Is Your Door Lock Components Names Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for door lock components names

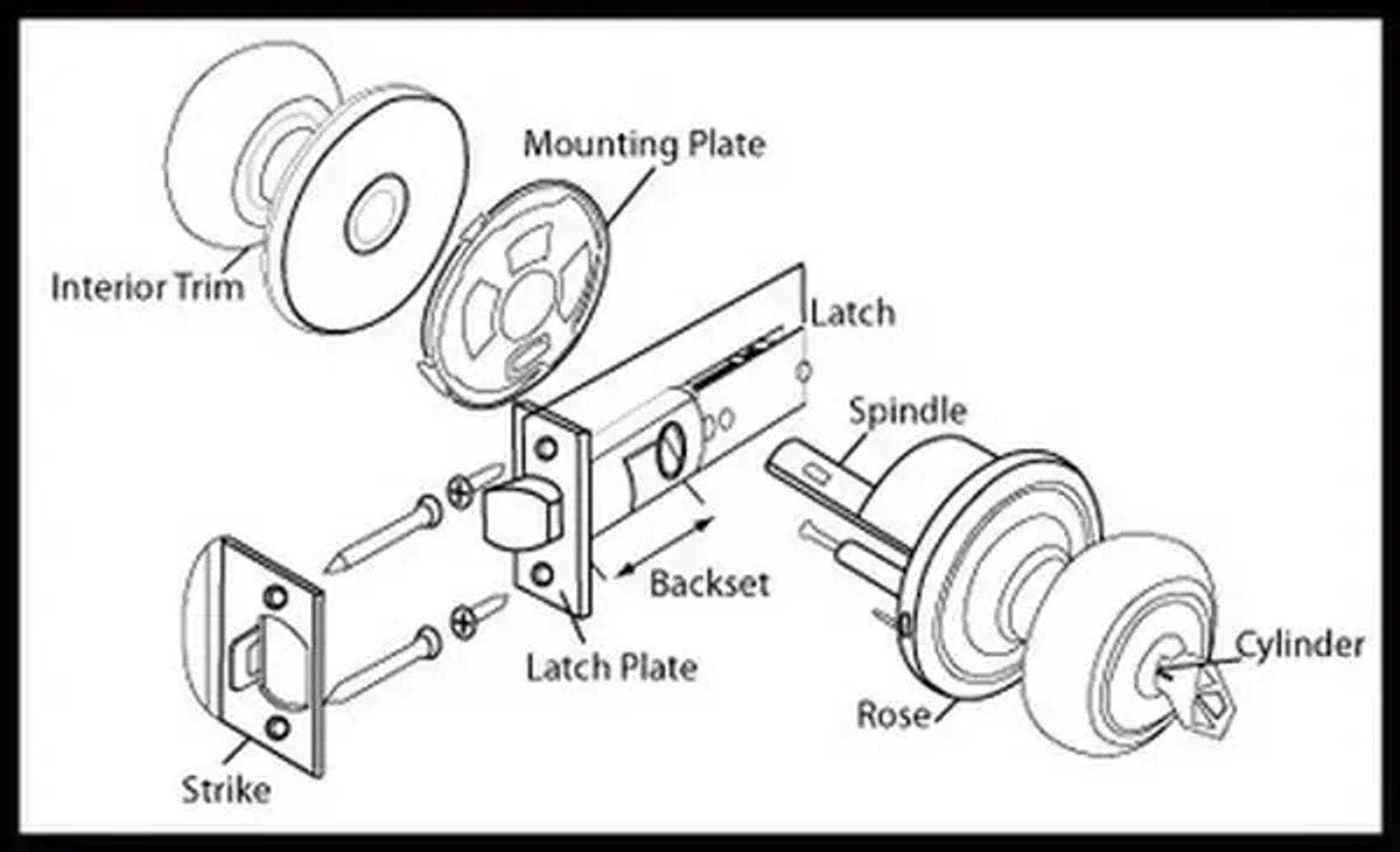

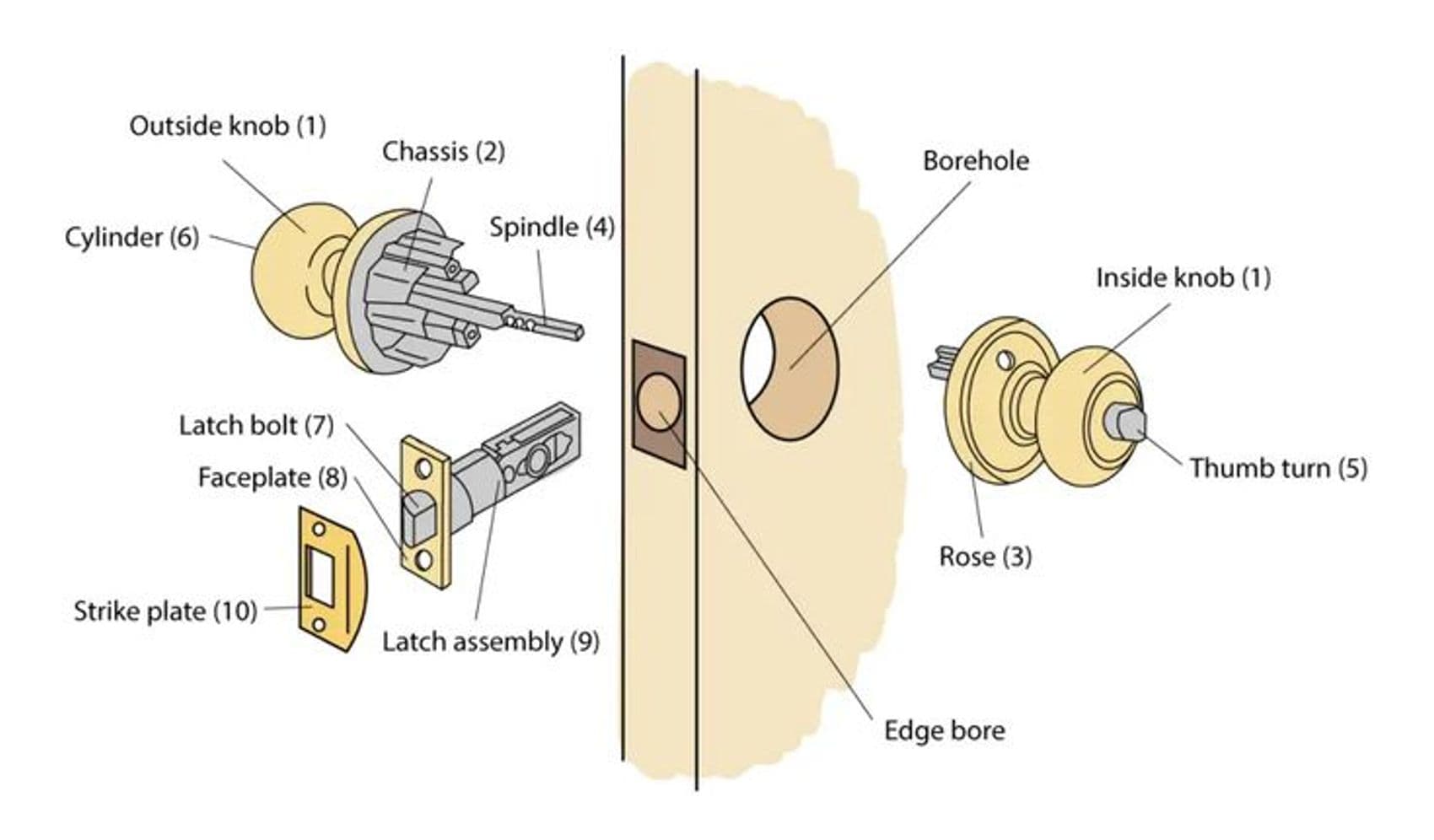

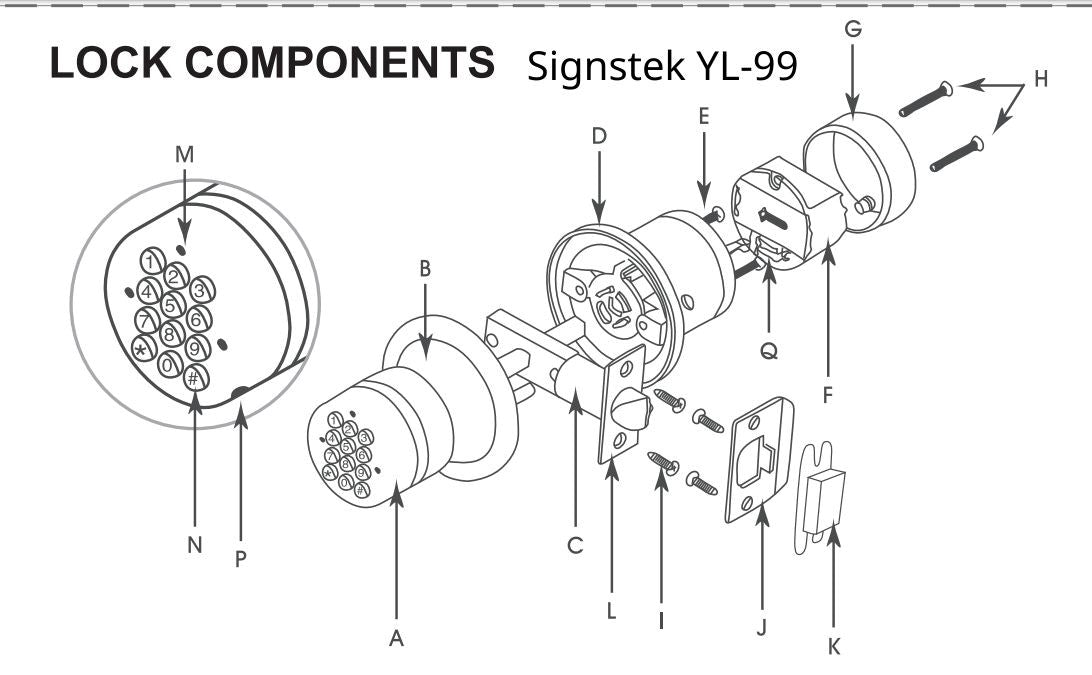

In the rapidly evolving global market for door lock components, sourcing high-quality products can be a daunting challenge for international B2B buyers. With the increasing demand for enhanced security solutions across various regions—including Africa, South America, the Middle East, and Europe—it is crucial to understand the intricate names and functions of door lock components. This guide delves into the essential elements of door locks, from cylinders and bolts to strike plates and latches, offering a comprehensive overview that caters to diverse applications and security needs.

Navigating this complex landscape requires not only knowledge of component types but also insight into supplier vetting, pricing strategies, and market trends. By equipping yourself with this information, you will be empowered to make informed purchasing decisions that align with your business objectives. Whether you are looking to enhance security in residential properties or commercial establishments, understanding the various door lock components and their functionalities can significantly improve your procurement process.

This guide aims to demystify the terminology associated with door lock components, providing actionable insights that facilitate smarter sourcing. As you explore the details within, you will gain the confidence to choose the right products for your specific requirements, ensuring that your investments contribute to the safety and security of your clientele.

Understanding door lock components names Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cylinder Locks | Feature a key-operated cylinder; available in single, double, and keyless variations. | Commercial buildings, offices, and retail stores. | Pros: Versatile, easy to rekey. Cons: Vulnerable to picking. |

| Deadbolts | Provide enhanced security with a solid metal bolt; typically key-operated or thumb turn. | Residential and high-security applications. | Pros: High security, difficult to force open. Cons: Requires a key for unlocking. |

| Smart Locks | Use electronic mechanisms for keyless entry; can be controlled via smartphone apps. | Hotels, office buildings, and smart homes. | Pros: Convenient, remote access. Cons: Dependence on technology, potential hacking risks. |

| Mortise Locks | Installed within the door; offer high security and durability with various locking options. | Commercial properties and high-security areas. | Pros: Strong and reliable. Cons: More complex installation. |

| Rim Locks | Surface-mounted locks that can be easily installed; commonly used in residential settings. | Apartments and residential doors. | Pros: Easy installation, cost-effective. Cons: Lower security compared to deadbolts. |

What Are the Characteristics of Cylinder Locks and Their B2B Suitability?

Cylinder locks are prevalent in various commercial settings due to their adaptability and ease of rekeying. They come in different forms, such as single-cylinder (keyed on one side) and double-cylinder (keyed on both sides), which can be tailored to specific security needs. For B2B buyers, the ability to rekey these locks without replacing the entire unit makes them a cost-effective choice for businesses that frequently change personnel or require different access levels.

Why Choose Deadbolts for Enhanced Security in B2B Applications?

Deadbolts are recognized for their robust construction, providing a significant security advantage over standard locks. They are typically used in residential settings but are increasingly being adopted in commercial applications where security is paramount. B2B buyers should consider the type of deadbolt—single or double-cylinder—based on their access needs. While they offer superior security, they require a key to unlock, which may be a consideration for high-traffic areas.

What Makes Smart Locks a Popular Choice for Modern Businesses?

Smart locks are revolutionizing access control in various sectors, including hospitality and corporate environments. These locks allow for keyless entry through mobile devices, providing convenience and flexibility. B2B purchasers should weigh the benefits of remote access and monitoring against potential cybersecurity risks. The ability to manage access permissions through software makes smart locks an attractive option for businesses looking to streamline operations and enhance security.

How Do Mortise Locks Provide Durability in Commercial Settings?

Mortise locks are embedded into the door, offering a higher level of security and durability compared to surface-mounted locks. They can accommodate multiple locking mechanisms, such as deadbolts and latches, making them suitable for various commercial applications. B2B buyers should consider the installation complexity and the need for professional assistance, as proper fitting is crucial for optimal security and functionality.

What Are the Benefits of Rim Locks for Residential and Low-Security Applications?

Rim locks are an economical option for residential properties, easily mounted on the door’s surface. They are often used in conjunction with other locking systems for added security. For B2B buyers, rim locks provide a straightforward solution for apartments or low-security buildings. However, they may not offer the same level of protection as deadbolts, making them less suitable for high-risk environments.

Key Industrial Applications of door lock components names

| Industry/Sector | Specific Application of door lock components names | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel room locks and access control systems | Enhances guest security and operational efficiency | Compliance with international security standards, ease of installation, and maintenance support. |

| Residential Construction | Residential door lock installations | Increases property security and market value | Durability, aesthetic appeal, and compatibility with smart home systems. |

| Commercial Real Estate | Access control for office buildings | Protects sensitive information and assets | Scalability for multiple units, integration with existing security systems, and robust warranties. |

| Automotive | Vehicle door locks and ignition systems | Ensures vehicle security and user convenience | Compliance with automotive safety standards and compatibility with various vehicle models. |

| Industrial Facilities | Locking mechanisms for warehouses and factories | Protects inventory and enhances workplace safety | Resistance to tampering, weatherproofing, and ease of use for employees. |

How Are Door Lock Components Used in the Hospitality Industry?

In the hospitality sector, door lock components are crucial for hotel room locks and access control systems. These locks enhance guest security by ensuring that only authorized individuals can access rooms and common areas. Moreover, modern electronic locking systems allow for efficient management of access permissions, reducing the risk of lost keys. For international B2B buyers, sourcing locks that comply with local security regulations and offer ease of installation and maintenance is essential to ensure smooth operations in various regions.

What Role Do Door Lock Components Play in Residential Construction?

In residential construction, door lock components are vital for securing homes. Builders and contractors prioritize high-quality locks to increase property security and boost market value. Buyers from regions with varying security needs must consider the durability and aesthetic appeal of locks, as well as their compatibility with smart home systems. This ensures that the locks meet both functional requirements and the design expectations of homeowners, particularly in markets like Europe and South America, where smart technology adoption is on the rise.

How Are Door Lock Components Applied in Commercial Real Estate?

In commercial real estate, door lock components are integral to access control systems in office buildings. These systems protect sensitive information and assets by restricting access to authorized personnel only. B2B buyers in this sector should look for scalable solutions that can accommodate multiple units and integrate seamlessly with existing security systems. Additionally, robust warranties and support services are critical factors to consider, especially in diverse markets across Africa and the Middle East, where business operations may face unique challenges.

Illustrative image related to door lock components names

Why Are Door Lock Components Important for the Automotive Industry?

In the automotive industry, door lock components play a significant role in vehicle security and user convenience. Modern vehicles utilize advanced locking mechanisms for doors and ignition systems, which must comply with stringent automotive safety standards. For B2B buyers, sourcing locks that are compatible with various vehicle models and offer reliable performance is essential. This ensures that automotive manufacturers can maintain high safety standards while providing features that enhance the user experience, particularly in competitive markets across Europe and South America.

How Do Door Lock Components Function in Industrial Facilities?

In industrial facilities, door lock components are critical for securing warehouses and factories. These locking mechanisms protect valuable inventory and enhance workplace safety by restricting access to authorized personnel only. B2B buyers in this sector should prioritize locks that are resistant to tampering and weatherproof, ensuring they can withstand the rigors of industrial environments. Additionally, ease of use for employees is a key consideration, especially in regions like the Middle East, where operational efficiency is paramount for business success.

3 Common User Pain Points for ‘door lock components names’ & Their Solutions

Scenario 1: Misalignment of Door Lock Components Leading to Security Breaches

The Problem:

B2B buyers often encounter issues where door lock components, such as the strike plate and latch, do not align correctly. This misalignment can occur during installation or due to wear and tear over time. When the latch fails to engage properly with the strike plate, it can leave doors vulnerable, compromising the security of the facility. This situation is particularly concerning for businesses that handle sensitive materials or operate in high-risk areas, as it can lead to unauthorized access and potential theft or damage.

The Solution:

To address this challenge, it’s essential to conduct regular maintenance checks on door lock components. Buyers should invest in high-quality locks designed for durability and reliability. When installing new locks, ensure that the strike plate is positioned accurately on the door frame. This can be achieved by using a shim or adjusting the strike plate’s screws to achieve a snug fit with the latch. Regularly inspect the latch and strike plate for signs of wear or misalignment, and address any issues immediately to prevent security breaches. Furthermore, consider using adjustable strike plates that can accommodate minor misalignments, providing an added layer of security.

Scenario 2: Confusion Over Door Lock Component Terminology

The Problem:

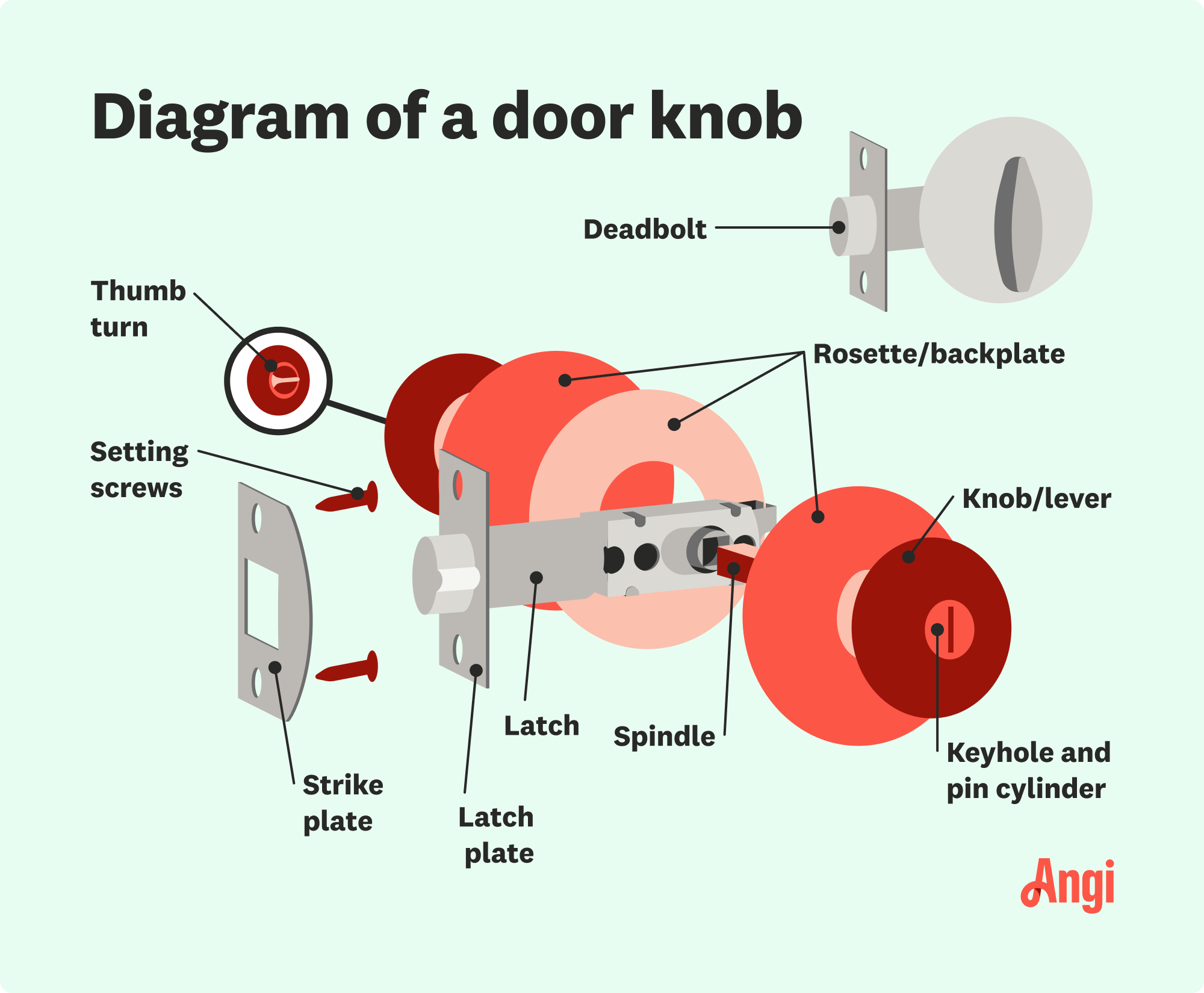

Many B2B buyers, especially those who are new to sourcing door lock components, often struggle with the complex terminology associated with these products. Terms like “cylinder,” “latch,” and “deadbolt” can be confusing, leading to difficulties in selecting the right components for specific security needs. This lack of understanding can result in poor purchasing decisions, which may not only compromise security but also lead to wasted resources and increased costs.

The Solution:

To mitigate this confusion, companies should invest in comprehensive training for their procurement teams. This training should cover the different types of door lock components, their specific functions, and the security levels they offer. Additionally, creating a glossary of terms can serve as a quick reference guide for staff. When sourcing products, buyers should consult with suppliers who provide detailed descriptions and specifications for each component. Furthermore, engaging with industry professionals or attending workshops can deepen understanding and help buyers make informed decisions, ensuring they select the most suitable door lock components for their needs.

Scenario 3: Difficulty in Integrating Smart Lock Technologies

The Problem:

As businesses increasingly adopt smart lock technologies for enhanced security, many B2B buyers face challenges in integrating these advanced systems with existing door lock components. Compatibility issues can arise, particularly if the current infrastructure does not support digital locks. This can lead to frustration, delays in implementation, and potential security vulnerabilities if older systems remain in use alongside new technologies.

The Solution:

To effectively integrate smart locks, businesses should start by conducting a thorough assessment of their existing door lock systems and infrastructure. This includes evaluating the compatibility of current components with potential smart lock solutions. Buyers should partner with reputable manufacturers that offer smart locks designed for easy integration with traditional locking systems. Additionally, investing in a professional installation service can ensure that the smart locks are configured correctly and securely. Providing training for staff on how to operate these new technologies is also crucial, as it helps in maximizing the benefits of upgraded security systems while minimizing the risk of operational disruptions.

Strategic Material Selection Guide for door lock components names

When selecting materials for door lock components, it’s essential to consider the specific performance requirements and environmental conditions that will affect their longevity and functionality. Here, we analyze four common materials used in door lock components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Brass in Door Lock Components?

Brass is a popular choice for door lock components due to its excellent machinability and corrosion resistance. It typically exhibits good strength and durability, making it suitable for various applications. Brass can withstand moderate temperatures and pressures, which is beneficial in environments with fluctuating conditions. Its natural antimicrobial properties also help in maintaining hygiene, which can be particularly advantageous in high-traffic areas.

Pros and Cons of Brass: Brass is relatively easy to manufacture, allowing for intricate designs and finishes, which can enhance the aesthetic appeal of door locks. However, it can be more expensive than other metals, and its softer nature can make it susceptible to wear over time, especially in high-use scenarios.

Impact on Application: Brass components are compatible with various media, including residential and commercial applications. However, in regions with high humidity or saltwater exposure, additional protective coatings may be necessary to prevent corrosion.

How Does Stainless Steel Compare for Door Lock Components?

Stainless steel is renowned for its strength and resistance to corrosion, making it an ideal choice for door lock components exposed to harsh environments. It can withstand high temperatures and pressures, ensuring reliability in various applications, including industrial settings.

Pros and Cons of Stainless Steel: The durability of stainless steel translates to a longer lifespan for door lock components, reducing the need for frequent replacements. However, the manufacturing process can be more complex and costly compared to materials like brass or plastic.

Impact on Application: Stainless steel is suitable for applications requiring high security and durability, such as commercial buildings and outdoor installations. International buyers should ensure compliance with relevant standards (e.g., ASTM A240) to guarantee quality and performance.

What Role Does Zinc Die-Casting Play in Door Lock Components?

Zinc die-casting is often used for creating intricate and lightweight door lock components. This material offers good corrosion resistance and can be produced at a lower cost, making it an attractive option for manufacturers.

Pros and Cons of Zinc Die-Casting: The primary advantage of zinc die-casting is its ability to create complex shapes with high precision, which can reduce assembly time and costs. However, it is less durable than brass or stainless steel and may not perform well in extreme conditions.

Impact on Application: Zinc die-casting is suitable for low to moderate security applications, such as residential locks. Buyers in regions with high humidity should consider additional protective coatings to enhance durability.

Why Choose Plastic for Certain Door Lock Components?

Plastic materials, such as polycarbonate or nylon, are increasingly used in door lock components due to their lightweight nature and resistance to corrosion. They can withstand a range of temperatures, making them versatile for various applications.

Pros and Cons of Plastic: The low cost and ease of manufacturing plastic components make them appealing for budget-conscious projects. However, they may not provide the same level of security or durability as metal components, which can limit their application in high-security environments.

Impact on Application: Plastic components are often used in residential locks and interior applications. International buyers should ensure that the plastic used meets relevant safety and performance standards, such as those set by ASTM or ISO.

Summary Table of Material Selection for Door Lock Components

| Material | Typical Use Case for door lock components names | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Residential and commercial locks | Good machinability and aesthetics | Susceptible to wear | Medium |

| Stainless Steel | High-security and outdoor locks | Excellent strength and durability | Higher manufacturing complexity | High |

| Zinc Die-Casting | Low to moderate security locks | Cost-effective and precise | Less durable in extreme conditions | Low |

| Plastic | Interior and residential locks | Lightweight and corrosion-resistant | Limited security and durability | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing door lock components tailored to specific market needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for door lock components names

What Are the Main Stages in the Manufacturing Process of Door Lock Components?

The manufacturing of door lock components involves a series of meticulous stages designed to ensure both functionality and security. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with the careful selection of raw materials. Common materials used in door locks include brass, stainless steel, and zinc alloys, each chosen for their durability, corrosion resistance, and aesthetic qualities.

Once selected, these materials undergo initial processing, which may involve cutting, melting, or alloying. For instance, brass may be melted and poured into molds to create specific shapes. Quality checks during this stage are crucial to ensure that the materials meet industry standards for hardness and tensile strength.

Illustrative image related to door lock components names

What Techniques Are Commonly Used in Forming Door Lock Components?

The forming stage is where raw materials are shaped into the components of door locks. Techniques such as die casting, machining, and stamping are frequently employed.

-

Die Casting: This method is ideal for creating complex shapes with precise dimensions. Molten metal is injected into a mold, allowing for high production rates and reduced material waste.

-

Machining: For components requiring intricate designs, machining techniques like CNC (Computer Numerical Control) milling and turning are used. This process allows for high precision and can accommodate various design specifications.

-

Stamping: This technique is often used for producing flat components like strike plates and faceplates. Metal sheets are stamped into shape, which is both cost-effective and efficient for mass production.

How Are Door Lock Components Assembled?

After forming, the components move to the assembly stage. This process involves fitting various parts together to create a fully functional lock. For instance, the cylinder, bolts, and latches must be assembled with precision to ensure that they work seamlessly.

Assembly may be performed manually or through automated systems, depending on the manufacturer’s capabilities. Quality control checkpoints during this stage include verifying the fit of components and ensuring that they function correctly when operated. Misalignment or improper assembly can lead to security vulnerabilities, making this stage critical.

What Finishing Techniques Are Used to Enhance Door Lock Components?

The final stage, finishing, involves applying coatings and treatments to enhance the appearance and durability of the door lock components. Techniques such as electroplating, powder coating, and anodizing are commonly used.

-

Electroplating: This process involves depositing a thin layer of metal onto the component to improve corrosion resistance and aesthetic appeal. It is particularly common for decorative elements of locks.

-

Powder Coating: This method applies a dry powder that is then cured under heat, creating a hard finish that is both durable and visually appealing.

-

Anodizing: Primarily used for aluminum components, anodizing increases corrosion resistance and can also provide a range of colors for aesthetic purposes.

What Are the Quality Control Standards for Door Lock Components?

Quality assurance in the manufacturing of door lock components is paramount, especially given the critical role these products play in security. Adherence to international standards such as ISO 9001 ensures that manufacturers maintain consistent quality throughout their processes.

What Are the Key Quality Control Checkpoints?

Quality control is typically segmented into several checkpoints, including:

-

Incoming Quality Control (IQC): This stage checks the quality of raw materials upon arrival at the manufacturing facility. Verification against specifications ensures that only materials meeting quality standards proceed to production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are performed to monitor quality. This includes checking dimensions, tolerances, and functionality at different stages of assembly.

-

Final Quality Control (FQC): Once the components are assembled, a final inspection ensures that all products meet the required specifications and standards before they are packaged and shipped.

What Testing Methods Are Commonly Used in Quality Control?

Testing methods employed during quality assurance can include:

-

Functional Testing: This involves simulating real-world use to ensure that locks operate smoothly and securely.

-

Durability Testing: Components are subjected to stress tests to assess their strength and longevity under various conditions.

-

Corrosion Resistance Testing: Components may be exposed to saline solutions to evaluate their resistance to rust and corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure quality:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and overall operational standards of suppliers.

-

Requesting Quality Reports: Suppliers should be able to provide documentation outlining their quality control processes, including details on compliance with international standards and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures, ensuring that products meet specified requirements before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers must be aware of specific nuances related to quality control that can vary by region. For example, compliance with CE marking in Europe signifies that products meet EU safety, health, and environmental protection standards. Similarly, in markets like Saudi Arabia, adherence to local regulations and certifications may be required.

Understanding these regional differences can aid buyers in selecting suppliers who not only meet their quality standards but are also compliant with local regulations, ensuring smoother transactions and better product reliability.

In summary, the manufacturing and quality assurance processes for door lock components are intricate and critical to ensuring security and functionality. B2B buyers should prioritize understanding these processes and actively engage in verifying the quality standards of their suppliers to make informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door lock components names’

When sourcing door lock components, having a structured approach is essential for ensuring quality, compatibility, and security. This guide provides a checklist that B2B buyers can follow to streamline their procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensure that the components meet your security needs and fit your application. Consider the types of locks you require (e.g., deadbolts, lever locks) and the materials (e.g., brass, stainless steel) that will best suit your environment. This will help you communicate effectively with suppliers and avoid compatibility issues later on.

Step 2: Identify Key Components Needed

Make a comprehensive list of all the components you need for your door lock systems. Common components include cylinders, latches, strike plates, and handles. Each of these plays a significant role in the lock’s functionality and security, so ensure you understand the specifications and variations for each component.

Step 3: Research Potential Suppliers

Thorough research on potential suppliers is vital for quality assurance and reliability. Look for manufacturers or distributors with a solid reputation in the industry. Check for reviews, certifications, and their experience in supplying door lock components to businesses similar to yours.

- Key Questions:

- What is their production capacity?

- Do they have a track record of timely deliveries?

Step 4: Verify Supplier Certifications

Before proceeding with any supplier, confirm their industry certifications and compliance with international standards (e.g., ISO, ANSI). This ensures that the components you purchase meet safety and quality benchmarks, which is crucial for maintaining your business’s reputation and security.

- What to Look For:

- Quality management systems

- Compliance with local and international regulations

Step 5: Request Samples for Quality Assessment

Always request samples before finalizing your order. This allows you to assess the quality of the components firsthand and ensure they meet your technical specifications. Evaluating samples can reveal potential issues with fit or functionality that could affect your final product.

Step 6: Negotiate Terms and Pricing

Once you have narrowed down your suppliers, engage in discussions about pricing, payment terms, and delivery schedules. Transparent negotiations can lead to better pricing and favorable terms that can enhance your cash flow and overall profitability.

- Considerations:

- Bulk purchasing discounts

- Payment terms (e.g., net 30, net 60)

Step 7: Establish a Clear Communication Plan

Effective communication is essential throughout the sourcing process. Establish a clear line of communication with your supplier to address any concerns or questions promptly. Regular updates on order status, shipping, and potential issues will foster a strong working relationship.

By following this step-by-step checklist, B2B buyers can navigate the procurement of door lock components with greater confidence, ensuring they select the right products that meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for door lock components names Sourcing

Understanding the cost structure and pricing dynamics of door lock components is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section provides a comprehensive analysis of the key cost components, price influencers, and strategic buyer tips to optimize procurement strategies.

What Are the Key Cost Components in Door Lock Manufacturing?

The cost structure of door lock components typically comprises several critical elements:

-

Materials: The choice of materials, such as brass, stainless steel, or plastic, significantly impacts the overall cost. High-quality materials enhance durability and security but may increase the upfront price.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Automated production techniques can reduce labor costs, while skilled labor is necessary for intricate designs and customizations.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with running the manufacturing facility. Efficient operations can help mitigate these costs.

-

Tooling: Custom tooling for specific lock designs can be a significant initial investment. However, it is crucial for ensuring precision and quality in the production of specialized components.

-

Quality Control (QC): Implementing robust QC processes adds to the cost but is essential for maintaining safety standards and ensuring product reliability, especially for international certifications.

-

Logistics: Transportation costs are influenced by distance, shipping methods, and customs duties. These can vary dramatically based on the Incoterms agreed upon in the purchase contract.

-

Margin: Suppliers often apply a margin that reflects their operational costs and desired profit levels. This margin can vary based on market competition and supplier relationships.

How Do Price Influencers Affect Door Lock Components Pricing?

Several factors can influence the pricing of door lock components in B2B transactions:

-

Volume/MOQ (Minimum Order Quantity): Suppliers typically offer discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing and reduce per-unit costs.

-

Specifications and Customization: Customized components often come at a premium. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Components that meet specific quality standards or certifications may incur higher costs. Buyers must weigh the benefits of enhanced security against the added expense.

-

Supplier Factors: The reputation, location, and reliability of suppliers can affect pricing. Established suppliers may charge more but often provide better guarantees and support.

-

Incoterms: The choice of Incoterms can influence total costs significantly. Buyers must consider who bears the costs and risks at each stage of the shipping process.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, navigating the complexities of door lock component procurement requires strategic planning:

-

Negotiate Terms Upfront: Establish clear expectations regarding pricing, delivery timelines, and quality standards before finalizing agreements. This can help prevent misunderstandings and additional costs later.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential replacement costs over the product’s lifespan. This holistic view can lead to better investment decisions.

-

Leverage Regional Insights: Understand local market conditions, including demand fluctuations and currency exchange rates, to enhance negotiation leverage.

-

Build Long-term Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

Conclusion

In conclusion, comprehensively understanding the cost structure and pricing dynamics of door lock components is crucial for B2B buyers. By focusing on key cost components, recognizing price influencers, and implementing strategic negotiation tactics, buyers can optimize their procurement processes and achieve significant cost efficiencies. As always, it’s essential to approach pricing with flexibility and openness to ensure a mutually beneficial relationship with suppliers.

Disclaimer: Prices may vary based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing door lock components names With Other Solutions

Introduction: Exploring Alternatives to Door Lock Components

In the realm of security solutions, understanding the various components of door locks is crucial for B2B buyers. However, as the market evolves, alternative technologies and methods have emerged that can provide similar or enhanced security features. This section evaluates traditional door lock components against alternative solutions, allowing buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Door Lock Components Names | Smart Lock Technology | Keyless Entry Systems |

|---|---|---|---|

| Performance | High security, reliable | Moderate to high security, depends on technology | Moderate security, depends on access control measures |

| Cost | Varies by components; generally affordable | Higher initial investment, potential long-term savings | Mid-range cost; installation can vary |

| Ease of Implementation | Generally straightforward installation | May require professional installation | Simple installation for some models, complex for others |

| Maintenance | Regular maintenance needed for optimal function | Software updates needed; hardware maintenance is minimal | Requires battery replacements and occasional updates |

| Best Use Case | Residential and commercial applications needing robust security | Smart homes, tech-savvy users, businesses wanting remote access | High-traffic environments where key distribution needs to be controlled |

Detailed Breakdown of Alternatives

Smart Lock Technology

Smart locks offer enhanced convenience and flexibility compared to traditional door lock components. These locks can be controlled remotely via smartphones, allowing users to grant access to guests without being physically present. While they provide moderate to high security, their performance heavily relies on the technology and network stability. The initial investment is typically higher than traditional locks, but the long-term savings on re-keying and enhanced security features can offset the cost. However, smart locks require regular software updates and may necessitate professional installation depending on the complexity of the system.

Illustrative image related to door lock components names

Keyless Entry Systems

Keyless entry systems eliminate the need for physical keys, making them ideal for high-traffic environments such as offices or shared facilities. These systems can range from simple keypad entries to more sophisticated biometric systems. While they offer moderate security, the effectiveness largely depends on the access control measures in place. The cost is generally mid-range, with installation complexity varying based on the type of system chosen. Maintenance involves replacing batteries and ensuring the system is updated regularly, which can be a consideration for facilities management.

Conclusion: Making the Right Choice for Your Security Needs

When considering door lock components and their alternatives, B2B buyers should assess their specific security requirements, budget constraints, and implementation capabilities. Traditional door lock components provide a reliable and straightforward solution for many applications, while smart locks and keyless entry systems offer advanced features that may suit modern business environments. By evaluating the pros and cons of each solution, buyers can select the most appropriate security measures that align with their operational needs and enhance overall safety.

Essential Technical Properties and Trade Terminology for door lock components names

Understanding the technical specifications and terminology associated with door lock components is crucial for international B2B buyers. This knowledge not only facilitates informed purchasing decisions but also ensures that the selected products meet the specific needs of various applications. Below are essential technical properties and trade terms relevant to door lock components.

What Are the Key Technical Properties of Door Lock Components?

-

Material Grade

– The material used in door lock components significantly influences durability and security. Common materials include stainless steel, brass, and zinc alloy. Stainless steel is known for its corrosion resistance, making it ideal for outdoor applications, while brass offers a classic aesthetic and good corrosion resistance. Understanding material grades helps buyers assess the longevity and suitability of locks for their specific environments. -

Tolerance

– Tolerance refers to the allowable variation in dimensions of lock components. Precision in manufacturing is critical, as even minor discrepancies can affect the functionality of locks. A tolerance of ±0.01 mm might be standard for high-security locks, ensuring that parts fit together seamlessly. Buyers should prioritize manufacturers that maintain strict tolerances to enhance reliability and performance. -

Locking Mechanism Type

– Different locking mechanisms, such as deadbolts, spring bolts, or smart locks, offer varying levels of security. Understanding the mechanism type is essential when selecting locks for specific applications, as each has unique advantages. For instance, deadbolts provide superior security compared to spring bolts, making them preferable for external doors. -

Finish

– The finish of door lock components affects both aesthetics and performance. Options such as polished chrome, matte black, or oil-rubbed bronze not only impact the visual appeal but also influence corrosion resistance. Buyers should consider finishes that complement the architectural style while ensuring durability. -

Load Rating

– Load rating indicates the amount of force a lock can withstand before failure. This specification is critical for high-traffic areas or commercial applications where locks are subjected to frequent use. A higher load rating signifies a more robust product, which is essential for maintaining security in demanding environments.

What Are Common Trade Terms in Door Lock Components?

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products that are sold under another company’s brand name. For buyers, sourcing OEM products can ensure quality and compatibility, as these components are often designed to meet specific standards set by the brand they support. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and overall costs. Buyers should negotiate MOQs to align with their purchasing capabilities while ensuring they meet supplier requirements. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This term is essential for B2B transactions, as it helps buyers compare pricing, terms, and conditions across multiple suppliers, ultimately leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers to understand cost implications and risk management in international transactions. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. This is a critical factor for buyers, particularly in project planning and inventory management. Understanding lead times helps businesses ensure they have the necessary components available when needed, avoiding delays in project execution.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring that they select the most suitable door lock components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the door lock components names Sector

What Are the Key Market Drivers for Door Lock Components in International B2B?

The global door lock components market is experiencing significant growth, driven primarily by increasing security concerns and the rising demand for smart locking solutions. As urbanization continues in regions like Africa, South America, and the Middle East, the need for reliable and secure locking mechanisms has surged. In Europe, particularly in Germany, regulatory standards for safety and security are becoming more stringent, pushing manufacturers to innovate and enhance the quality of door lock components.

Illustrative image related to door lock components names

Emerging technologies, including IoT and smart home automation, are reshaping the sourcing landscape. B2B buyers are increasingly seeking door lock components that integrate seamlessly with smart home systems, offering features such as remote access and real-time monitoring. This trend is particularly pronounced in regions like Saudi Arabia, where the luxury market is expanding and consumers are more inclined to invest in high-tech security solutions.

Additionally, the rise of e-commerce has transformed the procurement process for B2B buyers. Suppliers and manufacturers are leveraging digital platforms to reach international markets, facilitating quicker transactions and a broader selection of door lock components. This shift is crucial for buyers in emerging markets, who can now access diverse products without geographical limitations.

How Is Sustainability Influencing the Sourcing of Door Lock Components?

Sustainability is becoming a cornerstone of sourcing strategies in the door lock components sector. As environmental awareness grows among consumers and businesses alike, B2B buyers are prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainable practices. This includes the use of recycled materials, eco-friendly production processes, and compliance with international environmental standards.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices, seeking certifications that indicate adherence to sustainability principles. Green certifications such as ISO 14001 or products made from certified sustainable materials are becoming essential criteria in the procurement process. By aligning with suppliers who prioritize sustainability, buyers can enhance their brand reputation while contributing to global efforts to reduce environmental impact.

Moreover, the demand for sustainable door lock components is also influencing product innovation. Manufacturers are exploring new materials and technologies that reduce carbon footprints while maintaining high security and functionality standards. This trend not only appeals to environmentally conscious consumers but also positions businesses favorably in a competitive marketplace.

What Is the Historical Context of Door Lock Components in B2B Markets?

The evolution of door lock components can be traced back to ancient civilizations, where basic locking mechanisms were created using wooden bolts and metal keys. Over centuries, advancements in metallurgy and engineering led to the development of more sophisticated locking systems, culminating in the modern locks we use today. The industrial revolution marked a significant turning point, enabling mass production and standardization of door lock components, making them more accessible and affordable for a wider audience.

In recent decades, the introduction of electronic and smart locks has further transformed the landscape. These innovations have not only improved security but also introduced new functionalities, such as remote access and integration with home automation systems. As the market continues to evolve, understanding this historical context can provide B2B buyers with insights into the reliability and security of various locking mechanisms, guiding their purchasing decisions in a rapidly changing environment.

Conclusion

Navigating the complexities of the door lock components market requires a keen understanding of current trends, sustainability practices, and historical developments. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, aligning with innovative and ethical suppliers will be crucial in meeting the demands of modern security needs. Emphasizing quality, sustainability, and technological integration will not only enhance procurement strategies but also contribute to broader business goals in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of door lock components names

-

How do I choose the right door lock components for my business?

Choosing the right door lock components involves understanding your specific security needs, the type of doors you have, and the level of traffic through those doors. Consider factors such as the material of the door, desired locking mechanism (e.g., deadbolt, latch), and whether you need additional features like smart technology or keyless entry. Consulting with a knowledgeable supplier can help you identify the best components based on durability, compliance with local security standards, and compatibility with existing systems. -

What are the most common types of door lock components?

Common door lock components include cylinders, latches, bolts, strike plates, and handles. Cylinders are crucial for key operation, while latches secure the door when closed. Deadbolts offer enhanced security, and strike plates reinforce the door frame. Understanding these components will help you select the right products that meet your security requirements and ensure proper functionality. -

What customization options are available for door lock components?

Many suppliers offer customization options for door lock components, allowing you to tailor products to your specifications. This can include variations in size, finish, and locking mechanisms. Additionally, some manufacturers provide branding options, such as engraving or color matching, to align with your corporate identity. Discussing your specific needs with suppliers can lead to tailored solutions that enhance both security and aesthetics. -

What is the minimum order quantity (MOQ) for door lock components?

Minimum order quantities (MOQs) for door lock components can vary significantly between suppliers. Typically, MOQs may range from a few dozen to several hundred units, depending on the type of component and the manufacturer’s production capabilities. It’s essential to clarify MOQs during negotiations, as some suppliers may offer flexibility for larger orders or ongoing partnerships. Understanding these terms can help you manage inventory and costs effectively. -

What payment terms should I expect when purchasing door lock components internationally?

Payment terms for international orders of door lock components often include options such as advance payment, letter of credit, or payment upon delivery. Common practices involve a deposit upfront, with the balance due upon shipment or delivery. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Ensure you also account for currency exchange rates and potential transaction fees, which can impact overall costs. -

How do I vet suppliers for door lock components?

Vetting suppliers involves assessing their reliability, reputation, and product quality. Start by checking their certifications, such as ISO standards, and customer reviews. Request samples to evaluate the quality of their components firsthand. Engaging in direct communication can also provide insights into their customer service and responsiveness. Building a relationship with suppliers through visits or meetings can further ensure that they meet your business standards and expectations. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of door lock components should have robust quality assurance (QA) processes in place. This typically includes regular inspections, testing of materials, and adherence to international standards. Ask about their QA certifications and processes, as well as warranty offerings for their products. Understanding the supplier’s commitment to quality will help you ensure that the components you receive are reliable and meet your security needs. -

What logistics considerations should I keep in mind when sourcing door lock components?

When sourcing door lock components internationally, logistics play a critical role in ensuring timely delivery. Consider shipping methods, lead times, and potential customs regulations that may affect your order. It’s also wise to discuss the supplier’s ability to handle logistics, including packaging, tracking, and insurance options. Establishing clear communication regarding delivery expectations will help mitigate delays and ensure a smooth procurement process.

Top 1 Door Lock Components Names Manufacturers & Suppliers List

1. Locksmiths – Key Terminology

Domain: locksmiths.co.uk

Registered: 1996 (29 years)

Introduction: Locksmith Terminology includes various terms related to locks and their components. Key product details include: 1. Anti-thrust bolt: A security device that cannot be pushed back when shot out. 2. Automatic deadlatch: A deadlatch that locks automatically when the door is closed. 3. Backplate: The plate fixed on a door to which lock parts are attached. 4. Barrel Bolt: A common door bolt with a roun…

Strategic Sourcing Conclusion and Outlook for door lock components names

As the global market for door lock components continues to evolve, strategic sourcing remains a pivotal factor for B2B buyers aiming to enhance security and operational efficiency. Understanding the intricate components of door locks, from cylinders to strike plates, empowers businesses to make informed purchasing decisions that prioritize quality and reliability. By leveraging knowledge of these components, buyers can effectively troubleshoot issues, select suitable products, and engage in fruitful negotiations with suppliers.

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the emphasis on sourcing high-quality door lock components is paramount. Establishing strong relationships with reputable manufacturers not only ensures access to superior products but also enhances supply chain resilience.

Looking ahead, the demand for innovative locking solutions is expected to rise, driven by advancements in technology and security needs. Now is the time for businesses to invest in strategic sourcing partnerships that can adapt to these changes. Take action today to secure your supply chain and enhance your security offerings, positioning your company for future success in the competitive landscape of door lock components.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.