly repairs. Buyers should request training for their staff on the proper operation and maintenance of hydraulic lifts, ensuring that employees understand how to identify warning signs of mechanical failure. Additionally, investing in remote monitoring technology can provide real-time insights into lift performance, allowing businesses to proactively address maintenance needs before they result in downtime.

Scenario 3: Ensuring Safety Compliance with Hydraulic Lifts

The Problem: Safety compliance is a critical concern for B2B buyers, particularly in industries with stringent regulations, such as healthcare and construction. Buyers may find it challenging to ensure that the hydraulic lifts they purchase meet all safety standards, potentially exposing their companies to legal liabilities and compromising worker safety. An example is a manufacturing facility where improper lift usage could lead to serious injuries or accidents.

The Solution: To ensure safety compliance, B2B buyers should familiarize themselves with local and international safety regulations regarding hydraulic lifts. When sourcing lifts, it’s essential to ask suppliers for documentation that demonstrates compliance with relevant safety standards, such as ISO certifications or CE markings in Europe. Investing in lifts equipped with safety features—like overload protection, emergency stop buttons, and stability sensors—can further enhance workplace safety. Additionally, providing thorough training for employees on the safe operation of hydraulic lifts, including proper loading techniques and emergency procedures, can significantly reduce the risk of accidents. Establishing a culture of safety within the organization, where employees feel empowered to report safety concerns, can also contribute to ongoing compliance and risk mitigation.

Strategic Material Selection Guide for hydrau lift

What Are the Key Materials Used in Hydraulic Lifts?

Hydraulic lifts are integral to various industries, and the selection of materials for their construction significantly impacts performance, durability, and cost. Below, we analyze four common materials used in hydraulic lift systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform in Hydraulic Lift Applications?

Key Properties: Steel is known for its high tensile strength and excellent load-bearing capabilities. It can withstand high pressure and is often treated for corrosion resistance, making it suitable for various environments.

Pros & Cons: The durability of steel is a major advantage, as it can handle heavy loads and resist deformation under stress. However, it is relatively heavy, which can complicate installation and transportation. Additionally, while steel is generally cost-effective, high-grade stainless steel can be expensive.

Impact on Application: Steel’s compatibility with hydraulic fluids is excellent, and it can be used in both indoor and outdoor applications, provided it is treated against corrosion.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local availability and compliance with international standards such as ASTM and DIN. In Europe, especially Germany, there is a strong preference for certified materials that meet stringent safety regulations.

What Role Does Aluminum Play in Hydraulic Lift Construction?

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it ideal for applications where weight is a concern. It also has a decent strength-to-weight ratio, which allows for efficient lifting.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, it is not as strong as steel, which can limit its application in heavy-duty lifts. Additionally, aluminum can be more expensive than steel, particularly when considering high-strength alloys.

Impact on Application: Aluminum is suitable for environments where corrosion is a significant concern, such as marine or chemical applications. However, its lower strength may restrict its use in heavy industrial settings.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that comply with local standards. In Europe, for example, EN standards dictate the quality and performance of aluminum used in lifting equipment.

Why Is Plastic Used in Some Hydraulic Lift Components?

Key Properties: Engineering plastics, such as polycarbonate or nylon, are lightweight and resistant to corrosion and chemicals. They are often used in seals and other non-structural components.

Pros & Cons: The primary advantage of plastic is its resistance to corrosion and chemicals, making it suitable for specific applications. However, plastics generally have lower strength compared to metals, which can limit their use in load-bearing components. They can also be less durable under high temperatures.

Impact on Application: Plastic components can enhance the longevity of hydraulic systems by preventing corrosion, especially in environments with aggressive fluids. However, their use must be carefully evaluated based on the lift’s load requirements.

Considerations for International Buyers: Buyers should ensure that the selected plastics meet relevant safety and performance standards, especially in regions with strict regulations like the EU.

How Does Stainless Steel Compare in Hydraulic Lift Systems?

Key Properties: Stainless steel offers exceptional corrosion resistance and strength, making it suitable for demanding environments. It can withstand high pressure and temperature variations.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, which is crucial for hydraulic systems exposed to moisture. However, it is often the most expensive option among the materials discussed, and its weight can be a drawback in certain applications.

Impact on Application: Stainless steel is ideal for medical and food processing applications where hygiene is paramount. Its compatibility with hydraulic fluids is excellent, ensuring reliable performance.

Considerations for International Buyers: Buyers must check for compliance with international standards such as ISO and ASTM to ensure quality and safety. In regions like the Middle East, where environmental conditions can be harsh, stainless steel is often preferred for its longevity.

Summary of Material Selection for Hydraulic Lifts

| Material | Typical Use Case for hydrau lift | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy industrial lifts | High strength and durability | Heavy weight complicates transport | Medium |

| Aluminum | Lightweight lifts | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic | Seals and non-structural parts | Corrosion and chemical resistance | Lower strength and durability | Low |

| Stainless Steel | Medical and food processing lifts | Exceptional corrosion resistance | High cost and weight | High |

This material selection guide offers valuable insights for B2B buyers looking to optimize their hydraulic lift systems. Understanding the properties and implications of each material can lead to more informed purchasing decisions, ensuring that the selected hydraulic lift meets both operational and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hydrau lift

What Are the Key Stages in the Manufacturing Process of Hydraulic Lifts?

The manufacturing process of hydraulic lifts is a meticulous endeavor that ensures safety, efficiency, and durability. Understanding these stages can significantly aid B2B buyers in evaluating suppliers and their capabilities.

1. Material Preparation

The foundation of any hydraulic lift lies in its materials. Manufacturers typically begin with the selection of high-strength steel or aluminum, chosen for their excellent weight-bearing properties and resistance to wear. The materials undergo rigorous testing for tensile strength and corrosion resistance.

Once selected, the materials are cut to size using advanced laser cutting or plasma cutting technologies, ensuring precision and minimizing waste. Additional components, such as hydraulic cylinders and valves, are sourced from reputable suppliers, often involving pre-qualification processes to confirm quality standards.

2. Forming Techniques

After material preparation, the next stage involves forming the components. Techniques such as bending, stamping, and machining are commonly employed. For example, the hydraulic cylinders are often machined to exact specifications to ensure optimal performance under pressure.

Welding is another critical process used to join components, where manufacturers may use techniques like MIG or TIG welding to achieve strong, reliable joints. The use of automated welding machines has increased consistency and reduced human error, which is crucial for high-stress components.

3. Assembly Procedures

The assembly phase is where all the manufactured components come together. A systematic approach is essential to ensure that each hydraulic lift functions as intended. This stage typically includes the installation of hydraulic systems, where pumps, valves, and cylinders are assembled in a controlled environment to prevent contamination.

Quality control checks are integrated into the assembly process. For instance, during the assembly of hydraulic cylinders, operators may perform leak tests to ensure that seals are correctly installed and functioning.

4. Finishing Touches

Finishing processes, such as painting or powder coating, enhance both the aesthetics and durability of the hydraulic lift. These finishes protect against corrosion and wear, making the lifts suitable for various environments, from warehouses to outdoor construction sites.

Final inspections are conducted to verify that the surface finish meets industry standards and that there are no defects in the structure.

How Is Quality Assurance Implemented in Hydraulic Lift Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of hydraulic lifts, ensuring that products not only meet but exceed safety and performance standards.

What International Standards Are Relevant for Hydraulic Lift Manufacturing?

International standards like ISO 9001 play a critical role in establishing a quality management system (QMS). This standard outlines requirements for consistent quality and continuous improvement, which are vital for manufacturers aiming for global competitiveness.

In addition to ISO certifications, industry-specific standards such as CE marking in Europe and API standards for equipment used in the petroleum industry are crucial. Compliance with these standards assures buyers that the lifts have been manufactured following strict safety protocols.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are established throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials and components for quality before they enter the manufacturing process.

- In-Process Quality Control (IPQC): During manufacturing, random inspections are conducted to ensure that production processes remain within defined parameters.

- Final Quality Control (FQC): Once the hydraulic lift is fully assembled, a comprehensive inspection checks for functionality, safety features, and overall quality before shipment.

What Testing Methods Are Commonly Used?

Manufacturers employ various testing methods to ensure hydraulic lifts meet performance specifications. Common testing methods include:

- Hydraulic Pressure Testing: This tests the lift’s ability to handle maximum pressure without leaks or failure.

- Load Testing: Simulated loads are applied to assess the lift’s performance and safety under operational conditions.

- Functional Testing: This ensures that all components, including safety features, operate correctly.

How Can B2B Buyers Verify Supplier Quality Control Measures?

When sourcing hydraulic lifts, B2B buyers should conduct thorough due diligence on potential suppliers. Here are some actionable steps to verify supplier quality control:

1. Request Documentation

Buyers should ask suppliers for documentation of their quality management systems, including ISO certifications, and any other relevant compliance certificates. This documentation serves as proof of the supplier’s commitment to quality.

2. Conduct Audits

On-site audits of suppliers can provide invaluable insight into their manufacturing processes and quality control measures. Buyers should look for transparency in operations and adherence to quality standards during these visits.

3. Engage Third-Party Inspection Services

Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can perform inspections and testing to verify that the hydraulic lifts meet specified standards before shipment.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control:

- Regulatory Compliance: Different countries have varying regulations regarding safety and quality standards. Buyers should ensure that their suppliers can meet these local regulations.

- Cultural Differences: Understanding cultural attitudes towards quality and safety can aid in building effective relationships with suppliers. For example, some regions may prioritize cost over quality, which could impact long-term reliability.

- Logistical Challenges: Buyers should consider potential logistical issues, such as delays in shipping or customs clearance, which can affect the timely delivery of compliant products.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing hydraulic lifts, ensuring they partner with reliable suppliers committed to quality and safety.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydrau lift’

The following guide is designed to assist B2B buyers in the process of sourcing hydraulic lifts, ensuring that you make informed decisions that align with your operational needs and compliance standards.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the hydraulic lift you need. Consider factors such as load capacity, lift height, and the type of materials being handled. Understanding these specifications helps narrow down potential suppliers and ensures that the equipment will meet your operational demands.

- Load Capacity: Determine the maximum weight the lift must handle.

- Lift Height: Identify the required vertical reach for your applications.

- Material Type: Consider whether the lift needs to be compatible with specific materials, like stainless steel for medical applications.

Step 2: Research Supplier Experience and Reputation

Evaluate the experience and reputation of potential suppliers in the hydraulic lift market. A supplier with a solid track record is more likely to provide reliable products and support.

- Industry Experience: Look for suppliers who specialize in your industry (e.g., construction, medical, or industrial).

- Customer Reviews: Seek testimonials and case studies from previous clients to gauge satisfaction and reliability.

Step 3: Verify Compliance with Safety Standards

Ensure that the hydraulic lifts meet all relevant safety and regulatory standards. Compliance is crucial to minimize workplace accidents and ensure legal adherence.

- Local Regulations: Familiarize yourself with the safety regulations specific to your region, including certifications like CE, ISO, or ANSI.

- Safety Features: Check for built-in safety mechanisms, such as overload protection and emergency stop buttons.

Step 4: Evaluate Customization Options

Assess whether the supplier offers customization options to tailor the hydraulic lift to your specific needs. Custom solutions can enhance efficiency and ergonomics in your operations.

- Modifications Available: Inquire about frame dimensions, lift strokes, and special materials.

- Industry-Specific Features: Look for options that cater to unique industry requirements, such as ESD-safe components for electronics manufacturing.

Step 5: Request Detailed Quotations

Once you have identified potential suppliers, request comprehensive quotations. This should include pricing, delivery timelines, warranties, and after-sales support.

- Cost Breakdown: Ensure the quotation details all costs, including shipping and installation.

- Warranty Terms: Understand the warranty coverage and what it entails in terms of repairs and maintenance.

Step 6: Assess After-Sales Support and Maintenance Services

Evaluate the level of after-sales support provided by the supplier. Reliable support can significantly reduce downtime and improve overall operational efficiency.

- Maintenance Packages: Inquire if the supplier offers maintenance services or training for your staff on equipment use.

- Response Times: Understand the supplier’s response times for service calls and support inquiries.

Step 7: Finalize the Purchase Agreement

After thorough evaluation, finalize the purchase agreement with the selected supplier. Ensure all terms discussed are clearly documented to avoid misunderstandings.

- Contract Clarity: Review the contract for clarity on delivery, payment terms, and service obligations.

- Legal Review: Consider having legal counsel review the agreement to safeguard your interests.

By following these steps, B2B buyers can effectively navigate the sourcing process for hydraulic lifts, ensuring that they select the best solution for their operational needs while maintaining compliance and safety standards.

Comprehensive Cost and Pricing Analysis for hydrau lift Sourcing

What Are the Key Cost Components in Sourcing Hydraulic Lifts?

When sourcing hydraulic lifts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel or specialized alloys, often used for hydraulic cylinders and structural components, can increase costs but enhance durability and safety.

-

Labor: Labor costs vary by region and are influenced by the skill level required for assembly and maintenance. In regions with higher labor costs, such as Europe, these expenses can be substantial, whereas emerging markets may offer lower labor costs.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling for specialized hydraulic lift designs can add to initial costs. However, investing in tooling that enhances precision and efficiency can lead to long-term savings.

-

Quality Control (QC): Ensuring that hydraulic lifts meet safety and performance standards requires a robust QC process. This can involve testing, inspections, and certifications, all of which contribute to the overall cost.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and the volume of the order. International buyers should consider logistics as a significant portion of the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the competitive landscape can help buyers gauge what constitutes a fair margin.

How Do Price Influencers Affect Hydraulic Lift Costs?

Several factors influence the pricing of hydraulic lifts, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Suppliers may provide discounts for larger orders, making it crucial for buyers to assess their needs carefully.

-

Specifications and Customization: Custom specifications can significantly affect pricing. Complex designs or specialized features tailored to specific industries may incur higher costs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but ensure compliance with safety standards, especially in regulated markets like Europe.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost.

What Tips Can Help Buyers Negotiate Better Prices for Hydraulic Lifts?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing outcomes:

-

Conduct Market Research: Understanding market rates and competitor pricing can empower buyers in negotiations. This knowledge helps in determining a fair price range.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational costs, and potential downtime when evaluating the overall cost of ownership.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better terms. Repeat business often encourages suppliers to offer favorable pricing and terms.

-

Request Quotes from Multiple Suppliers: Comparing quotes can highlight price discrepancies and provide leverage in negotiations.

-

Be Clear on Requirements: Clearly outline specifications and needs upfront to avoid misunderstandings that could lead to increased costs later.

Conclusion: What Should Buyers Keep in Mind When Sourcing Hydraulic Lifts?

When sourcing hydraulic lifts, buyers must navigate a complex landscape of costs and pricing influences. While indicative prices can vary, understanding the underlying cost components and price influencers can empower international buyers to make informed decisions. By employing strategic negotiation tactics and focusing on total cost of ownership, buyers can optimize their procurement processes and secure the best value for their investments.

Alternatives Analysis: Comparing hydrau lift With Other Solutions

Introduction to Alternative Lifting Solutions

In the realm of material handling and lifting solutions, hydraulic lifts have established themselves as a reliable choice for various industries. However, buyers often seek alternatives that may better suit their specific operational requirements, budget constraints, or application needs. This section will compare hydraulic lifts with two viable alternatives: electric lifts and mechanical lifts. Each solution has its own advantages and drawbacks, making it essential for B2B buyers to evaluate their options carefully.

Illustrative image related to hydrau lift

Comparison Table of Lifting Solutions

| Comparison Aspect | Hydrau Lift | Electric Lift | Mechanical Lift |

|---|---|---|---|

| Performance | High load capacity; smooth operation | Moderate load capacity; faster than hydraulic | Lower load capacity; limited speed |

| Cost | Moderate initial investment; low operating costs | Higher initial costs; moderate operating costs | Low initial investment; high maintenance costs |

| Ease of Implementation | Requires hydraulic setup and space | Easier to set up; compact design | Simple to install; minimal infrastructure |

| Maintenance | Low; periodic fluid checks needed | Moderate; requires electrical maintenance | High; frequent repairs needed |

| Best Use Case | Heavy industrial applications, construction | Warehousing, retail environments | Light-duty lifting tasks |

Electric Lifts: Advantages and Disadvantages

Electric lifts are powered by electric motors, making them an attractive alternative to hydraulic lifts for several applications. One of their key advantages is speed; they typically lift loads faster than hydraulic systems. Additionally, electric lifts require less space and can be more energy-efficient, particularly in environments like warehouses and retail spaces where mobility and quick access are essential. However, they may not support as heavy a load as hydraulic lifts and can have higher initial costs due to the motor and electrical setup. Maintenance can also be moderate, as electrical components may require regular checks and updates.

Mechanical Lifts: Pros and Cons to Consider

Mechanical lifts, often utilizing pulleys and levers, represent a more traditional lifting method. They are generally more cost-effective upfront, making them appealing for businesses with budget constraints. The installation process is straightforward, requiring minimal infrastructure. However, mechanical lifts come with limitations, such as lower load capacities and slower lifting speeds. Additionally, they often demand more frequent maintenance due to wear and tear on mechanical parts, which can lead to increased operational downtime.

Conclusion: Choosing the Right Lifting Solution for Your Business

When selecting a lifting solution, B2B buyers must consider various factors, including load capacity, speed, budget, and maintenance requirements. Hydraulic lifts excel in heavy-duty applications, while electric lifts offer speed and efficiency for lighter tasks. Mechanical lifts may suit budget-conscious operations but come with limitations that could hinder productivity. Ultimately, assessing your specific operational needs, including the nature of the loads to be lifted and the working environment, will guide you to the most effective solution for your business.

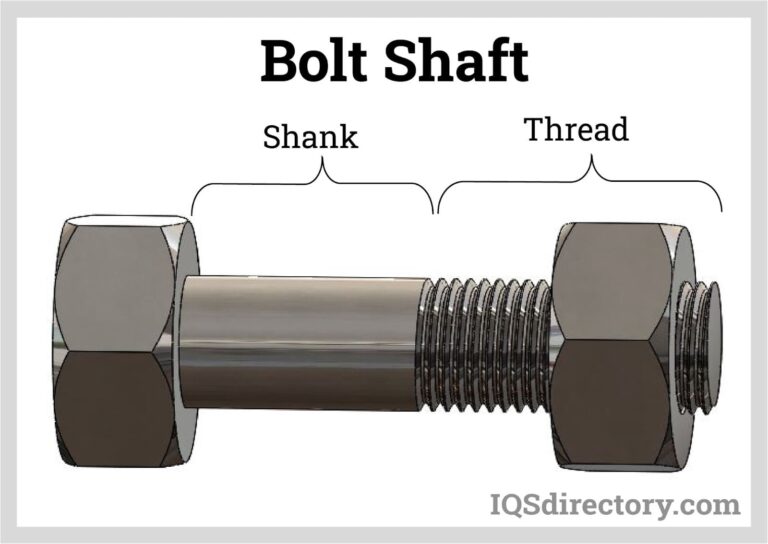

Essential Technical Properties and Trade Terminology for hydrau lift

What Are the Key Technical Properties of Hydraulic Lifts?

Understanding the essential specifications of hydraulic lifts is crucial for B2B buyers looking to make informed decisions. Here are some critical technical properties:

Illustrative image related to hydrau lift

1. Load Capacity

Load capacity refers to the maximum weight that a hydraulic lift can safely handle. Typically expressed in pounds or kilograms, this specification is vital for industries such as construction, manufacturing, and healthcare, where heavy equipment or patients need to be lifted. Selecting a lift with the appropriate load capacity ensures safety and operational efficiency, preventing accidents caused by overloading.

2. Lifting Height

Lifting height indicates how far the hydraulic lift can raise a load, measured from its lowest to highest point. This property is essential for applications where vertical space is limited or where loads must reach specific heights, such as in warehouses or automotive workshops. Buyers should evaluate the lifting height against their operational needs to avoid inefficiencies.

3. Pump Type

The type of pump used in hydraulic lifts (e.g., hand-operated, electric, or air-driven) significantly affects performance and user convenience. Electric pumps offer faster lifting times and require less manual effort, making them suitable for high-frequency operations. Understanding the pump type helps businesses choose a hydraulic lift that aligns with their workflow and labor capabilities.

Illustrative image related to hydrau lift

4. Cylinder Type

Hydraulic lifts can feature various cylinder designs, such as single-acting or double-acting cylinders. Single-acting cylinders lift loads using hydraulic pressure, while double-acting cylinders allow for lifting and lowering, providing more versatility. Knowing the cylinder type is crucial for applications requiring specific movement capabilities, like automotive repair or assembly line work.

5. Material Grade

The material used in constructing hydraulic lifts affects durability, weight, and corrosion resistance. Common materials include steel and aluminum, each offering different benefits. Steel provides strength for heavy loads, while aluminum is lighter and more resistant to corrosion. Buyers must assess material properties to ensure the lift can withstand their operational environment.

6. Safety Features

Safety features such as overload protection, emergency stop buttons, and safety valves are essential for ensuring the safe operation of hydraulic lifts. These features protect both the equipment and personnel, minimizing the risk of accidents. Understanding the safety specifications is critical for compliance with industry regulations and maintaining a safe work environment.

What Are Common Trade Terms in the Hydraulic Lift Industry?

Familiarity with industry jargon can streamline communications and negotiations. Here are several common terms used in the hydraulic lift sector:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end products. In the hydraulic lift industry, OEMs may provide parts like pumps or hydraulic cylinders. Understanding OEM relationships is essential for ensuring quality and compatibility in lift systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and initial investment costs. Knowing the MOQ helps businesses plan their purchases according to demand and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers use RFQs to compare quotes from different suppliers, helping them secure the best deals for hydraulic lifts. Understanding how to craft an effective RFQ can lead to better procurement outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is essential for international transactions, as they clarify shipping responsibilities, risk, and costs. This knowledge helps avoid disputes and ensures smooth logistics.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the hydraulic lift sector, lead times can vary based on customization and supplier capacity. Understanding lead times is crucial for project planning and ensuring timely availability of lifting equipment.

6. Customization Options

Customization options refer to the ability to tailor hydraulic lifts to specific requirements, such as size, capacity, and features. Buyers should be aware of available customization options to ensure the equipment meets their unique operational needs and regulatory compliance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting hydraulic lifts that best meet their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the hydrau lift Sector

What Are the Key Market Dynamics and Trends Influencing the Hydraulic Lift Sector?

The hydraulic lift sector is experiencing significant growth driven by various global factors. One of the primary drivers is the increasing demand for efficient material handling solutions across industries such as construction, automotive, aerospace, and healthcare. With urbanization and industrialization on the rise, particularly in regions like Africa, South America, and the Middle East, the need for reliable hydraulic lifts to manage heavy loads effectively is paramount. Additionally, advancements in technology, including the integration of IoT and automation, are reshaping the landscape, enabling predictive maintenance and enhancing operational efficiencies.

Illustrative image related to hydrau lift

Emerging trends indicate a shift towards customization in hydraulic lift solutions, catering to specific industry requirements. B2B buyers are increasingly seeking tailored solutions that offer improved ergonomics, safety features, and operational versatility. For instance, specialized lifts designed for unique applications—such as medical equipment handling or aerospace component positioning—are gaining traction. Moreover, the importance of compliance with international safety standards is becoming more pronounced, influencing sourcing decisions across the globe. Buyers from Europe, particularly Germany, are keen on high-quality products that adhere to stringent regulations, while those in developing regions may prioritize cost-effectiveness without compromising safety.

How Are Sustainability and Ethical Sourcing Shaping Hydraulic Lift Purchases?

The hydraulic lift sector is increasingly aligning with sustainability goals as environmental impact becomes a crucial factor in procurement decisions. Buyers are focusing on sourcing products that minimize carbon footprints and promote sustainable practices. This includes opting for hydraulic lifts constructed from recyclable materials and those that utilize environmentally friendly hydraulic fluids.

Ethical sourcing is also gaining prominence, as businesses recognize the importance of transparent supply chains. Buyers are now more inclined to partner with manufacturers who demonstrate commitment to fair labor practices and responsible sourcing. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential in supplier evaluations. By prioritizing these aspects, international B2B buyers can not only enhance their corporate social responsibility profiles but also appeal to a growing segment of environmentally conscious consumers.

Illustrative image related to hydrau lift

What Is the Brief Evolution of Hydraulic Lifts and Their Impact on Modern Industries?

The evolution of hydraulic lifts dates back to the 19th century, with the introduction of hydraulic systems in various engineering applications. Initially used in industrial settings, hydraulic lifts have transformed significantly over the years. The development of more sophisticated hydraulic cylinders and pumps has allowed for increased lifting capacities and enhanced safety features.

Today, hydraulic lifts are integral to numerous industries, enabling efficient movement of heavy loads and improving workplace safety. Their versatility has expanded from simple lifting tasks to complex applications in logistics, healthcare, and construction. This evolution has not only streamlined operations but has also fostered innovations in design and functionality, making hydraulic lifts a cornerstone of modern material handling solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of hydrau lift

-

How do I choose the right hydraulic lift for my business needs?

Selecting the right hydraulic lift involves assessing your specific requirements, including load capacity, height range, and application type. Consider the environment where the lift will be used, as certain models are better suited for industrial, medical, or construction settings. Additionally, evaluate customization options available from suppliers to ensure the lift meets your operational needs. Engaging with manufacturers to discuss your requirements can provide valuable insights and help identify the best solution tailored to your business. -

What are the advantages of hydraulic lifts over traditional elevators?

Hydraulic lifts offer several advantages, including the ability to handle heavier loads with less energy. They utilize Pascal’s Principle to transfer force through incompressible fluid, which allows for smooth and controlled lifting. Additionally, hydraulic systems can be more compact and easier to install than traditional roped elevators, making them suitable for various applications in diverse environments. They also tend to be more cost-effective in terms of maintenance and operation, particularly in industrial settings. -

What customization options are available for hydraulic lifts?

Customization options for hydraulic lifts can vary widely among manufacturers. Common modifications include frame dimensions, lift strokes, and speed adjustments. Other options may include special materials for specific environments, such as stainless steel for corrosive areas or ESD materials for electronic assembly. Suppliers often provide tailored solutions to meet unique operational needs, ensuring that the lift is optimized for your specific application and complies with local regulations. -

What is the typical minimum order quantity (MOQ) for hydraulic lifts?

Minimum order quantities (MOQs) for hydraulic lifts can differ based on the manufacturer and the specific model you are interested in. Generally, MOQs range from one unit for standard models to larger quantities for customized solutions. It’s important to communicate with potential suppliers to understand their MOQ policies and negotiate terms that suit your purchasing strategy, especially if you are looking to procure for multiple sites or projects. -

What payment terms should I expect when sourcing hydraulic lifts internationally?

Payment terms for international purchases of hydraulic lifts typically vary by supplier and may include options such as advance payment, letter of credit, or payment upon delivery. Some manufacturers may offer net terms (e.g., 30, 60, or 90 days) depending on your business relationship and creditworthiness. It’s advisable to clarify these terms upfront and consider securing a written agreement to avoid any misunderstandings, especially when dealing with international trade regulations and currency fluctuations. -

How can I ensure the quality and safety of hydraulic lifts from suppliers?

To ensure quality and safety, request certifications such as ISO 9001 or CE marking from suppliers, which indicate compliance with international standards. Additionally, inquire about the manufacturing process, materials used, and any testing procedures in place. Conducting site visits or audits can also help validate the supplier’s capabilities. Lastly, consider requesting customer references or case studies to gauge the reliability and performance of their hydraulic lifts in real-world applications. -

What logistics considerations should I keep in mind when importing hydraulic lifts?

When importing hydraulic lifts, it’s crucial to consider shipping methods, customs clearance, and potential tariffs or duties applicable in your country. Choose a reliable logistics partner familiar with heavy equipment to ensure safe and timely delivery. Additionally, factor in lead times for production and shipping, as these can vary significantly based on the origin and customization requirements. Planning for installation and after-sales support is also essential to minimize downtime once the lifts arrive. -

What industries commonly use hydraulic lifts, and what are their applications?

Hydraulic lifts are widely utilized across various industries, including construction, automotive, aerospace, and healthcare. In construction, they facilitate the movement of heavy materials and equipment. The automotive industry uses them for vehicle maintenance and assembly, while aerospace applications involve positioning large aircraft components. In healthcare, hydraulic lifts assist in patient handling and transport. Understanding these applications can help B2B buyers identify the best hydraulic lift solutions for their specific industry needs.

Top 5 Hydrau Lift Manufacturers & Suppliers List

1. Rhythm – HPT400 Heavy-Duty Patient Lift

Domain: rhythmhc.com

Registered: 2020 (5 years)

Introduction: {“SKU”:”HPT400″,”Weight Capacity”:”400 lbs”,”Construction”:”Heavy gauge steel construction”,”Spreader Bar”:”360° Six point spreader bar”,”Compatibility”:”Compatible with six, four and two point slings”,”Rear Casters”:”Lock to prevent movement while in-use for added stability and safety”,”Specifications”:{“Weight Capacity”:”400 lbs”,”Floor Clearance”:”5.5 inches”,”Lift Range”:”24 inches – 75 inches…

2. McMaster – Hydraulic Lifts & Jacks

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Hydraulic Lifts & Jacks, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Unidex – Hydraulic Lifts

Domain: unidex-inc.com

Registered: 1998 (27 years)

Introduction: Hydraulic lifts are designed to handle heavy and bulky loads in various applications, including construction, aerospace, automotive, industrial, marine, and mining. They operate using hydraulic cylinders, which can be single acting, double acting, or telescoping. Key components include a rod, piston, cylinder body, caps, seals, and a pump. Unidex offers a variety of hydraulic lifts, including tabl…

4. IQS Directory – Hydraulic Lifts

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Hydraulic lifts are mechanisms that utilize incompressible fluid to operate a piston and elevate a load, based on Pascal’s principle. Key components include a piston, cylinder, oil reservoir, pump, and valve. They are used in various applications such as car maintenance, warehouse logistics, and material handling. Advantages include cost-effectiveness, space efficiency, energy efficiency, and safe…

5. Lumex – Patient Hydraulic Lift

Domain: affordablemedicalusa.com

Registered: 2010 (15 years)

Introduction: Product Name: Lumex Patient Hydraulic Lift

Key Features:

– Six point spreader bar with 360 degree rotation

– Heavy gauge steel construction

– Hydraulic pump with ergonomic placement

– Manually adjustable foot pedal

– Compatible with Lumex two-point, four-point, and six-point slings

– Easy disassembly for storage

– Optional digital scale available

Maximum Weight Capacity: 400 lbs

Color Options: Blu…

Strategic Sourcing Conclusion and Outlook for hydrau lift

In conclusion, the strategic sourcing of hydraulic lifts presents a wealth of opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By understanding the fundamental mechanics of hydraulic systems and their diverse applications—from construction to healthcare—businesses can make informed decisions that enhance operational efficiency and safety.

Investing in high-quality hydraulic lifts not only optimizes material handling processes but also reduces long-term costs associated with maintenance and downtime. The importance of customization cannot be overstated; tailored solutions can meet specific industry needs and comply with local regulations, ensuring a competitive edge in your market.

As industries continue to evolve, the demand for innovative and reliable hydraulic lift solutions will only grow. We encourage buyers to leverage strategic sourcing to identify reputable manufacturers and suppliers that align with their unique requirements. Embrace this opportunity to enhance your operational capabilities and drive your business forward in a dynamic global landscape.

Illustrative image related to hydrau lift

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.