Is Your Flow Sensor Symbol Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for flow sensor symbol

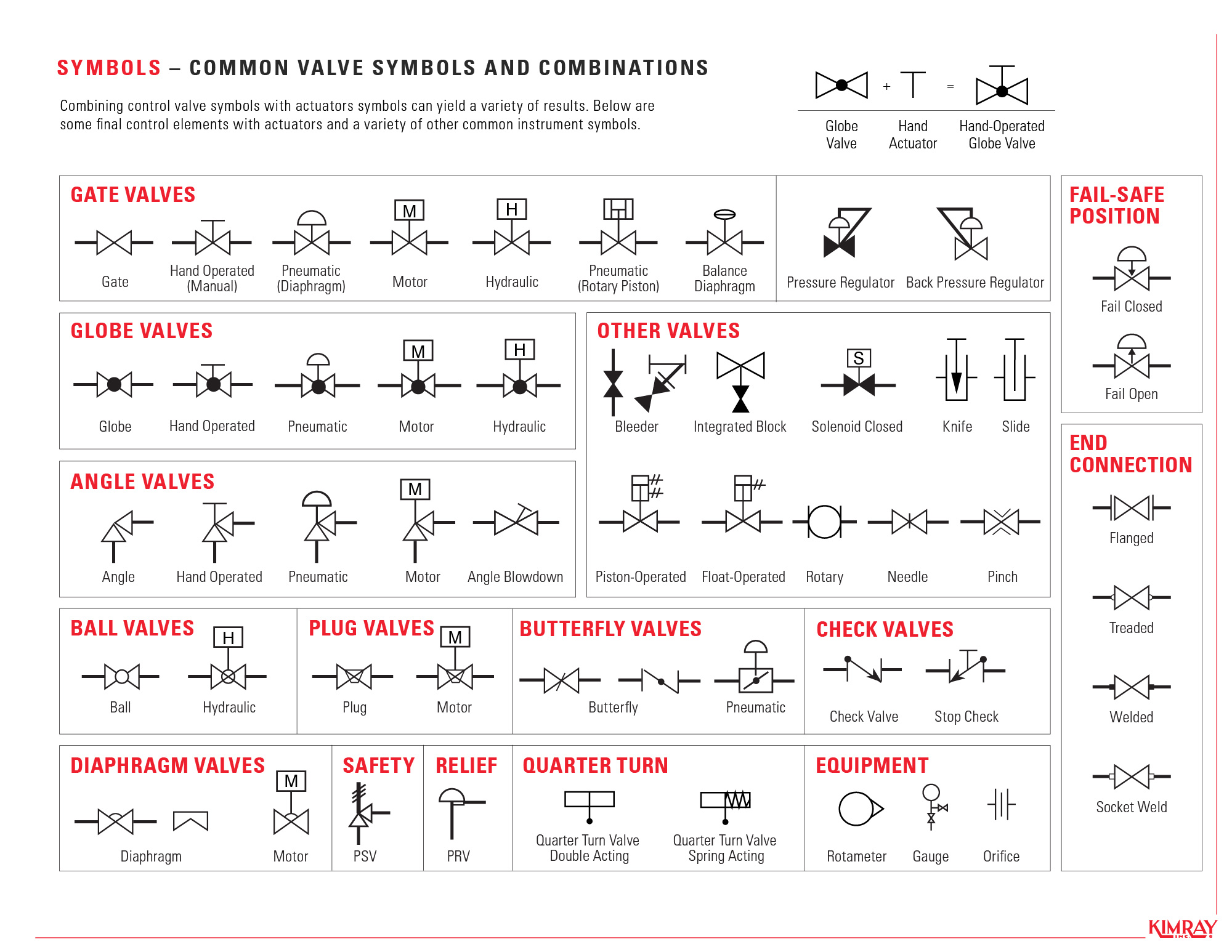

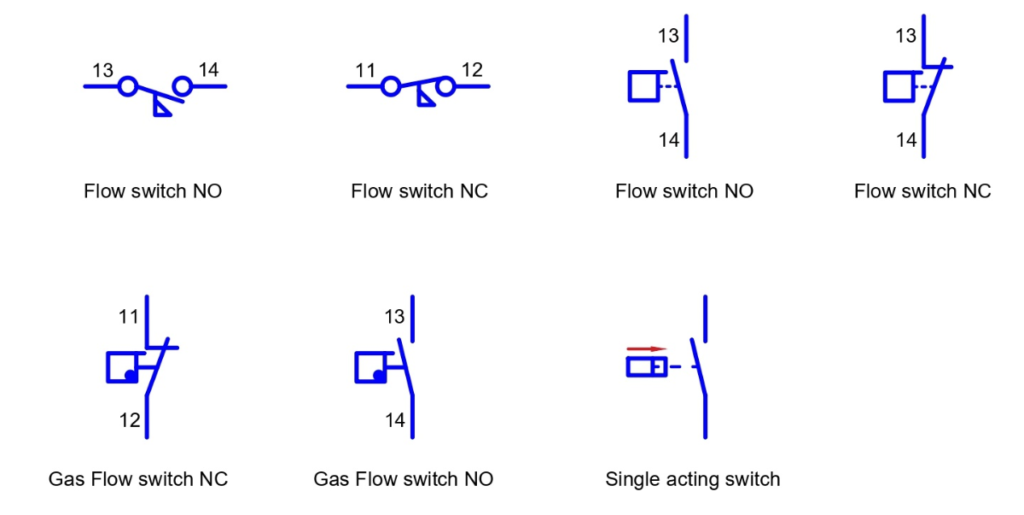

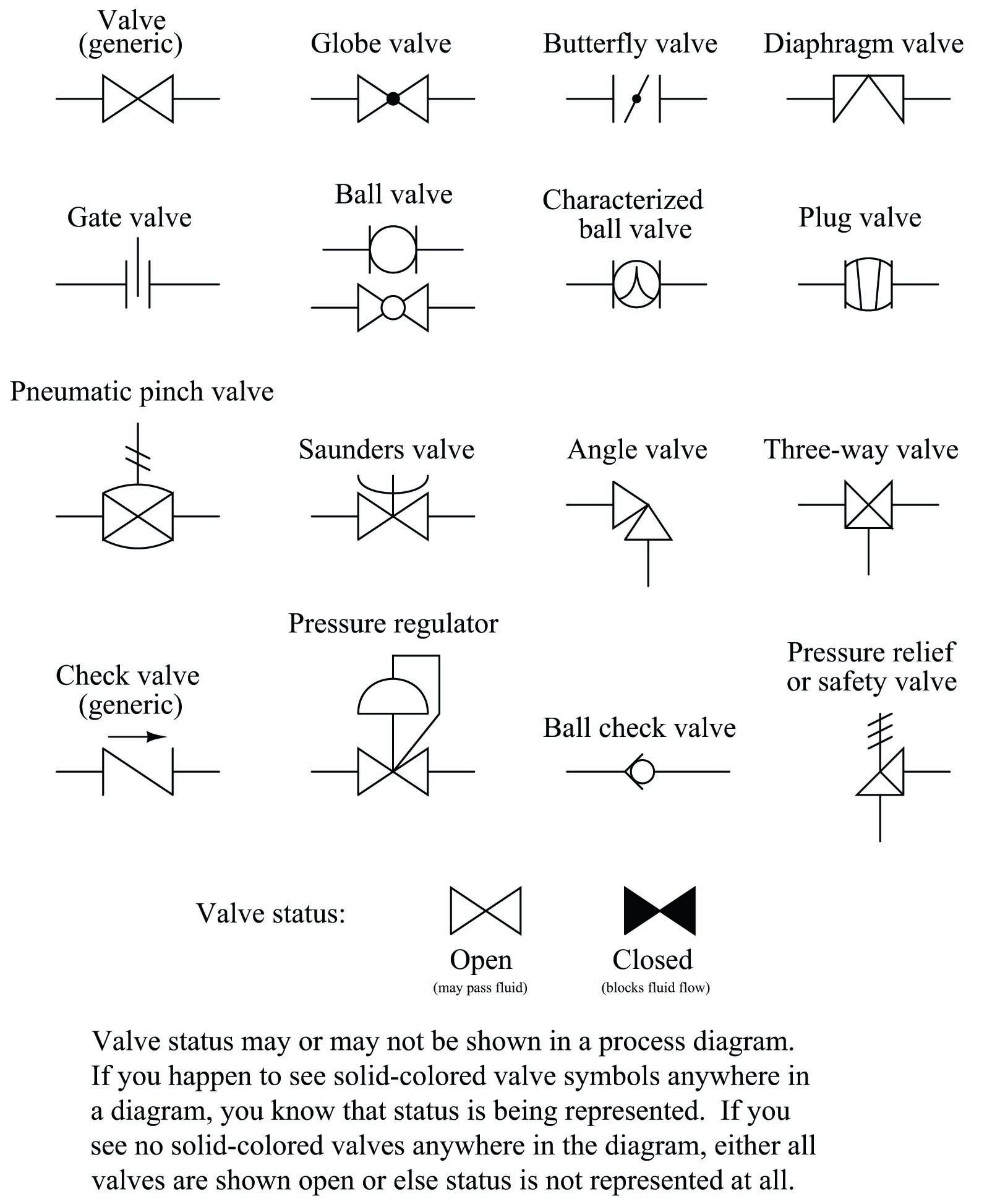

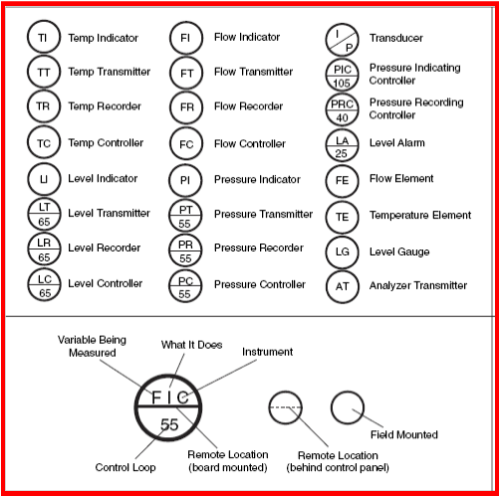

In today’s competitive industrial landscape, sourcing the right flow sensor symbols can be a daunting task for B2B buyers, especially those operating across diverse markets such as Africa, South America, the Middle East, and Europe. The complexity of various flow sensor applications and the multitude of available symbols can lead to confusion and miscommunication, ultimately impacting project timelines and budgets. This guide aims to demystify the global market for flow sensor symbols, providing an exhaustive overview of different types, their applications, and the standards governing their use.

Navigating through this comprehensive resource will empower international buyers to make informed purchasing decisions. The guide delves into critical aspects, including how to effectively vet suppliers, understand pricing structures, and recognize the significance of compliance with international standards. Whether you’re operating in sectors like manufacturing, water management, or process automation, this guide is designed to enhance your understanding of flow sensor symbols and their practical implications.

By providing actionable insights and expert recommendations, this resource equips B2B buyers, particularly those from emerging markets like Vietnam and Nigeria, with the knowledge necessary to streamline their procurement processes. With the right information at hand, you can confidently select flow sensor symbols that meet your operational needs and drive your business forward.

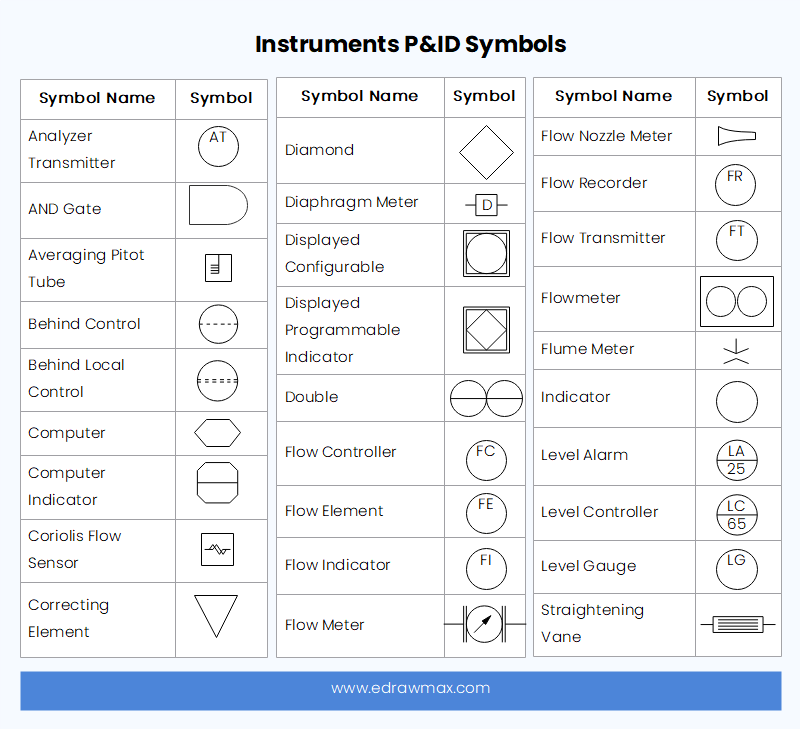

Understanding flow sensor symbol Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electromagnetic | Uses magnetic fields to measure flow; no moving parts | Water treatment, chemical processing | Pros: High accuracy, low maintenance. Cons: Higher initial cost. |

| Ultrasonic | Utilizes sound waves to measure flow; non-invasive | HVAC systems, water distribution | Pros: Versatile, can measure various fluids. Cons: Sensitive to temperature changes. |

| Differential Pressure | Measures flow based on pressure differences; often uses a venturi tube | Oil & gas, HVAC applications | Pros: Reliable and cost-effective. Cons: Requires regular calibration. |

| Turbine | Mechanical flow measurement; uses a rotating turbine | Water supply, fuel measurement | Pros: Simple design, good for high flow rates. Cons: Prone to wear and tear. |

| Vortex | Measures flow based on vortex shedding; suitable for various fluids | Process control, chemical industry | Pros: Wide range of applications, low maintenance. Cons: Less effective for low flow rates. |

What Are the Characteristics of Electromagnetic Flow Sensors?

Electromagnetic flow sensors operate by generating a magnetic field and measuring the voltage induced by the fluid flow. They are ideal for conductive liquids, making them suitable for applications in water treatment and chemical processing. Buyers should consider their initial investment, as these sensors typically have a higher upfront cost but offer excellent accuracy and lower maintenance needs over time. They are particularly advantageous in environments where long-term reliability is essential.

How Do Ultrasonic Flow Sensors Work and What Are Their Applications?

Ultrasonic flow sensors measure fluid flow using sound waves, making them non-invasive and suitable for a wide range of applications, including HVAC systems and water distribution networks. Their versatility allows them to measure various types of fluids, including those that are corrosive or dirty. B2B buyers should note that while they are generally easy to install and maintain, their performance can be sensitive to temperature variations, which may require careful consideration in certain environments.

What Are the Advantages of Differential Pressure Flow Sensors?

Differential pressure flow sensors operate by measuring the difference in pressure across a flow constriction, such as a venturi tube. They are widely used in oil and gas applications, as well as HVAC systems, due to their reliability and cost-effectiveness. Buyers should be aware that while these sensors are generally reliable, they require regular calibration to maintain accuracy. This ongoing maintenance can add to operational costs, making it crucial for buyers to assess their long-term needs.

Why Choose Turbine Flow Sensors for High Flow Rates?

Turbine flow sensors utilize a rotating turbine to measure flow, making them suitable for high flow rate applications, such as water supply and fuel measurement. Their simple mechanical design allows for easy installation and operation. However, buyers should consider that turbine sensors can be prone to wear and tear, which may necessitate more frequent replacements or maintenance. This factor is essential for businesses looking to optimize their operational efficiency.

What Makes Vortex Flow Sensors a Good Choice for Process Control?

Vortex flow sensors measure flow based on the principle of vortex shedding, making them suitable for various fluids in process control applications and the chemical industry. They offer a wide range of applications and low maintenance requirements, which can be appealing for B2B buyers. However, their effectiveness diminishes at low flow rates, so businesses should evaluate their specific flow conditions to ensure compatibility with vortex technology.

Key Industrial Applications of flow sensor symbol

| Industry/Sector | Specific Application of flow sensor symbol | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater | Monitoring flow rates in treatment facilities | Ensures regulatory compliance and operational efficiency | Durability in harsh environments, compatibility with existing systems |

| Oil and Gas | Flow measurement in pipelines for crude oil and gas | Enhances safety, reduces leaks, and optimizes resource extraction | Accuracy under varying pressures, explosion-proof certifications |

| Food and Beverage | Flow control in processing and bottling lines | Maintains quality and consistency of products | Hygiene standards, material compatibility with food-grade requirements |

| Chemical Processing | Monitoring chemical flow in production processes | Improves process control and minimizes waste | Resistance to corrosive substances, precise calibration capabilities |

| HVAC Systems | Airflow measurement in heating, ventilation, and air conditioning systems | Enhances energy efficiency and indoor air quality | Integration with smart building technologies, reliability in varying temperatures |

How is the Flow Sensor Symbol Used in Water and Wastewater Management?

In water and wastewater treatment facilities, flow sensors are crucial for monitoring flow rates and ensuring compliance with environmental regulations. The flow sensor symbol is used in P&ID diagrams to represent these sensors, facilitating clear communication among engineers and operators. For international buyers, sourcing sensors that can withstand harsh conditions, such as high humidity and corrosive chemicals, is essential. Additionally, compatibility with existing monitoring systems is a key consideration, ensuring seamless integration.

What Role Does the Flow Sensor Symbol Play in the Oil and Gas Industry?

In the oil and gas sector, flow sensors are used to measure the flow of crude oil and natural gas through pipelines. The flow sensor symbol indicates the location and type of sensors within system diagrams, allowing for effective monitoring and control. This application enhances safety by detecting leaks and optimizing resource extraction. Buyers need to ensure that the sensors are accurate under varying pressures and have necessary explosion-proof certifications, especially in regions with stringent safety regulations.

How are Flow Sensor Symbols Utilized in Food and Beverage Production?

In the food and beverage industry, flow sensors are employed in processing and bottling lines to ensure consistent flow rates. The flow sensor symbol is integral to system designs, helping maintain product quality and compliance with health regulations. International buyers must consider hygiene standards and materials that meet food-grade requirements. Additionally, the ability to integrate with existing processing equipment is vital for maintaining operational efficiency.

Why are Flow Sensor Symbols Important in Chemical Processing?

Flow sensors in chemical processing facilities monitor the flow of various chemicals during production. The flow sensor symbol is used in system schematics to represent these critical components, which help improve process control and reduce waste. Buyers in this sector should prioritize sensors that resist corrosive substances and offer precise calibration capabilities. This ensures safety and efficiency in managing hazardous materials, especially in regions with diverse chemical manufacturing standards.

How Do Flow Sensor Symbols Enhance HVAC System Efficiency?

In HVAC systems, flow sensors measure airflow to optimize heating, ventilation, and air conditioning processes. The flow sensor symbol is essential in system diagrams, guiding the installation and maintenance of these devices. This application improves energy efficiency and indoor air quality, critical for modern building management. Buyers should focus on sensors that can integrate with smart building technologies and demonstrate reliability across varying temperatures, particularly in regions with extreme climates.

3 Common User Pain Points for ‘flow sensor symbol’ & Their Solutions

Scenario 1: Misinterpretation of Flow Sensor Symbols Leading to Installation Errors

The Problem: Many B2B buyers, especially those in the manufacturing and processing sectors, struggle with the accurate interpretation of flow sensor symbols in technical documentation. This issue is particularly prevalent when working with diverse teams that may include engineers from different regions or with varying levels of expertise. Misinterpretation can lead to incorrect installations, causing costly downtime and safety hazards. For instance, a buyer might confuse a flow sensor symbol for a pressure gauge, leading to inappropriate equipment setup that fails to meet operational requirements.

The Solution: To overcome this challenge, buyers should invest in comprehensive training programs for their teams, focusing on the correct interpretation of flow sensor symbols. This can include workshops, online courses, or collaboration with suppliers who can provide educational resources. Additionally, utilizing standardized symbol libraries, such as those outlined in IEC 60617 or JIC/NFPA standards, can help ensure consistency in documentation. Implementing a verification step, where a qualified engineer reviews installation plans before execution, will further minimize the risk of errors.

Scenario 2: Inadequate Symbol Libraries Resulting in Design Delays

The Problem: Buyers often face significant delays in project timelines due to inadequate access to flow sensor symbol libraries. This is particularly true for companies in regions where local standards may differ from international norms. When companies lack the necessary symbols, their design teams may struggle to create accurate P&IDs (Piping and Instrumentation Diagrams), leading to inefficient workflows and project setbacks. In industries like oil and gas, these delays can translate into substantial financial losses and missed project deadlines.

The Solution: To address this issue, B2B buyers should proactively seek partnerships with software vendors that provide robust and up-to-date symbol libraries tailored to their specific industry needs. Leveraging tools like Capital X Panel Designer or other industry-standard software can facilitate access to a wide array of flow sensor symbols, ensuring that design teams have the resources they need. Regularly updating these libraries and integrating them into standard operating procedures will streamline workflows and enhance overall efficiency. Additionally, buyers should consider contributing to industry standards initiatives, helping to shape future symbol libraries that meet regional and international requirements.

Scenario 3: Difficulty in Customizing Flow Sensor Symbols for Unique Applications

The Problem: B2B buyers often encounter challenges when attempting to customize flow sensor symbols for unique applications, particularly in specialized industries such as pharmaceuticals or food and beverage. Standard symbols may not adequately represent the specific functionalities or configurations of sensors used in these sectors, leading to confusion during the design and implementation phases. This can result in miscommunication between design and operational teams, ultimately impacting product quality and compliance with regulations.

The Solution: To effectively customize flow sensor symbols, companies should adopt a collaborative approach that involves both design and operational teams. Conducting workshops that bring together engineers, operators, and regulatory experts can facilitate a deeper understanding of the specific needs and nuances of the application. Furthermore, utilizing software that allows for easy modification of existing symbols can empower teams to create custom representations that accurately reflect their operational requirements. This practice not only enhances clarity in documentation but also ensures compliance with industry regulations, ultimately improving product quality and operational efficiency.

Strategic Material Selection Guide for flow sensor symbol

What Are the Key Materials for Flow Sensor Symbols?

When selecting materials for flow sensor symbols, it’s crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: stainless steel, plastic, aluminum, and brass. Each of these materials has distinct characteristics that can significantly affect the performance and suitability of flow sensors in various applications.

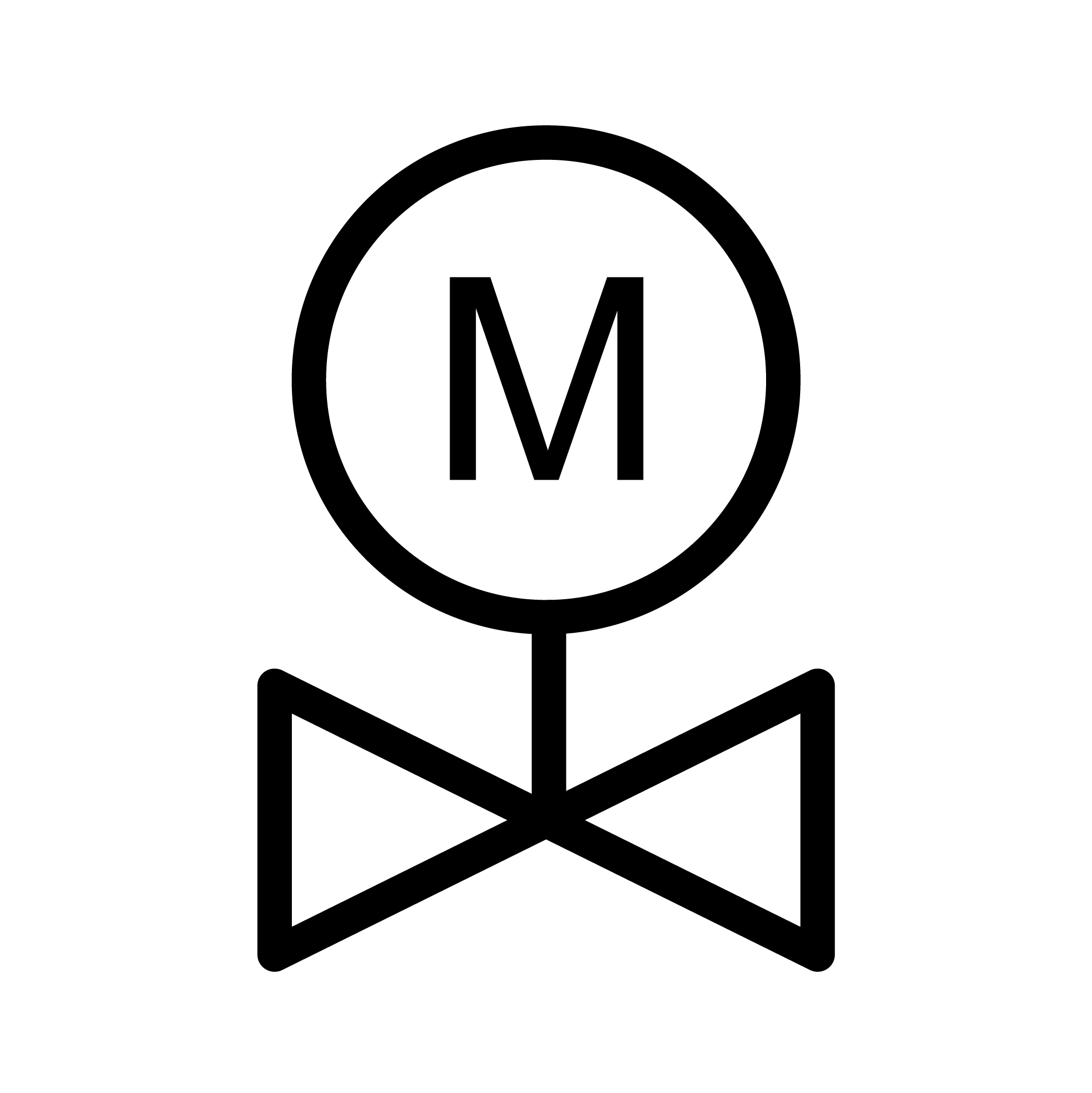

Illustrative image related to flow sensor symbol

How Does Stainless Steel Perform in Flow Sensor Applications?

Stainless steel is widely recognized for its excellent mechanical properties and corrosion resistance. It typically has a high-temperature rating (up to 1,200°F or 650°C) and can withstand high-pressure environments, making it suitable for various industrial applications. The durability of stainless steel ensures a long service life, reducing the need for frequent replacements.

Pros: Stainless steel offers exceptional durability and resistance to corrosion, which is vital for applications involving aggressive media. It is also compatible with a wide range of fluids, including water, oils, and chemicals.

Cons: The primary drawback of stainless steel is its cost, which is higher compared to other materials like plastic. Additionally, manufacturing processes can be complex, requiring specialized techniques for machining and welding.

Impact on Application: Stainless steel is ideal for applications in the food and beverage industry, pharmaceuticals, and chemical processing, where hygiene and material compatibility are critical.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with international standards like ASTM and DIN for quality assurance. Local sourcing may also affect availability and pricing.

Illustrative image related to flow sensor symbol

What Advantages Do Plastics Offer for Flow Sensors?

Plastic materials, such as polyvinyl chloride (PVC) and polycarbonate, are often chosen for their lightweight and cost-effective nature. They typically have a lower temperature and pressure rating, which limits their use in high-stress environments.

Pros: The primary advantage of plastic is its affordability and ease of manufacturing, allowing for rapid production and customization. Plastic sensors are also resistant to corrosion from many chemicals, making them suitable for specific applications.

Cons: However, plastics may not withstand high temperatures or pressures as effectively as metals. They can also be susceptible to degradation over time when exposed to UV light and certain chemicals.

Impact on Application: Plastics are commonly used in water treatment, irrigation systems, and low-pressure chemical applications where cost savings are a priority.

Considerations for International Buyers: Buyers should verify that the chosen plastic complies with relevant standards, particularly in the food and beverage sector, where certifications are essential.

How Does Aluminum Compare in Flow Sensor Symbol Applications?

Aluminum is another popular material for flow sensors, known for its lightweight and good thermal conductivity. It can handle moderate temperatures and pressures, making it suitable for various applications.

Pros: Aluminum is less expensive than stainless steel and offers a good balance between weight and strength. Its corrosion resistance can be enhanced with anodizing, making it suitable for outdoor applications.

Cons: While aluminum is versatile, it may not be suitable for highly corrosive environments without protective coatings. Additionally, it has lower mechanical strength compared to stainless steel.

Impact on Application: Aluminum is often used in HVAC systems, automotive applications, and some industrial processes where weight savings are crucial.

Considerations for International Buyers: Buyers should consider local regulations regarding aluminum use, especially in industries like automotive and aerospace, where specific standards apply.

What Role Does Brass Play in Flow Sensor Design?

Brass is a copper-zinc alloy that offers good corrosion resistance and excellent machinability. It is often used in applications requiring good thermal and electrical conductivity.

Pros: Brass is relatively inexpensive and easy to work with, making it suitable for various manufacturing processes. Its aesthetic appeal also makes it a popular choice for consumer products.

Cons: Brass may not be suitable for all chemical environments, particularly those involving strong acids or bases. Its mechanical properties are also less robust compared to stainless steel.

Impact on Application: Brass is commonly used in plumbing, fuel systems, and low-pressure applications where corrosion resistance is essential.

Considerations for International Buyers: Buyers should ensure that the brass used complies with local standards, particularly in plumbing and construction, where regulations can vary significantly.

Summary Table of Material Selection for Flow Sensor Symbols

| Material | Typical Use Case for flow sensor symbol | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage, chemical processing | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Water treatment, irrigation systems | Cost-effective and lightweight | Limited temperature/pressure ratings | Low |

| Aluminum | HVAC systems, automotive applications | Lightweight and good strength | Lower corrosion resistance without coatings | Medium |

| Brass | Plumbing, fuel systems | Good machinability and cost | Less suitable for strong acids/bases | Medium |

This comprehensive analysis provides B2B buyers with essential insights into material selection for flow sensor symbols, helping them make informed decisions based on their specific application needs and regional considerations.

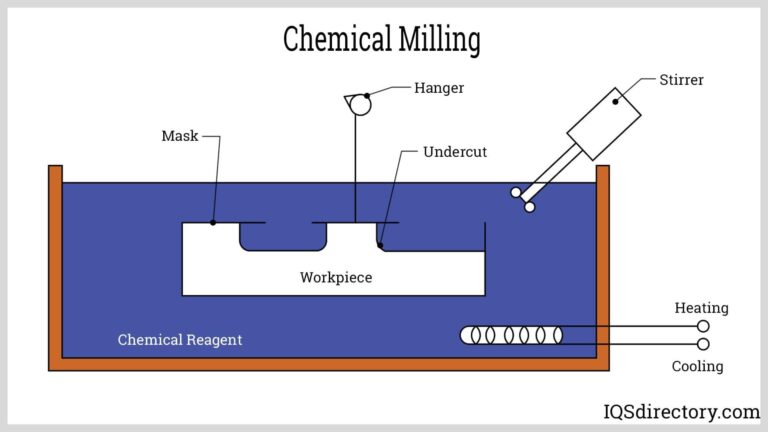

In-depth Look: Manufacturing Processes and Quality Assurance for flow sensor symbol

What Are the Key Stages in the Manufacturing Process of Flow Sensor Symbols?

The manufacturing process of flow sensor symbols involves several critical stages that ensure the final product meets industry standards and customer specifications. Understanding these stages is essential for B2B buyers looking to source quality components for their operations.

1. Material Preparation

The first step in manufacturing flow sensor symbols is the preparation of raw materials. Typically, manufacturers use high-quality materials such as plastics, metals, or composites that can withstand environmental factors like pressure, temperature, and corrosive substances. During this stage, materials are sourced from certified suppliers to ensure compliance with international standards.

2. Forming Techniques

Once the materials are prepared, various forming techniques are employed. Common methods include:

- Injection Molding: This is widely used for producing plastic components. It involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

- Machining: For metal components, precision machining techniques such as CNC (Computer Numerical Control) milling and turning are used to achieve tight tolerances and intricate designs.

- 3D Printing: This emerging technology is increasingly being utilized for prototyping and low-volume production, allowing for rapid iterations and custom designs.

3. Assembly Process

After individual components are manufactured, they are assembled into the final flow sensor symbol. This may involve:

Illustrative image related to flow sensor symbol

- Soldering and Wiring: For electronic flow sensors, soldering is essential to connect various electronic components.

- Mechanical Assembly: Components are assembled using screws, clips, or adhesives, depending on the design requirements.

- Quality Checks: During assembly, manufacturers conduct preliminary quality checks to ensure that components fit correctly and function as intended.

4. Finishing Touches

The final stage involves finishing processes that enhance the appearance and functionality of the flow sensor symbols. Techniques include:

- Surface Treatment: This may involve anodizing or painting for corrosion resistance and aesthetic appeal.

- Labeling and Marking: Proper labeling is crucial for compliance with international standards and for ease of identification in operational environments.

How Is Quality Assurance Implemented in Flow Sensor Symbol Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that products meet established standards before reaching the market. For B2B buyers, understanding the QA processes can be a key factor in supplier selection.

International Standards and Certifications

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines a framework for quality management systems. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for the oil and gas sector, can signal a manufacturer’s commitment to quality. Buyers should look for suppliers who can demonstrate compliance with these standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic inspections and tests throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications. This prevents defective materials from entering the production line.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to identify any defects early in the process. This can include measurements of dimensions and performance tests on components.

- Final Quality Control (FQC): Once the flow sensor symbols are fully assembled, a final inspection is performed. This may include functional testing, pressure testing, and visual inspections to ensure the product meets all quality standards.

What Testing Methods Are Commonly Used for Flow Sensor Symbols?

Testing methods are crucial for verifying the performance and reliability of flow sensor symbols. Common techniques include:

Illustrative image related to flow sensor symbol

- Calibration Testing: Ensures that the flow sensor provides accurate readings. This is often performed using standardized flow meters.

- Environmental Testing: Assessing how the sensors perform under various environmental conditions such as temperature, humidity, and pressure.

- Durability Testing: This includes stress tests to evaluate how well the sensors can withstand operational wear and tear.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying a supplier’s quality assurance processes is essential to ensure the reliability of flow sensor symbols. Here are several methods to achieve this:

- Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s processes, equipment, and adherence to quality standards. This is especially important for buyers in regions like Africa and South America, where local suppliers may have varying levels of quality control.

- Quality Reports: Requesting documentation such as QC reports, test results, and certifications can help buyers assess a supplier’s quality practices. Look for reports that detail the testing methods used and the outcomes of quality checks.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can validate compliance with international standards and help mitigate risks associated with sourcing.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly those from regions like the Middle East and Europe, should be aware of several nuances in quality control and certification:

- Regulatory Compliance: Different regions have distinct regulatory requirements. For example, CE marking is mandatory in Europe, while UL certification may be required in North America. Buyers should ensure that suppliers can meet these specific regulatory needs.

- Cultural Considerations: Understanding local manufacturing practices and quality standards can help buyers navigate potential challenges. For instance, suppliers in some regions may prioritize cost over quality, necessitating a more rigorous vetting process.

- Supply Chain Transparency: Buyers should seek suppliers who offer transparency in their supply chain. This includes traceability of materials and components, which can impact the overall quality of the final product.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance practices for flow sensor symbols, B2B buyers can make informed decisions, ensuring that they source reliable and high-quality components for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flow sensor symbol’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement of flow sensor symbols. These symbols are critical for the accurate representation of flow measurement systems in various engineering designs and documentation. By following this checklist, you will ensure that you select the right symbols that meet your project’s specifications and comply with industry standards.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the flow sensor symbols you need. This includes understanding the specific flow measurement technology (e.g., electromagnetic, ultrasonic, or mechanical) and the applicable standards in your region, such as ISO or IEC. Having precise specifications will help you communicate effectively with suppliers and avoid misunderstandings.

Step 2: Research Industry Standards

Familiarize yourself with relevant industry standards that dictate the use of flow sensor symbols, such as IEC 60617 or JIC/NFPA standards. Understanding these standards is crucial as they ensure that the symbols you use are universally recognized, enhancing clarity in technical documentation. Compliance with these standards can also be a requirement for regulatory approvals in many regions.

Illustrative image related to flow sensor symbol

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, including their experience and certifications related to flow sensor symbols. Look for case studies or references from companies in similar industries or geographical locations to gauge their reliability and service quality.

- Assess Supplier Capabilities:

- Ensure that the supplier can provide the specific symbols you need.

- Check for their ability to customize symbols according to your requirements.

Step 4: Request Samples or Mock-ups

Once you have narrowed down your list of suppliers, request samples or mock-ups of the flow sensor symbols. This step allows you to evaluate the quality, accuracy, and clarity of the symbols being offered. Ensure that the symbols meet your technical specifications and are compatible with your existing documentation.

Step 5: Review Pricing and Terms

Carefully review the pricing structure and terms of service from potential suppliers. Look for hidden costs related to shipping, customization, or licensing of symbols. A transparent pricing model will help you make informed decisions and avoid budget overruns.

- Negotiate Terms:

- Don’t hesitate to negotiate terms to ensure they align with your budget and project timelines.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications that validate their quality management systems, such as ISO 9001. These certifications indicate a commitment to quality and reliability, which is essential when sourcing technical components like flow sensor symbols.

Step 7: Finalize Order and Establish Communication Protocols

Once you have selected a supplier, finalize your order and establish clear communication protocols. Define points of contact and set expectations for updates on production timelines, delivery schedules, and any potential issues. Strong communication will facilitate a smooth procurement process and help resolve any challenges that may arise.

By following this structured checklist, you can confidently procure flow sensor symbols that meet your project’s needs while ensuring compliance with industry standards.

Comprehensive Cost and Pricing Analysis for flow sensor symbol Sourcing

What Are the Key Cost Components in Flow Sensor Symbol Sourcing?

In the sourcing of flow sensor symbols, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: This encompasses the raw materials required to manufacture the flow sensor symbols, such as electronic components, metals, and plastics. The quality and source of materials can significantly affect the price.

-

Labor: Labor costs are influenced by the skill level required for production, local wage rates, and the complexity of the assembly process. Regions with higher labor costs may result in elevated product prices.

-

Manufacturing Overhead: This includes indirect costs related to the production process, such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: The costs associated with creating and maintaining the tools and molds necessary for production can be substantial, particularly for custom designs. Tooling costs are often amortized over the production run.

-

Quality Control (QC): Ensuring that flow sensor symbols meet industry standards and specifications involves rigorous testing and quality assurance processes. Higher QC standards may lead to increased costs but can enhance product reliability.

-

Logistics: Transportation, warehousing, and handling costs are significant, especially for international shipments. These costs can vary greatly based on distance, shipping methods, and Incoterms used in the transaction.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. The margin can vary widely based on the supplier’s market position, competition, and perceived value of the product.

How Do Price Influencers Affect Flow Sensor Symbol Costs?

Several factors can influence the final price of flow sensor symbols:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly impact pricing. Larger orders often result in lower unit costs due to economies of scale, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom designs or specific technical specifications can lead to increased costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher-quality materials or those with specific certifications (such as ISO or CE) can increase costs. However, investing in quality can lead to better performance and longevity, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: The supplier’s reputation, reliability, and service level can also affect pricing. Engaging with established suppliers may come with a premium but can reduce risks associated with quality and delivery.

-

Incoterms: The choice of Incoterms affects the allocation of responsibilities and costs between buyers and sellers. Understanding these terms is vital for accurately assessing total costs.

What Are Effective Buyer Tips for Sourcing Flow Sensor Symbols?

When sourcing flow sensor symbols, particularly in international markets, buyers can optimize costs and ensure better value through strategic approaches:

-

Negotiate with Suppliers: Always engage in negotiations to secure better pricing, especially when placing large orders. Suppliers may offer discounts for bulk purchases or long-term contracts.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership rather than just the purchase price. Consider factors such as maintenance, durability, and performance, which can influence long-term costs.

-

Consider Local vs. International Sourcing: While international suppliers may offer lower prices, consider the implications of shipping costs, lead times, and potential tariffs. Local suppliers might provide faster delivery and reduced logistics costs.

-

Understand Pricing Nuances: Be aware of seasonal variations in pricing or any geopolitical factors that may impact supply chains. Staying informed can help in making timely purchasing decisions.

-

Request Sample Products: Before committing to large orders, request samples to assess quality and compatibility with your needs. This can prevent costly mistakes in bulk purchases.

Disclaimer on Pricing

Please note that prices for flow sensor symbols can vary widely based on the factors discussed above. The figures are indicative and subject to change based on market conditions, supplier negotiations, and individual buyer requirements. Always seek tailored quotes to obtain the most accurate pricing for your specific needs.

Alternatives Analysis: Comparing flow sensor symbol With Other Solutions

Understanding Alternatives to Flow Sensor Symbols

In the realm of industrial automation, flow sensor symbols play a critical role in the design and implementation of control systems. However, various alternatives exist that may provide different advantages depending on the specific requirements of a project. This analysis compares flow sensor symbols with two viable alternatives: flow meters and ultrasonic flow sensors. By examining these options, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Flow Sensor Symbol | Flow Meter | Ultrasonic Flow Sensor |

|---|---|---|---|

| Performance | Accurate representation in design | High accuracy in measurement | Non-intrusive, high accuracy |

| Cost | Low (design tool) | Moderate to high | High initial investment |

| Ease of Implementation | Requires CAD software knowledge | Simple installation | Moderate installation effort |

| Maintenance | No maintenance required | Periodic calibration needed | Minimal maintenance |

| Best Use Case | Design and schematics | Real-time flow measurement | Non-invasive flow assessment |

Detailed Breakdown of Alternatives

What Are Flow Meters and How Do They Compare?

Flow meters are devices used to measure the flow rate of liquids and gases in real-time. They provide highly accurate data, which is essential for applications where precise flow measurement is critical, such as in chemical processing or water treatment facilities. While they can be relatively easy to install, they often come with moderate to high costs, depending on the technology employed. Flow meters require periodic calibration to maintain accuracy, making them less ideal for operations seeking minimal maintenance. Their best use case lies in environments where real-time data is crucial for process control.

How Do Ultrasonic Flow Sensors Function as an Alternative?

Ultrasonic flow sensors operate by sending ultrasonic signals through the fluid and measuring the time it takes for the signals to return. This technology allows for non-invasive measurements, making it suitable for applications where traditional meters cannot be installed without interrupting flow. While ultrasonic sensors offer high accuracy and minimal maintenance, they typically represent a higher initial investment compared to traditional flow meters. Their best use case includes situations where installation accessibility is limited, or where non-intrusive measurement is paramount, such as in large pipelines or delicate systems.

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution for flow measurement and representation, B2B buyers should consider several factors including performance needs, budget constraints, ease of implementation, and long-term maintenance requirements. For organizations focused on accurate flow measurement in real-time, flow meters may be the preferred choice. In contrast, if minimizing disruption during installation is essential, ultrasonic flow sensors could be the better option. Ultimately, the decision should align with the specific operational goals and the nature of the processes involved, ensuring that the selected solution effectively meets the organization’s demands.

Essential Technical Properties and Trade Terminology for flow sensor symbol

What Are the Essential Technical Properties of Flow Sensor Symbols?

Understanding the technical properties associated with flow sensor symbols is crucial for B2B buyers engaged in the procurement of these components. Here are several key specifications that significantly influence the performance and reliability of flow sensors:

-

Material Grade

The material used in the flow sensor symbol, often dictated by the application, can affect durability and resistance to corrosion. Common materials include stainless steel, plastic, and alloys. Selecting the right material ensures that the sensor can withstand the operational environment, whether it’s high pressure, temperature fluctuations, or exposure to chemicals. -

Accuracy

Accuracy is a critical specification that defines how closely the flow sensor’s readings reflect the actual flow rate. It is typically expressed as a percentage of the reading. For B2B buyers, high accuracy is essential in applications where precise flow measurements are necessary, such as in pharmaceutical or food processing industries, where compliance with regulations is vital. -

Flow Range

This specification indicates the minimum and maximum flow rates that the sensor can measure. Understanding the flow range helps buyers select sensors that are suitable for their specific applications, ensuring that the sensor operates effectively within the required parameters without leading to inaccurate readings or equipment damage. -

Pressure Rating

The pressure rating of a flow sensor indicates the maximum pressure it can withstand without failing. This property is particularly important in industrial applications where high-pressure systems are common. Buyers must ensure that the sensor’s pressure rating aligns with the operational conditions to avoid costly failures. -

Electrical Specifications

This includes voltage, current, and power ratings necessary for the sensor’s operation. It is crucial for compatibility with existing systems and for ensuring that the sensor operates efficiently without causing overloads or failures. -

Response Time

Response time refers to how quickly the sensor can detect and report changes in flow conditions. A shorter response time is preferable in dynamic environments where flow rates can fluctuate rapidly. This is particularly relevant in industries such as oil and gas, where timely data is critical for decision-making.

What Trade Terminology Should B2B Buyers Understand When Dealing with Flow Sensors?

Familiarity with industry jargon can streamline the purchasing process and enhance communication with suppliers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for B2B buyers who may be sourcing flow sensors that will be integrated into larger systems or products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is important for budget-conscious buyers as it affects the overall cost and inventory management. Knowing the MOQ helps in planning purchases and avoiding overstock situations. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. It typically includes detailed specifications and quantities. B2B buyers should be familiar with crafting effective RFQs to ensure they receive competitive and accurate quotes from suppliers. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping. Understanding Incoterms is essential for B2B transactions, particularly in international trade, as they clarify who bears the risk and cost during transport. -

P&ID (Piping and Instrumentation Diagram)

A P&ID is a detailed diagram that shows the piping and related components of a physical process flow. It is essential for understanding how flow sensors integrate into larger systems. Buyers should be able to interpret P&IDs to ensure compatibility and proper installation of sensors. -

Calibration

Calibration is the process of adjusting the accuracy of a flow sensor. This term is vital for B2B buyers to understand, as regular calibration ensures the sensor continues to provide precise measurements over time, which is critical for operational efficiency and compliance with industry standards.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when procuring flow sensors, ultimately leading to improved operational efficiency and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the flow sensor symbol Sector

What Are the Current Market Dynamics and Key Trends Influencing the Flow Sensor Symbol Sector?

The flow sensor symbol market is experiencing significant growth driven by increased automation and the demand for precision in various industrial applications. Key factors propelling this market include the rise in smart manufacturing technologies and the integration of the Internet of Things (IoT) in industrial processes. As industries strive for efficiency and reduced operational costs, B2B buyers are seeking flow sensor symbols that facilitate better monitoring and control of fluid dynamics, essential for optimizing production lines.

Emerging trends include the growing adoption of advanced sensor technologies such as ultrasonic and electromagnetic flow sensors, which offer enhanced accuracy and reliability. These innovations are particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where there is a strong push for modernizing infrastructure and improving industrial capabilities. Additionally, the increasing focus on Industry 4.0 and digital transformation is driving demand for flow sensor symbols that can seamlessly integrate with existing systems and provide real-time data analytics.

Moreover, market dynamics are influenced by global supply chain challenges, which have necessitated a shift toward more localized sourcing strategies. Buyers are looking for suppliers that can provide timely deliveries and maintain quality standards despite disruptions. This presents an opportunity for manufacturers who can demonstrate flexibility and resilience in their supply chains while also ensuring adherence to international standards.

How Is Sustainability and Ethical Sourcing Impacting the Flow Sensor Symbol Market?

Sustainability has become a cornerstone of B2B procurement strategies, particularly in the flow sensor symbol sector. The environmental impact of manufacturing processes and the materials used in flow sensors are under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of eco-friendly materials and energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with businesses recognizing the importance of transparency in their supply chains. Certifications such as ISO 14001 for environmental management and adherence to REACH regulations for chemical safety are becoming critical criteria for B2B buyers. Suppliers that can provide evidence of their sustainability initiatives and ethical sourcing practices are more likely to build trust and secure long-term partnerships.

Furthermore, the demand for ‘green’ materials in flow sensor symbol production is on the rise. Buyers are increasingly looking for products made from recycled or biodegradable materials, as well as those that contribute to energy savings in their applications. This trend not only helps companies comply with regulations but also enhances their brand image in an environmentally conscious market.

How Has the Flow Sensor Symbol Sector Evolved Over Time?

The evolution of the flow sensor symbol sector can be traced back to the industrial revolution when the need for accurate measurement of fluid flow became paramount. Initially, mechanical devices dominated the market, but advancements in electronics led to the development of electronic sensors in the late 20th century. This transition allowed for greater precision and the ability to transmit data over longer distances.

As industries evolved, so did the technology behind flow sensors. The introduction of digital flow meters and the integration of smart technologies have transformed how fluid dynamics are monitored and controlled. Today, flow sensor symbols are not only vital for operational efficiency but also play a crucial role in meeting regulatory requirements and sustainability goals. The current landscape reflects a blend of tradition and innovation, with a clear trend toward automation and connectivity that defines the future of the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of flow sensor symbol

-

1. How do I choose the right flow sensor symbol for my application?

Selecting the appropriate flow sensor symbol depends on several factors, including the type of fluid, flow rate, and the specific application requirements. Consider the industry standards relevant to your region, such as IEC or JIC, to ensure compliance. Additionally, evaluate the compatibility of the symbol with existing systems or software. Engaging with your supplier for insights on the latest symbols and their applications can also help in making an informed decision. -

2. What are the common applications of flow sensor symbols in industrial settings?

Flow sensor symbols are widely used in various industrial applications, including water treatment, chemical processing, and HVAC systems. They help in monitoring fluid dynamics, ensuring proper flow rates, and maintaining system efficiency. In sectors like oil and gas, accurate flow measurement is critical for safety and operational efficiency. Understanding the specific needs of your industry will guide you in selecting the most relevant symbols. -

3. What factors should I consider when sourcing flow sensor symbols internationally?

When sourcing flow sensor symbols from international suppliers, consider factors such as product quality, compliance with local standards, and supplier reliability. Research the supplier’s reputation by checking reviews and certifications. Additionally, evaluate shipping costs, delivery times, and customs regulations that may impact your order. Establishing clear communication about your requirements can help mitigate risks and ensure smooth transactions. -

4. How can I verify the credibility of a supplier for flow sensor symbols?

To verify a supplier’s credibility, start by checking their business history, client testimonials, and industry certifications. Request references from previous clients and inquire about their experiences. Additionally, assess their product quality through samples or third-party testing reports. Engaging in direct communication can provide insights into their customer service and reliability, which is crucial for long-term partnerships. -

5. What customization options are available for flow sensor symbols?

Many suppliers offer customization options for flow sensor symbols to meet specific application needs. Customizations can include modifications in size, material, or design to fit unique requirements. It is essential to discuss your specific needs with the supplier and confirm their capabilities. Be sure to inquire about the lead time for custom orders and any additional costs involved in the process. -

6. What is the typical minimum order quantity (MOQ) for flow sensor symbols?

Minimum order quantities (MOQ) for flow sensor symbols can vary significantly depending on the supplier and the specific product. Some suppliers may have a low MOQ for standard symbols, while customized options may require larger orders. It’s advisable to clarify the MOQ with potential suppliers during initial discussions. Understanding their policies can help you manage inventory and cost-effectiveness in your purchasing strategy. -

7. What payment terms should I expect when purchasing flow sensor symbols internationally?

Payment terms for international purchases of flow sensor symbols can vary by supplier and region. Common terms include payment in advance, net 30, or letters of credit. It’s essential to discuss and negotiate payment options that align with your financial practices. Ensure that you also understand any currency exchange implications and additional fees that may arise during international transactions. -

8. How do I ensure quality assurance when sourcing flow sensor symbols?

To ensure quality assurance when sourcing flow sensor symbols, request documentation such as quality control reports and compliance certificates. Many reputable suppliers will provide these documents to verify that their products meet industry standards. Additionally, consider conducting third-party inspections or audits of the supplier’s facilities. Establishing a clear agreement on quality expectations and performance metrics can further protect your investment.

Top 3 Flow Sensor Symbol Manufacturers & Suppliers List

1. E4 Training – Hydraulic Instrumentation Symbols

Domain: e4training.com

Registered: 2000 (25 years)

Introduction: Hydraulic instrumentation symbols include: 1. Pressure measurement devices: – Pressure sensor with analogue output signal – Traditional pressure measuring manometer gauge 2. Hydraulic flow meter: – Fluid flow meter with digital display – Flow measurement in both directions using a Wheatstone bridge layout with four check valves 3. Fluid contamination monitor: – Inline particle counter or contamina…

2. Stoutmep – Pressure Sensors & Control Solutions

Domain: stoutmep.com

Registered: 2020 (5 years)

Introduction: 1. Pressure Sensor: Measures pressure of gases or liquids. 2. Variable Speed Drive (VSD): Enables variable control of motor speed and torque for optimum efficiency. 3. Flow Switch: Trips pumps on or off to control fluid flow. 4. Air Conditioning Controller: Electronic module that controls the HVAC system. 5. Carbon Monoxide Sensor: Measures and limits carbon monoxide levels. 6. CO2 Sensor: Measure…

3. EdrawMax – Diagramming Software

Domain: edrawmax.wondershare.com

Registered: 2003 (22 years)

Introduction: EdrawMax is a diagramming software that includes tools for creating circuit diagrams with sensor symbols. It offers various products such as EdrawMax for Desktop, EdrawMax Online, and EdrawMax for Mobile, catering to individuals, businesses, and educational institutions. The software provides features for flowcharts, Gantt charts, mind maps, and various types of diagrams including temperature, hum…

Strategic Sourcing Conclusion and Outlook for flow sensor symbol

In today’s competitive landscape, strategic sourcing of flow sensor symbols is essential for optimizing operations and ensuring compliance with international standards. By understanding the various flow sensor symbols and their applications, B2B buyers can enhance their procurement strategies, streamline processes, and improve overall efficiency. This is particularly crucial for industries in Africa, South America, the Middle East, and Europe, where local regulations and market conditions can vary significantly.

Illustrative image related to flow sensor symbol

Investing in high-quality flow sensor symbols not only aids in accurate flow measurement but also mitigates risks associated with operational failures. Buyers should prioritize suppliers who provide comprehensive resources, including sample drawings and compatibility with various industrial standards, to facilitate seamless integration into existing systems.

As we look towards the future, the demand for advanced flow measurement solutions will continue to rise. International buyers are encouraged to explore innovative suppliers and technologies that can elevate their operations. By proactively engaging with the right partners, businesses can position themselves for sustainable growth and success in an increasingly interconnected global market. Now is the time to take action and secure your supply chain for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.