Is Your Dc Electric Motor Wiring Diagram Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for dc electric motor wiring diagram

In today’s global market, sourcing reliable dc electric motor wiring diagrams poses a significant challenge for B2B buyers, particularly in emerging economies across Africa, South America, the Middle East, and Europe. With the intricate nature of DC motor configurations—such as shunt, series, and compound motors—understanding the correct wiring connections is crucial for ensuring optimal performance and safety in various applications. This guide offers a comprehensive exploration of dc electric motor wiring diagrams, including detailed descriptions of motor types, their specific applications, and insights into how to evaluate and select reputable suppliers.

By navigating the complexities of dc electric motor wiring, international buyers can make informed purchasing decisions that not only meet their operational needs but also align with budgetary constraints. This guide empowers stakeholders by providing actionable insights into cost considerations, technical specifications, and best practices for supplier vetting. Whether you are in Nigeria looking for robust solutions for industrial machinery or in Germany seeking advanced motor technologies, this resource is designed to enhance your procurement strategy, ensuring that you acquire the right components for your business’s success. Embrace the knowledge and tools provided in this guide to confidently navigate the global marketplace for dc electric motor wiring diagrams.

Understanding dc electric motor wiring diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Externally Excited | Field winding is not connected to the armature; requires separate power. | Specialized industrial applications | Pros: Greater control; Cons: Complex setup and cost. |

| Shunt DC Motor | Field windings are connected in parallel with the armature. | Conveyor systems, fans, and pumps | Pros: Stable speed; Cons: Less torque at startup. |

| Series DC Motor | Field windings are connected in series with the armature. | Cranes, hoists, and traction systems | Pros: High starting torque; Cons: Speed varies with load. |

| Compound DC Motor | Combines shunt and series fields; can be cumulatively or differentially compounded. | Textile machinery, elevators | Pros: Versatile performance; Cons: More complex wiring. |

| Differentially Compounded | Shunt and series fields oppose each other. | Applications requiring speed control | Pros: Improved speed regulation; Cons: Can be less efficient. |

What Are the Characteristics and Applications of Externally Excited DC Motors?

Externally excited DC motors are characterized by their separate field winding, which is not connected to the armature. This design allows for enhanced control over motor speed and torque, making them suitable for specialized industrial applications that require precise performance. B2B buyers should consider the complexity and costs associated with the additional power supply needed for the field winding, balancing these factors against the benefits of greater operational control.

How Do Shunt DC Motors Function and Where Are They Used?

Shunt DC motors have their field windings connected in parallel with the armature, providing stable speed under varying loads. This makes them ideal for applications like conveyor systems, fans, and pumps, where consistent performance is crucial. Buyers should evaluate their operational needs, as shunt motors can provide reliable performance but may exhibit lower torque at startup compared to other motor types.

What Makes Series DC Motors Ideal for Heavy Load Applications?

Series DC motors connect the field windings in series with the armature, resulting in high starting torque, making them particularly suited for applications such as cranes, hoists, and traction systems. However, buyers should be aware that the speed of series motors can vary significantly with changes in load, necessitating careful consideration of load conditions in the purchasing decision.

Why Choose Compound DC Motors for Versatile Applications?

Compound DC motors integrate both shunt and series windings, allowing for a versatile performance that can adapt to various load conditions. This makes them suitable for applications like textile machinery and elevators, where both speed and torque requirements can fluctuate. Buyers should note the complexity of their wiring and operational characteristics, ensuring they align with specific application needs.

What Are the Benefits and Challenges of Differentially Compounded DC Motors?

Differentially compounded DC motors feature opposing shunt and series fields, providing improved speed regulation in applications requiring precise control. While they can offer enhanced performance, buyers must consider potential efficiency drawbacks and the complexity of their wiring. Understanding the specific operational requirements will help in determining whether this motor type is the right fit for their applications.

Key Industrial Applications of dc electric motor wiring diagram

| Industry/Sector | Specific Application of dc electric motor wiring diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation in assembly lines | Increases efficiency and reduces labor costs | Quality of components, compatibility with existing systems |

| Agriculture | Irrigation systems and automated farming equipment | Enhances productivity and resource management | Durability in harsh environments, ease of maintenance |

| Transportation | Electric vehicles and material handling equipment | Reduces operational costs and carbon footprint | Compliance with local regulations, reliability of components |

| Mining | Conveyor systems and drilling machinery | Improves operational efficiency and safety | Robustness under extreme conditions, availability of spare parts |

| Renewable Energy | Wind and solar power generation systems | Supports sustainable practices and energy independence | Integration with existing infrastructure, scalability options |

How is the dc electric motor wiring diagram used in manufacturing applications?

In manufacturing, dc electric motor wiring diagrams are crucial for automating assembly lines. These diagrams provide clear instructions for connecting motors to control systems, ensuring that machinery operates smoothly and efficiently. By utilizing these diagrams, manufacturers can troubleshoot issues quickly, reducing downtime. For international buyers, particularly in regions like Africa and South America, sourcing motors with compatible wiring configurations is essential to maintain production efficiency and minimize disruptions.

What role does the dc electric motor wiring diagram play in agricultural technology?

In agriculture, dc electric motors drive irrigation systems and automated farming equipment. Wiring diagrams help farmers and equipment manufacturers set up these systems correctly, ensuring optimal performance. Accurate diagrams reduce the risk of wiring errors that could lead to equipment failure or inefficiency. For B2B buyers in emerging markets, understanding the specific environmental conditions that equipment will face is vital, as it informs the selection of durable components that can withstand variable climates.

How does the dc electric motor wiring diagram enhance transportation systems?

Transportation relies heavily on dc electric motors for electric vehicles and material handling equipment. Wiring diagrams are essential for ensuring that these motors are integrated correctly into vehicle systems, which enhances performance and safety. Businesses benefit from reduced operational costs and a lower carbon footprint. International buyers must consider local regulations regarding electric vehicles and ensure that their sourcing partners can provide compliant and reliable components.

In what ways does the dc electric motor wiring diagram benefit the mining sector?

In the mining industry, dc electric motors are integral to conveyor systems and drilling machinery. Wiring diagrams facilitate the proper installation and maintenance of these motors, which is critical for operational efficiency and safety in challenging environments. Buyers from regions with developing mining sectors, like parts of Africa, should prioritize sourcing robust motors that can endure extreme conditions while ensuring that wiring diagrams are readily available for maintenance and troubleshooting.

How is the dc electric motor wiring diagram important for renewable energy applications?

The renewable energy sector utilizes dc electric motors in wind and solar power generation systems. Wiring diagrams are vital for connecting these motors to power management systems, ensuring efficient energy conversion and distribution. By leveraging these diagrams, businesses can enhance their energy independence and sustainability efforts. International buyers should look for suppliers that offer comprehensive technical support and scalable solutions to adapt to their specific energy needs.

3 Common User Pain Points for ‘dc electric motor wiring diagram’ & Their Solutions

Scenario 1: Confusion Over Wiring Connections for Different Motor Types

The Problem: Many B2B buyers face the daunting task of understanding the various wiring connections for different types of DC motors, such as shunt, series, and compound motors. The complexity of these configurations can lead to installation errors, equipment malfunction, or even safety hazards. Buyers, especially those in emerging markets, may not have access to comprehensive training or resources, leaving them frustrated and unsure about how to proceed with wiring diagrams.

The Solution: To overcome this challenge, it is essential to utilize standardized wiring diagrams provided by reputable manufacturers. Buyers should seek out documentation that clearly outlines the specific connections for each motor type, including terminal markings and polarity specifications. A practical step is to create a reference guide that consolidates this information for quick access during installation. Engaging with suppliers who offer technical support and training resources can also empower buyers to better understand these diagrams. Additionally, considering online training modules or video tutorials can enhance the team’s comprehension and confidence in handling wiring connections.

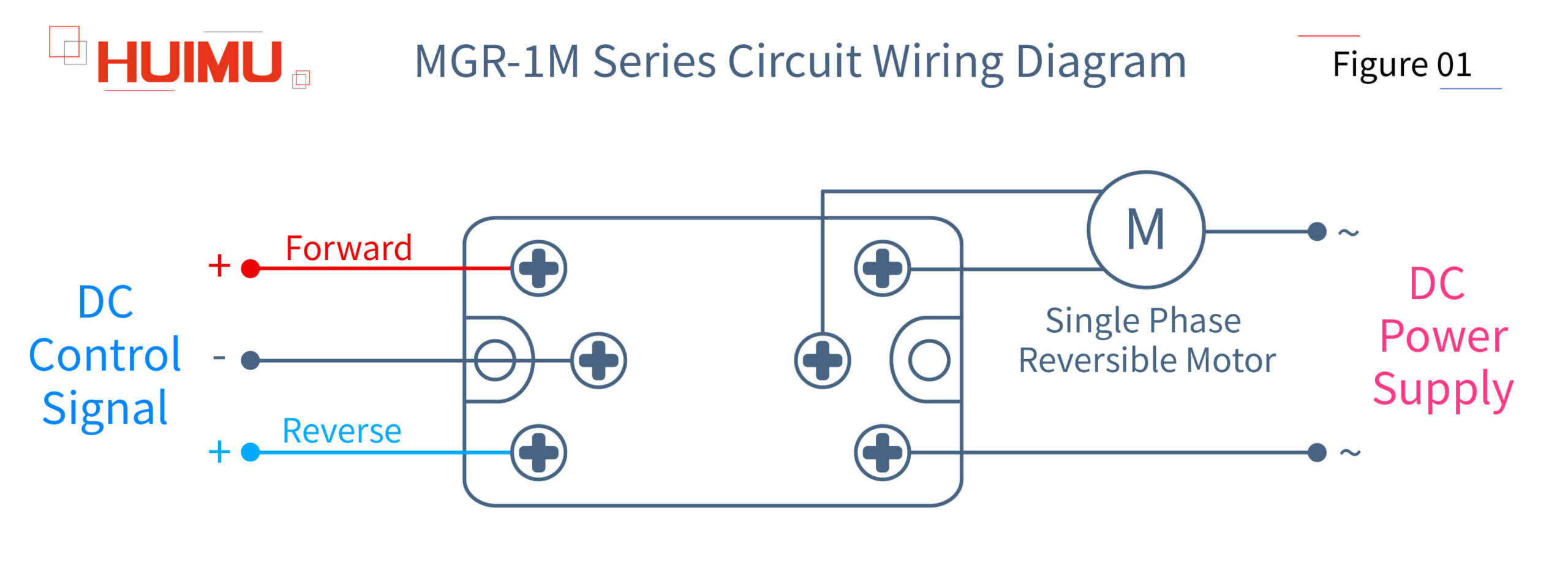

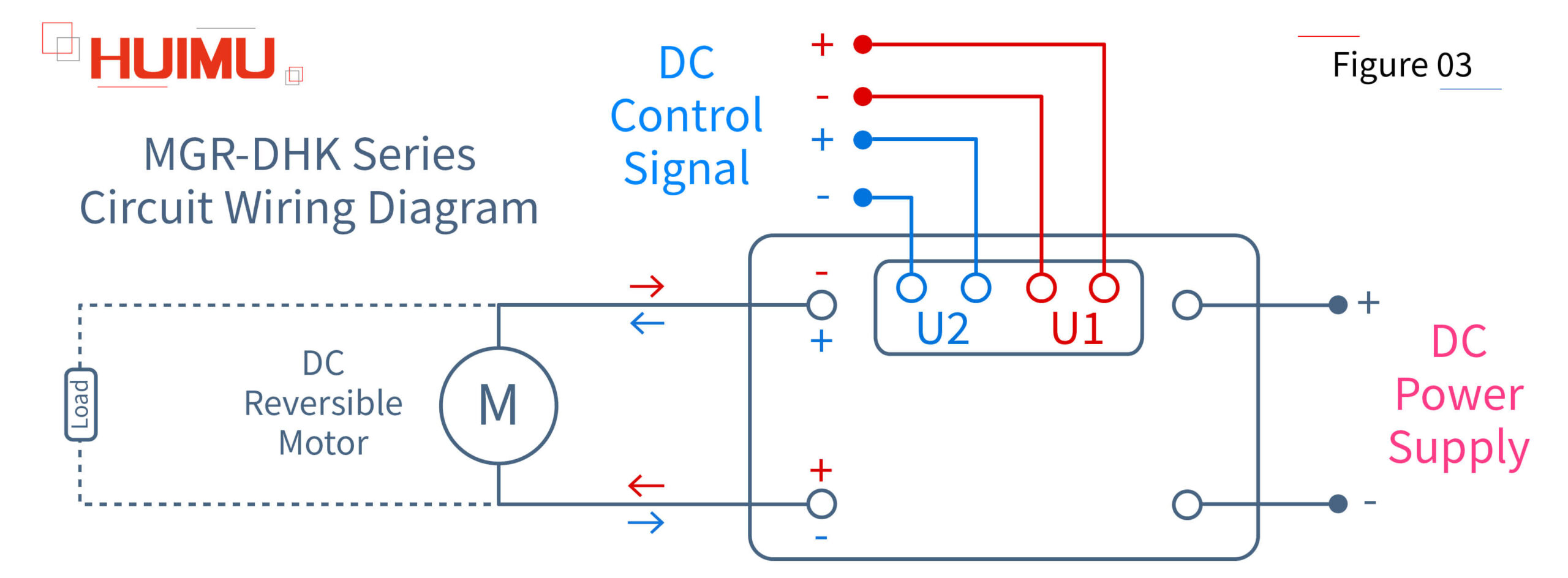

Scenario 2: Misinterpretation of Motor Rotation Direction

The Problem: A common issue faced by B2B buyers involves the misinterpretation of the rotation direction of DC motors based on their wiring diagrams. This can occur due to unclear markings or a lack of standardized symbols across different manufacturers. Miswiring can result in motors operating in the wrong direction, leading to production delays and increased costs, particularly in manufacturing and industrial applications.

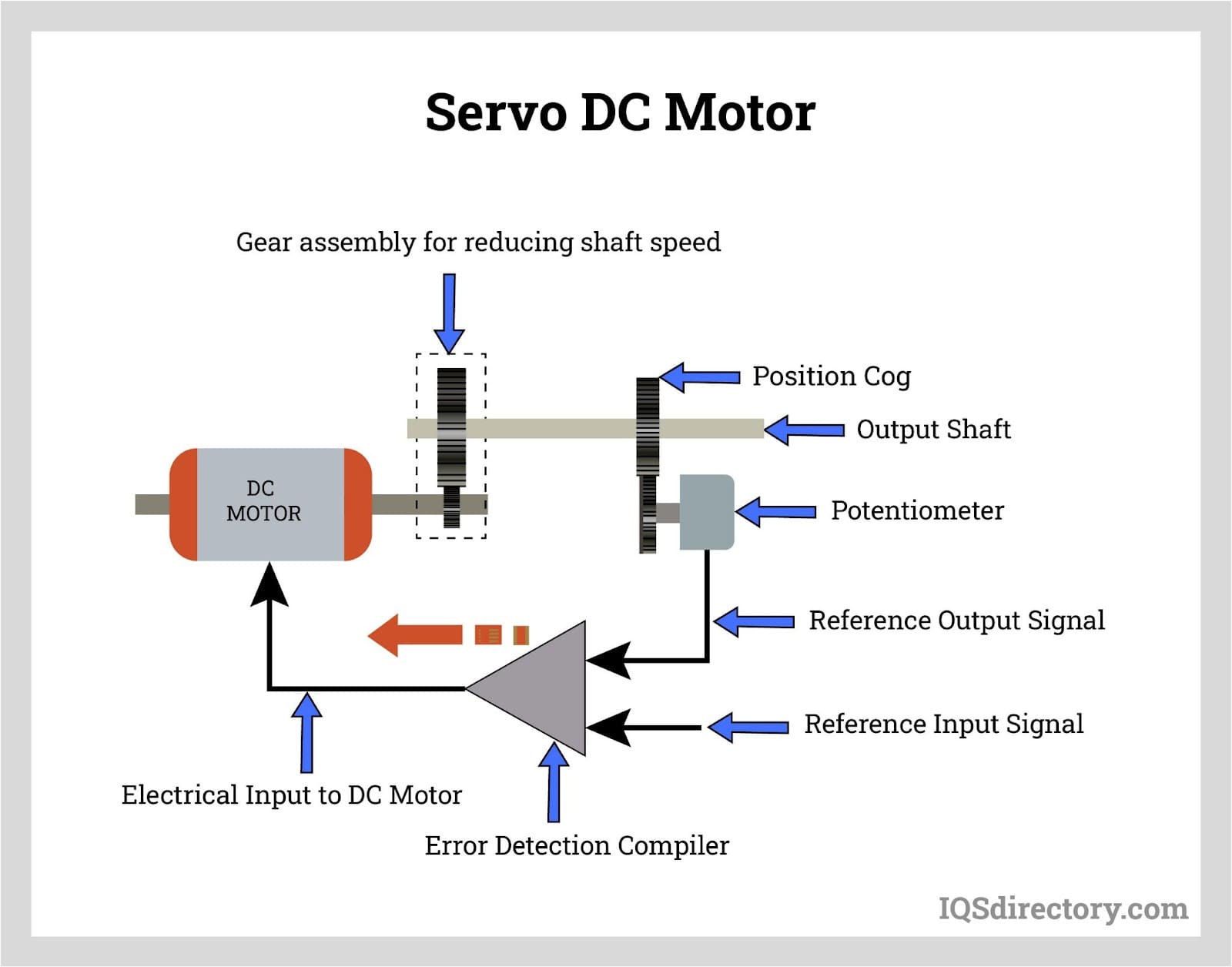

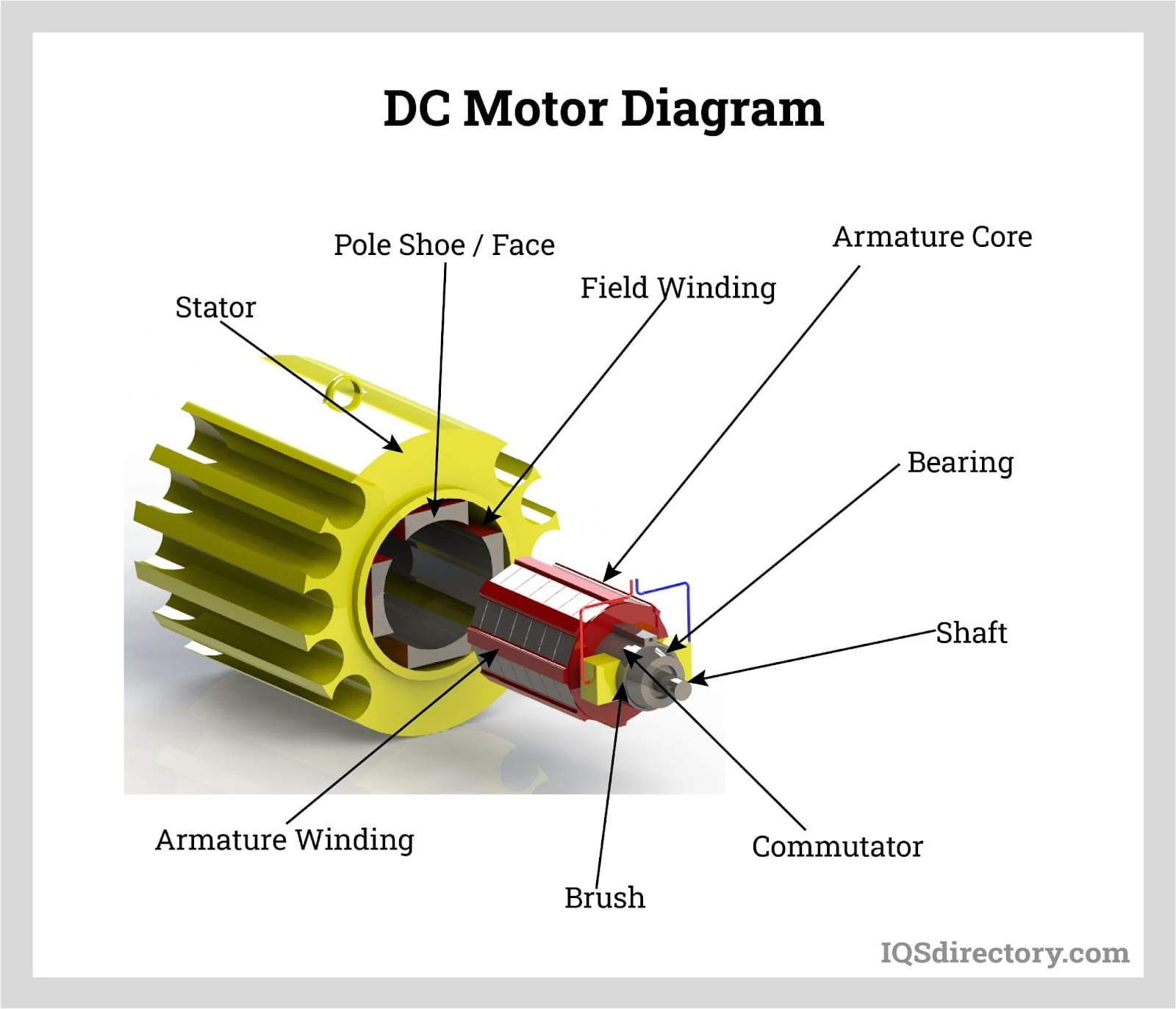

Illustrative image related to dc electric motor wiring diagram

The Solution: To mitigate this risk, buyers should ensure they have access to detailed diagrams that specify the required connections for both clockwise and counterclockwise rotation. It is advisable to implement a double-check system where team members verify the wiring against the schematic before powering the motor. Establishing a practice of labeling each wire and terminal during installation can also prevent confusion. Furthermore, buyers should prioritize sourcing motors and diagrams from manufacturers known for consistency in their documentation and support. This reduces the likelihood of errors and fosters a more efficient installation process.

Scenario 3: Difficulty in Sourcing Accurate and Reliable Wiring Diagrams

The Problem: In many regions, particularly in Africa and parts of South America, B2B buyers often struggle to find accurate and reliable wiring diagrams for DC motors. The lack of accessible resources can lead to the use of outdated or incorrect diagrams, resulting in improper installations and potential damage to the motors. This challenge is compounded by language barriers and varying electrical standards, which can further confuse the installation process.

The Solution: To address this issue, it is crucial for buyers to develop relationships with trusted suppliers who can provide updated and accurate wiring diagrams. Buyers should request documentation that complies with international standards, ensuring that it is relevant to their specific applications. Utilizing online platforms and forums dedicated to electrical engineering can also help in finding peer-reviewed diagrams and insights from other professionals in the field. Additionally, investing in local training workshops or seminars can enhance the workforce’s understanding of DC motor wiring, ensuring that they are equipped to handle installations confidently and correctly. This proactive approach not only helps in sourcing the right diagrams but also builds a knowledgeable team that can address future challenges effectively.

Strategic Material Selection Guide for dc electric motor wiring diagram

What Are the Key Materials for DC Electric Motor Wiring Diagrams?

When selecting materials for DC electric motor wiring diagrams, several factors influence performance and compatibility. Understanding the properties, advantages, and limitations of common materials is essential for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

1. Copper

Copper is the most widely used material for electrical wiring due to its excellent conductivity and thermal properties. It boasts a conductivity rating of approximately 59.6 x 10^6 S/m, making it highly efficient for electric motor applications.

Pros: Copper’s high electrical conductivity ensures minimal energy loss, enhancing the overall efficiency of DC motors. It is also relatively easy to work with, allowing for straightforward manufacturing processes.

Cons: However, copper is prone to corrosion, especially in humid environments, which can lead to degradation over time. Additionally, it is more expensive than alternatives like aluminum.

Impact on Application: Copper is compatible with various media and is often preferred in environments where reliability is critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider local availability and pricing fluctuations, particularly in regions with limited access to raw materials.

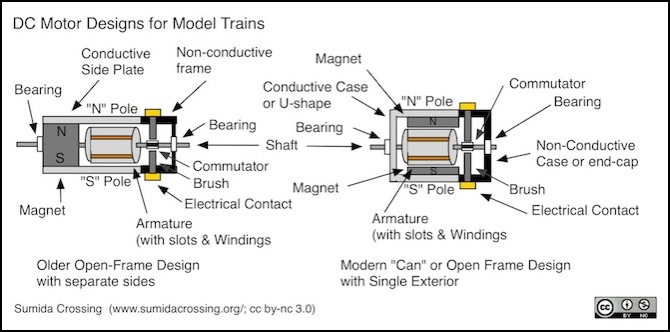

2. Aluminum

Aluminum is another common choice for wiring in DC motors, particularly in applications where weight is a concern. It has a conductivity rating of about 37.7 x 10^6 S/m, which is lower than copper but still adequate for many applications.

Pros: The lightweight nature of aluminum makes it ideal for portable or mobile applications. It is also resistant to corrosion, which can prolong the lifespan of wiring in adverse conditions.

Cons: The lower conductivity means that aluminum wires need to be thicker to carry the same current as copper, which can complicate design and increase material costs.

Illustrative image related to dc electric motor wiring diagram

Impact on Application: Aluminum is suitable for environments where weight reduction is essential, but it may not be the best choice for high-performance applications requiring minimal resistance.

Considerations for International Buyers: Buyers should ensure that aluminum wiring meets local standards and is suitable for the specific electrical load requirements of their applications.

3. PVC (Polyvinyl Chloride)

PVC is often used as insulation material for wiring in DC motors. It provides a good balance of electrical insulation and mechanical protection.

Illustrative image related to dc electric motor wiring diagram

Pros: PVC is highly resistant to moisture, chemicals, and abrasion, making it suitable for various environments. It is also cost-effective and easy to manufacture.

Cons: However, PVC has a lower temperature rating compared to other insulation materials, which can limit its use in high-temperature applications. Additionally, it can be less flexible than other materials, which may pose challenges in certain installations.

Impact on Application: PVC insulation is ideal for general-purpose applications but may not be suitable for environments with extreme temperatures or exposure to certain chemicals.

Considerations for International Buyers: Compliance with safety standards is critical, especially in regions with stringent regulations. Buyers should also consider the environmental impact of PVC, as it can be less eco-friendly compared to alternatives.

4. Teflon (PTFE)

Teflon, or PTFE, is known for its exceptional thermal and chemical resistance, making it suitable for high-performance applications.

Pros: Teflon can withstand extreme temperatures and is resistant to a wide range of chemicals, ensuring durability in challenging environments. Its low friction properties also enhance performance.

Cons: The primary drawback is its high cost compared to other insulation materials. Additionally, Teflon can be more challenging to work with during manufacturing.

Impact on Application: Teflon is ideal for applications requiring high thermal stability and chemical resistance, making it popular in specialized industries.

Considerations for International Buyers: Buyers should verify that Teflon insulation complies with relevant international standards and is suitable for their specific application requirements.

Illustrative image related to dc electric motor wiring diagram

Summary Table of Material Selection for DC Electric Motor Wiring Diagrams

| Material | Typical Use Case for dc electric motor wiring diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | General wiring for high-performance DC motors | Excellent conductivity and thermal properties | Prone to corrosion and higher cost | High |

| Aluminum | Lightweight applications, portable motors | Lightweight and corrosion-resistant | Lower conductivity, requires thicker wires | Medium |

| PVC | Insulation for general-purpose wiring | Cost-effective and moisture-resistant | Lower temperature rating, less flexible | Low |

| Teflon (PTFE) | High-performance applications requiring chemical resistance | Exceptional thermal and chemical resistance | High cost and manufacturing complexity | High |

By carefully considering these materials and their respective properties, B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dc electric motor wiring diagram

What Are the Main Stages in the Manufacturing Process of DC Electric Motor Wiring Diagrams?

The manufacturing process of DC electric motor wiring diagrams involves several crucial stages, each contributing to the overall performance and reliability of the motors. Understanding these stages is essential for B2B buyers, as they provide insight into the quality and durability of the products being procured.

Material Preparation: How Are Raw Materials Selected for Wiring Diagrams?

The first step in manufacturing involves sourcing high-quality materials such as copper for windings, insulation materials, and various metal components for the motor’s structure. Suppliers often assess the mechanical and electrical properties of these materials to ensure they meet industry standards. For instance, copper is preferred for its excellent conductivity, while specific insulation materials are selected based on thermal resistance and dielectric strength.

Illustrative image related to dc electric motor wiring diagram

Effective material preparation also includes cutting and shaping raw materials to precise specifications, ensuring they can be easily integrated into subsequent manufacturing stages.

Forming: What Techniques Are Used to Shape Components?

Once the materials are prepared, forming techniques are employed to create the various components of the DC motor. This may involve processes such as stamping, forging, or machining. For instance, the armature and field windings may undergo winding processes, where copper wire is carefully wound around a core to create electromagnetic fields.

Advanced technologies, such as computer numerical control (CNC) machining, are frequently utilized to achieve high precision and consistency in component dimensions. This is particularly important in the context of wiring diagrams, where accurate connections and configurations are crucial for optimal motor performance.

Assembly: How Are Components Assembled into Final Products?

The assembly stage brings together all the formed components into a complete DC electric motor. This includes connecting the armature, field windings, and commutator system as per the wiring diagram. Skilled technicians follow detailed assembly instructions, ensuring that each component is correctly positioned and secured.

Quality checks are integrated into the assembly process, with specific checkpoints to verify that connections conform to the wiring diagram specifications. This attention to detail helps prevent issues such as electrical shorts or mechanical failures during operation.

Finishing: What Processes Ensure the Motor Is Ready for Use?

The final stage in manufacturing involves finishing processes that enhance the motor’s durability and performance. This may include painting or coating the motor to protect against corrosion, as well as the installation of thermal protection devices.

Additionally, final inspections are conducted to ensure that the motor meets all design specifications and quality standards before it is packaged for shipment. This is a critical step in guaranteeing that B2B buyers receive a reliable product that meets their operational requirements.

What Quality Assurance Practices Are Essential in DC Electric Motor Manufacturing?

Quality assurance (QA) plays a pivotal role in ensuring that DC electric motors meet international and industry-specific standards. For B2B buyers, understanding these QA practices is vital for making informed purchasing decisions.

What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems that manufacturers must adhere to. This ensures consistent quality in products and services, which is essential for maintaining customer satisfaction. Other relevant standards may include CE marking for compliance with European health and safety regulations and API standards for specific applications in the oil and gas sector.

Buyers should verify that their suppliers are certified to these standards, as this indicates a commitment to quality and reliability.

How Are Quality Control Checkpoints Integrated Throughout the Manufacturing Process?

Quality control (QC) checkpoints are strategically integrated at various stages of the manufacturing process to ensure that products meet quality standards. These checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Materials that do not meet quality requirements are rejected or returned to suppliers.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process. This helps identify and rectify any deviations from quality standards in real-time.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive final inspection is carried out. This includes testing electrical performance, verifying dimensions against specifications, and ensuring that all components are correctly assembled according to the wiring diagram.

What Testing Methods Are Commonly Employed in Quality Assurance?

Several testing methods are employed to verify the functionality and safety of DC electric motors. These may include:

-

Electrical Testing: Measuring the resistance, insulation, and continuity of the windings to ensure proper functioning.

-

Performance Testing: Evaluating the motor’s performance under load conditions to ensure it meets operational specifications.

-

Thermal Testing: Assessing the motor’s temperature rise during operation to ensure it operates within safe limits.

These testing methods provide valuable data that can be used to make informed decisions about product quality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. This can be achieved through several methods:

-

Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess the quality management systems in place. This provides a firsthand look at the production processes and QC measures.

-

Reviewing Quality Reports: Buyers should request detailed quality reports, including results from IQC, IPQC, and FQC processes. These reports can offer insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly useful for international buyers who may face challenges in conducting direct audits.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may encounter specific challenges related to quality control. These include:

-

Regulatory Compliance: Different countries have varying regulations regarding motor manufacturing. Buyers must ensure that their suppliers comply with local laws and international standards.

-

Cultural Differences: Understanding the cultural and business practices of suppliers in different regions can enhance communication and collaboration, leading to better quality outcomes.

-

Logistical Considerations: International shipping can introduce risks such as damage during transit. Buyers should ensure that suppliers have robust packaging and handling procedures in place.

In conclusion, understanding the manufacturing processes and quality assurance practices for DC electric motor wiring diagrams is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc electric motor wiring diagram’

Introduction

In the rapidly evolving landscape of industrial machinery, sourcing a reliable DC electric motor wiring diagram is crucial for optimizing equipment functionality and ensuring operational safety. This guide provides a structured checklist to assist B2B buyers in procuring accurate and comprehensive wiring diagrams tailored to their specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first and most critical step in the procurement process. This includes understanding the type of DC motor you are working with—be it shunt, series, or compound—and the specific voltage and current requirements. By establishing these parameters upfront, you can ensure that the wiring diagram you source will meet your operational needs.

Step 2: Research Reputable Suppliers

Identifying reputable suppliers is essential for obtaining high-quality wiring diagrams. Look for manufacturers or distributors with a solid track record in the industry and positive customer feedback. Engage with suppliers who specialize in electrical components and have experience in your particular market, whether in Africa, South America, the Middle East, or Europe.

- Check Industry Certifications: Ensure that the suppliers hold relevant certifications such as ISO or IEC standards, which indicate compliance with international quality and safety regulations.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other buyers in your industry or region. This due diligence helps mitigate risks associated with supplier reliability and quality assurance.

- Conduct Site Visits: If possible, visit the supplier’s facilities to observe their operations and quality control processes firsthand.

Step 4: Request Custom Wiring Diagrams

Once you have shortlisted suppliers, inquire about the availability of custom wiring diagrams. Many suppliers offer tailored solutions that can be adapted to your specific motor type and application. This ensures that the diagram is not only accurate but also optimized for your equipment.

- Discuss Modification Capabilities: Confirm whether the supplier can accommodate future modifications or updates to the wiring diagram as your needs evolve.

Step 5: Verify Technical Support and Documentation

Ensure that the supplier provides comprehensive technical support along with the wiring diagram. This should include installation guides, troubleshooting tips, and customer service contact information. Having access to expert assistance can significantly reduce downtime during installation or maintenance.

- Check for Additional Resources: Look for supplementary resources such as online tutorials or user manuals that can enhance your understanding of the wiring diagram.

Step 6: Review Pricing and Delivery Terms

Analyze the pricing structure and delivery terms offered by your shortlisted suppliers. Ensure that the costs align with your budget while also considering the quality of the diagrams provided. Negotiate delivery timelines to ensure that you receive the diagrams in a timely manner, which is crucial for project planning.

- Consider Total Cost of Ownership: Factor in potential long-term savings through efficient installation and reduced maintenance when evaluating pricing.

Step 7: Finalize Your Order and Confirm Details

Once you have made your selection, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Clear communication at this stage helps prevent misunderstandings and ensures that you receive exactly what you need.

Illustrative image related to dc electric motor wiring diagram

- Establish a Follow-Up Plan: Set a timeline for follow-up communications to address any issues that may arise post-purchase.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing DC electric motor wiring diagrams, ensuring they make informed decisions that support their operational goals.

Comprehensive Cost and Pricing Analysis for dc electric motor wiring diagram Sourcing

What Are the Key Cost Components in Sourcing DC Electric Motor Wiring Diagrams?

When sourcing wiring diagrams for DC electric motors, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials, such as copper for windings and insulation materials, plays a significant role in the overall pricing. High-quality materials can enhance performance and reliability, which may justify higher initial costs.

-

Labor: Skilled labor is necessary for both the design and assembly of wiring diagrams. Labor costs can vary significantly based on geographical location, availability of skilled workers, and the complexity of the diagrams required.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and administrative expenses. These costs are often distributed across all products and can affect pricing strategies.

-

Tooling: The investment in specialized tools and equipment required for the production of wiring diagrams can also impact costs. If custom tools are needed, this may lead to increased upfront expenses.

-

Quality Control (QC): Implementing rigorous QC measures is essential to ensure the reliability and safety of DC motors. This includes testing and compliance with international standards, which can add to the overall cost.

-

Logistics: Shipping and handling costs vary based on the destination, which is particularly relevant for international buyers. Factors such as customs duties and import taxes can further influence total expenses.

-

Margin: Finally, suppliers will add their profit margin to the total costs, which can vary based on market conditions and competitive positioning.

How Do Price Influencers Affect the Cost of DC Electric Motor Wiring Diagrams?

Several factors can influence the pricing of DC electric motor wiring diagrams:

-

Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing. Larger orders typically benefit from economies of scale, reducing per-unit costs.

-

Specifications/Customization: Custom wiring diagrams tailored to specific motor types or applications may incur additional costs. Standardized diagrams tend to be less expensive due to reduced design time.

-

Materials: The choice of materials significantly impacts costs. Premium materials may enhance durability and performance but will increase initial investment.

-

Quality/Certifications: Buyers should consider the quality and any necessary certifications (e.g., ISO). Products with recognized certifications often come at a higher price but provide assurance of compliance with safety and performance standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may charge a premium for their products.

-

Incoterms: The agreed-upon Incoterms can affect the total cost of ownership by determining who is responsible for shipping, insurance, and customs duties.

What Are Effective Buyer Tips for Negotiating Prices in International Markets?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies can help optimize expenditure on DC electric motor wiring diagrams:

-

Negotiation: Engage in open discussions with suppliers about pricing and potential discounts for bulk orders. Highlighting long-term relationships can encourage suppliers to provide better terms.

-

Cost-Efficiency: Consider total cost of ownership rather than just the purchase price. This includes evaluating long-term performance, maintenance costs, and potential downtime.

-

Pricing Nuances: Be aware of local market conditions and pricing standards. Understanding the competitive landscape can empower buyers during negotiations.

-

Quality Assurance: Prioritize suppliers who offer warranties or guarantees on their products. This can mitigate risks associated with defective wiring diagrams.

-

Logistics Planning: Factor in logistics costs when assessing total pricing. Collaborating with suppliers who have efficient shipping processes can lead to significant savings.

While prices may vary based on numerous factors, buyers should approach sourcing with a comprehensive understanding of the cost structure and pricing influencers. This awareness can lead to more informed purchasing decisions and ultimately, cost-effective solutions for their operations.

Alternatives Analysis: Comparing dc electric motor wiring diagram With Other Solutions

Understanding Alternatives to DC Electric Motor Wiring Diagrams

In the realm of electric motors, particularly DC motors, wiring diagrams play a crucial role in ensuring proper connections and functionality. However, there are several alternative solutions and technologies that can achieve similar objectives. This section explores how DC electric motor wiring diagrams compare to other methods, providing insights that can assist B2B buyers in making informed decisions.

| Comparison Aspect | Dc Electric Motor Wiring Diagram | Alternative 1: AC Motor Wiring Diagram | Alternative 2: Brushless DC Motor Wiring Diagram |

|---|---|---|---|

| Performance | High torque at low speeds; efficient for variable load applications | Generally provides higher efficiency; better for constant speed applications | Offers high efficiency and durability; lower maintenance needs |

| Cost | Lower initial cost; affordable for small-scale applications | Often more expensive due to complexity | Higher upfront costs but savings in maintenance over time |

| Ease of Implementation | Relatively straightforward; requires basic electrical knowledge | More complex; requires specialized knowledge for installation | Moderate complexity; often involves advanced controls |

| Maintenance | Moderate; brushes may require replacement | Low; less wear and tear on components | Very low; no brushes to replace, leading to longer lifespans |

| Best Use Case | Ideal for applications needing variable speed control (e.g., electric vehicles) | Best for applications requiring consistent speed (e.g., fans) | Suitable for high-precision applications (e.g., robotics) |

What Are the Advantages and Disadvantages of AC Motor Wiring Diagrams?

AC motor wiring diagrams present a viable alternative to DC motor diagrams, particularly in applications where constant speed is required. The primary advantage of AC motors is their efficiency in converting electrical energy into mechanical energy, especially in high-load scenarios. However, they tend to be more expensive and require a deeper understanding of electrical systems for proper installation and troubleshooting. This complexity can be a barrier for companies without specialized staff.

How Do Brushless DC Motor Wiring Diagrams Compare?

Brushless DC motors (BLDC) are another alternative that excels in efficiency and longevity. They utilize electronic controllers, eliminating the need for brushes, which are common in traditional DC motors. This results in lower maintenance costs and a longer lifespan. However, the initial investment in brushless technology can be higher, and the installation process is often more complex, requiring advanced electronics knowledge. They are particularly beneficial in precision applications, such as robotics and automation, where performance and reliability are paramount.

Choosing the Right Solution: What Should B2B Buyers Consider?

When selecting between a DC electric motor wiring diagram and its alternatives, B2B buyers should consider several factors, including the specific application, budget constraints, and long-term maintenance implications. For projects requiring variable speed control and lower initial investment, a traditional DC motor might be the best choice. Conversely, for applications demanding efficiency and minimal maintenance, investing in brushless or AC motor technologies may yield better long-term returns. Understanding the unique advantages and limitations of each option will empower buyers to make decisions that align with their operational needs and goals.

Essential Technical Properties and Trade Terminology for dc electric motor wiring diagram

What are the Key Technical Properties of a DC Electric Motor Wiring Diagram?

When evaluating DC electric motors, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that international B2B buyers should consider:

-

Voltage Rating

The voltage rating indicates the maximum voltage the motor can safely handle. This is critical for ensuring compatibility with existing electrical systems. An incorrect voltage rating can lead to motor failure, increased maintenance costs, or even safety hazards. In regions like Africa and South America, where voltage standards may vary, confirming the voltage rating is paramount. -

Current Rating

The current rating specifies the maximum current the motor can draw under normal operating conditions. It is vital for determining the appropriate circuit breakers and wiring needed for installation. Overloading a motor can lead to overheating and damage, making it essential for buyers to match current ratings with their application requirements. -

Power Rating

Expressed in horsepower (HP) or kilowatts (kW), the power rating indicates the motor’s output capability. Understanding the power requirements of your application helps in selecting a motor that can achieve desired performance levels. This is particularly important in industries like manufacturing, where efficiency directly impacts productivity. -

Efficiency Class

The efficiency of a motor refers to how effectively it converts electrical energy into mechanical energy. Higher efficiency ratings reduce energy costs and environmental impact, which is increasingly important for businesses focused on sustainability. For B2B buyers, investing in high-efficiency motors can lead to long-term savings and improved operational performance. -

Insulation Class

Insulation class determines the motor’s ability to withstand high temperatures. Classes range from A (low thermal resistance) to H (high thermal resistance). Selecting the appropriate insulation class ensures reliability and longevity of the motor, particularly in harsh operating environments common in sectors like mining or oil extraction. -

Frame Size

The frame size of a motor specifies its physical dimensions and mounting requirements. It is crucial for ensuring that the motor fits within the designated space and can be properly mounted. This consideration can significantly affect installation time and costs.

What are Common Trade Terminologies Related to DC Electric Motor Wiring Diagrams?

Navigating the B2B landscape for DC electric motors involves familiarizing oneself with specific trade terminologies. Here are some key terms that decision-makers should know:

-

OEM (Original Equipment Manufacturer)

An OEM produces components that are used in the final assembly of a product. When sourcing DC motors, understanding whether you are dealing with OEM parts can assure you of quality and compatibility with your existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is important for budgeting and inventory management, especially for businesses in regions where capital may be limited. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a crucial step in the procurement process, enabling buyers to compare options and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms helps in clarifying who is responsible for shipping, insurance, and tariffs, thereby minimizing risks and misunderstandings in cross-border transactions. -

Torque

Torque is a measure of rotational force produced by the motor. It is essential for applications requiring high starting power or heavy loads, making it a critical factor for buyers in industrial sectors. -

Synchronous vs. Asynchronous Motors

These terms refer to the types of motors based on their operational characteristics. Synchronous motors run at a constant speed, while asynchronous motors vary with load. Knowing the difference aids in selecting the right motor type for specific applications.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing DC electric motors, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the dc electric motor wiring diagram Sector

What Are the Key Market Drivers and Trends in the DC Electric Motor Wiring Diagram Sector?

The global market for DC electric motors is being propelled by several key factors, including the increasing demand for energy-efficient solutions, technological advancements, and the growing adoption of automation across various industries. In regions such as Africa and South America, the push for industrialization is driving demand for reliable motor solutions, while in Europe, there is a strong emphasis on sustainability and reducing carbon footprints. Buyers are increasingly seeking motors that offer high efficiency and adaptability, prompting manufacturers to innovate in design and functionality.

Emerging technologies such as IoT integration are becoming prevalent, allowing for real-time monitoring and control of electric motors. This trend is particularly relevant for B2B buyers looking to enhance operational efficiency. Additionally, companies are focusing on modular designs and standardized wiring diagrams to simplify installation and maintenance, making sourcing decisions easier for international buyers. The demand for customized solutions tailored to specific applications is also rising, as businesses strive to optimize performance and reduce downtime.

How Are Sustainability and Ethical Sourcing Shaping the DC Electric Motor Wiring Diagram Market?

Sustainability is becoming a pivotal factor in the procurement of DC electric motors and their wiring diagrams. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and production methods that minimize waste and energy consumption.

Ethical sourcing is equally important, as B2B buyers seek suppliers who uphold high labor standards and fair trade practices. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential for companies looking to validate their commitment to sustainability. In the context of DC electric motor wiring diagrams, manufacturers are encouraged to use recyclable materials and provide clear documentation on the environmental impact of their products. This not only enhances brand reputation but also aligns with the growing consumer demand for responsible business practices.

What Is the Historical Context of DC Electric Motors Relevant to Today’s Market?

The evolution of DC electric motors can be traced back to the early 19th century, when pioneers like Michael Faraday laid the groundwork for electromagnetism. Over the decades, advancements in materials and technology have transformed DC motors from simple mechanical devices into sophisticated components integral to modern automation and control systems.

The introduction of various types of DC motors—such as shunt, series, and compound motors—has provided industries with options tailored to specific applications. This historical context is crucial for B2B buyers, as understanding the evolution of these technologies allows for more informed decisions regarding sourcing and integration into existing systems. As the market continues to evolve, ongoing innovation and adaptation will be essential to meet the demands of diverse sectors globally.

Frequently Asked Questions (FAQs) for B2B Buyers of dc electric motor wiring diagram

-

How do I troubleshoot common wiring issues in DC electric motors?

To troubleshoot wiring issues in DC electric motors, start by checking the power supply and ensuring all connections are secure and correctly configured according to the wiring diagram. Inspect for signs of damage or wear on the wires, connectors, and terminals. Use a multimeter to measure voltage at various points to identify discrepancies. If the motor does not operate, check the armature and field windings for continuity. Consult the wiring diagram to ensure the motor is properly wired, and consider replacing damaged components if necessary. -

What is the best wiring configuration for shunt DC motors?

The best wiring configuration for shunt DC motors involves connecting the field windings in parallel with the armature. This setup allows for consistent speed control and stable operation under varying loads. The shunt field provides a constant magnetic field, which is beneficial for applications requiring precise speed regulation. Ensure that the wiring diagram is followed closely to maintain the correct polarity and avoid potential damage. Additionally, consider the load characteristics and operational requirements when selecting this configuration. -

What factors should I consider when sourcing DC electric motor wiring diagrams internationally?

When sourcing DC electric motor wiring diagrams internationally, consider factors such as compliance with local electrical standards and regulations, the reliability of suppliers, and the availability of customer support. Evaluate the supplier’s experience in the industry and their understanding of specific motor types. Additionally, assess the quality of the diagrams provided, ensuring they are detailed and clear. Language barriers may also affect comprehension, so seek suppliers who offer diagrams in your preferred language or provide translation support. -

What are the minimum order quantities (MOQs) for customized wiring diagrams?

Minimum order quantities for customized wiring diagrams can vary significantly based on the supplier’s policies and production capabilities. Generally, MOQs may range from 10 to 100 units, depending on the complexity of the diagrams and the materials involved. To obtain the best pricing and ensure timely delivery, discuss your specific needs with potential suppliers. Some manufacturers may offer flexibility in MOQs for established buyers or larger projects, so it’s advisable to negotiate terms before finalizing the order. -

How can I ensure quality assurance (QA) in the wiring diagrams I receive?

To ensure quality assurance in the wiring diagrams, request samples or previous work from the supplier before committing to a large order. Look for suppliers that have ISO certifications or adhere to international quality standards. Additionally, implement a review process where engineers or technical staff can evaluate the diagrams for accuracy and completeness. Establish clear communication channels for addressing any discrepancies or issues promptly, and consider setting up regular audits or checks on the supplier’s output. -

What payment terms are typical for international suppliers of DC motor wiring diagrams?

Payment terms for international suppliers of DC motor wiring diagrams typically include options such as advance payment, net 30, or letter of credit. Many suppliers may require a deposit upfront, especially for customized diagrams, with the balance due upon delivery or after inspection. It’s important to negotiate terms that align with your financial capabilities while ensuring protection against potential risks. Always clarify the payment methods accepted, including wire transfers or credit terms, and consider using escrow services for large transactions. -

How do logistics and shipping affect the procurement of DC electric motor wiring diagrams?

Logistics and shipping can significantly impact the procurement of DC electric motor wiring diagrams by influencing delivery times and costs. When sourcing internationally, consider the shipping methods available, such as air freight for faster delivery or sea freight for cost savings. Additionally, factor in customs regulations and potential duties or taxes that may apply. Work with suppliers who have experience in international shipping and can provide tracking information to monitor the progress of your order. -

What customization options are available for DC electric motor wiring diagrams?

Customization options for DC electric motor wiring diagrams may include modifications to suit specific motor configurations, voltage requirements, or operational parameters. Suppliers can often tailor diagrams to match unique applications or integrate additional features, such as safety interlocks or sensor placements. When requesting customization, provide detailed specifications and clarify any particular standards or regulations to be followed. Collaborating closely with the supplier during the design phase can ensure the final product meets your exact needs.

Top 3 Dc Electric Motor Wiring Diagram Manufacturers & Suppliers List

1. Joliet Tech – NEMA DC Motor Connections

Domain: joliettech.com

Registered: 2002 (23 years)

Introduction: This company, Joliet Tech – NEMA DC Motor Connections, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Pinterest – DC Motor Wiring Guide

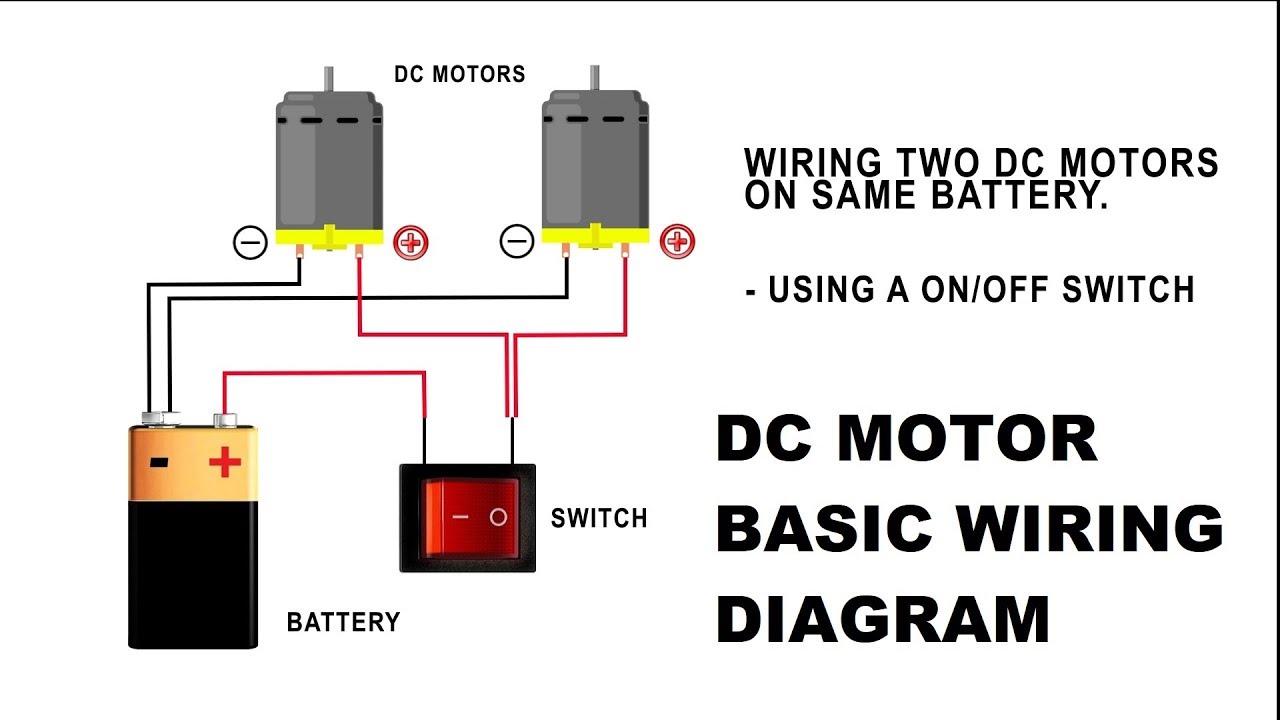

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: How to wire a DC motor on battery with switch and relay, basic wiring for DC current, DC electric motor wiring, parallel and serial battery connection, how to use switches, relays, basic electrical symbols.

3. WikiHow – Wiring a DC Motor Circuit

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: To wire a Variable or Fixed Speed DC Motor Circuit, you will need the following materials: a DC power supply (such as a battery or power pack), a DC motor (any size or type that uses DC current), a potentiometer (preferably with a high total resistance value, like a 1kΩ for a 9V battery), insulated wires (to prevent short circuits), and optionally a breadboard, electrical tape, or solder for conne…

Strategic Sourcing Conclusion and Outlook for dc electric motor wiring diagram

How Can Strategic Sourcing Enhance Your DC Electric Motor Wiring Solutions?

In the realm of DC electric motors, understanding wiring diagrams is essential for optimizing performance and ensuring compatibility across various applications. Strategic sourcing empowers international B2B buyers to access diverse motor types—shunt, series, and compound—each with unique wiring needs. By leveraging global suppliers, businesses can secure high-quality components that meet specific operational demands while also minimizing costs.

Investing in strategic sourcing not only enhances the reliability of motor systems but also facilitates access to innovative technologies and practices. This is particularly vital for markets in Africa, South America, the Middle East, and Europe, where diverse industrial requirements necessitate adaptable solutions.

As we look to the future, it is imperative for buyers to engage with reputable manufacturers and suppliers who can provide comprehensive wiring diagrams and technical support. This proactive approach will ensure sustained operational efficiency and a competitive edge in the marketplace. Embrace strategic sourcing today to elevate your DC electric motor capabilities and drive your business towards greater success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.