Is Your Glass Tube Rotameter Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for glass tube rotameter

In the complex landscape of industrial measurement, sourcing glass tube rotameters can pose significant challenges for international B2B buyers. These variable area flow meters are essential for accurately gauging the flow rates of liquids and gases across diverse applications—from chemical processing to water treatment. However, navigating the global market involves understanding various types of rotameters, their specific applications, and the nuances of supplier vetting to ensure quality and compliance with industry standards.

This guide offers a comprehensive overview of glass tube rotameters, detailing the different types available, their unique features, and the contexts in which they excel. We delve into critical considerations such as customization options, cost factors, and maintenance requirements, empowering buyers to make informed purchasing decisions. Additionally, we provide insights into regional market trends and supplier evaluation techniques, tailored specifically for buyers in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil.

By equipping you with the knowledge and tools needed to navigate the complexities of sourcing glass tube rotameters, this guide aims to enhance your procurement strategy, ensuring you find the right solutions that align with your operational needs and budgetary constraints. Whether you are a seasoned procurement professional or new to the industry, understanding the intricacies of glass tube rotameters will position you for success in today’s competitive market.

Understanding glass tube rotameter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Glass Rotameter | Clear glass tube, float indicates flow rate | Water treatment, HVAC, chemical processing | Pros: Cost-effective, easy to read; Cons: Fragile, limited pressure ratings. |

| Heavy-Duty Metal Rotameter | All-metal construction for high durability | Oil & gas, heavy industrial applications | Pros: High pressure/temperature tolerance; Cons: Higher cost, less visibility of flow. |

| Low-Volume Rotameter | Compact design for low flow rates | Laboratory experiments, small-scale systems | Pros: Space-efficient, accurate for small flows; Cons: Limited range, specific media compatibility. |

| Acrylic Rotameter | Lightweight acrylic body, visible flow indication | Aquaculture, medical applications | Pros: Low-cost, easy installation; Cons: Less durable than glass, limited chemical resistance. |

| Plastic Rotameter | Non-corrosive materials for aggressive fluids | Chemical processing, wastewater treatment | Pros: Resistant to harsh chemicals; Cons: Lower accuracy compared to glass models. |

What Are the Characteristics of Standard Glass Rotameters?

Standard glass rotameters are characterized by their clear glass tube and a float that rises and falls based on the flow rate of the fluid. They are primarily used in applications such as water treatment and HVAC systems, where visibility of the flow is essential. B2B buyers appreciate their simplicity and cost-effectiveness, although they should consider their fragility and limited pressure ratings when selecting for high-stress environments.

How Do Heavy-Duty Metal Rotameters Stand Out?

Heavy-duty metal rotameters feature robust all-metal construction, making them ideal for high-pressure and high-temperature applications found in the oil and gas sector. Their durability ensures long-term reliability, but this comes at a higher price point. Buyers must weigh the benefits of enhanced durability against the reduced visibility of the flow compared to glass alternatives.

What Makes Low-Volume Rotameters Suitable for Laboratories?

Low-volume rotameters are designed for measuring small flow rates, making them a staple in laboratory settings and small-scale systems. Their compact design allows for easy integration into tight spaces, and they provide accurate measurements for specific applications. However, B2B buyers should be aware of their limited flow range and specific compatibility with media types when making purchasing decisions.

Why Choose Acrylic Rotameters for Medical Applications?

Acrylic rotameters are lightweight and provide clear visibility of the fluid flow, making them suitable for applications in aquaculture and medical industries. They are cost-effective and easy to install, but their durability is less than that of glass models, and they may not withstand harsh chemicals. Buyers should consider the balance between cost and application-specific durability when selecting acrylic rotameters.

What Advantages Do Plastic Rotameters Offer for Chemical Processing?

Plastic rotameters are made from non-corrosive materials, making them ideal for measuring aggressive fluids in chemical processing and wastewater treatment applications. They are resistant to harsh chemicals, but buyers should note that they may offer lower accuracy compared to glass models. Understanding the specific requirements of the intended application will help buyers make informed decisions about using plastic rotameters.

Key Industrial Applications of glass tube rotameter

| Industry/Sector | Specific Application of glass tube rotameter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Monitoring flow rates in filtration systems | Ensures optimal operation and compliance with regulations | Accuracy, chemical compatibility, and temperature range |

| Chemical Processing | Measuring flow in batch processing | Enhances process efficiency and reduces waste | Material compatibility, pressure ratings, and size |

| Oil and Gas | Flow measurement in pipeline operations | Improves safety and operational efficiency | Durability, accuracy, and installation flexibility |

| Food and Beverage | Monitoring ingredient flow in production lines | Maintains quality control and production consistency | Sanitary design, material certifications, and ease of cleaning |

| HVAC Systems | Measuring airflow in ventilation systems | Optimizes energy consumption and enhances indoor air quality | Temperature and pressure ratings, as well as size |

How is a Glass Tube Rotameter Used in Water Treatment?

In water treatment facilities, glass tube rotameters are crucial for monitoring flow rates in filtration systems. By providing real-time visual flow data, they help operators ensure that filtration processes are running efficiently and within regulatory standards. International buyers must consider the rotameter’s accuracy and chemical compatibility, as varying water compositions can affect performance. Additionally, temperature range specifications are vital to ensure durability in diverse environmental conditions.

What Role Does a Glass Tube Rotameter Play in Chemical Processing?

In the chemical processing industry, glass tube rotameters are employed to measure flow rates during batch processing. Their straightforward design allows for easy monitoring of liquid and gas flows, which is essential for maintaining process efficiency and minimizing material waste. Buyers should focus on material compatibility with the chemicals being processed, as well as pressure ratings that can withstand the operational environment. Sourcing rotameters that meet international safety standards is also critical for compliance.

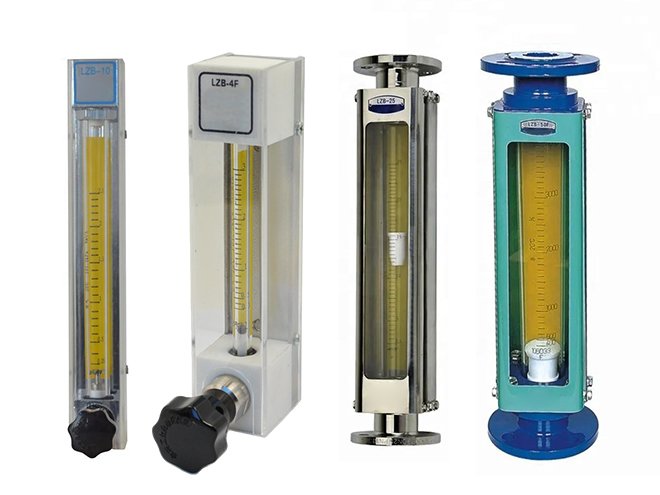

Illustrative image related to glass tube rotameter

Why are Glass Tube Rotameters Important in Oil and Gas?

In the oil and gas sector, glass tube rotameters are used to measure flow rates in pipeline operations, ensuring accurate monitoring of fluid movement. This is vital for enhancing operational efficiency and maintaining safety protocols. Buyers in this industry should prioritize durability and accuracy, as the harsh conditions can impact equipment performance. Furthermore, the ability to customize installation options can facilitate integration into existing systems, making sourcing decisions even more critical.

How Do Glass Tube Rotameters Benefit the Food and Beverage Industry?

In the food and beverage industry, glass tube rotameters are essential for monitoring the flow of ingredients in production lines. Their design allows for easy cleaning and maintenance, which is critical for maintaining hygiene standards. Buyers should ensure that the rotameters have appropriate sanitary certifications and are made from materials that comply with food safety regulations. The ability to provide consistent flow measurements contributes to quality control, ultimately enhancing product consistency.

What is the Significance of Glass Tube Rotameters in HVAC Systems?

Glass tube rotameters are utilized in HVAC systems to measure airflow, which is vital for optimizing energy consumption and ensuring indoor air quality. Accurate flow measurement allows for better control of heating and cooling systems, leading to cost savings and improved comfort. Buyers should consider the temperature and pressure ratings of the rotameters to ensure they can operate effectively in varying conditions. Sourcing rotameters that are easy to install and maintain will also enhance operational efficiency.

3 Common User Pain Points for ‘glass tube rotameter’ & Their Solutions

Scenario 1: Ensuring Accurate Flow Measurement in Varied Conditions

The Problem: B2B buyers often encounter challenges with ensuring accurate flow measurement, especially in environments with fluctuating temperatures and pressures. For instance, a chemical processing plant might experience variations in fluid properties due to temperature changes, affecting the density and viscosity of the medium being measured. This can lead to inaccurate readings from glass tube rotameters, which rely on a specific calibration to provide reliable flow measurements.

The Solution: To overcome this issue, buyers should prioritize sourcing rotameters that offer customizable calibration options based on the specific media being measured. When specifying a glass tube rotameter, it is crucial to select one that provides direct reading scales calibrated for the specific fluid density and operating conditions. Additionally, buyers should consider investing in rotameters with materials designed to withstand higher pressures and temperatures, such as stainless steel or PTFE-lined options, to ensure durability and accuracy. Regular maintenance and recalibration of the rotameter can further enhance measurement reliability, enabling businesses to maintain operational efficiency.

Scenario 2: Managing Corrosion and Material Compatibility

The Problem: In industries dealing with corrosive substances, such as chemical manufacturing or wastewater treatment, the compatibility of the rotameter materials with the fluid is critical. Buyers often find that standard glass tube rotameters are not suitable for aggressive chemicals, leading to premature failure and costly downtime. This poses a significant risk to both safety and operational continuity.

The Solution: B2B buyers should perform a thorough analysis of the chemical compatibility of the rotameter’s materials with the fluids being measured. Selecting a glass tube rotameter with a corrosion-resistant coating or using alternative materials like polycarbonate or high-grade stainless steel can mitigate this risk. It is advisable to consult with manufacturers to obtain detailed compatibility charts and opt for rotameters specifically designed for harsh environments. Investing in rotameters that come with certifications for chemical resistance can also provide peace of mind and ensure long-term reliability.

Scenario 3: Difficulties in Installation and Maintenance

The Problem: Many buyers face challenges during the installation and maintenance of glass tube rotameters, often due to a lack of clear guidance or compatibility with existing systems. Improper installation can lead to inaccurate measurements and increased wear on the rotameter, while maintenance procedures that are not straightforward can result in operational delays.

The Solution: To address installation and maintenance challenges, buyers should seek out suppliers who provide comprehensive installation guides and support. It is essential to choose rotameters that come with user-friendly features, such as easy-to-read scales and straightforward mounting options that accommodate both horizontal and vertical installations. Additionally, buyers should consider rotameters that offer modular components, allowing for easy replacement of parts without having to remove the entire unit. Regular training for maintenance staff on the proper handling and servicing of the rotameters can further enhance operational efficiency and minimize downtime. Engaging with suppliers for ongoing support and service contracts can also ensure that any issues are resolved quickly and effectively.

Strategic Material Selection Guide for glass tube rotameter

What Are the Key Properties of Common Materials Used in Glass Tube Rotameters?

When selecting materials for glass tube rotameters, it is crucial to consider their properties, especially regarding temperature and pressure ratings, as well as corrosion resistance. The most commonly used materials include glass, stainless steel, acrylic, and plastic composites. Each material has unique characteristics that can significantly impact performance and application suitability.

How Does Glass Perform in Glass Tube Rotameters?

Glass is the traditional material used for rotameter tubes due to its excellent clarity and resistance to a wide range of chemicals. It can typically withstand temperatures up to 150°C and pressures up to 2 bar. The primary advantage of glass is its transparency, allowing for easy visual monitoring of the flow. However, glass is brittle and can break easily, which raises safety concerns in high-pressure or high-traffic environments. For international buyers, glass rotameters must comply with safety standards like ASTM and DIN to ensure reliability and safety in various applications.

What Are the Benefits and Limitations of Stainless Steel in Rotameters?

Stainless steel is favored for its durability and resistance to corrosion, making it suitable for harsh environments and aggressive media. It can handle high pressures (up to 8700 PSI) and temperatures (up to 350°C), making it ideal for industrial applications. The downside is that stainless steel rotameters are typically more expensive than glass ones, and their opaque nature means that flow monitoring is not as straightforward. Buyers from regions with stringent industrial standards, such as Germany, may prefer stainless steel for its robustness and compliance with safety regulations.

How Does Acrylic Compare to Traditional Glass in Rotameters?

Acrylic is a lightweight and cost-effective alternative to glass, often used in low-pressure applications (up to 100 PSI) and lower temperature ranges (up to 65°C). Acrylic rotameters are less prone to breaking compared to glass, making them safer in certain environments. However, they are not as chemically resistant as glass or stainless steel, which limits their use with aggressive solvents. For international buyers, especially in emerging markets like Brazil, acrylic rotameters can provide a budget-friendly option while still meeting basic flow measurement needs.

What Role Do Plastic Composites Play in Rotameter Applications?

Plastic composites, such as polysulfone or PVC, are increasingly being used in rotameters due to their excellent chemical resistance and lightweight properties. These materials can typically handle temperatures up to 130°C and pressures around 145 PSI. The primary advantage of plastic composites is their ability to resist corrosion from aggressive chemicals, making them suitable for various applications, including water treatment and chemical processing. However, they may not offer the same level of durability as metal options, and their cost can vary widely based on the specific type of plastic used. Buyers from the Middle East and Africa should consider local chemical compatibility when selecting plastic composites for their applications.

Summary Table of Material Selection for Glass Tube Rotameters

| Material | Typical Use Case for glass tube rotameter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | General flow measurement in labs | Excellent clarity and chemical resistance | Brittle and prone to breakage | Low |

| Stainless Steel | Industrial applications with high pressures | High durability and corrosion resistance | Higher cost and opaque visibility | High |

| Acrylic | Low-pressure applications and educational use | Lightweight and cost-effective | Limited chemical resistance | Medium |

| Plastic Composites | Chemical processing and water treatment | Excellent chemical resistance | Less durable than metals | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for glass tube rotameter

What Are the Key Stages in the Manufacturing Process of Glass Tube Rotameters?

The production of glass tube rotameters involves several meticulous stages, each essential for ensuring the final product meets rigorous performance and quality standards.

Illustrative image related to glass tube rotameter

Material Preparation

The initial phase of manufacturing begins with the selection of high-grade materials. For glass tube rotameters, the primary materials include borosilicate glass for the tube, which offers excellent thermal resistance and chemical compatibility. Additionally, floats are typically made from materials such as stainless steel or other corrosion-resistant alloys, designed to withstand various fluid types. Other components like seals and fittings may utilize PTFE or other durable plastics, depending on the application requirements.

Forming the Glass Tube

Once materials are prepared, the next step is the forming of the glass tube. This is typically achieved through processes like blow molding or precision glass fabrication, where the glass is heated to a malleable state and shaped into the desired conical profile. The conical shape is crucial, as it allows for accurate flow measurement by enabling the float to rise and fall with varying flow rates. Advanced techniques, such as automated glass blowing, ensure uniformity and precision in tube dimensions, which are critical for accurate flow readings.

Assembly of Components

After the glass tube is formed, the assembly process begins. This involves inserting the float into the glass tube and securing it with end fittings, which may include valves or pressure gauges. Careful attention is paid to align the float within the tube to prevent any obstruction during operation. During assembly, manufacturers often employ specialized jigs and fixtures that help maintain alignment and integrity, ensuring that each unit adheres to the specified tolerances.

Finishing Touches

The final stage of manufacturing includes surface finishing and coating. This may involve applying protective coatings to enhance chemical resistance or improve visibility against the liquid or gas being measured. Additionally, calibration is performed to ensure that the rotameter is accurately measuring flow rates. This step is crucial, as it directly impacts the reliability of the device in practical applications.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of glass tube rotameter manufacturing, ensuring that each product meets international and industry-specific standards.

What International Standards Govern Rotameter Manufacturing?

Manufacturers often adhere to international quality management standards such as ISO 9001, which emphasizes a systematic approach to quality management and continuous improvement. In addition to general quality standards, industry-specific certifications like CE marking for products sold in Europe and API standards for oil and gas applications are critical. These certifications ensure that the products are safe, reliable, and meet the regulatory requirements of different markets.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically implemented throughout the manufacturing process to catch any defects early on. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor processes such as glass forming and assembly. This helps identify any deviations from quality standards in real-time.

- Final Quality Control (FQC): Before shipping, each rotameter undergoes rigorous testing to verify performance and accuracy. This may include flow rate testing, pressure tests, and visual inspections for defects.

What Testing Methods Are Commonly Used for Glass Tube Rotameters?

Various testing methods are employed to ensure the functionality and reliability of glass tube rotameters. These include:

- Hydraulic Testing: To assess the structural integrity of the rotameter under pressure.

- Flow Calibration Tests: To verify that the flow measurement is accurate across the specified range.

- Material Compatibility Testing: Ensuring the materials used can withstand the chemical properties of the fluids being measured.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial.

What Steps Can Buyers Take to Ensure Supplier Compliance with QC Standards?

-

Supplier Audits: Conducting on-site audits of the manufacturing facilities can provide insights into the supplier’s processes, quality control measures, and adherence to international standards.

-

Requesting Quality Reports: Buyers should request documentation that outlines the QC processes, including IQC, IPQC, and FQC results. These reports can provide transparency regarding the supplier’s commitment to quality.

-

Third-party Inspections: Engaging third-party inspection services can help validate the manufacturer’s claims about product quality and compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers should be aware of specific nuances related to quality control that may vary by region. For instance, buyers from Europe may place a higher emphasis on CE certification, while those in the Middle East may prioritize compliance with local industry standards. Additionally, understanding the local regulations and market expectations in each region can significantly affect the selection of suppliers and products.

By taking these proactive steps, B2B buyers can ensure they partner with manufacturers who prioritize quality and reliability in their glass tube rotameter products, ultimately leading to better operational performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass tube rotameter’

Introduction

This sourcing guide is designed for B2B buyers seeking to procure glass tube rotameters. It outlines a step-by-step checklist to ensure you make informed decisions, choose the right suppliers, and select products that meet your operational requirements. A thorough approach to sourcing can help mitigate risks and enhance your procurement strategy.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes flow rate, pressure, and temperature ranges. Understanding these parameters is vital as they determine the suitability of the rotameter for your specific application, whether it’s for liquids or gases.

- Flow Rate: Specify the minimum and maximum flow rates you will need to measure.

- Pressure and Temperature: Identify the operational limits for pressure and temperature to ensure compatibility with your processes.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers of glass tube rotameters. Look for manufacturers and distributors with a strong reputation in your industry and region.

- Industry Experience: Evaluate how long the supplier has been in the business and their track record.

- Geographic Reach: Ensure they can support your location, especially if you are operating in Africa, South America, or the Middle East.

Step 3: Evaluate Supplier Certifications

Before making a decision, it’s essential to verify that suppliers have the necessary certifications. This ensures that the products meet industry standards and safety regulations.

- Quality Standards: Check for certifications such as ISO 9001, which indicates quality management systems.

- Safety Compliance: Look for compliance with local and international safety standards relevant to your industry.

Step 4: Request Samples and Technical Documentation

Ask for samples or technical documentation from potential suppliers. This allows you to assess product quality and compatibility with your requirements.

Illustrative image related to glass tube rotameter

- Product Samples: Testing samples can help you evaluate the performance and accuracy of the rotameter.

- Technical Data Sheets: Review these documents to understand the specifications, installation requirements, and operating conditions.

Step 5: Review Pricing and Payment Terms

Gather quotes from multiple suppliers and compare pricing structures. Understanding the total cost of ownership, including shipping and potential duties, is crucial.

- Transparent Pricing: Ensure that the quotes include all costs, avoiding hidden fees.

- Payment Terms: Look for flexible payment options that align with your budgeting cycles.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize the terms of the purchase. This includes delivery schedules, warranties, and after-sales support.

- Delivery Schedule: Confirm the lead time for your order and any penalties for delays.

- Warranties: Ensure there is a clear warranty policy to protect your investment.

Step 7: Establish a Relationship with the Supplier

Building a strong relationship with your chosen supplier can lead to better service and future collaboration. Keep communication open and provide feedback on their products and services.

- Regular Check-Ins: Establish a routine for communication to discuss any ongoing needs or issues.

- Feedback Mechanism: Create a channel for providing feedback to enhance future transactions.

Following this checklist will help streamline your procurement process for glass tube rotameters, ensuring you select the right products and suppliers for your needs.

Comprehensive Cost and Pricing Analysis for glass tube rotameter Sourcing

When sourcing glass tube rotameters, understanding the cost structure and pricing dynamics is essential for B2B buyers. The total cost of ownership can vary significantly based on several components and influencing factors.

What Are the Key Cost Components in Glass Tube Rotameter Pricing?

-

Materials: The choice of materials directly impacts the cost of glass tube rotameters. Common materials include glass, stainless steel, and various plastics. High-quality materials may increase the initial purchase price but can enhance durability and performance, leading to lower maintenance costs over time.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. For instance, custom designs may require specialized labor, increasing overall costs. In regions with higher wage standards, such as Europe, labor costs can significantly affect pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, translating to lower prices for buyers.

-

Tooling: Customization often necessitates specific tooling, which can be a substantial upfront cost. Buyers should consider whether the tooling costs are amortized over large orders or if they are charged per unit.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and accuracy. While adding to production costs, robust QC can prevent costly failures in the field, making it a worthwhile investment.

-

Logistics: Shipping costs can vary based on the destination and chosen Incoterms. Buyers should factor in these costs, especially for international shipments where tariffs and customs fees may apply.

-

Margin: Suppliers generally include a profit margin in their pricing. This margin can be influenced by market competition, perceived value, and the supplier’s operational costs.

How Do Volume and Specifications Influence Glass Tube Rotameter Pricing?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts due to economies of scale. Buyers looking to source significant quantities should negotiate for better pricing based on their projected volume.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers must balance the need for tailored solutions with budget constraints. Standard models typically offer better pricing due to lower production costs.

-

Quality and Certifications: Certifications such as ATEX or IECEx can enhance product value but may also increase costs. Buyers should assess whether these certifications align with their operational requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their track record of quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms can significantly affect the final price. Buyers should understand terms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) to avoid unexpected costs in shipping and logistics.

What Negotiation Tips Can Help B2B Buyers Achieve Cost Efficiency?

-

Leverage Volume: When negotiating, emphasize your purchasing volume to secure better rates. Suppliers are often willing to provide discounts for larger orders.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide leverage in negotiations and ensure you are getting competitive pricing.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A higher upfront cost may be justified by lower long-term expenses.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local regulations that can impact the overall cost. This understanding can aid in making informed purchasing decisions.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better pricing, priority service, and enhanced collaboration on future projects.

Conclusion

While indicative prices for glass tube rotameters can range widely based on the factors discussed, understanding the detailed cost structure and pricing influencers enables buyers to make informed decisions. By strategically negotiating and considering the total cost of ownership, B2B buyers can optimize their sourcing strategy for glass tube rotameters, ensuring both quality and cost-effectiveness in their operations.

Alternatives Analysis: Comparing glass tube rotameter With Other Solutions

Exploring Alternatives to Glass Tube Rotameters

In the realm of flow measurement, the glass tube rotameter is a well-known solution praised for its simplicity and reliability. However, various alternatives exist that cater to different operational needs and environments. This section analyzes the glass tube rotameter against two viable alternatives: digital flow meters and magnetic flow meters. Each option offers unique advantages and potential drawbacks depending on the specific application and user requirements.

| Comparison Aspect | Glass Tube Rotameter | Digital Flow Meter | Magnetic Flow Meter |

|---|---|---|---|

| Performance | Moderate accuracy; best for low flow rates | High accuracy; suitable for various flow rates | Excellent accuracy; not suitable for low flow rates |

| Cost | Generally low-cost | Moderate to high cost | Higher initial investment |

| Ease of Implementation | Simple installation; minimal setup | Requires calibration and setup | Installation complexity; requires electrical supply |

| Maintenance | Low maintenance; visual inspection | Moderate; may require periodic calibration | Low; infrequent maintenance needed |

| Best Use Case | Low-flow applications; liquids and gases | High precision applications; various media | Conductive liquids; wastewater treatment |

What Are the Pros and Cons of Digital Flow Meters?

Digital flow meters leverage advanced technology to provide precise flow measurements, often with features like data logging and remote monitoring. Their high accuracy makes them suitable for various applications, including pharmaceuticals and food processing. However, they come at a higher cost and may require calibration to ensure accuracy. Additionally, installation can be more complex compared to glass tube rotameters, as they often need electrical supply and integration with existing systems.

What Are the Advantages and Disadvantages of Magnetic Flow Meters?

Magnetic flow meters, or magmeters, are designed to measure the flow of conductive liquids with exceptional accuracy. They are particularly effective in wastewater treatment and industrial applications. One major advantage is their ability to handle a wide range of flow rates without requiring recalibration. However, they are not suitable for non-conductive liquids and can be expensive to install due to the need for electrical connections and specialized setup. Their complexity can be a barrier for users unfamiliar with electrical instrumentation.

How to Choose the Right Flow Measurement Solution for Your Needs?

When selecting a flow measurement solution, B2B buyers should consider several factors, including the type of fluid being measured, required accuracy, cost constraints, and installation capabilities. For applications involving low flow rates and a need for visual monitoring, glass tube rotameters remain a strong choice. Conversely, if precision and data integration are paramount, digital flow meters may be more appropriate. In environments dealing with conductive liquids, magnetic flow meters can offer the best accuracy and reliability, albeit at a higher investment. Ultimately, aligning the choice with operational requirements and budget will lead to the best outcomes.

Essential Technical Properties and Trade Terminology for glass tube rotameter

What Are the Key Technical Properties of Glass Tube Rotameters?

When selecting a glass tube rotameter, understanding its essential technical properties is crucial for ensuring optimal performance in your specific application. Here are several critical specifications to consider:

-

Material Grade

Glass tube rotameters typically utilize borosilicate glass for the tube, which offers excellent thermal and chemical resistance. This material is essential for applications involving aggressive chemicals or high temperatures. The choice of material directly impacts the rotameter’s durability and lifespan, making it vital for B2B buyers to align their selection with the operational conditions of their processes. -

Flow Range

The flow range indicates the minimum and maximum flow rates that the rotameter can accurately measure, usually expressed in GPM (gallons per minute) or SCFM (standard cubic feet per minute). Understanding this range is critical for ensuring that the rotameter can handle the expected flow rates in your application. An inadequate flow range may lead to inaccurate readings and inefficient process management. -

Accuracy

Accuracy, often specified as a percentage of the full scale, indicates how closely the rotameter’s readings reflect the actual flow. For instance, an accuracy of ±2% means that the reading can deviate from the true flow by up to 2%. High accuracy is particularly important in industries such as pharmaceuticals and food processing, where precise measurements are crucial for compliance and quality assurance. -

Operating Pressure and Temperature

Each rotameter has specified limits for both operating pressure and temperature. Understanding these limits helps ensure that the device will function correctly without risk of failure. For example, if a rotameter is rated for a maximum pressure of 580 PSIG, exceeding this limit could lead to catastrophic failure. B2B buyers must consider their system’s pressure and temperature to avoid operational disruptions. -

Connection Type

The type of connection, such as NPT (National Pipe Thread) or ANSI flanges, is critical for compatibility with existing piping systems. Selecting the correct connection type ensures seamless integration into your processes, reducing installation time and costs. -

Calibration

Calibration refers to the process of adjusting the rotameter to ensure its accuracy against known standards. It is essential for maintaining measurement precision over time, especially in applications where flow rates can change. Regular calibration is a key aspect of quality control in many industries.

What Are Common Trade Terms Related to Glass Tube Rotameters?

Understanding industry jargon can significantly streamline communication and purchasing processes. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing glass tube rotameters, buyers may consider OEMs for customized solutions that meet specific requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget management and supply chain planning, especially for businesses looking to optimize inventory levels. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers for specific products. Submitting an RFQ for glass tube rotameters helps buyers obtain competitive pricing and clarify product specifications. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs and risk transfer. Familiarity with these terms can help B2B buyers negotiate better agreements and understand their liabilities in the supply chain. -

Calibration Certificate

This document verifies that a rotameter has been calibrated according to industry standards. It is essential for ensuring compliance and accuracy, particularly in regulated industries. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times for glass tube rotameters is crucial for project planning and ensuring that operations are not delayed.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that enhance your operational efficiency and product quality in your industry.

Illustrative image related to glass tube rotameter

Navigating Market Dynamics and Sourcing Trends in the glass tube rotameter Sector

What Are the Key Trends Influencing the Glass Tube Rotameter Market?

The global glass tube rotameter market is witnessing significant growth, driven by an increasing demand for precise flow measurement solutions across various industries. The rise in automation and digitization is prompting manufacturers to integrate advanced technologies into their products, such as IoT connectivity and smart sensors, enhancing data accuracy and real-time monitoring capabilities. In regions like Africa and South America, where industrialization is on the rise, there is a notable shift towards adopting reliable flow measurement devices that offer low maintenance and ease of use. In Europe, particularly in Germany, stringent regulations regarding emissions and energy consumption are pushing industries to utilize high-precision measuring instruments, further fueling demand for rotameters.

Emerging trends include the customization of glass tube rotameters to meet specific industry needs, such as chemical compatibility and operating conditions. This adaptability is crucial for sectors like pharmaceuticals and food processing, where precision is paramount. Additionally, as businesses increasingly prioritize supply chain transparency, international buyers are looking for manufacturers who provide detailed product specifications and certifications, ensuring compliance with local and international standards.

How Can Sustainability and Ethical Sourcing Impact the Glass Tube Rotameter Sector?

In today’s environmentally conscious market, the sustainability of products and ethical sourcing practices are becoming critical considerations for B2B buyers. The production of glass tube rotameters can have a significant environmental impact, from the extraction of raw materials to manufacturing processes. Companies are increasingly adopting sustainable practices by using recycled materials and reducing energy consumption during production.

Illustrative image related to glass tube rotameter

Ethical supply chains are essential, particularly for international buyers seeking to align with global sustainability goals. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can provide assurance of a manufacturer’s commitment to sustainable practices. Additionally, the use of non-toxic materials in the construction of rotameters is gaining traction, as industries strive to minimize their ecological footprint. Buyers are encouraged to seek suppliers who prioritize sustainability in their operations, thereby ensuring that their procurement practices contribute positively to environmental conservation.

How Has the Glass Tube Rotameter Evolved Over Time?

The evolution of glass tube rotameters can be traced back to their inception in the early 20th century when they were primarily used for simple flow measurement tasks. Initially, their design was rudimentary, relying on gravity and fluid dynamics principles to measure flow rates. Over time, advancements in materials and manufacturing technologies have significantly enhanced the performance and durability of rotameters.

Today, glass tube rotameters are available in various configurations and materials, including high-strength plastics and metals, catering to diverse industrial applications. The integration of digital technologies has further transformed these devices, enabling features such as remote monitoring and data logging. This evolution reflects a broader trend in the industrial sector toward increased accuracy, reliability, and efficiency in flow measurement, making glass tube rotameters a vital component in modern manufacturing and process control systems.

Frequently Asked Questions (FAQs) for B2B Buyers of glass tube rotameter

-

How do I choose the right glass tube rotameter for my application?

Selecting the appropriate glass tube rotameter involves assessing your specific application requirements. Consider factors such as the type of fluid (liquid or gas), flow rate range, operating pressure, and temperature conditions. It’s also vital to evaluate the chemical compatibility of the materials used in the rotameter, including the float and tube. Ensure that the rotameter’s accuracy and scale are suitable for your measurement needs. Consulting with suppliers who can provide detailed specifications and recommendations based on your operational context can further streamline your decision-making process. -

What are the key benefits of using glass tube rotameters?

Glass tube rotameters are favored for their simplicity, reliability, and cost-effectiveness. They provide direct visual flow measurement, which is particularly useful in applications where monitoring fluid conditions is crucial. Their design allows for low maintenance, as there are no moving parts that require frequent service. Additionally, these rotameters can operate without external power sources, making them ideal for various settings. Their adaptability to different media and customizable options for floats and tubes enhance their versatility across industries. -

What customization options are available for glass tube rotameters?

Most manufacturers offer a range of customization options for glass tube rotameters, including variations in tube materials, float designs, and scale markings. You can choose from different chemical-resistant materials for the float and tube to match the specific characteristics of the fluid being measured. Additionally, options for integration with electronic outputs, such as analog signals or digital interfaces, can be specified. Discussing your unique application needs with potential suppliers will help identify the most suitable customization options for your rotameter. -

What is the typical minimum order quantity (MOQ) for glass tube rotameters?

The minimum order quantity for glass tube rotameters can vary significantly by supplier and model. Many manufacturers set an MOQ to ensure cost-effectiveness in production and shipping. Typically, MOQs can range from a single unit for custom or specialized orders to larger quantities for standard models. It’s advisable to inquire directly with suppliers to understand their specific MOQs and any associated pricing tiers, especially if you are looking to place bulk orders. -

How can I ensure quality assurance (QA) when sourcing glass tube rotameters?

To ensure quality assurance when sourcing glass tube rotameters, request detailed product specifications and certifications from your suppliers. Look for manufacturers that adhere to international quality standards, such as ISO certifications. Additionally, consider asking for product samples or test reports to evaluate the performance and accuracy of the rotameters before committing to a larger order. Establishing a clear communication channel with your supplier regarding quality expectations can also help mitigate potential issues. -

What payment terms should I expect when ordering glass tube rotameters internationally?

Payment terms for international orders of glass tube rotameters can vary widely based on the supplier’s policies and your business relationship. Common payment options include upfront payments, letters of credit, or payment upon delivery. Some suppliers may offer net terms (e.g., 30, 60, or 90 days) for established clients. It’s essential to clarify payment terms before placing an order and to consider the implications of currency exchange rates and transaction fees when dealing with international suppliers. -

What logistics considerations should I keep in mind when importing glass tube rotameters?

When importing glass tube rotameters, it’s crucial to consider logistics factors such as shipping methods, lead times, and customs regulations. Select a reliable freight forwarder familiar with your destination country’s import requirements to ensure compliance with all regulations. Assess shipping options that balance cost and delivery speed, and factor in potential tariffs or duties that may apply. Planning for proper packaging is also essential to protect the glass components during transit. -

How can I vet suppliers of glass tube rotameters to ensure reliability?

To vet suppliers effectively, start by researching their market reputation and client reviews. Request references from other businesses in your industry who have sourced similar products. Verify their certifications and compliance with international quality standards. Engaging in direct communication with suppliers can also provide insights into their responsiveness and professionalism. Attending industry trade shows or exhibitions can further facilitate personal interactions and help build a trustworthy relationship with potential suppliers.

Top 6 Glass Tube Rotameter Manufacturers & Suppliers List

1. Brooks Instrument – Glass Tube VA Flow Meter

Domain: brooksinstrument.com

Registered: 1996 (29 years)

Introduction: {“Product Type”: “Glass Tube VA Flow Meter”, “Key Features”: {“Rugged”: true, “Economical”: true, “Easy to use”: true}, “Applications”: [“Industrial processes”, “Liquid level measurement and control instrumentation”, “Pharmaceutical production”, “Oil and gas pumping and refining processes”, “Fuel cell research”, “Chemical manufacturing”, “Analytical instrumentation”, “Wastewater treatment instrume…

2. ABB – FGM1190 Glass Tube Variable Area Flowmeter

Domain: new.abb.com

Registered: 1990 (35 years)

Introduction: Product Name: FGM1190 Glass Tube Variable Area Flowmeter

Design Types:

– FGM1190-87: Threaded pipe connection (DIN 2950)

– FGM1190-97: Vertical internal thread connection (DIN 11851, DIN 405 part 1 for food and beverage)

– FGM1190-98: Flange connection (DIN and ASME)

Applications: Flowrate measurements in various industries including system manufacture, food, water treatment plants, and chemical …

3. Dakota Instruments – Encased Glass Tube Flowmeters

Domain: dakotainstruments.com

Registered: 1997 (28 years)

Introduction: Encased Glass Tube Flowmeters available in Aluminum, Brass, 316 Stainless Steel, and PTFE-PFA. Ideal for measuring and controlling gases and liquids across low, medium, and high flow ranges. Features include:

– Heavy-duty construction with brushed stainless steel case for industrial applications.

– Flow rates up to 116 GPM / 440 L/min and 250 SCFM / 7080 L/min.

– Graduated for direct reading of wa…

4. KROHNE – Variable Area Flowmeters

Domain: krohne.com

Registered: 1995 (30 years)

Introduction: Variable area flowmeters, also known as rotameters, are used for measuring the volumetric flow rate of conductive and non-conductive liquids and gases. They operate without auxiliary power and are suitable for low flow rates of clean liquids or gases. KROHNE offers various models, including:

1. **H250 M40**: Modular design for liquids and gases, installation in any position, flange sizes DN15…150…

5. Instrumart – Rotameters

Domain: instrumart.com

Registered: 2004 (21 years)

Introduction: Rotameters are flow measuring instruments that consist of a uniformly tapered flow tube, a float, and a measurement scale. They measure the flow rate of gases or liquids by the position of the float in the tube, which is supported by the fluid flowing underneath. Key features include:

– Simple, reliable, and inexpensive design

– Low, nearly constant pressure drop

– Generally not suitable for lo…

6. King Instrument Co – Borosilicate Glass Metering Tube

Domain: kinginstrumentco.com

Registered: 1997 (28 years)

Introduction: This company, King Instrument Co – Borosilicate Glass Metering Tube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for glass tube rotameter

In conclusion, strategic sourcing of glass tube rotameters offers significant advantages for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These flow measurement devices are favored for their simplicity, reliability, and cost-effectiveness, making them ideal for a variety of applications across different industries. By leveraging customizability in materials and design, businesses can ensure compatibility with diverse chemical processes and operating conditions, enhancing operational efficiency and safety.

Moreover, the market for glass tube rotameters is poised for growth, driven by increasing demand for accurate flow measurement in various sectors, including water treatment, pharmaceuticals, and food processing. As the industry evolves, buyers are encouraged to partner with reputable suppliers that offer robust support and innovative solutions tailored to specific needs.

Investing in high-quality glass tube rotameters is not merely a purchase; it’s a strategic decision that can lead to improved productivity and cost savings. As you explore sourcing options, consider how these devices can enhance your operations and contribute to sustainable growth. Engage with trusted manufacturers today to discover the right solutions that align with your business objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to glass tube rotameter