Is Your Expansion Joints In Piping Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for expansion joints in piping

In the complex world of industrial piping systems, sourcing high-quality expansion joints can be a formidable challenge for B2B buyers. These critical components play a pivotal role in mitigating the stresses caused by thermal expansion, vibrations, and misalignments, ensuring the longevity and efficiency of piping networks across diverse industries. However, the global market is flooded with options, and navigating this landscape can be daunting, especially for buyers in regions like Africa, South America, the Middle East, and Europe, including countries such as Brazil and Nigeria.

This comprehensive guide is designed to empower international B2B buyers with the knowledge necessary to make informed purchasing decisions. It covers a wide array of topics, including the different types of expansion joints available, their specific applications in various industries, and best practices for vetting suppliers. Additionally, we delve into cost considerations, helping buyers understand the financial implications of their choices.

By providing actionable insights and expert guidance, this guide aims to simplify the procurement process, enabling you to select the most suitable expansion joints that meet your operational needs while optimizing performance and cost-effectiveness. Whether you’re addressing immediate supply chain concerns or planning for future projects, this resource is your essential companion in the quest for reliable and efficient piping solutions.

Understanding expansion joints in piping Types and Variations

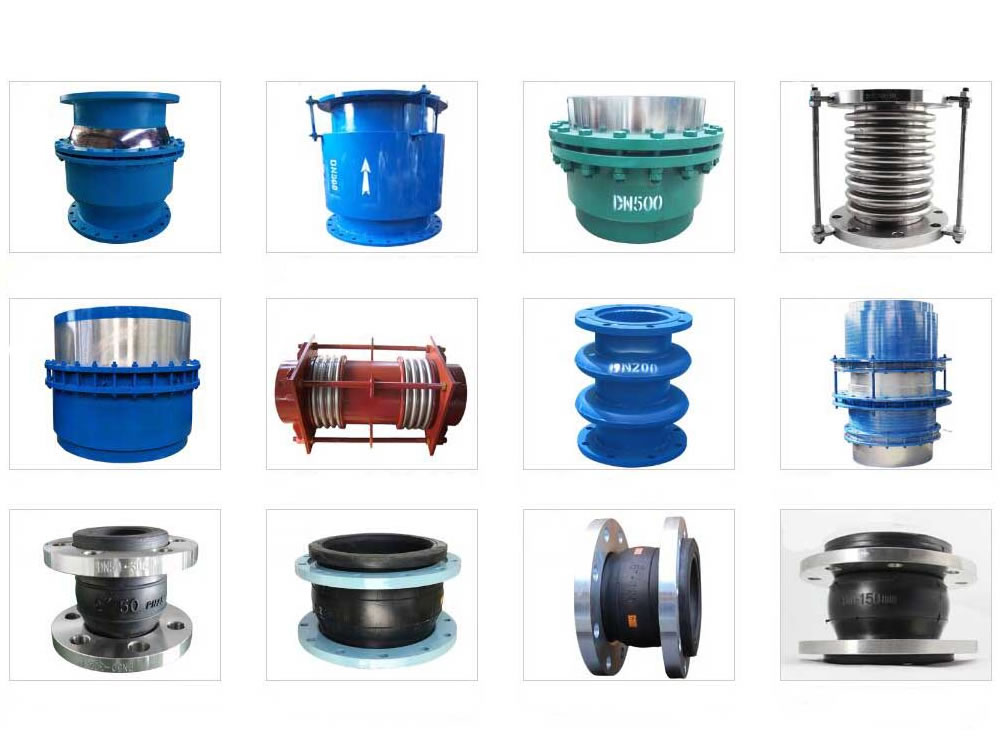

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Bellows Expansion Joints | Flexible metal bellows with convoluted design for high pressure. | Power plants, petrochemical, steel industries | Pros: High durability, suitable for extreme conditions. Cons: Higher initial cost. |

| Rubber Expansion Joints | Made from elastomeric materials, designed for lower pressure. | HVAC systems, water treatment plants | Pros: Cost-effective, good for low-pressure applications. Cons: Limited temperature range. |

| Fabric Expansion Joints | Lightweight, flexible fabric construction for moderate movement. | Chemical processing, food production | Pros: Lightweight, good for tight spaces. Cons: Less durable than metal options. |

| PTFE (Teflon) Expansion Joints | Resistant to chemical corrosion, flexible design. | Pharmaceutical, food and beverage industries | Pros: Excellent chemical resistance, non-stick properties. Cons: Not suitable for high pressure. |

| Hinged Expansion Joints | Allows angular movement while limiting lateral displacement. | Power generation, marine applications | Pros: Effective for angular deflection, compact design. Cons: Limited to specific movement types. |

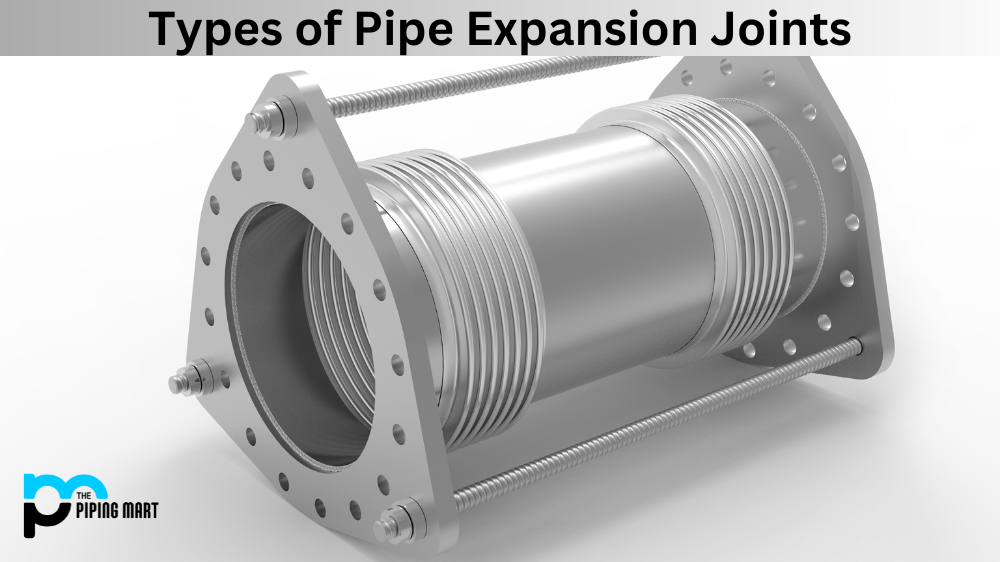

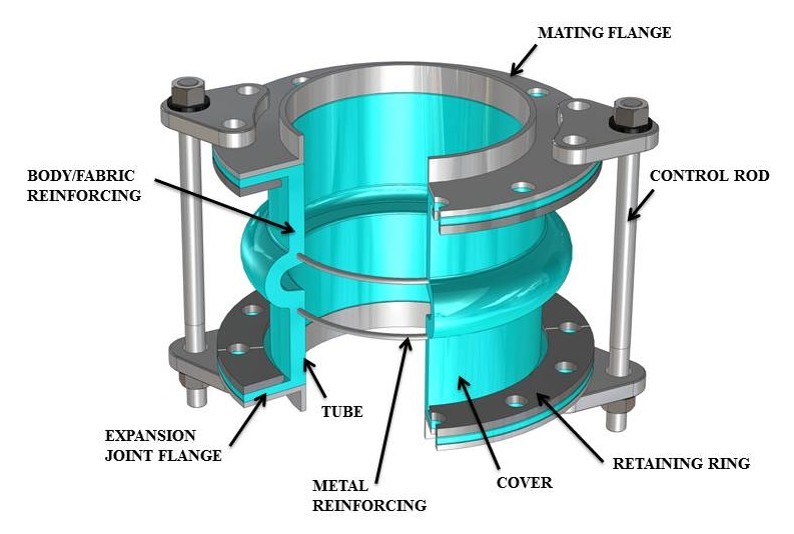

What are the Characteristics of Metal Bellows Expansion Joints?

Metal bellows expansion joints are engineered from stainless steel or other metals, featuring a series of convolutions that provide flexibility while withstanding high pressure and temperature variations. They are ideal for industries like power generation and petrochemical, where reliability under extreme conditions is paramount. When purchasing, consider factors such as material selection, design life, and expected movement capabilities, as these joints are essential for maintaining system integrity.

How Do Rubber Expansion Joints Benefit B2B Buyers?

Rubber expansion joints are crafted from elastomeric materials, making them a cost-effective solution for applications involving lower pressures and temperatures. Commonly found in HVAC systems and water treatment facilities, they provide good vibration dampening and flexibility. Buyers should evaluate the operating environment, as rubber joints may not perform well under extreme temperatures or aggressive chemical exposure, thus influencing long-term operational costs.

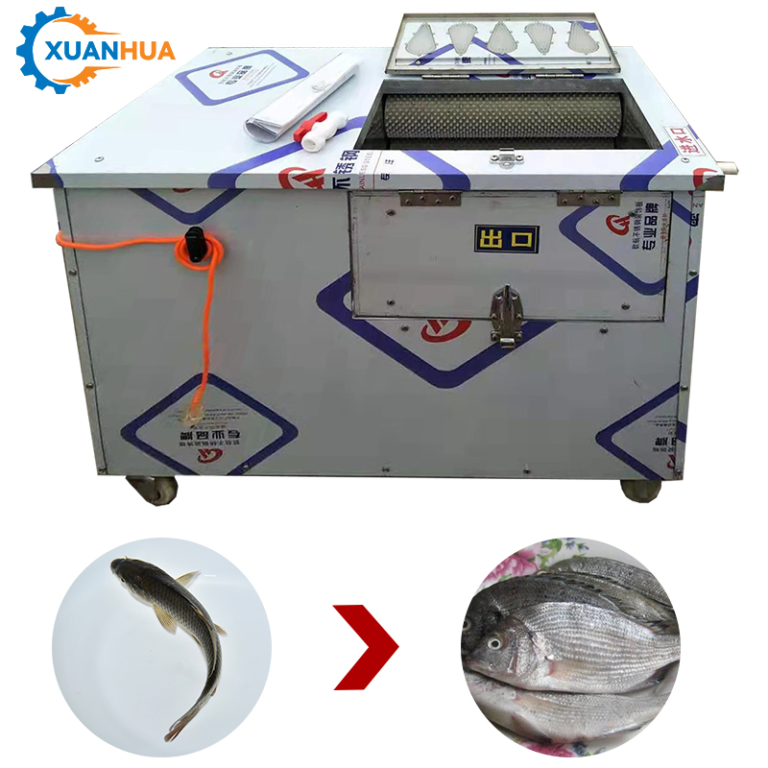

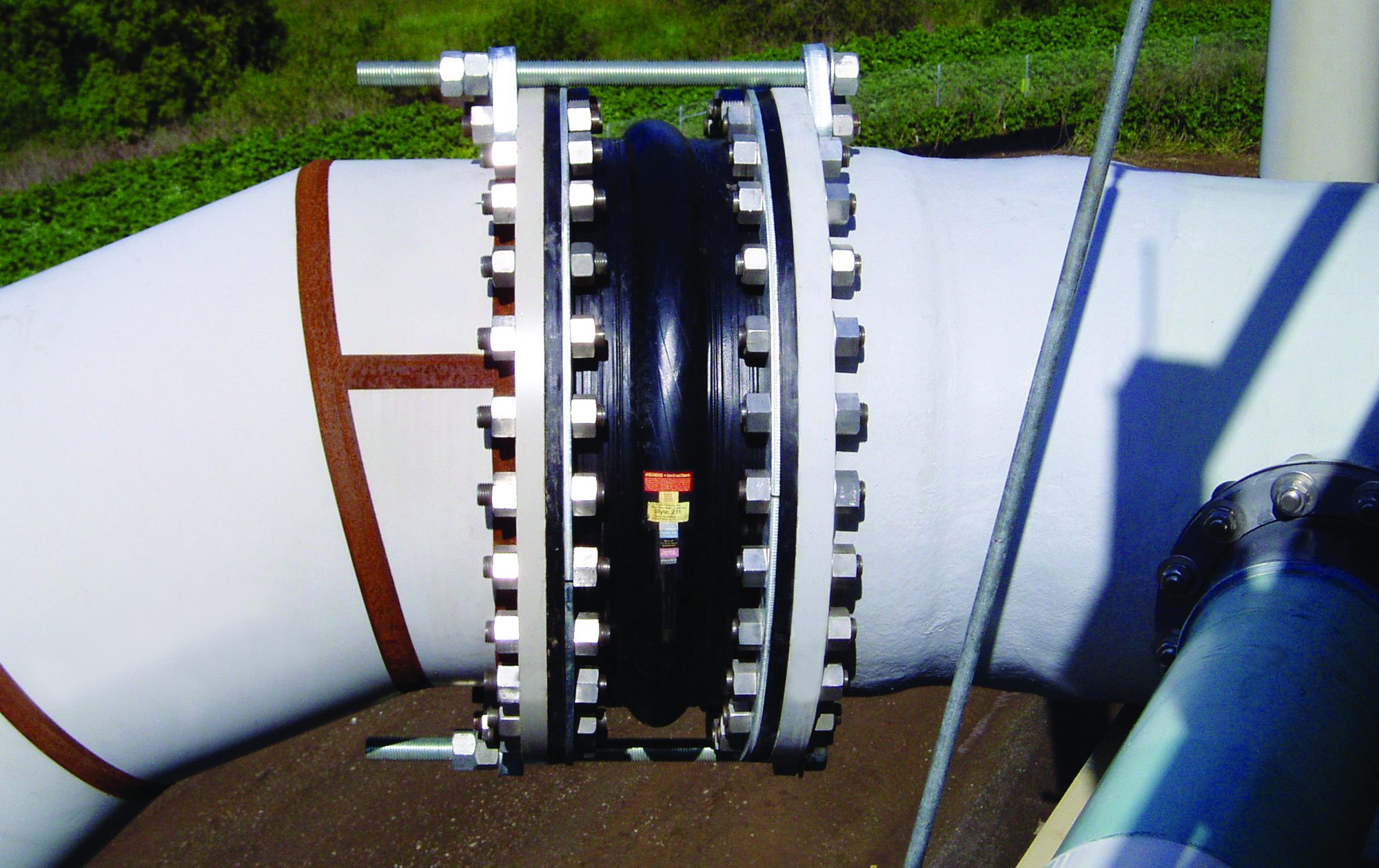

Illustrative image related to expansion joints in piping

What Makes Fabric Expansion Joints Suitable for Certain Applications?

Fabric expansion joints are lightweight and flexible, making them suitable for moderate movement and thermal expansion. They are often utilized in chemical processing and food production, where space constraints are a concern. When considering fabric joints, B2B buyers should assess the specific application requirements, including the type of media being conveyed and the operational environment, as these factors impact durability and performance.

Why Choose PTFE Expansion Joints for Chemical Resistance?

PTFE (Teflon) expansion joints are known for their exceptional chemical resistance, making them a preferred choice in pharmaceutical and food and beverage industries. Their flexible design accommodates thermal expansion while preventing contamination. Buyers should focus on compatibility with the specific chemicals involved and the operating conditions, as PTFE joints may not withstand high-pressure scenarios, which could limit their application scope.

What are the Advantages of Hinged Expansion Joints?

Hinged expansion joints allow for angular movement while minimizing lateral displacement, making them suitable for applications in power generation and marine settings. Their compact design helps save space in piping layouts. When purchasing hinged joints, consider the specific angular movement requirements and installation constraints, as improper selection could lead to mechanical failure or reduced service life.

Key Industrial Applications of expansion joints in piping

| Industry/Sector | Specific Application of expansion joints in piping | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy Sector | Thermal power plants | Reduces thermal stresses, prolongs equipment life | Material compatibility with high temperatures, pressure ratings |

| Petrochemical Industry | Oil refineries and pumping stations | Enhances system flexibility, minimizes downtime | Resistance to corrosive media, custom designs available |

| Chemical Processing | Chemical reactors and heat exchangers | Prevents leaks and failures, ensures safety | Compliance with industry standards, maintenance requirements |

| Water Treatment Facilities | Water pipelines and treatment plants | Maintains pressure stability, reduces maintenance costs | Durability against water chemistry, sizing for flow rates |

| HVAC Systems | Chilled water systems and ductwork | Enhances system efficiency, reduces noise and vibration | Temperature range, insulation needs, space constraints |

How Are Expansion Joints Used in the Energy Sector?

In thermal power plants, expansion joints are critical for managing the thermal expansion and contraction of piping systems. As temperatures fluctuate, these joints absorb movements, which reduces stress on pipes and connected equipment like turbines and boilers. This capability is essential for maintaining operational efficiency and minimizing downtime. International buyers, particularly from regions with varying climate conditions, must ensure that the expansion joints are made from materials that withstand high temperatures and pressures typical in energy applications.

What Role Do Expansion Joints Play in the Petrochemical Industry?

In oil refineries and pumping stations, expansion joints facilitate the safe transport of highly volatile substances while accommodating the dynamic movements caused by temperature changes and mechanical vibrations. They help to maintain system integrity and prevent leaks, which can lead to costly downtime and safety hazards. Buyers should consider sourcing expansion joints that are resistant to corrosion and capable of handling aggressive chemicals, ensuring compliance with industry standards.

Illustrative image related to expansion joints in piping

Why Are Expansion Joints Important in Chemical Processing?

Within chemical reactors and heat exchangers, expansion joints are vital for preventing leaks and maintaining safety in high-pressure environments. They help absorb the expansion caused by temperature variations, which can otherwise lead to catastrophic failures. B2B buyers in this sector should prioritize sourcing joints that meet stringent safety and durability standards, while also ensuring compatibility with the specific chemicals being processed.

How Do Expansion Joints Benefit Water Treatment Facilities?

In water treatment facilities, expansion joints are employed in pipelines to accommodate changes in pressure and temperature, ensuring a stable flow of water. They significantly reduce maintenance costs by preventing leaks and system failures. Buyers in this sector should focus on the durability of materials against various water chemistries and ensure that the sizing of the joints is appropriate for the expected flow rates.

What Advantages Do Expansion Joints Provide in HVAC Systems?

In HVAC systems, particularly in chilled water applications, expansion joints help to minimize noise and vibrations while enhancing overall system efficiency. They allow for the necessary flexibility in ductwork and piping, accommodating thermal expansion. Buyers should consider the temperature range and insulation requirements when sourcing these joints, ensuring they fit within the specific design constraints of their HVAC systems.

3 Common User Pain Points for ‘expansion joints in piping’ & Their Solutions

Scenario 1: High Failure Rates in Expansion Joints

The Problem: One of the prevalent challenges faced by B2B buyers is the frequent failure of expansion joints within piping systems, which can lead to costly downtime and extensive repairs. In industries such as oil and gas, where operational reliability is paramount, the consequences of failure can escalate rapidly. Buyers often discover that expansion joints are either not rated for the specific pressure and temperature conditions they encounter or are improperly installed, leading to premature wear and operational inefficiencies.

The Solution: To mitigate this issue, it is essential for buyers to conduct thorough assessments of the operating conditions before sourcing expansion joints. Start by reviewing the specific pressure, temperature, and movement requirements of your piping system. Consult with manufacturers who can provide detailed specifications and certifications for their products. Opt for metal bellows expansion joints, which offer superior performance under extreme conditions due to their high strength and resistance to corrosion. Additionally, ensure that installation practices are in accordance with the manufacturer’s guidelines to avoid misalignment or excessive torsion, which can contribute to failure. Regular maintenance checks can further prolong the life of the joints, ensuring that any potential issues are identified and addressed before they lead to significant failures.

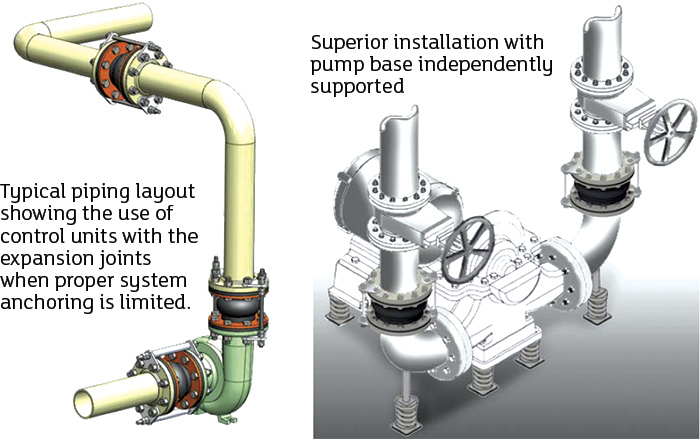

Illustrative image related to expansion joints in piping

Scenario 2: Inadequate Flexibility Causing Stress on Piping Systems

The Problem: Many buyers find that their piping systems lack adequate flexibility, resulting in excessive stress and potential damage to both the pipes and connected equipment. This is particularly common in regions with significant temperature fluctuations, where thermal expansion and contraction are inevitable. Without the proper expansion joints, these stresses can lead to leaks, misalignments, or even catastrophic failures.

The Solution: To address this pain point, buyers should prioritize the design phase of their piping systems by incorporating expansion joints that are tailored to accommodate expected movements. Engage with engineers who specialize in piping systems to analyze the thermal and mechanical conditions your system will face. Select expansion joints that provide sufficient axial, lateral, and angular movement capabilities, ensuring they can absorb the dimensional changes effectively. It may also be beneficial to implement a combination of expansion joints and other flexible components, such as pipe loops, to enhance overall system flexibility. Regularly review and update your system design to adapt to changing operational conditions, and conduct periodic evaluations to ensure the expansion joints are functioning as intended.

Scenario 3: Misalignment and Installation Errors Leading to Increased Downtime

The Problem: Misalignment during the installation of expansion joints is a common source of frustration for B2B buyers, particularly in complex piping systems. This misalignment can lead to increased wear and tear, operational inefficiencies, and unexpected maintenance requirements. In environments where downtime is costly, such as chemical processing or power generation, these installation errors can have significant repercussions.

The Solution: To prevent misalignment issues, buyers should invest in proper training for installation personnel, ensuring they understand the specific requirements for installing expansion joints. Utilizing alignment tools and techniques can facilitate a more accurate installation process. Moreover, consider working with suppliers who offer installation support or guidelines to streamline the process. A thorough inspection after installation is critical—check for proper alignment, secure connections, and the absence of unnecessary tension on the joints. Implementing a robust quality control process during installation will not only minimize downtime but also enhance the longevity and reliability of your piping systems. Regular training and updates on best practices can further empower your team to maintain optimal performance and reduce the likelihood of installation errors in the future.

Strategic Material Selection Guide for expansion joints in piping

What Are the Key Materials for Expansion Joints in Piping?

When selecting materials for expansion joints in piping systems, it is essential to consider their properties, advantages, and limitations to ensure optimal performance. Below, we analyze four common materials used in expansion joints: stainless steel, rubber, PTFE (Polytetrafluoroethylene), and fabric.

How Does Stainless Steel Perform in Expansion Joints?

Stainless steel is one of the most widely used materials for expansion joints due to its excellent mechanical properties. It typically offers high-temperature resistance (up to 1,200°F or 650°C) and can withstand significant pressure (up to 3000 psi). Its corrosion resistance makes it suitable for harsh environments, including chemical processing and oil refineries.

Pros: Stainless steel is durable and has a long service life, making it a cost-effective option in the long run. It also provides good flexibility, enabling it to absorb thermal expansions effectively.

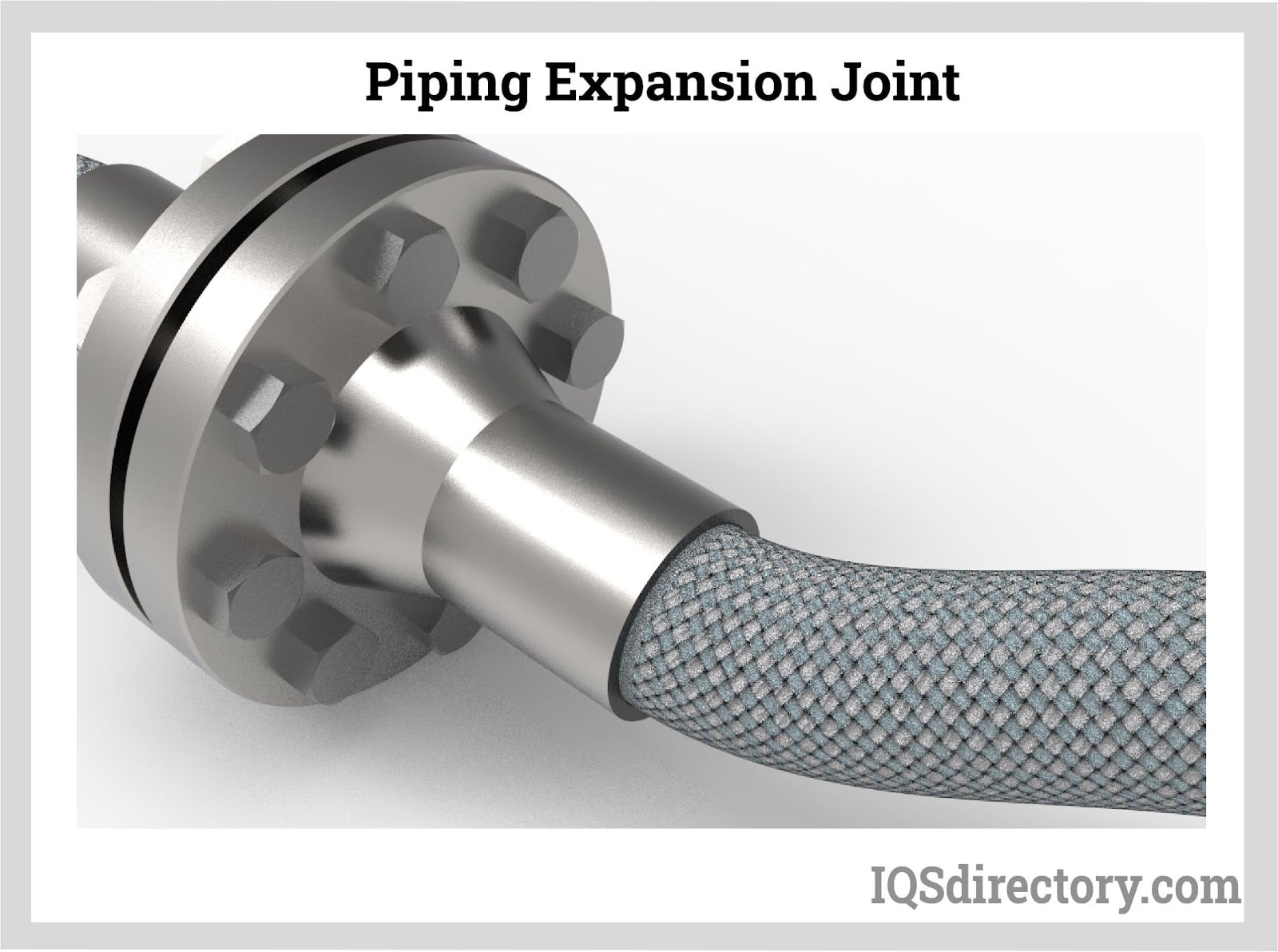

Illustrative image related to expansion joints in piping

Cons: The initial manufacturing cost can be high, and the complexity of forming stainless steel bellows may lead to longer lead times. Additionally, it may not be suitable for applications involving highly corrosive substances without proper alloy selection.

Impact on Application: Stainless steel is compatible with a wide range of media, including gases, liquids, and corrosive chemicals. Buyers must ensure compliance with international standards, such as ASTM or DIN, particularly in regions like Europe and the Middle East.

What Are the Benefits of Using Rubber in Expansion Joints?

Rubber expansion joints are commonly used in applications where flexibility is paramount. They can handle temperatures up to 250°F (121°C) and are particularly effective in absorbing vibrations and noise.

Pros: Rubber joints are generally less expensive than metal options, making them an attractive choice for budget-conscious projects. They are lightweight and easy to install, which can reduce labor costs.

Cons: Rubber has limitations in high-temperature and high-pressure applications. Over time, rubber can degrade due to environmental factors, leading to a shorter lifespan compared to metal joints.

Impact on Application: Rubber is suitable for water, air, and some chemical applications. Buyers in regions like Africa and South America should consider local environmental conditions, as extreme temperatures can affect rubber performance.

How Does PTFE Enhance Expansion Joint Performance?

PTFE is renowned for its chemical resistance and ability to handle extreme temperatures (up to 500°F or 260°C). It is often used in applications involving aggressive chemicals, making it a preferred choice in the chemical and pharmaceutical industries.

Pros: The primary advantage of PTFE is its exceptional resistance to corrosion and chemical attack. It also has low friction properties, which can enhance the efficiency of piping systems.

Cons: PTFE expansion joints can be more expensive than rubber and may require specialized manufacturing processes. They are also less flexible than rubber or metal options.

Impact on Application: PTFE is compatible with a wide range of aggressive media, making it ideal for chemical processing facilities. International buyers must ensure compliance with relevant industry standards, particularly in Europe and the Middle East, where regulations can be stringent.

What Role Does Fabric Play in Expansion Joint Applications?

Fabric expansion joints are typically used in high-temperature applications, such as exhaust systems in power plants. They can handle temperatures exceeding 1,000°F (538°C) and are often reinforced with metal for added strength.

Illustrative image related to expansion joints in piping

Pros: Fabric joints are lightweight and can be customized for specific applications, allowing for flexibility in design. They can also absorb vibrations and thermal expansions effectively.

Cons: The durability of fabric joints can be an issue, especially in abrasive environments. They may require more frequent replacements compared to metal options.

Impact on Application: Fabric expansion joints are suitable for flue gas applications and other high-temperature environments. Buyers should consider local manufacturing capabilities, as some regions may have limited access to high-quality fabric materials.

Summary Table of Material Selection for Expansion Joints

| Material | Typical Use Case for expansion joints in piping | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil refineries | High durability and temperature resistance | High initial cost, complex manufacturing | High |

| Rubber | Water, air, and low-pressure applications | Cost-effective and easy to install | Limited temperature and pressure range | Low |

| PTFE | Chemical and pharmaceutical industries | Exceptional chemical resistance | Higher cost, less flexibility | High |

| Fabric | High-temperature exhaust systems | Lightweight and customizable | Durability issues in abrasive environments | Medium |

This strategic material selection guide provides actionable insights for B2B buyers in various regions, ensuring informed decisions that align with industry standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for expansion joints in piping

What Are the Key Stages in the Manufacturing Process of Expansion Joints?

The manufacturing of expansion joints is a complex process that requires precision and attention to detail. Understanding the main stages involved can help B2B buyers make informed decisions when selecting suppliers.

How is Material Prepared for Expansion Joints?

The initial step in the manufacturing process involves the careful selection and preparation of materials. Commonly used materials include stainless steel, rubber, and plastics such as PTFE. For metal bellows, the material is typically sourced as sheets or coils.

Material preparation involves cutting the raw materials into the required dimensions, followed by cleaning to remove any contaminants. This is crucial, as impurities can affect the integrity of the final product. In addition, material testing may be performed to ensure it meets specific mechanical and chemical properties required for the application.

What Techniques are Used in Forming Expansion Joints?

Once the materials are prepared, the next stage is forming. For metal bellows, this often involves processes such as deep drawing or hydroforming. These techniques create the convoluted shapes necessary for flexibility and pressure containment.

Deep drawing employs a punch to press a flat sheet into a die, forming the bellows’ initial shape. Hydroforming uses high-pressure fluid to mold the material, allowing for more complex geometries and reducing the risk of defects. The goal during this stage is to achieve the desired flexibility while ensuring that the bellows can withstand the internal pressure of the piping system.

How is Assembly Performed for Expansion Joints?

After forming, the various components of the expansion joint, including the bellows, end fittings, and any necessary accessories, are assembled. This stage may involve welding, bolting, or other fastening techniques to ensure that all parts are securely attached.

Quality checks during assembly are vital. Each component should be inspected for dimensional accuracy and integrity before final assembly. This step helps to prevent issues that could arise during later stages of production or in the final product’s performance.

What Finishing Processes Are Involved in Expansion Joint Manufacturing?

The finishing stage involves several processes aimed at enhancing the durability and aesthetics of the expansion joints. This may include surface treatments like coating, painting, or passivation to improve corrosion resistance.

Finishing also often involves additional inspections to verify that the product meets specified tolerances and visual standards. At this point, proper documentation is generated, detailing the materials used and the processes followed, which can be critical for traceability in international markets.

What Quality Control Measures Are Implemented in Expansion Joint Manufacturing?

Quality control (QC) is essential in the manufacturing of expansion joints, given the critical role these components play in various industrial applications. An effective QC process not only ensures compliance with international standards but also enhances the reliability and safety of the products.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for manufacturers that adhere to international quality standards such as ISO 9001. This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with EU regulations or API (American Petroleum Institute) standards for oil and gas applications are crucial. These certifications indicate that the products have been tested and validated for specific applications and environments.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process to ensure that any defects are identified and rectified early. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): This occurs during the manufacturing stages, where operators monitor processes and perform checks to ensure that the product remains within specified tolerances.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing, where the complete product is tested against design specifications before shipment.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to validate the integrity and performance of expansion joints. Common methods include:

- Hydrostatic Testing: This tests the ability of the expansion joint to withstand internal pressure without leaking.

- Visual Inspection: A thorough examination of the finished product for any visible defects or irregularities.

- Dimensional Inspection: Measuring the dimensions of the expansion joints to ensure they meet the specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Buyers can take several steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing practices, quality control measures, and overall compliance with international standards.

-

Reviewing Quality Assurance Reports: Requesting documentation related to quality assurance practices, including test results and compliance certificates, can provide insight into the supplier’s reliability.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased assessment of the supplier’s products and processes. This is particularly valuable for buyers concerned about compliance and quality in diverse geographical markets.

What Are the Quality Control Considerations for International Buyers?

International buyers must also be aware of the nuances in quality control that may vary by region. For example, regulatory requirements may differ significantly between Europe and Africa, necessitating careful consideration of local compliance standards. Additionally, cultural differences in business practices can impact the reliability and transparency of suppliers.

Buyers should prioritize suppliers who demonstrate a commitment to international quality standards and are willing to provide clear documentation and evidence of their QC processes. This diligence can lead to stronger partnerships and reduced risk in procurement.

By understanding the manufacturing processes and quality assurance measures involved in the production of expansion joints, B2B buyers can make more informed decisions and ensure they are procuring high-quality products suitable for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expansion joints in piping’

Introduction

In the competitive landscape of international B2B procurement, sourcing the right expansion joints for piping systems is crucial for operational efficiency and reliability. This checklist serves as a practical guide to help buyers navigate the complexities of selecting the most suitable expansion joints, ensuring they meet both technical specifications and business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for the expansion joints. Consider factors such as the type of piping system, expected temperature and pressure ranges, and specific movement capabilities required (axial, lateral, or angular). Having precise specifications will facilitate communication with suppliers and help in evaluating their offerings effectively.

Step 2: Research Material Compatibility

Different materials—such as stainless steel, rubber, or PTFE—offer varying levels of performance under specific conditions. Assess the compatibility of materials with the media being transported (e.g., corrosive chemicals, steam) and the environmental factors (temperature fluctuations, exposure to elements). Choosing the right material not only enhances durability but also minimizes maintenance costs over time.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant industry certifications and standards, such as ISO 9001 or ASME compliance. Certifications indicate a commitment to quality and safety, which is essential in industries like petrochemicals or energy, where failure can have significant consequences. Request documentation to confirm these credentials and assess the supplier’s manufacturing processes.

Step 4: Assess Design Flexibility and Customization Options

Understand the design capabilities of suppliers and whether they can provide customized solutions tailored to your specific requirements. Expansion joints often need to accommodate unique piping configurations and operational challenges. Suppliers should be able to demonstrate their ability to create bespoke designs that enhance system performance.

Illustrative image related to expansion joints in piping

Step 5: Request Detailed Product Information

When narrowing down suppliers, request comprehensive product information, including technical datasheets, installation guidelines, and maintenance recommendations. This documentation is vital for understanding the performance characteristics and lifecycle of the expansion joints. It also aids in ensuring that the selected products align with your operational standards.

Step 6: Inquire About Lead Times and Availability

Supply chain dynamics can significantly affect project timelines, so it’s crucial to discuss lead times and product availability upfront. Confirm the supplier’s ability to deliver on time and assess any potential bottlenecks that could impact your operations. A reliable supplier should provide transparent timelines and maintain adequate stock levels to meet your needs.

Step 7: Evaluate After-Sales Support and Warranty Terms

After securing a supplier, evaluate the after-sales support they offer, including installation assistance, troubleshooting, and warranty provisions. Strong after-sales support can greatly reduce downtime and operational disruptions. Ensure that the warranty terms are clear and that they cover potential defects or performance issues over the expected lifecycle of the expansion joints.

By following this checklist, B2B buyers can make informed decisions when procuring expansion joints, ultimately enhancing the reliability and efficiency of their piping systems.

Comprehensive Cost and Pricing Analysis for expansion joints in piping Sourcing

What Are the Key Cost Components in Sourcing Expansion Joints for Piping?

When analyzing the cost structure for expansion joints in piping, several key components come into play. The primary cost elements include:

-

Materials: The choice of materials significantly impacts cost. Metal bellows, typically made from stainless steel, are more expensive but offer superior durability and resistance to high temperatures and corrosion compared to rubber or plastic alternatives. Each material’s cost fluctuates based on market conditions and availability.

-

Labor: Labor costs can vary widely depending on the location of manufacturing. Skilled labor is required for the precision manufacturing of bellows, which can increase costs, especially in regions where labor costs are higher.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and maintenance. Efficient manufacturing processes can help reduce overhead, but complex designs may require more intricate setups, increasing costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom expansion joints. These costs are often amortized over production runs, so larger orders can reduce the per-unit tooling expense.

-

Quality Control (QC): Investment in rigorous QC processes ensures the reliability and safety of expansion joints. This can be a significant cost, particularly if third-party certifications are required, which are essential for industries like petrochemicals and energy.

-

Logistics: Shipping costs can vary based on the size and weight of the joints, as well as the distance to the buyer’s location. International shipping may also involve customs duties, which can further inflate costs.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin can vary based on the supplier’s reputation, the complexity of the product, and market demand.

What Factors Influence the Pricing of Expansion Joints?

Several key factors can influence the pricing of expansion joints, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing can lead to significant cost savings. Suppliers often provide discounts for larger orders, which can help mitigate high per-unit costs.

-

Specifications and Customization: Customized expansion joints tailored to specific applications or environments usually incur higher costs due to the additional design and manufacturing complexities.

-

Materials: As mentioned earlier, the choice of material affects pricing. Specialty materials or those with enhanced performance characteristics will command higher prices.

-

Quality and Certifications: Products that meet international quality standards or industry-specific certifications may be priced higher but provide assurance of reliability and performance, which is crucial in high-stakes environments.

-

Supplier Factors: Supplier reputation, experience, and geographic location can affect pricing. Established suppliers with a track record of reliability may charge a premium.

-

Incoterms: The chosen Incoterms can also impact the total cost. Different terms dictate the responsibilities and costs associated with shipping, insurance, and customs clearance, which can lead to price variations.

What Are Effective Negotiation and Cost-Efficiency Strategies for Buyers?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding negotiation strategies can lead to better deals:

-

Total Cost of Ownership (TCO): Buyers should evaluate not just the initial purchase price but also the TCO, which includes maintenance, replacement, and operational costs over the product’s lifecycle. This holistic view can justify higher upfront costs for higher-quality products.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Regular communication and trust can foster a mutually beneficial partnership.

-

Market Research: Understanding current market trends, competitor pricing, and material costs can empower buyers during negotiations, enabling them to make informed decisions.

-

Flexible Specifications: If possible, being flexible with specifications can open up alternative solutions that may be more cost-effective while still meeting performance requirements.

-

Explore Multiple Suppliers: Engaging multiple suppliers for quotes can create competition, often resulting in better pricing. It also provides options for different lead times and product variations.

Conclusion

In summary, sourcing expansion joints in piping involves a multifaceted cost structure influenced by various factors. By understanding these components and employing effective negotiation strategies, international B2B buyers can optimize their sourcing decisions and achieve significant cost savings. It is essential to remain informed about market dynamics and supplier capabilities to ensure a successful procurement process. Please note that prices can vary widely based on the factors discussed, and buyers should seek detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing expansion joints in piping With Other Solutions

Exploring Alternatives to Expansion Joints in Piping Systems

In the realm of piping systems, expansion joints play a critical role in accommodating thermal expansion, vibration, and misalignment. However, there are alternative solutions that can also address these challenges. This section compares expansion joints with two viable alternatives: pipe loops and flexible connectors. By evaluating these options, B2B buyers can make informed decisions based on their specific requirements.

| Comparison Aspect | Expansion Joints In Piping | Pipe Loops | Flexible Connectors |

|---|---|---|---|

| Performance | Highly effective in absorbing thermal expansion and vibration; minimal pressure drop. | Effective for flexibility but may lead to increased pressure drops and space requirements. | Good flexibility and vibration absorption; limited in high-temperature applications. |

| Cost | Moderate initial investment; long-term cost savings through reduced maintenance. | Higher initial costs due to additional piping and fittings; ongoing maintenance costs. | Lower upfront costs; may require more frequent replacements. |

| Ease of Implementation | Relatively straightforward installation; can be customized. | More complex installation requiring significant space and design considerations. | Easy to install, often requiring minimal modifications to existing systems. |

| Maintenance | Low maintenance; designed for long service life. | Moderate maintenance; additional components may require regular checks. | Higher maintenance frequency; potential for wear and tear. |

| Best Use Case | Ideal for high-stress environments with significant thermal expansion, e.g., power plants and petrochemical facilities. | Suitable for applications where space allows and lower pressure drops are acceptable. | Effective in low to moderate pressure systems where flexibility is prioritized. |

In-Depth Analysis of Alternatives

What are Pipe Loops and Their Advantages?

Pipe loops involve creating a series of bends in the piping system to accommodate thermal expansion and contraction. While they can provide flexibility, the design often requires additional space and can lead to increased pressure drops due to the longer flow path. Pipe loops may be beneficial in applications where layout allows for their integration without compromising the efficiency of the system.

Pros:

– Can handle large thermal expansions.

– Effective for redirecting flow without significant pressure loss in well-designed systems.

Cons:

– Higher initial costs for materials and installation.

– Increased maintenance due to more components and potential wear on elbows.

How Do Flexible Connectors Compare?

Flexible connectors, typically made from materials like rubber or fabric, offer flexibility and vibration absorption, making them suitable for various applications. However, they may not perform as well in high-temperature or high-pressure environments compared to expansion joints. These connectors can be a cost-effective solution for less demanding applications.

Pros:

– Lower upfront costs.

– Easy to install and replace.

Cons:

– Limited lifespan in high-stress environments.

– More frequent maintenance and potential failures due to wear.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate piping solution, B2B buyers should consider several factors, including the operational environment, budget constraints, and specific application requirements. Expansion joints are often the best choice for high-stress environments where thermal expansion is significant. In contrast, pipe loops may suit projects with ample space and less stringent pressure requirements. Flexible connectors provide a cost-effective alternative for less demanding applications but may require more frequent maintenance. Evaluating these aspects will guide buyers toward the most effective solution for their piping systems.

Illustrative image related to expansion joints in piping

Essential Technical Properties and Trade Terminology for expansion joints in piping

What Are the Key Technical Properties of Expansion Joints in Piping?

Understanding the essential technical properties of expansion joints is crucial for B2B buyers, particularly in industries reliant on piping systems. Here are several critical specifications to consider:

-

Material Grade

Expansion joints are commonly made from materials like stainless steel, rubber, or PTFE. The choice of material affects durability, corrosion resistance, and temperature tolerance. For instance, stainless steel offers high strength and is ideal for high-temperature applications. Selecting the right material can significantly impact the performance and longevity of piping systems. -

Pressure Rating

This specification indicates the maximum internal pressure an expansion joint can withstand. Pressure ratings are crucial for ensuring the safety and reliability of piping systems, particularly in high-stakes industries such as petrochemical and energy. Understanding pressure ratings helps buyers select suitable expansion joints that can handle the operational demands without failure. -

Temperature Tolerance

Each expansion joint type has a defined temperature range that it can operate within. This property is essential for applications involving hot fluids or gases, as exceeding the temperature limits can lead to material degradation or joint failure. B2B buyers must ensure that the selected expansion joint aligns with the operational temperature of their systems. -

Movement Capabilities

Expansion joints are designed to accommodate various movements, including axial compression, lateral offset, and angular rotation. Understanding these capabilities allows buyers to choose the right joint for their specific piping configuration, ensuring effective absorption of thermal expansion and preventing undue stress on the system. -

Cycle Life

This term refers to the number of operational cycles an expansion joint can undergo before experiencing failure. A longer cycle life indicates better durability and less frequent replacement, which is critical for minimizing downtime and maintenance costs. B2B buyers should assess the cycle life against their operational needs to ensure optimal investment. -

End Fittings

These components connect the expansion joint to the piping system. Common types include flanged or butt-weld ends. The choice of end fittings can influence installation ease and compatibility with existing systems. Buyers should consider the connection method that best suits their operational requirements.

What Are the Common Trade Terms Related to Expansion Joints?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces components that are integrated into larger systems. In the context of expansion joints, understanding OEM specifications ensures that buyers receive products that meet their operational standards and compatibility requirements. -

MOQ (Minimum Order Quantity)

This term refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategy and manage inventory costs effectively, especially when dealing with customized or specialized expansion joints. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It’s essential for buyers to specify their requirements clearly in an RFQ to receive accurate pricing and product options, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms helps buyers anticipate costs and risks associated with shipping expansion joints, crucial for international transactions. -

Lead Time

This term refers to the time taken from placing an order to the delivery of the product. Knowing the lead time is vital for project planning and ensuring that expansion joints arrive when needed to avoid delays in construction or maintenance schedules. -

Warranty Period

The warranty period is the duration during which a supplier guarantees the performance of the expansion joint. Understanding warranty terms helps buyers assess the reliability and quality assurance of their purchases, providing peace of mind in their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing expansion joints for their piping systems, ensuring optimal performance and reliability.

Navigating Market Dynamics and Sourcing Trends in the expansion joints in piping Sector

What Are the Current Market Trends Influencing Expansion Joints in Piping?

The global market for expansion joints in piping systems is witnessing dynamic changes driven by several key factors. Increasing industrialization and urbanization in regions such as Africa, South America, and the Middle East are creating heightened demand for efficient piping systems, particularly in sectors like energy, petrochemicals, and manufacturing. As these industries expand, the need for reliable and flexible piping solutions that can accommodate thermal expansion and mechanical vibrations becomes paramount.

Emerging technologies such as IoT and predictive maintenance are revolutionizing sourcing strategies for expansion joints. B2B buyers are now leveraging data analytics to optimize inventory management and improve system reliability. This shift towards smart systems allows for more informed decision-making regarding the procurement of expansion joints, ensuring that businesses can anticipate maintenance needs and reduce downtime.

Moreover, sustainability is becoming a focal point in sourcing strategies. Buyers are increasingly prioritizing suppliers that offer environmentally friendly products and practices. This trend is particularly significant in Europe and parts of Africa, where regulatory frameworks are evolving to enforce stricter environmental standards. As a result, manufacturers are innovating to provide expansion joints made from sustainable materials or designed for enhanced durability, thereby minimizing lifecycle environmental impact.

How Are Sustainability and Ethical Sourcing Shaping the Expansion Joints Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the expansion joints sector. The environmental impact of manufacturing processes and materials used in expansion joints can be substantial. Consequently, businesses are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing recyclable materials.

Incorporating ‘green’ certifications into sourcing decisions is becoming more common. Certifications like ISO 14001, which focuses on effective environmental management systems, are now pivotal in evaluating potential suppliers. Buyers are also looking for materials that are not only durable but also sourced responsibly, such as stainless steel that adheres to ethical mining practices.

Additionally, the trend towards circular economy principles is influencing sourcing decisions. Buyers are more inclined to choose products designed for longevity and recyclability, reducing waste and promoting resource efficiency. This shift not only aligns with corporate social responsibility objectives but also enhances brand reputation and customer loyalty, particularly in markets where consumers are becoming increasingly environmentally conscious.

What Is the Historical Context Behind Expansion Joints in Piping?

The evolution of expansion joints in piping systems can be traced back to the early industrial age, where the need for flexible connections in steam and water systems became apparent. Initially, rudimentary designs focused on simple bellows made from leather or fabric. However, as industrial processes advanced and the demand for more robust solutions grew, manufacturers began experimenting with metal bellows, significantly improving durability and performance.

Illustrative image related to expansion joints in piping

By the mid-20th century, the introduction of stainless steel revolutionized the expansion joints market, providing enhanced resistance to corrosion and high temperatures. This innovation paved the way for widespread adoption across various sectors, including petrochemical and energy industries, where thermal expansion and mechanical vibrations posed significant challenges. Today, expansion joints are integral components of modern piping systems, reflecting decades of engineering advancements and material science innovations that continue to evolve in response to emerging industrial needs.

Conclusion

In conclusion, the expansion joints market is experiencing significant transformations driven by technological advancements, sustainability considerations, and the evolving needs of global industries. For B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that align with both operational requirements and ethical standards. As the market continues to evolve, staying ahead of these trends will be crucial for achieving competitive advantage and ensuring long-term success.

Frequently Asked Questions (FAQs) for B2B Buyers of expansion joints in piping

-

How do I select the right expansion joint for my piping system?

Choosing the right expansion joint involves assessing your piping system’s specific requirements, including operating temperature, pressure, and the types of movements expected (axial, lateral, or angular). Consider the medium being transported, as it may dictate the material compatibility—stainless steel is often preferred for high-temperature and corrosive environments. Additionally, consult with suppliers about custom designs that can accommodate unique installation challenges or specifications. Always review product certifications and compliance with international standards to ensure reliability and safety. -

What is the best material for expansion joints in high-temperature applications?

For high-temperature applications, metal bellows made from stainless steel are the optimal choice due to their strength, durability, and resistance to thermal expansion. Stainless steel can handle extreme temperatures while maintaining integrity under pressure. In contrast, rubber and fabric materials might degrade under high heat, making them less suitable for such environments. Always confirm the material specifications with your supplier to ensure they meet the thermal requirements of your specific application. -

What are the typical lead times for ordering expansion joints internationally?

Lead times for international orders of expansion joints can vary significantly based on factors such as manufacturing location, material availability, and customization requirements. Standard expansion joints may have lead times of 4-6 weeks, while custom designs could take 8-12 weeks or longer. It’s advisable to discuss timelines directly with suppliers and factor in potential shipping delays, especially when importing to regions with stricter customs regulations. Planning ahead can help mitigate any disruptions in your project timelines. -

What is the minimum order quantity (MOQ) for expansion joints?

The MOQ for expansion joints often depends on the manufacturer and the complexity of the design. Many suppliers may have a standard MOQ ranging from 10 to 50 units for standard products, while custom designs may require larger orders to justify production costs. It’s essential to communicate your specific needs to the supplier and inquire about flexibility in MOQs, especially for initial orders or trial runs. Some manufacturers may offer lower quantities for prototypes or testing phases. -

How can I ensure quality assurance (QA) when sourcing expansion joints?

To ensure quality assurance when sourcing expansion joints, first, verify that your supplier adheres to recognized industry standards and certifications, such as ISO or ASME. Request detailed documentation of the manufacturing processes, including material certifications and test results. Conducting factory audits or quality inspections before shipment can also help assess the manufacturing conditions. Establishing a good communication channel with your supplier allows for ongoing quality checks throughout the production process. -

What payment terms should I expect when sourcing expansion joints internationally?

Payment terms for international orders of expansion joints typically vary by supplier and can range from upfront payment to net 30 or net 60 terms. Many suppliers may require a deposit (often 30-50%) at the time of order, with the balance due upon shipment or delivery. It’s crucial to negotiate terms that align with your cash flow and project timelines. Consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

What logistics considerations should I keep in mind when importing expansion joints?

When importing expansion joints, consider shipping methods that balance cost and delivery time. Air freight is faster but more expensive, while sea freight is economical for larger shipments but may take longer. Be aware of customs regulations in your country, including duties and taxes, to avoid unexpected costs. Working with a logistics partner experienced in handling industrial products can streamline the process, ensuring compliance and timely delivery. -

Can expansion joints be customized to fit unique piping configurations?

Yes, expansion joints can be customized to meet specific piping configurations and operational requirements. Many manufacturers offer tailored solutions that accommodate unique dimensions, movement capabilities, and environmental conditions. When requesting customization, provide detailed specifications, including the intended application and any constraints of your piping system. Collaborating closely with the supplier during the design process can help ensure the final product meets your exact needs and enhances system performance.

Top 8 Expansion Joints In Piping Manufacturers & Suppliers List

1. IQS Directory – Expansion Joints

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Expansion joints are designed to accommodate movement in pipes, ducts, and other pipeline components caused by thermal and mechanical vibrations. They expand with rising temperatures and contract when temperatures decrease, providing secure support to piping systems. Common materials used include metal (usually aluminum), rubber, and braided materials. Metal expansion joints are ideal for signific…

2. Flexonics – Piping Expansion Joints

Domain: flexonics.com

Registered: 1996 (29 years)

Introduction: Flexonics offers a range of piping expansion joints designed to accommodate thermal expansion and contraction in piping systems. Key features include:

– **Sizes Available**: Expansion joints are available in various sizes ranging from 2″ to 144″.

– **Design Components**: Metal bellows expansion joints consist of a flexible bellows element, end fittings (flanges or butt-weld ends), and accessory i…

3. Crane Engineering – Piping Expansion Joints

Domain: blog.craneengineering.net

Registered: 2003 (22 years)

Introduction: A piping expansion joint is installed in piping systems to absorb vibrations and shock, relieve anchor stress, reduce noise, and compensate for misalignment. They allow pipes to move in three ways: axial compression or extension, lateral offset, and angular deflection. Expansion joints come in three materials: metal (for thermal expansion), rubber (for vibration absorption and shock), and braided …

4. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems, offering a variety of designs in rubber, stainless steel, and polytetrafluoroethylene (PTFE). Their expansion joints are designed to protect equipment from thermal expansion, vibration, and ground movement, ensuring safe and reliable operations. Key features include:

– **Materials**: Rubber (EPDM, Neopren…

5. Reddit – Steel Expansion Test

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Material: Steel, Length: 20 m, Temperature Change (Delta T): 25 K, Axial Expansion (Delta L): 5.75 mm, Test Pressure: 12 bar, Working Pressure: 6 bar.

6. Garlock – Expansion Joints

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. PDBlowers – Pipe Expansion Joints

Domain: pdblowers.com

Introduction: Pipe Expansion Joints isolate the blower or vacuum pump from other system components to allow for thermal expansion and misalignment of the piping. Common flanged rubber expansion joints feature single or double arched bellows constructed of molded elastomers, specifically EPDM elastomer for standard single arch models. Functions include reducing flange loading on the blower, allowing thermal expa…

8. Grainger – Pipe Expansion Joints

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Pipe Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for expansion joints in piping

As the demand for reliable and efficient piping systems continues to rise across various industries, understanding the critical role of expansion joints is paramount for international buyers. Strategic sourcing of expansion joints not only enhances the durability and performance of piping systems but also mitigates risks associated with thermal expansion, vibrations, and misalignments. By integrating high-quality expansion joints into your operations, you can significantly reduce maintenance costs and prolong the lifespan of your equipment.

For buyers in Africa, South America, the Middle East, and Europe, prioritizing local suppliers who understand regional requirements can facilitate smoother procurement processes and foster stronger partnerships. Emphasizing customization in design and material selection will ensure that the expansion joints meet specific application needs, whether in energy, petrochemical, or process industries.

Looking ahead, the market for expansion joints is set to evolve with advancements in materials and technology. By staying informed and proactively sourcing innovative solutions, you can position your organization for success in an increasingly competitive landscape. Now is the time to evaluate your expansion joint needs and collaborate with trusted suppliers to secure the best solutions for your piping systems.

Illustrative image related to expansion joints in piping

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.