Is Your Glass Cutter Machine Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for glass cutter machine

The global market for glass cutter machines is evolving rapidly, presenting unique challenges for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses seek to enhance their production capabilities and improve efficiency, sourcing the right glass cutting equipment becomes a critical task. Whether you are looking for advanced automated systems or versatile handheld cutters, understanding the nuances of different types, applications, and features is essential for making an informed purchase.

This comprehensive guide delves into the various glass cutter machines available on the market, exploring their specific applications—from intricate artistic designs to large-scale industrial use. Buyers will gain insights into the latest technologies, including ergonomic designs that minimize hand fatigue and cutting systems that ensure precision and reduce waste. Additionally, the guide provides valuable information on vetting suppliers, comparing costs, and understanding warranty options, which are crucial for mitigating risks associated with international purchasing.

By equipping B2B buyers with the knowledge needed to navigate this complex landscape, this guide empowers decision-makers to make strategic investments in glass cutting machinery that enhance productivity and meet their unique operational needs. Whether you are in Germany or Saudi Arabia, our insights aim to simplify your sourcing process and optimize your glass cutting capabilities.

Understanding glass cutter machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handheld Glass Cutters | Lightweight, portable, manual operation | Small-scale projects, hobbyists | Pros: Cost-effective, easy to use. Cons: Limited precision for large pieces. |

| Automated Glass Cutters | Computer-controlled, high precision | Mass production, industrial applications | Pros: High efficiency, consistent results. Cons: Higher initial investment, requires training. |

| Circle Cutters | Specialized for creating circular cuts | Decorative glasswork, signage | Pros: Accurate circular cuts, versatile. Cons: Limited to circular shapes. |

| Score-and-Break Systems | Combines scoring and breaking in one tool | Large installations, custom glass designs | Pros: Reduces labor time, enhances accuracy. Cons: More expensive than basic cutters. |

| Pistol Grip Glass Cutters | Ergonomically designed for comfort and control | Art glass projects, stained glass work | Pros: Reduces hand fatigue, precise scoring. Cons: May require maintenance for optimal performance. |

What Are Handheld Glass Cutters and When Should Businesses Use Them?

Handheld glass cutters are the most basic type of cutting tool, designed for manual operation. They are lightweight and portable, making them ideal for small-scale projects or hobbyist use. These tools are generally cost-effective and easy to use, but they may not provide the precision required for larger pieces of glass. B2B buyers should consider the volume and scale of their projects when selecting handheld cutters, as they are best suited for simple tasks rather than complex designs.

How Do Automated Glass Cutters Enhance Production Efficiency?

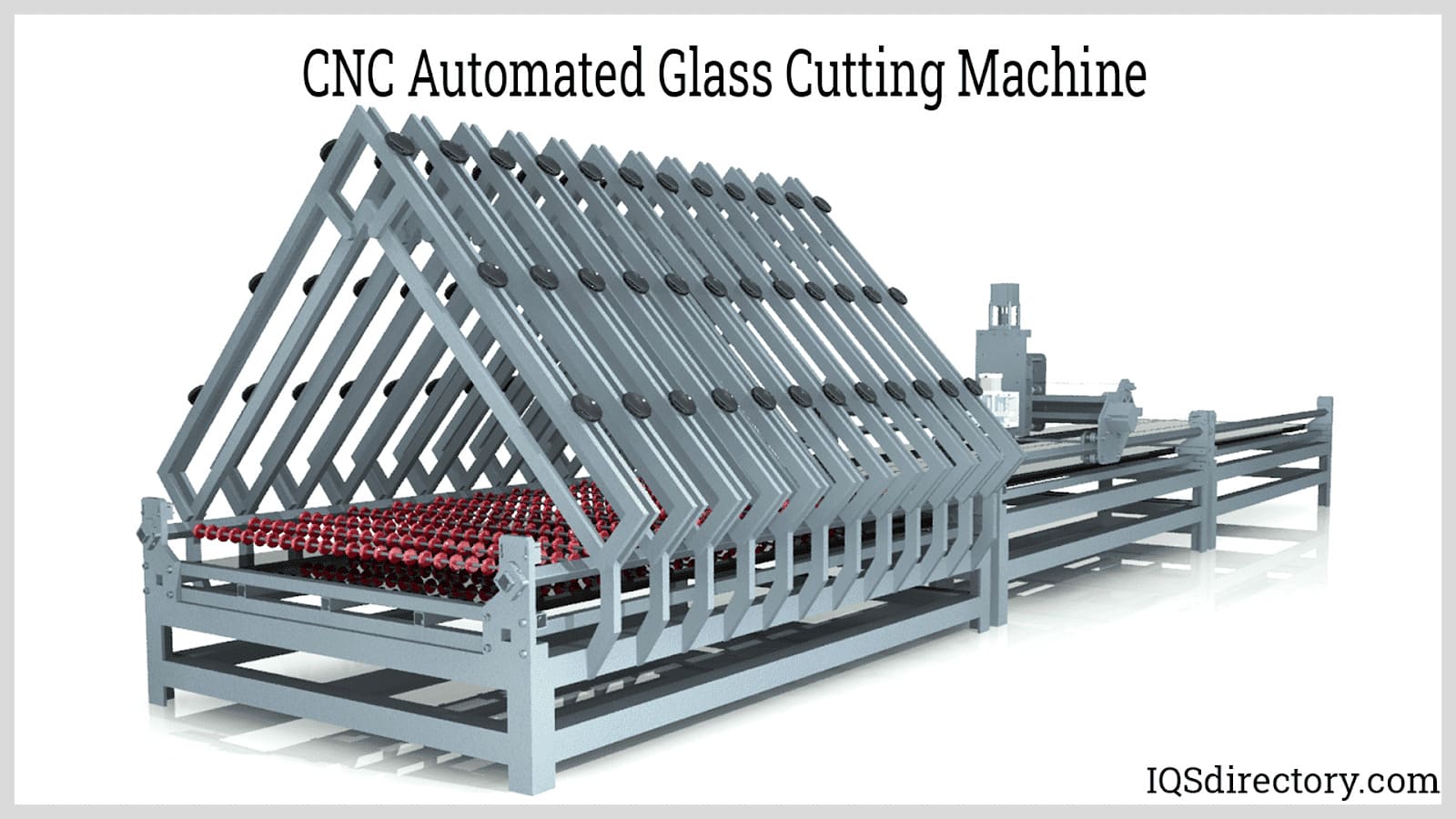

Automated glass cutters leverage computer-controlled systems to achieve high precision and efficiency. They are particularly beneficial for mass production and industrial applications, where consistent results are crucial. While these machines can significantly reduce labor time and improve accuracy, they come with a higher initial investment and may require specialized training for operators. B2B buyers should evaluate their production needs and long-term goals when considering automated options.

What Are the Advantages of Using Circle Cutters in Glass Projects?

Circle cutters are specialized tools designed to create precise circular cuts in glass. They are commonly used in decorative glasswork and signage, where accuracy is essential. The primary advantage of circle cutters is their ability to produce clean, uniform circles, enhancing the quality of finished products. However, their functionality is limited to circular shapes, which may not meet the needs of all projects. B2B buyers should assess their design requirements before investing in this type of cutter.

How Do Score-and-Break Systems Improve Accuracy in Glass Cutting?

Score-and-break systems combine the functions of scoring and breaking glass into a single tool, making them particularly useful for large installations and custom glass designs. These systems enhance accuracy and can significantly reduce labor time compared to traditional methods. However, they tend to be more expensive than basic cutting tools. Businesses looking to streamline their glass cutting processes while maintaining quality should consider these systems as a viable option.

Why Choose Pistol Grip Glass Cutters for Ergonomic Benefits?

Pistol grip glass cutters are ergonomically designed for comfort and control, making them an excellent choice for art glass projects and stained glass work. These tools reduce hand fatigue during extended use, allowing for more precise scoring. While they may require maintenance to ensure optimal performance, their user-friendly design makes them a popular choice among artists and craftspeople. B2B buyers should consider the comfort and ease of use when selecting glass cutting tools for their teams.

Key Industrial Applications of glass cutter machine

| Industry/Sector | Specific Application of glass cutter machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Precision cutting for windows and facades | Enhances aesthetic appeal and energy efficiency | Durability, ease of use, and compatibility with various glass types |

| Automotive | Cutting glass for vehicle windows and mirrors | Improves safety and reduces production costs | Compliance with safety standards and precision in cutting |

| Art & Craft | Creating custom glass art pieces | Allows for creative designs and artistic expression | Variety of cutting tools, ergonomic design, and ease of handling |

| Electronics & Appliances | Manufacturing glass components for displays | Increases production efficiency and reduces waste | Automation capabilities and precision cutting features |

| Glass Recycling | Scoring and cutting recycled glass materials | Supports sustainability efforts and cost savings | Versatility in handling different glass thicknesses and types |

How is a glass cutter machine utilized in the construction and architecture sector?

In the construction and architecture sector, glass cutter machines are essential for precision cutting of windows and facades. These machines ensure that glass pieces fit perfectly into frames, enhancing both the aesthetic appeal and energy efficiency of buildings. International buyers, particularly from regions like Europe and the Middle East, must consider the durability and ease of use of these machines, as well as their compatibility with various types of glass, including tempered and laminated glass.

What role does a glass cutter machine play in the automotive industry?

In the automotive industry, glass cutter machines are used to cut glass for vehicle windows and mirrors. The precision of these machines is crucial for ensuring safety and compliance with industry standards. For B2B buyers in Africa and South America, sourcing machines that adhere to safety regulations and provide high precision in cutting is vital to reduce production costs and improve overall vehicle quality.

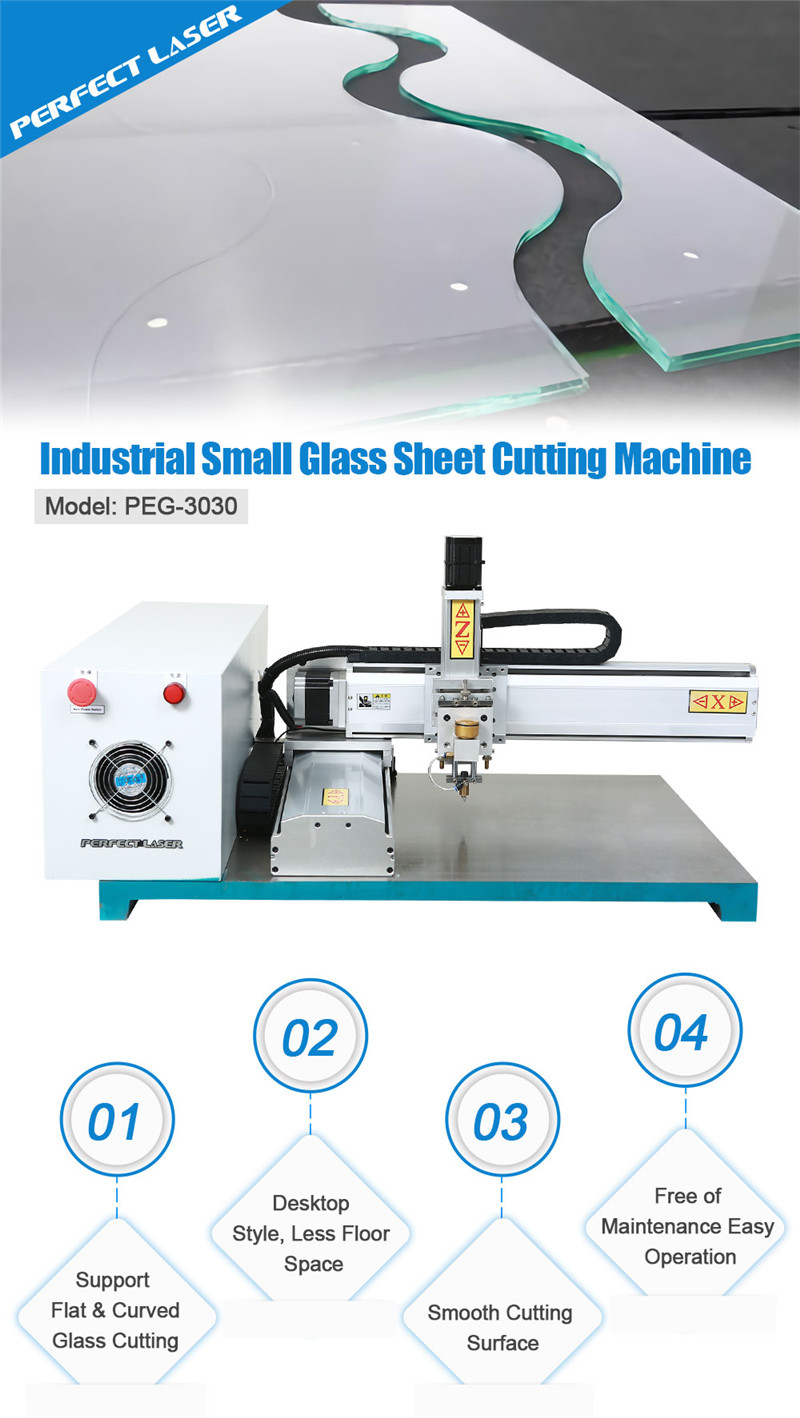

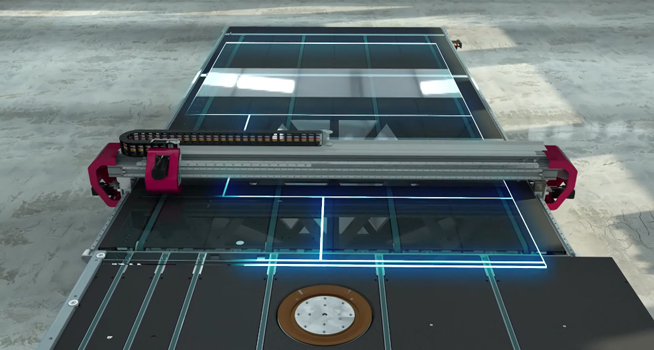

Illustrative image related to glass cutter machine

How can artists and crafters benefit from using glass cutter machines?

Artists and crafters utilize glass cutter machines to create custom glass art pieces, allowing for intricate designs and unique artistic expressions. These machines simplify the cutting process, making it easier for creators to work with various glass thicknesses and shapes. Buyers in the art and craft sector should focus on ergonomic designs and a variety of cutting tools to accommodate different artistic styles and preferences.

In what ways do glass cutter machines support the electronics and appliances sector?

In the electronics and appliances industry, glass cutter machines are critical for manufacturing glass components used in displays and other products. The precision cutting capabilities of these machines help to increase production efficiency and minimize waste. B2B buyers should look for machines that offer automation features and high precision to meet the demands of fast-paced production environments.

How does glass recycling benefit from the use of glass cutter machines?

Glass recycling operations rely on glass cutter machines to score and cut recycled glass materials into manageable sizes. This process supports sustainability efforts by enabling the reuse of glass while also providing cost savings. Buyers in this sector should prioritize machines that can handle various types and thicknesses of glass, ensuring versatility and efficiency in recycling processes.

3 Common User Pain Points for ‘glass cutter machine’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality Leading to Wasted Materials

The Problem: B2B buyers often face challenges with inconsistent cutting quality when using glass cutter machines. This inconsistency can stem from various factors, such as improper scoring technique, inadequate tools, or worn-out cutting wheels. In industries where precision is paramount, such as glass manufacturing or custom glass fabrication, even minor discrepancies can lead to significant material waste and increased operational costs. Buyers may find that their projects require additional grinding or adjustments, further complicating the workflow.

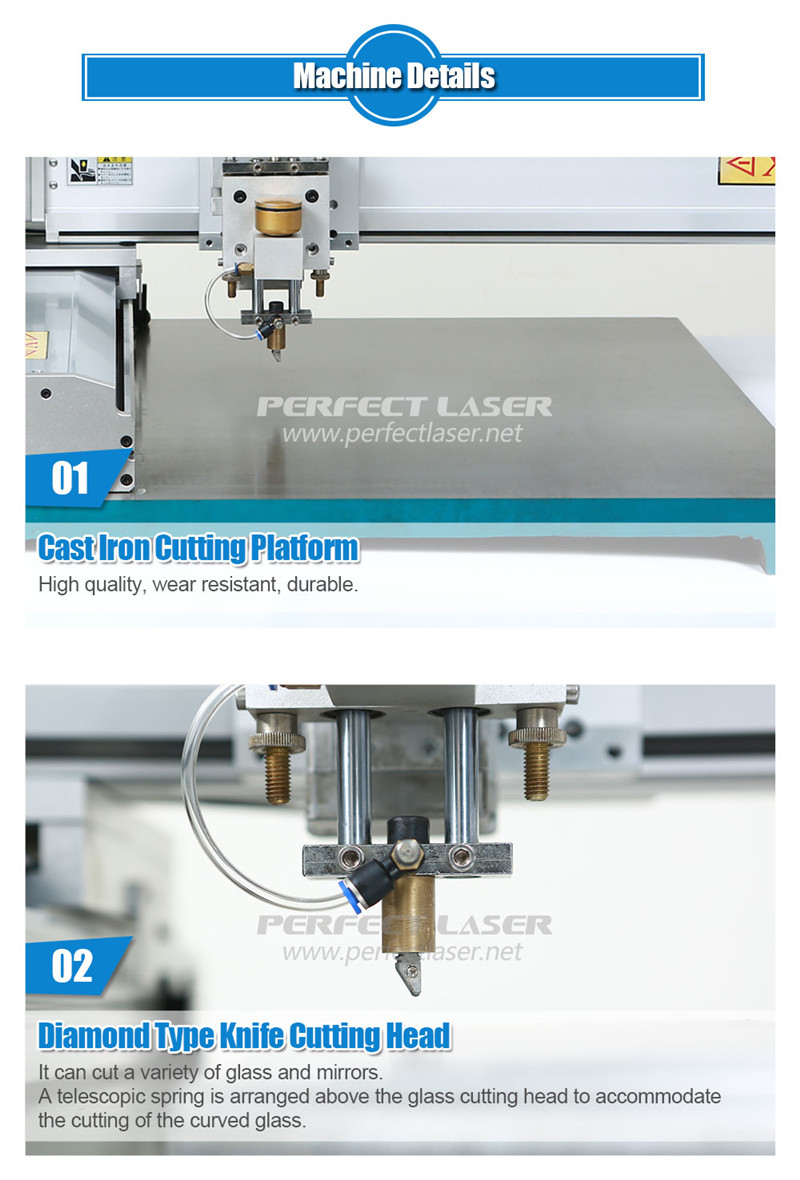

The Solution: To ensure consistent cutting quality, B2B buyers should prioritize sourcing high-quality glass cutter machines with features that support precision. For instance, selecting machines with ergonomic designs that maintain an optimal cutting angle can significantly improve scoring accuracy. Additionally, investing in glass cutters that utilize carbide wheels or advanced scoring systems can enhance durability and cutting efficiency. Regular maintenance, including replacing worn wheels and lubricating moving parts, is essential for optimal performance. Training staff on proper scoring techniques and implementing quality control measures can also help mitigate inconsistencies.

Scenario 2: Operator Fatigue and Safety Concerns During Extended Use

The Problem: Operators frequently experience hand fatigue and discomfort when using traditional glass cutter machines, especially during extended work sessions. This fatigue not only affects productivity but can also lead to safety concerns, as tired operators may become less attentive, increasing the risk of accidents. In industries that require repetitive cutting tasks, such as stained glass art or construction, the toll on physical well-being can be significant.

The Solution: To address operator fatigue, B2B buyers should consider investing in ergonomic glass cutter machines designed to minimize strain. Features such as comfortable grips, adjustable cutting pressure, and reduced weight can make a substantial difference. Additionally, implementing rotational shifts among operators can help distribute the workload and reduce the risk of fatigue. Providing training on proper body mechanics during cutting tasks, alongside regular breaks to prevent repetitive strain injuries, can further enhance workplace safety and operator comfort.

Scenario 3: Difficulty in Achieving Complex Cuts for Custom Projects

The Problem: B2B buyers often struggle with achieving intricate and complex cuts needed for custom projects, particularly in artistic glass applications or architectural designs. Traditional glass cutter machines may lack the versatility required to handle a variety of shapes and sizes, leading to frustration and potential project delays. This issue can be particularly challenging for businesses that rely on unique, bespoke glass products, as the inability to execute complex cuts can limit creativity and customer satisfaction.

The Solution: To overcome this challenge, buyers should look for advanced glass cutter machines that offer specialized features, such as automated cutting systems or circle-cutting capabilities. These tools can enable precise and intricate designs while streamlining the cutting process. Investing in modular systems that can be adapted for various project requirements allows for greater flexibility and creativity. Additionally, utilizing computer-aided design (CAD) software in conjunction with the glass cutter can facilitate complex cut planning, ensuring that operators have clear guidelines to follow. Regular training sessions on utilizing these advanced features can empower operators to maximize their tools’ capabilities, ultimately leading to improved project outcomes and customer satisfaction.

Strategic Material Selection Guide for glass cutter machine

When selecting materials for glass cutter machines, it’s essential to consider their properties, advantages, and limitations. The choice of material can significantly affect performance, durability, and overall cost, making it a critical decision for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in glass cutter machines.

What Are the Key Properties of Aluminum in Glass Cutter Machines?

Aluminum is a popular choice for various components of glass cutter machines due to its lightweight and corrosion-resistant properties. With a temperature rating of approximately 660°C, aluminum can withstand moderate heat without deforming. Its excellent strength-to-weight ratio makes it suitable for handheld and automated cutting systems.

Pros: Aluminum is durable, lightweight, and resistant to rust, making it ideal for portable glass cutters. Its lower cost compared to other metals allows manufacturers to keep production costs down.

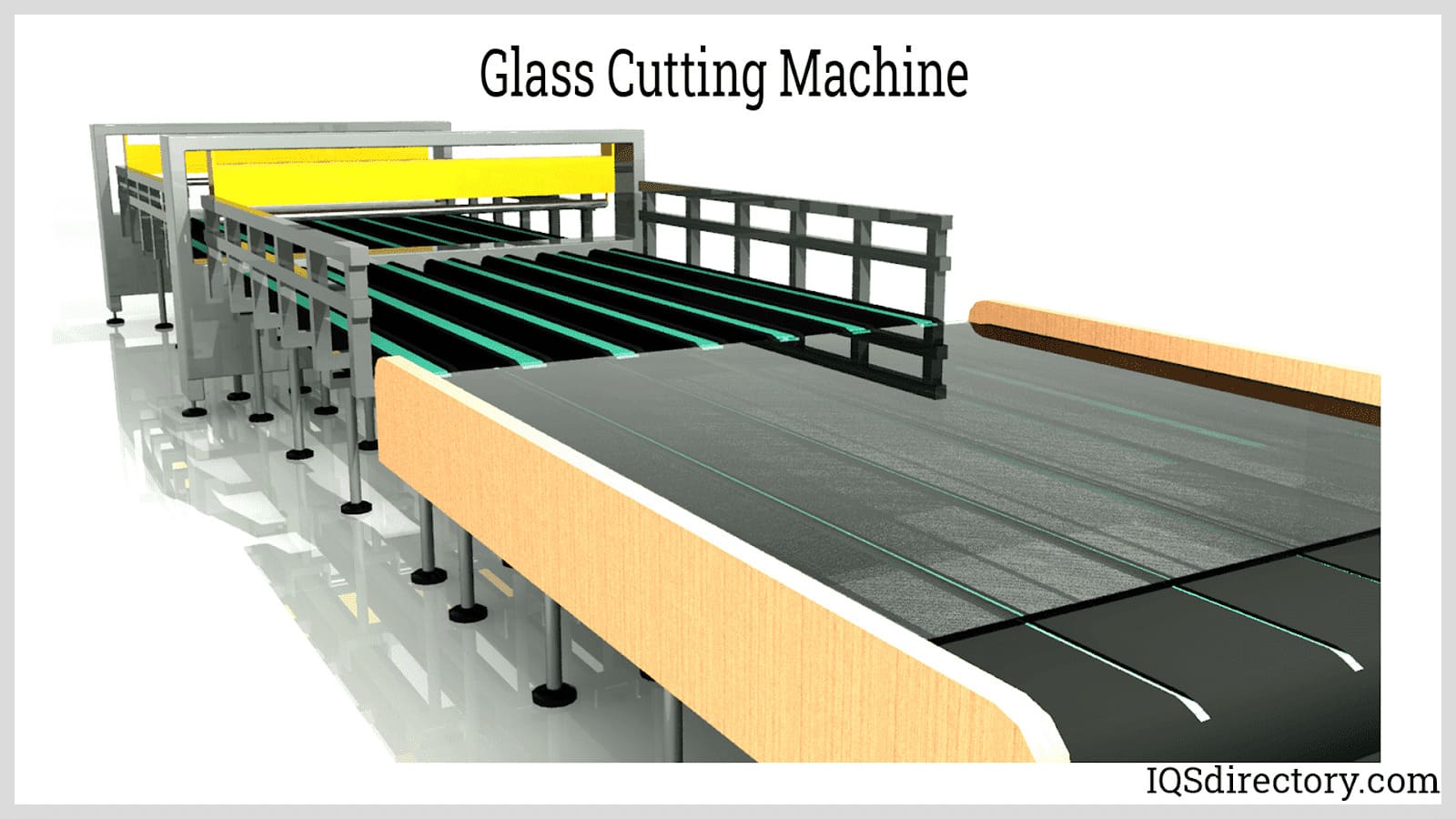

Illustrative image related to glass cutter machine

Cons: While aluminum is strong, it is not as durable as steel, particularly under high-pressure applications. It may also require additional coatings for enhanced wear resistance.

Impact on Application: Aluminum is compatible with various cutting media, including stained glass and tempered glass, making it versatile for different projects.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should ensure that aluminum components meet these standards for quality and safety.

How Does Steel Compare as a Material for Glass Cutter Machines?

Steel, particularly high-carbon steel, is often used for cutting wheels and blades due to its exceptional hardness and durability. It can withstand high pressure and temperature, making it suitable for heavy-duty applications.

Pros: Steel offers superior strength and longevity, making it ideal for high-performance glass cutting machines. Its ability to maintain sharp edges over time reduces the frequency of replacements.

Cons: Steel is heavier than aluminum, which may impact the portability of handheld devices. Additionally, it is prone to corrosion unless properly treated or coated.

Impact on Application: Steel is highly effective for cutting thicker glass types, ensuring clean and precise cuts. It is particularly beneficial in industrial settings where high-volume cutting is required.

Considerations for International Buyers: Buyers should look for steel components that comply with local regulations and standards. In regions like Europe, adherence to EN standards is essential for quality assurance.

What Advantages Does Plastic Offer for Glass Cutter Machines?

Plastic materials, such as polycarbonate or acrylic, are increasingly used in non-critical components of glass cutter machines. They are lightweight, flexible, and can be molded into various shapes.

Pros: Plastic is cost-effective and can be produced in various colors and designs, making it aesthetically appealing. It is also resistant to corrosion and less likely to cause damage to glass surfaces.

Cons: Plastic lacks the strength and durability of metals, making it unsuitable for high-stress applications. It may also degrade over time under UV exposure.

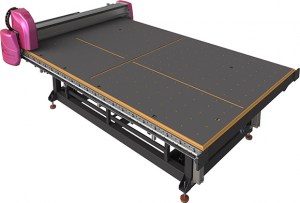

Illustrative image related to glass cutter machine

Impact on Application: Plastic components are often used in handles and guards, providing a lightweight option that enhances user comfort during operation.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with safety standards, especially in regions with strict regulations on manufacturing materials.

Why Is Composite Material Gaining Popularity in Glass Cutter Machines?

Composite materials, often a blend of plastic and metal fibers, are becoming popular due to their unique properties. They offer a balance between strength and weight, making them suitable for various applications.

Pros: Composites are lightweight yet robust, providing excellent performance in terms of durability and resistance to wear. They can also be engineered for specific applications, enhancing versatility.

Cons: The manufacturing process for composites can be more complex and costly than for traditional materials. Additionally, they may require specialized equipment for repairs.

Impact on Application: Composites are ideal for high-performance cutting machines that require precision and durability, particularly in intricate designs.

Illustrative image related to glass cutter machine

Considerations for International Buyers: Buyers should verify that composite materials meet international standards for safety and performance, particularly in regions with stringent regulations.

Summary Table of Material Selection

| Material | Typical Use Case for glass cutter machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Handheld and automated cutters | Lightweight and corrosion-resistant | Less durable than steel | Low |

| Steel | High-performance cutting wheels | Superior strength and longevity | Heavier and prone to corrosion | Med |

| Plastic | Handles and guards | Cost-effective and flexible | Lacks strength for high-stress use | Low |

| Composite | High-performance cutting machines | Lightweight yet robust | Complex manufacturing process | High |

This strategic material selection guide provides valuable insights for B2B buyers, allowing them to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for glass cutter machine

What Are the Main Stages of Manufacturing Glass Cutter Machines?

The manufacturing process of glass cutter machines involves several key stages, ensuring that the final product meets the high standards required in the industry. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, typically including metals for the frame and cutting mechanisms, as well as specialized materials like carbide for the cutting wheels. Quality checks are performed on these materials to ensure they meet specific standards for durability and performance.

-

Forming: In this stage, the prepared materials are shaped into components. Techniques such as precision machining, stamping, and molding are commonly used to create the various parts of the glass cutter. Advanced CNC (Computer Numerical Control) machines are often employed to ensure accuracy and consistency in shaping components.

-

Assembly: The assembly stage involves bringing together all the individual components into a complete machine. This can include the integration of ergonomic features, such as handles and grips, as well as the installation of cutting wheels and lubrication systems. Automated assembly lines may be used to enhance efficiency, but skilled technicians also play a crucial role in ensuring that everything is assembled correctly.

-

Finishing: Once assembled, the glass cutter machines undergo finishing processes such as polishing, coating, and painting to enhance aesthetics and protect against corrosion. These processes also contribute to the overall durability of the product, ensuring it can withstand the rigors of use in various environments.

How Is Quality Assurance Implemented in Glass Cutter Machine Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for glass cutter machines, involving adherence to international standards and rigorous testing procedures.

-

International Standards: Many manufacturers aim to comply with ISO 9001, which outlines requirements for a quality management system. This certification demonstrates a commitment to consistent quality, customer satisfaction, and continuous improvement. Additionally, compliance with industry-specific standards such as CE marking (in Europe) or API standards can be crucial for market entry in different regions.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet predefined quality standards before they enter the production line.

– In-Process Quality Control (IPQC): During the manufacturing stages, random inspections are conducted to monitor processes and identify any defects early.

– Final Quality Control (FQC): Once the machines are fully assembled, a thorough inspection is performed, including functionality tests and aesthetic evaluations, to ensure they meet all specifications. -

Common Testing Methods: Various testing methods are employed to assess the performance and durability of glass cutter machines. These may include:

– Functional Testing: Evaluating the cutting efficiency and precision of the machine.

– Durability Testing: Subjecting the machine to prolonged use to identify any weaknesses.

– Safety Testing: Ensuring that all safety features function correctly to protect the user.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to ensure product reliability and performance.

-

Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control practices. An on-site visit allows buyers to observe the production environment, evaluate machinery, and assess quality control measures firsthand.

-

Quality Assurance Reports: Requesting detailed QA reports from suppliers can help buyers understand how quality is maintained throughout the manufacturing process. These reports should outline compliance with international standards and include results from various testing phases.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be conducted at various stages of the manufacturing process, ensuring that the products meet the buyer’s specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of several nuances related to quality control when sourcing glass cutter machines.

-

Cultural Differences: Quality standards and practices can vary significantly across regions. Buyers should familiarize themselves with local manufacturing practices and quality expectations to ensure compatibility with their own standards.

-

Import Regulations: Different countries have specific regulations regarding product safety and quality. Understanding these regulations is crucial to avoid complications during importation. For instance, CE marking is essential for products sold in the European market, while other regions may have different certification requirements.

-

Communication with Suppliers: Effective communication with suppliers is vital for ensuring that quality expectations are clearly understood and met. Buyers should establish clear quality criteria upfront and maintain open channels for discussing any quality concerns that arise during production or delivery.

-

Long-term Relationships: Building long-term relationships with reliable suppliers can facilitate better quality assurance. As suppliers become familiar with a buyer’s quality expectations, they are more likely to prioritize those standards in their manufacturing processes.

Conclusion

The manufacturing processes and quality assurance measures for glass cutter machines are integral to delivering high-quality products that meet the demands of international markets. B2B buyers should prioritize suppliers who adhere to rigorous manufacturing standards and demonstrate a commitment to quality through transparent practices and effective communication. By understanding the intricacies of manufacturing and quality control, buyers can make informed decisions that enhance their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass cutter machine’

In the competitive landscape of glass processing, selecting the right glass cutter machine is crucial for optimizing production efficiency and ensuring quality outputs. This guide provides a structured approach to sourcing the most suitable glass cutter machine for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the types of glass you will be cutting, the thickness range, and the complexity of cuts required. Consider whether you need features such as automated cutting systems or manual tools, which can significantly affect your workflow and efficiency.

- Glass Types: Identify if you will be working with standard glass, tempered glass, or specialty types like stained glass.

- Cutting Precision: Assess the precision needed for your projects, which may dictate the choice of cutting technology.

Step 2: Research and Compare Available Models

Take the time to research various models available in the market. Different glass cutter machines offer diverse features and capabilities, so comparing them will help you identify which models align with your specifications.

- User Reviews: Read user reviews and testimonials to gauge real-world performance and reliability.

- Brand Reputation: Focus on established brands known for quality and customer support in the glass cutting industry.

Step 3: Evaluate Potential Suppliers

Before making a purchase, vet potential suppliers thoroughly. A reliable supplier will provide you with the necessary support and ensure the quality of the machines they offer.

- Company Profiles: Request detailed company profiles and case studies to understand their experience and market presence.

- References: Ask for references from other B2B buyers in similar industries or regions to validate the supplier’s credibility.

Step 4: Verify Certifications and Compliance

Ensure that the machines meet industry standards and certifications relevant to your region. Compliance with safety and quality regulations is essential to avoid operational disruptions.

- Safety Standards: Check for compliance with international safety standards, which can vary by region, especially in markets like Europe and the Middle East.

- Warranty and Support: Look for suppliers that offer a comprehensive warranty and after-sales support to address any issues that may arise.

Step 5: Assess Cost vs. Value

While price is an important factor, it should not be the sole determinant in your decision-making process. Evaluate the total cost of ownership, including maintenance, operational costs, and potential productivity gains.

- Initial Costs: Compare the upfront costs of different models against their features and expected lifespan.

- Long-term Value: Consider the machine’s efficiency, reliability, and how it aligns with your production goals to determine its overall value.

Step 6: Request Demonstrations or Samples

If possible, request a demonstration of the glass cutter machine or seek samples of cuts made by the machine. This firsthand experience can help you assess the machine’s performance and ease of use.

- Functionality Test: Evaluate how well the machine performs the tasks you require, focusing on precision and ease of operation.

- Operator Feedback: If your team will be using the machine, involve them in the evaluation process to gather insights on usability.

Step 7: Finalize Your Decision and Negotiate Terms

Once you have selected a suitable supplier and model, finalize your decision. Negotiate the terms of purchase, including price, delivery timelines, and payment options.

Illustrative image related to glass cutter machine

- Contract Details: Ensure all aspects of the purchase agreement are clear, including warranties and service agreements.

- Payment Options: Discuss flexible payment options that suit your budget and cash flow requirements.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing glass cutter machines, ensuring they select equipment that meets their operational needs and enhances productivity.

Comprehensive Cost and Pricing Analysis for glass cutter machine Sourcing

What Are the Key Cost Components for Glass Cutter Machines?

When analyzing the cost structure for sourcing glass cutter machines, several key components must be taken into account. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects the overall cost. High-quality steel or carbide for cutting wheels can increase the initial price but improve durability and performance. Additional components, such as ergonomic grips and lubrication systems, also contribute to material costs.

-

Labor: Labor costs vary by region and can influence pricing. In countries with higher labor costs, such as Germany, manufacturers may charge more for their machines. Conversely, sourcing from regions with lower labor costs can offer savings but may raise concerns regarding quality.

-

Manufacturing Overhead: This includes costs related to the operation of the manufacturing facility, such as utilities and depreciation. Efficient production processes can help minimize these costs, affecting the final price.

-

Tooling: The investment in specialized tools for manufacturing specific designs can be significant. Custom tooling for unique cutter shapes or functionalities will increase the upfront costs but can provide a competitive advantage in niche markets.

-

Quality Control: Implementing rigorous QC processes ensures that each machine meets industry standards. This may involve additional costs for testing and certification, which should be factored into pricing.

-

Logistics: Shipping costs vary greatly depending on the destination, mode of transport, and the volume of the order. For international buyers, understanding the logistics involved is crucial to avoid unexpected expenses.

-

Margin: The profit margin that suppliers add to their costs can vary based on market conditions, competition, and perceived value. Buyers should be aware of this when negotiating prices.

How Do Price Influencers Impact Glass Cutter Machine Sourcing?

Several factors can influence the pricing of glass cutter machines, particularly for international B2B buyers. Understanding these can help in making informed purchasing decisions.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Buyers should assess their needs to determine the optimal order size to benefit from volume discounts.

-

Specifications and Customization: Machines tailored to specific needs may come at a premium. Custom features such as advanced cutting systems or additional safety mechanisms can significantly increase costs.

-

Material Quality and Certifications: Machines made from premium materials with industry certifications tend to be priced higher. Buyers should consider the long-term benefits of investing in quality equipment versus opting for lower-priced alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) can help buyers manage costs effectively. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting the overall price.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing glass cutter machines, buyers should consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Leverage potential future business to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, durability, and operational efficiency. A higher initial investment may lead to lower long-term costs.

-

Understand Pricing Nuances for International Markets: For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics, import tariffs, and exchange rates is essential for accurate cost assessments.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows buyers to compare prices and terms, ensuring they secure the best deal available.

-

Stay Informed on Market Trends: Keeping abreast of industry trends can help buyers anticipate price changes and make timely purchasing decisions.

By understanding these cost components, price influencers, and effective negotiation strategies, B2B buyers can make informed decisions when sourcing glass cutter machines, leading to better value and operational efficiency.

Alternatives Analysis: Comparing glass cutter machine With Other Solutions

Understanding Alternatives in Glass Cutting Solutions

When considering glass cutting solutions, it’s essential to evaluate not only the glass cutter machine but also various alternatives that may suit different operational needs and budgets. The right choice can depend on factors such as performance, cost, ease of implementation, and maintenance requirements. Below is a comparison of the glass cutter machine against two viable alternatives: handheld glass cutters and automated cutting systems.

Comparison Table

| Comparison Aspect | Glass Cutter Machine | Handheld Glass Cutter | Automated Cutting System |

|---|---|---|---|

| Performance | High precision for various shapes | Good for simple cuts, less precision | Extremely high precision, ideal for complex designs |

| Cost | Moderate ($50-$200) | Low ($10-$100) | High ($500-$5000) |

| Ease of Implementation | Easy to set up and use | Very easy, portable | Requires training and installation |

| Maintenance | Low maintenance, replaceable parts | Minimal maintenance | Moderate, regular calibration needed |

| Best Use Case | Small to medium projects | Small DIY projects | Large-scale production and intricate designs |

Detailed Breakdown of Alternatives

Handheld Glass Cutter

Handheld glass cutters are simple tools that allow for manual scoring and breaking of glass. They are highly portable and cost-effective, making them an excellent choice for small DIY projects or hobbyists. However, their performance can be limited when it comes to precision and the ability to handle larger pieces of glass. Users must also have a steady hand and experience to achieve clean cuts, which can be a downside for those unfamiliar with glass cutting techniques.

Illustrative image related to glass cutter machine

Automated Cutting System

Automated cutting systems represent the pinnacle of glass cutting technology, offering unparalleled precision and efficiency. These systems are capable of producing intricate designs and handling large volumes of glass with ease. However, the initial investment is significantly higher, which may not be feasible for smaller businesses or individual artisans. Additionally, these systems require specialized training for operators and regular maintenance, which can complicate their implementation in smaller operations.

Conclusion: Choosing the Right Glass Cutting Solution

When selecting the appropriate glass cutting solution, B2B buyers must consider their specific operational needs, budget constraints, and the scale of their projects. For small to medium-scale operations, a glass cutter machine offers a balanced mix of performance and cost-efficiency. In contrast, if the focus is on intricate designs or large-scale production, investing in an automated cutting system may yield better long-term benefits despite the higher upfront costs. Handheld glass cutters remain a practical option for smaller DIY tasks or budget-conscious buyers. Ultimately, the right choice should align with the buyer’s production goals and available resources.

Essential Technical Properties and Trade Terminology for glass cutter machine

What Are the Key Technical Properties of a Glass Cutter Machine?

Understanding the technical specifications of glass cutter machines is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties to consider:

1. Material Grade

The material used in the construction of glass cutters significantly affects their durability and performance. High-grade materials, such as carbide or high-speed steel, are often used for cutting wheels, as they provide sharper edges and longer lifespan. For buyers, opting for higher material grades ensures that the tools can withstand rigorous use, resulting in less frequent replacements and lower long-term costs.

2. Cutting Angle

The optimal cutting angle, typically maintained at 90 degrees, is vital for achieving clean and precise cuts. Machines designed to maintain this angle consistently help reduce the risk of chipping or cracking glass, which is particularly important for high-value projects. Buyers should prioritize machines that offer adjustable or fixed cutting angles to meet their specific needs.

3. Scoring Pressure

Consistent scoring pressure is essential for producing accurate cuts without damaging the glass. Machines that feature adjustable pressure settings allow users to tailor their approach based on glass thickness and type. This capability minimizes waste and enhances the quality of finished products, making it a critical specification for B2B buyers focused on efficiency.

Illustrative image related to glass cutter machine

4. Ease of Use

B2B buyers should consider the ergonomics of glass cutter machines, such as designs that reduce hand fatigue and enhance comfort during prolonged use. Features like pistol grips, lightweight designs, and self-lubricating mechanisms can significantly improve user experience. A machine that is easy to use not only increases productivity but also reduces the learning curve for new operators.

5. Compatibility with Cutting Systems

Many glass cutter machines are designed to work with various cutting systems, such as automated or manual setups. Understanding compatibility is essential for buyers who may need to integrate the cutter with existing equipment. This flexibility can lead to more efficient operations and reduced capital expenditures on additional tools.

6. Warranty and Support

A robust warranty and accessible customer support are indicators of a manufacturer’s confidence in their product. B2B buyers should seek machines that come with comprehensive warranties, as this can provide peace of mind regarding potential defects or issues. Additionally, reliable customer support can facilitate smoother operations and quicker resolutions to problems.

What Are Common Trade Terms Used in the Glass Cutting Industry?

Familiarizing yourself with industry terminology is equally important for making informed purchasing decisions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the glass cutting industry, understanding OEM relationships can help buyers ensure they are sourcing high-quality components and accessories compatible with their machines.

Illustrative image related to glass cutter machine

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory levels effectively and avoid overstocking or underordering, which can impact cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. By issuing an RFQ, buyers can compare prices and terms from multiple suppliers, enabling them to negotiate better deals and ensure they are receiving competitive offers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms is essential for B2B buyers to clarify shipping costs, risk, and delivery responsibilities, thereby preventing disputes and ensuring smooth transactions.

5. Lead Time

Lead time is the period between placing an order and receiving it. For glass cutter machines, knowing the lead time can help buyers plan their projects effectively and manage client expectations.

6. Service Level Agreement (SLA)

An SLA is a contract that outlines the expected service levels between a supplier and a buyer. This is particularly important in B2B relationships, as it defines the quality and timeliness of service, ensuring that both parties have clear expectations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing glass cutter machines, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the glass cutter machine Sector

What Are the Key Trends Shaping the Global Glass Cutter Machine Market?

The glass cutter machine market is experiencing notable growth driven by various global factors. Increasing demand for precision in glass cutting, especially in architectural and artistic applications, is prompting advancements in technology. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focused on sourcing machines that enhance operational efficiency and reduce waste. Emerging technologies, such as automated cutting systems and ergonomic designs, are becoming essential features. For instance, products that maintain a consistent scoring angle and pressure are gaining popularity, as they minimize user fatigue and improve accuracy.

In addition to technological advancements, the global trend toward customization is reshaping sourcing strategies. Buyers are looking for machines capable of handling diverse glass types and thicknesses, which has led to an expansion in product offerings. Furthermore, the rise of e-commerce platforms is facilitating easier access to suppliers, allowing international buyers to compare products and prices seamlessly. As the market evolves, understanding these dynamics will be crucial for B2B buyers aiming to make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Influencing the Glass Cutter Machine Sector?

Sustainability is becoming a core concern within the glass cutter machine sector, reflecting a broader shift in B2B procurement practices. Buyers are increasingly prioritizing machines that have a lower environmental impact, both in terms of production and operational efficiency. This includes sourcing equipment that utilizes renewable materials and minimizes energy consumption during use.

Ethical supply chains are also gaining traction. B2B buyers are expected to ensure that their suppliers adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and specific green certifications for materials used in machine production can serve as indicators of a supplier’s commitment to sustainability.

Investing in machines that are designed with sustainability in mind not only aligns with corporate social responsibility goals but can also lead to cost savings through reduced waste and energy efficiency. As global regulations tighten and consumer preferences shift towards sustainable products, the importance of these considerations in sourcing will only increase.

How Has the Glass Cutter Machine Market Evolved Over Time?

The evolution of glass cutter machines can be traced back to manual tools used by artisans centuries ago. Initially, these tools were simple hand-held devices that required significant skill and practice. However, as the demand for glass in construction and decorative arts grew, so did the need for more efficient and precise cutting tools.

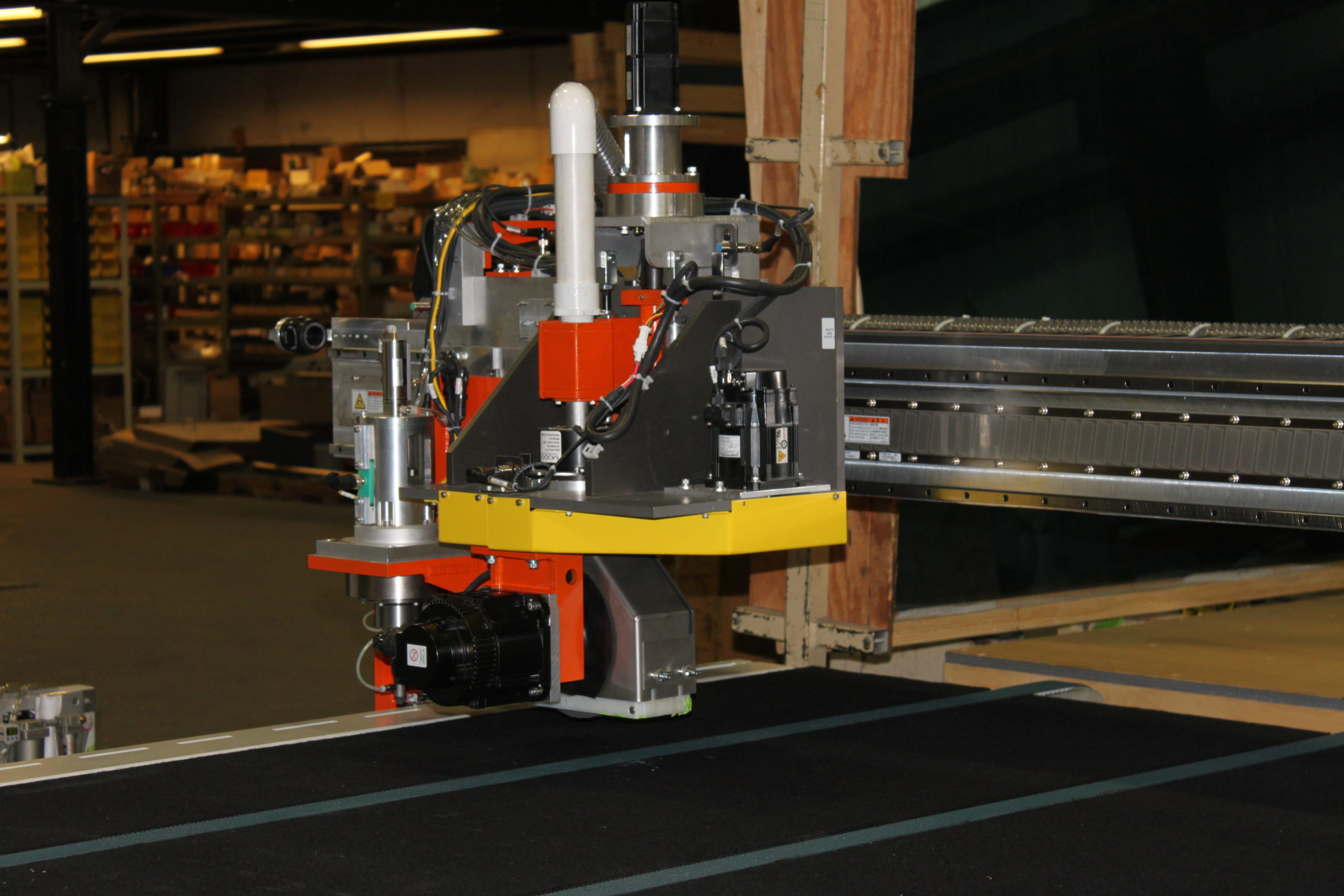

Illustrative image related to glass cutter machine

The introduction of powered glass cutters revolutionized the industry, enabling faster production rates and more intricate designs. Over the years, technological advancements have continued to shape the market, with the development of automated cutting systems that enhance precision and reduce waste. Today, modern glass cutter machines integrate smart technologies, including programmable settings and user-friendly interfaces, catering to the needs of a diverse range of industries. This ongoing evolution highlights the importance of adaptability and innovation in meeting the demands of a global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of glass cutter machine

-

How do I choose the right glass cutter machine for my business needs?

Selecting the right glass cutter machine depends on your specific requirements, including the types of glass you work with, the volume of production, and the complexity of the cuts needed. For intricate designs, consider machines that offer precision cutting capabilities and adjustable settings. Additionally, evaluate the machine’s durability and warranty options. It’s also beneficial to consult with suppliers who can provide demonstrations or samples to ensure the machine meets your expectations. -

What are the key features to look for in a glass cutter machine?

When sourcing a glass cutter machine, look for features such as adjustable scoring pressure, ergonomic design to reduce hand fatigue, and the ability to maintain a consistent cutting angle. Machines with carbide cutting wheels tend to offer longer life and cleaner cuts. If you plan to work with larger glass pieces, ensure the machine can accommodate various sizes. Furthermore, consider additional functionalities like automated cutting systems for increased efficiency. -

What customization options are available for glass cutter machines?

Many manufacturers offer customization options for glass cutter machines to meet specific business needs. This may include modifications in size, cutting speed, or additional features tailored to your projects. Discuss your requirements with potential suppliers to explore available options. Customization can enhance productivity and align the machine’s capabilities with your operational goals, ultimately resulting in better efficiency and output quality. -

What is the minimum order quantity (MOQ) for glass cutter machines?

The minimum order quantity (MOQ) for glass cutter machines can vary significantly between suppliers. Some manufacturers may have an MOQ of one machine, while others may require bulk orders to offer competitive pricing. It’s advisable to inquire directly with suppliers about their MOQ policies and any potential discounts for larger orders. Understanding these terms can help you budget effectively and negotiate better deals. -

What payment terms can I expect when purchasing glass cutter machines internationally?

Payment terms for international purchases of glass cutter machines typically vary by supplier and country. Common options include advance payment, letters of credit, or payment upon delivery. It’s crucial to clarify these terms before finalizing the order. Additionally, consider using escrow services for added security during transactions, ensuring that funds are released only when you receive the machinery as agreed. -

How can I ensure quality assurance for my glass cutter machines?

To ensure quality assurance, verify that the manufacturer follows international quality standards, such as ISO certifications. Request detailed product specifications and, if possible, samples or test runs to evaluate performance. Additionally, inquire about the warranty and after-sales support offered by the supplier. Regular inspections during production can also help maintain quality and ensure that the machines meet your specifications. -

What logistics considerations should I keep in mind when importing glass cutter machines?

Logistics play a critical role in importing glass cutter machines. Key considerations include shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling machinery to facilitate the import process. Ensure that all shipping documentation is accurate to avoid delays at customs. Additionally, plan for potential storage needs upon arrival, especially if the machines are part of a larger batch. -

How do I vet suppliers for glass cutter machines in the international market?

Vetting suppliers involves several steps to ensure reliability and quality. Start by researching their reputation through online reviews, industry forums, and trade associations. Request references from previous clients and check their track record for on-time delivery and customer service. Additionally, consider visiting the supplier’s facility if possible, or arranging a virtual tour. Certifications and compliance with international standards can also indicate a supplier’s credibility and commitment to quality.

Top 4 Glass Cutter Machine Manufacturers & Suppliers List

1. Inland Craft – ScoreOne Glass Cutter

Domain: inlandcraft.com

Registered: 1996 (29 years)

Introduction: {“name”: “ScoreOne glass cutter”, “SKU”: “50050”, “price”: “$74.95”, “key_features”: [“Maintains optimum 90º cutting angle at all times”, “Maintains consistent scoring pressure from start to finish”, “Eliminates hand and wrist fatigue”, “Easier to accurately follow pattern lines”, “Allows comfortable sitting while scoring glass”, “Start and finish scores closer to the glass edge”, “Includes carbid…

2. Edhoy – Glass Cutting Tools

Domain: edhoy.com

Registered: 1997 (28 years)

Introduction: Glass Cutters & Cutting Systems: A wide variety of high-quality cutting tools and equipment for artists, hobbyists, and professionals. Includes traditional handheld cutters, circle cutters, and advanced cutting systems for precision cuts and intricate designs. Products are sourced from trusted brands, ensuring high-quality materials and durability. Ideal for both seasoned glass artists and beginne…

3. Rainbow Art Glass – CJ’s Glass Cutting Oil 8oz.

Domain: shoprainbowartglass.com

Registered: 2018 (7 years)

Introduction: Glass Cutters & Tools – Stained Glass Supplies – Rainbow Art Glass

Key Products:

1. CJ’s Glass Cutting Oil 8oz. – $7.95

2. Value Pistol Grip Glass Cutter Oil Fed Carbide Wheel – $8.88 (Currently Unavailable)

3. Toyo Pistol Grip Glass Cutter w/ CJ’s Cutting Oil – $36.95

4. Toyo Pistol Grip Supercutter w/ TAP Wheel – $35.88

5. Fletcher Pistol Grip Cutter – $56.68

6. Gryphon Studio Pistol Glass Cutt…

4. Wazer – Desktop Waterjet for Glass Cutting

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best CNC machine options for cutting glass include waterjet machines for precision and ease of use, particularly for thick glass (10-12mm). A desktop waterjet, such as the Wazer, can cut up to 12mm thick borosilicate and 19mm thick sodaglass, priced at $9999. For round glass bars, a 4th axis mill or a surface grinder with a diamond wheel is recommended for accuracy. Industrial CNC machines like th…

Strategic Sourcing Conclusion and Outlook for glass cutter machine

In summary, strategic sourcing for glass cutter machines presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The diverse range of glass cutting tools—from handheld devices to advanced cutting systems—allows businesses to select equipment that aligns with their specific project requirements and operational efficiency. Key features such as ergonomic designs, precision cutting capabilities, and reduced waste not only enhance productivity but also improve the overall quality of glasswork.

Investing in high-quality glass cutter machines is essential for companies aiming to stay competitive in the global market. By leveraging strategic sourcing practices, businesses can ensure they acquire the best tools at optimal prices, leading to long-term cost savings and increased customer satisfaction.

Looking ahead, as the demand for customized glass solutions grows, the importance of selecting the right cutting equipment will only intensify. We encourage B2B buyers to explore the latest innovations in glass cutting technology and assess suppliers that offer not only quality products but also comprehensive support services. This proactive approach will empower your business to thrive in the evolving glass industry landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to glass cutter machine

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.