Is Your Heat Exchanger Type Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for heat exchanger type

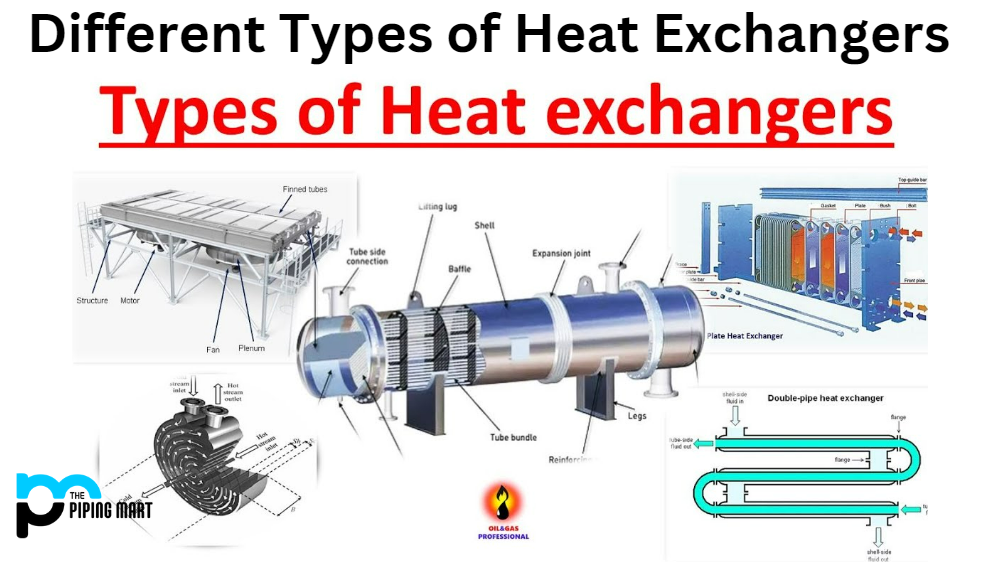

In today’s competitive landscape, sourcing the right heat exchanger type can be a daunting task for international B2B buyers. With diverse applications spanning industries such as food and beverage, pharmaceuticals, and energy, the challenge lies not only in selecting the most efficient design but also in ensuring compliance with regional standards and specifications. This comprehensive guide delves into the intricacies of various heat exchanger types, including plate and frame, shell and tube, and scraped surface exchangers, providing a clear understanding of their applications and operational efficiencies.

As you navigate through this guide, you’ll discover actionable insights on supplier vetting processes, cost considerations, and maintenance best practices. We specifically address the unique challenges faced by buyers from Africa, South America, the Middle East, and Europe, including Germany and Vietnam, equipping you with the knowledge to make informed purchasing decisions. Our objective is to empower you to optimize your procurement strategies, ensuring that you select heat exchangers that not only meet your technical requirements but also enhance your operational efficiency and sustainability goals. By leveraging the information presented, you can confidently engage with suppliers and streamline your sourcing process, ultimately driving your business success in the global market.

Understanding heat exchanger type Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plate and Frame | Compact design with corrugated plates; easy to clean and maintain | Food, beverage, dairy, pharmaceuticals | Pros: High efficiency, easy maintenance; Cons: Limited to low to medium viscosity fluids. |

| Shell and Tube | Consists of tubes within a shell; suitable for viscous fluids | Dairy, beverages, chemical processing | Pros: Handles high pressures; Cons: More complex maintenance, larger footprint. |

| Scraped Surface | Features scraping blades to prevent product build-up; versatile | Viscous, sticky, or heat-sensitive products | Pros: Effective heat transfer for challenging products; Cons: Higher initial cost, specialized maintenance. |

| Monotube | Single inner tube design; compact and efficient | Heat-treating applications with large particles | Pros: Simple design, effective for large particulates; Cons: Limited heat transfer surface area. |

| Double Tubesheet | Two tubesheets for leak detection; minimizes fluid mixing | Pharmaceutical applications, critical processes | Pros: Enhanced safety and leak detection; Cons: More expensive, complex design. |

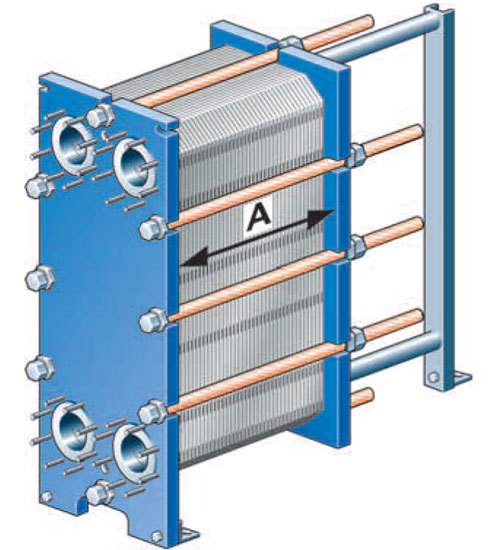

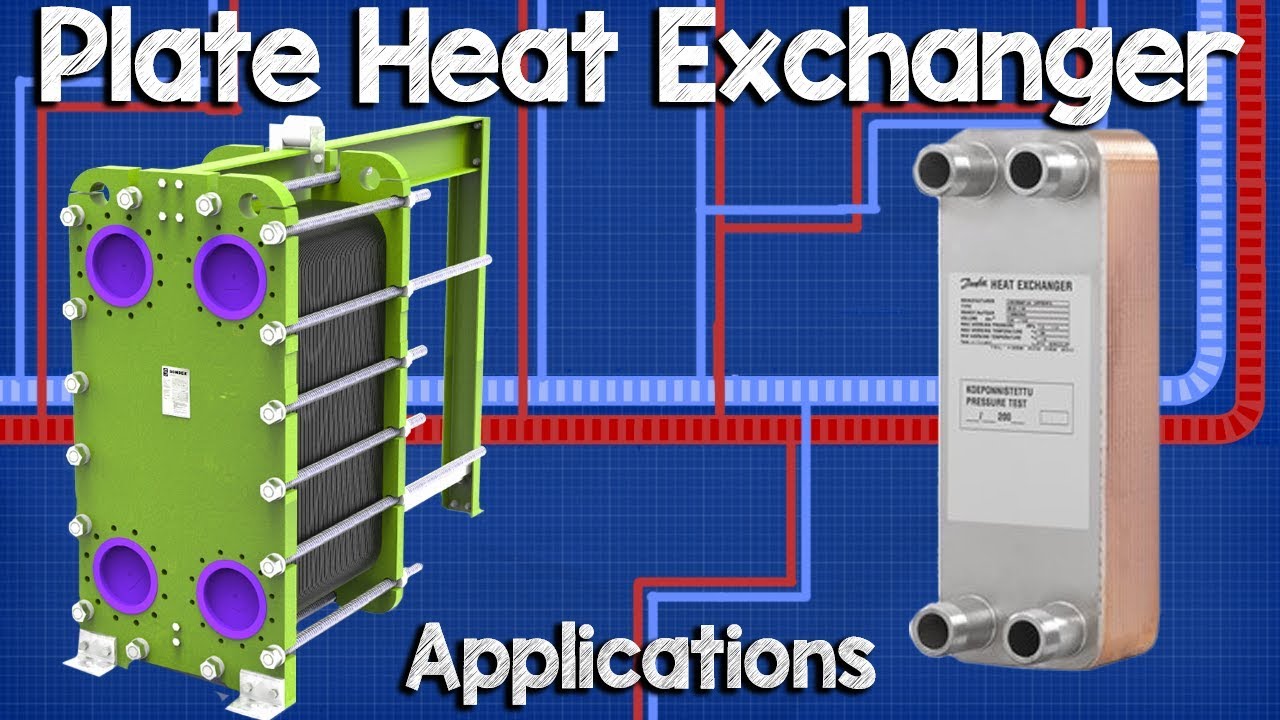

What are the Characteristics of Plate and Frame Heat Exchangers?

Plate and frame heat exchangers are designed with multiple corrugated plates arranged in a frame, allowing for efficient heat transfer between fluids. They excel in applications requiring low to medium viscosity fluids, such as milk and beverages. When purchasing, consider the ease of maintenance and cleaning, as the modular design allows for quick access to individual plates. This type is ideal for businesses focused on hygiene and operational efficiency.

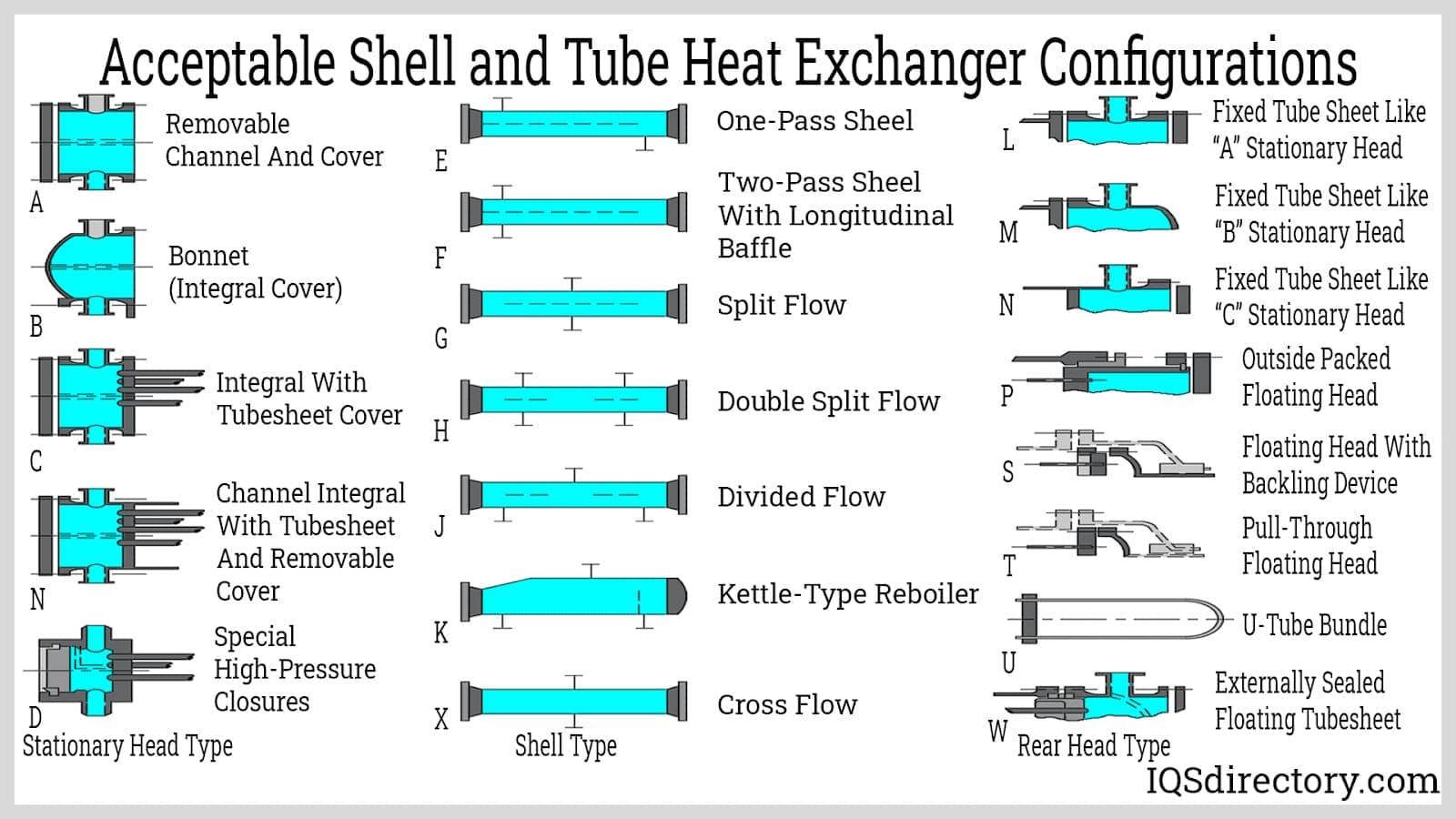

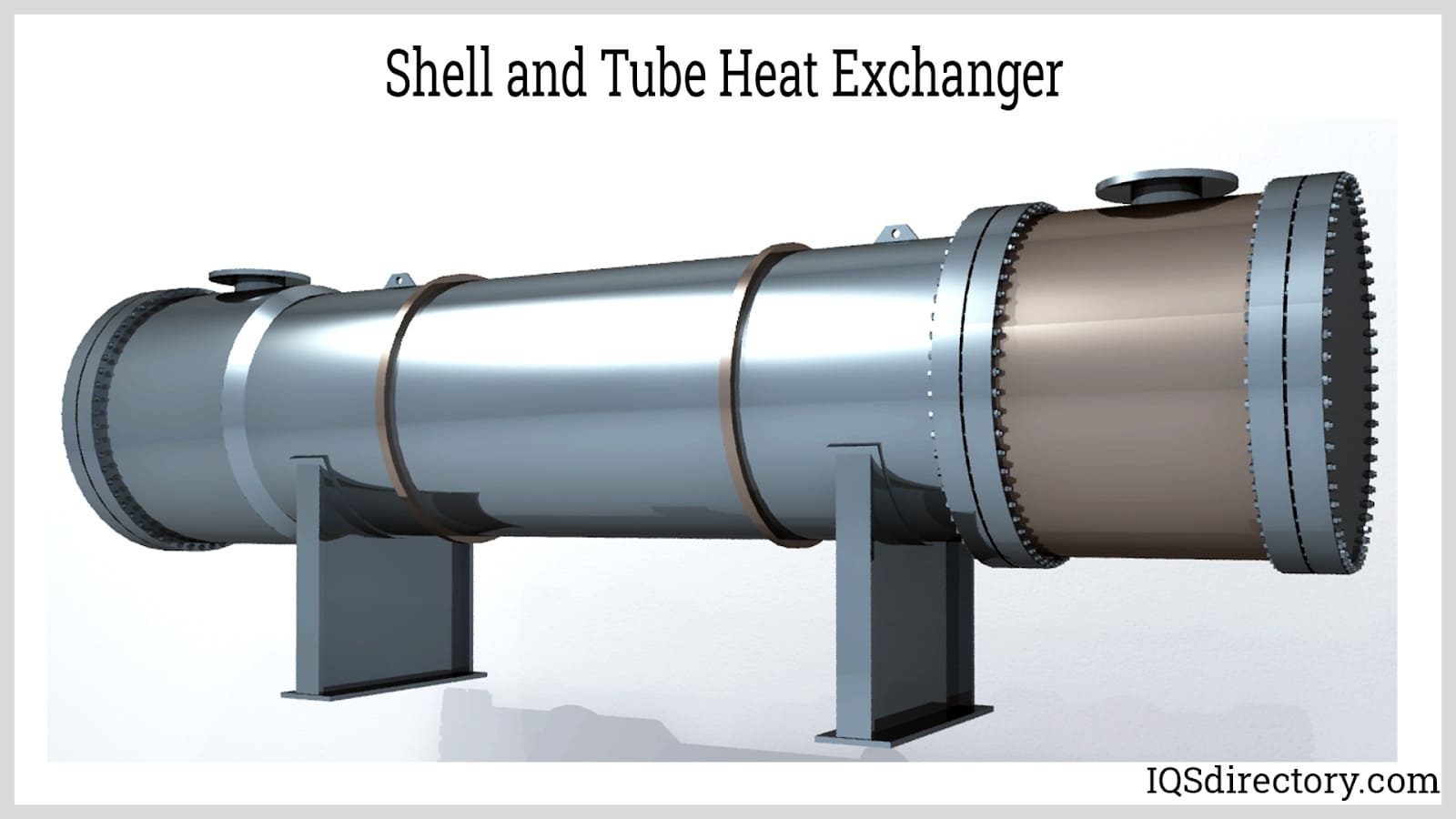

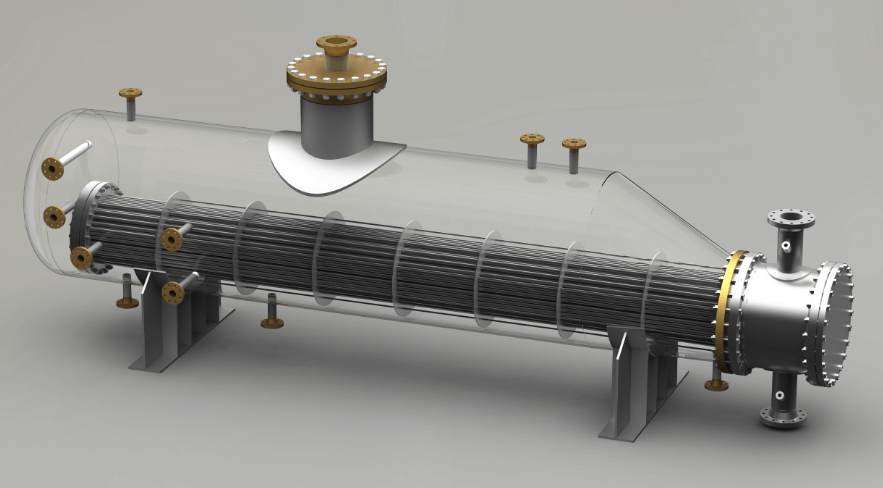

How Do Shell and Tube Heat Exchangers Work?

Shell and tube heat exchangers consist of a series of tubes enclosed within a shell, allowing for the transfer of heat between different fluids. This design accommodates a wide range of fluid viscosities, making it suitable for dairy products and chemical processing. B2B buyers should evaluate the complexity of maintenance and installation, as these systems can be larger and require more space. Their ability to handle high pressures and flow rates makes them a popular choice in industrial settings.

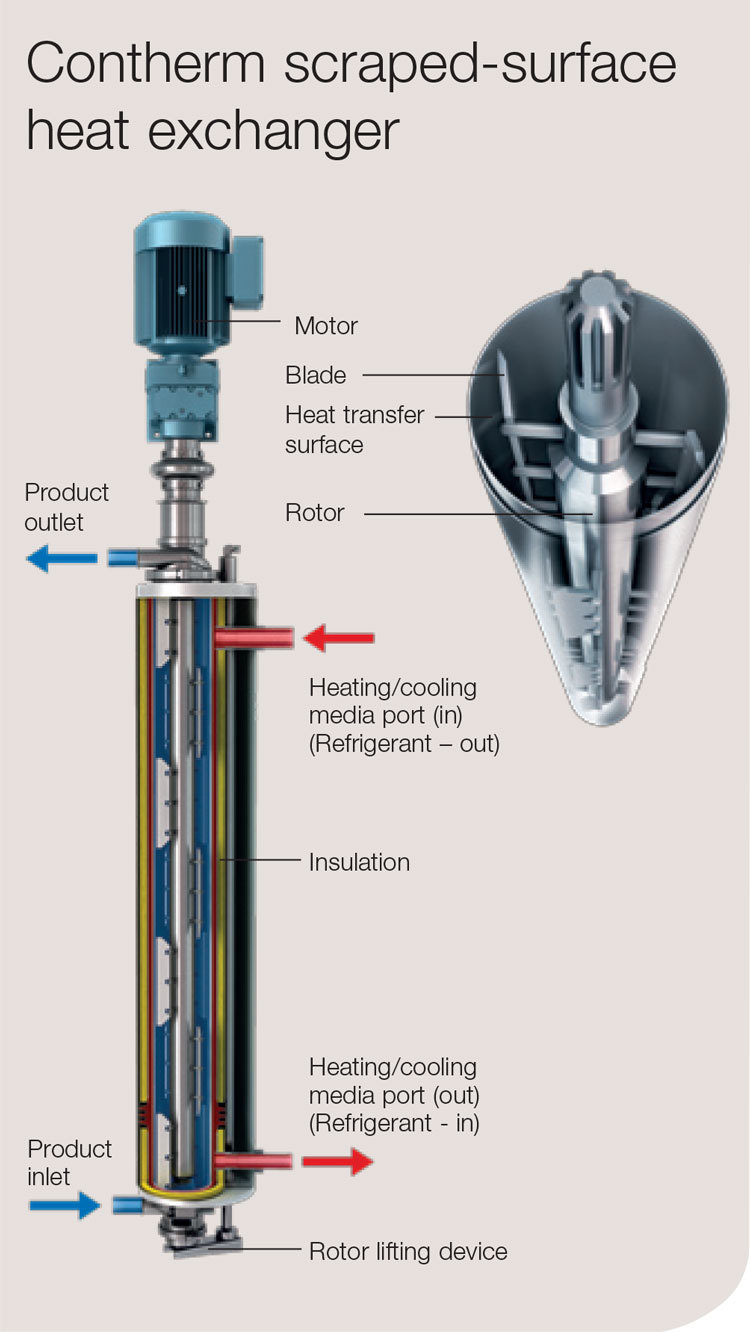

When Should You Consider Scraped Surface Heat Exchangers?

Scraped surface heat exchangers are specifically designed for highly viscous or sticky products, utilizing scraping blades to maintain heat transfer efficiency. They are ideal for applications involving products like mayonnaise and gelatins. Buyers should weigh the initial investment against the benefits of effective heat transfer and product quality. Although these units can be more expensive and require specialized maintenance, their performance in challenging conditions often justifies the cost.

What Are the Benefits of Monotube Heat Exchangers?

Monotube heat exchangers, featuring a single tube design, are compact and efficient for heat-treating applications that involve large particles. They are particularly beneficial for processes requiring minimal space. B2B buyers should consider the trade-off between simplicity and heat transfer efficiency, as the limited surface area may restrict performance in high-demand applications. Ideal for industries handling bulk materials, they represent a straightforward solution for specific heating needs.

Why Choose Double Tubesheet Heat Exchangers?

Double tubesheet heat exchangers provide an extra layer of safety by minimizing the risk of fluid mixing through the use of two tubesheets. This design is particularly valuable in pharmaceutical applications where contamination could have serious consequences. Buyers should assess the higher costs and complex design against the added safety features and reliability. The investment can be worthwhile for businesses prioritizing quality assurance and operational integrity in sensitive processes.

Key Industrial Applications of heat exchanger type

| Industry/Sector | Specific Application of heat exchanger type | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Pasteurization of dairy products | Enhances product safety and extends shelf life | Compliance with hygiene standards; energy efficiency |

| Pharmaceutical | Temperature control in drug formulation | Ensures product efficacy and safety | Material compatibility; precise temperature control |

| Oil and Gas | Heat recovery in refining processes | Reduces energy consumption and operational costs | Durability under high pressure; resistance to corrosion |

| Chemical Processing | Cooling of exothermic reactions | Prevents overheating and maintains optimal reaction rates | Material selection for chemical compatibility |

| Cosmetics and Personal Care | Heating and cooling of emulsions | Improves product quality and consistency | Customization for specific viscosity and particulate size |

How Are Heat Exchangers Used in the Food and Beverage Industry?

In the food and beverage sector, heat exchangers are critical for processes such as pasteurization, which ensures the safety of dairy products like milk and cream. By efficiently transferring heat, these exchangers maintain the necessary temperatures to eliminate pathogens while preserving product quality. For international buyers, especially in regions like Africa and South America, sourcing heat exchangers that meet local health regulations and energy efficiency standards is crucial. Additionally, understanding the specific viscosity of products can guide the selection of plate or shell and tube designs.

What Role Do Heat Exchangers Play in Pharmaceutical Applications?

In the pharmaceutical industry, heat exchangers are vital for maintaining the precise temperature conditions required during drug formulation. These devices prevent thermal degradation of sensitive compounds and ensure uniform mixing. Buyers must consider the compatibility of materials used in heat exchangers with various chemicals and the need for stringent hygiene standards. For international buyers from Europe and the Middle East, certifications and compliance with Good Manufacturing Practices (GMP) are essential factors when sourcing these systems.

How Are Heat Exchangers Beneficial in Oil and Gas Industries?

Heat exchangers in the oil and gas industry are primarily employed in refining processes to recover heat, thereby improving energy efficiency and reducing operational costs. They play a crucial role in managing the heat generated during exothermic reactions, which is vital for maintaining safe and efficient production environments. For B2B buyers in regions with extreme temperatures, such as parts of Africa and the Middle East, sourcing durable heat exchangers that can withstand high pressures and resist corrosion is paramount to ensure long-term operational reliability.

What Applications Do Heat Exchangers Have in Chemical Processing?

In chemical processing, heat exchangers are utilized for cooling exothermic reactions to prevent overheating, which can lead to safety hazards and reduced product quality. These devices allow for controlled temperature management, essential for maintaining optimal reaction rates. Buyers should focus on selecting heat exchangers made from materials that are resistant to the specific chemicals being processed. For international buyers, especially from regions like South America and Europe, understanding local regulations on chemical handling and safety will influence sourcing decisions.

How Are Heat Exchangers Used in the Cosmetics and Personal Care Industry?

In the cosmetics industry, heat exchangers facilitate the heating and cooling of emulsions, critical for product quality and consistency. These systems ensure that formulations, such as creams and lotions, are processed at optimal temperatures without compromising their stability. Buyers need to consider the specific requirements for viscosity and the presence of particulates in their products. For international buyers, particularly from Germany and Vietnam, customization options and adherence to international safety standards are essential when sourcing heat exchangers for cosmetic applications.

3 Common User Pain Points for ‘heat exchanger type’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Heat Exchanger for Specific Applications

The Problem: B2B buyers often struggle to determine which type of heat exchanger—be it plate and frame, shell and tube, or scraped surface—is most suitable for their specific application. This confusion can arise from varying viscosity levels, the presence of particulates, or the need for hygienic processing, especially in industries like food and pharmaceuticals. Such uncertainty can lead to inefficient processes, increased energy costs, and potential product contamination, ultimately affecting the bottom line.

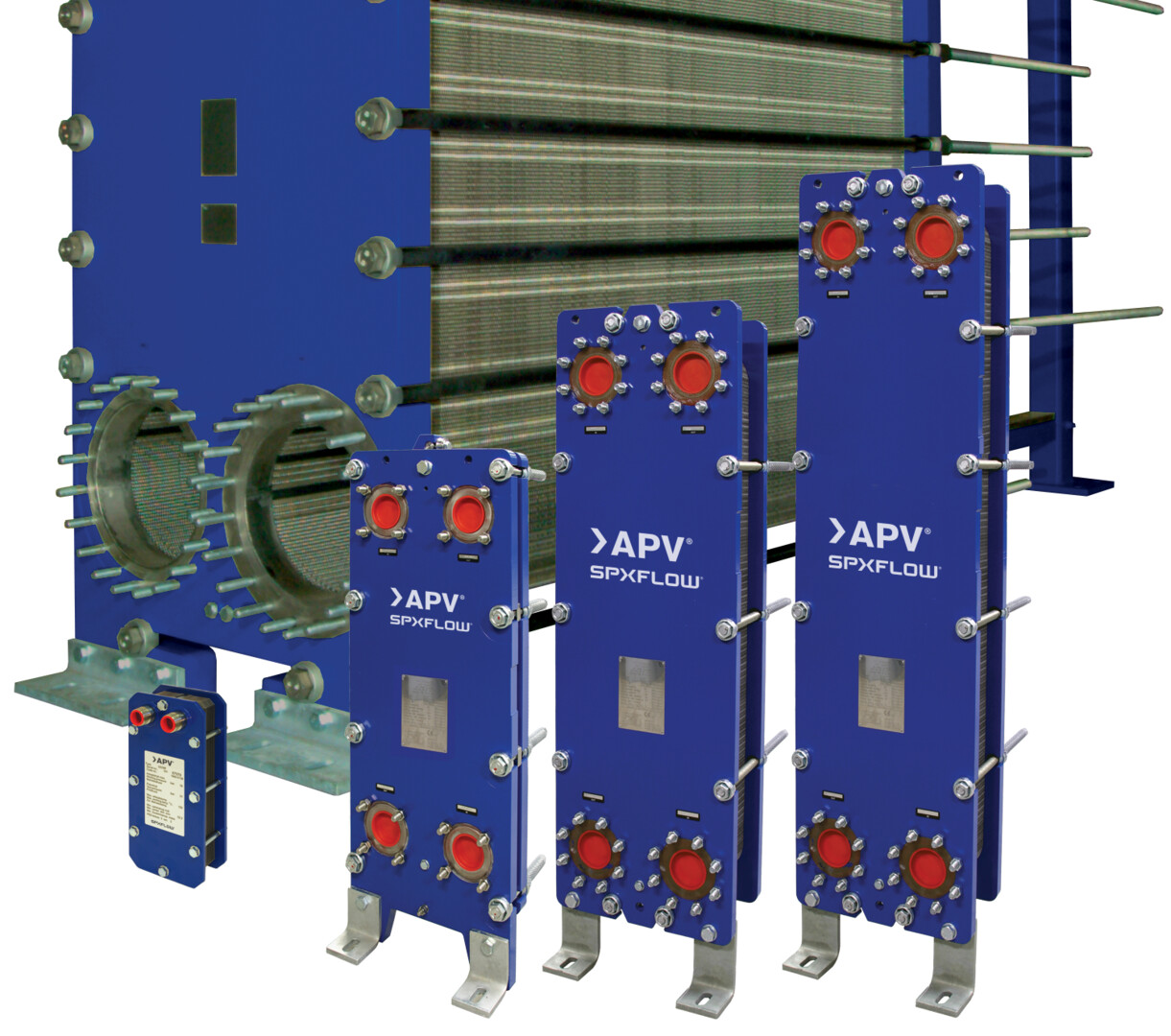

Illustrative image related to heat exchanger type

The Solution: To effectively choose the right heat exchanger, buyers should conduct a thorough analysis of their processing requirements. Start by evaluating the physical properties of the fluids involved, such as viscosity and particulate content. For low to medium viscosity fluids with minimal particulates, a plate and frame heat exchanger is often ideal due to its efficient heat transfer capabilities and ease of maintenance. Conversely, for thicker fluids or those containing particulates, a shell and tube heat exchanger may be more appropriate, as its design accommodates higher viscosities and larger solids. For sticky or heat-sensitive products, a scraped surface heat exchanger is recommended to maintain product integrity. Engaging with manufacturers who can provide detailed specifications and case studies relevant to your industry can further assist in making an informed decision.

Scenario 2: Maintenance Challenges Leading to Downtime

The Problem: Regular maintenance of heat exchangers can be a daunting task for B2B buyers, particularly when downtime leads to significant production losses. Common issues include fouling, leaks, and gasket failures, which can compromise efficiency and lead to costly repairs. This challenge is exacerbated in regions with limited access to replacement parts or technical expertise, particularly in emerging markets across Africa and South America.

The Solution: To mitigate maintenance challenges, buyers should prioritize the selection of heat exchangers that offer ease of maintenance and are designed for longevity. For instance, opting for heat exchangers with clip-on gaskets can significantly reduce the time and effort required for regasketing. Additionally, implementing a routine maintenance schedule that includes regular inspections and cleaning can help identify potential issues before they escalate. Training in-house maintenance personnel on specific maintenance protocols can also be beneficial, ensuring that they are equipped to handle minor issues independently. Establishing a reliable relationship with local suppliers for parts and service can further minimize downtime and improve operational efficiency.

Scenario 3: Energy Inefficiency and High Operational Costs

The Problem: Many B2B buyers find themselves facing escalating energy costs due to inefficient heat exchange processes. This inefficiency can stem from outdated equipment, improper sizing, or a lack of optimization in the heat transfer process. In competitive markets, such operational inefficiencies can significantly erode profit margins, making it crucial for businesses to find solutions that enhance energy efficiency.

The Solution: To address energy inefficiency, buyers should consider conducting an energy audit of their current heat exchange systems. This audit will help identify areas where improvements can be made, such as optimizing the flow rates or upgrading to more efficient models. When selecting a new heat exchanger, it’s vital to assess the design and materials used. For example, a plate heat exchanger can offer superior thermal efficiency compared to a shell and tube design, particularly in applications with lower viscosity fluids. Additionally, integrating advanced control systems that monitor and adjust the operation of the heat exchangers in real-time can further enhance efficiency. Collaborating with energy consultants who specialize in industrial processes can provide valuable insights into the best practices for reducing energy consumption and operational costs.

Strategic Material Selection Guide for heat exchanger type

What Are the Key Materials Used in Heat Exchanger Manufacturing?

When selecting materials for heat exchangers, it is crucial to consider their properties, advantages, and disadvantages in relation to specific applications. The following analysis focuses on four common materials: stainless steel, carbon steel, titanium, and copper. Each material has unique characteristics that can significantly impact performance, cost, and suitability for various industrial applications.

How Does Stainless Steel Perform in Heat Exchangers?

Stainless steel is widely regarded for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures and pressures. Common grades like 304 and 316 are particularly favored due to their robust mechanical properties and resistance to oxidation.

Pros: Stainless steel offers durability and longevity, making it ideal for applications involving aggressive media, such as food and pharmaceuticals. Its ability to maintain structural integrity at high temperatures also enhances its performance in heat transfer.

Cons: The primary drawback of stainless steel is its higher cost compared to other materials, which may impact budget-sensitive projects. Additionally, the manufacturing complexity can lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids and high-purity applications. Its compliance with international standards such as ASTM and DIN makes it a preferred choice for B2B buyers in Europe and beyond.

What Advantages Does Carbon Steel Offer for Heat Exchangers?

Carbon steel is another common material used in heat exchangers, particularly in less corrosive environments. It is known for its strength and ability to handle high pressures, making it suitable for many industrial applications.

Pros: The cost-effectiveness of carbon steel is a significant advantage, as it is generally cheaper than stainless steel and titanium. Its robustness also allows for easier fabrication and welding.

Cons: However, carbon steel is prone to corrosion, which limits its use in applications involving aggressive or corrosive fluids. Regular maintenance and protective coatings are often necessary to prolong its lifespan.

Impact on Application: Carbon steel is suitable for applications such as oil and gas, where the media is less corrosive. Buyers from regions like Africa and South America may find carbon steel more accessible due to its affordability.

Illustrative image related to heat exchanger type

Why Choose Titanium for Heat Exchangers?

Titanium is a premium material known for its exceptional corrosion resistance and lightweight properties. It is particularly effective in environments where other metals would fail due to aggressive chemicals.

Pros: The primary advantage of titanium is its ability to withstand harsh conditions without degrading, which makes it ideal for applications in chemical processing and marine environments. Its lightweight nature also contributes to reduced transportation and installation costs.

Cons: The main limitation of titanium is its high cost, which can be a barrier for some projects. Additionally, titanium’s manufacturing processes can be complex, requiring specialized equipment.

Impact on Application: Titanium is particularly favored in industries where corrosion is a significant concern, such as pharmaceuticals and marine applications. Buyers in regions like the Middle East, where harsh environmental conditions prevail, may prioritize titanium for its durability.

Illustrative image related to heat exchanger type

What Role Does Copper Play in Heat Exchanger Design?

Copper is renowned for its excellent thermal conductivity, making it a popular choice for heat exchangers where efficient heat transfer is critical. It is often used in smaller-scale applications or where space is a concern.

Pros: The high thermal conductivity of copper allows for efficient heat exchange, reducing energy consumption and improving overall system performance. It is also relatively easy to fabricate and join.

Cons: The primary disadvantage of copper is its susceptibility to corrosion, particularly in seawater or acidic environments. This limits its applicability in certain industries.

Impact on Application: Copper is commonly used in HVAC systems and refrigeration, where efficient heat transfer is essential. Buyers from Europe and South America may prefer copper for its performance in specific applications, despite its limitations in corrosive environments.

Summary Table of Heat Exchanger Materials

| Material | Typical Use Case for heat exchanger type | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical processing | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| Carbon Steel | Oil and gas applications | Cost-effective and robust | Prone to corrosion | Low |

| Titanium | Chemical processing and marine environments | Exceptional corrosion resistance | High cost and complex manufacturing | High |

| Copper | HVAC systems and refrigeration | High thermal conductivity | Susceptible to corrosion | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions based on application needs, budget constraints, and compliance with international standards.

Illustrative image related to heat exchanger type

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchanger type

What Are the Main Stages in Manufacturing Heat Exchangers?

The manufacturing process for heat exchangers involves several critical stages, each essential to ensuring product efficiency and quality. Understanding these stages helps B2B buyers assess the capabilities of potential suppliers.

How Are Materials Prepared for Heat Exchanger Production?

Material preparation is the foundation of heat exchanger manufacturing. The choice of materials—such as stainless steel, titanium, or specialized alloys—depends on the specific application and operating conditions. High-quality raw materials are procured based on industry standards and specifications. For instance, stainless steel is preferred in food and beverage applications due to its corrosion resistance and hygienic properties.

Before forming, the materials undergo rigorous quality checks, including chemical composition analysis and mechanical property testing. These assessments ensure that the materials meet the required standards for strength, durability, and safety.

What Techniques Are Used in Forming Heat Exchangers?

The forming stage involves several techniques tailored to the type of heat exchanger being produced. Common methods include:

Illustrative image related to heat exchanger type

- Stamping and Punching: Used for creating plate heat exchangers, these methods involve shaping metal sheets into the required plate designs.

- Bending and Rolling: Shell and tube heat exchangers require tubes to be bent and rolled into specific shapes, ensuring proper fluid flow and heat transfer.

- Welding: This is a critical step, especially for shell and tube designs, where tubes must be securely joined to the tubesheet and shell. Various welding techniques, such as TIG or MIG welding, are employed to ensure strong, leak-proof joints.

The choice of forming technique is crucial as it directly impacts the performance characteristics of the heat exchanger, including pressure drop and thermal efficiency.

How Is Assembly Conducted for Heat Exchangers?

Assembly is a meticulous process that requires precision to ensure the integrity of the heat exchanger. For plate heat exchangers, plates are stacked and aligned within a frame, with gaskets inserted to prevent leaks. In shell and tube designs, tubes are positioned within the shell and secured using baffles to enhance fluid dynamics.

During assembly, it’s vital to follow specific procedures to maintain cleanliness, especially in industries like food and pharmaceuticals, where contamination is a significant concern. The assembly process may also include installing insulation and protective coatings to enhance thermal efficiency and longevity.

What Finishing Processes Are Common in Heat Exchanger Manufacturing?

Finishing processes improve the durability and efficiency of heat exchangers. Common techniques include:

Illustrative image related to heat exchanger type

- Surface Treatment: Processes such as passivation enhance corrosion resistance, particularly for stainless steel components.

- Polishing: This is especially important for applications requiring high hygiene standards, as it minimizes crevices where bacteria can grow.

- Coating: Heat exchangers may be coated with specialized materials to improve thermal conductivity and reduce fouling.

These finishing processes not only enhance the performance of heat exchangers but also ensure compliance with industry regulations and standards.

What Quality Assurance Standards Apply to Heat Exchanger Manufacturing?

Quality assurance is critical in the manufacturing of heat exchangers, particularly in industries where safety and efficiency are paramount. B2B buyers should be familiar with relevant international and industry-specific standards that govern manufacturing processes.

Which International Standards Are Relevant for Heat Exchanger Quality Control?

ISO 9001 is the most widely recognized quality management standard applicable to heat exchanger manufacturers. It outlines the requirements for a quality management system (QMS), ensuring that organizations can consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, specific industry standards such as CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications may apply. These certifications signify compliance with safety and performance criteria relevant to specific applications.

What Are the Key QC Checkpoints in Heat Exchanger Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process. Key QC checkpoints include:

- Incoming Quality Control (IQC): This stage involves checking raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Throughout manufacturing, periodic inspections are conducted to ensure that processes adhere to quality standards. This includes monitoring welding quality, dimensional accuracy, and assembly integrity.

- Final Quality Control (FQC): Once the heat exchanger is assembled, it undergoes final inspections, including pressure testing, leak testing, and performance evaluations to verify that it meets the required specifications.

These checkpoints help identify potential issues early in the production process, reducing the risk of defects and ensuring that the final product meets performance expectations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control practices of potential suppliers is essential. Here are effective strategies to ensure that suppliers adhere to high standards:

What Audit Processes Can Buyers Use to Assess Supplier QC?

Conducting audits of suppliers is a proactive approach to verifying quality control practices. Buyers can perform:

Illustrative image related to heat exchanger type

- On-site Audits: Visiting manufacturing facilities allows buyers to observe processes firsthand, assess compliance with standards, and evaluate the overall quality culture of the organization.

- Supplier Self-Assessments: Requesting self-assessment reports can provide insights into the supplier’s quality management practices and any certifications they hold.

How Can Buyers Use Reports and Third-Party Inspections to Ensure Quality?

Buyers should request documentation such as quality manuals, inspection reports, and test results to validate the supplier’s claims. Third-party inspections can also provide an unbiased assessment of a supplier’s quality control processes. Engaging certified inspectors can help ensure that products meet the necessary standards before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding these can help buyers avoid compliance issues.

- Cultural Considerations: Communication styles and business practices may differ, necessitating a tailored approach to supplier interactions.

- Logistical Challenges: Buyers should consider how transportation and customs regulations may affect the delivery and quality assurance of heat exchangers.

By being informed about these nuances, B2B buyers can make more informed decisions when selecting suppliers and ensure that their procurement processes align with quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchanger type’

Introduction

When sourcing heat exchangers, international B2B buyers must navigate various technical specifications, supplier qualifications, and market conditions. This practical sourcing guide provides a structured checklist to ensure that buyers select the most suitable heat exchanger type for their specific application. From understanding technical requirements to evaluating supplier reliability, following these steps will help streamline the procurement process.

Step 1: Define Your Technical Specifications

Start by outlining the precise technical requirements of your heat exchanger. Consider factors such as the type of fluids involved, operating temperatures, pressure ratings, and the viscosity of the materials. Knowing these specifications ensures that the heat exchanger selected will efficiently meet operational demands without risking performance failures.

Illustrative image related to heat exchanger type

- Fluid Properties: Identify the nature of the fluids (e.g., corrosive, non-corrosive, viscous) to determine the material and design needed.

- Temperature and Pressure Requirements: Specify maximum and minimum operating temperatures and pressures to ensure safe operation.

Step 2: Identify the Appropriate Heat Exchanger Type

Understanding the different types of heat exchangers is crucial for making an informed decision. The most common types include plate and frame, shell and tube, and scraped surface heat exchangers. Each type has unique advantages suited for specific applications.

- Application Suitability: For example, plate heat exchangers are ideal for low to medium viscosity fluids, while shell and tube designs can accommodate more viscous materials.

- Maintenance Needs: Consider how easy it is to maintain each type, as this can impact long-term operational efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from clients in similar industries or regions to gauge their reliability and expertise.

- Supplier Reputation: Look for suppliers with a proven track record in delivering high-quality heat exchangers.

- Local Support: Ensure that the supplier can provide local support for installation and maintenance, which is critical for minimizing downtime.

Step 4: Check Compliance and Certifications

Verify that the heat exchangers comply with international standards and certifications relevant to your industry. Compliance ensures that the equipment meets safety, efficiency, and environmental standards.

- Industry Standards: Familiarize yourself with standards such as ASME, ISO, or local regulations that may apply to your region.

- Supplier Certifications: Confirm that the supplier holds the necessary certifications to guarantee product quality and safety.

Step 5: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotes that outline pricing, delivery timelines, and terms of service. Comparing these quotes will provide insights into the market rates and help identify the best value.

- Cost Breakdown: Ensure that quotes include a breakdown of costs, including shipping, installation, and any additional services.

- Negotiation Leverage: Use competitive pricing to negotiate better terms or additional services such as extended warranties or maintenance agreements.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by the supplier. Strong post-purchase support can be vital for troubleshooting and maintenance, especially in complex installations.

- Warranty Terms: Understand the warranty coverage and conditions, as this reflects the supplier’s confidence in their product.

- Technical Support Availability: Ensure that technical support is readily available to address any operational issues post-installation.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that the purchase agreement clearly outlines all terms, including delivery schedules, payment terms, and service level expectations. A well-defined agreement protects both parties and helps prevent disputes.

- Clear Specifications: Include specific technical specifications in the contract to ensure that the delivered product meets your requirements.

- Contingency Plans: Discuss contingency plans for delays or issues during installation to ensure that operations can continue smoothly.

By following this checklist, B2B buyers can confidently navigate the sourcing process for heat exchangers, ensuring they select the best option for their needs while minimizing risks and maximizing efficiency.

Comprehensive Cost and Pricing Analysis for heat exchanger type Sourcing

What Are the Key Cost Components in Sourcing Heat Exchangers?

When sourcing heat exchangers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts the price. For example, stainless steel is commonly used for its durability and resistance to corrosion, but it is more expensive than carbon steel. Specialty materials, such as titanium for highly corrosive environments, will also drive costs higher.

-

Labor: Labor costs vary by region and complexity of manufacturing. Highly skilled labor is essential for precision engineering in heat exchanger production, particularly for custom designs. In regions with lower labor costs, such as parts of South America and Africa, this can lead to a more favorable pricing structure.

-

Manufacturing Overhead: This includes costs associated with running the production facility, including utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, but this may require an initial investment in technology.

-

Tooling: Custom tooling may be necessary for specialized designs, adding to the upfront costs. Buyers should consider whether the supplier has the necessary tooling capabilities or if additional investment is needed.

-

Quality Control (QC): Ensuring that heat exchangers meet industry standards involves QC costs. Certifications like ISO 9001 or specific industry standards (e.g., ASME for pressure vessels) can add to the overall price but are essential for ensuring product reliability.

-

Logistics: Transportation costs can vary significantly based on the origin and destination, especially for international shipping. Incoterms play a crucial role in determining who bears these costs and responsibilities.

-

Margin: Finally, suppliers will include a profit margin in their pricing, which can vary based on the supplier’s market position, brand reputation, and customer relationships.

What Factors Influence Pricing for Heat Exchangers?

Several factors can influence the pricing of heat exchangers, particularly for international buyers:

-

Volume/MOQ: Suppliers often offer tiered pricing based on order volume. Higher quantities can lead to significant cost savings, making it essential for buyers to evaluate their needs and consider bulk purchases.

-

Specifications and Customization: Custom designs tailored to specific applications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges later in the procurement process.

-

Material Quality and Certifications: Higher-quality materials and certifications ensure durability and performance, but they come at a premium. Buyers in regulated industries, such as pharmaceuticals, should prioritize these factors despite the higher costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their products due to their track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is critical for international buyers as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can significantly affect the total landed cost of the equipment.

What Tips Can Help Buyers Negotiate Better Prices for Heat Exchangers?

To achieve cost efficiency when sourcing heat exchangers, B2B buyers should consider the following strategies:

Illustrative image related to heat exchanger type

-

Negotiation: Engage in discussions with suppliers to explore price reductions, especially if committing to larger orders. Building a strong relationship can also lead to better terms and pricing.

-

Total Cost of Ownership (TCO): Assess not only the initial purchase price but also the long-term costs associated with maintenance, efficiency, and potential downtime. A slightly higher upfront cost may result in lower TCO if the equipment is more efficient or requires less maintenance.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations, import tariffs, and shipping costs that can affect final pricing. Engaging with suppliers who understand local market conditions can provide valuable insights.

Disclaimer on Indicative Prices

Prices for heat exchangers can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing heat exchanger type With Other Solutions

Introduction to Heat Exchanger Alternatives

When selecting a heat transfer solution, understanding the alternatives to traditional heat exchangers is crucial for B2B buyers. Various technologies and methods can achieve similar goals in heat transfer applications, each with unique strengths and weaknesses. This comparison will focus on the effectiveness, cost, implementation ease, maintenance, and best use cases for each solution, allowing buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Heat Exchanger Type | Alternative 1: Direct Contact Heat Exchanger | Alternative 2: Air-Cooled Heat Exchanger |

|---|---|---|---|

| Performance | High efficiency for low to medium viscosity fluids | High efficiency for heat transfer; limited by fluid type | Efficient for cooling applications, less effective for heating |

| Cost | Moderate initial investment, low operating costs | Lower initial cost, but higher operational costs | Higher initial investment, moderate operating costs |

| Ease of Implementation | Requires skilled installation and setup | Easier to install, minimal skill needed | Moderate installation complexity, requires space for air circulation |

| Maintenance | Regular maintenance needed for cleaning and gasket replacement | Minimal maintenance, but requires monitoring for fouling | Low maintenance, but periodic cleaning of fins required |

| Best Use Case | Ideal for food, beverage, and pharmaceutical applications | Suitable for applications with compatible fluids, such as water | Best for cooling processes in industrial settings |

Detailed Breakdown of Alternatives

Direct Contact Heat Exchanger

Direct contact heat exchangers facilitate heat transfer by allowing the two fluids to mix directly. This method is particularly effective for applications involving gases and liquids, such as in power plants or water treatment facilities.

Illustrative image related to heat exchanger type

Pros:

– High thermal efficiency due to direct contact.

– Lower initial setup costs compared to traditional heat exchangers.

Cons:

– Not suitable for applications where fluid mixing is not allowed (e.g., in food processing).

– Higher operational costs associated with fluid treatment and maintenance due to fouling.

Air-Cooled Heat Exchanger

Air-cooled heat exchangers use ambient air to cool or heat process fluids. They are often used in applications where water is scarce or when cooling needs to be achieved without the use of cooling towers.

Pros:

– Lower water consumption and environmental impact.

– Generally lower maintenance requirements compared to water-cooled systems.

Cons:

– Less effective in humid conditions where air density is lower.

– Larger footprint required for air circulation, which may not be feasible in all facilities.

Illustrative image related to heat exchanger type

Conclusion: Choosing the Right Heat Transfer Solution

When selecting a heat transfer solution, B2B buyers must evaluate the specific needs of their operations, including the types of fluids involved, space constraints, and budget considerations. While heat exchangers offer high efficiency and reliability, alternatives like direct contact and air-cooled heat exchangers may provide viable solutions depending on the application. Assessing performance, cost, ease of implementation, and maintenance will empower buyers to make the most informed decision for their processing needs.

Essential Technical Properties and Trade Terminology for heat exchanger type

What Are the Key Technical Properties of Heat Exchanger Types?

When selecting a heat exchanger, understanding its technical properties is crucial for ensuring optimal performance and cost-effectiveness. Here are some of the most critical specifications to consider:

1. Material Grade

The material used in the construction of a heat exchanger significantly affects its durability, thermal conductivity, and resistance to corrosion. Common materials include stainless steel, titanium, and carbon steel. For instance, stainless steel is often preferred in food processing due to its resistance to corrosion and ease of cleaning. B2B buyers must evaluate the material grade based on the application environment, ensuring the heat exchanger can withstand specific chemical exposures and temperature variations.

2. Heat Transfer Efficiency

This property indicates how effectively a heat exchanger can transfer heat between fluids. It is influenced by design factors such as surface area, flow arrangement, and fluid velocities. Higher efficiency can lead to reduced energy costs and improved processing times, making it a vital consideration for manufacturers aiming to enhance productivity while minimizing expenses.

3. Pressure Rating

The pressure rating defines the maximum pressure the heat exchanger can handle safely. This specification is critical in applications involving high-pressure fluids, as operating beyond this limit can lead to failures or leaks. B2B buyers should align the pressure rating with their operational requirements to ensure safety and compliance with industry standards.

4. Tolerance Levels

Tolerance levels refer to the acceptable deviations in dimensions and specifications during manufacturing. High tolerance levels are essential for ensuring proper fit and function, particularly in applications where precise heat transfer is necessary. For B2B buyers, understanding tolerance levels is important for minimizing maintenance issues and ensuring long-term reliability.

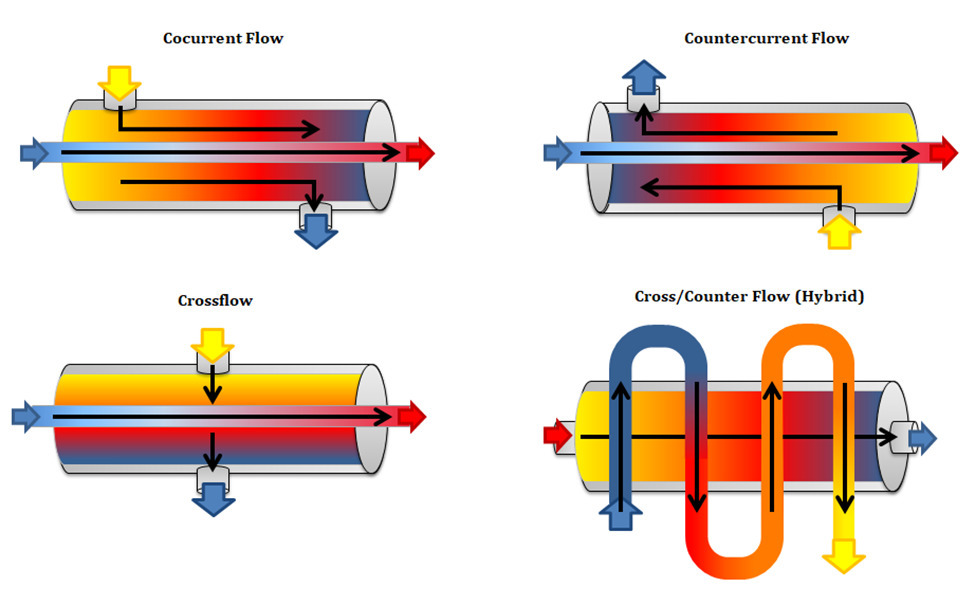

5. Flow Arrangement

Heat exchangers can be designed in various flow arrangements, including counterflow, parallel flow, and crossflow. Each arrangement has implications for efficiency and application suitability. For example, counterflow designs typically offer higher efficiency for heat transfer due to the temperature gradient maintained across the heat exchanger. B2B decision-makers should consider flow arrangements based on the specific thermal and processing needs of their operations.

6. Cleaning and Maintenance Requirements

The ease of cleaning and maintenance is a significant factor, especially in industries where hygiene is paramount, such as food and pharmaceuticals. Some heat exchangers are designed for easy disassembly, allowing for efficient cleaning processes. Understanding these requirements can help B2B buyers select a heat exchanger that minimizes downtime and operational disruptions.

What Are the Common Trade Terminology and Jargon in Heat Exchanger Purchasing?

Navigating the procurement process requires familiarity with specific industry terms that facilitate communication between buyers and suppliers. Here are some essential terms:

Illustrative image related to heat exchanger type

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for ensuring that the heat exchangers meet industry standards and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers to understand, as it can impact inventory management and cash flow. Knowing the MOQ helps in planning purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. For B2B transactions, an RFQ is essential for comparing pricing and terms from multiple vendors, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and obligations associated with their purchases.

5. Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead times is critical for B2B buyers to ensure that they can meet their operational timelines and avoid disruptions in production.

6. Fouling

Fouling is the accumulation of unwanted material on solid surfaces, which can impede heat transfer efficiency. Recognizing the potential for fouling in specific applications is crucial for selecting the appropriate heat exchanger and planning for maintenance needs.

By comprehending these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the heat exchanger type Sector

What Are the Current Market Dynamics and Key Trends in the Heat Exchanger Sector?

The global heat exchanger market is experiencing robust growth, driven by increasing demand for energy efficiency and sustainability across various industries, including food and beverage, pharmaceuticals, and HVAC systems. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek innovative solutions, emerging technologies such as digital monitoring and automation are reshaping sourcing strategies. For example, the integration of IoT (Internet of Things) allows real-time performance monitoring, optimizing maintenance schedules, and enhancing operational efficiencies.

Another significant trend is the rise of modular heat exchanger designs, enabling easier scalability and customization to fit specific processing requirements. This flexibility is particularly appealing to manufacturers in regions with diverse production needs, such as Germany and Vietnam, where local regulations and market demands vary. Additionally, the trend toward hybrid heat exchangers, which combine features of different designs (e.g., plate and shell), is gaining traction, offering improved thermal performance and space efficiency.

International buyers should also be aware of fluctuating raw material prices and supply chain disruptions caused by geopolitical tensions and natural disasters. Establishing relationships with multiple suppliers and investing in local sourcing options can mitigate risks and ensure more stable procurement processes. By staying attuned to these market dynamics, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Illustrative image related to heat exchanger type

How Is Sustainability Influencing Sourcing in the Heat Exchanger Market?

Sustainability has emerged as a critical factor in sourcing decisions within the heat exchanger sector. As environmental regulations tighten globally, businesses are increasingly held accountable for their environmental impact. This shift necessitates the adoption of ethical sourcing practices that prioritize environmentally friendly materials and processes. Heat exchangers made from recyclable materials, such as stainless steel, are becoming more prevalent, as they not only reduce waste but also enhance the overall efficiency of operations.

Moreover, certifications such as ISO 14001 for environmental management systems and LEED (Leadership in Energy and Environmental Design) for sustainable building practices are gaining importance. B2B buyers are encouraged to seek suppliers with these certifications, ensuring that their procurement strategies align with broader corporate social responsibility (CSR) goals. Implementing energy-efficient designs and processes can lead to significant cost savings and enhance brand reputation, particularly in markets where consumers are increasingly eco-conscious.

Furthermore, the emphasis on sustainability is prompting manufacturers to invest in research and development of innovative heat exchanger technologies, such as those that utilize alternative refrigerants or improve energy recovery systems. By focusing on sustainable sourcing, companies can not only meet compliance requirements but also position themselves as leaders in a rapidly evolving market.

Illustrative image related to heat exchanger type

What Is the Evolution of Heat Exchanger Technology?

The evolution of heat exchanger technology has significantly influenced the B2B landscape. Initially, heat exchangers were simple devices used primarily in industrial applications. Over the decades, advancements in materials science and engineering have led to the development of more efficient designs, such as the plate and frame and shell-and-tube heat exchangers, which cater to specific industry needs.

In recent years, the trend has shifted toward compact and modular designs that offer increased efficiency and flexibility. The advent of digital technologies has further transformed the sector, enabling predictive maintenance and real-time monitoring, which improve reliability and reduce downtime. As industries continue to demand higher performance and sustainability, the evolution of heat exchanger technology will likely focus on enhancing thermal efficiency while minimizing environmental impact.

International buyers must stay informed about these historical advancements to better understand current capabilities and future trends, allowing them to make strategic sourcing decisions that align with their operational and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchanger type

-

How do I select the right heat exchanger for my application?

Selecting the appropriate heat exchanger involves assessing your specific application requirements, including fluid types, viscosity, and temperature ranges. For low to medium viscosity fluids, plate and frame heat exchangers are efficient due to their compact design. Shell and tube exchangers are better suited for more viscous fluids or those containing particulates. Consider maintenance needs, energy efficiency, and the space available for installation. Consulting with suppliers about your processing conditions can provide tailored recommendations. -

What are the advantages of using plate and frame heat exchangers?

Plate and frame heat exchangers offer several advantages, including high heat transfer efficiency due to their large surface area and the ability to easily modify capacity by adding or removing plates. They are also easier to clean, which is crucial in hygienic applications like food and beverage processing. Their compact size allows for space-efficient installations, making them suitable for facilities with limited space. Additionally, they have lower ownership costs compared to other types, such as shell and tube exchangers. -

What customization options are available for heat exchangers?

Many manufacturers offer customization options to meet specific operational needs. Customizations can include variations in materials (such as stainless steel or specialized alloys), gasket types, and plate designs tailored for specific fluid characteristics. Additionally, heat exchangers can be designed for specific pressure and temperature ratings. When sourcing, inquire about the manufacturer’s capabilities for customization and any associated lead times to ensure the final product meets your specifications. -

What is the minimum order quantity (MOQ) when sourcing heat exchangers?

The minimum order quantity (MOQ) for heat exchangers can vary significantly between suppliers and depends on factors such as production capabilities and material availability. Some suppliers may allow orders as low as one unit, particularly for custom designs, while others may have higher MOQs for standard models. It is advisable to communicate your requirements clearly with potential suppliers to understand their MOQ policies and negotiate if necessary, especially for bulk orders. -

What payment terms should I expect when sourcing heat exchangers internationally?

Payment terms for international transactions can differ widely among suppliers. Common terms include advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days). It’s crucial to clarify payment options upfront, including any deposits required and the acceptable currency. Ensure that payment terms align with your cash flow and procurement processes. Establishing a good relationship with your supplier can also lead to more favorable payment arrangements. -

How can I ensure the quality of heat exchangers from international suppliers?

To ensure quality, request certifications and compliance documentation, such as ISO 9001 or industry-specific standards. Conduct a thorough vetting process by reviewing supplier histories, customer testimonials, and product samples if possible. Consider arranging factory visits or third-party inspections to verify manufacturing processes. Additionally, inquire about warranties and after-sales support, as these factors can provide further assurance of product quality and reliability. -

What are the logistics considerations for importing heat exchangers?

Logistics for importing heat exchangers involve several factors, including shipping methods, customs clearance, and lead times. Discuss with your supplier the best shipping options based on your location and urgency. Ensure that you understand the customs regulations in your country, including any tariffs or duties applicable to heat exchangers. It’s also important to consider warehousing and distribution options upon arrival to ensure a smooth supply chain operation. -

What are the common applications for different types of heat exchangers?

Heat exchangers serve various applications depending on their design. Plate and frame heat exchangers are ideal for low to medium viscosity fluids, commonly used in dairy and beverage processing. Shell and tube exchangers handle more viscous products, such as lotions and gels, due to their robust design. Scraped surface heat exchangers are best for sticky or heat-sensitive products, including sauces and creams. Understanding these applications can guide you in selecting the right type for your processing needs.

Top 5 Heat Exchanger Type Manufacturers & Suppliers List

1. Paul Mueller – Heat Exchangers

Domain: paulmueller.com

Registered: 1995 (30 years)

Introduction: Shell & Tube Heat Exchangers: Consist of a tube pack and a shell; effective for high temperatures and pressures; relatively cheap; can be fouled by viscous fluids; declining market share in favor of plate heat exchangers.

Plate & Frame Heat Exchangers: Made of plates in a frame; high heat transfer efficiency; easy to clean and maintain; available in gasketed, brazed, or welded designs; gasketed …

2. Thermopedia – Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Heat exchangers are devices used to transfer heat between two or more fluids, which can be single or two-phase. They can be categorized by flow configuration (Counter Flow, Cocurrent Flow, Crossflow, and hybrids) and by construction (Recuperative and Regenerative). Recuperative heat exchangers have separate flow paths for each fluid, while regenerative heat exchangers have a single flow path for a…

3. IQS Directory – Heat Exchangers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Heat exchangers are designed to transfer heat between two fluids without intermixing. They utilize barriers with high thermal conductivity to facilitate heat exchange. Key types include shell and tube, plate, finned tube, and air-cooled varieties. The heat transfer process involves convection and conduction, with critical parameters such as heat transfer coefficient (U-factor), logarithmic mean te…

4. Lando – Heat Exchangers

Domain: lando-chillers.com

Registered: 2016 (9 years)

Introduction: Lando is a leading manufacturer of various types of heat exchangers in China, including: 1. Fin Heat Exchanger 2. Plate Heat Exchanger 3. Shell and Tube Heat Exchanger 4. Casing Heat Exchanger. Heat exchangers can facilitate gas-to-gas, liquid-to-gas, or liquid-to-liquid heat transfer through solid separators or direct fluid contact. Types of heat exchanger systems include: 1. Air-cooled system 2….

5. TubeTech – Shell and Tube Heat Exchangers

Domain: tubetech.com

Registered: 1997 (28 years)

Introduction: Shell and tube heat exchangers are widely used devices for heat exchange, featuring two working fluids that exchange heat via thermal contact through tubes within a cylindrical shell. They are compact, simple in construction and maintenance, and effective across a wide temperature and pressure range. Key types include: 1. Shell and Tube Heat Exchanger Bundle – removable tube bundles for maintenanc…

Strategic Sourcing Conclusion and Outlook for heat exchanger type

In conclusion, the selection of the appropriate heat exchanger is critical for optimizing efficiency and reducing operational costs across diverse industries, including food, beverage, dairy, and pharmaceuticals. Each type—be it plate and frame, shell and tube, or scraped surface—offers unique advantages tailored to specific processing needs. Understanding these distinctions allows international buyers to make informed decisions that align with their operational requirements and budget constraints.

Strategic sourcing of heat exchangers not only enhances product quality and safety but also ensures compliance with hygiene standards, particularly in regions like Africa, South America, the Middle East, and Europe. By prioritizing quality and supplier reliability, businesses can mitigate risks associated with supply chain disruptions and maintenance challenges.

Illustrative image related to heat exchanger type

Looking ahead, as industries evolve and sustainability becomes paramount, the demand for innovative heat exchanger solutions will only grow. Buyers are encouraged to engage with suppliers who prioritize cutting-edge technology and responsive service. By investing in the right heat exchanger now, businesses can position themselves for success in an increasingly competitive landscape. Embrace this opportunity to enhance your processing capabilities and drive long-term growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.