Is Your Custom Beverage Cans Containers Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for custom beverage cans containers

In the competitive landscape of the beverage industry, sourcing custom beverage cans containers that align with both product integrity and brand identity can pose a significant challenge for B2B buyers. With consumers increasingly drawn to unique, visually appealing packaging, the right can not only protects your product but also serves as a powerful marketing tool. This comprehensive guide delves into the intricacies of custom beverage cans containers, covering essential aspects such as types of materials, applications across various beverage categories, supplier vetting processes, and cost considerations.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate the complexities of global sourcing, understanding these elements becomes crucial. This guide empowers you to make informed purchasing decisions by highlighting best practices for selecting suppliers, ensuring quality, and optimizing costs. Whether you are looking for sustainable options or innovative designs to elevate your brand’s presence in the market, this resource will equip you with the insights needed to thrive in a dynamic industry. By leveraging the information presented, you can streamline your procurement process and ultimately enhance your product’s appeal, ensuring it stands out in a crowded marketplace.

Understanding custom beverage cans containers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Aluminum Cans | Lightweight, fully recyclable, customizable labels | Craft beverages, energy drinks, cocktails | Pros: Eco-friendly, excellent shelf presence; Cons: Initial setup costs can be high. |

| Printed Beverage Boxes | Made from durable materials, customizable design options | Retail packaging, event promotions, gift sets | Pros: Great for branding, protects contents; Cons: May require larger minimum orders. |

| Multi-Pack Beverage Carriers | Designed for holding multiple cans, often with handles | Retail sales, festivals, and events | Pros: Convenient for consumers, enhances visibility; Cons: Limited design flexibility. |

| Eco-Friendly Cans | Made from sustainable materials, often with reduced carbon footprint | Organic beverages, health drinks | Pros: Appeals to eco-conscious consumers; Cons: May have a higher price point. |

| Specialty Beverage Containers | Unique shapes or sizes tailored for specific drinks | Niche markets, limited-edition products | Pros: Stands out in the market; Cons: Higher production costs and longer lead times. |

What Are the Characteristics of Custom Aluminum Cans?

Custom aluminum cans are the industry standard for packaging a variety of beverages, including craft beers, hard seltzers, and energy drinks. Their lightweight nature and recyclability make them an attractive option for environmentally-conscious brands. B2B buyers should consider customization options, such as full-color labels and the choice of can ends, which can enhance brand visibility and appeal. The durability of aluminum also helps in preserving the quality of beverages, making them a reliable choice for suppliers.

How Do Printed Beverage Boxes Serve B2B Needs?

Printed beverage boxes are designed to protect and showcase products while providing ample space for branding. These boxes are ideal for various applications, including retail packaging and promotional events. B2B buyers should evaluate the material quality and customization options available, as these factors significantly influence customer perception. Additionally, the ability to order in bulk can streamline inventory management for businesses, making printed boxes a practical choice for many beverage producers.

What Are the Benefits of Multi-Pack Beverage Carriers?

Multi-pack beverage carriers are specifically designed to hold several cans together, often featuring convenient handles for easy transport. This type of packaging is particularly useful for retail sales and events, where consumers prefer to purchase multiple items at once. B2B buyers should consider the design flexibility and branding potential of these carriers, as they can significantly enhance product visibility. However, businesses must also be mindful of the minimum order quantities that may apply.

Why Choose Eco-Friendly Cans for Your Beverage Packaging?

Eco-friendly cans are increasingly popular among brands looking to reduce their environmental impact. Made from sustainable materials, these cans appeal to a growing demographic of eco-conscious consumers. B2B buyers should assess the cost-benefit ratio when considering eco-friendly options, as they may come with a higher price point. However, the long-term advantages, such as brand loyalty and market differentiation, can outweigh initial investments.

What Unique Opportunities Do Specialty Beverage Containers Offer?

Specialty beverage containers, which include unique shapes and sizes tailored for specific drinks, provide brands with an opportunity to stand out in competitive markets. These containers are especially useful for niche products or limited-edition runs, attracting consumers’ attention. B2B buyers should be aware that while these containers can enhance brand appeal, they often involve higher production costs and longer lead times. It’s crucial for businesses to weigh these factors against the potential for increased sales and brand recognition.

Key Industrial Applications of custom beverage cans containers

| Industry/Sector | Specific Application of custom beverage cans containers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Craft Beverage Producers | Packaging for craft beers, hard seltzers, and kombucha | Enhances brand visibility and product freshness | Sustainability, design options, and minimum order quantities |

| Ready-to-Drink (RTD) Beverages | Custom cans for energy drinks and functional beverages | Attracts health-conscious consumers with vibrant branding | Shelf-life requirements, regulatory compliance, and material quality |

| Event and Catering Services | Single-serve beverage packaging for events | Convenient and appealing presentation for consumers | Customization options, order flexibility, and delivery timelines |

| Retail and Supermarkets | Multi-pack cans for retail displays | Increases sales through eye-catching designs | Packaging durability, cost-effectiveness, and shipping logistics |

| E-commerce and Direct-to-Consumer | Direct shipping of custom-labeled cans | Streamlines fulfillment and enhances customer experience | Packaging integrity during transit, design versatility, and speed of delivery |

How Are Custom Beverage Cans Containers Used in Craft Beverage Production?

Craft beverage producers utilize custom beverage cans to package their offerings, including craft beers, hard seltzers, and kombucha. These cans serve as a mobile advertisement, enhancing brand visibility on retail shelves. By offering vibrant designs and durable construction, producers can ensure their products remain fresh and appealing to consumers. International buyers should consider sustainability factors and design options when sourcing, as these elements can significantly influence marketability in regions like Europe and South America.

What Are the Benefits of Custom Beverage Cans for Ready-to-Drink Beverages?

In the ready-to-drink sector, custom beverage cans are essential for packaging energy drinks and functional beverages. The use of bold, eye-catching labels helps attract health-conscious consumers looking for convenience and quality. For businesses in Africa and the Middle East, ensuring compliance with local regulations and understanding shelf-life requirements are critical when sourcing these cans. Additionally, selecting high-quality materials can enhance product preservation and customer satisfaction.

How Do Event and Catering Services Utilize Custom Beverage Cans?

Event and catering services often rely on single-serve custom beverage cans to provide a convenient and appealing option for guests. These cans can be tailored with unique branding or event-specific designs, enhancing the overall experience. For B2B buyers in Europe and Africa, sourcing considerations include customization options and flexibility in order sizes to accommodate various event scales. Timely delivery is also crucial to ensure that products arrive fresh and ready for consumption.

Why Are Multi-Pack Cans Important for Retail and Supermarkets?

In retail environments, multi-pack custom beverage cans play a vital role in attracting consumers. Eye-catching designs can significantly increase sales by making products more noticeable on crowded supermarket shelves. For businesses in regions like South America and Europe, sourcing durable packaging that withstands transportation and shelf display is essential. Cost-effectiveness and efficient shipping logistics are also important factors that buyers should prioritize when procuring these containers.

How Do E-commerce and Direct-to-Consumer Brands Benefit from Custom Cans?

E-commerce and direct-to-consumer brands utilize custom-labeled beverage cans to streamline fulfillment and enhance customer experience. By offering unique packaging that reflects their brand identity, these businesses can create a memorable unboxing experience for customers. Buyers from international markets must consider packaging integrity during transit, ensuring that the cans arrive undamaged. Moreover, flexibility in design and rapid delivery times can significantly influence consumer satisfaction and brand loyalty.

3 Common User Pain Points for ‘custom beverage cans containers’ & Their Solutions

Scenario 1: Navigating Design and Branding Challenges for Custom Beverage Cans

The Problem: One of the most significant challenges faced by B2B buyers in the beverage packaging sector is the intricate process of designing custom cans that effectively convey their brand identity. Buyers often struggle with aligning their creative vision with the technical specifications required for printing. This can lead to confusion over color accuracy, label dimensions, and overall visual appeal, resulting in products that fail to resonate with consumers or meet market standards.

The Solution: To overcome these design hurdles, B2B buyers should leverage the design tools provided by custom beverage can suppliers. Many companies offer online platforms where buyers can upload their logos and graphics, adjust dimensions, and preview designs before finalizing orders. It is crucial to utilize templates provided by suppliers to ensure that designs fit properly on the cans. Additionally, buyers should communicate closely with their suppliers to understand color profiles (like CMYK vs. RGB) and material choices (such as BOPP labels) that affect print quality. Collaborating with design professionals who have experience in beverage branding can also enhance the effectiveness of the packaging.

Scenario 2: Managing Supply Chain and Inventory Concerns

The Problem: International B2B buyers often face the challenge of managing supply chain logistics and inventory levels when ordering custom beverage cans. Delays in production or shipping can lead to stockouts, impacting their ability to meet customer demand. Additionally, buyers may struggle with minimum order quantities (MOQs), which can lead to excess inventory if sales forecasts are not accurate.

The Solution: To mitigate these issues, buyers should establish a strong relationship with reliable suppliers who offer flexible order quantities and transparent timelines. This relationship can facilitate better communication regarding lead times and potential delays. Additionally, implementing a just-in-time inventory system can help manage stock levels more efficiently. Buyers should also consider utilizing software tools for demand forecasting to make more accurate predictions about sales trends, thus allowing for better planning of orders. Furthermore, having a few trusted backup suppliers can provide alternatives in case of unforeseen disruptions in the supply chain.

Scenario 3: Ensuring Sustainability and Regulatory Compliance

The Problem: With growing consumer demand for environmentally friendly products, B2B buyers are increasingly pressured to select packaging solutions that are sustainable and compliant with local regulations. Navigating the complexities of material sustainability, recyclability, and regulatory requirements across different regions (especially in Africa, South America, and Europe) can be daunting. Buyers fear that failing to meet these standards could lead to reputational damage or legal issues.

The Solution: To address these sustainability concerns, buyers should conduct thorough research on the environmental impact of the materials used in custom beverage cans. Partnering with suppliers who prioritize sustainability—such as those offering fully recyclable aluminum cans—is essential. Buyers should also stay informed about local regulations regarding packaging materials in their target markets. Engaging with sustainability consultants can provide additional insights into best practices and compliance strategies. Furthermore, incorporating sustainability messaging on the packaging itself can enhance brand reputation and appeal to eco-conscious consumers. Regularly reviewing supplier certifications and sustainability reports can also help ensure that chosen partners align with buyers’ environmental goals.

Strategic Material Selection Guide for custom beverage cans containers

What Are the Key Properties of Common Materials Used in Custom Beverage Cans?

When selecting materials for custom beverage cans, it is crucial to consider their properties, advantages, and limitations. The most common materials include aluminum, steel, glass, and plastic. Each material has unique characteristics that affect performance, cost, and suitability for various applications.

How Does Aluminum Perform as a Material for Beverage Cans?

Aluminum is the industry standard for beverage cans due to its excellent properties. It is lightweight, corrosion-resistant, and has a high strength-to-weight ratio, making it ideal for both carbonated and non-carbonated beverages. Aluminum cans can withstand high pressure, which is essential for carbonated drinks.

Pros: Aluminum cans are easily recyclable, which appeals to environmentally conscious consumers. They also provide an excellent barrier against light and oxygen, preserving the beverage’s freshness.

Cons: The manufacturing process can be complex and costly, particularly for custom designs. Additionally, aluminum cans may dent easily, impacting their aesthetic appeal.

International Considerations: For buyers in Africa, South America, the Middle East, and Europe, compliance with local recycling regulations and standards such as ASTM and DIN is essential. Countries like Germany have stringent recycling laws, making aluminum an attractive option due to its recyclability.

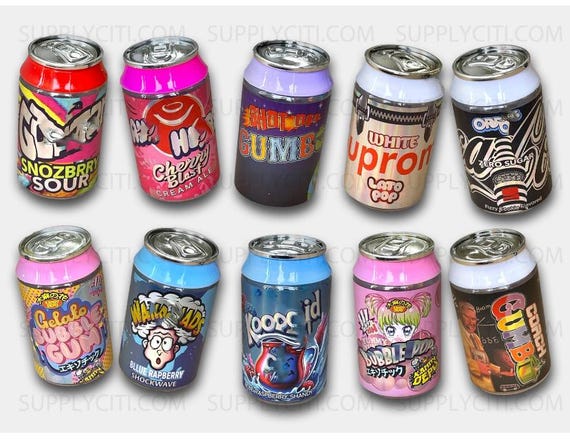

Illustrative image related to custom beverage cans containers

What Are the Advantages and Disadvantages of Steel Beverage Cans?

Steel is another material used for beverage cans, particularly in markets where cost is a significant factor. Steel cans are heavier than aluminum but offer excellent durability and resistance to punctures.

Pros: Steel cans are less expensive to produce than aluminum, making them a cost-effective option for manufacturers. They also provide good protection against external factors, ensuring the beverage remains uncontaminated.

Cons: Steel is prone to rust if not coated properly, which can affect the product’s shelf life. Moreover, the weight of steel cans can increase shipping costs.

International Considerations: Buyers should be aware of the varying regulations for steel packaging in different regions. For example, in Europe, compliance with food safety standards is critical, and buyers must ensure that the coatings used are safe for food contact.

How Does Glass Compare as a Material for Beverage Packaging?

Glass is often used for high-end beverages like craft beers and premium juices due to its aesthetic appeal and inert nature, which does not interact with the beverage.

Pros: Glass offers excellent barrier properties against gases and moisture, preserving flavor and carbonation. It is also fully recyclable without loss of quality.

Cons: The fragility of glass makes it prone to breakage during transport and handling, leading to potential losses. Additionally, glass is heavier than both aluminum and steel, increasing shipping costs.

International Considerations: In regions with robust recycling programs, such as parts of Europe, glass can be a preferred choice. However, buyers in developing markets may face challenges related to breakage and recycling infrastructure.

What Role Does Plastic Play in Custom Beverage Cans?

Plastic, particularly PET (polyethylene terephthalate), is increasingly being used for beverage containers due to its lightweight and shatterproof nature.

Pros: Plastic cans are highly versatile and can be produced in various shapes and sizes. They are also less expensive to manufacture and transport due to their lightweight.

Cons: Plastic is less environmentally friendly than aluminum or glass, as it is not as widely recyclable. Additionally, it may not provide the same level of barrier protection, which can affect the beverage’s quality over time.

International Considerations: Buyers should consider local recycling capabilities and regulations regarding plastic. In regions like Europe, there is a growing push for sustainable packaging solutions, which may affect the acceptance of plastic containers.

Summary Table of Material Selection for Custom Beverage Cans

| Material | Typical Use Case for custom beverage cans containers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Carbonated beverages, craft beers, energy drinks | Lightweight and recyclable | Higher manufacturing complexity | Medium |

| Steel | Non-carbonated beverages, lower-cost options | Cost-effective and durable | Prone to rust if uncoated | Low |

| Glass | Premium beverages, craft beers, juices | Excellent barrier properties | Fragile and heavy | High |

| Plastic | Soft drinks, water, low-cost beverages | Lightweight and versatile | Less recyclable and barrier protection | Low |

This guide provides a comprehensive overview of material selection for custom beverage cans, equipping international B2B buyers with the insights needed to make informed decisions based on their specific market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom beverage cans containers

What Are the Main Stages of the Manufacturing Process for Custom Beverage Cans?

Manufacturing custom beverage cans involves several critical stages, each designed to ensure high-quality and efficient production. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Beverage Cans?

The process begins with the selection and preparation of aluminum sheets, which are the primary material for beverage cans. Aluminum is favored for its lightweight nature, durability, and recyclability. Suppliers often source aluminum alloy sheets that meet specific industry standards, ensuring optimal performance and sustainability.

The sheets undergo cleaning and treatment to remove any contaminants that could affect the quality of the final product. This preparation step is crucial, as impurities can lead to defects during the forming process.

What Techniques Are Used in the Forming of Beverage Cans?

Once the material is prepared, the next stage is forming. This typically involves several techniques such as stamping and drawing. In the stamping process, the aluminum sheets are cut into circular blanks. These blanks are then drawn into cup shapes using a deep-drawing technique, which helps form the can body while maintaining the material’s integrity.

Advanced machinery is employed during this stage to ensure precision and reduce waste. The use of hydraulic presses and CNC machines allows for high-speed production and consistency in dimensions, which is vital for proper sealing and labeling later in the process.

How Are Custom Beverage Cans Assembled?

Assembly involves attaching the can ends (lids) to the formed bodies. This is achieved through a seaming process that ensures a tight seal, preventing leakage and maintaining product integrity. The can ends are typically designed to be compatible with various closure types, including standard ends and specialized lids for carbonated beverages.

During this stage, manufacturers often utilize automated systems to enhance efficiency and reduce human error. The assembly line is designed for rapid throughput while maintaining rigorous quality standards.

What Finishing Processes Are Applied to Custom Beverage Cans?

The finishing stage focuses on applying coatings and labels to the cans. A protective coating is often applied to the inside of the can to prevent corrosion and preserve the beverage’s flavor. The exterior is then printed with high-quality graphics that reflect the brand’s identity.

Printing techniques such as digital, flexographic, or lithographic printing are employed to achieve vibrant and durable designs. The choice of printing method may vary based on order size, lead time, and the specific requirements of the beverage brand.

What Are the Quality Assurance Measures for Custom Beverage Cans?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets international standards and customer expectations. This involves adhering to various industry-specific regulations and implementing comprehensive quality control (QC) checkpoints.

What International Standards Are Relevant for Custom Beverage Cans?

Manufacturers of custom beverage cans often adhere to international standards such as ISO 9001, which outlines quality management principles. Compliance with ISO 9001 ensures that processes are consistently monitored and improved, resulting in high-quality products.

In addition to ISO standards, region-specific certifications may be relevant. For example, CE marking is essential for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. In regions like Africa and South America, local regulations may also dictate specific quality requirements.

Illustrative image related to custom beverage cans containers

What QC Checkpoints Should B2B Buyers Look For?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any deviations from quality standards in real-time.

-

Final Quality Control (FQC): Before shipment, finished products undergo comprehensive inspections to confirm they meet all specifications and standards.

These checkpoints are crucial for maintaining quality and consistency, providing B2B buyers with confidence in the reliability of the products they purchase.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can include:

-

Conducting Audits: Regular audits of suppliers’ facilities can help buyers assess their adherence to quality standards and production practices. An audit should evaluate the entire manufacturing process, from raw material sourcing to final product inspection.

-

Requesting QC Reports: Suppliers should provide detailed quality control reports that outline testing methods, results, and compliance with relevant standards. These reports can serve as evidence of the supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality processes and product integrity. This is particularly important for international buyers, as it can help bridge the gap in communication and trust.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are commonly employed during the quality assurance process for custom beverage cans. These include:

-

Visual Inspection: Ensures that cans are free from physical defects such as dents, scratches, or misalignments.

-

Pressure Testing: For carbonated beverages, cans undergo pressure testing to ensure they can withstand the internal pressure without leaking.

-

Leak Testing: This method checks for any leaks in the seams or lids, which is critical for maintaining product quality.

-

Durability Testing: Cans may be subjected to various stress tests to evaluate their performance during transportation and handling.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various QC and certification nuances when sourcing custom beverage cans. Different regions may have distinct regulatory requirements that affect product safety, labeling, and environmental impact.

Illustrative image related to custom beverage cans containers

For instance, while European buyers may prioritize CE marking and compliance with EU directives, buyers from Africa and South America may focus on local certifications that guarantee safety and quality.

Understanding these nuances is essential for B2B buyers to ensure compliance and avoid potential legal issues. It is advisable to engage with local experts or consultants who can provide insights into regional requirements and facilitate smoother transactions.

Conclusion

In summary, the manufacturing processes and quality assurance measures for custom beverage cans are intricate and multifaceted. By understanding these processes, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet both their quality expectations and regulatory requirements. This knowledge not only enhances product quality but also strengthens brand reputation in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom beverage cans containers’

In the competitive landscape of beverage production, choosing the right custom beverage cans containers is crucial for brand visibility and product protection. This guide provides a comprehensive checklist to streamline your sourcing process, ensuring you select the best options for your business needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your beverage cans, including size, material, and type of closure. Understanding the technical aspects is vital for ensuring compatibility with your production line and meeting regulatory standards. Consider factors such as:

– Capacity: Determine the volume (e.g., 12 oz, 16 oz) that aligns with your product offerings.

– Material: Choose between aluminum and other materials based on sustainability goals and product preservation needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom beverage cans. Look for companies with a proven track record in your specific beverage sector. Key elements to investigate include:

– Experience: Evaluate how long the supplier has been in business and their expertise in your beverage category.

– Portfolio: Review their previous projects to assess quality and design capabilities.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers possess the necessary certifications, such as ISO standards or food safety certifications. This ensures that they adhere to industry regulations and maintain quality control. Look for:

– Quality Assurance: Confirm that the supplier has a robust quality management system in place.

– Sustainability Practices: Check if they follow environmentally-friendly practices, which can enhance your brand’s image.

Illustrative image related to custom beverage cans containers

Step 4: Request Samples

Always request samples of the custom beverage cans before placing a large order. This step allows you to assess the quality, durability, and design of the containers firsthand. When evaluating samples, consider:

– Print Quality: Ensure that the graphics and labels are vibrant and durable.

– Structural Integrity: Test the cans for strength and resistance to damage during transport.

Step 5: Compare Pricing and Lead Times

Gather quotes from multiple suppliers to understand the market rate for your custom beverage cans. Compare not only the pricing but also the lead times for production and delivery. Key aspects to analyze include:

– Minimum Order Quantities (MOQ): Ensure the supplier’s MOQ aligns with your production needs.

– Shipping Options: Investigate shipping costs and timelines, particularly for international orders.

Step 6: Assess Customer Support and Communication

A responsive customer support team can significantly enhance your sourcing experience. Evaluate the supplier’s communication practices and responsiveness during your initial interactions. Important considerations include:

– Availability: Ensure that the supplier has dedicated representatives for inquiries and support.

– After-Sales Service: Confirm if they offer assistance for reorders, adjustments, or issues that may arise post-purchase.

Step 7: Finalize Your Order and Terms

Once you’ve selected a supplier, finalize the order details, including pricing, payment terms, and delivery timelines. Make sure to have a clear contract that outlines all terms to avoid misunderstandings. Consider:

– Payment Flexibility: Discuss options for payment plans or discounts for larger orders.

– Return Policies: Understand the terms for returns or replacements in case of defects or discrepancies.

Illustrative image related to custom beverage cans containers

Following this checklist will help you make informed decisions when sourcing custom beverage cans containers, ultimately enhancing your brand’s market presence and operational efficiency.

Comprehensive Cost and Pricing Analysis for custom beverage cans containers Sourcing

What Are the Key Cost Components in Custom Beverage Can Production?

When sourcing custom beverage cans, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects pricing. Aluminum, for instance, is widely used due to its lightweight and recyclable properties. The cost of aluminum can fluctuate based on global market conditions, impacting overall pricing.

-

Labor: Labor costs vary by region and depend on the complexity of the customization process. Skilled labor is often needed for quality printing and assembly, which can increase costs.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Customization often requires specialized tools and molds, which can entail significant upfront costs. These tooling expenses are typically amortized over large production runs, making it crucial for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Rigorous QC processes are essential to ensure product consistency and safety. Costs associated with QC, including testing and inspections, should be factored into the overall pricing.

-

Logistics: Shipping and handling costs can vary widely based on the destination. International shipping may involve customs duties, taxes, and insurance, which are important for buyers in Africa, South America, the Middle East, and Europe.

-

Margin: Suppliers typically mark up their costs to ensure a profit. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Custom Beverage Can Costs?

Several factors influence the pricing of custom beverage cans, including volume, specifications, materials, quality certifications, supplier reliability, and Incoterms.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Buyers should assess their demand forecasts to optimize order sizes.

-

Specifications/Customization: The level of customization, such as unique shapes or prints, can affect costs. More complex designs usually incur higher production and tooling costs.

-

Materials: The choice between standard and premium materials can lead to significant price variations. Buyers should weigh the benefits of higher quality against budget constraints.

-

Quality/Certifications: Compliance with industry standards can increase costs but is essential for market acceptance. Buyers in regions with stringent regulations must factor this into their sourcing decisions.

-

Supplier Factors: A supplier’s reliability and reputation can influence pricing. Established suppliers with proven track records may charge a premium for their services.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) determine the responsibility for shipping costs and risks. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers of Custom Beverage Cans?

For international buyers, effective negotiation can lead to significant cost savings. Here are some strategic tips:

-

Leverage Volume Discounts: Use projected sales data to negotiate better rates based on larger order quantities.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs to identify potential areas for negotiation, such as logistics or QC expenses.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with shipping, storage, and waste management.

-

Understand Pricing Nuances: Be aware of local market conditions and currency fluctuations, especially when sourcing from different regions.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time.

Conclusion

Understanding the cost and pricing dynamics of custom beverage cans is essential for B2B buyers. By considering the various cost components, price influencers, and effective negotiation strategies, buyers can make informed decisions that align with their business goals. Always remember to request indicative pricing and quotes tailored to your specific needs, as market conditions and supplier capabilities can lead to significant variations in costs.

Alternatives Analysis: Comparing custom beverage cans containers With Other Solutions

Exploring Alternatives to Custom Beverage Cans Containers

In the competitive beverage industry, selecting the right packaging solution is crucial for brand visibility and product preservation. While custom beverage cans containers are a popular choice, various alternatives exist that may better suit specific needs or preferences. This analysis will compare custom beverage cans containers against two viable alternatives: custom beverage boxes and glass bottles.

Comparison Table

| Comparison Aspect | Custom Beverage Cans Containers | Custom Beverage Boxes | Glass Bottles |

|---|---|---|---|

| Performance | Excellent barrier protection; ideal for carbonated and non-carbonated drinks. | Good protection; suitable for non-carbonated beverages and promotional packaging. | Superior protection; ideal for premium products and long-term storage. |

| Cost | Moderate to high; varies based on volume and customization. | Generally lower; cost-effective for bulk orders. | Higher; costs associated with production, transport, and recycling. |

| Ease of Implementation | Requires specialized equipment for filling and sealing. | Simple design and production process; easy to implement with existing operations. | Requires careful handling and storage; more complex logistics. |

| Maintenance | Minimal; cans are durable and recyclable, requiring little upkeep. | Moderate; boxes may need to be stored properly to maintain shape. | High; breakage risk and more intensive cleaning for reuse. |

| Best Use Case | Ideal for craft beverages, soft drinks, and energy drinks; great for brands looking to enhance shelf appeal. | Best for seasonal promotions, specialty beverages, and gift packs; effective for direct-to-consumer sales. | Perfect for premium brands, artisanal beverages, and products emphasizing sustainability. |

Detailed Breakdown of Alternatives

Custom Beverage Boxes

Custom beverage boxes serve as a versatile alternative to cans, particularly for brands focusing on non-carbonated beverages such as wine, cocktails, or specialty drinks. They offer an excellent canvas for branding with vibrant prints and can be designed to be visually appealing for shelf display. The cost is generally lower, especially for bulk orders, making them an attractive option for businesses looking to optimize their packaging budget. However, they may lack the durability of cans, particularly for transport, and are best suited for products that do not require carbonation.

Glass Bottles

Glass bottles are often associated with premium products, offering a perception of quality and sustainability. They provide superior protection for beverages, making them ideal for long-term storage and products that need to maintain flavor integrity. However, they come with higher production and transportation costs, and their weight can increase shipping expenses. Additionally, glass requires careful handling due to the risk of breakage, which can complicate logistics. Glass bottles work best for artisanal brands and those targeting a market segment that values environmental sustainability and premium packaging.

Conclusion: Making the Right Choice for Your Beverage Packaging

When selecting a packaging solution, B2B buyers should consider their product type, target market, and budget. Custom beverage cans containers excel in durability and shelf appeal, making them a strong choice for a wide range of beverages. However, for brands focusing on non-carbonated drinks or seasonal promotions, custom beverage boxes may offer a cost-effective and visually appealing option. On the other hand, glass bottles can elevate brand perception for premium products but come with higher costs and logistical challenges. By carefully analyzing these alternatives, businesses can choose the most effective packaging solution that aligns with their strategic goals and market demands.

Essential Technical Properties and Trade Terminology for custom beverage cans containers

What Are the Key Technical Properties of Custom Beverage Can Containers?

When selecting custom beverage can containers, it is crucial for B2B buyers to understand several technical properties that impact both the product and brand presentation. Here are essential specifications to consider:

Illustrative image related to custom beverage cans containers

-

Material Grade

Beverage cans are typically made from aluminum or steel, with aluminum being the more common choice due to its lightweight and recyclable nature. The material grade influences durability, weight, and resistance to corrosion. High-grade aluminum cans, such as those with a thickness of 0.25 mm, can withstand internal pressure from carbonated beverages while ensuring the integrity of the product during transport. -

Tolerance

Tolerance refers to the permissible variation in dimensions of the can, such as diameter and height. For beverage cans, a typical tolerance is ±0.5 mm. Maintaining strict tolerances is essential for ensuring proper sealing and compatibility with canning equipment. Poor tolerance can lead to leaks and increased production waste, impacting overall costs. -

Capacity

The capacity of beverage cans varies widely, commonly ranging from 12 oz (355 ml) to 16 oz (473 ml) for most beverages. Understanding the capacity is vital for aligning product offerings with consumer preferences and market demands. Custom sizes can also differentiate brands and cater to specific niches, such as craft beverages. -

Labeling Options

The choice of labeling material (e.g., BOPP, paper, or direct print) significantly affects the can’s shelf appeal and durability. BOPP labels, for instance, are resistant to water and UV rays, making them suitable for beverages that may be exposed to moisture. High-quality labeling can enhance brand visibility and consumer engagement on retail shelves. -

Recyclability

Sustainability is a key concern for modern consumers and businesses alike. Aluminum cans are fully recyclable, and their recyclability can significantly influence purchasing decisions. B2B buyers should consider the environmental impact of their packaging choices and the potential for promoting their products as eco-friendly. -

Seam Quality

The seam quality of a can is critical for preventing leaks and ensuring product freshness. Cans are typically sealed using a double seam technique, and the quality of this seam can be measured in terms of its integrity and strength. A reliable seam reduces spoilage and enhances consumer trust in the product.

What Are Common Trade Terms Used in the Custom Beverage Can Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several key terms to familiarize yourself with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the beverage can industry, an OEM can refer to companies that manufacture the cans themselves, allowing brands to focus on their product development and marketing strategies. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. It can vary based on the supplier, type of can, and customization level, influencing the overall cost-effectiveness of the purchase. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific order. This is crucial for B2B buyers to compare costs and services among different suppliers, ensuring they receive the best deal for their custom beverage cans. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is important for managing logistics and understanding shipping costs. -

Lead Time

Lead time is the period between placing an order and receiving the goods. This is particularly critical in the beverage industry, where time-to-market can affect sales. Understanding the lead time helps in planning production schedules and inventory levels. -

Sustainability Certification

This term refers to certifications that verify a product’s environmental impact. Certifications such as FSC (Forest Stewardship Council) for paper or recycled content certifications for aluminum cans can enhance brand reputation and appeal to eco-conscious consumers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their product strategies and market demands, ultimately leading to a more successful business operation.

Navigating Market Dynamics and Sourcing Trends in the custom beverage cans containers Sector

Market Overview & Key Trends in Custom Beverage Cans Containers

The global custom beverage cans containers market is experiencing significant growth, driven by a surge in consumer demand for unique and sustainable packaging solutions. Key trends influencing this market include the rise of craft beverages, increased focus on branding through packaging, and technological advancements in printing and design. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly attuned to these trends as they seek to differentiate their products in competitive markets.

One notable trend is the shift toward customization, where brands leverage innovative design tools to create eye-catching packaging that resonates with consumers. Companies are increasingly utilizing digital printing technology to produce vibrant, high-quality labels that enhance brand visibility on retail shelves. Additionally, the adoption of e-commerce and direct-to-consumer sales models has prompted manufacturers to offer smaller batch sizes, allowing businesses to test new products and designs without significant upfront investment.

Illustrative image related to custom beverage cans containers

Furthermore, the growing emphasis on sustainability is reshaping sourcing strategies. As consumers become more environmentally conscious, brands are prioritizing recyclable materials and sustainable production practices. This shift not only meets consumer expectations but also aligns with regulatory pressures across various regions, making it crucial for international buyers to stay informed about emerging sustainability standards in packaging.

How Does Sustainability Impact Sourcing in the Custom Beverage Cans Sector?

Sustainability is a pivotal consideration for B2B buyers in the custom beverage cans containers sector, influencing both product selection and supplier relationships. The environmental impact of packaging materials is under scrutiny, with aluminum cans being favored for their recyclability and lower carbon footprint compared to other materials. This preference is particularly pronounced in regions like Europe, where stringent regulations on waste management and sustainability are in place.

Ethical sourcing plays a critical role in building brand reputation and consumer trust. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials, minimizing waste during production, and ensuring fair labor practices throughout their supply chains. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 are becoming essential benchmarks for verifying the sustainability claims of suppliers.

Moreover, the integration of sustainable practices can lead to cost savings in the long run. By investing in eco-friendly packaging solutions, companies can benefit from reduced disposal costs and enhanced brand loyalty among environmentally conscious consumers. As the demand for sustainable products continues to grow, B2B buyers must prioritize sourcing from suppliers that align with their values and meet the expectations of their target markets.

What is the Historical Context of Custom Beverage Cans Containers in the B2B Landscape?

The custom beverage cans containers sector has evolved significantly over the past few decades, transitioning from traditional glass bottles to lightweight, versatile aluminum cans. Initially favored for their durability and portability, aluminum cans became the packaging choice for a wide range of beverages, including soft drinks, beers, and energy drinks.

The 1990s marked a pivotal moment in the industry, as advancements in canning technology and printing allowed for greater customization and branding opportunities. This era saw the rise of craft breweries and niche beverage producers, who leveraged unique can designs to differentiate themselves in a crowded marketplace. As consumer preferences shifted toward artisanal and locally-produced drinks, the demand for custom beverage cans surged.

Today, the market is characterized by a blend of innovation and sustainability, with manufacturers continuously exploring new materials and production methods to meet evolving consumer demands. As international B2B buyers navigate this dynamic landscape, understanding the historical context and ongoing trends will be essential in making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom beverage cans containers

-

How do I choose the right custom beverage can supplier for my business?

Selecting the right supplier involves evaluating several key factors. Start by assessing their experience in the industry, particularly with your type of beverage. Request samples to evaluate the quality of their products and printing capabilities. Check for certifications that ensure compliance with international standards, especially regarding safety and sustainability. Additionally, read reviews and testimonials from other clients to gauge their reliability and customer service. Finally, consider their logistics capabilities, including shipping times and costs to your region. -

What is the minimum order quantity (MOQ) for custom beverage cans?

Minimum order quantities can vary significantly between suppliers. Typically, MOQs for custom beverage cans range from 240 to 480 cans, depending on the supplier and customization level. It’s crucial to discuss your needs upfront to ensure the supplier can accommodate smaller or larger orders. If you anticipate fluctuating demand, consider negotiating terms that allow for flexibility in reordering without incurring additional fees. -

What customization options are available for beverage cans?

Most suppliers offer a variety of customization options, including label design, can size, and material finish. You can choose from different printing techniques, such as digital or flexographic printing, to achieve your desired aesthetic. Additionally, some suppliers allow for custom shapes or unique can ends, which can enhance product differentiation. Always verify design templates and guidelines to ensure your artwork meets production specifications. -

What are the typical lead times for ordering custom beverage cans?

Lead times can vary based on the supplier and the complexity of your order. Generally, expect a turnaround of 2 to 4 weeks from the approval of your design. For larger orders or complex customizations, it may take longer. Always confirm the expected lead time before placing your order, and consider planning for potential delays in shipping, especially for international orders. -

How do I ensure quality assurance for my custom beverage cans?

To maintain quality assurance, establish clear communication with your supplier about your expectations and specifications. Request samples of both the can and the printed design prior to full production. Many suppliers conduct in-process inspections and final quality checks; inquire about these practices. Additionally, consider including quality clauses in your contract to safeguard your interests and ensure you receive products that meet your standards. -

What payment terms should I expect when ordering custom beverage cans?

Payment terms can differ widely among suppliers. Most require a deposit upon order confirmation, typically ranging from 30% to 50% of the total cost, with the balance due before shipping. Some suppliers may offer payment plans or credit terms for repeat customers. It’s crucial to clarify payment methods accepted (e.g., bank transfer, credit card) and any associated fees, especially for international transactions. -

Are there specific regulations for importing beverage cans into my country?

Yes, importing beverage cans can involve various regulations, including labeling requirements, health and safety standards, and customs duties. Each country has its own import regulations, so it’s essential to research the specific requirements for your region. Engage with a customs broker if necessary to navigate the complexities of international trade and ensure compliance with all local laws. -

How can I effectively manage logistics for my custom beverage can orders?

Effective logistics management starts with understanding your supplier’s shipping capabilities and timelines. Choose a supplier with experience in international shipping to minimize delays and complications. Discuss freight options, including air or sea freight, and consider the associated costs. Additionally, track your shipments closely and maintain open communication with your supplier to address any issues promptly. Implementing an efficient inventory management system can also help you anticipate needs and streamline reordering processes.

Top 3 Custom Beverage Cans Containers Manufacturers & Suppliers List

1. Stomp Stickers – Custom Beverage Boxes

Domain: stompstickers.com

Registered: 2018 (7 years)

Introduction: Custom Printed Beverage Boxes & Carriers from Stomp Stickers. Price range starts from $253.50 for various types including Beer Boxes, Cocktail & Seltzer Boxes, Wine Boxes, Hard Cider Boxes, Kombucha Boxes, Tea Boxes, Coffee Boxes, Soda Boxes, Craft Beverage Boxes, and CBD Beverage Boxes. Wine Gift Boxes priced at $181.75. Features include durable construction, vibrant printing, and customizable de…

2. Oktober Design – Custom Pre-Labeled 12oz Aluminum Beverage Cans

Domain: oktoberdesign.com

Registered: 2016 (9 years)

Introduction: 12oz Custom Pre-Labeled Aluminum Beverage Cans + Ends

– Price: $156.00

– Size: 12oz (355ml)

– Packaging: 240 cans per box, 2 box minimum order quantity

– End Types: Standard 202 B64 profile, SuperEnd®, 360 End®

– Label Material Options: Glossy White, Matte White, Transparent, Silver

– Label Dimensions: 3.5″ H x 8.125″ W with a 0.125” bleed

– Label Formats: PDF or AI (300-800 dpi resolution, CMYK, …

3. Illing Company – Custom Printed Aluminum Cans

Domain: illingcompany.com

Registered: 2002 (23 years)

Introduction: Custom Printed 12 oz. Aluminum Can, available for decoration with direct print or shrink sleeve labeling, in stock with domestic manufacturing, cost-effective options, shorter lead times, and low minimum order quantities (MOQs).

Strategic Sourcing Conclusion and Outlook for custom beverage cans containers

In the rapidly evolving beverage industry, strategic sourcing of custom beverage cans is critical for brands aiming to differentiate themselves in competitive markets. High-quality, custom-printed aluminum cans not only enhance brand visibility but also ensure product integrity through their durability and sustainability. By leveraging innovative design tools and maintaining strong supplier relationships, businesses can streamline their procurement processes and respond swiftly to market demands.

International buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize sourcing strategies that align with their unique market needs. Customization options, including label designs and packaging formats, allow companies to create impactful marketing narratives that resonate with local consumers. Moreover, embracing environmentally friendly materials can bolster a brand’s reputation, appealing to the growing demand for sustainable products.

Looking ahead, the opportunity for growth in the custom beverage can sector is substantial. By investing in strategic sourcing and fostering partnerships with reliable manufacturers, brands can not only enhance their product offerings but also position themselves for long-term success. Take the next step in your sourcing journey by exploring innovative solutions that elevate your beverage packaging.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom beverage cans containers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.