Is Your Door Entry Latch Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for door entry latch

In today’s interconnected world, sourcing the right door entry latch can be a significant challenge for B2B buyers navigating the global market. With an array of options available, from residential to commercial latches, understanding the nuances of quality, security standards, and regional compliance becomes imperative. This comprehensive guide delves into the diverse types of door entry latches, their various applications, and essential factors to consider during the supplier vetting process, including pricing, materials, and certifications.

As international buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Saudi Arabia and Brazil) face unique market dynamics, this guide is designed to empower them with actionable insights. By providing a thorough analysis of cost structures and trends in the door hardware industry, we aim to equip decision-makers with the knowledge necessary to make informed purchasing decisions.

Whether you are looking to enhance security in residential buildings or optimize access control in commercial spaces, this guide will serve as a valuable resource. By understanding the full spectrum of options and best practices in sourcing door entry latches, you can streamline your procurement process, ensuring that your investments align with both quality standards and budgetary constraints.

Understanding door entry latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt Latch | High security, requires key for operation | Commercial and residential doors | Pros: Excellent security; Cons: Can be more expensive and complex to install. |

| Mortise Latch | Fits into a pocket within the door | High-end residential and commercial | Pros: Aesthetic appeal; Cons: Requires precise installation and may need special tools. |

| Drive-In Latch | No faceplate, fits directly into the door | Residential interior doors | Pros: Easy installation; Cons: Limited security features compared to deadbolts. |

| Electronic Keyless Latch | Keypad entry, programmable access | Commercial settings, smart homes | Pros: Convenient access control; Cons: Requires power source and may be vulnerable to hacking. |

| Surface-Mounted Latch | Mounted on the surface of the door | Screen doors, storm doors | Pros: Simple installation; Cons: Less secure than embedded latches. |

What Are the Key Characteristics of Deadbolt Latches for B2B Buyers?

Deadbolt latches are renowned for their security features, making them ideal for both commercial and residential applications. They require a key for operation, which adds an extra layer of protection against unauthorized access. B2B buyers should consider the ANSI grade of the deadbolt, as higher grades indicate better security performance. While they may come at a higher price point and require more complex installation, the investment is often justified in high-security environments.

How Do Mortise Latches Stand Out in the Market?

Mortise latches are designed to fit into a pocket within the door, providing a clean and sophisticated appearance. Commonly used in high-end residential and commercial settings, they offer a blend of aesthetics and functionality. B2B buyers should evaluate the compatibility of the latch with existing door structures, as installation can be more intricate and may require specialized tools. Their visual appeal can enhance the overall design of a property, making them a favored choice for upscale projects.

What Makes Drive-In Latches a Practical Choice?

Drive-in latches are characterized by their straightforward installation, as they fit directly into the door without the need for a faceplate. They are primarily used in residential interior doors, making them a popular choice for quick and easy upgrades. Buyers should note that while they are user-friendly and cost-effective, their security features are generally less robust compared to deadbolts. This can be an important consideration for B2B buyers focused on balancing budget constraints with security needs.

Why Are Electronic Keyless Latches Gaining Popularity?

Electronic keyless latches offer a modern approach to door security with keypad access and programmable entry codes. They are particularly suitable for commercial settings and smart homes, where convenience and flexibility are paramount. B2B buyers should consider the operational requirements, such as the need for a power source and the potential for vulnerabilities to hacking. Despite these concerns, their ease of use and ability to manage access effectively make them a compelling option for forward-thinking businesses.

What Advantages Do Surface-Mounted Latches Provide?

Surface-mounted latches are installed on the exterior of the door, making them easy to fit and replace. They are commonly used for screen and storm doors, where security is less of a concern. B2B buyers should appreciate their simplicity and low installation costs, but should also weigh the trade-off in terms of security when compared to other latch types. These latches are best suited for applications where ease of access and budget are prioritized over high security.

Key Industrial Applications of door entry latch

| Industry/Sector | Specific Application of door entry latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Access control for hotel room doors | Enhances guest security and privacy | Durability, aesthetic appeal, compliance with local regulations |

| Residential Construction | Installation in new residential buildings | Provides safety and convenience for homeowners | Fire ratings, adaptability to various door types, cost-effectiveness |

| Commercial Security | Latching systems for office buildings | Protects sensitive areas and restricts access | ANSI grading, tamper resistance, compatibility with electronic systems |

| Manufacturing | Door latches for industrial facilities | Ensures safety and efficiency in high-traffic areas | Heavy-duty materials, weather resistance, ease of installation |

| Retail | Latching mechanisms for store entry points | Enhances security and customer flow | Versatility, visual appeal, ease of maintenance |

How Are Door Entry Latches Used in the Hospitality Industry?

In the hospitality sector, door entry latches are essential for securing hotel room doors. They provide guests with the assurance of safety and privacy, which is paramount in maintaining a positive guest experience. Buyers in this industry need to consider the durability and aesthetic appeal of the latches, as they must withstand frequent use while complementing the hotel’s design. Additionally, compliance with local safety regulations is crucial, particularly in regions like Europe and the Middle East, where building codes can be stringent.

What Role Do Door Entry Latches Play in Residential Construction?

For residential construction, door entry latches are integral components in new homes, ensuring safety and convenience for residents. These latches come in various types, including fire-rated options that meet safety standards for emergency exits. International buyers, particularly in Africa and South America, should focus on adaptability to different door styles and ease of installation to enhance project efficiency. Cost-effectiveness is also a significant consideration, as it impacts overall project budgets.

How Do Door Entry Latches Enhance Security in Commercial Buildings?

In commercial security applications, door entry latches are vital for protecting sensitive areas within office buildings. They restrict access to authorized personnel and can be integrated with electronic security systems for enhanced protection. Businesses must prioritize ANSI grading for latches to ensure they meet security standards, especially in high-risk environments. Buyers should also look for tamper-resistant features and compatibility with existing security frameworks to maximize their investment.

Why Are Door Latches Critical in Manufacturing Settings?

Manufacturing facilities utilize door latches to maintain safety and efficiency in high-traffic areas. Heavy-duty latches are designed to endure rigorous use while ensuring that areas remain secure from unauthorized access. When sourcing latches for industrial environments, considerations such as weather resistance and ease of installation are essential. Buyers must select latches made from robust materials that can withstand harsh conditions, particularly in regions with extreme climates.

How Do Retail Environments Benefit from Effective Door Latching Mechanisms?

In retail settings, door entry latches facilitate both security and customer flow. They must be reliable yet easy to operate to ensure a seamless shopping experience. Retailers should consider the versatility of latching mechanisms that can adapt to various door styles and sizes while also being visually appealing to enhance store aesthetics. Ease of maintenance is another critical factor, as it impacts operational efficiency and customer satisfaction.

3 Common User Pain Points for ‘door entry latch’ & Their Solutions

Scenario 1: Difficulty Sourcing Durable Door Entry Latches for Harsh Environments

The Problem: B2B buyers, especially those in regions with extreme weather conditions such as the Middle East or South America, often struggle to find door entry latches that can withstand environmental stressors. Common issues include latches that corrode or malfunction due to high humidity or saline environments, leading to increased maintenance costs and potential security risks. Buyers may face the challenge of ensuring that their chosen latches are not only functional but also durable enough to last in harsh climates, which can lead to frustration and operational delays.

The Solution: To address this challenge, buyers should prioritize sourcing latches made from corrosion-resistant materials, such as stainless steel or specialized alloys. When evaluating products, look for door latches that are specifically rated for extreme weather conditions and have undergone rigorous testing for durability. Engage with suppliers who provide detailed product specifications and certifications, such as ANSI grades, which indicate the quality and reliability of the latch. Additionally, consider investing in latches with a protective coating or finish that can further enhance their lifespan in challenging environments. Establishing strong relationships with reputable suppliers can also facilitate access to custom solutions tailored to specific environmental needs, ensuring longevity and reducing replacement frequency.

Scenario 2: Ensuring Compliance with Fire Safety Regulations

The Problem: In sectors such as construction and property management, compliance with fire safety regulations is critical. Buyers often face challenges in selecting door entry latches that meet local and international fire safety standards, particularly in regions like Europe where regulations can be stringent. Failure to comply can result in legal repercussions, increased liability, and significant costs associated with retrofitting or replacing non-compliant hardware.

The Solution: To navigate this issue, B2B buyers should familiarize themselves with the fire safety codes relevant to their projects, such as UL or EN standards. When selecting door entry latches, prioritize those that are UL-listed or certified for fire resistance. Additionally, work closely with manufacturers who specialize in fire-rated products and can provide documentation proving compliance. Implement a thorough review process for all hardware specifications during the planning phase, ensuring that all door latches are compliant before installation. Regular training for procurement teams on current regulations can also mitigate compliance risks and enhance knowledge about available compliant products.

Scenario 3: Managing Inventory and Replacement Parts for Door Entry Latches

The Problem: For companies managing multiple properties or large facilities, keeping track of door entry latch inventory and ensuring timely replacements can be a logistical nightmare. Stockouts or delays in acquiring specific latch types can disrupt operations, compromise security, and lead to increased repair costs. Moreover, the challenge of coordinating various suppliers for different latch types complicates inventory management, leading to inefficiencies and increased overhead.

The Solution: To streamline inventory management, businesses should adopt a centralized inventory system that tracks latch usage and alerts procurement teams when stock levels are low. Establishing relationships with a single, reliable supplier who can provide a comprehensive range of door entry latches—covering both standard and specialized types—can simplify the procurement process and reduce lead times. Additionally, consider implementing a just-in-time inventory strategy to minimize excess stock while ensuring that critical latches are always available when needed. Regular audits of inventory and usage patterns will also help in forecasting demand accurately, thus preventing stockouts and maintaining operational efficiency. Engaging in bulk purchasing agreements can further enhance cost savings and ensure a steady supply of necessary components.

Strategic Material Selection Guide for door entry latch

What Are the Key Materials Used in Door Entry Latches?

When selecting materials for door entry latches, several options stand out due to their unique properties, advantages, and limitations. Understanding these materials is crucial for international B2B buyers who must consider factors such as durability, cost, and compliance with regional standards.

How Does Steel Perform as a Material for Door Entry Latches?

Steel, particularly stainless steel, is a popular choice for door entry latches due to its exceptional strength and durability. It exhibits high resistance to corrosion, making it suitable for both indoor and outdoor applications. Steel latches can withstand significant wear and tear, which is essential in high-traffic areas.

Pros: The primary advantages of steel latches include their robustness and long lifespan, which can reduce replacement frequency. They also offer good security features, often meeting high-grade safety standards.

Cons: However, steel can be heavier than other materials, which may complicate installation. Additionally, while stainless steel is resistant to rust, it can still corrode under certain conditions if not properly maintained.

International Considerations: Buyers from regions like the Middle East and Europe should ensure that the steel latches comply with ASTM or DIN standards for quality assurance. In humid climates, the choice of stainless steel over carbon steel is advisable to prevent rust.

What Advantages Does Brass Offer in Door Entry Latch Manufacturing?

Brass is another common material used in the manufacturing of door entry latches. Known for its aesthetic appeal, brass offers a warm, attractive finish that is often preferred in residential settings.

Pros: Brass latches are resistant to corrosion and have antimicrobial properties, making them suitable for environments where hygiene is a concern. They are also relatively easy to machine, allowing for intricate designs.

Cons: On the downside, brass is softer than steel, which can make it less durable in high-stress applications. It may also require more frequent polishing to maintain its appearance.

International Considerations: For buyers in South America and Africa, it is essential to consider local environmental conditions that may affect brass’s longevity. Compliance with local standards for metal finishes can also impact marketability.

How Do Zinc-Alloy Latches Compare in Terms of Performance?

Zinc alloy is frequently used in door entry latches due to its cost-effectiveness and versatility. This material can be molded into various shapes and finishes, making it an attractive option for manufacturers.

Pros: Zinc-alloy latches are lightweight and resistant to rust, making them suitable for a wide range of applications. They also tend to be less expensive than steel and brass, which can lower overall production costs.

Cons: However, zinc alloys may not be as strong as steel, which could lead to potential security concerns in high-risk areas. They may also be less durable under extreme temperatures.

International Considerations: Buyers should ensure that zinc-alloy latches meet the necessary compliance standards in their regions, such as JIS in Japan or other local certifications. Understanding the local market’s preferences for aesthetics and durability is also crucial.

What Role Does Plastic Play in Door Entry Latch Applications?

Plastic latches are becoming increasingly popular, especially in residential applications. They offer a lightweight alternative to metal latches and can be produced in various colors and designs.

Pros: The primary advantages of plastic latches include their resistance to corrosion and ease of installation. They are also less expensive to produce, which can be beneficial for budget-conscious projects.

Cons: However, plastic latches may not offer the same level of security as metal options and can be prone to wear over time. Their performance can also be affected by extreme temperatures, leading to brittleness or deformation.

International Considerations: In regions like Africa, where temperature fluctuations are common, buyers should consider the specific type of plastic used to ensure it can withstand local conditions. Compliance with safety standards is also critical for market acceptance.

Summary Table of Material Properties for Door Entry Latches

| Material | Typical Use Case for door entry latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-security commercial applications | Exceptional strength and durability | Heavier, potential for corrosion | Medium |

| Brass | Residential settings | Aesthetic appeal and antimicrobial | Softer, requires maintenance | Medium |

| Zinc Alloy | General-purpose applications | Lightweight and cost-effective | Less strong, temperature sensitivity | Low |

| Plastic | Budget-friendly residential applications | Corrosion-resistant and lightweight | Lower security, wear over time | Low |

This strategic material selection guide aims to equip B2B buyers with the insights necessary to make informed decisions when sourcing door entry latches for various applications across global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for door entry latch

Manufacturing door entry latches involves a series of well-defined processes and strict quality assurance measures to ensure the final product meets both safety and performance standards. This section provides an in-depth exploration of the typical manufacturing processes and quality control (QC) protocols that B2B buyers should consider when sourcing door entry latches.

What Are the Main Stages in Manufacturing Door Entry Latches?

The manufacturing process for door entry latches typically consists of four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Door Entry Latch Manufacturing?

Material preparation is a critical first step. Manufacturers often use materials such as stainless steel, brass, or zinc alloy due to their durability and resistance to corrosion. The selection of material will depend on the intended use of the latch—residential versus commercial applications may require different specifications.

Materials are sourced from certified suppliers, and before processing, they undergo Incoming Quality Control (IQC) checks to ensure they meet the required standards. This may include verifying material specifications and conducting tests for structural integrity.

What Techniques Are Used in Forming Door Entry Latches?

The forming stage involves transforming raw materials into the desired latch shapes. Common techniques include:

- Stamping: This involves using dies to cut and shape metal sheets into latch components. It’s a cost-effective method suitable for high-volume production.

- Machining: For more intricate designs, machining techniques such as CNC (Computer Numerical Control) milling and turning are employed to create precise components.

- Casting: In some cases, especially for complex shapes, casting methods may be used where molten metal is poured into molds.

Each technique has its advantages and is chosen based on the design complexity, volume requirements, and cost considerations.

How Are Door Entry Latches Assembled?

After forming, the next step is assembly. This involves combining various components such as the latch body, strike plate, and locking mechanism. Automated assembly lines are commonly used for efficiency, but manual assembly may also occur for specialized products.

Quality checks are crucial during this stage to ensure that all parts fit together correctly and function as intended. This is typically referred to as In-Process Quality Control (IPQC), where operators inspect the assembly at various points to catch defects early.

What Finishing Processes Are Applied to Door Entry Latches?

Finishing processes enhance the appearance and durability of door entry latches. Common finishing techniques include:

- Plating: Applying a thin layer of metal, such as nickel or chrome, to improve corrosion resistance and aesthetic appeal.

- Powder Coating: This provides a durable finish that can withstand harsh environmental conditions, making it ideal for outdoor latches.

- Anodizing: Often used for aluminum latches, this process increases resistance to corrosion and wear.

Finishing not only improves the latch’s visual appeal but also extends its lifespan, which is a significant selling point for B2B buyers.

What Quality Assurance Standards Are Relevant for Door Entry Latches?

Quality assurance is paramount in the manufacturing of door entry latches. International standards such as ISO 9001 play a crucial role in guiding manufacturers in establishing effective quality management systems. Compliance with ISO standards ensures that manufacturers consistently produce high-quality products.

What Industry-Specific Certifications Should B2B Buyers Look For?

In addition to general ISO certifications, specific industry standards may apply. For example:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe.

- API Certification: Relevant for latches used in oil and gas applications, ensuring they meet industry-specific safety and performance standards.

B2B buyers should verify that their suppliers possess the necessary certifications, as these can significantly affect product reliability and market acceptance.

How Are Quality Control Checkpoints Established?

Quality control is typically structured around several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducts regular inspections during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Involves comprehensive testing of the finished product to ensure it meets all specifications and performance criteria.

Common testing methods include functional tests, stress tests, and corrosion resistance tests. These procedures help identify any potential issues before products are shipped.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are several methods to ensure compliance and reliability:

-

Supplier Audits: Conducting regular audits can provide insights into a supplier’s manufacturing processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand how quality is managed at each stage of production.

-

Third-Party Inspections: Engaging independent inspection agencies to verify compliance can provide additional assurance of product quality.

-

Certifications and Documentation: Buyers should request copies of relevant certifications and quality control documentation, ensuring they align with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances is particularly important for buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Regional regulations and standards may vary significantly, impacting the choice of suppliers.

- Regional Compliance: Buyers should familiarize themselves with specific regional requirements, such as local certifications or testing standards, to ensure compliance.

- Cultural Differences: Understanding cultural attitudes toward quality and manufacturing practices can also influence supplier relationships and negotiations.

By being informed about these factors, B2B buyers can make more strategic decisions when sourcing door entry latches, ensuring they receive high-quality products that meet their specific needs.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures is essential for B2B buyers in selecting reliable suppliers for door entry latches. By focusing on these key areas, buyers can enhance their procurement strategies and ensure they receive products that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door entry latch’

To assist B2B buyers in sourcing door entry latches effectively, this guide provides a structured checklist designed to ensure a thorough procurement process. By following these steps, businesses can make informed purchasing decisions that meet their specific needs.

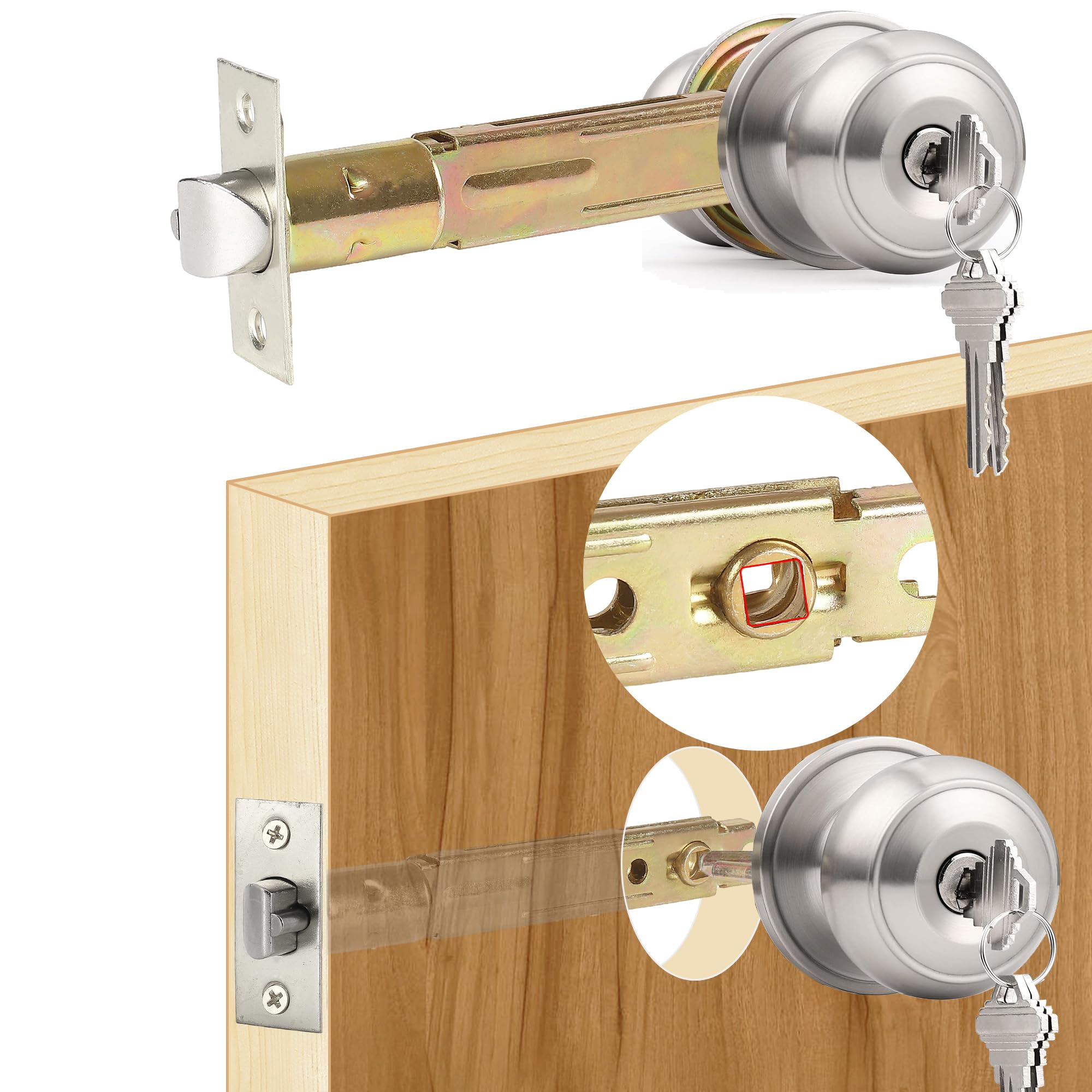

Illustrative image related to door entry latch

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the door latches meet the functional and safety requirements of your project. Consider the following aspects:

– Latch Type: Determine whether you need a deadbolt, passage latch, or a keyed entry latch.

– Material and Finish: Choose materials that align with durability and aesthetic preferences, such as stainless steel for longevity or brass for a classic look.

Step 2: Assess Compliance and Standards

Verify that the door latches comply with local and international standards relevant to your region. This is essential for safety and reliability.

– Fire Ratings: For certain applications, such as commercial buildings, ensure latches meet fire safety standards (e.g., UL ratings).

– ANSI Grades: Check the American National Standards Institute (ANSI) grades to assess security levels; higher grades indicate better security.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers before making a commitment. A reliable supplier can significantly impact product quality and service.

– Company Background: Review the supplier’s history, including years in business and market reputation.

– References and Case Studies: Request testimonials or case studies from similar industries to gauge their performance and reliability.

Step 4: Compare Pricing and Quality

Price is an important factor, but it should be balanced with quality. Compare quotes from multiple suppliers, ensuring you understand what is included.

– Bulk Discounts: Inquire about pricing tiers for bulk purchases, which can lead to significant savings.

– Quality Assurance: Ask about quality control processes to ensure the latches meet your specifications consistently.

Step 5: Request Samples

Before finalizing your order, request samples of the latches you intend to purchase. This step allows you to assess the product firsthand.

– Testing for Fit and Function: Ensure the latch fits well with your existing door systems and operates smoothly.

– Material Evaluation: Inspect the finish and material quality to confirm they align with your expectations.

Step 6: Understand Lead Times and Delivery Options

Clarify lead times and delivery options with your supplier to avoid delays in your project timeline. Effective logistics management is vital for timely project completion.

– Production Time: Ask how long it typically takes to manufacture and ship the latches.

– Shipping Methods: Discuss available shipping options and costs, especially for international orders, to ensure they fit your timeline and budget.

Step 7: Negotiate Terms and Finalize the Contract

Once you are satisfied with the samples and supplier terms, negotiate the final contract. Clear terms help prevent misunderstandings later.

– Payment Terms: Discuss payment schedules and methods that work for both parties.

– Warranty and Returns: Ensure the contract includes warranty terms and a clear return policy for defective products.

By following this checklist, B2B buyers can navigate the sourcing process for door entry latches more effectively, ensuring they select the right products for their needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for door entry latch Sourcing

What are the Key Cost Components in Door Entry Latch Manufacturing?

When sourcing door entry latches, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials like stainless steel, brass, and high-grade plastics are frequently used. Prices can fluctuate based on global supply chain conditions and raw material availability.

-

Labor: Labor costs vary widely depending on the manufacturing location. Regions with lower labor costs, such as parts of South America or Asia, may offer competitive pricing, but may also affect lead times and quality control.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. This cost is typically amortized over the production run, so higher volume orders may dilute this expense.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is essential, particularly for markets with strict safety standards. This can increase costs but is necessary to avoid costly recalls or reputation damage.

-

Logistics: Shipping costs can vary based on the Incoterms agreed upon. For buyers in regions like Africa or the Middle East, understanding shipping routes and potential tariffs is vital for accurate cost forecasting.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary significantly based on the supplier’s market position and the competition in the region.

How Do Price Influencers Affect Door Entry Latch Sourcing?

Several factors influence the pricing of door entry latches, which international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs. Suppliers may offer significant discounts for bulk purchases, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom latches designed to meet specific requirements, such as unique finishes or locking mechanisms, can incur additional costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as UL ratings for fire safety) can increase costs but are often necessary to meet regulatory requirements in different regions.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) can have significant implications for total costs. Buyers should clarify responsibilities for freight, insurance, and tariffs to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Door Entry Latch Sourcing?

For B2B buyers, especially those from regions like Saudi Arabia, Brazil, and others, here are some actionable tips:

-

Negotiate Effectively: Building a strong relationship with suppliers can lead to better terms. Don’t hesitate to negotiate pricing, especially for larger orders or long-term contracts.

-

Focus on Total Cost of Ownership (TCO): While the initial purchase price is important, consider the long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality latches may yield savings over time.

-

Understand Pricing Nuances: Prices may vary based on geographic location, market demand, and currency fluctuations. Buyers should stay informed about market trends and pricing changes in their regions.

-

Leverage Technology: Utilize online platforms and tools for price comparisons and supplier evaluations. This can help in identifying the best deals and ensuring competitive pricing.

Disclaimer on Indicative Prices

It is important to note that prices for door entry latches can vary widely based on the factors mentioned above. The indicative prices provided by suppliers may change due to market conditions, production costs, and shipping variables. Therefore, it is advisable for buyers to obtain updated quotes directly from suppliers when making purchasing decisions.

Alternatives Analysis: Comparing door entry latch With Other Solutions

When considering security and access control solutions, it’s essential to evaluate various options to determine the most suitable fit for specific needs. While door entry latches are widely used for residential and commercial applications, alternative solutions also exist that can enhance security and accessibility. This section compares door entry latches with electronic locks and biometric access systems, providing insights for international B2B buyers.

| Comparison Aspect | Door Entry Latch | Electronic Lock | Biometric Access System |

|---|---|---|---|

| Performance | Reliable for basic security needs | Offers remote access and audit trails | Highly secure, unique identification |

| Cost | Typically low-cost, starting at $5 | Moderate to high, $50 to $200 | High initial investment, $100 to $500+ |

| Ease of Implementation | Simple installation | Requires wiring or battery management | Complex installation, may need professionals |

| Maintenance | Minimal, occasional lubrication | Moderate, requires battery changes | High, regular updates and maintenance |

| Best Use Case | Residential and light commercial | Businesses needing remote access control | High-security areas requiring strict access |

What Are the Benefits and Drawbacks of Electronic Locks Compared to Door Entry Latches?

Electronic locks provide a significant upgrade over traditional door entry latches by offering features such as remote access, programmable codes, and audit trails. This makes them an excellent option for businesses that require flexible access control. However, the cost can be a barrier, as these systems often range from $50 to $200, depending on features. Moreover, installation can be more complex, sometimes requiring professional assistance, and maintenance includes battery replacement and software updates.

How Do Biometric Access Systems Measure Up Against Door Entry Latches?

Biometric access systems use unique physical traits, such as fingerprints or facial recognition, to grant access, making them one of the most secure options available. They are ideal for high-security environments, such as government buildings or data centers. However, the high initial investment (typically $100 to $500+) and the complexity of installation can deter smaller businesses. Maintenance is also more demanding, requiring regular updates and checks to ensure the technology remains functional.

Illustrative image related to door entry latch

Conclusion: How Should B2B Buyers Select the Right Door Entry Solution?

When selecting the right door entry solution, B2B buyers must evaluate their specific security needs, budget constraints, and the environment in which the system will be implemented. For basic security needs at a low cost, traditional door entry latches remain effective. However, for businesses requiring advanced features like remote access and detailed tracking, electronic locks may be more appropriate. Biometric systems should be reserved for situations demanding the highest levels of security, despite their higher costs and maintenance requirements. Ultimately, understanding the unique context and requirements of each application will guide buyers toward the most effective solution.

Essential Technical Properties and Trade Terminology for door entry latch

What Are the Key Technical Properties of a Door Entry Latch?

When sourcing door entry latches for commercial or residential applications, understanding the technical properties is crucial. Here are some essential specifications to consider:

1. Material Grade

The material grade of a door latch typically includes options like stainless steel, brass, or zinc alloy. Stainless steel is favored for its corrosion resistance and durability, making it suitable for outdoor applications. Brass, while aesthetically pleasing, may not be as robust in adverse weather conditions. Selecting the right material affects not only the latch’s lifespan but also its security features, which is a top priority for B2B buyers.

Illustrative image related to door entry latch

2. ANSI Grade

The American National Standards Institute (ANSI) provides a grading system for locks and latches, classified from Grade 1 (highest security) to Grade 3 (basic security). Grade 1 latches are typically used in commercial settings where high security is essential, while Grade 3 is suitable for residential applications. Understanding ANSI grades helps buyers assess the level of security required for their projects.

3. Backset Measurement

Backset refers to the distance from the edge of the door to the center of the latch or lock. Common backset measurements include 2-3/8 inches and 2-3/4 inches. Choosing the correct backset is vital for compatibility with existing door hardware and can prevent installation issues. This specification is particularly important for manufacturers and contractors who need to ensure product consistency.

4. Tolerance Levels

Tolerance levels indicate how much a latch can deviate from its specified dimensions without affecting performance. A tighter tolerance usually results in a better fit and enhanced security. For B2B buyers, understanding tolerance levels can help in selecting products that meet specific installation requirements and standards, ultimately reducing the risk of product failure.

5. Finish Options

The finish of a door latch can affect both its aesthetic appeal and functionality. Common finishes include satin nickel, oil-rubbed bronze, and polished brass. The choice of finish is not just about appearance; it also affects corrosion resistance and maintenance. Buyers should consider finishes that align with their design vision while ensuring durability.

What Trade Terminology Should B2B Buyers Understand When Sourcing Door Entry Latches?

Navigating the world of door entry latches involves familiarizing oneself with specific industry jargon. Here are key terms that can facilitate smoother transactions:

Illustrative image related to door entry latch

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of door latches, partnering with OEMs can help ensure quality and compatibility with existing systems. This is crucial for businesses looking to maintain brand integrity and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to avoid overstocking or underordering. It can significantly impact procurement strategies, especially for international buyers who may be managing logistics and costs.

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests a quote from suppliers for specific products. This document typically includes details such as quantities, specifications, and delivery timelines. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is critical for international buyers to manage shipping costs, risks, and responsibilities effectively.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the door latch industry, lead times can vary based on the manufacturer’s location and production capacity. Being aware of lead times helps B2B buyers plan their projects more effectively and manage client expectations.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the door entry latch Sector

What Are the Current Market Dynamics and Key Trends in the Door Entry Latch Sector?

The global market for door entry latches is experiencing significant growth, driven by increasing construction activities, urbanization, and rising demand for enhanced security solutions. Emerging technologies, such as smart locks and keyless entry systems, are reshaping the landscape, offering B2B buyers innovative options that combine convenience with security. In regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for products that not only meet functional requirements but also align with aesthetic preferences and technological advancements.

B2B buyers are also prioritizing products with customizable features, such as adjustable backsets and various finishes, which cater to diverse architectural styles. This flexibility is particularly important in emerging markets, where local preferences vary significantly. Additionally, the rise of e-commerce platforms has streamlined sourcing, enabling international buyers to access a wider array of suppliers and products. The focus on efficiency in supply chains is further emphasized by the demand for rapid delivery options and just-in-time inventory management, allowing businesses to reduce overhead costs and improve responsiveness to market changes.

How Is Sustainability and Ethical Sourcing Shaping the Door Entry Latch Market?

Sustainability is becoming a cornerstone in the door entry latch sector, with increasing awareness of environmental impacts influencing purchasing decisions. B2B buyers are now seeking suppliers that prioritize eco-friendly materials and processes. This trend is particularly pronounced in Europe and the Middle East, where stringent regulations and consumer expectations regarding sustainability are driving change. Buyers should look for products made from recycled or sustainably sourced materials, as well as those that carry certifications such as LEED or Energy Star, which signify adherence to environmental standards.

Ethical sourcing is equally critical, as businesses are increasingly held accountable for their supply chain practices. This includes ensuring fair labor practices and minimizing environmental impact throughout the production cycle. Buyers can enhance their brand reputation by partnering with suppliers who demonstrate transparency in their sourcing and manufacturing processes. Embracing these principles not only aligns with corporate social responsibility (CSR) goals but also appeals to a growing segment of consumers who prioritize sustainability when making purchasing decisions.

What Is the Historical Context of Door Entry Latches in B2B Markets?

Historically, door entry latches have evolved from basic mechanical devices to sophisticated electronic systems. In the early 20th century, latches were primarily made of heavy metals and operated manually, focusing mainly on functionality. With advancements in technology, the latter half of the century saw the introduction of various locking mechanisms, including deadbolts and electronic latches, which provided enhanced security.

Illustrative image related to door entry latch

In the past two decades, the rise of smart technology has transformed the sector dramatically. Smart door latches equipped with Wi-Fi or Bluetooth connectivity allow users to control access remotely, providing increased convenience and security. This evolution reflects broader trends in the B2B landscape, where technology integration and user-centric design are paramount. As the market continues to innovate, staying informed about these historical shifts can help B2B buyers make strategic sourcing decisions that align with both current trends and future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of door entry latch

-

How do I choose the right door entry latch for my business needs?

Selecting the appropriate door entry latch involves assessing the specific requirements of your installation. Consider factors like the type of door (interior or exterior), security needs, and compatibility with existing hardware. Evaluate the latch’s material, finish, and ANSI security ratings to ensure durability and protection. Additionally, check for features such as tamper resistance or fire ratings, especially for commercial applications. Consulting with your suppliers for their recommendations based on your unique requirements can also help streamline your decision-making process. -

What are the most important features to consider in a door entry latch?

When sourcing door entry latches, prioritize features such as security ratings (ANSI grades), ease of installation, and compatibility with your door type. Look for adjustable backsets to fit various door thicknesses, as well as options for different finishes that match your aesthetic requirements. Additionally, consider latches with enhanced security features, such as deadbolts or tamper-resistant designs, especially for high-risk areas. Understanding your specific application will help you identify which features are essential for your needs. -

What are the common minimum order quantities (MOQs) for door entry latches?

Minimum order quantities (MOQs) for door entry latches can vary significantly based on the manufacturer and the complexity of the product. Typically, MOQs can range from as low as 50 units for standard latches to several hundred for customized or specialized products. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you’re testing a new market or product line. Establishing a good relationship with your supplier may also provide opportunities for lower MOQs or trial orders. -

What should I look for when vetting suppliers for door entry latches?

When vetting suppliers, assess their reputation, experience in the industry, and production capabilities. Check for certifications that ensure quality standards, such as ISO or UL listings. Request references or case studies from past clients to gauge their reliability and service levels. Additionally, consider their responsiveness to inquiries and willingness to provide samples or detailed product information. A supplier with a strong commitment to quality assurance and customer service will be invaluable for your long-term success. -

What payment terms are typically offered by suppliers of door entry latches?

Payment terms can vary widely among suppliers, but common practices include net 30, net 60, or payment upon delivery. Some suppliers may offer discounts for early payment or larger orders. When negotiating terms, consider your cash flow and the financial stability of your business. It’s essential to clarify any additional costs, such as shipping or customs duties, to avoid unexpected expenses. Building a good relationship with your supplier may also lead to more favorable payment conditions. -

How can I ensure quality assurance in door entry latches?

To ensure quality assurance in your door entry latches, request detailed product specifications and certifications from suppliers. Implement a quality control process that includes inspections upon receipt of goods, checking for compliance with international standards. Consider conducting random sampling of products for testing their durability and functionality. Establishing a clear communication channel with your supplier regarding quality expectations will help address any issues promptly, ensuring a consistent supply of high-quality products. -

What are the logistics considerations when importing door entry latches?

When importing door entry latches, consider logistics factors such as shipping methods, customs regulations, and lead times. Work with suppliers who have experience in international shipping to navigate customs clearance efficiently. Be aware of import duties and taxes that may apply to your shipments. Developing a reliable logistics plan that includes warehousing and distribution will help streamline your operations and reduce delays. Additionally, consider local regulations regarding product standards and certifications in your target market. -

Can I customize door entry latches for my brand?

Many manufacturers offer customization options for door entry latches, allowing you to tailor products to your brand’s specifications. Customization can include unique finishes, branding elements, or specific functionality. When discussing options with suppliers, provide clear specifications and quantities to facilitate the design process. Keep in mind that customization may require higher MOQs and longer lead times. Establishing a collaborative relationship with your manufacturer can lead to innovative solutions that enhance your product offerings.

Top 4 Door Entry Latch Manufacturers & Suppliers List

1. Harney Hardware – Keyed Entry Latch

Domain: harneyhardware.com

Registered: 2004 (21 years)

Introduction: Residential Door Latches available at Harney Hardware include:

1. Residential Keyed / Entry Latch, UL Fire Rated, Adjustable 2 3/8 In. To 2 3/4 In.

– Product #: 87371

– Finish: Venetian Bronze

– Price: $6.47

2. Residential Keyed / Entry Latch, UL Fire Rated, Adjustable 2 3/8 In. To 2 3/4 In.

– Product #: 87370

– Finish: Satin Stainless Steel

– Price: $6.47

3. Residential…

2. NU-SET – Kwikset and Schlage Door Latches

Domain: nusetlock.com

Registered: 2005 (20 years)

Introduction: NU-SET carries Kwikset and Schlage door latches for entry and deadbolt. The door latches are commercial grade 2 and UL listed. Available finishes include bright brass, antique brass, and satin chrome. Specific products include:

– NuSet 2-3/8″ Backset Entry Latch, Square Corner, Brass, UL Listed, Regular price $10.00

– NuSet 2-3/8″ Backset Entry Latch, Square Corner, Oil Rubbed Bronze, UL Listed,…

3. Signature Hardware – Exterior Entry Doors and Lock Sets

Domain: signaturehardware.com

Registered: 2004 (21 years)

Introduction: Exterior Entry Door and Lock Sets from Signature Hardware include 65 results with various finishes such as Antique Brass, Antique Copper, Antique Pewter, Black Powder Coat, Brushed Nickel, Chrome, Dark Bronze, Matte Black, Oil Rubbed Bronze, Satin Black, Satin Brass, and Satin Nickel. The materials used include Brass, Bronze, Ceramic, and Zinc. The design options feature Contemporary and Modern st…

4. Rejuvenation – Exterior Door Hardware Collection

Domain: rejuvenation.com

Registered: 1997 (28 years)

Introduction: Exterior door hardware collection includes exterior door sets, knobs, and deadbolt combos. Features lever and knob styles, single or double cylinder deadbolts, and screen door hardware. Available in various colors: gold, black, silver, brown. Materials include solid brass, bronze, porcelain, and crystal. Finishes like oil-rubbed bronze, polished nickel, and aged brass. Collections include Putman, …

Strategic Sourcing Conclusion and Outlook for door entry latch

In conclusion, the strategic sourcing of door entry latches presents significant opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The diverse range of latches, from residential to commercial applications, underscores the importance of understanding local market needs and preferences. Buyers should prioritize quality, security ratings, and compatibility with existing door hardware to ensure they meet industry standards and customer expectations.

Engaging with reliable suppliers and manufacturers who offer a variety of finishes and functionalities can enhance the competitive edge in local markets. Additionally, leveraging bulk purchasing and establishing long-term partnerships can lead to cost efficiencies and improved supply chain reliability.

Looking ahead, international buyers should remain vigilant about evolving market trends, including the increasing demand for smart and eco-friendly door hardware solutions. As consumer preferences shift, aligning sourcing strategies with these trends will be crucial. We encourage B2B buyers to explore innovative products and foster connections with manufacturers to stay ahead in the competitive landscape of door entry latches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to door entry latch

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.