Is Your Expanded Metal For Bbq Grill Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for expanded metal for bbq grill

In today’s competitive landscape, sourcing expanded metal for BBQ grills poses significant challenges for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, navigating the complexities of material selection, supplier reliability, and cost efficiency can be daunting. Expanded metal is not just a functional component; it plays a pivotal role in enhancing the cooking experience, ensuring durability, and providing the necessary support for various grilling applications.

This comprehensive guide delves into the diverse types of expanded metal suitable for BBQ grills, highlighting their unique applications, including grates, baskets, and smoker components. It will also cover crucial aspects of supplier vetting, emphasizing the importance of quality assurance and compliance with international standards. Additionally, we will provide insights into cost considerations, helping you make informed purchasing decisions that align with your business objectives.

By equipping you with actionable insights and practical knowledge, this guide empowers international B2B buyers to navigate the global market confidently. You will gain clarity on selecting the right expanded metal products that meet your specific needs while fostering relationships with reliable suppliers. With this resource at your disposal, you can ensure that your procurement process is both efficient and effective, ultimately enhancing your product offerings and customer satisfaction in the competitive BBQ grill industry.

Understanding expanded metal for bbq grill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Raised Expanded Metal | Diamond-shaped openings, greater strength | Commercial grills, industrial kitchens | Pros: Excellent load-bearing capacity; durable. Cons: Rough edges may damage delicate foods; harder to clean. |

| Flattened Expanded Metal | Smooth surface, easier to clean | Residential grills, catering services | Pros: Safer for cooking smaller items; easier to maintain. Cons: Slightly less strength than raised versions; may warp under heavy loads. |

| Stainless Steel Expanded Metal | Corrosion-resistant, high durability | High-end grills, outdoor kitchens | Pros: Long-lasting; resistant to rust; retains heat well. Cons: Higher cost; may require specific welding equipment for modifications. |

| Heavy-Duty Expanded Metal | Thicker gauge, robust design | Commercial BBQ pits, large-scale events | Pros: Exceptional strength; ideal for heavy items. Cons: Heavier and may require more robust grill frames; increased shipping costs due to weight. |

| Custom-Cut Expanded Metal | Tailored sizes and shapes for specific needs | Custom grill fabrication, specialty applications | Pros: Fits unique designs; maximizes cooking efficiency. Cons: Longer lead times; potential for higher costs depending on specifications. |

What Are the Key Characteristics of Raised Expanded Metal for Grills?

Raised expanded metal features diamond-shaped openings that provide exceptional strength, making it suitable for commercial grills and industrial kitchens. Its robust design supports heavy items, ensuring durability during high-volume cooking. However, the rough edges can pose a risk to delicate foods, and cleaning can be more challenging compared to other types. Buyers should consider the balance between strength and ease of use based on their grilling needs.

Why Choose Flattened Expanded Metal for Your Grill?

Flattened expanded metal offers a smooth surface that is easier to clean and safer for cooking smaller items. This type is ideal for residential grills and catering services, where presentation and food safety are paramount. While it may not support as much weight as raised expanded metal, its ease of maintenance and reduced risk of food damage make it a popular choice. Buyers should weigh these factors against their specific cooking applications.

What Advantages Does Stainless Steel Expanded Metal Provide?

Stainless steel expanded metal is known for its corrosion resistance and high durability, making it an excellent option for high-end grills and outdoor kitchens. This type retains heat well and is less likely to rust, ensuring longevity even in harsh environments. However, the higher cost and potential need for specialized welding equipment may be barriers for some buyers. When considering stainless steel, buyers should evaluate their budget and the expected lifespan of their grills.

When Should You Consider Heavy-Duty Expanded Metal?

Heavy-duty expanded metal is characterized by a thicker gauge, providing robust design ideal for commercial BBQ pits and large-scale events. Its exceptional strength allows it to handle heavy items without warping or bending. While this type is perfect for serious grilling applications, its weight can necessitate more robust grill frames, and shipping costs may be higher. Buyers should assess their operational requirements and budget when considering heavy-duty options.

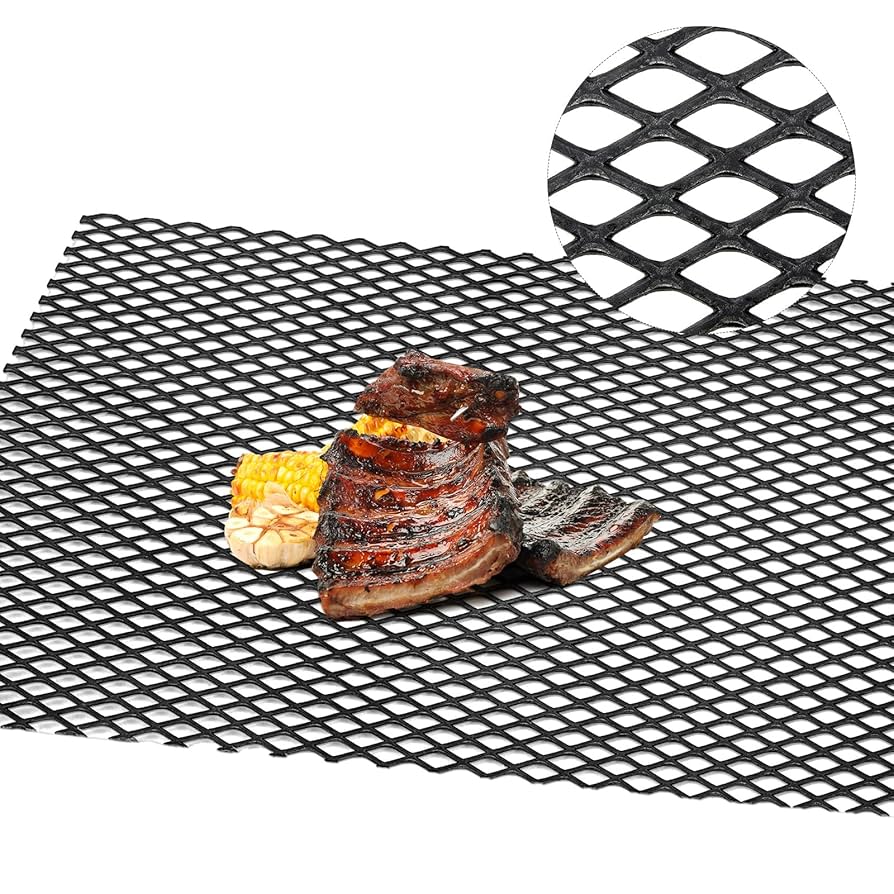

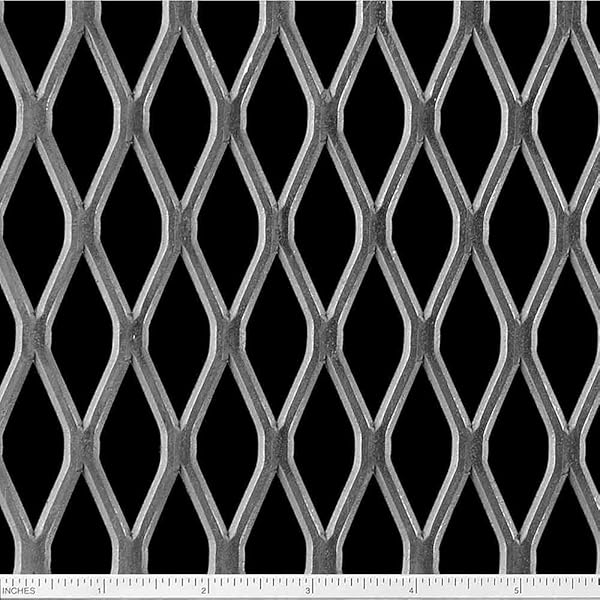

Illustrative image related to expanded metal for bbq grill

How Can Custom-Cut Expanded Metal Enhance Your Grilling Experience?

Custom-cut expanded metal allows for tailored sizes and shapes to meet specific grilling needs, making it a go-to option for custom grill fabrication and specialty applications. This flexibility maximizes cooking efficiency and ensures a perfect fit for unique designs. However, the longer lead times and potentially higher costs associated with custom orders should be considered. Buyers looking for a bespoke solution should evaluate the trade-offs of customization against their grilling objectives.

Key Industrial Applications of expanded metal for bbq grill

| Industry/Sector | Specific Application of expanded metal for bbq grill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Custom BBQ grills for restaurants and catering services | Enhanced cooking efficiency and durability, leading to better food quality and customer satisfaction | Material thickness and type (stainless vs. mild steel), custom sizes |

| Hospitality | BBQ grills for hotels and resorts’ outdoor dining areas | Attracts guests with high-quality outdoor cooking experiences, boosting revenue | Aesthetic design, rust resistance for longevity in outdoor settings |

| Manufacturing | Production of large-scale BBQ grill systems | Streamlined production processes, reduced costs, and improved safety features | Compliance with safety standards, bulk purchasing options |

| Retail | Retail BBQ grill displays and showcases | Eye-catching displays enhance customer engagement and sales potential | Customization options, weight capacity for displaying products |

| Agriculture | BBQ pits for agricultural fairs and events | Provides a communal cooking space, enhancing community engagement and event success | Easy assembly, portability, and weather resistance |

How is Expanded Metal Used in the Food Service Industry?

In the food service sector, expanded metal is vital for creating custom BBQ grills tailored to the specific needs of restaurants and catering services. These grills offer enhanced cooking efficiency, allowing chefs to prepare high-quality meals while ensuring even heat distribution. Buyers in this sector should consider the material thickness and type—such as stainless steel for durability or mild steel for cost-effectiveness—while also focusing on custom sizes to fit specific kitchen layouts.

What Role Does Expanded Metal Play in Hospitality Settings?

Hotels and resorts frequently utilize expanded metal for BBQ grills in outdoor dining areas. These grills not only provide guests with a unique cooking experience but also enhance the aesthetic appeal of the venue. The use of rust-resistant materials is crucial for ensuring the longevity of the grills in outdoor environments. For international buyers, understanding local weather conditions and choosing the appropriate finish can significantly impact the grill’s lifespan and maintenance needs.

Illustrative image related to expanded metal for bbq grill

How is Expanded Metal Beneficial for Manufacturing Large-Scale BBQ Grills?

In manufacturing, expanded metal is used to produce large-scale BBQ grill systems that cater to both commercial and residential markets. The material allows for streamlined production processes, reducing costs and improving safety features through its robust design. Buyers should prioritize compliance with safety standards and consider bulk purchasing options to optimize their supply chain efficiency, especially when catering to large events or festivals.

How Do Retailers Utilize Expanded Metal for BBQ Grill Displays?

Retailers often employ expanded metal in the design of BBQ grill displays and showcases, leveraging its durability and aesthetic appeal to attract customers. An eye-catching display can significantly enhance customer engagement and boost sales potential. When sourcing expanded metal for this application, retailers should focus on customization options and ensure that the material can support the weight of the products being displayed, thereby ensuring safety and stability.

What are the Agricultural Applications for Expanded Metal BBQ Pits?

Agricultural fairs and events benefit from expanded metal BBQ pits, which provide a communal cooking space that enhances community engagement. These pits are designed for easy assembly and portability, making them ideal for outdoor events. Buyers in this sector should consider weather resistance and the ease of transport when selecting expanded metal, ensuring that the BBQ pits can withstand varying environmental conditions while remaining functional and appealing to attendees.

3 Common User Pain Points for ‘expanded metal for bbq grill’ & Their Solutions

Scenario 1: Sourcing High-Quality Expanded Metal for Grills

The Problem: Many B2B buyers, especially those in regions like Africa and South America, struggle to find reliable suppliers of high-quality expanded metal suitable for BBQ grills. The challenge often lies in the inconsistency of material quality and specifications from various manufacturers, leading to products that may not withstand high temperatures or rust over time. Inconsistent thickness and mesh sizes can also result in poor cooking performance, affecting the end product’s quality and safety.

The Solution: To overcome this challenge, buyers should prioritize sourcing from reputable suppliers that provide detailed product specifications, including thickness, mesh size, and material grade. Establishing a relationship with manufacturers that offer certifications or quality assurance can help ensure the expanded metal meets industry standards. Additionally, consider requesting samples before placing bulk orders to evaluate the material’s durability and suitability for grilling applications. Leveraging online platforms and trade shows can also be beneficial for connecting with trusted suppliers who specialize in BBQ grill components.

Illustrative image related to expanded metal for bbq grill

Scenario 2: Choosing the Right Type of Expanded Metal for Specific Grilling Needs

The Problem: B2B buyers often face confusion when selecting the appropriate type of expanded metal for specific grilling applications, such as smoking or direct grilling. The choice between raised and flattened expanded metal can significantly impact cooking efficiency and food quality. Without adequate knowledge, buyers might purchase the wrong type, leading to issues such as uneven cooking or food falling through the grate.

The Solution: To address this issue, buyers should educate themselves on the differences between raised and flattened expanded metal. Raised expanded metal is typically stronger and better suited for larger cuts of meat, while flattened expanded metal provides a smoother surface that is easier to clean and safer for delicate foods. It’s advisable to consult with manufacturers or industry experts to understand the best applications for each type. Buyers should also consider their target market’s preferences—if they cater to a gourmet audience, opting for flattened expanded metal may enhance the overall grilling experience. Creating a product guide that outlines the pros and cons of each type can aid in making informed purchasing decisions.

Scenario 3: Ensuring Proper Installation and Maintenance of Expanded Metal Grates

The Problem: After purchasing expanded metal for BBQ grills, many B2B buyers encounter difficulties during installation and maintenance. Improper installation can lead to structural failures or safety hazards, while neglecting maintenance can result in rust and degradation of the metal, affecting the longevity of the grill. This is particularly critical for buyers in humid climates where metal is more susceptible to corrosion.

The Solution: To mitigate these issues, buyers should invest time in learning about the proper installation techniques for expanded metal grates. Utilizing installation guides from manufacturers can provide step-by-step instructions tailored to different grill models. Additionally, incorporating regular maintenance routines, such as cleaning with non-corrosive solutions and applying protective coatings, can significantly extend the lifespan of the metal. Buyers should also consider training staff on best practices for both installation and maintenance to ensure consistent quality and safety across their products. Engaging with online forums or communities focused on BBQ grilling can provide further insights and shared experiences that enhance knowledge and expertise in managing expanded metal components.

Strategic Material Selection Guide for expanded metal for bbq grill

What Are the Key Materials for Expanded Metal Used in BBQ Grills?

When selecting expanded metal for BBQ grills, the choice of material is crucial for performance, durability, and overall user satisfaction. Below, we analyze four common materials used in expanded metal applications for BBQ grills, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform as a Material for Expanded Metal Grills?

Key Properties: Steel expanded metal is known for its strength and high-temperature resistance. It can withstand temperatures exceeding 1,000°F (538°C), making it suitable for various grilling applications.

Pros & Cons: Steel is durable and cost-effective, often available at a lower price point compared to other materials. However, it is prone to rust and corrosion if not properly coated or maintained. This limitation can impact longevity, especially in humid or coastal environments.

Illustrative image related to expanded metal for bbq grill

Impact on Application: Steel is compatible with high-heat grilling and smoking, but its susceptibility to rust necessitates careful consideration of the grill’s storage conditions.

International Buyer Considerations: Buyers from regions with high humidity, such as parts of Africa and South America, should prioritize galvanized or coated steel options. Compliance with ASTM standards is common in North America, while DIN standards may be more relevant in Europe.

What Are the Benefits of Stainless Steel for Expanded Metal Grills?

Key Properties: Stainless steel expanded metal offers excellent corrosion resistance and can withstand high temperatures, making it ideal for outdoor cooking applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, which extends the lifespan of BBQ grills. However, it comes at a higher cost compared to standard steel, which may deter budget-conscious buyers.

Illustrative image related to expanded metal for bbq grill

Impact on Application: Stainless steel is well-suited for grilling, as it provides a non-reactive surface that doesn’t impart flavors to food. This makes it particularly desirable for grilling delicate items like fish and vegetables.

International Buyer Considerations: Buyers should ensure that the stainless steel used meets international standards, such as ASTM A240 for stainless steel sheets. This is particularly important in regions like Europe, where quality standards are stringent.

Why Choose Aluminum for Expanded Metal Grills?

Key Properties: Aluminum expanded metal is lightweight and resistant to corrosion, making it an excellent choice for portable grills or outdoor cooking equipment.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and transport. However, it has a lower melting point compared to steel, which may limit its use in high-heat applications. Additionally, aluminum can be more expensive than standard steel.

Impact on Application: Aluminum is ideal for grilling lighter foods and in scenarios where weight is a concern, such as camping or tailgating. However, its lower durability may not make it suitable for heavy-duty grilling.

International Buyer Considerations: Buyers should look for aluminum that complies with international standards, such as ASTM B221, especially in regions with specific material regulations.

What Role Does Carbon Steel Play in Expanded Metal Grills?

Key Properties: Carbon steel expanded metal is known for its strength and ability to withstand high temperatures. It is often used in heavy-duty applications.

Pros & Cons: Carbon steel is generally more affordable than stainless steel and offers excellent heat retention. However, it is prone to rust and requires regular maintenance to prevent corrosion.

Impact on Application: This material is suitable for high-temperature grilling and smoking but may require protective coatings or treatments to enhance its longevity.

Illustrative image related to expanded metal for bbq grill

International Buyer Considerations: Buyers should consider the specific environmental conditions of their region, as carbon steel may not perform well in humid climates without proper treatment. Compliance with ASTM standards is also advisable.

Summary Table of Material Selection for Expanded Metal BBQ Grills

| Material | Typical Use Case for expanded metal for bbq grill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General grilling and smoking | Cost-effective and durable | Prone to rust | Low |

| Stainless Steel | High-end grilling and delicate food preparation | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Portable grills and lightweight applications | Lightweight and corrosion-resistant | Lower melting point | Medium |

| Carbon Steel | Heavy-duty grilling and smoking | Affordable and strong | Requires maintenance to prevent rust | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to source expanded metal for BBQ grills, ensuring informed decisions based on material properties, advantages, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal for bbq grill

What Are the Main Stages in the Manufacturing Process of Expanded Metal for BBQ Grills?

The manufacturing process of expanded metal for BBQ grills typically involves several key stages that ensure the final product meets industry standards for durability and performance.

-

Material Preparation: The process begins with selecting the right type of metal, commonly mild steel or stainless steel, depending on the desired properties of the grill. The chosen metal sheets are then cut to the required dimensions. For BBQ grills, the most commonly used thickness ranges from 1/8″ to 1/4″ (3.175 mm to 6.35 mm) to ensure sufficient strength and support.

-

Forming: This stage involves the actual expansion of the metal sheets. The sheets are fed into a machine that cuts and stretches the metal simultaneously, creating a series of interconnected diamond-shaped openings. The forming process can be done through different techniques, including mechanical expansion, where a machine applies pressure to stretch the metal, or hydraulic expansion, which uses fluid pressure to achieve the desired shape.

-

Assembly: After forming, the expanded metal sections may be assembled into specific configurations, such as grates or baskets, based on the design requirements. This may involve welding or fastening pieces together to ensure structural integrity and alignment.

-

Finishing: The final stage involves surface treatments to enhance durability and appearance. Common finishing processes include galvanizing, powder coating, or applying high-temperature resistant paint, which not only protects against corrosion but also improves the aesthetic appeal of the product.

What Key Techniques Are Used in the Manufacturing of Expanded Metal?

Various techniques are employed throughout the manufacturing process to enhance the quality and performance of expanded metal for BBQ grills.

-

Mechanical Expansion: This is the most prevalent method, as it allows for precise control over the size and shape of the expanded openings. The mechanical expansion process is highly efficient and can be automated for large-scale production.

-

Hydraulic Expansion: Although less common, hydraulic expansion is beneficial for thicker sheets or when a more intricate pattern is required. This technique can produce a smoother finish and more uniform expansion.

-

Welding and Fabrication: Advanced welding techniques, such as MIG or TIG welding, are used for assembling components. These methods ensure strong joints and enhance the overall durability of the grill parts.

What Quality Assurance Practices Are Essential for Expanded Metal Production?

Quality assurance (QA) is critical in the manufacturing of expanded metal for BBQ grills, ensuring that products meet international and industry-specific standards.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which outlines the requirements for a quality management system. This certification is crucial for B2B buyers looking for reliable suppliers. Additionally, products may need to comply with CE marking requirements for safety in the European market and API standards for certain applications.

-

Quality Control Checkpoints: Effective QA involves several checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early in the process.

- Final Quality Control (FQC): Finished products undergo rigorous testing for dimensions, strength, and surface finish.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of suppliers, ensuring that the expanded metal products meet their requirements.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturer’s processes, equipment, and compliance with quality standards. This hands-on assessment provides insights into the operational capabilities and quality culture of the supplier.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QA processes in place, including any non-conformance issues and corrective actions taken. These reports should outline the testing methods used and the outcomes of quality checks.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality. These organizations typically offer certifications that confirm compliance with international standards, adding an extra layer of assurance for buyers.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing expanded metal for BBQ grills.

-

Understanding Regional Standards: Different regions may have varying standards for materials and manufacturing processes. It’s essential for buyers to familiarize themselves with local regulations and standards applicable in their markets.

-

Supply Chain Transparency: Given the complexities of international trade, ensuring supply chain transparency is vital. Buyers should seek suppliers who are willing to share information about their sourcing practices and production methods.

-

Cultural Considerations: Communication styles and business practices can differ across regions. Building strong relationships with suppliers through clear communication can enhance collaboration and facilitate smoother transactions.

Conclusion

For B2B buyers in the expanded metal market, understanding the manufacturing processes and quality assurance practices is vital for making informed purchasing decisions. By considering the main stages of production, key techniques, and the importance of rigorous quality control, buyers can ensure they source high-quality expanded metal that meets their specific needs for BBQ grills. Engaging in proactive verification methods and understanding regional nuances will further enhance the reliability of their supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal for bbq grill’

When sourcing expanded metal for BBQ grills, it’s essential to approach the process methodically. This guide outlines critical steps to ensure that you procure the right materials effectively and efficiently, catering specifically to the unique needs of your business.

Step 1: Define Your Technical Specifications

Begin by determining the specific requirements for the expanded metal you need. This includes deciding on the type of metal (e.g., stainless steel or mild steel), mesh size, and thickness. Proper specifications will ensure compatibility with your grilling systems and enhance performance.

- Mesh Size: Consider using a medium mesh size (1/2 to 3/4 inch) to prevent smaller food items from falling through while allowing for even cooking.

- Thickness: Generally, a thickness of at least 1/8 inch is recommended for durability and stability.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in expanded metal products. Look for manufacturers with a proven track record in the BBQ and outdoor cooking industries.

- Supplier Reputation: Seek reviews and testimonials from previous customers to gauge reliability.

- Product Range: Ensure the supplier offers a variety of options that meet your defined specifications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This will help you assess the supplier’s capability to meet your needs.

- Quality Assurance: Ask about their quality control processes to ensure that the expanded metal meets industry standards.

- Certifications: Verify any relevant certifications that indicate compliance with international standards.

Step 4: Request Samples

Request samples of the expanded metal to evaluate the material quality firsthand. This step is vital to ensure that the product meets your specifications and performance expectations.

- Physical Inspection: Assess the surface finish, thickness, and overall sturdiness.

- Test Performance: If possible, conduct preliminary tests to see how the material performs under grilling conditions.

Step 5: Negotiate Pricing and Terms

Once you’ve selected potential suppliers and evaluated their products, begin the negotiation process. Discuss pricing, minimum order quantities, delivery timelines, and payment terms to find a mutually beneficial agreement.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Lead Times: Ensure that the supplier can meet your delivery needs without compromising quality.

Step 6: Finalize the Order and Confirm Logistics

After agreeing on terms, finalize your order and confirm logistics. Ensure that all details are documented clearly to avoid misunderstandings.

- Shipping Arrangements: Discuss shipping methods and costs, especially if sourcing internationally.

- Inspection Upon Arrival: Plan for an inspection of the materials upon receipt to verify that they meet the agreed specifications.

Step 7: Establish a Long-term Relationship

After your initial order, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and customized solutions tailored to your business needs.

Illustrative image related to expanded metal for bbq grill

- Feedback Loop: Maintain open communication to provide feedback on the products and services.

- Future Needs: Discuss any potential future needs that may arise as your business grows.

By following these steps, you can confidently source expanded metal for BBQ grills that meets your specific requirements, ensuring a successful and satisfying grilling experience for your customers.

Comprehensive Cost and Pricing Analysis for expanded metal for bbq grill Sourcing

What Are the Key Cost Components in Sourcing Expanded Metal for BBQ Grills?

When sourcing expanded metal for BBQ grills, understanding the cost structure is critical for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of metal used significantly influences the price. Common materials include mild steel and stainless steel, with the latter typically being more expensive due to its corrosion resistance and durability. For instance, A-36 mild steel is often favored for its affordability, while 304 stainless steel may be chosen for high-end applications.

-

Labor: Labor costs can vary depending on the manufacturing location and the complexity of the production process. Skilled labor is required for cutting, shaping, and finishing the expanded metal, which can raise costs, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This includes costs related to running the production facility, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The initial investment in tools and machinery to produce expanded metal can be substantial. This cost is often amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Ensuring that the expanded metal meets industry standards requires investment in quality control processes. This can include testing for tensile strength, surface finish, and dimensional accuracy.

-

Logistics: Shipping and handling costs can vary greatly based on the distance from the manufacturing facility to the buyer, as well as the mode of transport. International shipping may involve additional tariffs and duties, particularly for B2B buyers in regions like Africa and South America.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

What Influences Pricing for Expanded Metal in International Markets?

Several factors can influence the pricing of expanded metal for BBQ grills, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating for favorable terms on volume can significantly reduce overall expenses.

-

Specifications and Customization: Custom sizes, thicknesses, or finishes may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials or those that meet specific certifications (e.g., food-grade standards) typically come at a premium. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Established suppliers may offer better quality but at a higher price point, while emerging suppliers may provide competitive rates.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact total costs.

What Are Effective Buyer Tips for Sourcing Expanded Metal?

For B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing effectiveness:

-

Negotiate Wisely: Use market research to inform your negotiations. Understanding prevailing rates and supplier capabilities can provide leverage in discussions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with durability, maintenance, and potential replacements. Investing in higher-quality expanded metal can lead to lower TCO.

-

Be Aware of Pricing Nuances: International pricing can be affected by currency fluctuations, local economic conditions, and geopolitical factors. Keeping an eye on these trends can help in making informed purchasing decisions.

-

Request Samples: Before committing to a large order, request samples to evaluate the material’s quality and suitability for your specific application.

-

Establish Strong Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to new product offerings.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to obtain accurate quotes tailored to your needs.

Illustrative image related to expanded metal for bbq grill

Alternatives Analysis: Comparing expanded metal for bbq grill With Other Solutions

Understanding Alternatives for BBQ Grill Solutions

When evaluating materials for BBQ grills, it’s crucial to consider various alternatives to expanded metal. This analysis will help B2B buyers identify the most suitable solution based on performance, cost, implementation, maintenance, and specific use cases. The following comparison highlights expanded metal against two viable alternatives: stainless steel grates and cast iron grates.

Comparison Table

| Comparison Aspect | Expanded Metal For BBQ Grill | Stainless Steel Grates | Cast Iron Grates |

|---|---|---|---|

| Performance | Excellent heat distribution and airflow; supports even cooking. | Good heat retention; rust-resistant; easy to clean. | Superior heat retention; ideal for searing and creating grill marks. |

| Cost | Generally affordable; varies with thickness and material. | Higher initial cost; long-term durability offers value. | Moderate to high; depends on size and brand. |

| Ease of Implementation | Easy to cut and weld; customizable shapes and sizes. | Typically pre-made; requires specific grill size compatibility. | Heavy and requires careful handling; can be cumbersome to install. |

| Maintenance | Minimal maintenance; prone to rust if not coated. | Low maintenance; resistant to corrosion and easy to clean. | Requires seasoning to maintain non-stick surface; prone to rust without care. |

| Best Use Case | Ideal for outdoor cooking and smoking; versatile for various food types. | Best for general grilling; suitable for a range of meats and vegetables. | Perfect for high-heat cooking and achieving grill marks; great for steaks. |

Detailed Breakdown of Alternatives

Stainless Steel Grates

Stainless steel grates are a popular choice among BBQ enthusiasts due to their durability and resistance to rust and corrosion. They offer good heat retention, which allows for even cooking across the surface. The ease of cleaning is another significant advantage, as food residues do not stick as easily compared to other materials. However, the initial cost can be higher than expanded metal, making it a more significant investment upfront. For businesses focused on longevity and ease of maintenance, stainless steel may be the preferred choice.

Cast Iron Grates

Cast iron grates are renowned for their ability to retain heat, making them ideal for achieving sear marks on meats. They provide excellent cooking performance, especially for high-heat grilling. However, cast iron is heavier and requires more maintenance, including regular seasoning to prevent rust. This makes them less convenient for some users, particularly those who prioritize mobility or ease of use. Despite their higher maintenance needs, the flavor profile they can provide is often unmatched, appealing to gourmet BBQ establishments.

Conclusion

Selecting the right grill solution involves understanding the specific needs of your business and the cooking environment. Expanded metal offers a balance of affordability, performance, and versatility, making it suitable for various outdoor cooking scenarios. However, if your focus is on durability and ease of cleaning, stainless steel grates might be the better investment. Conversely, if your goal is high-performance grilling with exceptional heat retention, cast iron could be the ideal choice. By weighing these factors, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for expanded metal for bbq grill

What Are the Key Technical Properties of Expanded Metal for BBQ Grills?

When selecting expanded metal for BBQ grills, several technical properties are essential for ensuring durability, safety, and performance. Here are some critical specifications to consider:

-

Material Grade

The most common materials for expanded metal used in BBQ grills are A-36 mild steel and 304 stainless steel. A-36 is cost-effective and offers good strength, while 304 stainless steel provides superior corrosion resistance, making it ideal for outdoor environments. For international buyers, understanding material grade is vital for compliance with local regulations and for ensuring product longevity. -

Mesh Size

Mesh size refers to the dimensions of the openings in the expanded metal. For BBQ grills, a mesh size of 1/2 inch to 3/4 inch is often recommended. This size allows for effective heat distribution while preventing smaller food items from falling through. Choosing the right mesh size impacts cooking efficiency and the quality of grill marks on the food. -

Thickness

The thickness of the expanded metal can significantly influence its strength and stability. Common thicknesses range from 1/8 inch (3.175 mm) to 1/4 inch (6.35 mm). Thicker materials offer more durability and can withstand heavier food loads, which is essential for commercial applications where the grill may be subjected to continuous use. -

Flattened vs. Raised

Expanded metal can be either flattened or raised. Flattened expanded metal is preferred for BBQ grills due to its smoother surface, which aids in easy cleaning and prevents delicate foods from tearing. This choice can affect the user experience, especially for businesses focusing on high-quality food presentation. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. In the context of expanded metal, it is crucial to maintain tight tolerances to ensure that the grates fit securely and function optimally. Variances can lead to structural issues or uneven cooking surfaces, impacting the overall grilling experience.

What Are Common Trade Terms Related to Expanded Metal for BBQ Grills?

Understanding industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of expanded metal for BBQ grills, OEMs often supply components to grill manufacturers, ensuring that the materials meet specific design and performance criteria. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For expanded metal products, MOQs can vary significantly based on the supplier and material specifications. Understanding MOQ is crucial for B2B buyers to manage inventory levels and costs effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. When sourcing expanded metal for BBQ grills, submitting an RFQ allows businesses to compare offers and select the best supplier based on price, quality, and delivery terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for international buyers to understand shipping costs, risks, and responsibilities associated with the purchase of expanded metal. -

Lead Time

Lead time refers to the time taken from placing an order to the product being delivered. For B2B buyers, knowing the lead time for expanded metal can aid in planning production schedules and managing customer expectations. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that the materials meet specific quality and safety benchmarks. For international buyers, ensuring that the expanded metal complies with relevant certification standards is vital for regulatory compliance and product quality assurance.

By understanding these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, ensuring that they select the right expanded metal for their BBQ grill applications.

Navigating Market Dynamics and Sourcing Trends in the expanded metal for bbq grill Sector

What Are the Key Trends Influencing the Expanded Metal for BBQ Grill Market?

The global market for expanded metal in the BBQ grill sector is experiencing significant transformation driven by evolving consumer preferences and technological advancements. One of the primary trends is the shift towards higher-quality materials such as stainless steel and aluminum, which offer durability and resistance to corrosion. This trend is particularly relevant for international B2B buyers in regions like Africa and South America, where environmental conditions can be harsh on metal products.

Illustrative image related to expanded metal for bbq grill

Additionally, the rise of outdoor cooking as a lifestyle choice has led to an increased demand for customized and specialized grill components, including expanded metal grates that cater to various cooking methods such as smoking and grilling. This customization trend is facilitated by advancements in fabrication technologies, enabling manufacturers to produce tailor-made solutions that meet specific customer requirements.

Moreover, e-commerce platforms are becoming a vital sourcing channel for B2B buyers, allowing them to access a wider range of products and suppliers globally. This shift is particularly beneficial for businesses in Europe, like Germany, where convenience and efficiency in procurement are paramount. It is essential for buyers to stay informed about these market dynamics to make strategic sourcing decisions that align with their operational needs.

How Does Sustainability Influence Sourcing Decisions in the Expanded Metal Sector?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers in the expanded metal sector. The environmental impact of metal production is significant, with traditional manufacturing processes contributing to high levels of waste and carbon emissions. As a result, there is a growing emphasis on ethical sourcing practices, where businesses prioritize suppliers that adopt sustainable manufacturing methods and materials.

Buyers are increasingly looking for suppliers who can provide ‘green’ certifications, such as ISO 14001, which indicates a commitment to minimizing environmental impact. Moreover, the use of recycled materials in the production of expanded metal is gaining traction. For instance, sourcing expanded metal made from recycled steel not only reduces the carbon footprint but also enhances the sustainability profile of BBQ grill products.

In regions like the Middle East and Africa, where environmental regulations are becoming stricter, aligning with suppliers who prioritize sustainability can also mitigate risks associated with compliance. As consumers become more environmentally conscious, B2B buyers must ensure that their sourcing strategies reflect these values to maintain competitiveness and appeal to their end customers.

Illustrative image related to expanded metal for bbq grill

What Is the Historical Context of Expanded Metal in BBQ Grill Manufacturing?

The use of expanded metal in BBQ grill manufacturing dates back several decades, originating from the need for robust and versatile cooking surfaces. Initially, expanded metal was primarily used in commercial settings, where durability and heat resistance were paramount. Over time, as outdoor cooking gained popularity, the application of expanded metal expanded into residential markets, catering to a growing demographic of grilling enthusiasts.

The evolution of expanded metal has been significantly influenced by advancements in metallurgy and manufacturing processes. Techniques such as flattening and custom sizing have enhanced the functionality of expanded metal, allowing for better heat distribution and ease of cleaning. Today, expanded metal is not only favored for its strength but also for its ability to deliver aesthetically pleasing grill marks, making it a preferred choice among both professional chefs and home grillers.

In summary, the historical trajectory of expanded metal reflects broader trends in consumer behavior and technological innovation, shaping its current position as a staple material in the BBQ grill sector. Understanding this evolution can provide B2B buyers with valuable insights into product development and market opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal for bbq grill

-

How do I choose the right expanded metal for my BBQ grill?

Selecting the appropriate expanded metal for your BBQ grill involves considering factors like mesh size, thickness, and type. For grilling, a mesh size of ½ to ¾ inch is typically ideal, as it provides ample support for various foods while allowing for even heat distribution. Additionally, choose flattened expanded metal for ease of cleaning and safe handling of smaller items like vegetables. Ensure that the thickness is at least 1/8 inch to provide the necessary durability and support during cooking. -

What is the best type of expanded metal for grilling applications?

Flattened expanded metal is generally regarded as the best type for grilling applications due to its smooth surface, which minimizes the risk of tearing delicate foods and makes cleaning easier. It allows for better food placement and can accommodate smaller items without falling through the grate. Raised expanded metal, while stronger, can be less practical for grilling due to its rough edges. Consider your cooking style and food types when making a choice. -

What are the typical minimum order quantities (MOQ) for expanded metal?

Minimum order quantities for expanded metal can vary significantly among suppliers. Generally, MOQs can range from 100 to 500 square feet, depending on the supplier’s policies and the specific type of expanded metal required. When sourcing internationally, it’s advisable to confirm the MOQ with your supplier, as this can affect your overall costs and inventory management. Discussing customization options may also provide flexibility in order sizes. -

How can I vet suppliers for expanded metal in international markets?

To vet suppliers effectively, start by researching their reputation and experience in the industry. Look for customer reviews, case studies, and references from previous clients. Verify their certifications and compliance with international quality standards, such as ISO 9001. Additionally, consider visiting their manufacturing facility if possible, or request virtual tours. Establishing clear communication and asking for samples can also help assess the quality of their products before placing larger orders. -

What payment terms should I expect when sourcing expanded metal?

Payment terms can vary widely based on supplier policies and the nature of the transaction. Common terms include a 30% deposit upfront with the balance due before shipping, or net 30 to 60 days after delivery. It’s essential to negotiate terms that align with your cash flow and operational needs. Ensure that all payment terms are clearly outlined in your purchase agreement to avoid misunderstandings. -

What quality assurance measures should I look for in expanded metal products?

When sourcing expanded metal, inquire about the supplier’s quality assurance processes. Look for certifications that indicate adherence to international standards, such as ASTM or EN norms. Suppliers should provide documentation on material specifications, testing methods, and inspection protocols. Regular quality checks and traceability of materials used in manufacturing are also indicators of a reliable supplier, ensuring that the expanded metal meets your performance requirements. -

What logistics considerations should I keep in mind when importing expanded metal?

Logistics play a crucial role in the timely delivery of expanded metal. Consider factors such as shipping methods, lead times, and customs regulations in your country. Work with suppliers who have experience in international shipping to navigate these complexities. It’s advisable to use freight forwarders who can manage transportation and customs clearance efficiently. Additionally, ensure that your supplier provides proper documentation to facilitate smooth importation. -

How can I customize expanded metal products to fit my specific BBQ grill design?

Customization options for expanded metal include adjusting mesh size, thickness, and dimensions to fit your specific BBQ grill design. Many suppliers offer tailored solutions based on your requirements. When discussing customization, provide detailed specifications and any design drawings if available. Be clear about your intended use and any particular challenges you face. Collaborating closely with the supplier can lead to a product that perfectly meets your grilling needs.

Top 10 Expanded Metal For Bbq Grill Manufacturers & Suppliers List

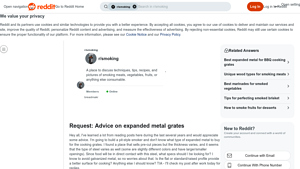

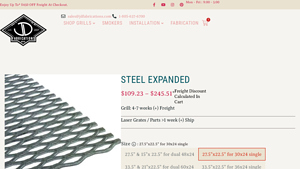

1. MetalsDepot® – Expanded Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Expanded Steel Sheet Online! Steel Expanded Metal is a sheet product that has been slit and stretched to a wide array of diamond shaped openings. Offers savings in weight and metal, free passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Specifications: MIL-M-17194D, ASTM F1267-91, Type I Standard (Raised) & Type II Flattened (smooth) sur…

2. BBQ Smoker Mods – Vortex Grill Grates

Domain: bbqsmokermods.com

Registered: 2014 (11 years)

Introduction: Expanded Metal Grates / Fire Baskets – Smoker Parts | BBQ Smoker Mods. Products include various grill grates and fire baskets made from stainless steel and designed for different smoker brands such as Big Green Egg, Kamado, Weber, and more. Key products include Vortex Grill Grates, LavaLock Cooking Grates, and Fire Box Charcoal/Wood Baskets, with prices ranging from $21.00 to $109.99. Special pric…

3. Expanded Metal Grates – Key Specifications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Expanded metal grates for cooking in a pit-style smoker; specifications to consider include thickness, type of steel (avoid galvanized), and surface profile (flat vs. raised). Recommendations suggest using regular flat expanded carbon steel, ensuring the metal thickness is sufficient to prevent warping, and being cautious about opening sizes to prevent food from falling through.

4. Westbrook Metals – Expanded Metal Grill for BBQ Pits

Domain: westbrookmetals.com

Registered: 2002 (23 years)

Introduction: Metal and Accessories for Outdoor Sports Equipment, Hunting and BBQ Pits and Smokers. Products include: 1. Expanded Metal Grill/Grate for BBQ Pits and Smokers – 3/4″ #9 flattened expanded metal grating, preferred for outdoor cooking, easy to weld A-36 mild steel or self-mount 304 stainless steel. 2. BBQ Grill & Pit Thermometers – Stainless steel, hermetically-sealed thermometers with 1/2″ NPT thre…

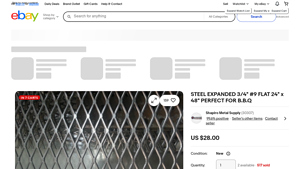

5. Shapiro Metal Supply – STEEL EXPANDED 3/4 #9 FLAT

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”STEEL EXPANDED 3/4″ #9 FLAT”,”Dimensions”:”24″ x 48″”,”Condition”:”New”,”Quantity Available”:”2″,”Price”:”US $28.00″,”Shipping Cost”:”US $58.30 UPS Ground”,”Location”:”Saint Louis, Missouri, United States”,”Seller”:”Shapiro Metal Supply”,”Seller Rating”:”99.6% positive feedback”,”Total Sold”:”517″,”California Prop 65 Warning”:”Metal products may contain one or more chemicals known…

6. Expanded Metal Sheet Mesh – BBQ Grill Mesh

Domain: expandedmetalsheetmesh.com

Registered: 2020 (5 years)

Introduction: For BBQ grills, the ideal size of expanded steel mesh holes is around 1/2 to 3/4 inch. This size provides enough surface area to hold food without the risk of smaller items falling through. Larger holes can be used for smoking or grilling larger cuts of meat, while smaller openings offer more support and control. Grill enthusiasts often choose between raised and flattened expanded steel mesh. Rais…

7. Smoking Meat Forums – Expanded Metal Grates

Domain: smokingmeatforums.com

Registered: 2005 (20 years)

Introduction: Expanded Metal Grates, Thickness: 1/8″ (0.125″ or 3.175 mm) recommended, Type: Flattened Expanded Metal, Standard Size: 3/4″ #9, Material: Carbon Steel, Availability: Local steel supply houses or online, Price Reference: $76 for a 2×4′ piece on Amazon, Open Area: 64%.

8. BBQ Brethren – Expanded Metal Charcoal Basket

Domain: bbq-brethren.com

Registered: 2003 (22 years)

Introduction: Expanded metal for charcoal basket; commonly used gauges include 9 gauge and 18 gauge; standard mesh sizes are 1/2″ and 3/4″; available at Home Depot and Lowe’s; 3/4″ #9 is a common industry standard; thicker gauges recommended for durability; local sheet metal fabrication shops can custom cut; full sheets (4’x8′) available for around $60; smaller pre-cut sheets available for convenience at higher…

9. JD Fabrications – Steel Expanded Metal Grates

Domain: jdfabrications.com

Registered: 2011 (14 years)

Introduction: Product Name: Steel Expanded Metal Grates

Price Range: $109.23 – $245.51

Freight Discount: Up to $450 OFF at checkout

Shipping Time: Grill – 4-7 weeks, Laser Grates/Parts – >1 week

Available Sizes:

– 27.5″ & 15″ x 22.5″ for dual 48×24

– 27.5″ x 22.5″ for 30×24 single

– 33.5″ & 21″ x 22.5″ for dual 60×24

– 33.5″ x 22.5″ for 36×24 single

– 45.5″ & 21″ x 22.5″ for dual 72×24

– 45.5″ x 22.5″ for 48×2…

10. Metal Mesh Corp – Expanded Metal BBQ Grill

Domain: metalmeshcorp.com

Registered: 2019 (6 years)

Introduction: Expanded Metal BBQ Grill is a type of expanded metal mesh, available in standard (raised) and flattened forms. It is characterized by its economical, durable, and versatile nature, with easy installation and low resistance to wind loads. The grill can be cut to fit and comes in various materials, including carbon steel, stainless steel, and aluminum. It features a skid-resistant surface and is sui…

Strategic Sourcing Conclusion and Outlook for expanded metal for bbq grill

In the evolving landscape of BBQ grill manufacturing, the strategic sourcing of expanded metal presents a unique opportunity for international buyers. By understanding the nuances of mesh size, type, and material—such as the advantages of flattened versus raised expanded metal—businesses can significantly enhance the quality and functionality of their grilling products. The right choices not only ensure superior cooking performance but also contribute to the longevity and reliability of the grills, ultimately boosting customer satisfaction and brand loyalty.

As global markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality expanded metal is set to rise. Sourcing from reputable suppliers who can provide consistent quality and customization options will be crucial for staying competitive. It’s essential for B2B buyers to prioritize partnerships that emphasize quality assurance and timely delivery.

Looking ahead, the focus should be on innovation in material technology and design to meet the diverse preferences of grill enthusiasts worldwide. By embracing strategic sourcing, businesses can position themselves at the forefront of the BBQ grill industry, ready to capitalize on emerging trends and consumer demands. Take action now by exploring reliable suppliers and enhancing your product offerings with premium expanded metal solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.