Is Your Fluidized Bed Aquarium Filters Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for fluidized bed aquarium filters

In the evolving landscape of aquatic systems, sourcing high-efficiency fluidized bed aquarium filters is a pressing challenge for international B2B buyers. These advanced filtration solutions are crucial for maintaining optimal water quality in both commercial aquaculture and ornamental aquarium setups. However, navigating the diverse market landscape can be daunting due to variations in technology, pricing, and supplier reliability. This comprehensive guide addresses these complexities by providing in-depth insights into the various types of fluidized bed filters, their applications across different industries, and essential criteria for supplier vetting.

By exploring the latest innovations in filtration technology, cost considerations, and the operational benefits of fluidized bed systems, this guide empowers buyers from Africa, South America, the Middle East, and Europe—such as Brazil and Vietnam—to make informed purchasing decisions. Buyers will learn how to evaluate suppliers effectively, understand the implications of product specifications, and ensure compliance with regional standards. Additionally, actionable tips on optimizing filter performance and maintenance will be discussed, allowing businesses to enhance their operational efficiency while reducing environmental impact. By leveraging the knowledge within this guide, B2B buyers can confidently navigate the global market for fluidized bed aquarium filters, securing solutions that meet their unique needs and challenges.

Understanding fluidized bed aquarium filters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Fluidized Bed Filter | Utilizes fine silica sand as media, promotes high surface area. | Aquaculture, ornamental fish farms | Pros: High efficiency, self-cleaning; Cons: Requires precise flow control. |

| Moving Bed Biofilm Reactor (MBBR) | Employs plastic media (K1, Hel-X) in a suspended, fluidized state. | Large-scale aquaculture systems | Pros: Excellent nitrification, space-efficient; Cons: More complex to operate. |

| Undergravel Fluidized Filter | Integrates with substrate, allowing for biological filtration. | Home aquariums, small setups | Pros: Easy installation, low maintenance; Cons: Limited capacity for larger tanks. |

| Sump Fluidized Bed Filter | Combines fluidized bed with sump systems for enhanced filtration. | Professional aquariums, aquaculture | Pros: Customizable, high water turnover; Cons: Requires more space and setup time. |

| Hybrid Fluidized Bed Filter | Merges fluidized bed technology with other filtration methods. | Research facilities, custom setups | Pros: Versatile, tailored filtration; Cons: Higher initial investment. |

What are the Characteristics of Standard Fluidized Bed Filters?

Standard fluidized bed filters are characterized by their use of fine silica sand as the filtration media. This design maximizes the surface area for beneficial bacteria growth, which is crucial for effective nitrification. They are widely used in aquaculture and ornamental fish farms due to their high efficiency in removing toxic ammonia and nitrite. B2B buyers should consider the required flow rates and maintenance needs, as these filters can be sensitive to variations in water flow.

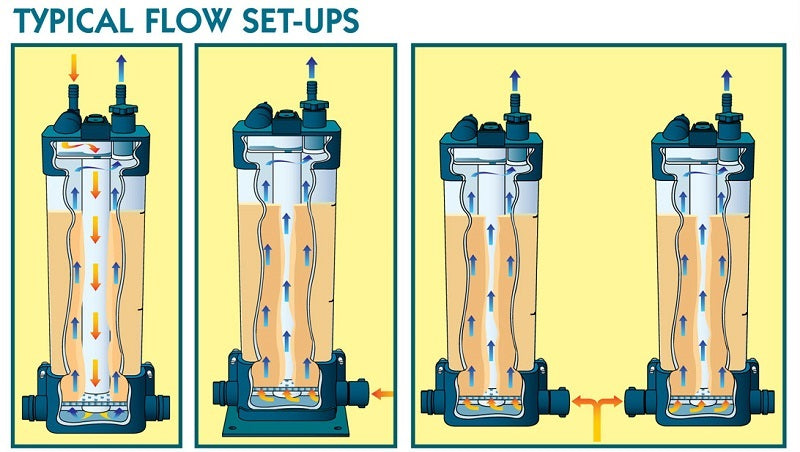

How Do Moving Bed Biofilm Reactors Function?

Moving Bed Biofilm Reactors (MBBR) utilize specialized plastic media that remains suspended in a fluidized state, allowing for optimal contact between water and bacteria. This technology is particularly beneficial in large-scale aquaculture systems, where efficient nitrification is essential for maintaining water quality. When purchasing MBBR systems, buyers should evaluate the complexity of operation and potential space requirements, as these systems can be more intricate than traditional filters.

What are the Benefits of Undergravel Fluidized Filters?

Undergravel fluidized filters integrate directly with the aquarium substrate, providing biological filtration without occupying additional space. They are ideal for home aquariums and smaller setups, offering ease of installation and low maintenance. However, buyers should be aware of their limited capacity for larger tanks, which may necessitate supplementary filtration solutions.

Why Choose Sump Fluidized Bed Filters for Professional Use?

Sump fluidized bed filters combine the advantages of fluidized bed technology with sump filtration systems, allowing for enhanced water quality management. These filters are particularly suited for professional aquariums and aquaculture operations due to their ability to handle high water turnover and customizable setups. Buyers should consider the additional space requirements and the complexity of installation when evaluating these systems.

Illustrative image related to fluidized bed aquarium filters

What Makes Hybrid Fluidized Bed Filters Unique?

Hybrid fluidized bed filters integrate fluidized bed technology with other filtration methods, providing a versatile solution for various applications, including research facilities and custom setups. They allow for tailored filtration processes that can address specific water quality needs. However, buyers should be prepared for a higher initial investment and the need for more advanced maintenance protocols compared to standard filters.

Key Industrial Applications of fluidized bed aquarium filters

| Industry/Sector | Specific Application of fluidized bed aquarium filters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aquaculture | Filtration in commercial fish farms for species like tilapia | Enhances water quality, promotes fish health, and reduces mortality rates | Sourcing efficiency, flow rate compatibility, and maintenance support |

| Water Treatment Facilities | Wastewater treatment in municipal plants | Reduces nitrogen and phosphorus levels, meeting environmental regulations | Compliance with local regulations, filter media durability, capacity |

| Research Institutions | Experimental setups for aquatic biology studies | Provides a controlled environment for research on aquatic ecosystems | Customization options, scalability, and ease of maintenance |

| Marine Parks and Aquariums | Filtration for large-scale public aquariums | Maintains optimal conditions for diverse marine life, enhancing visitor experience | Size and adaptability to various tank designs, energy efficiency |

| Hydroponics and Aquaponics | Integration into nutrient cycling systems | Supports plant growth by improving water quality and nutrient availability | Compatibility with existing systems, filtration media selection |

How Are Fluidized Bed Aquarium Filters Used in Aquaculture?

In the aquaculture industry, fluidized bed aquarium filters are integral for maintaining optimal water quality in fish farms, particularly for high-density species such as tilapia. These filters effectively convert toxic ammonia and nitrite into less harmful nitrate, significantly reducing fish mortality rates. For international buyers, especially in regions like Africa and South America, sourcing filters that ensure high flow rates and efficient nitrification processes is crucial. Additionally, the ability to service these systems easily is a key requirement, as operational downtime can lead to significant losses.

What Role Do Fluidized Bed Filters Play in Water Treatment Facilities?

Municipal water treatment facilities utilize fluidized bed aquarium filters to manage wastewater effectively. These filters help in reducing nitrogen and phosphorus levels, thereby ensuring compliance with stringent environmental regulations. For buyers in the Middle East and Europe, it is essential to consider the durability of filter media and the capacity of the system to handle varying wastewater loads. Furthermore, filters that offer a self-cleaning feature can minimize maintenance efforts and costs, making them an attractive option for large-scale facilities.

How Are Fluidized Bed Filters Used in Research Institutions?

Research institutions leverage fluidized bed aquarium filters for controlled aquatic biology experiments. These filters provide a stable environment, crucial for studying the interactions within aquatic ecosystems. International buyers looking for specialized filtration solutions must ensure that these systems can be customized to meet specific research requirements. Additionally, scalability is vital, as research projects may vary in size and complexity, necessitating adaptable filtration solutions.

What Benefits Do Fluidized Bed Filters Provide for Marine Parks and Aquariums?

In marine parks and public aquariums, fluidized bed filters are employed to maintain high water quality for diverse marine life. These filters enhance the visitor experience by ensuring that aquatic habitats are clean and stable. Buyers in Europe and other regions should focus on filters that can adapt to various tank sizes and configurations, as well as those that offer energy-efficient operation. The ability to maintain optimal conditions is paramount for the health of marine species and the overall success of the facility.

How Are Fluidized Bed Filters Integrated into Hydroponics and Aquaponics?

In hydroponics and aquaponics systems, fluidized bed aquarium filters play a critical role in nutrient cycling. They improve water quality, which is essential for plant growth, by efficiently filtering out waste products. Buyers from emerging markets in South America and Asia should prioritize systems that are compatible with existing hydroponic setups and offer a range of filtration media options. Efficient filtration not only enhances plant health but also contributes to sustainable farming practices, making these systems increasingly valuable in the agricultural sector.

3 Common User Pain Points for ‘fluidized bed aquarium filters’ & Their Solutions

Scenario 1: Managing Ammonia Levels in Aquaculture Systems

The Problem:

B2B buyers in the aquaculture sector often face challenges in managing ammonia levels in their systems. High ammonia concentrations can lead to toxic environments for fish and other aquatic organisms, resulting in decreased health and productivity. This issue is particularly pressing in high-density aquaculture setups where the biological load is significant. Buyers may find that traditional filtration methods are insufficient, leading to fluctuations in water quality and increased mortality rates among stock.

The Solution:

To effectively address ammonia management, buyers should consider integrating fluidized bed aquarium filters into their systems. These filters utilize a unique design that promotes the growth of beneficial bacteria responsible for nitrification, which converts toxic ammonia into less harmful nitrates. When sourcing fluidized bed filters, it is crucial to select models that have a proven track record in aquaculture applications, particularly those with high surface area media, such as K1 or Hel-X. Properly sizing the filter for the system’s water volume and biological load is essential; buyers should consult with manufacturers to ensure optimal flow rates and media specifications. Additionally, regular monitoring of ammonia levels and maintaining an appropriate flow rate will enhance the effectiveness of the filter, ensuring a stable and healthy aquatic environment.

Scenario 2: Space Constraints in Aquatic Facilities

The Problem:

Many B2B buyers operating in urban settings or smaller facilities often encounter space limitations when installing filtration systems. Traditional filters may require significant footprint and headspace, which can restrict operational efficiency and complicate maintenance routines. This challenge is particularly acute in regions where real estate is at a premium, such as in parts of Europe and Asia, where maximizing every square meter is essential for profitability.

The Solution:

Fluidized bed filters are inherently space-efficient due to their vertical design and compact footprint. Buyers should look for models that allow for high media volumes while minimizing the required space. When selecting a fluidized bed filter, it’s beneficial to choose options that are modular, enabling easy integration into existing setups without necessitating extensive redesign. Additionally, buyers can optimize space by considering multi-functional units that combine filtration, aeration, and circulation. Regular maintenance protocols should also be established, emphasizing quick access to components for cleaning or media replacement, thus ensuring that space constraints do not hinder filter performance.

Scenario 3: High Operational Costs and Energy Efficiency

The Problem:

In today’s competitive market, many B2B buyers are pressured to reduce operational costs, particularly in energy consumption. Traditional filtration systems can be energy-intensive, driving up electricity costs and impacting overall profitability. This challenge is exacerbated in regions where energy prices are volatile, such as parts of Africa and South America, making it crucial for buyers to adopt more efficient technologies.

The Solution:

Fluidized bed aquarium filters are known for their energy efficiency, particularly when designed for low flow rates, which maximize contact time with beneficial bacteria while minimizing energy consumption. Buyers should prioritize filters that come with energy-efficient pumps and consider the total cost of ownership rather than just the initial investment. Sourcing energy-efficient equipment can provide long-term savings. Furthermore, implementing automation and monitoring systems can help track energy usage and optimize operational parameters, ensuring that the system runs at peak efficiency. Regular maintenance and timely upgrades of filter components will also contribute to sustained energy efficiency, ultimately lowering operational costs while maintaining water quality.

Strategic Material Selection Guide for fluidized bed aquarium filters

What Are the Common Materials Used in Fluidized Bed Aquarium Filters?

Fluidized bed aquarium filters are essential for maintaining water quality in aquatic environments. The effectiveness of these filters largely depends on the materials used in their construction. Here, we analyze four common materials: polyethylene, PVC, stainless steel, and ceramic media, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyethylene Perform in Fluidized Bed Filters?

Polyethylene is a popular choice for fluidized bed filters due to its lightweight and corrosion-resistant properties. It can withstand temperatures up to 80°C (176°F) and has good chemical resistance, making it suitable for various aquatic environments.

Pros: Polyethylene is durable, cost-effective, and easy to manufacture. Its flexibility allows for intricate designs, which can enhance filtration efficiency.

Illustrative image related to fluidized bed aquarium filters

Cons: While it has good impact resistance, it may not withstand high-pressure applications as effectively as other materials. Over time, exposure to UV light can degrade polyethylene, necessitating protective measures in outdoor installations.

Impact on Application: Polyethylene is compatible with a variety of filtration media, including sand and K1 media. However, it may not be suitable for high-temperature applications.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial, especially for buyers in regions with strict regulations. Polyethylene’s affordability makes it a favored choice in developing markets like Africa and South America.

Illustrative image related to fluidized bed aquarium filters

What Role Does PVC Play in Fluidized Bed Filters?

PVC (Polyvinyl Chloride) is another widely used material in the construction of fluidized bed aquarium filters. It has excellent chemical resistance and can handle temperatures up to 60°C (140°F).

Pros: PVC is lightweight, cost-effective, and easy to install. Its rigidity provides structural integrity, making it suitable for various filter designs.

Cons: PVC can become brittle over time, especially when exposed to UV light, which may limit its lifespan in outdoor applications. Its lower temperature tolerance compared to polyethylene can also be a drawback.

Impact on Application: PVC is ideal for housing and piping in fluidized bed filters, but it may not be suitable for high-temperature or high-pressure environments.

Considerations for International Buyers: Buyers should ensure that PVC products comply with local and international standards. Its low cost makes it attractive for markets in the Middle East and South America.

Illustrative image related to fluidized bed aquarium filters

Why Choose Stainless Steel for Fluidized Bed Filters?

Stainless steel is often selected for its strength and corrosion resistance, particularly in high-performance applications. It can withstand temperatures exceeding 100°C (212°F) and is highly durable.

Pros: Stainless steel offers exceptional longevity and can handle high-pressure situations. Its aesthetic appeal also makes it suitable for high-end aquarium setups.

Cons: The primary drawback is its cost, which is significantly higher than plastic materials. Manufacturing stainless steel components can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is particularly effective in applications requiring high durability and resistance to harsh conditions. It is compatible with various filtration media, including ceramic and sand.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that comply with local standards, especially in regions like Europe where regulations may be stricter.

How Effective Are Ceramic Media in Fluidized Bed Filters?

Ceramic media is often used in fluidized bed filters due to its high surface area and excellent biological filtration capabilities. It can withstand high temperatures and is chemically inert.

Pros: The high surface area of ceramic media promotes beneficial bacterial growth, enhancing the filtration process. It is also durable and resistant to chemical degradation.

Cons: Ceramic media can be more expensive than other materials and may require careful handling to avoid breakage. Its weight can also complicate installation.

Impact on Application: Ceramic media is particularly effective for biological filtration, making it suitable for aquariums with high fish loads.

Considerations for International Buyers: Buyers should consider the sourcing of ceramic media, ensuring it meets international quality standards. Its higher cost may be a factor for buyers in price-sensitive markets.

Summary Table of Material Selection for Fluidized Bed Aquarium Filters

| Material | Typical Use Case for fluidized bed aquarium filters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Housing and piping in filters | Lightweight and corrosion-resistant | UV degradation over time | Low |

| PVC | Structural components and piping | Cost-effective and easy to install | Brittle over time | Low |

| Stainless Steel | High-performance applications | Exceptional durability | High cost and complex manufacturing | High |

| Ceramic Media | Biological filtration media | High surface area for bacteria growth | More expensive and fragile | Medium |

This analysis provides a comprehensive overview of material options for fluidized bed aquarium filters, aiding international B2B buyers in making informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for fluidized bed aquarium filters

Fluidized bed aquarium filters have become a crucial component in maintaining optimal water quality in aquaculture and aquarium systems. For B2B buyers, understanding the manufacturing processes and quality assurance protocols is essential to ensure they are sourcing reliable and effective filtration systems. This section delves into the typical manufacturing stages, key quality control measures, and relevant international standards that buyers should be aware of.

What Are the Main Stages in the Manufacturing Process of Fluidized Bed Aquarium Filters?

The manufacturing process of fluidized bed aquarium filters typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the durability and efficiency of the final product.

Material Preparation: What Materials Are Used?

The primary materials used in fluidized bed filters are high-density polyethylene (HDPE) and polypropylene, known for their resistance to corrosion and chemical degradation. Other components may include specialized media like K1 micro and K1, which provide a high surface area for beneficial bacteria to thrive. During material preparation, suppliers must ensure that all raw materials meet specified quality standards, including proper storage conditions to prevent contamination.

Forming: How Are the Components Shaped?

The forming stage involves shaping the raw materials into the necessary components of the filter. This can include injection molding for plastic parts and extrusion processes for producing filter media. Advanced techniques such as 3D printing may also be employed for prototyping and producing complex geometries. Precision in this stage is vital, as even minor defects can affect the filter’s performance and longevity.

Assembly: What Does the Assembly Process Involve?

After forming, the components are assembled into the final filter unit. This process often involves both manual and automated techniques to ensure efficiency and precision. Key elements such as pumps, valves, and media must be integrated seamlessly to provide optimal fluidization and filtration. During assembly, manufacturers typically perform preliminary checks to confirm that all components fit correctly and function as intended.

Finishing: How Is the Final Product Prepared for Sale?

The finishing stage includes cleaning, surface treatment, and packaging. Filters may undergo a thorough cleaning process to remove any manufacturing residues. Surface treatments, such as UV stabilization, may be applied to enhance durability against environmental factors. Finally, the products are packaged securely to prevent damage during transport. This stage is crucial for ensuring that filters arrive at their destination in perfect condition.

Illustrative image related to fluidized bed aquarium filters

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a critical aspect of the manufacturing process for fluidized bed aquarium filters. Buyers should be familiar with various international and industry-specific standards that govern product quality.

Which International Standards Are Relevant?

ISO 9001 is the most recognized quality management standard globally, emphasizing customer satisfaction and continuous improvement. Manufacturers producing fluidized bed filters should ideally be ISO 9001 certified, indicating that they adhere to strict quality management principles. Other relevant certifications may include CE marking, which signifies compliance with European health, safety, and environmental protection standards.

What Industry-Specific Standards Exist?

In the aquaculture industry, compliance with standards set by the American Petroleum Institute (API) and other relevant organizations ensures that products meet specific performance and safety requirements. These standards help guarantee that the filters are effective in reducing harmful substances in aquatic environments.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential throughout the manufacturing process to identify and rectify issues early on. Common checkpoints include:

Incoming Quality Control (IQC)

At this stage, raw materials are inspected upon arrival to ensure they meet specified quality standards. This includes checking for proper certification, physical properties, and any signs of damage or contamination.

In-Process Quality Control (IPQC)

During the manufacturing process, in-process checks are performed at various stages. This can include monitoring temperatures during molding, ensuring correct assembly techniques, and validating that components are functioning as intended. Regular documentation of these checks helps maintain a consistent quality standard.

Final Quality Control (FQC)

Before the filters are packaged, a final quality control inspection is conducted. This typically involves testing the filters for flow rates, structural integrity, and overall performance. Any defective products are either reworked or discarded to ensure that only high-quality filters reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is crucial to ensure that they are receiving high-quality products. Here are several methods to consider:

What Steps Can Buyers Take to Audit Suppliers?

Conducting an audit of potential suppliers is one effective way to assess their quality control measures. This can involve visiting manufacturing facilities, reviewing their quality management systems, and examining their compliance with relevant standards.

How Important Are Quality Control Reports?

Requesting quality control reports from suppliers is another essential step. These reports should detail the results of IQC, IPQC, and FQC processes, providing transparency about how the filters were manufactured and tested.

Are Third-Party Inspections Beneficial?

Engaging third-party inspection services can also add an extra layer of assurance. These independent organizations can perform inspections and tests on behalf of buyers to confirm that products meet specified quality standards before shipment.

What Are the Specific Quality Control Considerations for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of additional nuances in quality control:

How Do Regional Standards Affect Quality Assurance?

Different regions may have specific regulatory requirements that affect product quality. Buyers should ensure that their suppliers are compliant with both local regulations and international standards to avoid legal complications.

What Role Does Shipping Play in Quality Control?

Shipping methods can impact the integrity of fluidized bed filters. Buyers should discuss shipping options with suppliers to ensure that products are adequately protected during transit, as improper handling can lead to damage and performance issues.

Illustrative image related to fluidized bed aquarium filters

In conclusion, understanding the manufacturing processes and quality assurance protocols for fluidized bed aquarium filters is crucial for B2B buyers. By being informed about manufacturing stages, relevant standards, and quality control measures, buyers can make educated decisions when sourcing these essential filtration systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fluidized bed aquarium filters’

The following guide serves as a comprehensive checklist for B2B buyers looking to source fluidized bed aquarium filters. This resource will help ensure that you make informed decisions and procure filters that meet your operational needs effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Consider factors such as the size of the aquarium, the flow rate needed, and the specific type of media to be used in the filter. This will help in narrowing down the options and ensuring compatibility with your existing systems.

Illustrative image related to fluidized bed aquarium filters

- Flow Rate Requirements: Determine the gallons per hour (GPH) necessary for efficient filtration.

- Media Type: Identify whether you need sand, K1 micro, or another type of media based on your aquaculture objectives.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in fluidized bed aquarium filters. Look for companies with a proven track record in the industry and positive reviews from previous clients.

- Supplier Background: Investigate how long they have been in business and their market presence in your region.

- Product Range: Ensure they offer a variety of filters that align with your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your potential suppliers hold the necessary certifications and adhere to international quality standards. This is crucial for ensuring product reliability and performance.

- ISO Certifications: Look for ISO 9001 or other relevant certifications indicating quality management.

- Environmental Compliance: Check if the suppliers meet environmental regulations, particularly if you operate in regions with strict compliance requirements.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of the fluidized bed filters. Testing samples allows you to assess the product’s quality, performance, and suitability for your specific needs.

- Performance Testing: Evaluate how well the filter performs under simulated conditions similar to your operational environment.

- Material Quality: Inspect the materials used in the construction of the filter for durability and effectiveness.

Step 5: Inquire About Warranty and Support

A robust warranty and reliable customer support are vital considerations when sourcing fluidized bed aquarium filters. This ensures that you have recourse should any issues arise post-purchase.

- Warranty Terms: Understand the duration and coverage of the warranty. A longer warranty typically indicates higher confidence in product quality.

- Technical Support: Confirm that the supplier provides ongoing technical support and assistance, especially during installation and maintenance.

Step 6: Negotiate Pricing and Terms

Engage in discussions with suppliers to negotiate pricing and payment terms. This is a critical step that can significantly impact your overall budget and cash flow.

- Bulk Purchase Discounts: Inquire about discounts for larger orders or long-term commitments.

- Payment Flexibility: Discuss payment terms that align with your financial strategy, such as installment options or deferred payments.

Step 7: Finalize Logistics and Delivery

Once you have agreed on pricing and terms, finalize the logistics of the order, including shipping and delivery timelines. Clear communication at this stage will help avoid delays and misunderstandings.

- Shipping Options: Explore various shipping methods to find the most cost-effective and timely option for your location.

- Tracking and Communication: Ensure that the supplier provides tracking information and maintains open lines of communication throughout the delivery process.

By following this checklist, B2B buyers can streamline the sourcing of fluidized bed aquarium filters and ensure they select the best products for their operational requirements.

Comprehensive Cost and Pricing Analysis for fluidized bed aquarium filters Sourcing

What Are the Key Cost Components in Fluidized Bed Aquarium Filters?

When sourcing fluidized bed aquarium filters, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. High-quality polyethylene and specialized media (such as K1 micro or Hel-X) often command higher prices due to their durability and efficiency. Additionally, the cost of silica sand and any proprietary filter media can vary widely.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it is essential to consider the trade-off with quality control.

-

Manufacturing Overhead: This includes the costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce these overheads, positively influencing the final price.

-

Tooling: Initial tooling costs for custom designs or modifications can be significant. Buyers should factor these into the overall cost, especially if they require specific features or sizes.

-

Quality Control (QC): High-quality filters require rigorous testing and QC processes, which add to the overall production cost. Certifications related to safety and environmental standards can also influence pricing.

-

Logistics: Shipping and handling costs vary based on the distance from the manufacturer and the mode of transport. International buyers should consider these costs, particularly when sourcing from overseas suppliers.

-

Margin: Supplier margins will vary based on market conditions and competition. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Affect Sourcing Decisions for Fluidized Bed Filters?

Several factors can influence pricing when sourcing fluidized bed aquarium filters:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should evaluate their needs against minimum order quantities (MOQ) set by suppliers.

-

Specifications and Customization: Custom filters designed to meet specific requirements may incur additional costs. Buyers should be clear about their needs to avoid unexpected expenses.

-

Quality and Certifications: Filters meeting international quality standards typically cost more. Ensure that any certifications align with your market’s regulatory requirements to avoid compliance issues.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer higher prices but come with assurances of quality and service.

-

Incoterms: Understanding the terms of trade (like FOB, CIF, DDP) can significantly affect total costs. International buyers should be aware of who bears the risk and costs at each stage of transport.

What Are Effective Buyer Tips for Negotiating Fluidized Bed Filter Prices?

Navigating the pricing landscape requires strategic negotiation and cost-efficiency measures:

-

Leverage Volume Discounts: If your business can commit to larger orders, use this as leverage to negotiate better pricing. Suppliers often provide discounts for bulk purchases.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the maintenance, operational, and disposal costs associated with the filters. A lower initial price may lead to higher TCO if the product is not durable or efficient.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide insights into market pricing and help identify the best deals. Establish relationships with multiple vendors for future negotiations.

-

Understand Pricing Nuances for International Sourcing: Factors like currency fluctuations, tariffs, and import duties can impact final costs. Always factor these into your budget to avoid surprises.

-

Request Transparency on Pricing Components: Ask suppliers to break down their pricing structure. Understanding how costs are allocated can help in negotiations and in identifying areas where you can seek cost reductions.

Conclusion

In the competitive landscape of fluidized bed aquarium filters, a thorough understanding of cost structures and pricing influencers is essential for B2B buyers. By employing strategic negotiation tactics and considering the total cost of ownership, businesses can optimize their sourcing decisions, ensuring they receive high-quality products at competitive prices. Always remain informed about market trends and supplier capabilities to make the best sourcing choices.

Alternatives Analysis: Comparing fluidized bed aquarium filters With Other Solutions

When evaluating filtration solutions for aquariums, it’s essential to consider various alternatives to fluidized bed filters. Each method has its strengths and weaknesses, which can significantly impact water quality, operational costs, and overall efficiency. This analysis will compare fluidized bed aquarium filters with two other popular filtration methods: canister filters and hang-on-back (HOB) filters.

| Comparison Aspect | Fluidized Bed Aquarium Filters | Canister Filters | Hang-On-Back (HOB) Filters |

|---|---|---|---|

| Performance | High efficiency in biological filtration; excellent at handling fluctuating ammonia levels | Strong mechanical, chemical, and biological filtration; customizable media options | Good for smaller aquariums; effective for mechanical and biological filtration |

| Cost | Moderate initial investment; potential for long-term savings due to efficiency | Higher initial cost; ongoing media replacement costs | Low to moderate cost; affordable initial investment |

| Ease of Implementation | Requires space and technical setup; installation can be complex | Moderate complexity; requires plumbing and setup | Easy to install; suitable for beginners |

| Maintenance | Low maintenance due to self-cleaning properties; periodic sand replacement needed | Regular maintenance required; media replacement can be cumbersome | Easy to maintain; media cartridges need frequent replacement |

| Best Use Case | Ideal for larger aquariums or aquaculture systems with high bioloads | Versatile for various aquarium sizes; suitable for freshwater and marine setups | Best for small to medium-sized tanks; convenient for hobbyists |

What Are the Advantages and Disadvantages of Canister Filters?

Canister filters are well-regarded for their versatility and high capacity for filtration media. They can accommodate multiple types of filter media, including mechanical, chemical, and biological, which allows for a tailored approach to water quality management. However, the initial investment can be higher, and the setup may require more plumbing and technical knowledge. Regular maintenance is necessary, including cleaning and replacing filter media, which can be time-consuming. Canister filters are best suited for medium to large aquariums where advanced filtration is needed.

How Do Hang-On-Back (HOB) Filters Compare?

Hang-on-back filters are a popular choice among aquarium hobbyists due to their ease of installation and maintenance. They are typically less expensive upfront and can be a great option for smaller tanks. HOB filters provide adequate mechanical and biological filtration, making them suitable for many freshwater setups. However, they may struggle with larger tanks or those with heavy bioloads, as their filtration capacity is limited compared to canister or fluidized bed filters. Regular media replacement is required, which can add to long-term costs and maintenance efforts.

Conclusion: How Should B2B Buyers Choose the Right Aquarium Filter?

When selecting a filtration solution, B2B buyers should assess their specific needs, including tank size, bioload, and maintenance capabilities. Fluidized bed filters excel in high-efficiency biological filtration, making them ideal for larger systems or aquaculture applications. Canister filters offer versatility and strong performance for various setups but come with higher costs and maintenance demands. On the other hand, HOB filters provide an economical and user-friendly option for smaller tanks. Understanding these distinctions will empower buyers to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for fluidized bed aquarium filters

What Are the Key Technical Properties of Fluidized Bed Aquarium Filters?

When evaluating fluidized bed aquarium filters, several technical properties are critical for ensuring optimal performance and longevity. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

1. Material Grade

The materials used in fluidized bed filters, such as polyethylene or high-density polypropylene, significantly impact durability and resistance to chemical degradation. High-quality materials ensure that filters can withstand harsh aquatic environments, prolonging their lifespan and reducing the need for replacements. B2B buyers should prioritize products made from materials that comply with international standards for safety and performance.

2. Flow Rate

Flow rate, measured in gallons per hour (GPH), indicates the volume of water that can be filtered in a given time frame. An optimal flow rate is crucial for effective nitrification, as it affects the contact time between water and beneficial bacteria. Lower flow rates typically enhance filtration efficiency by allowing more time for ammonia and nitrite removal. Buyers should select filters with adjustable flow rates to accommodate varying tank sizes and aquatic life.

3. Surface Area of Filter Media

The surface area of the filter media is vital for biological filtration. Filters with high surface area media, such as K1 micro or Hel-X, provide more attachment sites for beneficial bacteria, enhancing the nitrification process. A filter’s efficiency can be significantly improved by maximizing the surface area, making it a key specification for B2B buyers focusing on performance.

4. Self-Cleaning Mechanism

Many fluidized bed filters feature a self-cleaning mechanism, allowing media to agitate and remove debris naturally. This design reduces maintenance requirements and ensures consistent filtration performance. Buyers should consider filters with effective self-cleaning capabilities to minimize operational downtime and labor costs.

5. Operating Temperature Range

Understanding the operating temperature range of a fluidized bed filter is crucial for compatibility with various aquatic environments. Filters designed to operate effectively within specific temperature ranges can prevent malfunction and ensure optimal performance. B2B buyers should confirm that the filters meet the temperature needs of the fish or plants in their systems.

What Are the Common Trade Terms Related to Fluidized Bed Aquarium Filters?

Familiarity with industry terminology is essential for B2B buyers to navigate the purchasing process effectively. Here are some common trade terms relevant to fluidized bed aquarium filters.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products and ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as understanding MOQ helps in budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is an essential part of the procurement process, enabling buyers to compare offerings and negotiate better deals. A well-structured RFQ can lead to significant cost savings.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and liabilities, ensuring smoother international transactions.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the product. Understanding lead times is crucial for inventory planning and ensuring that business operations run smoothly. B2B buyers should consider lead times when evaluating suppliers to avoid disruptions.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing fluidized bed aquarium filters, ensuring optimal performance and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the fluidized bed aquarium filters Sector

What Are the Current Market Dynamics and Key Trends in Fluidized Bed Aquarium Filters?

The global market for fluidized bed aquarium filters is experiencing robust growth driven by several key factors. Increasing awareness of water quality and aquatic health, particularly among B2B buyers in emerging markets like Africa and South America, is propelling demand. As urbanization accelerates in regions such as Southeast Asia and Latin America, the need for efficient and effective water filtration systems becomes critical, especially in aquaculture and commercial aquarium settings. Furthermore, advancements in filtration technology, including the use of high-surface-area media like K1 and Hel-X, are enhancing the efficiency and effectiveness of these systems, making them more appealing to businesses.

Emerging trends in B2B sourcing include the shift towards digital procurement platforms that facilitate easier access to suppliers and product information. Buyers are increasingly leveraging data analytics to assess supplier performance and product quality, ensuring that they make informed purchasing decisions. Additionally, the adoption of IoT technology for monitoring water quality in real-time is becoming more prevalent, allowing businesses to maintain optimal conditions for aquatic life while reducing operational costs.

How Are Sustainability and Ethical Sourcing Impacting the Fluidized Bed Aquarium Filters Market?

Sustainability has become a pivotal concern in the fluidized bed aquarium filters sector, influencing sourcing strategies and product design. The environmental impact of traditional filtration materials and practices has prompted buyers to seek ‘green’ alternatives. This includes the use of recycled materials in the construction of filters and the adoption of energy-efficient designs that minimize carbon footprints.

Ethical sourcing is equally important, as businesses prioritize suppliers who demonstrate a commitment to sustainable practices and social responsibility. Certifications such as ISO 14001 and other environmental standards are becoming increasingly important for B2B buyers, serving as indicators of a supplier’s commitment to sustainability. By aligning their purchasing decisions with these values, companies can not only improve their market positioning but also meet the growing consumer demand for environmentally responsible products.

What Is the Brief Evolution and History of Fluidized Bed Aquarium Filters?

The evolution of fluidized bed aquarium filters is rooted in the advancements made in aquaculture and aquarium management. Initially developed for large-scale aquaculture operations to efficiently manage waste, these filters have transitioned into the mainstream aquarium market due to their superior filtration capabilities. Research conducted by universities and industry stakeholders highlighted the advantages of fluidized bed systems over traditional filtration methods, showcasing their ability to significantly reduce harmful nitrogen compounds in aquatic environments.

As the technology matured, the design and materials used in these filters improved, leading to more compact, efficient, and user-friendly systems. This evolution has opened new avenues for B2B buyers, who now have access to a range of advanced filtering solutions tailored to meet specific operational needs in various markets, including commercial aquariums, fish farms, and ornamental pond setups. The continuous innovation in this space ensures that fluidized bed aquarium filters remain a crucial component in achieving optimal water quality and ecological balance.

Frequently Asked Questions (FAQs) for B2B Buyers of fluidized bed aquarium filters

-

How do I select the right fluidized bed aquarium filter for my business needs?

Choosing the right fluidized bed filter involves evaluating your specific requirements, such as tank size, the type of aquatic life, and water quality needs. Assess the filter’s flow rate, which should match your aquarium’s capacity for optimal efficiency. Consider the surface area of the media used in the filter; higher surface areas generally support more beneficial bacteria, enhancing filtration. Additionally, review supplier specifications and past performance metrics to ensure reliability and efficiency that aligns with your operational goals. -

What are the advantages of using fluidized bed filters in aquaculture systems?

Fluidized bed filters offer several advantages in aquaculture, including superior biological filtration efficiency and the ability to handle high ammonia levels effectively. They create a stable environment for beneficial bacteria to thrive, significantly improving water quality. These filters also require less maintenance due to their self-cleaning capabilities, which reduce operational downtime. Furthermore, their compact design saves space, making them suitable for various installations, from small aquariums to large-scale aquaculture operations. -

What is the typical lead time for ordering fluidized bed aquarium filters from suppliers?

Lead times for fluidized bed filters can vary based on the supplier’s location, manufacturing capabilities, and order volume. Generally, you can expect a lead time of 4-8 weeks for standard orders. Custom orders may take longer due to additional design and production considerations. It’s advisable to communicate directly with suppliers regarding their production schedules and shipping capabilities to ensure timely delivery, especially if you have specific deadlines or seasonal demands. -

What are the minimum order quantities (MOQ) for fluidized bed aquarium filters?

Minimum order quantities can differ significantly between suppliers, often ranging from 10 to 100 units for fluidized bed filters. Factors influencing MOQ include manufacturing costs, product customization, and supplier policies. For B2B buyers, it’s beneficial to negotiate MOQs based on your business needs and potential for future orders. Some suppliers may offer flexibility for first-time buyers or larger, long-term contracts, so it’s essential to discuss these terms upfront. -

How can I vet suppliers of fluidized bed aquarium filters for quality assurance?

Vetting suppliers is crucial to ensure product quality and reliability. Start by checking for certifications and industry standards compliance, such as ISO or equivalent. Request samples to assess the filter’s performance and build quality firsthand. Additionally, investigate supplier reputations through customer reviews and case studies. Engaging in conversations with current clients can provide insights into the supplier’s reliability, customer service, and responsiveness to issues. -

What customization options are available for fluidized bed aquarium filters?

Many suppliers offer customization options for fluidized bed filters, allowing you to tailor features such as size, media type, and flow rates to suit specific applications. Customization may also include branding, packaging, or additional components like pumps and fittings. Discuss your requirements with potential suppliers to explore available options and any associated costs. Be mindful that custom orders may have longer lead times and higher MOQs. -

What payment terms should I expect when sourcing fluidized bed aquarium filters internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments upon order confirmation, and balances due upon shipment. International buyers often utilize letters of credit or escrow services to mitigate risk. Always clarify payment terms during negotiations, including currency, payment methods, and any potential fees. Understanding these terms in advance will help you manage cash flow effectively and ensure smooth transactions. -

How do I handle logistics and shipping for fluidized bed aquarium filters?

Logistics for international shipping of fluidized bed filters requires careful planning to address customs regulations, shipping methods, and costs. Collaborate with your supplier to determine the most efficient shipping options based on delivery time and budget. Consider using freight forwarders who specialize in aquaculture equipment for streamlined processes. Ensure all documentation, including commercial invoices and shipping labels, are accurately completed to avoid delays at customs.

Top 3 Fluidized Bed Aquarium Filters Manufacturers & Suppliers List

1. Aqua Fish – Fluidized Bed Filters

Domain: en.aqua-fish.net

Registered: 2005 (20 years)

Introduction: Fluidized Bed Filters are a type of aquarium filtration system that offers several advantages and disadvantages. They are particularly effective in heavily stocked, planted, and marine aquariums. Key benefits include: 1. Maintenance Reduction: They require less maintenance and can run longer without clogging. 2. CO2 Preservation: They do not reduce CO2 levels, which is beneficial for plants. 3. Hi…

2. Ziss – Bubble Bio Moving Bed Filter

Domain: aquariumcoop.com

Registered: 2012 (13 years)

Introduction: Ziss Bubble Bio Moving Bed Filter | Price: $31.99 | Features: Creates a strong colony of beneficial bacteria, tough and durable construction, suitable for turtle tanks, operates on air supply, fits inside the aquarium, easy to remove intake sponge, media starts moving from day one, keeps media clean, handles large amounts of ammonia.

3. Fluidized Bed Filtration – Easy Setup System

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Fluidized moving bed filtration setup can be created using a $10 27-gallon tote or a $20 55-gallon barrel filled 60% with MBBR media. The system can be fluidized using wavemakers. This filtration method is noted for being simple and not particularly challenging to set up.

Strategic Sourcing Conclusion and Outlook for fluidized bed aquarium filters

In conclusion, fluidized bed aquarium filters present a compelling option for international B2B buyers seeking efficient and effective filtration solutions. Their unique design not only enhances water quality by promoting beneficial bacterial growth but also addresses the increasing demand for sustainable aquaculture practices across diverse markets. The integration of high surface area media, such as K1 micro, optimizes filtration performance, making these systems particularly advantageous for aquaculture operations in regions like Africa and South America, where fish farming is rapidly expanding.

Strategic sourcing of these filters can lead to significant cost savings and improved operational efficiency. By partnering with reputable manufacturers and distributors, businesses can ensure they are acquiring high-quality products that meet the specific needs of their local markets.

As the global demand for aquarium and aquaculture solutions continues to rise, now is the time for buyers in Europe and the Middle East to invest in fluidized bed filters. By leveraging these advanced filtration systems, companies can not only enhance their product offerings but also position themselves as leaders in the sustainable aquaculture movement. Engage with suppliers today to explore how fluidized bed aquarium filters can transform your business operations.

Illustrative image related to fluidized bed aquarium filters

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.